Page 1

OWNER'S MANUAL

®

Lock-N-Load

™

Classic

Metallic Press

*Photo shows optional

Automatic Primer Feed

(Item No. 0 70 905)

Shell Holder and Die

Page 2

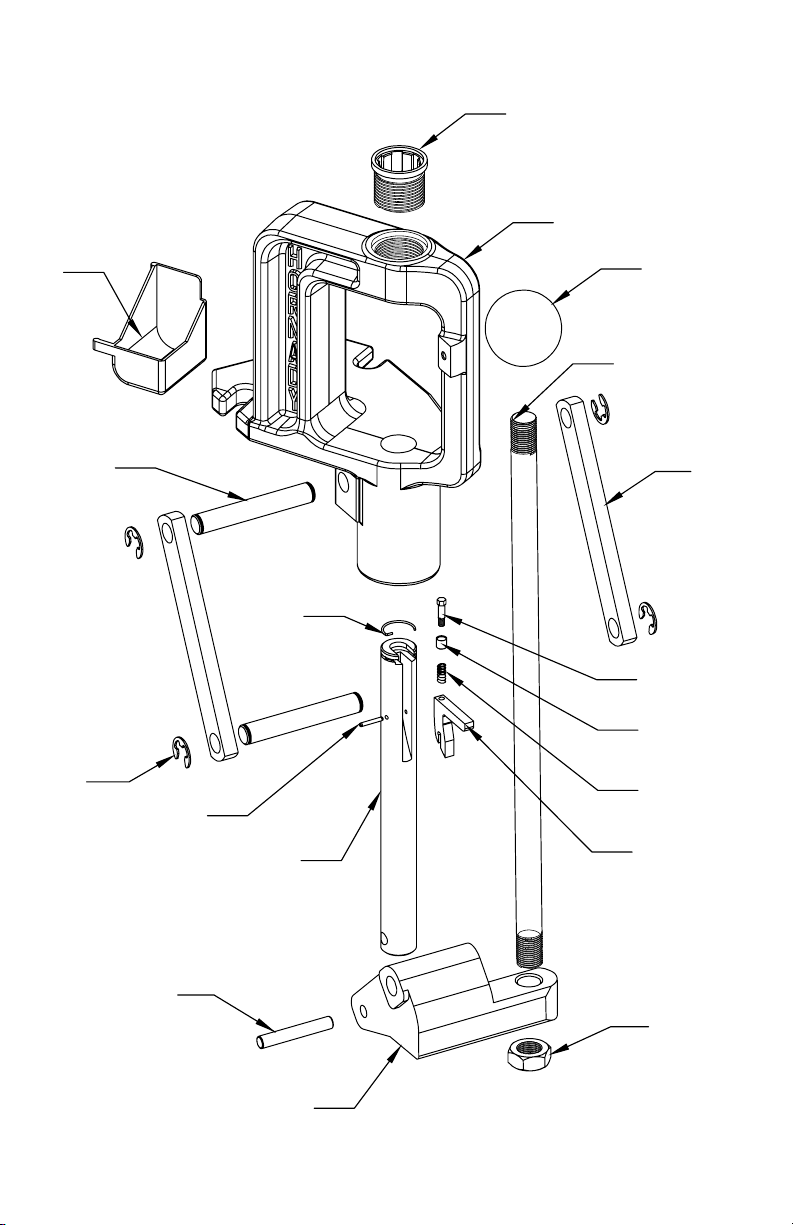

EXPLODED VIEW

1

2

3

9

6

10

8

11

4

5

7

15

16

17

18

12

14

13

- 2 - - 3 -

Page 3

PARTS LIST

Item

No. Part No. Qty. Description

1 392301 1 Bushing Press LNL

2 19 0214 1 Frame

3 480090 1 Primer Catcher

4 480003 1 Knob Handle

5 390657 1 Handle

6 390070 2 Pin Link

7 390071 2 Link

8 380053 1 Spring Shell Holder

9 390081 4 Clip E 1/2

10 390661 1 Pin Roll 3/32 x 5/8 Slotted

11 390697 1 Ram

12 390072 1 Pin Dowel 5/16 x 2

13 19 0 215 1 Toggle

14 390027 1 Nut Jam 5/8-18

POSITIVE PRIMING SYSTEM (PPS) SHOWN BELOW

15 390035 1 Large Primer Punch

16 390006 1 Large Primer Cup

17 390007 1 Primer Cup Spring

18 19 0213 1 Primer Arm

390034 1 Small Primer Punch

390005 1 Small Primer Cup

Page 4

PARTS LIST

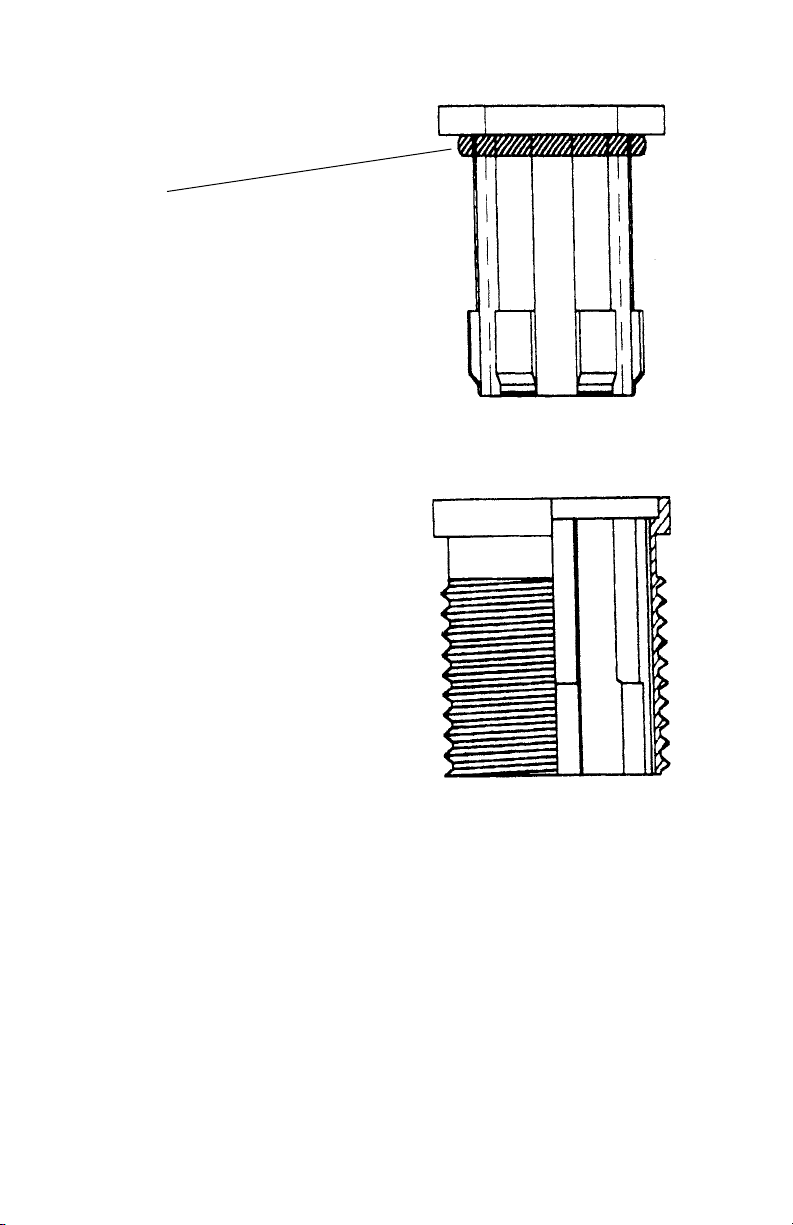

Lock-N-Load® Die Bushing

Part #392302

O – Ring

Part #392303

Lock-N-Load® Press Bushing

Part #392301

Lock-N-Load® Die Bushings

Lock-N-Load® die bushings are available in convenient packs

of two, three, or ten. Put a Lock-N-Load® die bushing on all of

your favorite dies for maximum reloading efficiency.

Lock-N-Load® Die Bushings

(2-pack) No. 044094

Lock-N-Load® Die Bushings

(3-pack) No. 044093

Lock-N-Load® Die Bushings

(10-pack) No. 044096

- 4 - - 5 -

Page 5

NO-RISK LIFETIME WARRANTY

All Hornady reloading tools and accessories are warranted against material

defects and workmanship for the life of the product. Simply stated – if it breaks,

