Page 1

OWNER'S MANUAL

®

LOCK-N-LOAD

B ULLET

FEEDER

(PISTOL)

Page 2

Table of Contents

ASSEMBLY

ASSEMBLY

Pistol Bullet Feeder .......................................................... Page 3

CHANGE-OVERS

The Hornady Lock-N-Load® Pistol Bullet Feeder is capable of feeding most pistol

bullets. Refer to this section when changing bullet caliber, type, or brand.

Pistol Bullet Feeder .......................................................... Page 11

Plate Height

Wiper Adjustment

Drop Tube Funnel

Drop Tube

Bullet Feed Die

APPENDIX

APPENDIX B

Lock-N-Load® AP™ Press Mounting Template .......................... Page 15

- 2 -

ASSEMBLY: PISTOL BULLET FEEDER

Page 3

Lock-N-Load® AP™ Pistol Bullet Feeder

OVERVIEW

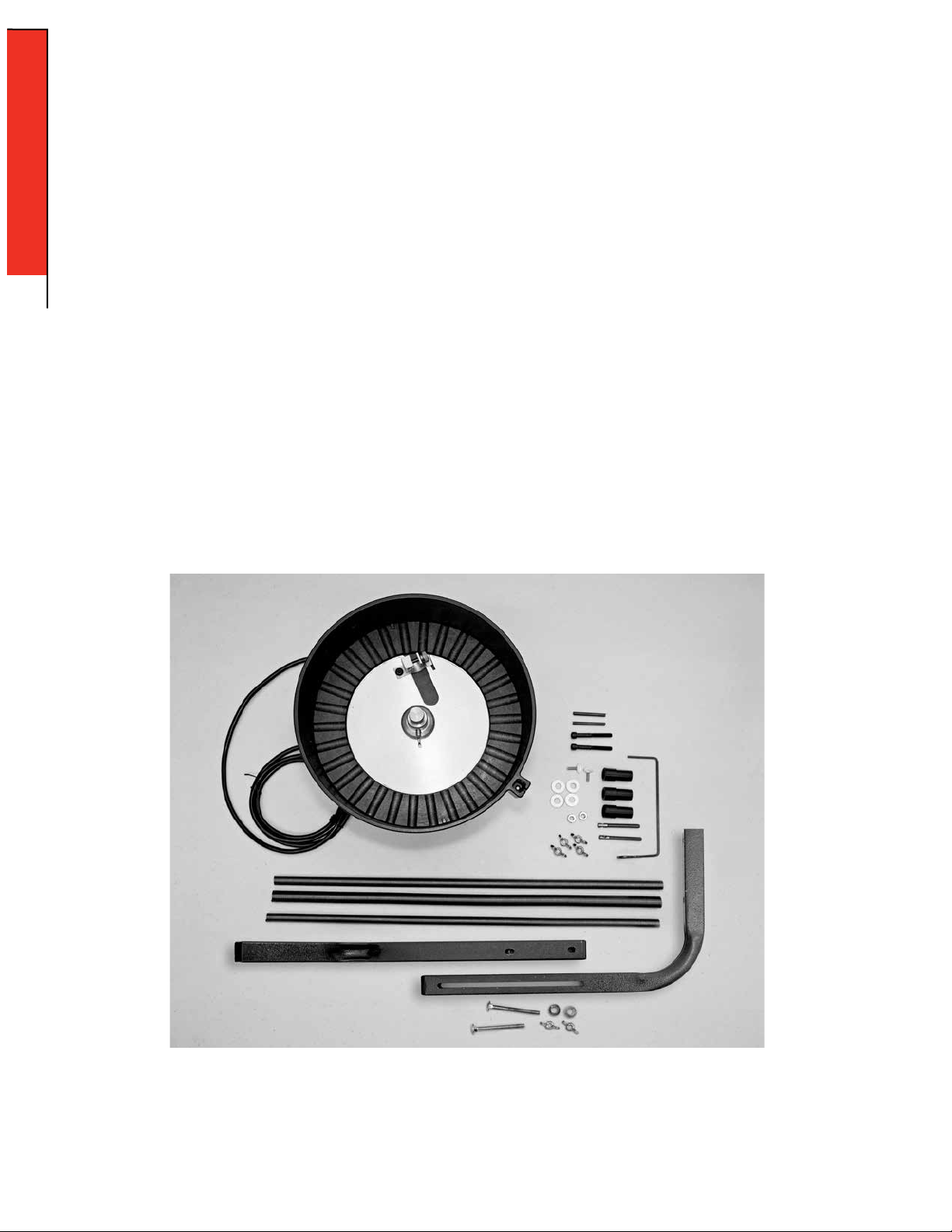

Your new Lock-N-Load® AP™ Pistol Bullet Feeder has been packaged to ensure minimal vibration and damage during transportation.

