Page 1

®

Lock-N-Load

AMMO

PLANT

•AutoProgressive(AP)

ReloadingPress

•PowderMeasure

&CaseActivated

PowderDrop

•CaseFeeder

•BulletFeeder

Page 2

TABLE OF CONTENTS

Lock-N-Load

®

Auto Progressive (AP) Reloading Press

Steps

Overview.....................................................................................................................5

Tools needed for assembly and set up ........................................................................5

1: Mounting the Lock-N-Load Auto Progressive .......................................................6

2: Determine which shell plate is required for your application ...............................7

2A: Installing the Shell Plate .....................................................................................8

2B: Removing the Shell Plate.....................................................................................9

3: Operation of your Lock-N-Load Auto Progressive Press ......................................10

4: Automatic Primer Feed Assembly ......................................................................11

4A: Installing the Primer Body .................................................................................11

4B: Installing the Primer Slide, Large or Small ........................................................ 11

4C: Installing the Primer Punch Assembly, Large or Small ......................................11

4D: Installing the Primer Tubes ...............................................................................11

4E: Installing the Primer Tube Housing ...................................................................11

4F: Primer Tube Support Installation .......................................................................12

5: Loading the Primer Tube ....................................................................................13

6: Changing Primer Tubes .....................................................................................14

7: Automatic Primer Feed Inspection .....................................................................15

8: Installing the Deluxe Powder Measure with Case Activated Powder Drop .......... 15

9: Lock-N-Load quick change bushing system ......................................................16

10: Die Mounting Instructions .................................................................................16

11: Preparing to Load ..............................................................................................17

12: Adjusting the Auto Advance Mechanism ...........................................................18

Maintenance of the Lock-N-Load AP .................................................................. 19

Tips for a Trouble-Free Operation .......................................................................20

Page

List of Illustrations

Figures

1. AP Mounting ........................................................................................................6

2. Installing Shell Plate ...........................................................................................8

3. Removing Shell Plate...........................................................................................9

4. Primer Feed System ...........................................................................................12

5. Filling the Priming System.................................................................................13

6. Lock-N-Load Powder Measure ...........................................................................15

7. Hornady Lock-N-Load System ............................................................................16

8. Pawl Adjustment ..............................................................................................18

Charts

1. Shell Plate Selection Chart ..................................................................................7

2. Trouble Free Operation .......................................................................................10

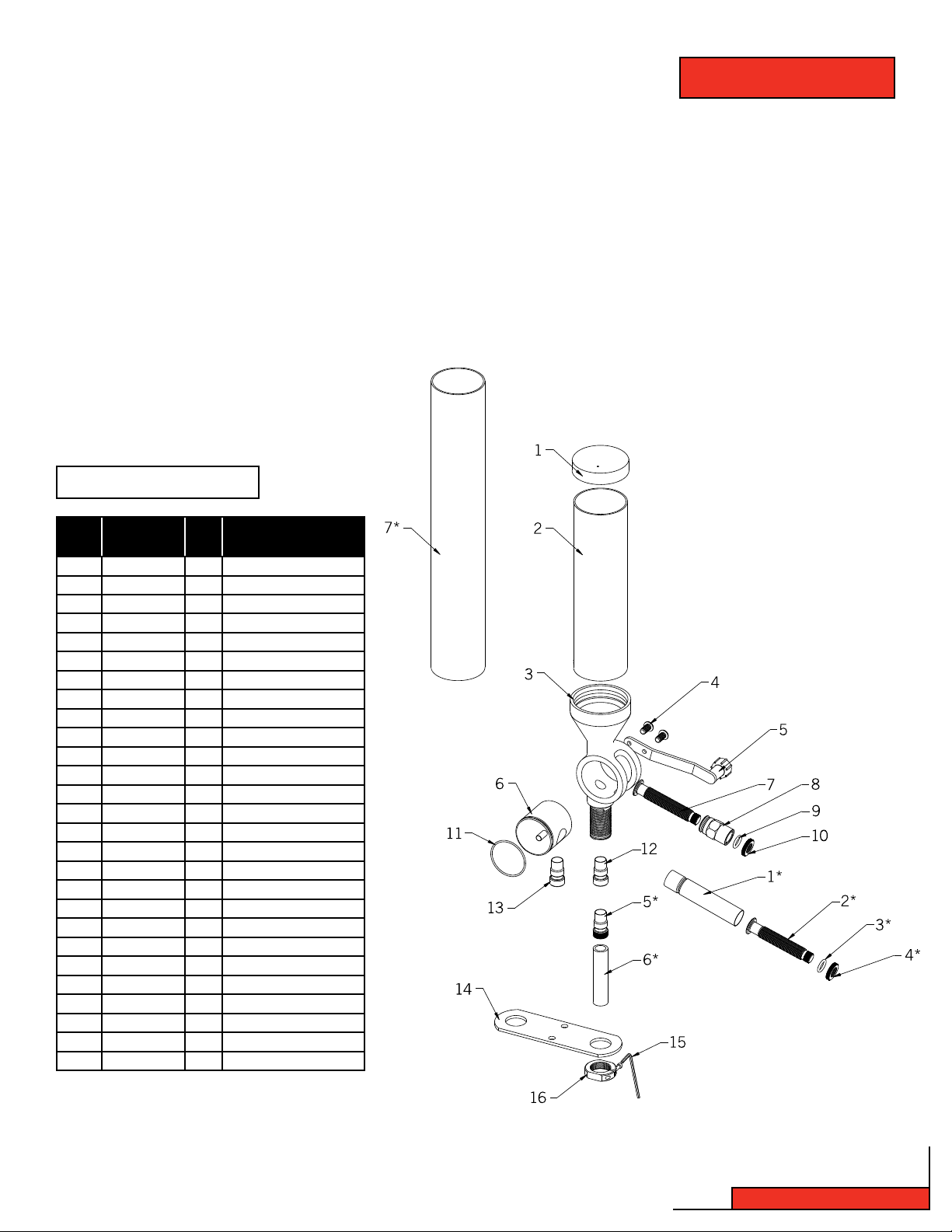

3. Bill of Materials ...................................................................................................3

