HORNE H-2501 Installation, Operating, & Maintenance Instructions

Horne Engineering Ltd

Horne Engineering Ltd

PO Box 7, Rankine Street

Johnstone, Renfrewshire

Scotland PA5 8BD

Tel 01505 321 455

Fax 01505 336 287

HORNE

Email technical@horne.co.uk

Web www.horne.co.uk

HORNE 25 THERMOSTATIC MIXING VALVE

Type H-2501

Installation, Commissioning, Operating & Maintenance Instructions

1 Installing the Horne 25 TMV

1.1 Install the Horne 25 TMV as close as possible to the outlet to comply with HTM

2027 and HTM 2040. The dead leg from the Horne 25 TMV to the outlet should

not exceed 2 metres.

1.2 The Hot & Cold water supplies should be from a common source, i.e. the static

pressures should be equal.

1.3 Isolating valves must be fitted to the hot & cold water supply pipes.

1.4 The Horne 25 TMV can be fitted in any attitude with the mixed water outlet

pointing upwards, downwards, horizontally or at any angle between these planes.

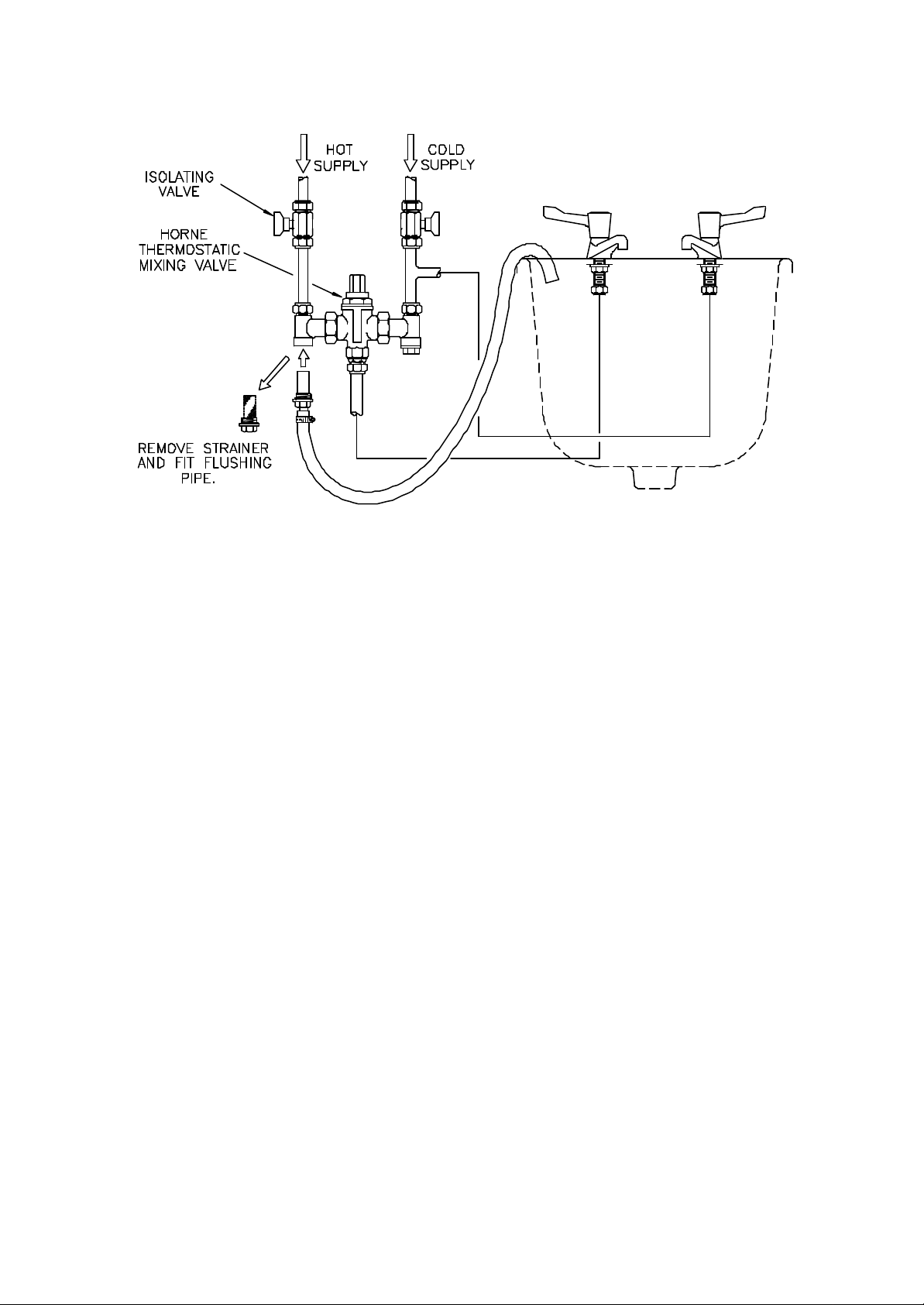

2 FLUSHING OF PIPEWORK TO WATER SUPPLY BYLAWS (SCOTLAND) 2003

AND THE WATER SUPPLY (WATER FITTINGS) REGULATIONS 1999.

2.1 The most common cause for complaint regarding the performance of a valve is

traced to dirt or debris in the TMV or check valves.

2.2 Before a Horne 25 is commissioned, the hot and cold water pipework should be

thoroughly flushed using the FLUSHING KIT shown in the diagram overleaf. The

FLUSHING KIT comprises a screwed adapter to fit the strainer body and a plastic

pipe to enable water to be flushed to drain. The kit may be ordered separately.

2.3 DO NOT FLUSH THE PIPEWORK BY REMOVING THE STRAINER

BASKETS AND OPENING THE TAPS.

2.4 DO NOT OPEN the hot water tap before flushing the hot and cold water pipework.

Issue 3 8/05 1

Horne Engineering Ltd

2.5 The flushing procedure is as follows :-

2.6 During this procedure, keep the hot and cold water taps closed.

2.7 Close the hot and cold water ISOLATING VALVES.

2.8 Unscrew the END CAP (16) and remove the STRAINER BASKET (14) from the

strainer at the hot inlet.

2.9 Screw the FLUSHING KIT into the STRAINER BODY (13).

2.10 Place the outlet of the flushing pipe where it can drain freely. If draining into a

wash basin or bath, make sure that the plug is NOT in place and that water passing

through the flushing pipe is free to drain.

2.11 Open the hot water ISOLATING VALVE and allow any air in the pipework to

