Page 1

OWNER'S MANUAL

®

LOCK-N-LOAD

AP™

RELOADING

PRESS

Page 2

Table of Contents

ASSEMBLY

ASSEMBLY

AP Press ......................................................................... Page 3

Powder Measure .............................................................. Page 10

OPERATIONS .......................................................... Page 15

CHANGE-OVERS

Refer to this section when changing calibers on the Lock-N-Load® AP™ Press

AP Press ......................................................................... Page 19

Shell Plate

Die Set

Primer Components

Primer Slide

Primer Tube

Primer Punch

Powder Measure ............................................................. Page 21

Changing Powder

Metering Insert/Rotor

Powder Sleeve/PTX Expande

TROUBLE SHOOTING

Lock-N-Load® AP Press ................................................... Page 26

Shell Plates .................................................................... Page 26

APPENDIX

APPENDIX A

Dies & Reloading Essentials Sizing Chart ............................... Page 27

APPENDIX B

Lock-N-Load® AP Press Mounting Template ............................ Page 31

- 2 -

ASSEMBLY: AP PRESS

Page 3

Lock-N-Load® AP Reloading Press

OVERVIEW

Your new Lock-N-Load® Auto Progressive (AP) Reloading Press has been packaged to insure minimal vibration and damage during transportation.

Remove all the parts from the packing box (see page 2) and spread them out over a large flat surface. Refer to the Lock-N-Load® AP™ Reloading

Press parts list and exploded view on the next two pages and check to make sure all necessary parts are identified.

The manual provides step-by-step instructions and suggestions that make set-up and operation easy and understandable.

If at any time during operation you feel like you are forcing the press, stop and identify the problem. Do not force anything, or damage could occur.

Powders and primers are explosive if handled carelessly! Always work slowly and carefully without distractions and wear eye protection. Try to

avoid touching primers with oily fingers. The oil on your fingers may contaminate the primers and cause them to misfire.

Tools needed for assembly and set-up:

• 7⁄16" End Wrench

• (2) 1⁄2" End Wrenches

• 15⁄16" End Wrench

• 3⁄32" Hex Wrench (included)

• 1/8" Hex Wrench (included)

• 5⁄32" Hex Wrench

• Needle Nose Pliers

• Electric Drill

• 5/16" Hex Wrench

ASSEMBLY

Hand loading is very safe, but before reloading any

case please read the following warnings.

• Primers may explode if subjected to impact or heat.

• Keep away from the opening end of the Primer Tube at

all times.

• Variations may occur with different brands and condition of

cartridge cases, which can cause inconsistent primer and bullet

seating. Sort and inspect all of your cases before reloading.

• Verify your powder charges at frequent intervals to

insure consistency.

• Careless or improper hand loading techniques can result in

serious personal injury. Make sure there are no distractions while

you are reloading.

• Before operating this press, be sure you have read and

understand all the instructions contained in this manual, and

that you understand the principals of hand loading.

ASSEMBLY: AP PRESS

- 3 -

Page 4

Lock-N-Load® Auto Progressive (AP) Reloading Press

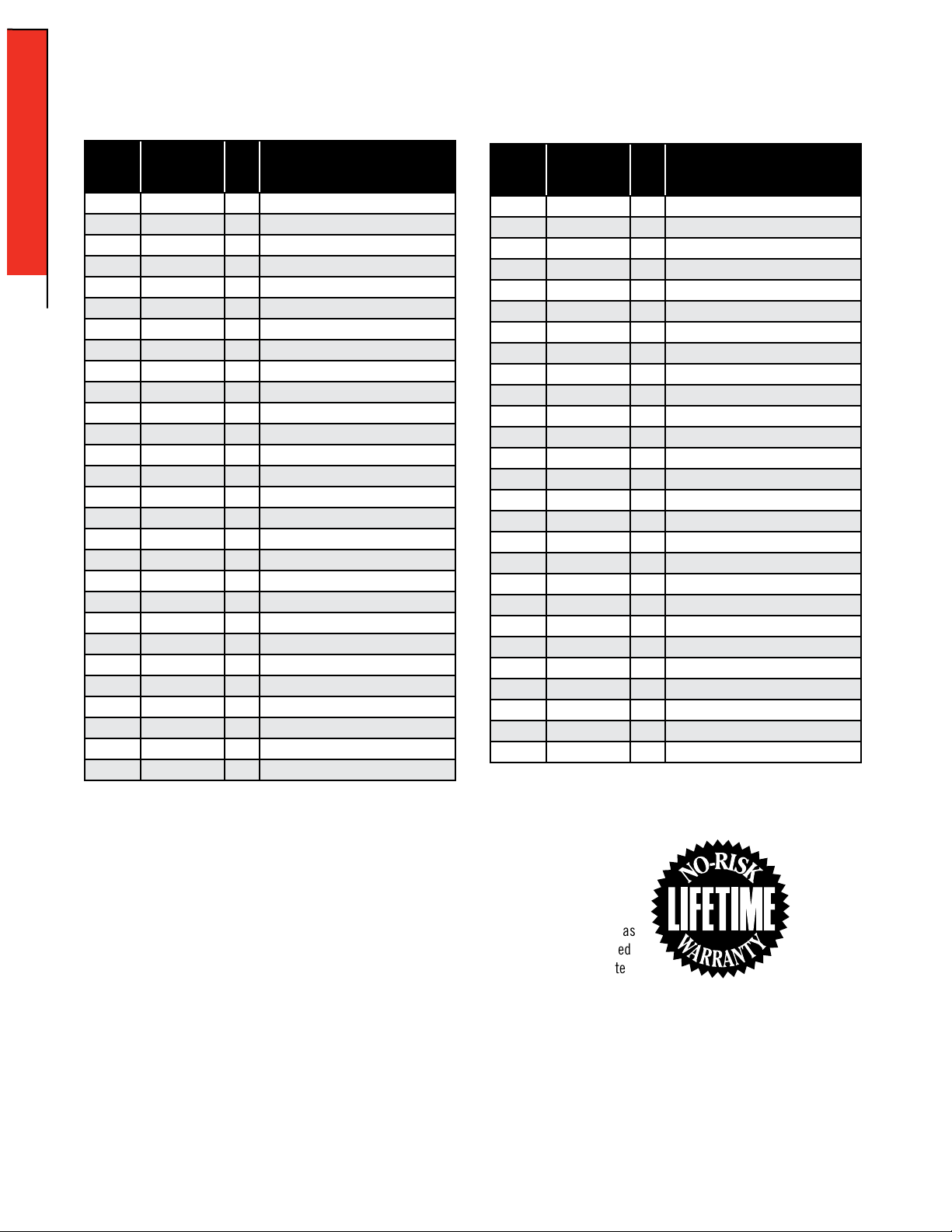

PARTS LIST

Production

ASSEMBLY

Item No.

1 398 318 1 Support Primer Tube

2 398356 1 Tube Primer Pickup, Large

3 398355 1 Tube Primer Pickup, Small

4 398358 1 Tube Primer, Large

5 398357 1 Tube Primer, Small

6 398322 1 Housing Tube Primer

7 392220 1 Screw, BHCS 1/4-20 X 1/2

8 392202 1 Lock-N-Load® AP Bracket

9 392342 1 SHCS SS 3/8-16 X 3/4

10 398359 1 Primer Follower

11 392338 1 Screw, SHCS 10-24 X 1/2

12 Shell Plate (Sold Separately)

13 392455 1 Bracket Box Cartridge

14 398 319A 1 Housing Body Primer Tube

15

15

16

17

18

19

20

21

22

23

24

26

26

27

Part No. Qty. Description

392218 1 Primer Slide, Large Assembly

392219 1 Primer Slide, Small Assembly

392336 1 Spring Primer Slide

392363 1 Spring Case Retainer

398695 1 AP Breakaway Cam Wire

398698 1 Nut, 8-32

190216 1 Frame

392368 6 Clip C, C-50

480039 1 Box Catcher

392408 2 Lock-N-Load® AP™ Link

398309T 1 Sub Plate

398505 1 Primer Seater Punch, Small

398507 1 Primer Seater Punch, Large

392467 1 Spring Counter Balance

Item No.

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

47

48

49

50

51

52

54

55

Production

Part No. Qty. Description

392345 1 3/8 Flat Washer SS

392355 1 Drive Hub

392356 1 Drive Shaft

392231 2 Screw, BHSCS 8-32 X 3/8

392344A 2 Pawl

392423 2 Spring Pawl

392306 2 Dowel Pin 1/8 X 1/2

392221 2 Screw, FHCS 1/4-28 X 3/8

290029 1 Spent Primer Tube

398163 1 Ram Assembly

398422 3 Grease Zerk™

392343 1 Toggle

392340 1 Pin Yoke

392424 5 Spring Washer

392417 2 Pin Link Toggle

390027 1 Nut Jam, 5/8-18

390657 1 Handle

480003 1 Knob

392358A 1 Index Wheel

390081 2 Clip E 1/2

392302 5 Lock-N-Load® Bushing, Male

392303 5 Lock-N-Load® Bushing O-Ring

392365 1 Spent Primer Tube, Plastic

392301 5 Lock-N-Load® Bushing, Female

398697 1 Breakaway Cam Plunger

398696 1 Breakaway Cam Wire Spring

9987 1 DVD

We guarantee every one of our reloading tools and accessories for life

Hornady reloading tools and accessories are warranted against material defects and workmanship

for the life of the products. Parts which by nature of their function are subject to normal wear such as

springs, pins, bearings, etc… and parts which have been altered, abused, or neglected are excluded

from the warranty. Hornady electronic components are covered by a one-year warranty from the date

of purchase.

If the product is deemed defective by either workmanship or material, the reloading tool or accessory will either be repaired,

reconditioned or replaced at Hornady Manufacturing Company’s option. If it breaks, we’ll repair it or replace it at no charge.

To return a product, call toll free (800) 338-3220 and ask for Customer Service. They will provide instructions for return if the

problem can’t be solved over the phone. Prices and or specifications are subject to change without notice. For the best prices on

any of our products, contact your nearest Hornady dealer.

Hornady Manufacturing Company cannot assume liability for damage which may result from use of the products or information

given herein, since Hornady had no control over the manner in which its products or components are used during reloading.

