Page 1

The highest

level of

reloading

precision.

Page 2

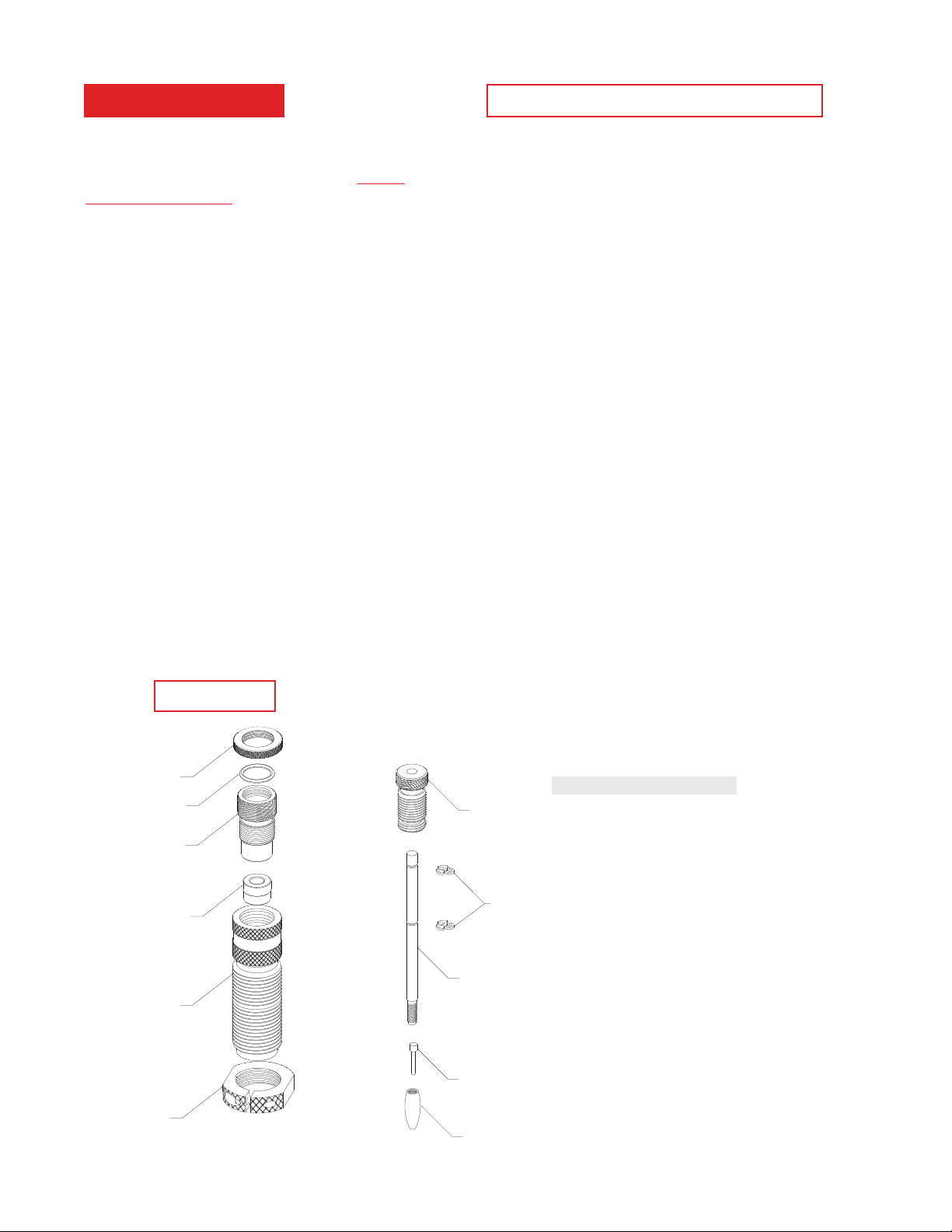

A

B

C

D

E

F

G

H

I

J

K

BEFORE USING DIES

DIE SETTINGS AND ADJUSTMENTS

Before using your new die, disassemble and carefully clean

the inside surfaces. A rust preventative has been applied at

the factory to protect the die during shipping and must be

removed before reloading. We recommend Hornady ONE

SHOT Gun Cleaner and Dry Lube.

Inspect all cartridge cases and discard those with cracks,

splits and other visible defects. Wipe cases clean with a soft

cloth to remove grit and other foreign material which may

scratch the die. Before sizing, lubricate the cases with one

of the case lubes available from Hornady (ONE SHOT Case

Lube or UNIQUE, a hard paste). No matter the method of

lubrication, all necked cases in a full length die require

some lubrication. A small amount of lubrication on the case

neck while using a neck size die will minimize stretching.

Little or no lubrication on necked cases in a full length die

will result in a stuck case. Over-lubrication will cause dents

in the shoulder, damaging the appearance. (If you do get a

case stuck in a die, Hornady will remove

the case without

damaging the die and return it to you. Please enclose $4.00

for postage and handling.)

