Page 1

NEW

DIMENSION

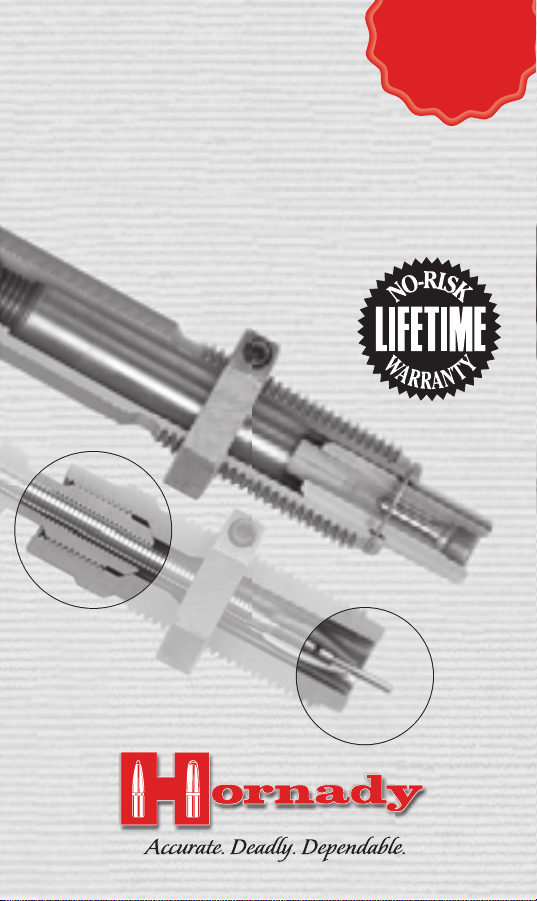

Custom-GradeTM Dies

Zip Spindle™ provides

precise adjustment

and positive lock-down

New and

Improved

Zip Spindle

TM

Headed

Decapping

Pin

™

Page 2

BEFORE USING DIES

Before using your new dies, disassemble and carefully clean

the inside surface of the sizing and seating dies (and the

expander die if a three-die set.) A rust preventive oil is applied

at the factory to protect the dies during shipping and must be

removed before reloading. Any commercial solvent or cleaner

(like our ONE SHOT Gun Cleaner and Dry Lube) will suffi ce.

Inspect all cartridge cases and discard those with cracks,

splits and other visible defects. Wipe cases clean with a soft

cloth to remove grit and other foreign matter which may

scratch the die. Before sizing, lubricate the cases with one of

the case lubes available from Hornady (ONE SHOT Case Lube

or UNIQUE, a hard paste.) No matter the method of lubrication,

all rifl e cases must be lubricated (Hornady’s Titanium Nitride

three-die sets are lube-free.) We don’t recommend the use of

oil-type lubes; they may contaminate the powder inside the case.

Little or no lube on rifl e cases will result in a stuck case.

Over-lubrication will cause dents in the shoulder, damaging

appearance. (If you do get a case stuck in a die, we can remove

the case without damaging the die and return it to you. Please

send the die to our Customer Service Department with $4 for

postage & handling charges.)

Page 3

ADJUSTING THE SIZE DIE

To adjust the expander/decap assembly:

1. Loosen the spindle lock.

2. Adjust the spindle so approximately 3/16"

of the decap pin is below the end of the die

(SEE PHOTO.)

(NOTE: The new Zip Spindle is lightly threaded to

provide a positive no-slip lock. In its free state, the Zip Spindle can

be pulled up and down to make quick adjustments, or can be

threaded for more precise adjustments.)

3. Make sure the threads on the spindle and collet are engaged

and tighten the spindle lock until the spindle no longer rotates.

4. Verify that the decap pin is only extended 3/16" below die.

(Note: The new Hornady Zip Spindle comes with an easily replaceable

headed decap pin. If during use or adjustment, the pin breaks, an

extra decap pin has been provided. Remove the spindle assembly, unthread the expander/retainer, remove the decap pin head, and replace

with the new decap pin.)