Remove all the parts from the packing box (see page 2) and spread them over a large flat surface. Refer to the parts list and exploded view

on the next two pages and check to make sure all necessary parts are identified.

This manual provides step-by-step instructions that make set-up and operation easy and understandable.

ASSEMBLY

Tools needed for assembly and set-up:

• 7/16" End Wrench

• 3/16" Hex Wrench

• 1/4" Drill Bit

• Electric Drill

ASSEMBLY: PISTOL BULLET FEEDER

- 3 -

Page 4

Lock-N-Load® Auto Progressive (AP™) Pistol Bullet Feeder

PARTS LIST

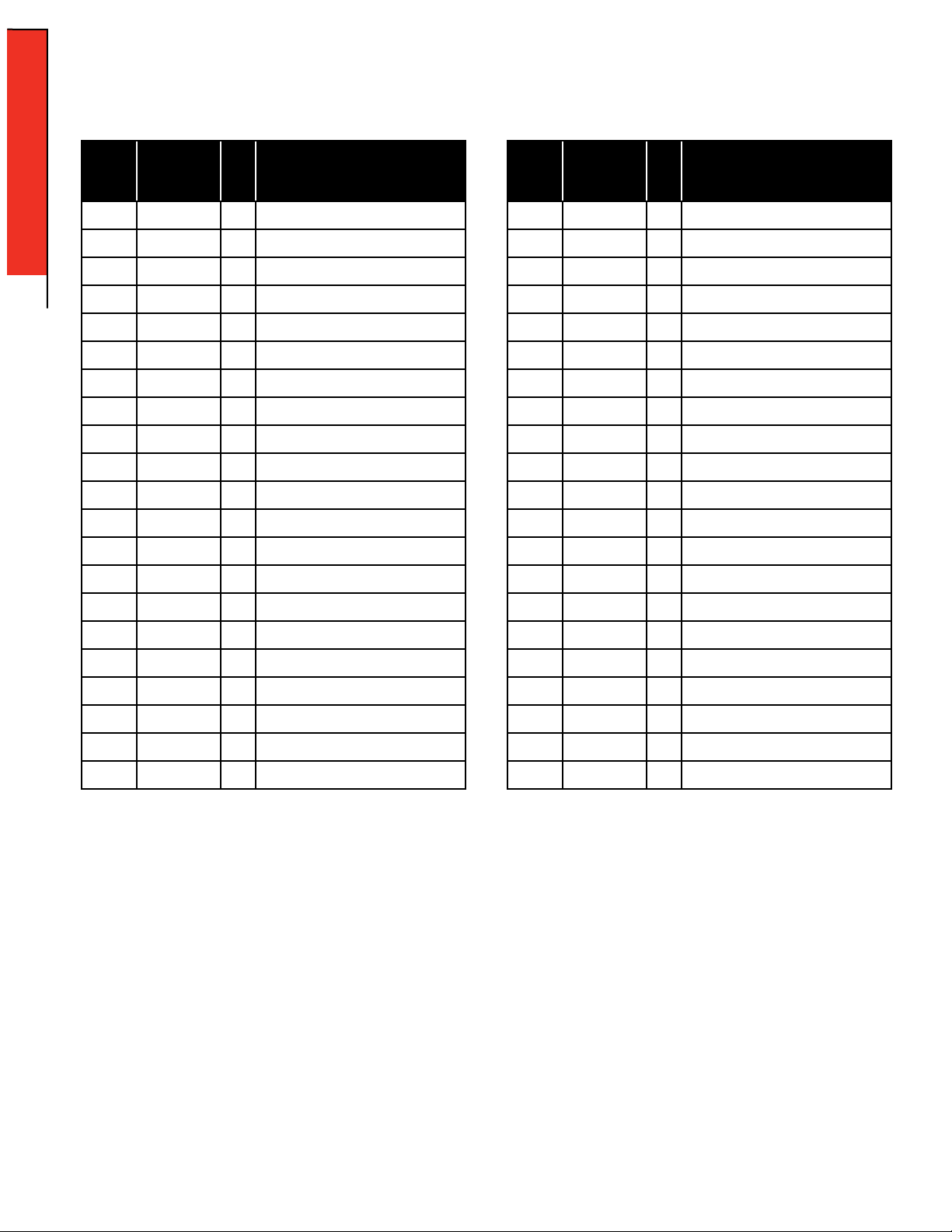

Production

ASSEMBLY

Item No.

