Page 1

Hornady® Lock-N-Load™ Concentricity Tool

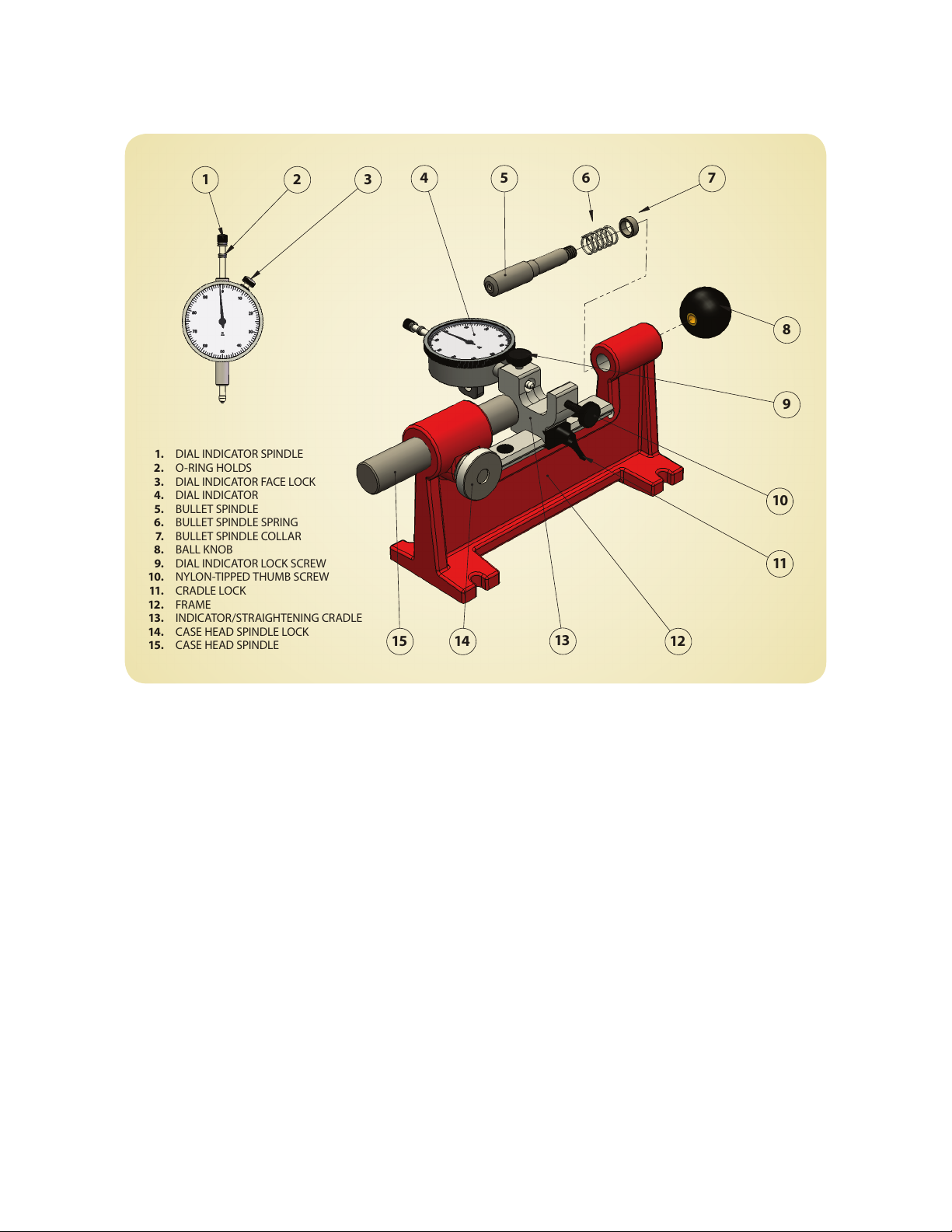

4 5 6

8

9

10

11

12

13

1415

7

321

DIAL INDICATOR SPINDLE

1.

O-RING HOLDS

2.

DIAL INDICATOR FACE LOCK

3.

DIAL INDICATOR

4.

BULLET SPINDLE

5.

BULLET SPINDLE SPRING

6.

BULLET SPINDLE COLLAR

7.

BALL KNOB

8.

DIAL INDICATOR LOCK SCREW

9.

NYLON-TIPPED THUMB SCREW

10.

CRADLE LOCK

11.

FRAME

12.

INDICATOR/STRAIGHTENING CRADLE

13.

CASE HEAD SPINDLE LOCK

14.

CASE HEAD SPINDLE

15.