- 4 -

ASSEMBLY: AP PRESS

Page 5

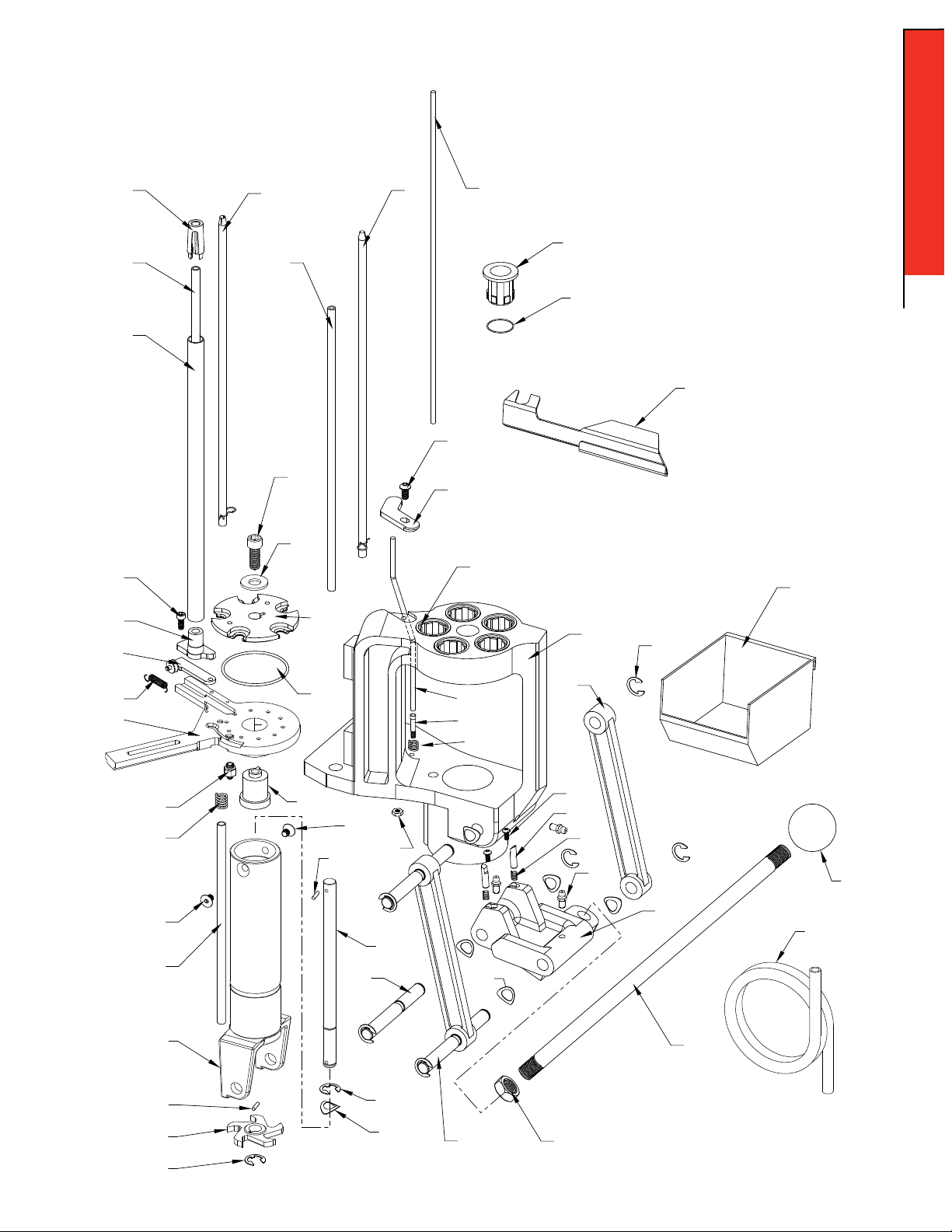

Lock-N-Load® AP Reloading Press

EXPLODED VIEW

1

4

6

11

ASSEMBLY

2

3

10

49

5

50

13

7

9

8

28

52

22

14

15

16

24

26

27

35

36

37

29

12

17

34

35

40

19

30

18

54

55

41

23

31

32

20

33

38

21

45

39

51

44

34

47

48

48

41

42

43

ASSEMBLY: AP PRESS

- 5 -

Page 6

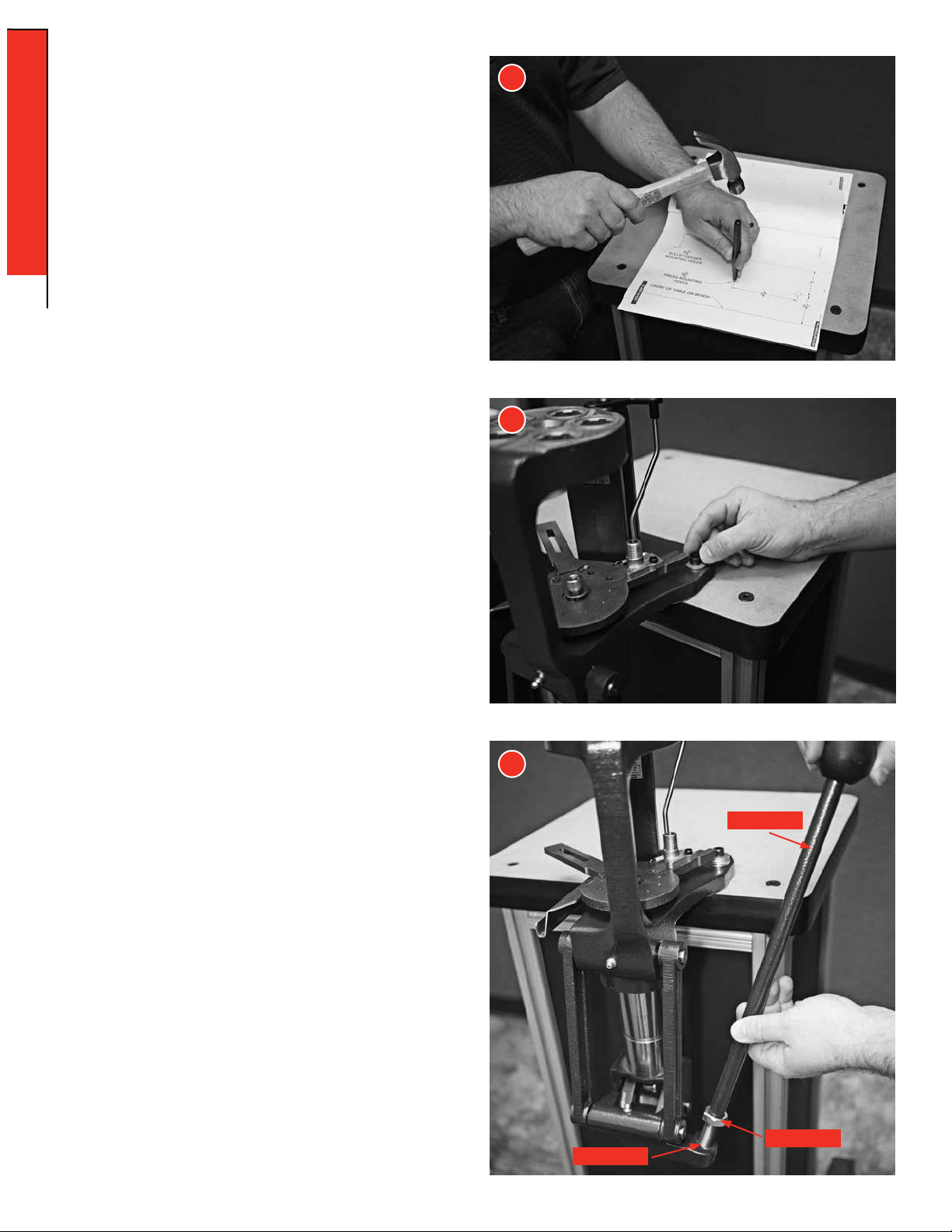

Mounting the Lock-N-Load®

1

Auto Progressive

Your work area should be well lit and have plenty of room for

1

your reloading accessories. Your Hornady Lock-N-Load® AP™

ASSEMBLY

should be mounted securely 2 1/4" from the edge of a solid level

bench and 3.75" apart and at least 16" from the nearest wall.

Use the template found on the last page and a hole punch to

help locate each hole. (Check for obstructions on or below the

bench before you drill any holes.)

Place cartridge catcher bracket under press, line up holes in press

2

with holes in bracket.Insert and firmly tighten both bolts.

Mount the press using two 5/16" bolts that are long enough to

secure the press to the bench with plenty of clearance for the

nuts. (Due to variation of benches, these bolts are not provided.)

We also recommend using 5/16" flat washers top and bottom, in

addition to lock washers on the bottom side.

2

Insert and firmly tighten both bolts.

Thread the press Handle into the Toggle at the bottom of the press

3

and tighten the Jam Nut using a 15/16" wrench.

3

Handle

- 6 -

Jam Nut

Toggle

ASSEMBLY: AP PRESS

Page 7

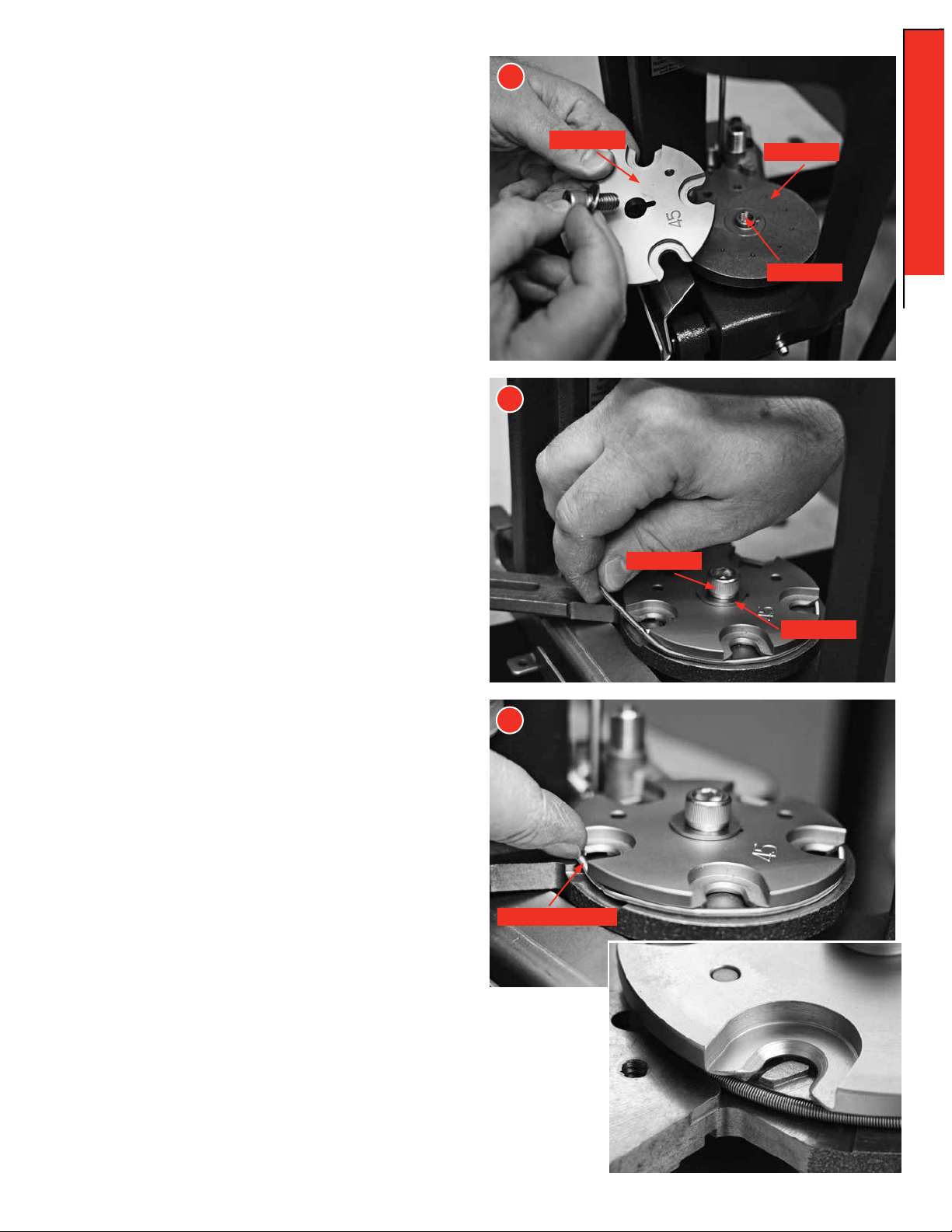

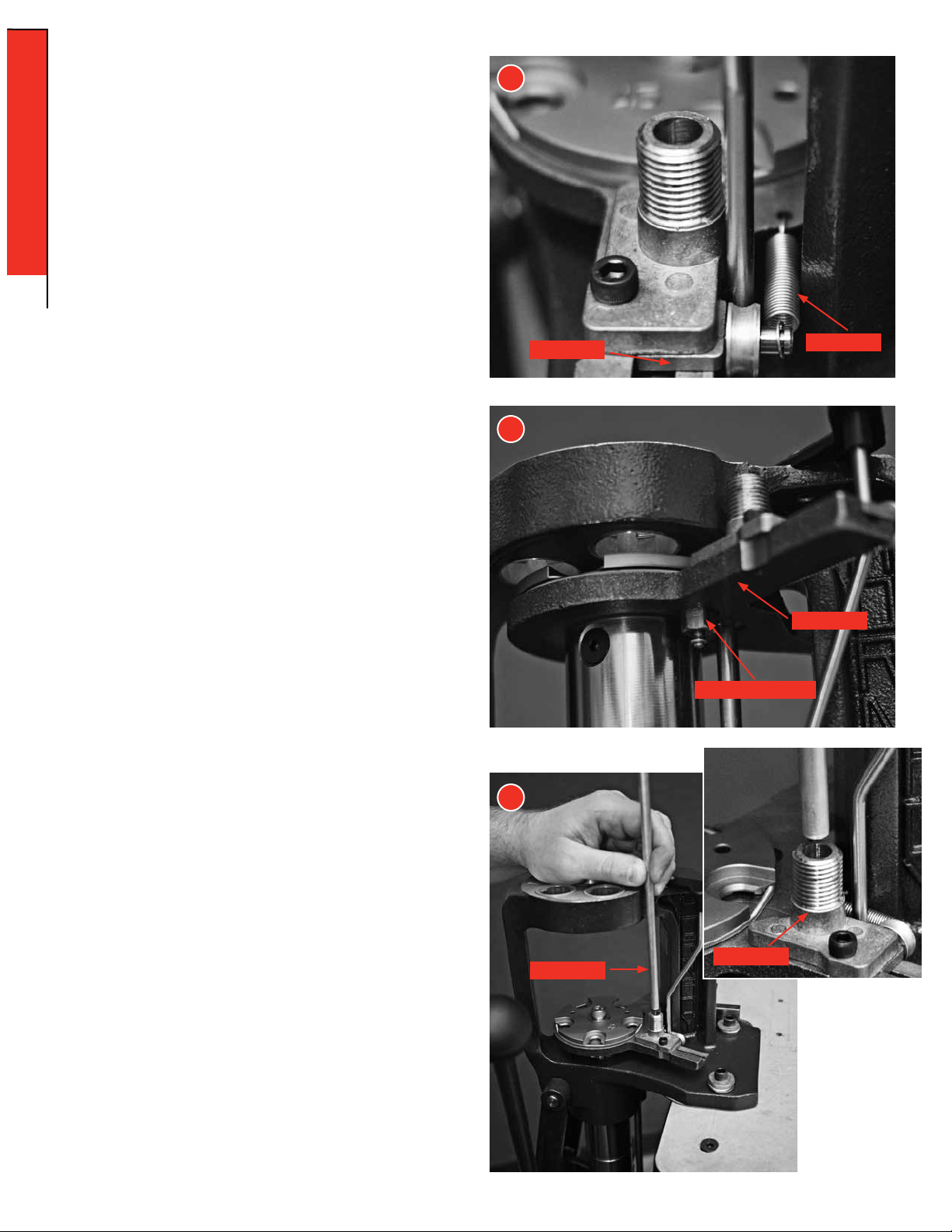

Determine which shell plate is required

for your application

Refer to Appendix A to determine the correct shellplate.

Installing the Shell Plate

4

Put a small amount of general-purpose grease on the Shell Plate Ball

Detents located on bottom side of Shell Plate, and on the top surface

of the Sub-Plate.

4

ASSEMBLY

Shell Plate

Sub-Plate

Align the Shell Plate (12) with the keyed Drive Hub.

Place the 3/8" Shell Plate Retainer Bolt (9) thru the 3/8" Flat Washer

(28), (large end up) and thread the bolt into the Drive Hub (29).

Gently tighten the bolt using a 5/16" Allen wrench.

DO NOT over-tighten bolt, as It may damage Drive Hub or Pawls.

Stretch the Case Retainer Spring (17) around the Shell Plate (12).

5

While cycling the Press, push the Case Retainer Spring into the

relieved area on the Sub-Plate.

6

Drive Hub

5

Retainer Bolt

Flat Washer

6

You will have to cycle the press a couple of stations to achieve

these results.

Removing the Shell Plate

Use a 5/16" Allen wrench to remove the Bolt and shell plate. If the

bolt is over tightened, use the Hornady Lock-N-Load® Deluxe Die

Wrench (Item No. 396495 sold separately) to hold the shell plate

while loosening the Bolt. This will prevent damage to the Drive Hub

and/or Pawls.

Case Retainer Spring

ASSEMBLY: AP PRESS

- 7 -

Page 8

Automatic Primer Feed Assembly

7

Installing the Primer Slide, Large or Small

7

Lower the handle.