1 392011 3 Nut Hex 10-32 Zinc

2 399209 1 Steel Knurled Thumb Screw

3 399213 1 Tube Spring Clamp

4 399210 1 BHCS 10-32 X 1/4

5 399 214 1 Tube Bullet Drop Funnel Large

5 399215 1 Tube Bullet Drop Funnel Medium

5 399216 1 Tube Bullet Drop Funnel Small

6 399205 1 Screw Adjustment Bullet Feed

7 399206 1 Screw Lock Nut Adjustment

8 398067 1 Rubber Washer Flat

9 399208 1 Center Plate Adjustment Nut

10 398400 1 Thumb Screw 1/4-20 X 1/2

11 399202 1 Hopper Turning Plate

12 398401 2 Screw FHSCS 10-32 X 1/4

13 399201 1 Bullet Feed Wheel - Pistol

Part No. Qty. Description

Item No.

Production

Part No. Qty. Description

20 399102 1 Spur Gear 1.200 P.D. 24 Tooth

21 39924 4 1 FHCS 1/4-20 X 1/2

22 398381 1 Pin Spirol 1/8 X 3/4

23 398399 1 Motor Bullet Feeder

24 399222 2 Screw Bullet Wiper

25 399242 6 Nut Wing 1/4-20

26 399223 2 Spring Wiper Bullet Feed

27 399224 2 Thumb Screw 8-32 X 1/2

28 399217 1 Tube Holder Bullet Feeder

29 399200 1 Bullet Feed Hopper

30 399211 2 SHCS 1/4-20 X 2

31 39 0128 6 Washer Flat 1/4"