4. Exploded View ......................................................................................................4

Lock-N-Load® AP Reloading Press

- 2 -

Page 3

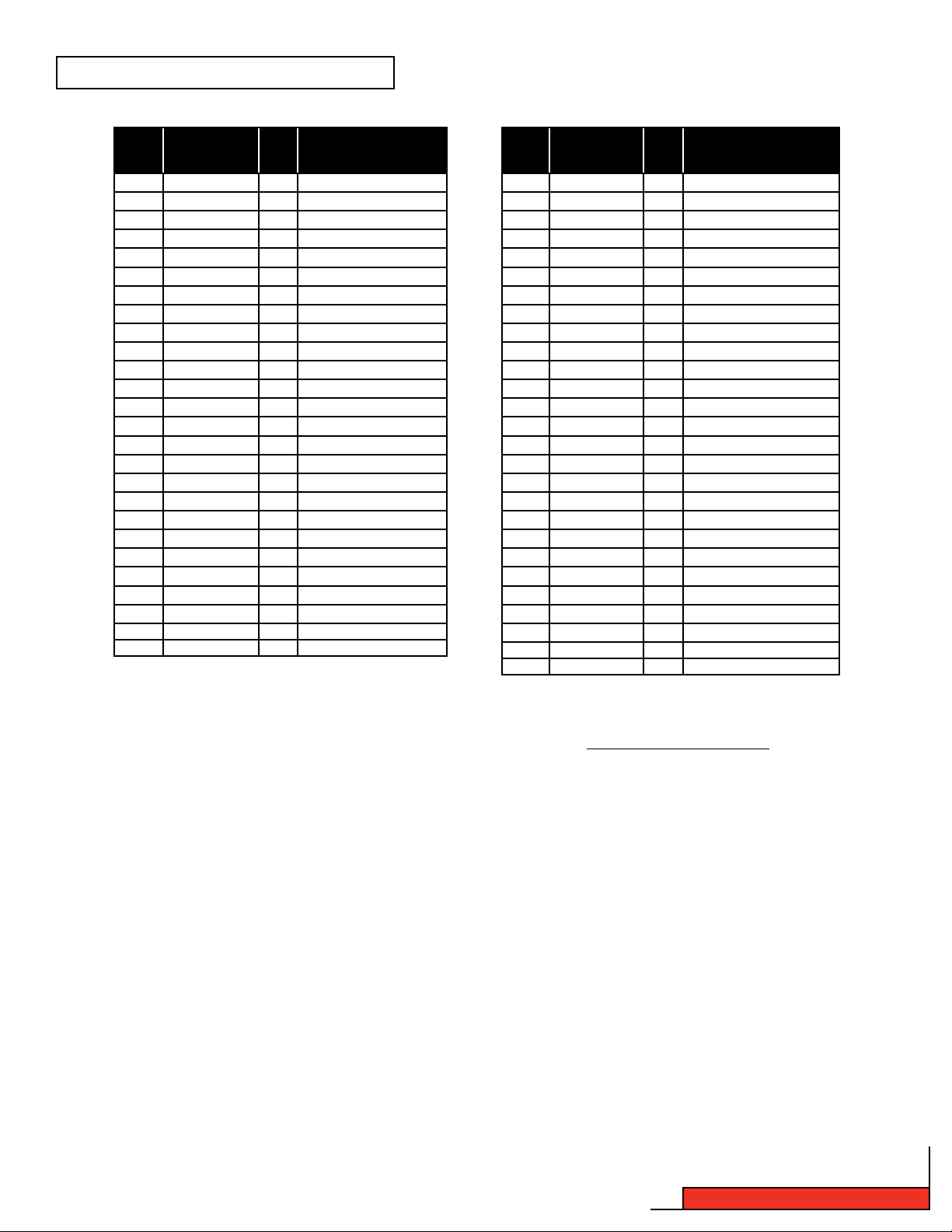

BILL OF MATERIALS: LOCK-N-LOAD AP

ITEM

PRODUCTION

NO.

10 398359 1 PRIMER FOLLOWER

11 392338 1 SCREW SHCS 10-24 X 1/2

13 392455 1 BRACKET BOX CARTRIDGE

14 398319A 1 HOUSING BODY PRIMER TUBE

15 392218 1 PRIMER SLIDE LARGE ASSY.

15 392219 PRIMER SLIDE SMALL ASSY.

16 392336 1 SPRING PRIMER SLIDE

17 392363 1 SPRING CASE RETAINER

18 392210 1 CAM FEED PRIMER

19 39 2011 2 NUT NEX 10-32

20 190216 1 FRAME

21 392368 6 CLIP C C-50

22 480039 1 BOX CATCHER

23 392408 2 LINK LNLAP

24 398309T 1 SUB PLATE

26 398505 1 PRIMER SEATER PUNCH SMALL

26 398507 1 PRIMER SEATER PUNCH LARGE

PART NO.

1 398318 1 SUPPORT PRIMER TUBE

2 398356 1 TUBE PRIMER PICKUP LARGE

3 398355 1 TUBE PRIMER PICKUP SMALL

4 398358 1 TUBE PRIMER LARGE

5 398357 1 TUBE PRIMER SMALL

6 398322 1 HOUSING TUBE PRIMER

7 392220 1 SCREW BHCS 1/4-20 X 1/2

8 392202 1 BRACKET LNLAP

9 392342 1 SHCS SS 3/8-16 X 3/4

QTY. DESCRIPTION

ITEM

PRODUCTION

NO.

27 392467 1 SPRING COUNTER BALANCE

28 392345 1 3/8 FLAT WASHER SS

29 392355 1 DRIVE HUB

30 392356 1 DRIVE SHAFT

31 392231 2 SCREW BHSCS 8-32 X 3/8

32 392344A 2 PAWL

33 392423 2 SPRING PAWL

34 392306 2 DOWL PIN 1/8 X 1/2

35 392221 2 SCREW FHCS 1/4-28 X 3/8

36 290029 1 SPENT PRIMER TUBE

37 392359 1 RAM

38 398422 3 GREASE ZERK™

39 392343 1 TOGGLE

40 392340 1 PIN YOKE

41 392424 5 SPRING WASHER

42 392417 2 PIN LINK TOGGLE

43 390027 1 NUT JAM 5/8-18

44 390657 1 HANDLE

45 480003 1 KNOB

46 392357 1 YOKE

47 392358A 1 INDEX WHEEL

48 3900 81 2 CLIP E 1/2

49 392302 5 LOCK-N-LOAD BUSHING MALE

50 392303 5 LOCK-N-LOAD BUSHING O-RING

51 392365 1 SPENT PRIMER TUBE PLASTIC

52 392301 5

53 398715 1

PART NO

QTY. DESCRIPTION

LOCK-N-LOAD BUSHING FEMALE

WASHER

“We guarantee every one of our reloading tools and accessories for Life” No-Risk, Lifetime Warranty

Hornady reloading tools and accessories are warranted against material defects and workmanship for the life of the

products. Parts which by nature of their function are subject to normal wear such as springs, pins, bearings, etc…

and parts which have been altered, abused, or neglected are excluded from the warranty.

If the product is deemed defective by either workmanship or material, the reloading tool or accessory will either be

repaired, reconditioned or replaced at Hornady Manufacturing Company’s option. If it breaks, we’ll repair it or replace

it at no charge.

To return a product, call toll free (800) 338-3220 and ask for Customer Service. They will provide instructions for return

if the problem can’t be solved over the phone. Prices and or specifications are subject to change without notice. For the

best prices on any of our products, contact your nearest Hornady dealer.

Hornady Manufacturing Company cannot assume liability for damage which may result from use of the products or

information given herein, since Hornady had no control over the manner in which its products or components are used

during reloading.