Place the Primer Slide (15) flat side up in the groove on the

ASSEMBLY

Sub-Plate (24) and slide forward. The bump on the bottom

side of the slide is the travel stop as well as an alignment

guide while the slide is in the retracted position.

Attach the Spring to the Sub-Plate with the open end up (you

may need to use needle nose pliers). Attach the other end of

the Spring to the pin on the Primer Slide.

Installing the Primer Punch Assembly,

8

Large or Small

Raise the Ram to the top of the stroke.

Screw the Primer Seater Punch (26) into the Sub-Plate from

the bottom side.

Tighten the Primer Seater Punch assembly until it is snug

using a wrench. (Do not over-tighten the Primer Punch).

Installing the Primer Tubes

9

Place the tube of your choice (large or small primers) in the

center hole of the Primer Body with the shoulder section of

the tube facing down. Make sure the tube is fully seated in

the Primer Body (14).

8

9

Primer Slide

Spring

Sub Plate

Primer Seater Punch

- 8 -

Primer Tube

Primer Body

ASSEMBLY: AP PRESS

Page 9

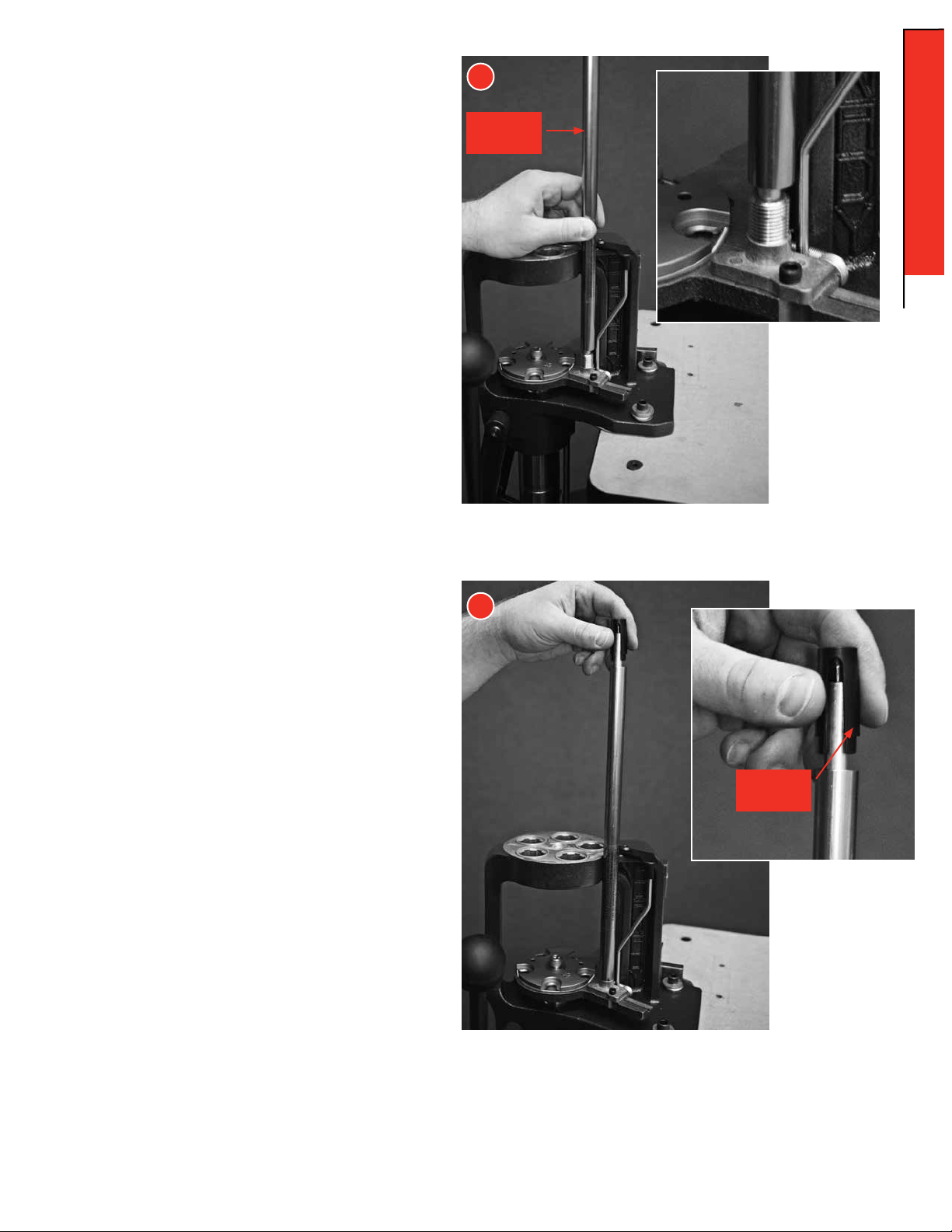

Installing the Primer Tube Housing

10

Slip the threaded end of the Primer Tube Housing (6) over

the Primer tube and onto the Primer Body.

Screw the Primer Tube Housing on to the Primer Body (14)

clockwise: tighten very lightly. Lower the handle.

10

ASSEMBLY

Primer Tube

Housing

Primer Tube Support installation

11

Place the Primer Tube Support (1) over the Primer Feed

Tube and slip the three tapered “fingers” inside the Primer

Tube Housing. This will create a recess that allows the

Primer Filler Tube to properly align with the Primer Feed

tube during refillings.

11

Primer Tube

Support

Assembly of the Lock-N-Load® AP Press is now complete. Please proceed to the Powder Measure

assembly section on the next page.

ASSEMBLY: AP PRESS

- 9 -

Page 10

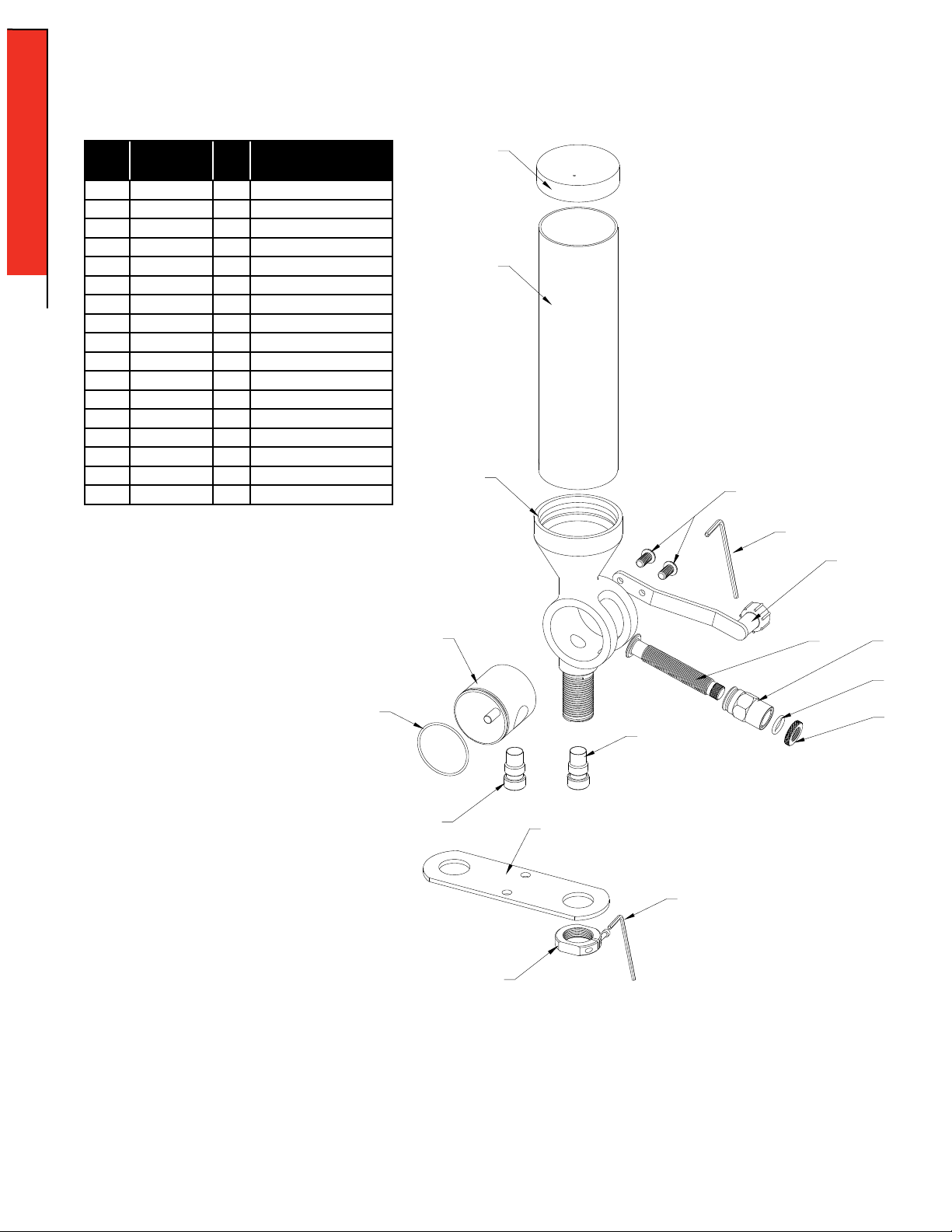

Lock-N-Load® Powder Measure

PARTS LIST

Item

ASSEMBLY

Production

No.

Part Number

1 170405 1 HOPPER CAP

2 398520 1 HOPPER

3 392740 1 BODY

4 392719 2 SCREW BHSCS 10-32 X 3/8

5 392752 1 HANDLE ASSEMBLY

6 392741 1 ROTOR

7 392743 1 METERING PLUNGER

8 392742 1 SLEEVE

9 480083 1 O-RING 1/2 ID X 11/16 OD

10 392764 1 NUT LOCK METERING UNIT

11 392766 1 O-RING 1 1/2 ID X 1 5/8 OD

12 390702 1 SMALL DROP TUBE

13 390701 1 LARGE DROP TUBE

14 392760 1 MOUNTING BRACKET

15 390656 1 3/32” HEX WRENCH

16 O44000 1 LOCK RING

17 390653 1 1/8” HEX WRENCH

Qty. Description

EXPLODED VIEW

1

2

3

4

17

Precautions for the

Powder Measure:

• Always change the metering units with

the handle and the metering unit in the

horizontal position, and after you have

dropped the charge. If you allow the

Handle to fall while changing units, you

will drain the Hopper.

• Be sure that you have the proper

Lock-N-Load® device locked in place,

before operating.

11

13

5

6

7

8

9

10

12

14

15

16

• Always verify your charges with a scale

before loading.

• Any moisture in the unit will cause

powder to stick, and charge weights will

vary dramatically.

- 10 -

ASSEMBLY: POWDER MEASURE

Page 11

Lock-N-Load® Case Activated Powder Drop

PARTS LIST

Item

16* 392703 1 17 CAL. SLEEVE

20* 290030 1 .355 POWDER THRU EXPANDER

20* 290031 1 .357 POWDER THRU EXPANDER

20* 290032 1 .400 POWDER THRU EXPANDER

20* 290033 1 .430 POWDER THRU EXPANDER

20* 290034 1 .451 POWDER THRU EXPANDER

20* 290035 1 .452 POWDER THRU EXPANDER

20* 290037 1 .475 POWDER THRU EXPANDER

20* 290038 1 .500 POWDER THRU EXPANDER

* (Sold Separately)

Production

No.

Part Number

1 392721 2 BHSCS 10-32 X 1.00

2 392708 2 MOUNTING CLAMP

3 392710 1 ROTOR ARM

4 392719 5 BHSCS 10-32 X 3/8

5 392715 2 SHOULDER NUT

6 398735 1 PIVOT

7 398737 1 DRIVE LINK

8 398736 1 MEASURE LINK

9 398742 2 BHSCS 10-32 X 1.25

10 392717 1 GROOVE PIN 3/16 X 7/8

11 392718 1 SPRING PIN 1/8 X 3/8

12 392707 1 UPPER BRACKET

13 398739 2 SPRING NUT

14 398738 1 RETURN SPRING

15 392705 1 DROP TUBE

17 392701 1 #1 POWDER SLEEVE

18 392702 1 #2 POWDER SLEEVE

19 392700 1 PISTOL POWDER SLEEVE

21 392704 1 MEASURE ADAPTER

22 392706 1 LOWER BRACKET

23 398741 1 LOCKING BOLT

24 392722 1 RETAINING RING

25 O44000 1 LOCK RING

26 392302 1 LOCK -N-LOAD BUSHING

Qty. Description

EXPLODED VIEW

6

1

2

4

3

5

7

ASSEMBLY

9

8

11

4

16

10

*

12

13

17

18

19

14

15

1

9

20

*

22

23

2

21

25

26

24

13

ASSEMBLY: POWDER MEASURE

- 11 -

Page 12

Assembly of Lock-N-Load®

1

Case Activated Powder Drop

The Case Activated Powder Drop helps make reloading faster

and easier than ever before. It automatically activates and

ASSEMBLY

dispenses a charge with every pull of the handle, but only

when a case is present in the station. Plus, it works with

Lock-N-Load® bushings. (You can remove and change

Hornady powder measures with a quick turn, without

changing adjustments.) The Case Activated Powder Drop

unit can be used ONLY on the Hornady Lock-N-Load® Powder

Measure.

The Lock-N-Load® Powder Measure comes with the Standard

Rotor & Standard Metering Insert installed, with the Pistol

Rotor & Pistol Metering Insert packaged separately.

Your Lock-N-Load® Powder Measure has been treated with

a rust preventative that must be removed prior to use. We

recommend that you clean and degrease all metal parts with

Hornady One Shot Cleaner and Dry Lube.

Removing

Metering Unit

2

To Disassemble for Cleaning:

Set the Rotor with the Metering Unit perpendicular to the axis

1

of the Body, press the Push Button and hold it down while

removing the Metering Unit.