32 398418 1 Bushing (HEYCO 1147) Black

33 399219 1 Tube Drop Small

33 399243 1 Tube Drop Medium

14 399212 3 Nut Hex 1/4-20

15 399207 1 Center Pin Bullet Plate

16 399218 1 Spur Gear 1.500 P.D., 30 Tooth

17 398313 8 Screw FHSCS 10-32 X 3/4

18 399203 1 Bullet Feeder Base Plate

19 398402 1 Ideler Gear Shaft

33 399221 1 Tube Drop Large

34 398332 1 Switch 2 Position

36 399358 1 Support Tube-Bottom

37 399359 1 Support Tube-Top

38 399360 2 1" Square Finishing Plug

39 399362 2 1/4-20x2.5 Carriage Bolt

- 4 -

ASSEMBLY: PISTOL BULLET FEEDER

Page 5

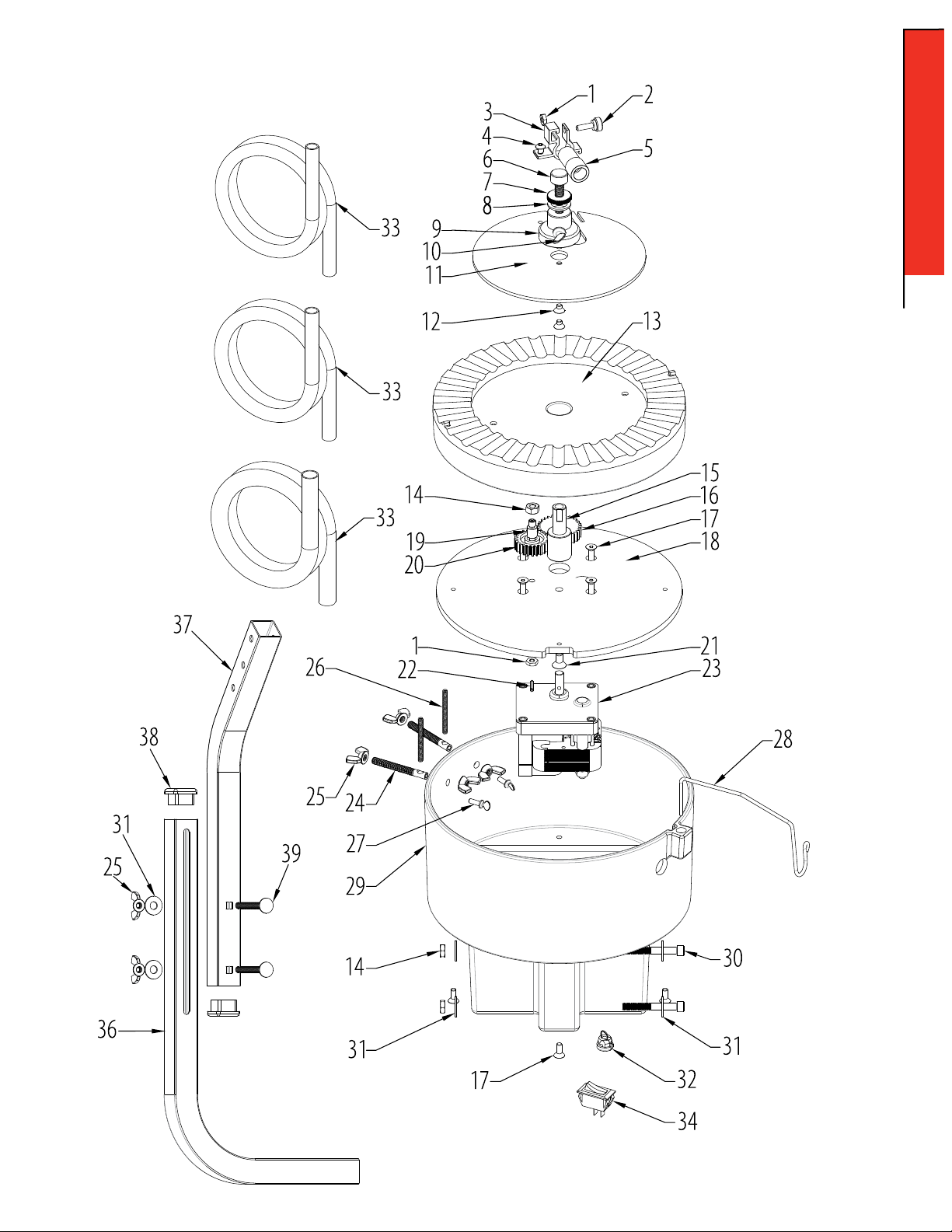

Lock-N-Load® AP™ Pistol Bullet Feeder

EXPLODED VIEW

ASSEMBLY

ASSEMBLY: PISTOL BULLET FEEDER

- 5 -

Page 6

Mounting the Bullet Feeder

1

to the Bench

Refer to Appendix B for the template.

1

ASSEMBLY

Place the template on the table in the location you would

like to mount the press and Lock-N-Load® AP™ Pistol Bullet

Feeder. Drill ¼" holes for the placement of the Square Tubing

Mounting Bracket.

Use ¼" bolts with ¼" Flat Washers (not provided, due to

2

different thicknesses of tables) on top of the Square Tubing

Mounting Bracket and also one on the bottom of the bench.

2

Once the Support Tube-Bottom (36) is securely attached to

3

the bench top, line up the Support Tube-Top on the front of

the tube, oriented as shown in the exploded view on page 27.

Slide a ¼-20x2.5 Carriage Bolt (39) through one of the square

holes in the top tube and through the slot in the bottom tube.

Place a ¼” Flat Washer (31) over the bolt and thread on a

¼-20 Wing Nut (25). Repeat with another bolt, washer, and

nut through the other square hole. The height of this tube

may need to be adjusted at a later time in order to allow

bullets to slide freely down the Drop Tube (33).

- 6 -

ASSEMBLY: PISTOL BULLET FEEDER

Page 7

Mounting the Bullet Feed Hopper to the

Square Tubing Mounting Bracket

Slide the Hopper (29) over the top of the Square Tubing

4

Mounting Bracket (37), with the open face of the Hopper facing

the front of the bench or table.

Place a ¼-20 X 2 SHCS Bolt (30) with one ¼" Flat Washer (31)

5

through the top hole of the Bullet Feed Hopper and the Square

Tubing Bracket.