- 3 -

Lock-N-Load® AP Reloading Press

Page 4

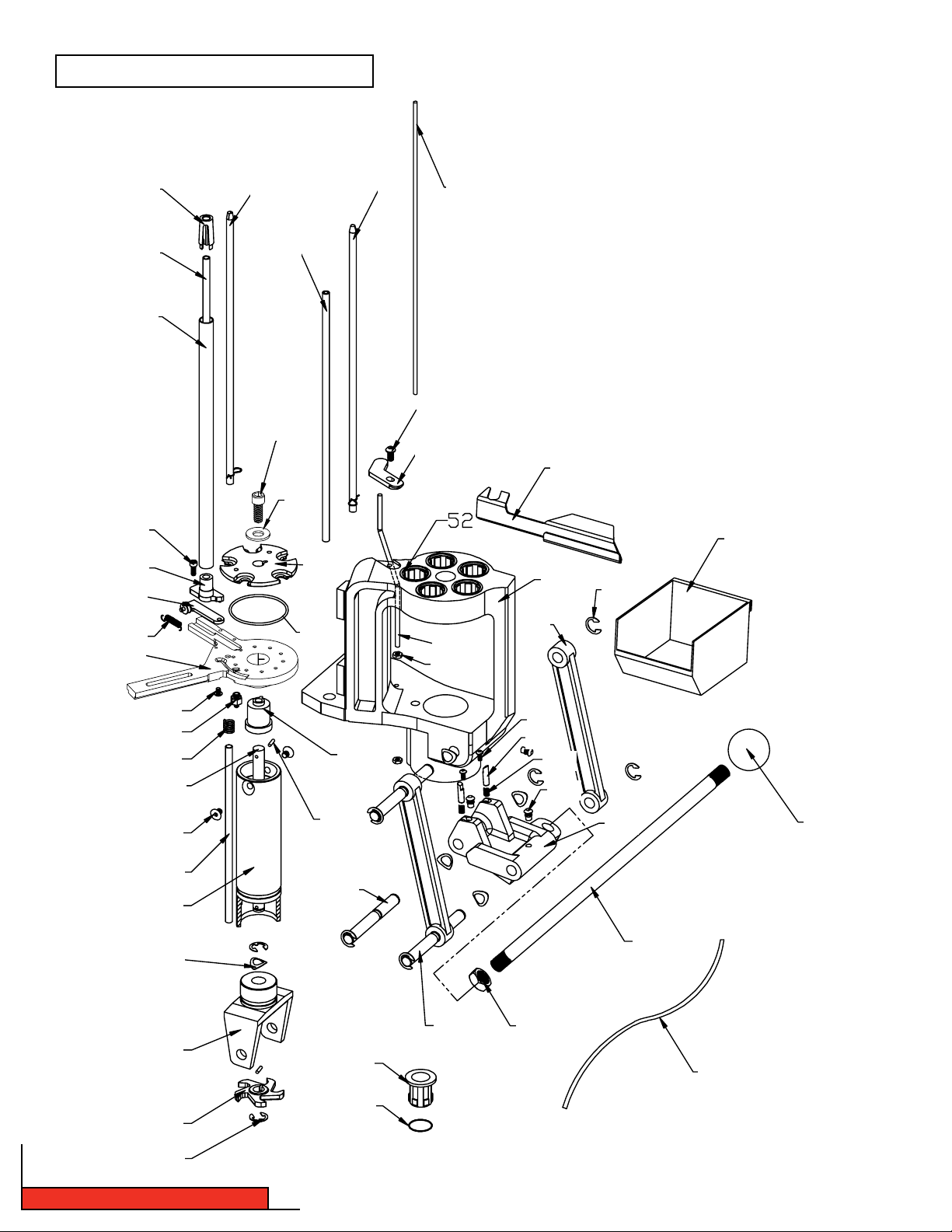

EXPLODED VIEW: LOCK-N-LOAD AP

11

14

15

16

24

1

4

2

5

3

10

6

7

9

8

13

28

22

12

17

20

23

21

18

19

25

26

27

30

35

36

37

41

46

47

48

34

40

29

49

50

31

32

42 43

33

38

39

45

44

51

Lock-N-Load® AP Reloading Press

- 4 -

- 4 -

Page 5

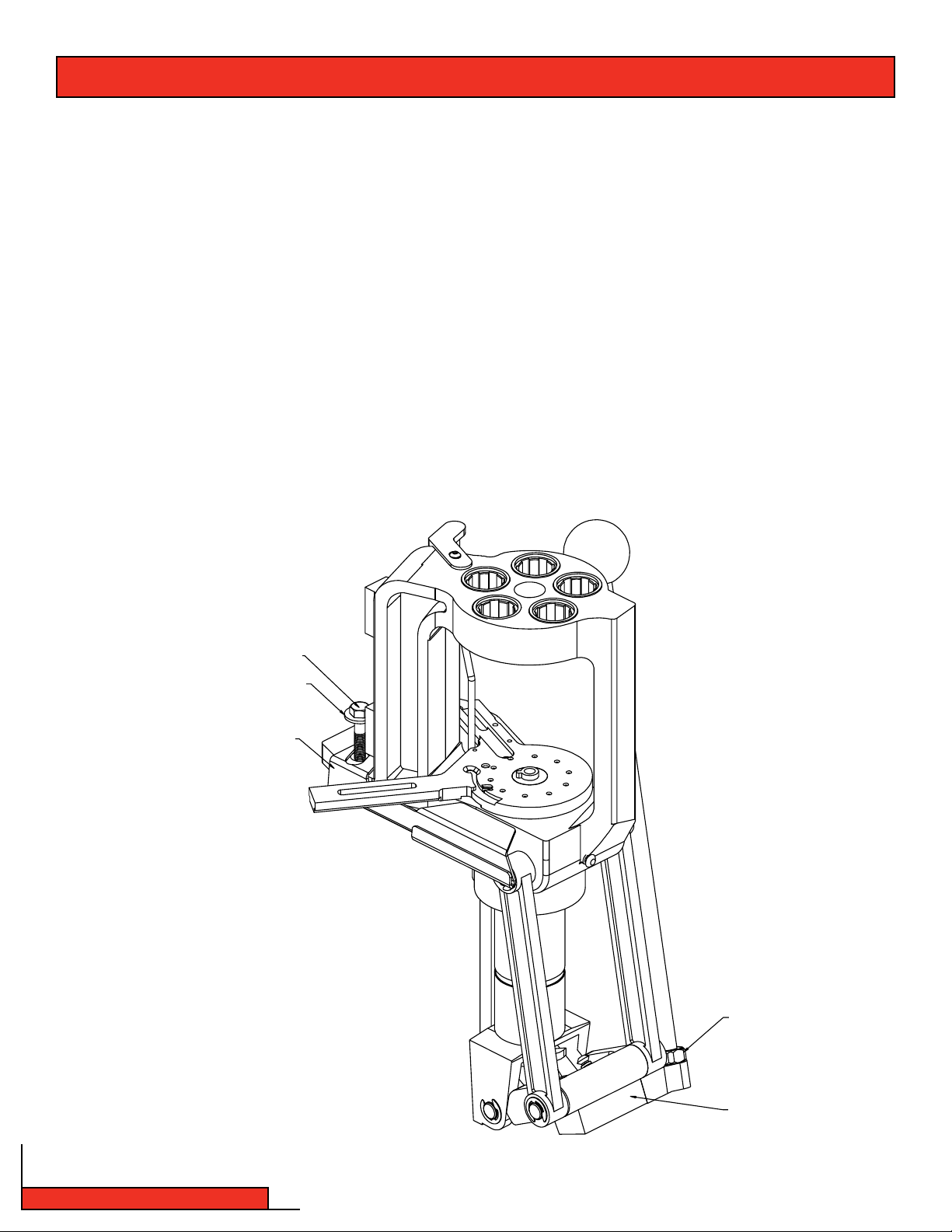

OVERVIEW OF LOCK-N-LOAD® AUTO PROGRESSIVE (AP) RELOADING PRESS

Your new Lock-N-Load Auto Progressive (AP) reloading press has been packaged to insure minimal vibration and damage

during transportation.