NOTE: Do NOT remove push button. It is permanently installed

and does not need cleaning.

Unscrew the Drop Tube (15) from the bottom of the

2

Powder Measure.

Remove the Handle, or Rotating Arm from the Powder

Measure, by removing the two attaching screws with a 1/8"

hex wrench.

Slide the Rotor out of the Body by pressing gently on the

3

handle side of the Rotor.

NOTE: Be careful not to drop or otherwise damage the Rotor

while it is out of the Body.

Drop Tube

3

- 12 -

Rotor Body

ASSEMBLY: POWDER MEASURE

Page 13

Remove the Lock Nut, O-Ring and Sleeve from the Metering

4

Plunger.

Spray all metal parts liberally with Hornady One Shot® Gun

Cleaner and Dry Lube. Be sure all rust preventative has been

removed.

Allow it to dry thoroughly before reassembling.

4

Lock Nut

O-Ring

ASSEMBLY

To Re-Assemble After Cleaning:

Reverse the procedure in the first five steps above.

5

Due to the tight machining tolerances of the Rotor and Body,

they must be properly aligned to reassemble.

DO NOT FORCE IT OR PERMANENT DAMAGE WILL OCCUR.

5

6

Lower

Assembly

Installing the Case Activated Powder

Drop (Lower Assembly)

Screw the Measure Adapter (21) (Lower Assembly) onto the

6

Lock-N-Load® Bushing several turns. Place lower Assembly

into top of press and rotate to lock into the Lock-N-Load®

Bushing.

7

Select the appropriate powder bushing sleeve for your

application (Refer to Chart on page 22). Insert the bushing,

with the deep counter sink facing up, into the top of the

measure adapter.

If using a Powder Through Expander Sleeve (PTX Sleeve), insert

the PTX Sleeve with the deep countersink facing up, into the

top of the Measure Adapter.

Lock-N-Load

7

Bushing

Bushing Sleeve

PTX Sleeve

ASSEMBLY: POWDER MEASURE

Powder

or

- 13 -

Page 14

Final Powder Measure Assembly

Insert the Powder Drop Tube into the lower assembly

8

Connect the Link (8) to Lower Assembly by sliding the Link over

the Thumb Screw (23).

8

ASSEMBLY

Tighten the Thumb Screw.

Attach PTX Powder Measure Stop.

Attach Spring (14).

9

(For adjustment, refer to Chart on page 24).

Link Arm

Thumb Screw

9

PTX Stop

Drop Baffle into Powder Hopper to prevent powder bridging

10

and help produce consistent charges.

10

Spring

Baffle

- 14 -

ASSEMBLY: POWDER MEASURE

Page 15

Operation of your Lock-N-Load® Auto Progressive Press

The Hornady Lock-N-Load® AP™ utilizes a high strength aluminum alloy frame with a compound linkage system

which operates the 2" diameter cylindrical ram. The Ram houses a drive shaft that is attached to the shell plate

at the upper end and the index wheel at the lower end. The toggle contains two spring actuated pawls which

alternately engage the index wheel to advance the shell plate through the different reloading stations.

As the handle is lowered, the right Pawl contacts the Index Wheel, advancing the Shell Plate during the first

1 1/2" of upward travel of the Ram. With this upward travel, the cases become aligned with the dies at the

top of the Press. As the Shell Plate comes to the top of the press, it guides the cartridge cases into the five die

stations to perform the reloading operations except priming.

The handle is then raised to complete the stroke, lowering the Shell Plate. When the Shell Plate comes to within

1 3/4" of the bottom, the left Pawl engages the Index Wheel which advances the Shell Plate into position over the

primer to seat it into the case that was just sized and de-primed. Pushing back on the handle with

moderate force will seat the new primer into the case.

Once the dies are in place, and all stations are filled, the proper sequence for reloading is listed below.

®

• Place an empty case into station one. (Using the optional Lock-N-Load

AP™ Case Feeder, this step is

automatically done for you.)

®

• Insert bullet into the powder charged case in station four (or use the optional Lock-N-Load

Bullet Feeder)

• Lower the handle.

• Powder drops into the newly primed case at station three.

• Raise the handle and seat a new primer in the de-primed case that has now moved to station two.

• Loaded cartridge is automatically ejected at station five when handle is raised.

OPERATION

OPERATION: AP PRESS

- 15 -

Page 16

Primer Filler Tube

(Large or Small)

OPERATION

Installing the Shell Plate

• Put a small amount of general-purpose grease on the

Shell Plate Ball Detents located on bottom side of Shell

Plate (3), and on the top surface of the Sub-Plate (6).

• Align the Shell Plate (3) with the keyed Drive Hub (5).

• Place the 3/8" Shell Plate Retainer Bolt (1) through

the 3/8" Flat Washer (2), (large end up) and thread the

bolt into the Drive Hub (5).

• Tighten the bolt (1) using a 5/16" Allen wrench, only

tight enough to prevent it from coming loose.

• Stretch the Case Retainer Spring over the top of the

Shell Plate (3).

• While cycling the Press, push the Case Retainer Spring

into the relieved area on the Sub-Plate (6). You will

have to cycle the press a couple of stations to receive

these results.

1 – Shell Plate

Retainer Bolt

2 – Flat Washer

3 – Shell Plate

4 – Retainer Spring Groove

5 – Drive Hub

6 – Sub Plate

EZject

Loading the Primer Tube

Carefully transfer the primers out of their factory package

into a Hornady Primer Turning Plate and orientate them

“shiny side up.” Then holding the Primer Filler Tube (large

of small) like a pencil bring the plastic primer pick up tip

over each primer and gently press it over the primers. The

primers will be pushed into the filler tube one on top of

another. Continue loading the primer filler tube until you

have picked up approximately 100 primers.

Make sure the cotter pin is in place; turn the Primer

Filler Tube upside down. At the top of the exposed Primer

Filler Tube, there may be several primers still held and

visible. Gently shake the tube to release the primers.

Align the Primer Filler Tube (large of small) to the Primer

Feed Tube (large of small) using the Primer Tube Support.

Remove the cotter pin from the Primer Filler Tube (large of

small) and fill the Primer Feed Tube (large of small). The

capacity of the primer tube is 100 primers.

Do not over fill the primer tube.

Insert the Primer Follower into the Primer Tube (large of

small). This will help the primers feed more reliably.

Primer Filler Tube

(Large or Small)

Primer Filler Tube

(Large or Small)

Primer Feed Tube

(Large or Small)

Primer Tube Support

Primer Tube Housing

- 16 -

OPERATION: AP PRESS

Page 17

Preparing to Load

To begin reloading, start with a single empty cartridge case and run it through all of the loading stations. This will allow you to check your

adjustments. Refer to instructions provided with the die set for set up and proper adjustment.

Sizing a case

• Make sure the sizing die is adjusted properly, and the de-priming pin knocks out the old primer.

Seating a primer

• Check and make sure the Primer Slide picked up a primer from the Primer Tube (large or small).

• When you cycle the press and the handle comes to a stop, you will have to push the handle away from you past the stop to seat the primer.

Push until it stops but don’t force it. Seating the primer requires a firm push.

• Lower the handle of the press slowly to rotate the shell plate to start the next operation. If there is

resistance on the shell plate, the primer is improperly seated and not allowing the Shell Plate to rotate.

Drop powder in the case using the case activated powder drop

• Verify the weight on a properly calibrated scale.

Seat a bullet in the powder charged case

• Begin lowering the handle to rotate the shell plate to this station.

• Place a bullet on top of the case and lower the handle the rest of the way. (You may need to position the bullet over the case neck between

your thumb and forefinger until the bullet enters the alignment sleeve).

OPERATION

Station 5

• This station can be used for a Taper Crimp Die when reloading pistol cartridges that headspace off the case mouth.

* Any manufacturer’s Taper Crimp Die will work in Station 5 with the AP’s EZject™ System.

• Properly adjusted, a taper crimp die removes all case-flare from the expander die without damaging or squeezing into the bullet.

Next, lower the handle, advance the shell plate to the next station. The loaded round will rotate and contact the EZject™ System underneath the

shell plate. This EZject™ System will automatically eject the loaded round from the press. Never force the handle. Measure the case for proper

length and check it against the data in your reloading book.

Once you are satisfied with the first completed cartridge, repeat the process with another single case, advancing slowly from station to station

until you eject the finished cartridge from the press with the case ejector.

After you are comfortable, load the press with consecutive cases for reloading. Do not rush! After you advance the cases through each station,

inspect everything to insure proper function at each station. If anything looks out of place, or if you lose track of what you are doing, STOP!

Remember, it’s safer to begin slowly than it is to assume you need to reload a large number of cartridges during each session. Don’t force the

handle at any time, and be sure that all mechanical parts are properly lubed.

SAFETY NOTE: Be safe! Double check your powder loads at frequent intervals to insure the powder charge is working properly.

OPERATION: AP PRESS

- 17 -

Page 18

OPERATION

Adjusting the Auto Advance Mechanism

The Auto Advance Mechanism is fully adjusted at the Hornady factory and should not require further adjustment. In the event that you feel your shell

plate is not advancing properly, check all other options listed in this manual before attempting to adjust the mechanism’s pawls.

All adjustments should be made in extremely small increments.

Through everyday use, the pawls on your press may gradually wear and may need to be adjusted to compensate for this wear. Before making

adjustments, you should understand what each pawl does.

As the operating handle is lowered and raised through a complete

cycle, each pawl in turn engages the index wheel at the bottom

of the press. The index wheel is connected through the

driveshaft to the shell plate. As each pawl engages the

index wheel it advances the shell plate either at the top or

bottom of the cycle.

The right pawl (as you face the press) advances the

shell plate as the ram travels up when the handle is

pulled down. The left pawl advances the wheel on

the down stroke of the handle and should advance

the shell plate to the detent holes in the sub-plate.

If the shell plate doesn’t advance enough on the

down stroke of the ram, only the left pawl needs

adjustment.

The right pawl is too low if the shell plate stops

short of the detent, which can be felt as you rotate

the shell plate into place by hand in a clockwise

direction. If the pawl is too high, you will feel a slight

double click on the handle as the pawl disengages and

the shell plate is locked into place by the detents.

Pawl Adjustment Screw

Left Pawl

Right Pawl

The same is true for the left pawl which indexes on the

up stroke of the handle (down stroke of the ram.) Likewise,

if the plate doesn’t advance far enough on the up stroke

of the ram, only the right pawl needs to be adjusted. Don’t

assume that both pawls need adjusting.

Do only one pawl at a time to keep from becoming confused.

The height of each pawl determines how far the shell plate will advance when that pawl comes in contact with the indexing wheel. To adjust the pawls,

increase the height of the chosen pawl to increase the advancement of the shell plate in that direction. Or decrease the height of the pawl to decrease

the shell plate advancement in that direction.

There is a set screw on each pawl.

• Turn the set screw clockwise to lower the pawl.

• Turn the set screw counterclockwise to raise the pawl.

Become familiar with these pawls from the onset and see how they operate. You will then find it much easier to adjust the pawls, should you need to do

so in the future.

For additional assistance, please contact our technical service staff at 800-338-3220 or email webmaster@hornady.com.

- 18 -

OPERATION: AP PRESS

Page 19

Setup / Changeover of Auto Progressive Reloading Press

®

When changing calibers on the Lock-N-Load

may need to be changed or verified.

• Shell plate

• Dies

• Primer Components

Primer Slide

Primer Tube

Primer Punch

Determine which shell plate is required for your application

Refer to Appendix A for proper Shell Plate selection.

NOTE: Hornady shell plates that are sold in the plastic boxes are the only ones

that will fit the AP Press with EZject™ System. These shell plates (which are

sold separately) are manufactured with a groove on the bottom side.

AP™ Press, three components

Shell Plate

Refer to ASSEMBLY: AP PRESS Page 8 for instructions

on removing and installing the Shell Plate

Determine the dies needed.

The Hornady Lock-N-Load® AP™ Press is designed to use

Hornady dies as well as most other dies with a 7/8"-14 threaded

body. However, the characteristics of each die is different and

will determine the setup and capabilities of the press. For

example, using the Hornady Pistol Taper Crimp/Seating Die will

free up a station on the press so that a Powder Cop Die may be

used. Please see the various layout options below to help locate

your dies on the press.

Die Mounting Instructions

For initial die cleaning and individual die adjustment

instructions, please refer to the instruction sheet that came

with your die set.

Lock-N-Load® quick change bushing system

The Lock-N-Load® system is based on the positive locking

action of the bolt action rifle. Just like the bolt action rifle, the

locking action is incredibly strong and simple.

Once the dies and the powder measure are adjusted for loading,

these settings are locked in place by tightening the Lock Ring

that is provided with all Hornady dies and powder measures.

How the Lock-N-Load® works:

• Insert the Lock-N-Load® bushing into the press and turn it

clockwise to lock it in place.

• Adjust the die to the desired position and lock the setting in

place with the die’s lock ring.

Once Lock-N-Load® bushings are installed, Dies and Powder Drop

can be removed from the press with a quick counterclockwise

turn. Since the Lock-N-Load® bushing is locked in place, the dies

and the Powder Drop remain set exactly as you left them.

For added speed and convenience, Hornady offers inexpensive

Quick Change Powder Dies for use with the Case Activated

Powder Drop.

CHANGE-OVER

Feed

Case

Eject

Ammo

Taper Crimp/

Seating Die

Pistol

Bullet Feeder

Size and

De-Prime Die

Typical

Pistol Die Setup

on the Hornady

Lock-N-Load

Ammo Plant

Die

Prime

Case

LNL Powder

Drop with

Powder Cop

(optional)

PTX

Die Setup Configurations

Feed

Case

Eject

Ammo

Taper

Crimp

Die

Size and

De-Prime Die

Alternate

Pistol Die Setup

on the Hornady

Lock-N-Load

Ammo Plant

Seating

Die

Prime

Case

LNL Powder

Drop with

Pistol

Bullet Feeder

Die

PTX

Feed

Case

Eject

Ammo

Feed

Bullet

Open

Size and

De-Prime Die

Rifle Die Setup

on the Hornady

Lock-N-Load

Ammo Plant

Seating

Die

CHANGE-OVER: AP PRESS

Typical

Prime

Case

Lock-N-Load

Powder Drop

Powder

Cop

(optional)

- 19 -

Page 20

Changing Primer Components

When changing from a large primer to a small primer (or vice

1

versa), you need to change the Primer Feed Tube Primer Slide

and Punch Assembly.