To adjust the full-length size die, follow these steps:

1. Raise the press ram to highest position without camming over.

2. Thread the full-length die into the press until the base touches

the shell holder head.

3. Tighten the lock ring against the press and tighten the set

screw with the allen wrench.

(Note: Firearm action types and chamber dimensions vary causing

excess headspace. To eliminate the headspace, adjust the full-length

die upward.)

3/16"

Page 4

ADJUSTING THE SEATING DIE

Hornady bullet seating dies feature a fl oating

in-line sleeve designed to minimize bullet

run-out (misalignment caused by a canted

bullet.) The cartridge neck and bullet are

aligned in the fl oating sleeve prior to

seating the bullet for in-line, precise bullet

seating.

These universal seating dies are manufactured by caliber (.224, .243, .308, .358,

etc...) and not by specifi c cartridge

(222 Remington, 240 Weatherby Magnum,

30-30 Winchester, 35 Whelen, etc...)

Prior to seating, make sure the steel

seating stem is positioned in the alignment

sleeve (see die parts list.) Also, make sure

the cases are chamfered before seating.

When properly adjusted, Hornady’s seating

die may appear as though it’s not threaded

far enough into the press (they are adjusted

for long or short cases). Don’t be alarmed. As few as

three threads need be screwed into the die for precise

and accurate reloading.

(Note: As with all seating dies, when seating lubricated lead bullets,

lubricant will build-up within the die causing variations in seating.

Clean and inspect as needed.)

Page 5

SEATING WITHOUT A CRIMP

1 Insert a sized case into the shell holder and lower the handle

and back out the seater adjustment screw. If you have the

seater adjustment screw too low to start, you may run out

of adjustment.

2 Thread the seating die into the press until you feel

resistance. At that point, the crimp ring has come in contact

with the mouth of the case.

3 Back the die out of the press one turn to prevent the case

from being crimped

the handle and return the ram to its starting position.

4 Insert a bullet in the case mouth - lower the handle so

the cartridge and bullet enter the alignment sleeve. Upon

completion of the stroke, the bullet should be barely seated

in the case.

5 Adjust the seater adjustment screw down in small

increments, each time operating the handle until the bullet

is seated to the desired length. At the completion of each

stroke, inspect the cartridge for the correct overall length.

—

tighten the die body lock ring. Raise

Page 6

SEATING WITH A CRIMP

To begin, refer to the procedure for SEATING WITHOUT A

CRIMP. Follow the procedure throughout, however, DO NOT

TIGHTEN THE DIE BODY LOCK RING.

1 Once you’ve reached the preferred seating depth for the

bullet, back out the seater adjustment screw a few turns.

2 Raise the ram, with the cartridge, to the top of the stroke.

3 Thread the seater die body into the press until it meets

resistance (again, at that point, the mouth of the case has

met resistance with the crimper.)

4 Thread the seater die body into the press in small increments

(one-sixteenth turns) each time operating the handle. At the

completion of each stroke, inspect the cartridge for the

proper crimp.

5 Once you’ve reached the desired crimp (with the cartridge

still in the die), tighten the die body lock ring. Then, while

holding down the handle, thread the seater adjustment screw

downward until it contacts the bullet.

(NOTE: On presses with a cam-over action, back out the adjusting

screw 1/8 to 1/4 of a turn to allow for cam-over.)

6 Raise the handle and remove the cartridge. Check the lock

ring to make sure it’s still tight. Try another case with a

bullet. If the desired seating depth and crimp are

attained, then you can begin seating and crimping in one

operation. If not, make the needed minor adjustments.

(NOTE: For uniform crimps, cases must all be trimmed to a

uniform length.)

Page 7

NECKING UP

The elliptical shape of the expander allows the reloader to

expand the mouth of the case as well as “neck up” from one

caliber to a larger caliber without the use of a tapered expander.

The expander is tapered at the top as well as the bottom to

“neck up” in stages. For example, you can use Hornady’s 25

caliber and 30 caliber expanders to neck up from a 22 caliber to

30 caliber.