Remove all the parts from the packing box and spread them out over a large flat surface. Refer to the parts list on pages

19 and 20 and check to make sure all necessary parts are identified.

The manual provides step-by-step instructions and suggestions that make set-up and operation easy and understandable.

If at any time during operation you feel like you are forcing the press, stop and identify the

problem. Do not force anything, or damage could occur. Powders and Primers are explosive

if handled carelessly! Always work slowly and carefully without distractions and wear

eye protection. Try to avoid touching primers with oily fingers. The oil on your fingers may

contaminate the primers and cause them to misfire.

Tools needed for assembly and set-up:

•7⁄ 16" End Wrench

•(2) 1 ⁄ 2" End Wrenches

•15 ⁄16" End Wrench

•3 ⁄ 32" Hex Wrench (included)

•5⁄32" Hex Wrench

•Needle Nose Pliers

•Electric Drill

•5/16" Hex Wrench

•1/8" Hex Wrench (included)

Hand loading is very safe, but before reloading any case

please read the following warnings.

•Primers may explode if subjected to impact or heat.

•Keep away from the opening end of the Primer Tube at

all times.

•Variations may occur with different brands and condition

of cartridge cases, which can cause inconsistent primer

and bullet seating. Sort and inspect all of your cases

before reloading.

•Verify your powder charges at frequent intervals to

insure consistency.

•Careless or improper hand loading techniques can result

in serious personal injury. Make sure there are no

distractions while you are reloading.

•Before operating this press, be sure you have read and

understand all the instructions contained in this manual,

and that you understand the principals of hand loading.

- 5 -

Lock-N-Load® AP Reloading Press

Page 6

INSTRUCTIONS FOR LOCK-N-LOAD® AUTO PROGRESSIVE (AP) RELOADING PRESS

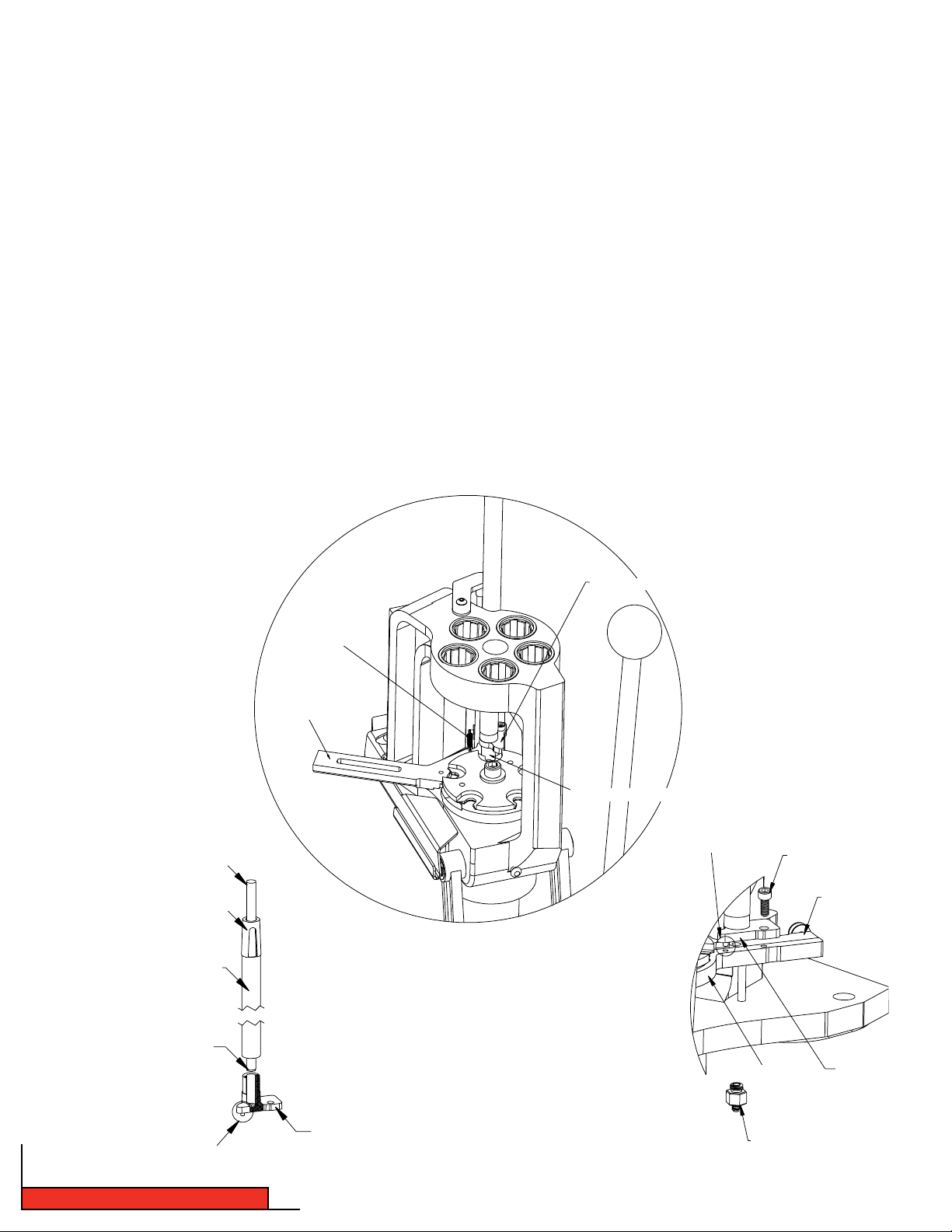

Step 1: Mounting the Lock-N-Load® Auto Progressive

•Your work area should be well lit and have plenty of room for your reloading accessories. Your Hornady Lock-N-Load

AP should be mounted securely 2 1/4" from the edge of a solid level bench. (Check for obstructions on or below

the bench before you drill any holes.)

•Mount the press using (2) 5/16" bolts that are long enough to secure the press to the bench with plenty of

clearance for the nuts. (Due to variation of benches, these bolts are not provided.) We also recommend using

5/16" flat washers top and bottom, in addition to lock washers on the bottom side.

•Insert and secure the right-hand mounting bolt first. Next, insert and secure the left-hand bolt, placing the

cartridge catcher bracket (13) underneath the bolt head and washer before tightening.

•Thread the press Handle (44) into the Toggle (39) at the bottom of the press and tighten the Jam Nut (43)

using a 15/16" wrench.