4

ASSEMBLY

Square Tubing

Bracket

5

SHCS Bolt

Place a ¼-20 X 2 SHCS Bolt (30) with one ¼" Flat Washer

6

(31) through the bottom hole of the Bullet Feed Hopper and

the Square Tubing Mounting Bracket.

If you are having issues with bullets not being able to keep

up feeding (approximately 100 bullets in 5 to 6 minutes),

switch the bolt from the bottom hole to the middle hole.

Flat Washer

6

SHCS Bolt

Flat Washer

ASSEMBLY: PISTOL BULLET FEEDER

- 7 -

Page 8

Place a ¼" Flat Washer (31) over the end of each of the two

7

Bolts just previously place through the Bullet Feed Hopper

and Square Tubing Mounting Bracket.

Place a ¼-20 Hex Nut (14) onto the two ¼-20 X 2 SHCS Bolts

and tighten snug.

7

ASSEMBLY

Tighten Hex Nut

Bullet Feed Hopper Set Up

Loosen ¼-20 Thumb Screw (10).

8

8

Loosen Lock Nut (7) on the Adjustment Screw (6).

9

Thumb Screw

9

Adjustment

Screw

Lock Nut

- 8 -

ASSEMBLY: PISTOL BULLET FEEDER

Page 9

Bullet Feed Hopper Set Up (con't)

10

Raise the Hopper Turning Plate (11) by turning the

10

Adjustment Screw (6) clockwise.

Raise the Bullet Guide Plate above the bottom of the slots

on the Bullet Feed Wheel Pistol far enough to hold a bullet

base first against the Bullet Feed Wheel Pistol.

Place a bullet that you plan on loading facing base first up

11

against the Bullet Guide Plate and against the Bullet Feed

Wheel Pistol. Next to this bullet, place another bullet so that

the nose is facing the center of the Bullet Feed Wheel Pistol.

You will then need to adjust the Bullet Guide Plate either

up or down to get a bullet to stay on the Bullet Feed Wheel

Pistol base first, but fall off the Bullet Feed Wheel Pistol

if the bullet is nose first towards center of the Bullet Feed

Wheel Pistol.

ASSEMBLY

Adjustment

Screw

Hopper Turning

Plate

11

Bullet Feed

Wheel Pistol

Bullet Wiper (Bottom Wiper)

Install the wipers as with one Wing Nut

outside of the Bullet Feed Hopper on the Wiper Screw

12

Loosen the wing nuts.

Place two bullets nose to nose in a slot close to the height

of the first or bottom wiper screw and Wiper Spring (26).

Adjust the first wiper spring and screw to wipe off the

outside bullet.

Tighten down the two wing nuts and the thumb screw.

(25)

installed on the

(24)

Bullet Guide

Plate

12

.

Hopper

Wiper Screw

Wing Nuts

Wiper Spring

ASSEMBLY: PISTOL BULLET FEEDER

- 9 -

Page 10

Bullet Wiper (Top Wiper)

13

Wing Nuts

Install the wipers as shown in with one Wing Nut installed on

13

the outside of the Bullet Feed Hopper) on the Wiper Screw.

Place one bullet facing the center of the Bullet Feed Wheel

ASSEMBLY

Pistol base first. Next to it, place a bullet facing nose first

to the center of Bullet Feed Wheel Pistol. The bullet that is

facing nose first, push the nose down a little so the base

is sticking up.

Adjust the second Wiper Spring and Wiper Screw to just

miss the nose of the first bullet but kick the base of the

second bullet.

Tighten down the two Wing Nuts and the Thumb Screw.

Drop Funnel

Select the correct size of Drop Funnel for your application.

14

9MM/38/.357 ...........(375 I.D.) ............Item No. 399216

40 S&W/10 MM ........(406 I.D.) ............Item No. 399215

.44/.451/.452 ............ (530 I.D.) ............Item No. 399214

14

Wiper Screw

Wiper Spring

Thumb Screw

Insert the Drop Funnel (5) into Tube Spring Clamp (3). You will

15

want the front edge (outside edge) of the Drop Funnel as close

to the Bullet Feed Wheel Pistol without touching the Bullet Feed

Wheel Pistol.

Tighten the Knurled Thumb Screw (2) on the side of the Tube

Spring Clamp. Only snug this screw, DO NOT over tighten this

screw.