ADJUSTING THE EXPANDER DIE

(Three-die sets only)

The expander assembly is designed to put a slight “bell” or fl are

on the case mouth. For uniform fl aring, trim all case to their

proper length.

To adjust the expander die body, raise th

press ram to its full height with a case i

the shell holder. Thread the expander die

into the press until the expander touches

the case mouth. Raise the handle and sc

down the die in small increments (each

inspecting the mouth) until the mouth o

case has been fl ared just enough to sea

bullet. Tighten the die body lock ring and set screw. Keep in

mind that an excessive fl are can eventually shorten case life,

and may keep the case from properly entering the seating die.

Page 8

DIE SET

PARTS LIST

Key Description Part No.

A Zip Spindle Lock 398731

B Size Die Body *

C Zip Spindle 398567

D Headed Decap Pin 390222

E Expander *

Decap Retainer

F Seater Adjustment 044100

Screw

G Seater Lock Nut 044800

H Washer 398067

*Caliber specific part numbers are assigned to these items.

Key Description Part No.

I Seater Die Body *

J Retaining Ring 396430

K Seating Stem *

L Alignment Sleeve *

M Expander Die Body *

(3 Die only)

N Lock Ring Screw 390200

O Sure-Loc Lock Ring 044000

P Allen Wrench 390656

Page 9

PRODUCT WARRANTY

WARRANTY: Hornady product warranty extends to the

original purchaser of the reloading dies. Hornady product

warranty does not apply to commercial reloaders.

WARRANTY COVERAGE: Hornady reloading dies are

warranted against defective materials and workmanship.

Hornady NEW DIMENSION dies are guaranteed not to

break or wear out from normal use. THIS WARRANTY IS

VOID IF THE PRODUCT (1) has been damaged by accident

or unreasonable use, neglect, improper service or other

causes not arising out of defects in material or workmanship, or (2) has been altered or repairs have been made

or attempted by other than authorized factory personnel,

or (3) is used commercially or (4) has been altered or

defaced in any way. Reloading dies will be either replaced

or reconditioned (at Hornady’s discretion) when product is

returned prepaid, to: HORNADY WARRANTY REPAIR

SERVICE, 3625 OLD POTASH HIGHWAY, GRAND ISLAND, NE

68803. The replacement will continue the warranty of the

original product, or ninety days, whichever is longer.

Page 10

ACCESSORIES

MicroJust

The economical way to achieve optimum bullet seating

depth for benchrest accuracy and consistency. Simply

replace the standard seating depth adjustment stem on

your New Dimension Custom Grade Dies with the MicroJust

Seating stem. Allows you to precisely set bullet seating

depth in .001" increments.

No. 044090

™

L-N-L Die and Conversion Bushings

Simply insert a Hornady conversion bushing into

your RCBS® Rock Chucker or other reloading

press using a 1¼-12 thread, and you’re ready

to start using the Lock-N-Load System. It’s the

easiest way to get the most out of your reloading

press. These bushings let you take advantage

of Hornady’s Lock-N-Load technology even if you

own a competitor’s reloading press. The Lock-NLoad Conversion kit includes three die bushings

and one conversion bushing.

L-N-L Press Conversion Bushing No. 044095

(2-pk.) L-N-L Die Bushings No. 044094

(3-pk.) L-N-L Die Bushings No. 044093

(10-pk.) L-N-L Die Bushings No. 044096

L-N-L Conversion Kit No. 044099

Page 11

HORNADY WARRANTY REGISTRATION

Please return in envelope within 20 days of purchase.

Name ___________________________________________

Address __________________________________________

City ____________________________________________

State ________________________ Zip _______________

email ___________________________________________

Item Purchased ____________________________________

Serial No. ________________________________________

Dealer Name ______________________________________

City ____________________________________________

State ________________________ Zip _______________

Send to:

Hornady Manufacturing

P.O. Box 1848 • Grand Island, NE 68802-1848

Page 12

P.O. Box 1848 • Grand Island, NE 68802-1848

(308) 382-1390 •

5/05 780140

www.hornady.com

Loading...

Loading...