Figure 1: AP Mounting

5/16 BOLT

5/16 FLAT WASHER

CARTRIDGE CATCHER BRACKET (13)

JAM NUT (43)

Lock-N-Load® AP Reloading Press

TOGGLE (39)

- 6 -

Page 7

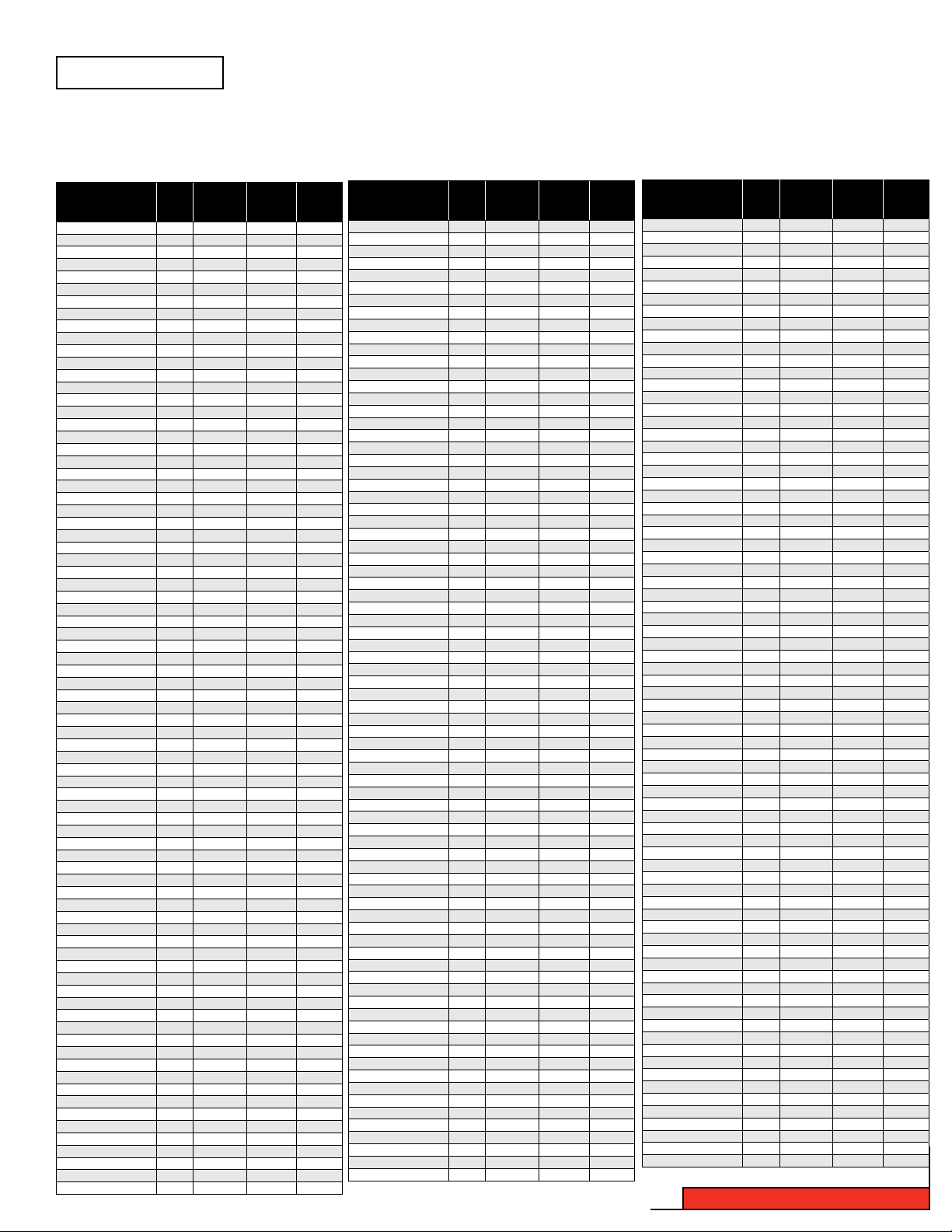

SHELL PLATES

Step 2: Determine which shell plate is required for your application

See Chart 1 below to help with this selection.

* Hornady shell plates that are sold in the

plastic boxes are the only ones that will

fit the AP Press with EZject

™

System.

These shell plates (which are sold

separately) are manufactured with a

groove on the bottom side.