- 10 -

ASSEMBLY: PISTOL BULLET FEEDER

15

Bullet Feed

Wheel Pistol

Knurled Thumb

Screw

Tube Spring

Clamp

Drop Funnel

Page 11

Setup / Changeover of the Lock-N-Load® Pistol Bullet Feeder

The Hornady Lock-N-Load® Pistol Bullet Feeder is capable of feeding most pistol bullets. When changing bullet caliber, type, or brand, the

following components on the Bullet Feeder may need to be changed or verified. Hopper Plate Height.

• Bottom Wiper Location

• Top Wiper Location

• Drop Tube Funnel

• Drop Tube

• Bullet Feeder Dies

Hopper Plate Height

1

Loosen ¼-20 Thumb Screw and the Lock Nut on the

Adjustment Screw.

Raise the Bullet Guide Plate by turning the Adjustment Screw

clockwise.

Raise the Bullet Guide Plate above the bottom of the slots on

the Bullet Feed Wheel Pistol far enough to hold a bullet base

first against the Bullet Feed Wheel Pistol.

Place two bullets onto the Bullet Feed Wheel, one with the

2

nose toward the center, and the other with the base toward

the center. Rotate the Adjustment Screw to adjust the Bullet

Guide Plate either up or down to get a the nose down bullet to

fall off the plate, yet keep the base down bullet on the Bullet

Guide Plate.

Once the Bullet Guide Plate position is acceptable, tighten

the Lock Nut and then the ¼-20 Thumb Screw.

1

Adjustment Screw

Thumb Screw

2

Bullet Feed Wheel

Lock Nut

Adjusting the Bottom Wiper

3

The bottom wiper is used to remove the top bullet when two

bullets are double-stacked on the Feed Wheel Plate.

To adjust the spring location, loosen the two Wing Nuts and

slide the assembly in or out. The spring should be located so

the top bullet is knocked off the bottom bullet as the Bullet

Feed Wheel turns. Tighten down the two wing nuts and the

thumb screw.

Loosen the thumb screw and move the spring so that it just

clears the Bullet Feed Wheel. The spring should not contact

the Feed Wheel Plate during normal operation.

With a little trial and error, the spring should be adjusted

so that it knocks off the top bullet without disturbing the

bottom bullet.

CHANGE-OVER

3

Wing Nut

Wing Nut

Thumb Screw

CHANGE-OVER: PISTOL BULLET FEEDER

- 11 -

Page 12

Adjusting the Top Wiper

4

The Top Wiper is intended to remove nose heavy bullets that do

not fall off when pointed nose down on the Bullet Feed Plate .

Place two bullets onto the Bullet Feed Wheel near the Top

Wiper, one with the nose toward the center, and the other with

the base toward the center. Push the nose down a little on the

bullet that is nose toward so the base is sticking up.

Adjust the second wiper spring and wiper screw to just miss

the nose of the first bullet but kick the base of the second

bullet.

Tighten down the two wing nuts and the thumb screw.

Switching Drop Tube Funnel

5

Select the correct size of Drop Funnel for your application.

9MM/38/.357 .............. (375 I.D.) .......... Item No. 399216

40 S&W/10 MM ........... (406 I.D.) ..........Item No. 399215

.44/.451/.452 .............. (530 I.D.) ..........Item No. 399214

Insert the Drop Funnel into Tube Spring Clamp. You will want

the front edge (outside edge) of the Drop Funnel as close to the

Bullet Feed Wheel Pistol without touching the Bullet Feed Wheel

Pistol.

Tighten the Knurled Thumb Screw on the side of the Tube

Spring Clamp. Only snug this screw, DO NOT over tighten this

screw.

4

Wiper Screw

Wiper Spring

5

Wing Nut

Thumb Screw

Tube Spring

Clamp

Knurled Thumb

Screw

Drop Tube Funnel

Switching the Drop Tube

6

Select the correct size of Drop Tube for your application.

9MM/38/.357 .............. (375 I.D.) .......... Item No. 399219

40 S&W ....................... (406 I.D.) ..........Item No. 399243

.44/.451/.452 .............. (530 I.D.) ..........Item No. 399221

Slip the Drop Tube into the hole on the bottom right side of the

Bullet Feed Hopper. Insert the end of the Drop Tube into the

back end of the Drop Funnel. Insert the straight end of the Drop

Tube Holder into the hole on the bottom right side of the hopper.