escape until water begins to flow to drain. Allow water to flow to drain until it is

perfectly clean and free from any dirt or debris.

2.12 Close the hot water ISOLATING VALVE.

2.13 Remove the FLUSHING KIT and replace the STRAINER BASKET (14) and END

CAP (16).

2.14 Repeat for the cold water inlet.

2.15 Re-open both ISOLATING VALVES.

2.16 The flushing procedure has now been completed.

Issue 3 8/05 2

Horne Engineering Ltd

3 COMMISSIONING A NEW HORNE 25 TMV

3.1 Open the hot water tap and allow water to run through the Horne 25 TMV.

3.2 Check that the hot and cold water supplies are at or near their designated

temperatures and pressures.

3.3 Measure the temperature at the hot water tap. This is the temperature of the mixed

water.

3.4 If necessary, make minor adjustments to the temperature setting as described in

Section 4 below.

3.5 CARRY OUT A COLD WATER FAILURE TEST AS BELOW

3.5.1 Close the cold water isolating valve and simultaneously measure the mixed water

temperature. The flow of mixed water should immediately stop and then a drip or

trickle may be seen. The temperature of any water coming from the tap should not

be more than 2C above the mixed water temperature measured in 3.3 above.

3.5.2 If the Horne 25 TMV performs satisfactorily, close the hot water tap and open the

cold water isolating valve.

3.5.3 If the water coming from the tap is at a temperature of more than 2C above the

mixed water temperature setting, then the Horne 25 TMV is not cutting off the hot

water supply properly. The most likely cause for this to happen is dirt inside the

TMV. It should be dismantled and thoroughly cleaned and the pipework flushed

again. See 2.5 - 2.16.

3.6 The Horne 25 TMV is supplied with WFBS listed integral single check valves

located in each of the inlet couplings. To ensure the check valves are working

properly, proceed as follows :-

3.6.1 Start with both hot and cold taps closed and both hot and cold water isolating

valves open.

3.6.2 Close the cold water supply isolating valve.

3.6.3 Remove the cold water inlet STRAINER CAP (16) at the inlet to the Horne 25

TMV. After initial draining of water, there should be no flow whatsoever. This

indicates that the check valve at the cold water inlet is giving a tight shut-off.

3.6.4 Replace the cold water inlet STRAINER CAP (16) and open the cold water

isolating valve.

3.6.5 Close the hot water supply isolating valve.

Issue 3 8/05 3

Loading...

Loading...