1

Primer Feed

Tube

Primer Slide

Punch Assembly

If there are primers in the Primer Feed Tube, you will need to

2

empty it before changing the tubes. If the Primer Feed Tube is

already empty, skip to next step.

Remove the Cap Screw, cup your hand under the Primer Tube

and rotate the Primer Feed Body Assembly clockwise to catch

the primers. After the tube is empty, rotate the body back in

place and re-install the mounting screw.

Disconnect the Spring from the roller pin and remove the

3

Primer Slide. Remove the Primer Tube Support and the Primer

Feed Tube.

Fill the primer tube as described in the Operations Section.

CHANGE-OVER

2

3

Spring

The Primer Seater Punches are installed from the bottom side

4

of the Sub-Plate. Raise the Ram to the top of the stroke. Use

a wrench to loosen the Primer Seater Punch and unscrew

it from the Sub-Plate. When installing a new Primer Seater

Punch, tighten it snug with a wrench. Do not over tighten the

Primer Punch.

- 20 -

CHANGE-OVER: AP PRESS

Primer Slide

4

Primer Seater

Punch

Page 21

Setup / Changeover of Powder Measure

When changing cartridges, three components on the Powder

Measure may need to be changed or verified.

• Powder type in the hopper.

• Metering Insert and/or Metering Rotor

• Powder Sleeve or PTX Expander

Emptying Powder in Hopper

NOTE: The Lock-N-Load® Powder Measure should be emptied of

all powder prior to storage. Prolonged exposure to powder may

cause the plastic tube to become cloudy, discolored, or even

brittle.

To remove powder from the Lock-N-Load® Powder Measure

hopper, either use the Hornady Powder Measure Drain Insert

(sold separately 050125) or remove the entire Powder Measure

assembly from the press, remove the cap, and pour back into the

original powder measure container. Cycle the rotor a few times

while holding the powder measure over a container to remove

the powder from the rotor. Finally remove the Metering Insert to

inspect for any residual powder.

Changing Meter Insert and Rotor

The Lock-N-Load® Powder Measure ships with two sets of Rotors

and Standard Inserts. The Pistol Rotor and Standard Insert are

for powder charges from approximately 0.5 grains to 17 grains.

The Rifle Rotor and Standard Insert are for powder charges from

approximately 15 grains to 100 grains.

Additional inserts are available and sold separately to make

change overs and reloading quicker and easier by storing the

Metering Insert with the die set so minimal adjustments are

needed when changing cartridges.

1

To change the insert, press the button on the side of the rotor.

While pressing the button, pull and wiggle the Metering Insert

out of the Rotor body. To install the new Metering Insert, press

and hold the button on the side of the rotor, align the flats on the

Metering Insert with the body of the Powder Measure, and press

the insert into the Rotor. Verify the insert is fully inserted

by firmly pulling on the Metering Insert.

NOTE: If there is powder in the hopper and the Metering Insert

is on the bottom of the stroke, removing the Metering Insert will

cause powder to empty out of the Powder Measure hopper and

onto your work area.

If you are changing from a pistol cartridge to a rifle cartridge

(or vice versa), you will need to change the Rotor in the Powder

Measure.

2

To remove the Rotor, first remove the Metering Insert following the

Instructions above. Next, remove the two screws from the side of

the Rotor. Slide the Rotor out of the Powder Measure body.

Insert the correct Rotor by gently sliding it into the Powder

3

Measure body. The manufacturing tolerances are very tight on

the both the rotor and Powder Measure body, so caution should

be used to prevent causing damage to the either component.

Insert the correct Metering Insert and reattach the linkage with

the two screws.

1

Metering Insert

2

CHANGE-OVER

3

Rotor

CHANGE-OVER: POWDER MEASURE

- 21 -

Page 22

Changing Powder Sleeve or

PTX Expander

As a general rule, rifle cartridge cases will use either the

#1 or #2 Powder Sleeve. Pistol cases will need to use the

PTX sleeves when the Hornady Lock-N-Load® Bullet Feeder

is being used. Otherwise the Universal Pistol Powder Sleeve

will be used.

Refer to the chart below to select the proper Sleeve

or Expander.

Remove spring, PTX Stop and loosen thumb screw.

Remove Powder Measure body from lower assembly.

Turn lower assembly over so powder sleeve drops out.

Replace with proper Powder Sleeve or PTX Expander.

Reverse steps above to reassemble.

CHANGE-OVER

392700 392701 392702 392703

Universa l Pistol

Powder Sleeve

Most Pistol Cases* 7mm to 45 Cal . Rifle

*Doe s not flare case

290030 290031 290032 290033 290034 290035 290037 290038

.355 PTX .357 PT X

9mm Pi stol Cases 38 Cal. Pistol Cas es 10mm P istol Cases 44 Cal. Pistol Cases 45 Cal. Pis tol Cases 45 Cal. Pistol Cases 475 Cal . Pistol

(PTX = Powder Thru Ex pander)

- 22 -

#1 Pow der Sleeve #2 Po wder Sleeve 17 Cal. Po wder

Cases

20 to 270 Cal. R ifle

.40 0 PT X .430 PTX .451 P TX .45 2 PT X .475 PTX 50 0 PT X

CHANGE-OVER: POWDER MEASURE

Cases

Sleeve

17 Cal. Ri fle Cases

Cases

50 Cal . Pistol Cas es

Page 23

Adjusting the PTX Stop

Place Powder Measure Assembly onto the Lock-N-Load® AP™

Press in the proper station.

Remove PTX Spring and Stop from Powder Measure.

Insert a case into the shell plate under the powder measure and

operate the handle to raise the ram to its highest position.

Lower the Powder Measure by rotating it clockwise into the

press until the Powder Measure Rotor is fully rotated, but not

contacting the end of the slot in the Powder Measure Body.

Metering Inserts

should not

contact Powder

Measure Body

INCORRECT

(screw together)

Lower the Ram and attach the PTX Stop and Return Spring

between the two Spring Pins .

Check the Lock-N-Load® Powder Measure for correct

positioning to avoid interference from other dies. Secure the

Lock-N-Load® Powder measure to the Lock-N-Load® Bushing

by tightening the lock ring.

NOTE: Clean the Case Activated Powder Drop at the end of

each reloading session with a clean dry cloth to prevent a

buildup of excess powder. This helps prevent the internal

sleeve from sticking and spilling powder around the cartridge

cases as they are loaded.

CORRECT

INCORRECT

(screw apart)

Metering Inserts should

be 1/16" - 1/8" from

Powder Measure to

maximize stroke.

WARNING: If the Metering

Insert does not rotate fully

a complete charge will not

drop into case.

CHANGE-OVER

Install the PTX Powder Measure Stop

The PTX Powder Measure Stop (item no. 290049) is designed

to be used in conjunction with our PTX Expanders and the

Case Activated Powder Drop. The PTX Powder Measure Stop

serves as a way to precisely and positively stop the upward

travel of the Lock-N-Load

PTX Expanders to deliver consistently flared case mouths.

Make sure that the powder measure, using the Hornady

4

Case Activated Powder Drop, is set properly as per the

instructions included with that unit – the powder

measure should be cycling completely through its range

of motion. Remove the vertical spring from Case Activated

Powder Drop.

®

Powder Measure which allows the

4

CHANGE-OVER: POWDER MEASURE

- 23 -

Page 24

Holding the PTX Powder Measure Stop, unscrew one of the

5

cap screws until the threaded end of the screw is flush

with the inside of the slot.

5

Unscrew the other cap screw until approximately two

6

threads are showing.

Install the PTX Powder Measure Stop over the hex spring

7

mount with the cap screw that is protruding on the top.

CHANGE-OVER

6

7

- 24 -

CHANGE-OVER: POWDER MEASURE

Page 25

Place an empty, primed case into the station of the shell

8

plate that will rotate to the powder measure. Raise the ram

which will cycle the powder measure to the top of its stroke.

Thread the bottom cap screw in until the threaded end

bottoms out on the lower hex spring mount.

Lower the ram and replace the vertical spring on the

9

hex spring mount.

8

9

To adjust for more case mouth flare, continue to screw in

10

the bottom cap screw, for less case mouth flare, back it out.

Make small adjustments.

When adjusted as desired, tighten jam nuts to lock in

adjustment.

CHANGE-OVER

10

CHANGE-OVER: POWDER MEASURE

- 25 -

Page 26

Troubleshooting the Lock-N-Load® Ammo Plant

Tips for Trouble-Free Operation of the Lock-N-Load

Problems Solutions

Powder dropping around case

No primer in case

Shell Plate will not advance or does not index on station

Cases do not feed into Dies

Gun powder is sticking in the powder measure, or

inconsistent charge weights

Case retainer spring won’t fall off the shell plate

or it is getting kinked

• Correct bushing in place?

• Powder drop tube and measure adapter clean?

• Bushing installed deep counter sink side up?

• Primer slide properly adjusted?

• Correct primer punch installed?

• Primer slide spring in place?

• Correct primer slide installed?

• Primer body rotated counterclockwise when installed?

• Primer housing tube too tight?

• Primer not fully seated?

• Pawls correctly adjusted?

• Make sure you have the latest shell plate version with the groove on the bottom side.

• Die mouths beveled? (If not, return to manufacturer for repair.)

• Pawls timed correctly?

• Is the inside surface dry and clean?

• Try pouring a little powdered graphite thru the powder measure for lubricant.

Rub the outside of the powder hopper with a dryer sheet to eliminate static.

• Is there a burr on the shell plate where the spring groove and the case location meet?

• Is there a burr on the sides of the slot on the sub-plate? (With a

casefeeder, when you are setting up the timing, do not run the

case into the spring if the spring is up on the shell plate.)

®

AP™ Press

Cases are hitting the back corner of the shell plate when

feeding into the shell plate

Cases are not feeding into the shell plate far enough

Cases are tipping when going into the shell plate

Cases are falling on top of the V-Block

Drop tube is tight against the AP frame; will not allow

changing of tubes

Cases are falling mouth first out of the bowl

Cases are getting caught in the open hole on the bowl

The shell plate is hitting the V-Block when it’s rotating

Shell Plate Troubleshooting

Timing is severely out of adjustment

The Shell Plate does not rotate freely after mounting

TROUBLESHOOTING

*If you reach a point where you cannot get the press to work, please call our technical service staff at 800-338-3220 or write us by visiting: Hornady.com/contact_us.

Slow timing down or readjust V-Block location

Speed timing up or using the wrong V-Block

Readjust V-Block location

Readjust the bracket, square tubing

Readjust the bracket, square tubing

Close the door adjustment

Open the door adjustment

Lower the cam wire

Problems Solutions

The Index Pawls may have been damaged

• You may be trying to use the wrong version of shell plate. Your shell plate must have a groove

cut on the bottom side.

• Dirt or debris between the shell plate and the drive hub

• The Ball Detent bodies are not below flush on the underside of the Shell Plate.

• The Shell Plate is warped or damaged

- 26 -

TROUBLESHOOTING

Page 27

APPENDIX A

Rifle Dies & Reloading Essentials (Reference Chart)

Rifle

Cartridge

17 HORN ET .172 5 46118 I 046202 0 44101 — — — #3 / 3 905 43 #3 / 3 926 03 Sm R fl / 095 314 — * / 39 094 2 Small #1 / 3 92154

17 REM FIREBALL .172 5 46117 I 046200 04 4101 — — — #16 / 3 905 56 #16 / 3 92616 Sm R fl / 095 314 — * / 39 094 2 Small #1 / 392154

17 REM .172 546200 III 0 46201 044101 — — — # 16 / 390 556 #16 / 39 2616 Sm R fl / 09 5314 — * / 3 909 42 Small #1 / 39 2154

17/222 .172 546202 IV — — — — — #16 / 3 905 56 #16 / 3 92616 S m Rfl / 09 5314 — * / 3 909 42 Small #1 / 39 2154

17/2 23 .172 546204 IV — — — — — #16 / 3 905 56 #16 / 3 92616 Sm R fl / 095 314 — * / 39 094 2 Small #1 / 39 2154

20 V T .204 546205 III 046206 0 44139 — — 046038 #16 / 3 905 56 #16 / 392 616 Sm R fl / 09 5314 — #2 2 / 390 940 Small #14 / 392167

20 TACTICAL .204 546209 III 046208 0 44139 — — 046038 #16 / 3 905 56 #16 / 392 616 Sm R fl / 09 5314 — #2 2 / 390 940 Small #14 / 392167

20 4 RUGER .204 546201 I 046590 04 4139 — — 046038 #16 / 3 905 56 #16 / 3 92616 S m Rfl / 09 5314 — # 22 / 39 094 0 Small #1 4 / 39216 7

22 HO RNET .224 54 6212 I 04 6213 0 44102 — — 046066 #3 / 3 905 43 #3 / 3 926 03 Sm R fl / 095 314 — # 1 / 39094 3 Small #2 / 3 92155

22 K-HORNE T .224 546214 IV — — — — 046066 #3 / 39 054 3 #3 / 3 926 03 Sm R fl / 095 314 — # 1 / 390 943 Small # 2 / 39215 5

5.7x28 FN .224 546203 III 04 6212 04 4136 — — — # 37 / 39 0577 — / — Sm R fl / 095 314 — #1 / 39 094 3 Small #2 / 39 2155