CHANGE-OVER

Next place the Drop Tube into the hook of Drop Tube Holder.

Testing Hopper Setup

7

At this time, place about 100 bullets into the Bullet Feed

Hopper and turn on the Switch on the bottom right corner of the

Bullet Feed Hopper.

You will want to hold the end of the Drop Tube in your hand at

this time to catch the bullets that will fall out of the tube.

At this time, make sure you have the Bullet Wipers set correctly.

If they are not, shut off the Switch and readjust the Bullet

Wipers. You may need to do this a couple of times, until you

have them set correctly and the bullets are falling base first

every time.

If the hopper plate is jumping or not rotating smoothly, your

Drop Tube Funnel is too close to the Bullet Feed Wheel Pistol.

This needs backed off until the Bullet Feed Wheel Pistol rotates

smoothly.

If the bullets are feeding correctly, tighten down the Bullet

Guide Plate Thumb Screw, and Snug Lock Nut.

6

Drop Tube Funnel

Drop Tube

7

Drop Tube Funnel

Drop Tube

- 12 -

CHANGE-OVER: PISTOL BULLET FEEDER

Page 13

Bullet Feed Die Set Up

Disassemble the die and lay the parts out on a flat surface.

Degrease every part of the die.

Reassemble the die as you took it apart.

Collet “A” goes in first with the open slots facing the bottom

of the die.

Collet “B” goes in next with the open slots facing the bottom

of the die.

Thread the Lock Ring back onto the Adjustment Screw until

the Lock Ring is near the top end of the Adjustment Screw.

Place the O-Ring over the threads of the Adjustment Screw

until it is close to the Lock Ring.

Screw the Adjustment Screw into the die. Screw it down until

the end of the Adjustment Screw is just touching “Collet B”.

With the Adjustment Screw touching the top Collet, back the

Adjustment Screw off ½ turn and lock down the Lock Ring

against the top of the Die Body.

At this time you should be able to shake the die and hear the

two Collets move up and down just a little bit. If you hear

this, the die is set up correctly.

Adjustment Screw

Lock Ring

Collet “B”

O-Ring

Collet “A”

Die Adjustment Lock-N-Load® AP

Screw on the Lock Ring to the outside threads of the Die Body.

Screw on the Lock-N-Load® Bushing to the outside threads of

the Die Body.

Place the die into the top of the press and inserting it into

the Lock-N-Load® Bushing in the Press Body.

Die Adjustment for a NON Lock-N-Load® AP

Place a Flared Case for your set up in the previous station.

Case mouths should be flared to the approximate dimensions

listed below.

380/9MM ................. .385"

38/357 ...................... .387"

40S&W/10MM ........... .430"

44 SPL/44 MAG ......... .460"

.451/.452 ................... .481"

Raise the ram to the top of the stroke.

Screw the Die Body down until it touches the top of the case.

Lower the ram to the bottom of the stroke.

Screw the Die Body down ½ turn and lock down the Lock Ring.

At this time the die should be set.

Place 5 or 6 bullets base first into the top of the die.

™

™

CHANGE-OVER

Bullet Feeder Die

Die Set Up

Place the case into the Shell Plate in the station before the Bullet Feeder Die

so when the press rotates, the Flared Case will be inserting into the Bullet

Feeder Die. Continue to raise the Ram to the top of the stroke. You will not be

able to see or hear anything at this time.

Lower the Ram slowly.

You should be able to see a bullet that dropped on top of the case mouth. If

the bullet dropped onto the case mouth and you can see it, you should have

been able to hear a little noise coming from the collets. This is a correct

sound, it will do this every time that the collets work correctly.

If the collets didn’t drop a bullet, lower the Die Body approximately 1/16"

turn and repeat the previous 3 steps. Repeat these steps until you get a

bullet to fall onto the case every time.

CHANGE-OVER: PISTOL BULLET FEEDER

- 13 -

Page 14

- 14 -

Page 15

APPENDIX B - TEMPLATE Lock-N-Load® AP

™

- 15 -

Page 16

P.O. Box 1848, Grand Island, Nebraska 68802-1848

308-382-1390 • 800-338-3220 • Fax: 308-382-5761

399176 03/2014

www.hornady.com • webmaster@hornady.com

Loading...

Loading...