Shell Plate/

Cartridge Dia

17 RE M .17 2 16 392616 390556

17 RE M FIREB ALL .172 16 392616 390556

17-222 .1 72 16 392616 390556

17-22 3 .17 2 16 392616 390556

20 TACTICAL .2 04 16 392616 390556

20 4 RUGER .204 16 392616 390556

218 BE E .222-.224 7 392607 39 0547

22 RCFM-JET .222-.223 6 392606 39 0546

219 ZIPPER .224 2 392602 390542

22 HO RNET .2 24 3 39260 3 390543

22 K- HORNE T .224 3 392603 390543

22 PP C .2 24 6 392606 39054 6

22 0 SWIF T .224 4 392604 390544

22 0 VT .224 16 392616 390556

221 R EM FIR EBAL .224 16 392616 390556

222 REM . 224 16 392616 390556

22 2 REM MA G .224 16 392616 390556

22- 250 AC K IMP .224 1 392601 3 90541

22-250 REM .2 24 1 392601 3 90541

22 3 REM . 224 16 392616 390556

22 3 WSSM .224 35 392635 390575

22 4 WBY MAG .224 17 N/A 390557

22 5 WIN .224 4 392604 390544

5.6 X50 M AG .224 16 392616 390556

5.6x57 .224 1 392601 390 541

5.7 J OHNSON S PITF IRE .224 22 392622 390562

5.7 X28 MM FN .224 37 N/A 390577

22 S AV HP .227 2 392602 39 0542

5.6X52R .2 27 2 392602 3 90542

24 0 WBY MA G .243 1 392601 3 90541

24 3 WIN .243 1 392601 39 0541

24 3 WSSM .243 35 392635 390575

244/6MM REM .243 1 392601 39 0541

6MM I NT .243 1 392601 3 90541

6MM P PC .243 6 392606 390546

6MM R EM BR .243 1 392601 3 90541

6MM T CU .243 16 392616 390556

6MM-22 3 .243 16 392616 390556

6MM-28 4 .243 1 392601 3 90541

6X4 7 REM .243 16 392616 390556

25 AU TO .251 37 N/A 390577

25 W SSM .257 35 392635 390575

25 0 SAV .257 1 392601 3 90541

25-06 REM .257 1 392601 3905 41

25 -20 WIN .257 7 392607 390547

25-2 84 .257 1 392601 390 541

25-35 WIN .257 2 392602 39 0542

25 6 WIN MA G .257 6 392606 390546

25 7 RBTS .257 1 392601 3 90541

25 7 WBY MA G .257 5 392605 390545

25 RE M .257 12 392612 39 0552

26 0 REM .26 4 1 392601 3 90541

26 4 WIN MA G .264 5 392605 390545

6.5 CREEDMOOR .264 1 392601 39 0541

6.5 GRENDEL .264 6 392606 390546

6.5 J AP .264 34 N/A 390574

6.5 JDJ .264 4 392604 3905 44

6.5 M ANN .264 20 N/A 390560

6.5 R EM MAG .264 5 392605 390545

6.5-06 .264 1 392601 390 541

6.5-2 84 .264 1 392601 3 90541

6.5MM TCU .264 16 392616 390556

6.5X55 SCAN (SWEDISH) .264 19 392619 390559

6.5X57 .264 1 392601 39 0541

6.5X68 .264 30 392630 390570

6.5 C ARC .264-.267 21 N/A 390561

27 0 REN .277 3 392603 390543

27 0 WBY MAG .277 5 392605 390545

27 0 WIN .277 1 392601 3 90541

27 0 WSSM .277 35 392635 39 0575

6.8 R EM SPC .277 12 392612 390552

28 0 REM ACK I MP .284 1 392601 3 90541

28 0 REM/ 7MM E XP .284 1 392601 3 90541

28 4 WIN .284 1 392601 390 541

7MM MERRILL .284 4 392604 39 0544

7MM R EM BR .284 1 392601 39 0541

7MM R EM MAG .28 4 5 392605 3905 45

7MM R EM ULTR A MAG

7MM R SAUM .284 5 392605 3905 45

Shell

Holde r #

.284 5 3

Shell

Plate

Item#

Shell

Holder

Item #

92605 390545

Shell Plate/

Cartridge Dia

7MM S TW .284 5 392605 390545

7MM T CU .284 16 392616 390556

7MM W BY MAG .284 5 392605 3 90545

7MM W SM .284 35 392635 390575

7MM-08 .284 1 392601 39 0541

7MM -223 IN GRAM .284 16 392616 390556

7X 30 WATE RS .284 2 392602 390542

7X47 HELM .284 16 392616 390556

7X 57 (7MM M AUSE R) .284 1 392601 39 0541

7X57R .284 13 392613 390553

7X 61 S&H .284 35 392635 390575

7X64 .284 1 392601 39 0541

7X65R .284 13 392613 390553

7.3 5 CAR C .298 21 N/A 390561

30 R EM .308 12 392612 390552

30 HE RRE TT .308 2 392602 390542

30 L UGER .308 8 392608 3 90548

30 M1 C ARBIN E .308 22 392622 390562

300 H&H .308 5 392605 39 0545

300 OLYMPIC (OSSM) .308 35 392635 390575

300 RCM .308 5 392605 390545

30 0 REM ULT RA MAG .308 5 392605 3905 45

300 RSAUM .308 5 392605 390545

300 SAV .308 1 392601 390 541

30 0 WBY MA G .308 5 392605 3905 45

30 0 WIN MA G .308 5 392605 390545

300 WSM .308 35 392635 390575

30-06 SPRINGFIELD .308 1 392601 390 541

30 -30 AC K IMP .3 08 2 392602 3 90542

30-30 WIN .308 2 3926 02 390542

30 -378 W BY MAG .308 14 392614 390554

30 -40 K RAG .308 11 392611 3905 51

30 7 WIN .308 33 N/A 390573

30 8 MARL IN EX PRESS .308 27 N/A 390567

30 8 NORMA M AG .308 5 392605 390545

30 8 WIN .308 1 392601 3 90541

309 JDJ .3 08 27 N/A 390567

30MM MERRILL .308 4 392604 39 0544

30TC .308 1 3 92601 39 0541

7.5 S WIS S .308 2 392602 390542

7.6 2X3 9 .3 08-.310 6 392606 39 0546

7.6 2 RUS SIAN .308-.312 23 392623 390563

30 MAUSER .309 8 392608 3905 48

30 3 SAV .3 11 33 N/A 390573

32 AU TO .311-.312 22 392622 390562

30 3 BRIT ISH .312 11 392611 390551

32 H &R MAG .312 36 392636 3 90576

