Page 1

Custom-Grade™ Dies

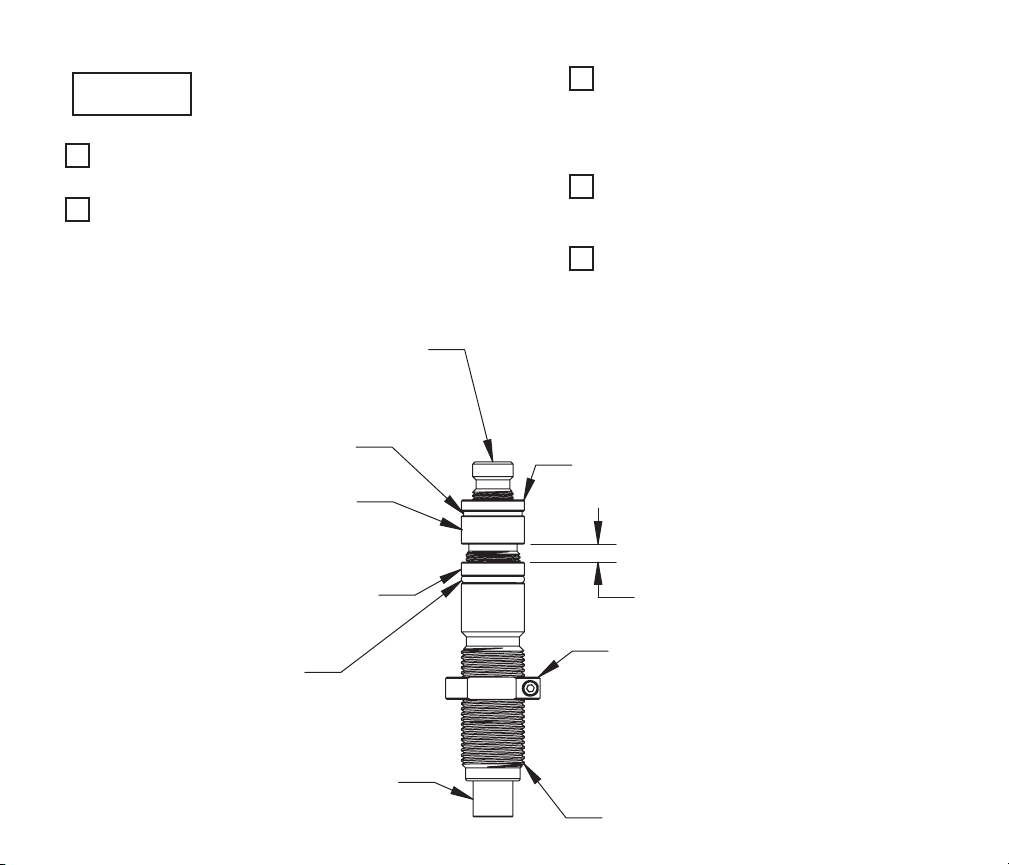

Crimp/Seater Die

Crimp/Seater Die

Page 2

Depend ing on the calib er of die set /alignme nt

set up

1.

As wi th all dies, disassemble the Crimp/Seater

Die and clean thoroughly.

2.

Reassemble according to illustration, setting the

dist ance between the Crimp Adjust Screw and

the Crimp Adjust Lock Ring to approximately ¼

inch. When tightened properly, the Crimp Adjust

Lock Ring should have firm tension on t he O-ring

against the Seater Die Body.

sleeve yo u are using, the H ornady Crimp /Seater Di e

will ei ther "tape r" or "roll" cri mp your cases.

Seat Adjust Screw

(adjusts bullet seating depth)

3.

With a case in the shell holder, raise the press

ram to the top of its stroke. Screw the assembled

Crimp/ Seater Die into the press unt il resistance

is felt. This resist ance is the case star ting to

crimp in the Alignment Sleeve.

4.

Screw the Sure-Loc Lock Ring down against the

press or Lock-N-L oad® Bushing and lock into

place by tightening the cap screw on the ring.

5.

Loosen the Crimp Adjust Lock Ring while holding

the Crimp Adjust Screw and then back the Crimp

Adjus t Screw off approximately ½ turn. Retighten

the Crimp Adjust Lock Ring while holding the

Crimp Adjust Screw.