Instruction Sheet

Setup

The Hornady® Lock-N-Load™ Concentricity Tool ships

pre-assembled with a bullet spindle (5) that will work for

most applications. However, if a smaller or larger spindle

(included) is required, simply unscrew the ball knob (8),

remove the bullet spindle (5), bullet spindle spring (6) and

bullet spindle collar (7), then place the spring and collar on

the spindle of your choice and reassemble in the frame.

Place the dial indicator (4) in the dial indicator hole located

on the indicator/straightening cradle (13). Secure the dial

indicator by tightening the dial indicator lock screw (9) to

hold the dial indicator (4) in position.

Pull the dial indicator spindle (1) back and slide the o-ring

holds (2) down to hold the dial indicator spindle (1) from

protruding too far into the indicator cradle opening. Also,

back the nylon-tipped thumbscrew (10) out of the indicator cradle opening. This will allow the first cartridge to be

easily inserted into the Hornady® Lock-N-Load™ Concentricity Tool.

Loosen the case head spindle lock (14) and slide the case

head spindle (15) rearward.

Place selected cartridge case head in the case head spindle

(15) and slide the spindle forward guiding the bullet into

the recess in the bullet spindle (5). Continue to push the

cartridge forward until the ball knob (8) moves approximately 1/8 inch away from the frame (12) (this 1/8 inch is

a place to start and may be increased or decreased to the

user’s preference). Now, lock the case head spindle (15) in

place by tightening the case head spindle lock (14).

Cartridges can now be removed and replaced by pulling

the ball knob (8) away from the tip of the cartridge which

will create clearance between the bullet spindle (5) and tip

of the cartridge.

Slide the o-ring holds (2) on the dial indicator spindle (1)

back to allow spindle to come into contact with the bullet.

Loosen the indicator/straightening cradle (13) by loosening

the cradle lock (11), then slide the cradle until the indicator is located where the ogive meets the shank of the

bullet. (This position can be adjusted according to bullet

design and/or user preference). Now tighten the indicator/

straightening cradle (13) with the cradle lock (11).

Adjust the o-ring holds (2) on the dial indicator spindle (1)

so that the spindle only drops .020" to .030" when the cartridge is removed from the concentricity tool. This allows

the cartridge to be removed and replaced easily.

Page 2

Operation

Straightening Cartridges

At this point you are ready to start inspecting and, if needed,

correcting cartridge concentricity.

Place a cartridge in the tool and rotate to indicate run-out.

Note: If the bullet spindle (5) rotates with cartridge, hold ball

knob (8) to keep it from rotating, as the cartridge MUST rotate

between stationary centers to deliver an accurate measurement.

Set the dial indicator (4) to zero at the cartridges lowest setting

by loosening the dial indicator face lock (3) on the side of indicator and rotating the face, or by loosening the dial indicator

lock screw (9) and adjusting the indicator in or out.

WARNINGS:

Reloading is an enjoyable and rewarding hobby that is easily conducted with

safety. Carelessness or negligence can make any hobby, especially reloading,

hazardous. All Hornady® reloading tools and supplies are designed with the

user’s safety in mind. However, since Hornady® Mfg. Co. has no control over the

manner in which products or components are used in the reloading operation,

it cannot assume any liabilit y for damage, which may result from the use of the

products or the information given herein. It is the responsibility of you, the user,

to follow generally accepted safety practices.

Use all reloading tools and supplies as the manufacturer recommends. Study

the instructions carefully and become thoroughly familiar with the operation of

those tools and supplies.

Observe good housekeeping in the reloading area. Keep all tools and supplies

neat, clean and orderly. Promptly clean up all primer and powder spills.

With the cartridge at its lowest point on the dial indicator (4),

bring the nylon-tipped thumbscrew (10) into contact with the

bullet applying pressure. Watch the indicator and take past the

cartridge’s high point on the dial indicator (4) and then release

the nylon-tipped thumbscrew (10). Re-measure concentricity and repeat the process if necessary. The amount of force

required to correct the cartridge is determined by multiple

factors.

Best accuracy is generally achieved when cartridge concentricity is no more than .002"-.003".

Know your components. Study manufacturers’ manuals to properly identify all

components and use them according to their recommendations.

Perform all tasks relative to reloading only when you can give it your complete attention. Do not perform these activities when you are ill, fatigued, or

distracted. Develop a routine to avoid mistakes and haste.

Always wear eye protection. You assume reasonable risk during most reloading

related tasks and doing so without safety glasses is adding an unnecessary

additional risk.

Use only laboratory tested and approved reloading and component data and

reloading procedures. We highly recommend the Hornady® “Handbook of Cartridge Reloading” in its most current Edition as your source for the most modern

and current information.

1-308-382-1390 | PO Box 1848 | Grand Island, NE 68802 | hornady.com

07/09 #780023i

Loading...

Loading...