32 S &W .312 36 392636 390576

32 S &W LONG .312 36 692636 3 90576

32-20 WIN .312 7 392607 39 0547

327 FEDERAL .312 36 392636 3 90576

7.6 5 BEL GIAN .312 24 N/A 390564

7.7 JA P .312 1 392601 3 90541

8.15 X46 R .312-.330 2 392602 3905 42

7.5 SW ISS ORD EN . 315 48 N/A 390604

32 RE M .321 12 392612 390552

32 W IN SPL .321 2 392602 390542

32-40 WIN . 321 2 392602 3 90542

32 5 WSM .323 35 392635 39 0575

7.9 2X 33MM KUR Z .323 1 392601 39 0541

8MM R EM MAG .323 5 392605 390545

8MM-06 .323 1 392601 390 541

8X 50 LEB EL .323 49 N/A 390605

8X 57 (8M M MAUSE R) .323 1 392601 390 541

8X6 0 S .323 1 392601 390 541

8X6 8 S .323 30 392630 390570

8MM LEBEL (HANDGUN) .326 48 N/A 390604

8X56R HUNG-MA NN .329 47 N/A 390603

33 W IN .338 14 392614 39 0554

338 FEDERAL .338 1 392601 390 541

33 8 LAP UA .338 43 N/A 390583

33 8 MARL IN EX PRESS .338 52 N/A 390607

33 8 NORM A MAG .338 43 N/A 390583

33 8 RCM .338 5 392605 390545

33 8 REM ULT RA MAG .338 5 392605 3905 45

33 8 WIN MA G .338 5 392605 390545

338-06 .338 1 392601 3 90541

338-378 WBY MAG

Shell

Holde r #

.338 14 3

Shell

Plate

Item#

Shell

Holder

Item #

92614 39055 4

- 7 -

Shell Plate/

Cartridge Dia

34 0 WBY MA G .338 5 392605 3905 45

34 8 WIN .348 25 N/A 390565

35 7 SIG .355 10 392610 390550

38 0 AUTO .355 16 392616 390556

9MM LUGER .355 8 392608 390548

9X 21 .355 8 392608 3905 48

9X 23 WIN .355 8 392608 390548

38 AU TO .355-.357 8 392608 39054 8

38 SU PER AU TO .357 8 392608 390548

35 7 MAGNU M .357 6 392606 3905 46

35 7 REM MA X .357 6 392606 390546

357-44 B&D .357 30 392630 390570

38 SP ECIA L .357 6 392606 390546

35 RE M .357-.358 26 N/A 390566

35 7 HERRE TT .357-.358 2 392602 390542

35 W HELEN .358 1 392601 3 90541

35 0 REM MA G .358 5 392605 39 0545

35 6 WIN .358 33 N/A 390573

35 8 NORMA M AG .358 5 392605 390545

35 8 WIN .358 1 392601 3 90541

38 S&W .359 28 392628 390568

9X18 MAKAROV .365 8 392608 39054 8

9.3X57 .366 1 392601 3 90541

9.3X62 .366 1 392601 3 90541

9.3X74R .366 13 392613 390553

375 H&H .375 5 392605 390545

37 5 JDJ .375 27 N/A 390567

37 5 REM ULT RA MAG .375 5 392605 390545

37 5 RUGER .375 5 392605 390545

37 5 WIN .375 2 392602 390542

37 6 STEY R .375 15 N /A 390555

37 8 WBY MAG . 375 14 392614 39055 4

38 -55 WI N .375 2 392602 3905 42

10MM A UTO .400 10 392610 390550

38 -40 W IN .400 9 392609 390549

40 S &W .400 10 392610 390550

400 COR-BON .400 1 392601 390 541

41 REM M AG .410 29 392629 390569

40 5 WIN .4 11 42 N /A 3905 82

10.3X60 .415 25 N/A 390565

416 RE M MAG .416 5 392605 390545

416 RIG BY . 416 38 N/A 390578

416 RU GER . 416 5 392605 3905 45

416 WB Y MAG .416 14 392614 390554

40 4 JEFF ERY * .42 3 53 N /A 390608

44 -40 W IN .427 9 392609 390549

44 A UTO MA G .430 1 392601 39 0541

44 R EM MAG .430 30 392630 3 90570

44 S PECIA L .430 30 3 92630 390570

444 MARLIN .4 30 27 N/A 390567

44 5 SUPER M AG .4 30 30 392630 390570

45 AU TO .451 45 392645 390606

45 AU TO RIM MED .451 31 392631 390571

45 W IN MAG .451 45 3 92645 390606

45 C OLT .452 32 392632 390572

45 SC HOFIE LD .452 41 N/A 390 581

45 4 CASU LL .452 32 392632 390572

460 S&W .452 46 3 92646 390602

455 WEBLEY .455-.456 51 N/A 390601

45 /70 GO V .458 14 392614 39 0554

450 BUSHMASTER .458 1 392601 39 0541

45 0 MARL IN .458 5 392605 390545

45 0 NITR O EXPR ESS* .458 54 N/A 390609

45 0-4 00 NE 3" .458 25 N/A 390565

45 8 LOT T .458 5 392605 390545

458 SOCOM .458 1 392601 3 90541

45 8 WIN .458 5 392605 3905 45

46 0 WBY MA G .458 14 392614 39055 4

470 N ITRO E XPRE SS* . 474 55 N/A 390610

475 LINEBAUGH .475 14 392614 390554

48 0 RUGER .475 14 392614 390554

50 A &E .500 40 39264 0 390580

50 BEOWULF .500 6 3 92606 390546

500 S&W .500 44 392644 39058 4

50 A LASK AN .510- .512 25 N/A 390565

500 LINEBAUGH .510 25 N/A 390565

50 0 NITR O EXPR ESS* . 510 55 N/A 390610

Shell

Holde r #

Shell

Plate

Item#

Shell

Holder

Item #

Lock-N-Load® AP Reloading Press

Page 8

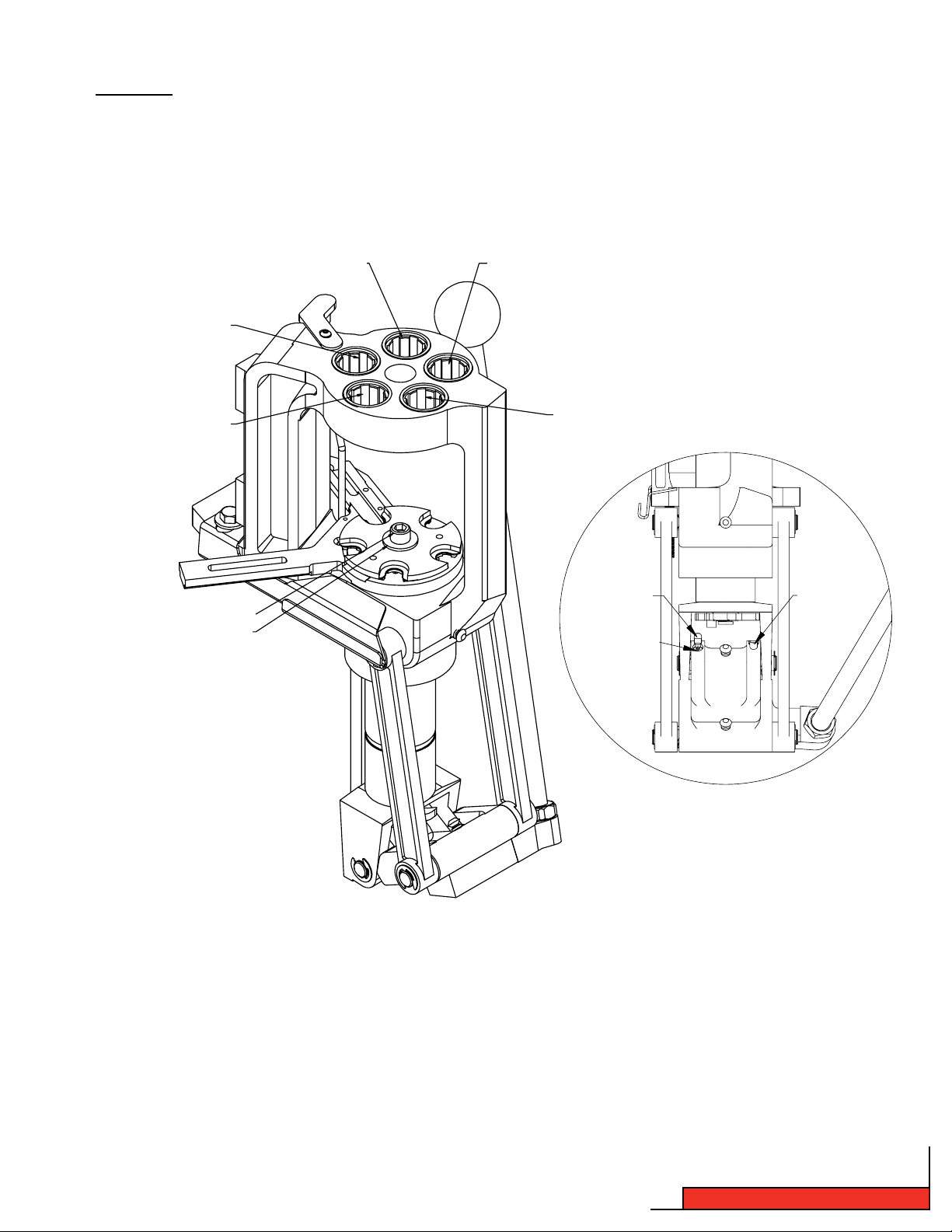

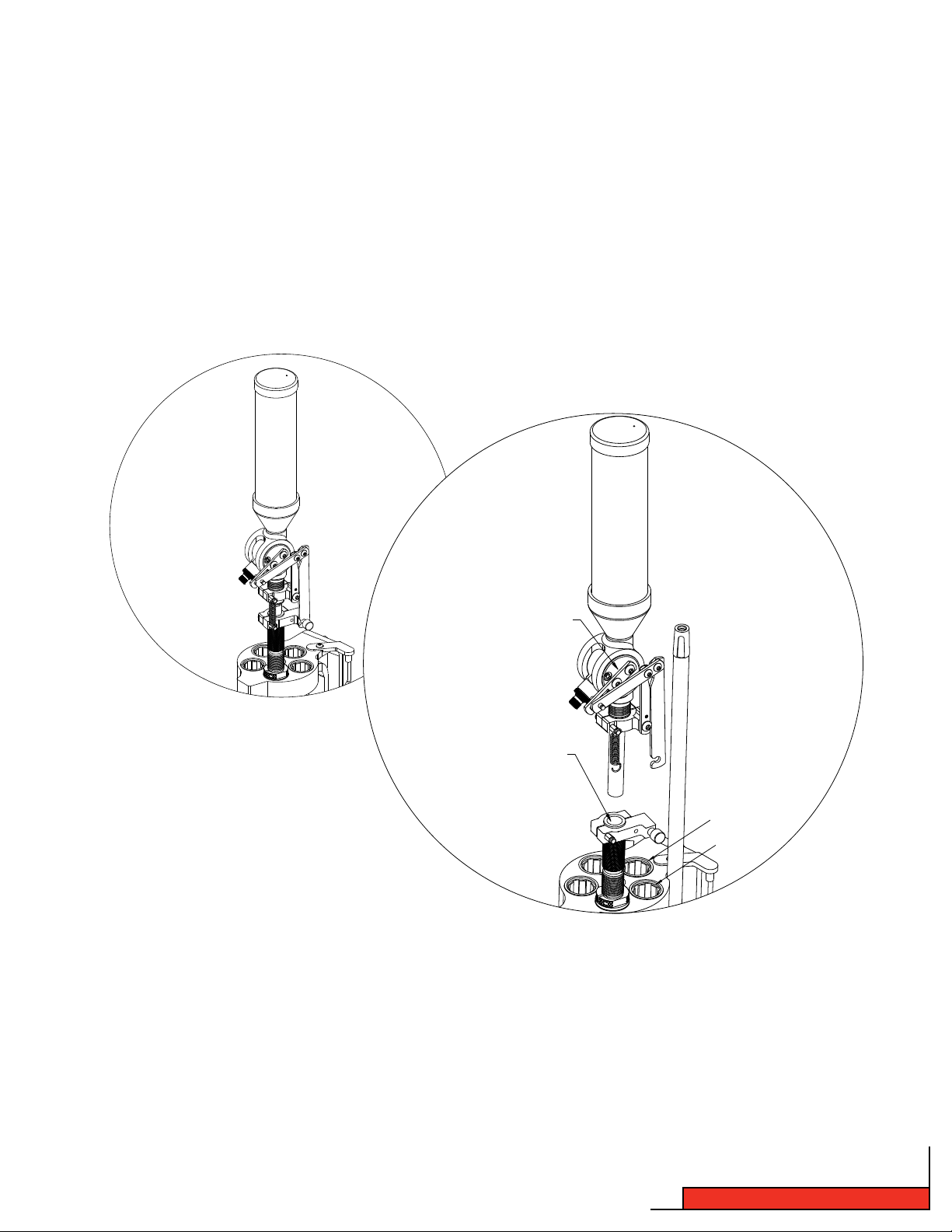

2A: Installing the Shell Plate

•Raise the Ram approximately 2" and place block under Sub Plate (24). This disengages the Index Pawls (32),

and allows for free rotation of the Shell plate.

•Put a small amount of general-purpose grease on the Shell Plate Ball Detents located on bottom side of Shell

Plate (12), and on the top surface of the Sub-Plate (24).

•Align the Shell Plate* with the keyed Drive Hub (29).