we’ll repair it or replace it at no charge (at Hornady Manufacturing Company’s

option).

Hornady reloading tools and accessories are warranted against defective

materials and workmanship only. This warranty is void if the product (1) has

been damaged by accident or unreasonable use, neglect, improper service or

other causes not arising out of defects in material or workmanship; or (2) has

been altered or repairs have been made or attempted by other than authorized

factory personnel; (3) is used commercially; or (4) has been altered or defaced

in any way.

This warranty supersedes all other warranties for Hornady products either

written or oral. No other warranty is expressed or implied.

Page 6

INSTRUCTIONS

Mount your new press securely

1

to a solid level bench.

Position the press on the bench with

the mounting holes far enough back

to provide firm support and still allow

clearance for the toggle.

Select a shell holder for the

2

cases you will be reloading.

It is retained in the recess in the top of

the ram by a detent spring. The spring

may at first prevent easy change in the

shell holder, but it will smooth out with

a few changes. The detent spring is

easily damaged, so use extreme care if

you must remove it. Refer to pages 10-11

for installing and using Lock-N-Load®

Bushings.

1

2

Insert and adjust the sizing die.

3

Take note, these presses slightly cam

over to allow you to exert maximum

pressure with reduced effort. Screw die

down until it is firmly against the shell

holder. The sizing die must be set when

the ram is at the top of the stroke and

not after the ram has cammed over.