218 BEE .224 546206 IV — — — — 046066 #7 / 3 905 47 #7 / 3 926 07 Sm R fl / 095 314 — # 1 / 390 943 Small #2 / 3 92155

221 REM FIREBALL .224 5 46210 III 046 211 044102 — — 046040 #16 / 3 905 56 #16 / 3 92616 Sm R fl / 095 314 — # 1 / 390 943 Small #2 / 3 92155

222 REM .224 546224 I 046225 04 4102 — — 046040 #16 / 3 90556 # 16 / 392616 S m Rfl / 09 5314 — #1 / 3 909 43 Small # 2 / 392155

223 REM .224 546228 I 046229 04 4102 — — 046040 #16 / 3 905 56 #16 / 3 92616 Sm R fl / 095 314 095340 #1 / 3 909 43 Small #2 / 39 2155

22 3 REM MATCH .224 — — 544229 04410 2 — — 544227 # 16 / 390 556 # 16 / 392616 S m Rfl / 09 5314 095340 #1 / 39 094 3 Small #2 / 3 92155

22 PPC .224 5 46216 IV — — — — 046053 #6 / 3 905 46 #6 / 3 926 06 Sm R fl / 095 314 — # 1 / 390 943 Small #2 / 39 2155

5.6 x50 MAG .224 546234 IV — — — — 046040 #16 / 3 90556 #16 / 39 2616 Sm R fl / 09 5314 — #1 / 39 094 3 Small #2 / 39 2155

219 ZIPPER .224 546208 IV — — — — 046040 #2 / 3 905 42 #2 / 3 926 02 Lg R fl / 09 5316 — #1 / 39 094 3 Large #2 / 39215 5

22 5 WIN .224 546232 III 046233 04412 7 — — 046040 # 4 / 390 544 # 4 / 392 604 L g Rfl / 0 9531 6 — #1 / 39 094 3 Large # 2 / 392155

224 WBY .224 546230 IV — — — — 046040 # 17 / 390 557 — / — L g Rfl / 0 9531 6 — #1 / 39 094 3 Large #2 / 39 2155

22/250 REM .224 546220 I 04 6221 04 4102 — — 046040 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #1 / 3 909 43 L arge #2 / 3 92155

22 /250 ACKL EY IMP .224 5 46219 IV — — — — 046040 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #1 / 3 909 43 Large #2 / 392155

22 0 SWIFT .224 546222 I 046223 04412 7 — — 046054 # 4 / 39054 4 #4 / 39 260 4 L g Rfl / 09 5316 — #1 / 3 909 43 Large #2 / 39 2155

5.6x57 .224 546236 IV — — — — — # 1 / 390541 #1 / 39 260 1 Lg Rfl / 0 953 16 — #1 / 3 909 43 Large #2 / 39 2155

22 3 WIN SS MAG .224 546223 I 046558 044707 — — — # 35 / 39 0575 #35 / 392635 Lg Rfl / 0 953 16 — #1 / 3 909 43 Large #2 / 39 2155

22/6MM .224 54 6249 III 046238 04 4127 — — 046054 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — #1 / 39 094 3 Large #2 / 3 92155

22 SAV HP .227 546240 IV — — — — — # 2 / 390 542 #2 / 390602 Lg R fl / 095 316 — # 2 / 390 944 Large #2 / 3 92155

5.6x52R .227 546238 IV — — — — — #2 / 39 0542 #2 / 390602 Lg Rfl / 0 95 316 — #2 / 3 909 44 Large #2 / 39 2155

6MM/223 .243 546248 IV — — — — 046047 #16 / 3 905 56 #16 / 3 92616 S m Rfl / 09 5314 — #3 / 3 909 45 Small # 3 / 392 156

6MM T CU .243 546256 IV — — — — 046047 #16 / 3 90556 #16 / 39 2616 S m Rfl / 09 5314 — #3 / 3 909 45 Small # 3 / 392156

6x47 REM .243 546258 IV — — — — 046047 # 16 / 390 556 #16 / 39 2616 Sm R fl / 09 5314 — # 3 / 390 945 Small # 3 / 392156

6x47 L APUA MAT CH .243 — — — — — — — # 1 / 390 541 #16 / 39 2616 Sm R fl / 09 5314 — # 3 / 390 945 Small # 3 / 392156

6MM PPC .243 546254 IV — — — — 046052 #6 / 3 905 46 #6 / 3 92606 S m Rfl / 09 5314 — #3 / 3 909 45 Small # 3 / 392156

6MM PPC MATCH .243 — — 54 4255 — — — 544253 #6 / 3 905 46 #6 / 3 926 06 Sm R fl / 095 314 — # 3 / 390 945 Small #3 / 39 2156

6MM INT .243 546252 IV — — — — 046041 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 095 316 — # 3 / 390 945 Large #3 / 3 92156

6MM REM BR .243 546432 IV — — — — 046047 #1 / 3 905 41 #1 / 3 926 01 Sm R fl / 095 314 — # 3 / 390 945 Small #3 / 3 9215 6

6MM REM BR MAT CH .243 — — 5 44251 — — — 544259 #1 / 39 0541 #1 / 39 2601 Sm R fl / 095 314 — # 3 / 390 945 Small #3 / 39 2156

6MM HAGAR .243 546303 IV — — — — — # 12 / 390 552 # 12 / 392612 S m Rfl / 09 5314 — #3 / 3 909 45 L arge #3 / 3 92156

6MM CREEDMOOR .243 546295 IV — — — — 046041 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #3 / 3 909 45 Large #3 / 392156

243 WIN .243 546244 I 046245 04 4103 — — 046041 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — # 3 / 390 945 L arge #3 / 3 92156

244/6MM REM .243 546246 I 046247 04410 3 — — 046041 # 1 / 390541 #1 / 39 2601 L g Rfl / 09 5316 — #3 / 3 909 45 Large #3 / 39 2156

6MM/284 .243 546250 IV — — — — 046041 #1 / 39 0541 #1 / 39 2601 Lg R fl / 095 316 — #3 / 39 094 5 Large # 3 / 39215 6

240 WBY .243 546242 IV — — — — 046041 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #3 / 3 909 45 Large #3 / 39 2156

243 WIN SS M AG .243 546225 I 046557 — — — — # 35 / 39 057 5 #35 / 392635 L g Rfl / 09 531 6 — # 3 / 390 945 Large #3 / 3 92156

25/20 WIN .257 546264 IV — — — — — # 7 / 390 547 # 7 / 392 607 S m Rfl / 09 5314 — #4 / 3 909 46 Small #4 / 39 2157

25 6 WIN .257 546272 IV — — — — — # 6 / 390 546 # 6 / 392 606 Sm R fl / 09 5314 — #4 / 39 094 6 Large #4 / 39215 7

25/35 WIN .257 546266 IV — — — — — #2 / 3 905 42 #2 / 3 92602 Lg Rfl / 0 95 316 — #4 / 3 909 46 Large #4 / 39 2157

25 REM .257 546260 III 046276 044104 — — — #12 / 3 905 52 #12 / 3 92612 L g Rfl / 09 5316 — #4 / 3 909 46 L arge #4 / 3 92157

25 0 SAV .257 546270 IV — — — — 046042 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #4 / 3 909 46 Large #4 / 39 2157

257 ROBERTS .257 5 46274 III 046275 044104 — — 046042 #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 95 316 — #4 / 3 909 46 Large #4 / 39 2157

25 WIN SS MA G .257 546263 IV — — — — — # 35 / 39 057 5 #35 / 392635 L g Rfl / 0 9531 6 — # 4 / 390 946 Large #4 / 3 92157

25/06 REM .257 546262 I 046263 044104 — — 046042 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 095 316 — # 4 / 390 946 Large #4 / 3 92157

25/284 .257 546268 IV — — — — 046042 #1 / 39 0541 #1 / 39 2601 Lg R fl / 095 316 — #4 / 39 094 6 Large # 4 / 39215 7

257 WBY .257 546276 III 046277 044104 — — 046042 #5 / 3 905 45 # 5 / 392 605 Lg R fl / 095 316 — #4 / 39 094 6 Large # 4 / 39215 7

6.5MMx47 MATCH .264 544650 — — — — — — #1 / 39 0541 — / — — / — — # 5 / 390 947 Small #4 / 39 2157

6.5MM TCU .264 546296 IV — — — — 046048 #16 / 3 90556 # 16 / 392616 S m Rfl / 09 5314 — #5 / 3 909 47 Small # 4 / 392157

6.5 GRENDEL .264 5 46291 I 046598 0 44164 — — — #6 / 3 905 46 #6 / 3 926 06 Sm R fl / 095 314 — # 5 / 390 947 Large #4 / 39215 7

6.5 J AP .264 546290 III 046291 04 4106 — — 046043 # 34 / 39 0574 — / — Lg Rfl / 0 953 16 — #5 / 3 909 47 L arge # 4 / 39215 7

6.5 J DJ .264 — — — — — — 046043 #4 / 39 054 4 #4 / 3926 04 Lg R fl / 095 316 — # 5 / 390 947 L arge #4 / 3 92157

6.5 MANN/SCH. .264 546292 IV — — — — 046043 #2 0 / 390 560 — / — L g Rfl / 09 5316 — #5 / 3 909 47 Large # 4 / 39215 7

6.5x55/SCAN. .264 546282 I 046283 044106 — — 046043 #19 / 3 905 59 #19 / 3 92619 Lg Rfl / 0 95 316 — #5 / 3 909 47 Large # 4 / 39215 7

260 REM .264 546269 III 0 46441 0 44106 — — 046043 #1 / 39 0541 #1 / 392601 Lg R fl / 095 316 — #5 / 39 0947 Large # 4 / 39215 7

6.5 CREEDMOOR .264 546289 I 046596 04 4106 — — 046043 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #5 / 3 909 47 L arge # 4 / 39215 7

6.5 C REEDMOOR MATCH .264 544655 — — — — — — # 1 / 390 541 # 1 / 392601 L g Rfl / 09 5316 — #5 / 3 909 47 L arge #4 / 3 92157

6.5x57 .264 546284 III 046285 044106 — — 046043 # 1 / 390541 #1 / 39 2601 L g Rfl / 09 5316 — #5 / 3 909 47 Large #4 / 392157

6.5/284 .264 546 301 III 046443 04410 6 — — 046043 #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 95 316 — #5 / 3 909 47 Large #4 / 39 2157

6.5/06 .264 546280 III 046281 044123 — — 046043 #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 95 316 — #5 / 3 909 47 Large #4 / 39 2157

Bullet Diameter

(inches)

Die Set

Die Series

Full-Length

Size Die

Seating Die

Expander Die

Taper Crimp

Die Only

Neck Size Die

Shell Holder

# / Item No.

Shell Plate

# / Item No.

Case

Feeder Plate

Size / Item No.

Bullet

FeederDie

Trimmer Pilot

# / Item No.

Primer Punch

Bullet

Puller Collet

# / Item No.

APPENDIX A

- 27 -

Page 28

APPENDIX A

Rifle Dies & Reloading Essentials (Reference Chart)

Rifle

Cartridge

6.5 R EM MAG .264 546294 IV — — — — 046043 #5 / 39 054 5 #5 / 3926 05 Lg R fl / 095 316 — # 5 / 390 947 L arge #4 / 3 92157

26 4 WIN MAG .264 546278 III 046279 044123 — — 046043 #5 / 3 905 45 #5 / 3 926 05 Lg R fl / 09 5316 — # 5 / 390 947 L arge #4 / 3 92157

6.5x68 .264 546286 III 046287 044123 — — 046043 # 30 / 39 057 0 # 30 / 39 263 0 Lg Rfl / 0 953 16 — #5 / 3 909 47 Large #4 / 39 2157

6.5 C ARC .268 546288 III 046289 044134 — — 046043 # 21 / 3905 61 — / — Lg Rfl / 0 95 316 — #5 / 3 909 47 Large # 4 / 392157

6.8MM REM SPC .277 546299 III 046 711 04 4713 — — — #12 / 3 905 52 #12 / 3 92612 Lg R fl / 09 5316 — # 6 / 390 948 Small # 5 / 392158

270 R EN .277 — — — — — — — #3 / 3 905 43 #3 / 3 926 03 Sm Rfl / 0 95 314 — #6 / 3 909 48 Small #5 / 3 92158

270 W IN .277 546300 I 046301 04 4107 — — 046051 # 1 / 390 541 # 1 / 392601 Lg R fl / 095 316 — #6 / 39 094 8 Large # 5 / 39215 8

270 W IN SHORT M AG .277 546297 I 046450 04 4161 — — 046055 #3 5 / 390 575 #35 / 392635 L g Rfl / 09 5316 — #6 / 39 094 8 Large # 5 / 39215 8

270 WBY .277 546298 III 046299 0 44107 — — 046051 #5 / 3 905 45 #5 / 3 926 05 L g Rfl / 09 5316 — #6 / 3 909 48 L arge #5 / 3 92158

7MM/2 23 INGRAM .284 546318 IV — — — — 046049 #16 / 3 90556 #16 / 39 2616 S m Rfl / 09 5314 — #7 / 3 909 49 Small # 6 / 392159

7MM TCU .284 546328 IV — — — — 046049 #16 / 3 905 56 #16 / 3 92616 Sm R fl / 095 314 — # 7 / 390 949 Small #6 / 3 92159

7x47 HELM .284 546306 IV — — — — 046049 #16 / 3 905 56 #16 / 3 92616 Sm R fl / 095 314 — # 7 / 390 949 Large #6 / 39215 9

7MM REM BR .284 546324 IV — — — — 046049 # 1 / 390541 #1 / 39 2601 Sm R fl / 095 314 — # 7 / 390 949 Large #6 / 3 92159

7x3 0 WATERS .284 546304 IV — — — — 046049 #2 / 39 0542 #2 / 39 260 2 L g Rfl / 0 9531 6 — # 7 / 390 949 Large #6 / 3 92159

7MM MERRILL .284 546322 IV — — — — 046044 # 4 / 390 544 # 4 / 39260 4 L g Rfl / 09 5316 — #7 / 39 094 9 Large # 6 / 39215 9