BUSHING SIZE

Measure the outside diameter of your loaded cartridge. Subtract .002" to

.003" from the neck diameter to determine bushing size. This allows for

brass spring back and a bullet press fit of .001" to .002"

.

FULL LENGTH DIE ADJUSTMENT

1. Insert the bushing (large end down) into the die body.

2. Raise the ram of the press to its highest position.

3. Thread the die into the press until the end of the die touches the shell

holder head.

4. Tighten the Lock Ring against the press and tighten the screw with the hex

wrench.

5. Adjust the expander decap assembly to the proper height.

Note: Firearm action types and chamber dimensions may vary, causing excess headspace. To el

iminate the excess head-space, adjust the die upward.

DECAPPING ADJUSTMENT

The decapping spindle assembly should be adjusted to remove spent

primers, yet not contact the web of the cartridge case. If adjusted too low,

damage can occur to the decapping assembly/ Slight tension of the Lock Nut

and O-Ring will allow the decapping assembly while preventing accidental

movement. Adjust the height until the decapping pin is 1/8" to 3/16" below

the end of the die.

NECK-SIZE DIE ADJUSTMENT

1. Insert the bushing, large end down, into the die body.

2. Raise the ram of the press to its highest position.

3. For maximum setback, thread the die into the press until the end of the die

touches the shell holder head.

4. To ad

just to your chamber, back the die out accordingly.

5. Tighten the Lock Ring against the press and tighten the screw with the hex

wrench.

6. Adjust the expander decap assembly to the proper height.

PARTS LIST

Key Description Part No.

A Bushing Cap *

B Neck Size Bushing *

C Size Die Body *

D Sure-Loc Ring 044000

E Large Spindle Retainer 396615

Small Spindle Retainer 396616

F O-Ring 396470

G Large E-Clip (2) 396622

Small E-Clip (2) 396621

H Large Decap Spindle 396619

Small Decap Spindle 396617

I Decap Pin 390222

J Elliptical Expander *

K Lock Nut 392764

* Caliber specific part numbers are assigned to these items.

Page 3

FEATURES

AVAILABLE DIES & BUSHINGS

SELF CENTERING SPINDLE ASSEMBLY

ensures precise, concentric neck

expansion.

SPINDLE ADJUST WITH O-RING

provides tension for easy adjustment

as well as positive locking.

KNURLED SPINDLE HOLDER makes it

quick and easy to change bushings

by hand.

SELF-ALIGNING NECK BUSHING

eliminates neck resizing problems.

SURE-LOC RING securely locks the die

to press adjustment.

ELLIPTICAL EXPANDER is specifically

designed for minimum friction and no

case-neck stretch.

REPLACEABLE HEADED DECAP PIN

is machined from select steel and

heat treated.

Full-

Die

Neck-

Size Die

CARTRIDGE

223 Rem.

22-250 Rem.

6MM PPC

6MM BR

243 Win.

308 Win.

.22 Cal. Bushings 6MM Bushings .30 Cal. Bushings

.242 Bushing No. 594242 .260 Bushing No. 594260 .332 Bushing No. 594332

.244 Bushing No. 594244 .262 Bushing No. 594262 .334 Bushing No. 594334

.246 Bushing No. 594246 .264 Bushing No. 594264 .336 Bushing No. 594336

.248 Bushing No. 594248 .266 Bushing No. 594266 .338 Bushing No. 594338

LEAD WARNING: Discharging firearms in poorly ventilated areas, cleaning firearms or handling ammunition

may result in exposure to lead and other substances known to cause birth defects, reproductive harm and other

serious physical injury. Have adequate ventilation at all times. Wash hands thoroughly after exposure.

AVERTISSEMENT PLOMB:

ou manipuler des munitions peut mener à une exposition au plomb ou à d’autres substances reconnues pour

causer des malformations infantiles, des troubles de reproduction et d’autres blessures physiques sérieuses.

Avoir une ventilation adéquate en tout temps. Laver ses mains minutieusement après l’exposition.

Length

544229 544227 Small #16 #1 #2

544221 544231 Large #1 #1 #2

544255 544253 Small #6 #3 #3

544251 544259 Small #1 #3 #3

544245 544243 Large #1 #3 #3

544359 544357 Large #1 #9 #7

These dies allow you to select the bushing of your choice.

Please select the bushing your cartridge and firearm require.

Décharger des armes dans des endroits peu ou mal ventilés, nettoyer des armes

Primer

Punch

Size

Shell

Holder

Trimmer

Pilot

Bullet

Puller

Collet

P.O. Box 1848 • Grand Island, NE 68802-1848

(308) 382-1390 • www.hornady.com

780144

Loading...

Loading...