3

- 6 - - 7 -

Page 7

Install primer arm into ram.

4

NOTE: Screw the proper seater punch/

cup for the type of primer you are using

into the arm before placing in ram. If

you are using the automatic primer

feed, it will be necessary to adjust the

feed body. The ram should be at the

top of the stroke. Adjust the primer

feed body so the primer retainer spring

is deflected by the primer cup (on

the primer arm) far enough to allow a

primer to drop (see APF instruction). Do

not overtighten the adjusting screw. It

should be tight enough to hold the unit

in place, but still allow the body to move

to prevent a primer from being caught

or crushed. REMEMBER, primers are

explosives – do not try to force a primer

in a case. If for some reason the Positive

Priming System (PPS) does not work

properly, stop to see why. Never try to

force the operation.

4

5

Clean, inspect and lubricate all

5

cases before resizing.

Using a case lube pad or Hornady® One

Shot® Case Lube, it is easy to lubricate

the body portion of the bottle neck

cases. A minimum of lubricant should be

used on the neck portion since trapped

lubricant may cause the shoulder to

buckle. Very little or no lubricant may

easily result in a stuck case.

Page 8

Place a lubricated case in

6

the shell holder and pull the

operating handle.

As the ram moves upward, you will see

the PPS primer arm pivot forward to

allow the decapped primer to deflect off

the arm into the primer catcher. As the

primer arm pivots, it moves into position

to pick up a new primer. If you are not

using the automatic primer feed, a

primer should be inserted by hand at the

top of the ram stroke.

With a primer in the cup, return

7

the handle to the rest position.

As the ram moves downward, the PPS

primer arm pivots back into position

under the decapped case and is

held in position by the ram and the

frame casting. As the ram continues

downward, the case is brought down

over the primer cup and the primer is

seated. Use care at this stage to feel

the primer “seat” correctly without

being crushed. Release pressure on the

operating handle and raise it slightly

to allow removal of the primed case.

Then insert another case and repeat the

operation.

6

7

- 8 - - 9 -

Page 9

Check case length (for cases to be

8

crimped) and trim with Hornady

Case Trimmer.

Chamfer inside and debur outside of

case mouth with Hornady Chamfering

and Deburring tool, and wipe case free

of all lubricant with clean dry cloth.

Please Note: Sizing before trimming can

result in Case Mouth not fitting over the

Trimmer Pilot.

8

Charge prepared cases with

9

selected powder

and weigh using either a scale, or

powder measure in conjunction with a

scale. Refer to the Hornady Handbook

of Cartridge Reloading or any other

reputable source for proper loads.

Replace the sizing die with

10

the seating die according to

instructions furnished with the

die set.

Remove the PPS primer arm at this time

to simplify bullet seating. The arm is

slotted and is easily removed by lifting

it up and out of the arm. The opening

in your press is large enough to easily

handle any modern cartridge with no

dif ficulty.

9

10

Page 10

HOW LOCK-N-LOAD® WORKS

The Lock-N-Load® Reloading System is Hornady’s unique bushing system that lets you

change dies with a simple flick of the wrist. With Lock-N-Load® technology in your

reloading press, you can stop loading, change dies, and start loading another caliber

in SECONDS. If you load more than one caliber, Lock-N-Load® will dramatically speed

up your reloading efforts.

This unique technology is featured on our Lock-N-Load® Classic™ and

Lock-N-Load® AP™ (Auto Progressive) reloading presses.

The Hornady Lock-N-Load® system is as easy as 1-2-3:

01 Insert the Lock-N-Load® die bushing into the press bushing and lock it into

place with a twist. The six locking lugs on the die and press bushings will hold it

securely in position.

02 Insert your standard die into the Lock-N-Load® Bushing.

03 Adjust the die to the proper position and lock your setting into place with

Hornady’s unique Sure-Loc® lock ring.

To change calibers, simply twist the die counterclockwise, remove die and insert

your next preset Lock-N-Load® die and bushing. Because they remain locked in

their Lock-N-Load® Bushings, your dies will remain exactly as you set them. The

positive locking action of the Lock-N-Load® Bushings holds the dies in rock solid,

perfect alignment. Once you try Lock-N-Load® from Hornady, you’ll NEVER want

to go back to your old system.

SIX LOCKING LUGS

The combination of the six lugs and the close tolerance of the tooling firmly

grip the die bushing in place in the press for maximum rigidity and accuracy in

reloading.

RUBBER O-RING ON DIE BUSHING

The O-ring on our die bushings gives you a better feel when the die is inserted

and holds the die tight against the locking lugs to prevent accidental loosening.

- 10 - - 11 -

Page 11

STEP 3

3

STEP 2

2

STEP 1

1

Page 12

P.O. Box 1848 • Grand Island, NE 68802-1848

(308) 382-1390 •

68 0015 08/2014

www.hornady.com

Loading...

Loading...