Rubber Flat Washer

Crimp Adjust Screw

(adjusts bullet seating depth)

Crimp Adjust Lock Ring

O-Ring

Alignment Sleeve

Seat Adjust Lock Ring

1/4"

Sure-Loc Lock Ring

Crimp/Seater Die

Page 3

6.

Now we will set the bullet seating depth. Loosen

the Seat Adjust Lock Ring and back the Seat

Adjus t Screw out several turns to assure that the

bullet won’t be seated too deep.

7.

Lower the press ram and set t he bullet on the

case. Raise the press ram, guiding the bullet /

case into the Crimp /Seater Die.

8.

While press ram is at the top of the s troke, thread

the Seat Adjust Screw into die until resistance is

felt. This resistance is the bullet start ing to seat

into the case.

9.

Set the bullet seat depth by lowering the press

ram, threading the Seat Adjust Screw into the die

and raising the press ram again until the desired

seating depth/car tridge length is obtained.

Note: Do not, at this t ime, t ighten the Seat Adjust

Lock Ring.

10.

Now we will set the crimp on the cartridge. Your

new Hornady® Crimp/ Seater die will achieve

this by adjusting the Crimp Adjust Screw as

opposed to loosening the Sure-Loc Lock Ring

and adjusting the entire body as with most seater

dies. Since the lock ring was set in step 4, it

doesn’t have to be moved.

11.

With the cartridge in the shell holder, raise the

press ram again to the top of its stroke.

12.

Loosen the Crimp Adjust Lock Ring several turns

while holding the Crimp Adjust Screw.

13.

Hold the Seat Adjus t Screw from turning and

thread the Crimp Adjust Screw into the die until

resistance is felt. This resistance is, again, the

case starting to crimp.

14.

Continue setting crimp by lowering press ram,

holding the Seat Adjust Screw, threading the

Crimp Adjus t Screw into the die in 1/8 turn

increments, and raising the press ram again

until the proper crimp is obtained. The 1/ 8 turn

recommendat ion is due to the fine adjustment

of the crimp. In the next step, a bullet will be

seated and crimped in one step and due to this,

an incorrect crimp or over excessive crimp will

resul t in bullet swaging or case bulging.

15.

Next, lower the press ram and remove the

cart ridge. Place the nex t set of component s

in the press and raise the ram to the top of the

stroke, guiding the case /bullet into the die. This

will seat the bullet as well as crimp it in the case.

16.

Fine tune the crimp/seat depth if necessary.

Remember when adjusting the Crimp Adjust

Screw, hold the Seat Adjust Screw and when

adjusting the Seat Adjust Screw, hold the Crimp

Adjus t Screw. Doing this will allow the crimp

amount to be adjusted without moving the

seating depth and vice versa.

17.

Once the crimp amount and the seat depth have

been obtained, the Crimp Adjust Lock Ring and

Seat Adjust lock ring will need to be tightened.

First, tighten the Crimp Adjust Lock Ring; you'll

need to hold the Crimp Adjus t Screw so it doesn't

move. T hen tighten the Seat Adjust L ock Ring

down firmly on the Rubber Flat Washer. Hold the

Seat Adjust Screw so it doesn't turn.

18.

Your die should now be set and will give you

years of reloading enjoyment.

Page 4

EXPLODED VIEW

4

3

1

10

ITEM NO. PART DESCRIPTION PART NO.

1 Die Bod y Seater T C/E XP 2.7 5 398900

2 Seat A djust Scre w 398907

3 Alignment Sleeve Varies w ith calib er

4 Seat ing Stem Varies wi th caliber

5 Crimp Adjust Screw 398905

6 Crim p Adjust L ock Ring 398906

7 O-Ring 480083

8 Washer Flat Rubber 398067

9 Ring L ock Seater Die 044800

10 Sure -Loc Lock R ing 044000

NOTE: When callin g for part s, please re ference par t number.

9

2

8

5

6

7

Page 5

P.O. Box 1848 • Grand Island, NE 68802-184 8

(308) 382-1390 • ww w.hornady.com

Loading...

Loading...