7MM/08 REM .284 5 46316 I 046317 04 4108 — — 046044 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #7 / 3 909 49 Large #6 / 392159

7x57-7MM MAUSER .284 546308 I 046309 044108 — — 046044 #1 / 39 0541 #1 / 392601 Lg R fl / 095 316 — #7 / 39 094 9 Large # 6 / 39215 9

7x57R .284 — — — — — — 046044 #13 / 3 905 53 #13 / 3 92613 Lg R fl / 09 5316 — # 7 / 390 949 L arge #6 / 3 92159

28 4 WIN .284 546302 III 046303 04 4108 — — 046044 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — # 7 / 390 949 L arge #6 / 3 92159

280 REM/7MM EXP .284 546320 I 046321 044108 — — 046044 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 095 316 — # 7 / 390 949 Large #6 / 3 92159

28 0 ACKLE Y IMP .284 546 321 III 046304 04 4108 — — 046044 #1 / 39 0541 #1 / 39 2601 Lg R fl / 095 316 — #7 / 39 094 9 Large # 6 / 39215 9

7x65R .284 546314 III 046315 04 4133 — — 046044 #13 / 3 905 53 #13 / 3 92613 Lg Rfl / 0 95 316 — #7 / 3 909 49 Large # 6 / 39215 9

7x6 1 S&H .284 5 46310 IV — — — — 046044 # 35 / 39 0575 #35 / 392635 L g Rfl / 09 5316 — #7 / 39 094 9 Large # 6 / 39215 9

7x64 .284 546312 III 046313 04410 8 — — 046044 #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 95 316 — #7 / 3 909 49 Large # 6 / 39215 9

7MM RE M SA ULTRA M AG .284 546309 III 046452 04410 8 — — 046056 #5 / 3 905 45 #5 / 3 926 05 L g Rfl / 09 5316 — #7 / 3 909 49 L arge #6 / 3 92159

7MM REM MAG .284 546326 I 046327 0 4410 8 — — 046044 # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #7 / 3 909 49 Large #6 / 39 2159

7MM W IN SHORT MAG .284 546327 I 046451 04 4108 — — 046056 # 35 / 39 0575 #35 / 392635 Lg Rfl / 0 95 316 — #7 / 3 909 49 Large # 6 / 39215 9

7MM W BY .284 546330 III 046331 044108 — — 046044 #5 / 3 905 45 #5 / 3 926 05 Lg R fl / 095 316 — # 7 / 390 949 Large #6 / 3 92159

7MM S TW .284 546440 IV — — — — 046044 #5 / 39 054 5 #5 / 39 2605 Lg Rfl / 0 95 316 — #7 / 3 909 49 Large # 6 / 39215 9

7MM RE M ULTRA MA G .284 546307 III 046454 04 4133 — — 046056 #5 / 3 905 45 #5 / 3 926 05 L g Rfl / 09 5316 — #7 / 3 909 49 L arge # 6 / 39215 9

7.3 5 CARC .300 546332 IV — — — — — # 21 / 390561 — / — L g Rfl / 09 531 6 — # 8 / 390 950 Large #7 / 3 92160

30 M1 C ARB .308 546503 II 046504 0 44142 044505 — — # 22 / 39 056 2 # 22 / 39 262 2 Sm R fl / 09 5314 — # 9 / 390 951 Small # 7 / 392 160

30 REM .308 — — — — — — 046050 #12 / 39 0552 # 12 / 392 612 L g Rfl / 0 9531 6 — # 9 / 390 951 Large #7 / 3 92160

300 AAC/WHISPER .308 546349 I 046459 04 4165 — — — #16 / 39 0556 #16 / 3 92616 Sm R fl / 095 314 — #9 / 39 0951 Small # 7 / 392 160

30 HERRETT .308 546334 IV — — — — 046050 #2 / 3 905 42 #2 / 39 260 2 Lg Rfl / 0 953 16 — #9 / 3 909 51 Large #7 / 39 2160

30/30 WIN .308 546342 I 046343 0 44111 — — 046050 #2 / 3 905 42 #2 / 3 926 02 Lg R fl / 09 5316 — # 9 / 390 951 L arge #7 / 3 9216 0

30 -30 ACKLEY I MP .308 546345 IV — — — — 046050 #2 / 3 905 42 #2 / 3 926 02 Lg R fl / 09 5316 — # 9 / 390 951 L arge #7 / 3 9216 0

30 3 SAV .308 546354 IV — — — — 046050 # 33 / 39 057 3 — / — L g Rfl / 0 9531 6 — # 9 / 390 951 L arge #7 / 3 92160

30 0 SAV .308 546348 III 046349 0 44111 — — 046050 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — # 9 / 390 951 Large #7 / 392160

APPENDIX A

30 MERRILL .308 546338 IV — — — — 046050 # 4 / 390 544 # 4 / 392 604 Lg Rfl / 0 95 316 — #9 / 3 909 51 Large # 7 / 39216 0

30 8 MARLIN EXP .308 546357 I 046358 044111 — — 046045 # 27 / 39 056 7 #27 / 392627 L g Rfl / 09 5316 — #9 / 3 909 51 Large #7 / 39 2160

7.5 S WIS S (7.5 X55 ) .308 546360 III 046361 0 44111 — — 046045 # 2 / 390 542 # 2 / 392 602 Lg Rfl / 0 95 316 — #9 / 3 909 51 Large # 7 / 39216 0

7.5 SWISS K31 .308 5 463 61 III 046362 0 44111 — — 046045 #2 / 390604 — / — L g Rfl / 09 5316 — #9 / 3 909 51 Large # 7 / 39216 0

308 WIN .308 546358 I 046359 0 44111 — — 046045 # 1 / 390541 #1 / 39 2601 L g Rfl / 09 5316 095345 # 9 / 390 951 Large #7 / 3 92160

30 8 WIN MATCH .308 — — 544359 — — — 544357 #1 / 3 905 41 #1 / 3 926 01 L g Rfl / 09 5316 095345 # 9 / 390 951 Large #7 / 3 92160

7.62 RUSS .308 546362 III 046363 0 44111 — — 046050 # 23 / 39 056 3 # 23 / 39 262 3 L g Rfl / 09 5316 — #9 / 39 0951 Large # 7 / 392160

30/40 KRAG .308 546344 IV — — — — 046045 #11 / 3 90551 # 11 / 39 2611 L g Rfl / 09 5316 — #9 / 3 909 51 Large #7 / 39 2160

30 TC .308 546335 I 046336 044111 — — 046045 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — # 9 / 390 951 Large #7 / 39 2160

30/06 .308 546340 I 046341 0 44112 — — 046045 #1 / 3 905 41 #1 / 39 260 1 L g Rfl / 0 9531 6 — # 9 / 390 951 L arge #7 / 3 92160

30/06 ACKL EY IMP .308 546341 IV — — — — 046045 #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #9 / 3 90951 Large #7 / 3 92160

30 0 H&H .308 546346 IV — — — — 046045 #5 / 3905 45 #5 / 3 926 05 Lg R fl / 095 316 — # 9 / 390 951 Large #7 / 3 92160

300 OLYMPIC .308 546355 IV — — — — — # 35 / 39 057 5 #35 / 392635 L g Rfl / 09 531 6 — # 9 / 390 951 Large #7 / 3 92160

30 0 REM SA ULTR A MAG .308 546347 I 046455 04 4160 — — 046057 #5 / 3 905 45 #5 / 3 92605 Lg Rfl / 0 953 16 — #9 / 3 909 51 Large #7 / 39 2160

30 8 NORMA MA G .308 546356 IV — — — — 046045 # 5 / 390 545 # 5 / 39260 5 L g Rfl / 09 5316 — #9 / 39 0951 Large # 7 / 392160

30 0 WIN SHOR T MAG .308 546369 I 046453 0 44160 — — 046057 #3 5 / 390575 #35 / 392635 Lg R fl / 095 316 — #9 / 39 0951 Large # 7 / 39216 0

30 0 RCM .308 546353 I 046592 0 44111 — — 046045 # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #9 / 3 909 51 Large # 7 / 39216 0

30 0 WIN MAG .308 546352 I 046353 0 44112 — — 046045 # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #9 / 3 909 51 Large # 7 / 39216 0

30 0 WBY .308 546350 I 046351 04 4112 — — 046045 #5 / 3 905 45 #5 / 3 926 05 Lg R fl / 09 5316 — # 9 / 390 951 L arge #7 / 3 9216 0

30 0 REM ULTRA MAG .308 546365 I 046447 0 44159 — — 046057 #5 / 3 905 45 #5 / 3 92605 Lg Rfl / 0 953 16 — #9 / 3 909 51 Large #7 / 39 2160

30/378 .308 546419 IV — — — — 046057 #14 / 3 905 54 #14 / 3 92614 Lg Rfl / 0 95 316 — #9 / 3 909 51 Large # 7 / 39216 0

307 WIN .308 — — — — — — 046045 # 33 / 39 057 3 — / — L g Rfl / 09 5316 — #9 / 3 909 51 Large # 7 / 39216 0

30 9 JDJ .308 — — — — — — 046045 # 27 / 39 056 7 — / — L g Rfl / 09 5316 — #9 / 3 909 51 Large #7 / 392160

7.6 2x3 9 .308 546424 I 046425 04 4126 — — — # 6 / 390 546 # 6 / 392 606 S m Rfl / 09 5314 — #9 / 3 90951 Large #7 / 3 92160

BLA NK CART 22- 45 CAL — 544591 IV — — — — — — / — — / — — / — — — / — — — / —

32 /20 WI N .311 546364 III 046365 0 44113 — — — # 7 / 390 547 # 7 / 392 607 S m Rfl / 09 5314 — #9 / 3 909 51 Small # 7 / 392 160

7.6 5 BEL G .3 12 546368 III 046369 0 44114 — — — #24 / 39 056 4 — / — L g Rfl / 09 531 6 — #10 / 39 0952 Large # 7 / 39216 0

303 BRITISH .312 546366 I 046367 0 44114 — — — #11 / 3 905 51 #11 / 39 2611 L g Rfl / 09 5316 — #10 / 3 909 52 Large # 7 / 392160

7.7 J AP .312 546370 III 046371 04 4114 — — — # 1 / 390541 #1 / 39 260 1 L g Rfl / 0 9531 6 — # 10 / 390 952 Large #7 / 3 92160

Bullet Diameter

(inches)

Die Set

Die Series

Full-Length

Size Die

Seating Die

Expander Die

Taper Crimp

Die Only

Neck Size Die

Shell Holder

# / Item No.

Shell Plate

# / Item No.

Feeder Plate

Size / Item No.

Case

FeederDie

Bullet

Trimmer Pilot

# / Item No.

Primer Punch

Puller Collet

Bullet

# / Item No.

- 28 - - 28 -

Page 29

APPENDIX A

Rifle Dies & Reloading Essentials (Reference Chart)

Rifle

Cartridge

32 /40 WIN .321 54 6374 IV — — — — — #2 / 3 905 42 #2 / 3 926 02 Lg R fl / 09 5316 — #11 / 39 095 3 Large #8 / 39216 1

32 W IN SPL .321 546372 IV — — — — — #2 / 3 905 42 #2 / 3 926 02 Lg R fl / 09 5316 — #11 / 39 095 3 Large #8 / 392161

32 REM .321 — — — — — — — #12 / 39 055 2 # 12 / 392612 Lg R fl / 095 316 — #12 / 3 909 54 Large # 8 / 392161

7.9 2x3 3 KU RZ .323 546375 III 046376 0 4413 7 — — — #1 / 39 0541 #1 / 392 601 Sm R fl / 09 5314 — #11 / 39 095 3 Large #8 / 392161

8MM M AUS .323 546382 I 046383 0 44116 — — — #1 / 3 905 41 #1 / 3 926 01 L g Rfl / 09 5316 — #11 / 390 953 Large #8 / 39216 1

8x60S .323 546376 III 046377 04 4116 — — — # 1 / 390541 #1 / 39 260 1 Lg Rfl / 0 953 16 — #11 / 390 953 Large #8 / 3 92161

8MM/06 .323 546380 IV — — — — — #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — #11 / 390 953 Large #8 / 39216 1

8x5 0R LEBE L .323 546383 IV — — — — — #49 / 390605 — / — Lg R fl / 09 5316 — #11 / 39 095 3 Large #8 / 392161

32 5 WSM .323 546387 IV — — — — — # 35 / 39 0575 #35 / 392635 L g Rfl / 09 5316 — #11 / 3 909 53 Large #8 / 392161

8x68S .323 546378 IV — — — — — # 30 / 39 0570 # 30 / 39 263 0 L g Rfl / 0 9531 6 — #11 / 39 095 3 Large #8 / 39 2161

8MM REM MAG .323 546384 IV — — — — — # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #11 / 3 90953 Large #8 / 3 92161

8.15 X46R .324 546386 IV — — — — — # 2 / 390 542 # 2 / 392 602 Lg Rfl / 0 95 316 — #11 / 3 909 53 L arge # 8 / 39216 1

8x56 HUNGARIAN-MANN .329 546385 IV — — — — — #47 / 390603 — / — Lg R fl / 095 316 — #11 / 39 095 3 Large #8 / 39216 1

33 W IN .338 546388 IV — — — — 046058 #14 / 3 905 54 #14 / 3 92614 Lg R fl / 09 5316 — # 13 / 390 955 Large #9 / 3 92162

33 8 FEDERAL .338 546397 III 046595 04 4131 — — 046058 #1 / 39 0541 #1 / 392601 Lg R fl / 095 316 — #13 / 3 909 55 Large # 9 / 392162

33 8 MARLI N EXPRE SS .338 546359 I 046597 0 44131 — — 046058 #52 / 390607 # 52 / 392652 Lg Rfl / 0 95 316 — #13 / 3 90955 Large #9 / 3 92162

33 8 NORMA MA G .338 — — — — — — 046058 # 43 / 39058 3 — / — L g Rfl / 09 5316 — #13 / 3 90955 Large #9 / 3 92162

338/06 .338 546395 IV — — — — 046058 #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 95 316 — #13 / 3 90955 Large #9 / 3 92162

33 8 RCM .338 546399 I 046594 044131 — — 046058 #5 / 3 905 45 #5 / 3 926 05 Lg R fl / 09 5316 — # 13 / 390 955 Large #9 / 3 92162

33 8 WIN MAG .338 546390 I 046391 044117 — — 046058 #5 / 3 905 45 #5 / 3 926 05 Lg R fl / 095 316 — #13 / 39 095 5 Large #9 / 39 2162

34 0 WBY .338 546392 IV — — — — 046058 # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #13 / 3 90955 Large #9 / 3 92162

33 8 ULTRA MA G .338 546389 III 046446 0 44117 — — 046058 # 5 / 39054 5 #5 / 39 2605 Lg R fl / 09 5316 — # 13 / 390 955 Large #9 / 3 92162

33 8 LAPUA .338 546393 III 046593 0 44117 — — 046058 # 43 / 39 058 3 — / — L g Rfl / 09 5316 — #13 / 3 909 55 Large #9 / 392162

33 8/37 8 WBY .338 546391 IV — — — — 046058 #14 / 39 0554 #14 / 392 614 L g Rfl / 0 9531 6 — #13 / 39 095 5 Large #9 / 39 2162

34 8 WIN .348 546394 IV — — — — — # 25 / 3905 65 — / — Lg Rfl / 0 95 316 — #14 / 3 909 56 Large # 9 / 39216 2

35 REM .358 546398 III 046399 04 4130 — — — # 26 / 39 056 6 — / — L g Rfl / 09 5316 — #15 / 3 90957 Large #9 / 3 92162

35 6 WIN .358 — — — — — — 046046 # 33 / 39 057 3 — / — L g Rfl / 0 9531 6 — # 15 / 390 957 Large #9 / 392162

35 8 WIN .358 546408 IV — — — — 046046 #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 953 16 — #15 / 390 957 Large #9 / 3 92162

35 0 REM MAG .358 546402 IV — — — — — # 5 / 390 545 # 5 / 392 605 L g Rfl / 0 9531 6 — # 15 / 390 957 Large #9 / 392162

35 WHELEN .358 546400 III 0 46401 0 44119 — — 046046 #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 095 316 — # 15 / 390 957 Large #9 / 39216 2

35 8 N MAG .358 546406 IV — — — — 046046 # 5 / 390 545 # 5 / 39260 5 L g Rfl / 09 5316 — #15 / 3 909 57 Large # 9 / 39216 2

9.3x57 .366 546410 III 046 411 04 4120 — — — #1 / 39 0541 #1 / 39 2601 L g Rfl / 09 5316 — # 20 / 39 0962 Large #9 / 39 2162

9.3x74R .366 546414 III 046 415 04412 0 — — — # 13 / 390 553 #13 / 39 2613 Lg R fl / 095 316 — # 20 / 39 096 2 Large #9 / 392162

9.3x62 .366 546412 III 046 413 044120 — — — #1 / 39 0541 #1 / 39 260 1 Lg Rfl / 0 95 316 — # 20 / 39 0962 Large # 9 / 39216 2

375 J DJ .375 — — — — — — — # 27 / 390567 — / — L g Rfl / 09 531 6 — #16 / 39 095 8 Large # 10 / 392163

38 /55 WCF .375 546537 IV — — — — — # 2 / 390 542 # 2 / 392 602 L g Rfl / 0 9531 6 — # 16 / 390 958 Large # 10 / 392163

375 W IN .375 546530 IV — — — — — #2 / 39 0542 #2 / 39 260 2 L g Rfl / 09 5316 — #16 / 3 909 58 Large #10 / 39 2163

376 STEYR .375 546417 IV — — — — — #15 / 39 0555 — / — Lg R fl / 09 5316 — # 16 / 390 958 Large # 10 / 392163

375 H&H .375 546416 I 046417 044121 — — — # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #16 / 3 909 58 Large #10 / 3 9216 3

375 R UGER .375 546415 I 04 6418 04 4121 — — — # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 953 16 — #16 / 390 958 Large # 10 / 392163

375 R EM ULTRA M AG .375 546450 IV — — — — — # 5 / 390 545 # 5 / 392 605 Lg R fl / 095 316 — #16 / 3 909 58 Large #10 / 392163

378 W BY .375 546418 IV — — — — — #14 / 3 9055 4 # 14 / 392 614 Lg Rfl / 0 953 16 — #16 / 390 958 Large # 10 / 392163

45 0/400 NE .410 546421 IV — — — — — #54 / 390609 — / — Lg R fl / 095 316 — # 17 / 390 959 Large #11 / 39 2164

40 5 WIN .411 546425 II 046456 04 4162 04 4571 — — # 42 / 39 0582 — / — Lg R fl / 095 316 — #17 / 39 095 9 Large # 11 / 39216 4

10.3x60 .415 546420 IV — — — — — # 25 / 390565 — / — L g Rfl / 09 531 6 — #17 / 39 095 9 Large # 11 / 39216 4

416 TAYL OR .416 546427 IV — — — — — # 5 / 390 545 — / — L g Rfl / 09 5316 — #17 / 3 909 59 Large # 11 / 39 2164

416 RIG BY .416 546428 IV — — — — — # 38 / 39 0578 — / — Lg R fl / 09 5316 — # 17 / 390 959 Large #11 / 39216 4

416 RUG ER .416 546429 IV — — — — — # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 953 16 — #17 / 3 90959 Large #11 / 39 2164

416 REM MAG .416 546426 IV — — — — — # 5 / 390 545 # 5 / 392 605 Lg R fl / 095 316 — #17 / 3 909 59 Large # 11 / 39 2164

416 WBY .416 546430 IV — — — — — #14 / 39 055 4 #14 / 3 926 14 L g Rfl / 09 5316 — # 17 / 390 959 L arge #11 / 3 92164

404 JEFFERY .423 546423 IV — — — — — #53 / 390608 — / — Lg R fl / 095 316 — #17 / 3 909 59 Large #12 / 392165

444 MARLIN .430 546551 II 046552 04 4149 044553 — — # 27 / 39 056 7 #27 / 392627 L g Rfl / 09 5316 — #18 / 3 909 60 L arge #12 / 3 9216 5

450 BUSHMASTER .452 546452 V 046422 044721 044550 04 4176 — #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — # 19 / 390 961 Large # 13 / 392 166

458 SOCOM .458 546464 III 046424 0 44190 — — — #1 / 3 905 41 #1 / 3 926 01 Lg R fl / 09 5316 — # 19 / 390 961 Small #13 / 392166

45 /70 GOV MT .458 546566 II 046567 0 44152 044568 — — #14 / 3 905 54 #14 / 3 92614 Lg R fl / 09 5316 — # 19 / 390 961 Large # 13 / 392166

450 MARLIN .458 546553 II 046587 04 4152 044568 — — # 5 / 390 545 # 5 / 392 605 Lg Rfl / 0 95 316 — #19 / 3 909 61 L arge #13 / 3 92166

45 0 NITRO E XPRESS .458 546433 IV — — — — — #54 / 390609 — / — N /A — #19 / 39 0961 Large #13 / 39 2166

45 8 WIN MAG .458 546569 II 046570 044153 044568 — — # 5 / 390 545 # 5 / 392 605 Lg R fl / 095 316 — #19 / 3 909 61 Large #13 / 392166

45 8 LOTT .458 546465 II 046457 044153 044572 — — #5 / 3 905 45 #5 / 3 92605 Lg Rfl / 0 95 316 — #19 / 3 90961 Large # 13 / 392166

46 0 WBY .458 546422 IV — — — — — # 14 / 390 554 #14 / 39 2614 Lg R fl / 095 316 — #19 / 3 909 61 Large #13 / 39 2166

470 NITRO EXP RESS .474 546434 IV — — — — — # 55 / 39 0610 — / — N/A — # 23 / 39 093 9 Large — / —

50/70 GOVT .510 546462 IV — — — — — — / — — / — L g Rfl / 0 9531 6 — # 50 / 39 0937 Large — / —

50 BEOWULF .500 — — — — — — — # 6 / 390 546 # 6 / 39260 6 L g Rfl / 09 5316 — # 50 / 39 093 7 Large — / —

50 ALASKAN .510 546586 IV — — — — — # 25 / 39 056 5 — / — L g Rfl / 09 5316 — # 50 / 39 093 7 Large — / —

50 0 NITRO E XPRESS .510 546435 IV — — — — — # 55 / 39 0610 — / — N/A — # 50 / 39 093 7 Large — / —

Bullet Diameter

(inches)

Die Set

Die Series

Full-Length

Size Die

Seating Die

Expander Die

Taper Crimp

Die Only

Neck Size Die

Shell Holder

# / Item No.

Shell Plate

# / Item No.

Feeder Plate

Size / Item No.

Case

FeederDie

Bullet

Trimmer Pilot

# / Item No.

Primer Punch

Puller Collet

Bullet

# / Item No.

APPENDIX A

- 29 -

Page 30

APPENDIX A

Pistol Dies & Reloading Essentials (Reference Chart)

Pistol

Cartridge

22 RC FM-JE T .224 5 46218 IV — — — — — #6 / 3 905 46 #6 / 39 2606 S m Pstl / 0 953 10 N/A #1 / 3 909 43 Small

25 AU TO .251 — — — — — — — # 37 / 39 057 7 — / — Sm P stl / 0 953 10 N/A #4 / 390 946 Small

30 LUGER .308 546336 IV — — — — — #8 / 3 905 48 #8 / 3 926 08 Sm Pst l / 095 310 N/A #9 / 39 0951 Small

30 MAUSER .309 — — — — — — — # 8 / 390 548 # 8 / 392 608 Sm Ps tl / 09 5310 N /A # 9 / 390 951 Small

32 AU TO .311 546506 II 046507 0 44113 044508 — — #2 2 / 390 562 # 22 / 392622 Sm Ps tl / 095 310 N /A #10 / 39 095 2 Small

32 S &W LONG/ H&R/

327 FEDE RAL

7.5 SWISS ORDEN .312 546504 IV — — — — — #48 / 390604 — / — Sm P stl / 09 5310 N/A #10 / 39 0952 Small

8MM L EBEL REV .326 546510 IV — — — — — #48 / 390604 — / — Lg P stl / 0 9531 2 N/A #11 / 39 095 3 Large

380 AUTO .355 5 46518 II 046519 044144 04 4517 — 044170 #16 / 39 055 6 #16 / 39 2616 Sm Ps tl / 09 5310 095330 #15 / 39 095 7 Small

TAPER CRIMP 9MM/9x21 .355 5 46 516 II 04 6516 0 44177 044517 04 4177 — #8 / 3 905 48 #8 / 3 926 08 — / — N /A # 15 / 390 957 Small

9MM LUGER/9x21 .355 54 6515 II 04 6516 044144 044 517 — 04 4170 #8 / 3 905 48 #8 / 3 926 08 Sm Pst l / 095 310 095330 #15 / 39 095 7 Small

357 SIG .355 546575 II 046576 044144 044577 — — #10 / 39 055 0 #10 / 3 926 10 Sm Pst l / 095 310 N/A #15 / 39 095 7 Small

9x23 .355 546532 IV — — — — — #8 / 3 905 48 # 8 / 3926 08 Sm Ps tl / 095 310 N /A #15 / 39 095 7 Small

38 S&W .357 546521 IV — — — — — #2 8 / 390 568 # 28 / 392628 Lg Ps tl / 09 5312 N /A #15 / 39 095 7 Large

38 SU PER AUTO .357 546524 II 046525 044144 044526 — — # 8 / 39054 8 #8 / 39 260 8 Sm P stl / 09 5310 N/A #15 / 39 0957 Small

357 HERRETT .357 546396 IV — — — — — #2 / 3 905 42 #2 / 3 926 02 Lg Ps tl / 09 5312 N/A #15 / 3909 57 Large

357 B&D/44 .358 546404 IV — — — — — #30 / 3 9057 0 #3 0 / 392 630 Lg Ps tl / 09 5312 N /A #15 / 39 095 7 Large

38 SP ECIAL .357 546527 II 046528 04 4145 044523 — — # 6 / 390 546 # 6 / 392 606 Lg Ps tl / 09 5312 095331 #15 / 39 0957 Small

357 MAGNUM .357 546527 II 046528 04 4145 044523 — — #6 / 3 90546 # 6 / 392 606 Lg Ps tl / 09 5312 095331 #15 / 39 0957 Small

357 REM MA X .357 546527 II 046528 04 4145 044523 — — # 6 / 390 546 # 6 / 392 606 Lg Ps tl / 09 5312 095331 #15 / 39 0957 Small

COWBOY 38-357-357 MAX .357 546528 III 046528 044591 044591 — — #8 / 3 905 48 # 8 / 39260 8 Lg Ps tl / 09 5312 N/A #15 / 39 0957 Small

9x18 MAKAROV .364 54 6512 II 046513 0 4415 4 044514 — — # 8 / 390 548 # 8 / 392 608 Sm Ps tl / 095 310 N /A #15 / 39 095 7 Small

40 S &W .400 546533 II 046534 04 4146 044535 — 044171 #10 / 3 905 50 #10 / 39 2610 Sm P stl / 0 9531 0 095332 #2 1 / 390 941 Small

TAPER CRIMP 40 S&W .400 546534 II 046534 044178 044535 044178 04 4171 # 10 / 390 550 #10 / 3 92610 Lg Ps tl / 09 5312 N /A #2 1 / 390 941 Small

10MM A UTO .400 546533 II 046534 044146 044535 — 0 44171 #10 / 39 055 0 #10 / 3 926 10 Lg Ps tl / 09 5312 095332 # 21 / 3909 41 Large

TAPER CRIMP 10MM .400 546534 II 046534 0 4417 8 044535 0 4417 8 044171 #10 / 3 905 50 #10 / 39 2610 L g Pstl / 0 953 12 N/A #2 1 / 390 941 Large