•Place the 3/8" Shell Plate Retainer Bolt (9) thru the 3/8" Flat Washer (28), (large end up) and thread the bolt

into the Drive Hub (29).

•Tighten the bolt (9) using a 5/16" Allen wrench, only tight enough to prevent it from coming loose.

•Stretch the Case Retainer Spring (17) over the top of the Shell Plate (12).

•Remove Block from under Sub-Plate (24) and make sure it is in the Retainer Spring Groove (17A).

•While cycling the Press, push the Case Retainer Spring (17) into the relieved area on the Sub-Plate (24).

You will have to cycle the press a couple of stations to receive these results.

•Check to make sure the Drive Pawls (32) are properly timed by cycling the press with the handle. A properly

timed press will rotate the Shell Plate so the Ball Detents on the Shell Plate always engage the recesses in

the Sub Plate.

EZject

Figure 2: Installing Shell Plate

SHELL PLATE RETAINER BOLT (9)

FLAT WASHER (28)

SHELL PLATE (12)

RETAINER SPRINGGROOVE (17A)

DRIVE HUB (29)

SUB PLATE (24)

Lock-N-Load® AP Reloading Press

- 8 -

Page 9

When properly adjusted, it is not necessary to assist the Shell Plate to rotate into the Detents, and you should not feel

a double click on the handle of the press as it indexes. If the adjustment is too long, it is normally felt as a double

click on the handle of the press. You may have to cycle the press very slowly to feel this. The pawl engagement is set

at the factory and very seldom requires adjustment by the user.

Figure 3: Removing Shell Plate

STATION 1

STATION 5

SHELL PLATE RETAINER BOLT (9)

FLAT WASHER (28)

STATION 2

STATION 3

STATION 4

LEFT PAWL

ADJUSTMENT

RIGHT PAWL

PAWL

SCREW

2B: Removing the Shell Plate

•

Use a 5/16" Allen wrench to remove the Bolt (9)

and to remove the shell plate.

•

Remove the Case Retainer Spring (17)

- 9 -

Lock-N-Load® AP Reloading Press

Page 10

SHELL PLATE TROUBLESHOOTING

•If the timing is severely out of adjustment, the Index Pawls (32) may have been damaged as outlined on page 9.

•If the Shell Plate does not rotate freely after mounting, check for these conditions:

•You may be trying to use the wrong version of shell plate. Your shell plate must have a groove cut on the bottom side.

•Dirt or debris between the shell plate and the drive hub.

•The Ball Detent bodies are not below flush on the underside of the Shell Plate.

•The Shell Plate is warped or damaged.

• If you reach a point where you cannot get the press to work, please call our technical service staff at

800-338-3220 or email webmaster@hornady.com.

Step 3: Operation of your Lock-N-Load® Auto Progressive Press

The Hornady Lock-N-Load AP utilizes a high strength aluminum alloy frame with a compound linkage system which

operates the 2" diameter cylindrical ram. The Ram houses a drive shaft that is attached to the shell plate at the upper

end and the index wheel at the lower end. The toggle contains two spring actuated pawls which alternately engage the

index wheel to advance the shell plate through the different reloading stations.

As the handle is lowered, the right Pawl contacts the Index Wheel, advancing the Shell Plate during the first 1½" of

upward travel of the Ram. With this upward travel, the cases become aligned with the dies at the top of the Press. As the

Shell Plate comes to the top of the press, it guides the cartridge cases into the five die stations to perform the reloading

operations except priming.

The handle is then raised to complete the stroke, lowering the Shell Plate. When the Shell Plate comes to within 1 3/4" of

the bottom, the left Pawl engages the Index Wheel which advances the Shell Plate into position over the primer to seat it

into the case that was just sized and de-primed. Pushing back on the handle with moderate force will seat the new primer

into the case.

Once the dies are in place, and all stations are filled, the proper sequence for reloading is listed below.

•Place an empty case into station one. (Using the optional LNL-AP Case Feeder, this step is automatically done for you.)

•Insert bullet into the powder charged case in station four.

•Lower the handle.

•Powder drops into the newly primed case at station three.

•Raise the handle and seat a new primer in the de-primed case that has now moved to station two.

•Loaded cartridge is automatically ejected at station five when handle is raised.

Lock-N-Load® AP Reloading Press

- 10 -

Page 11

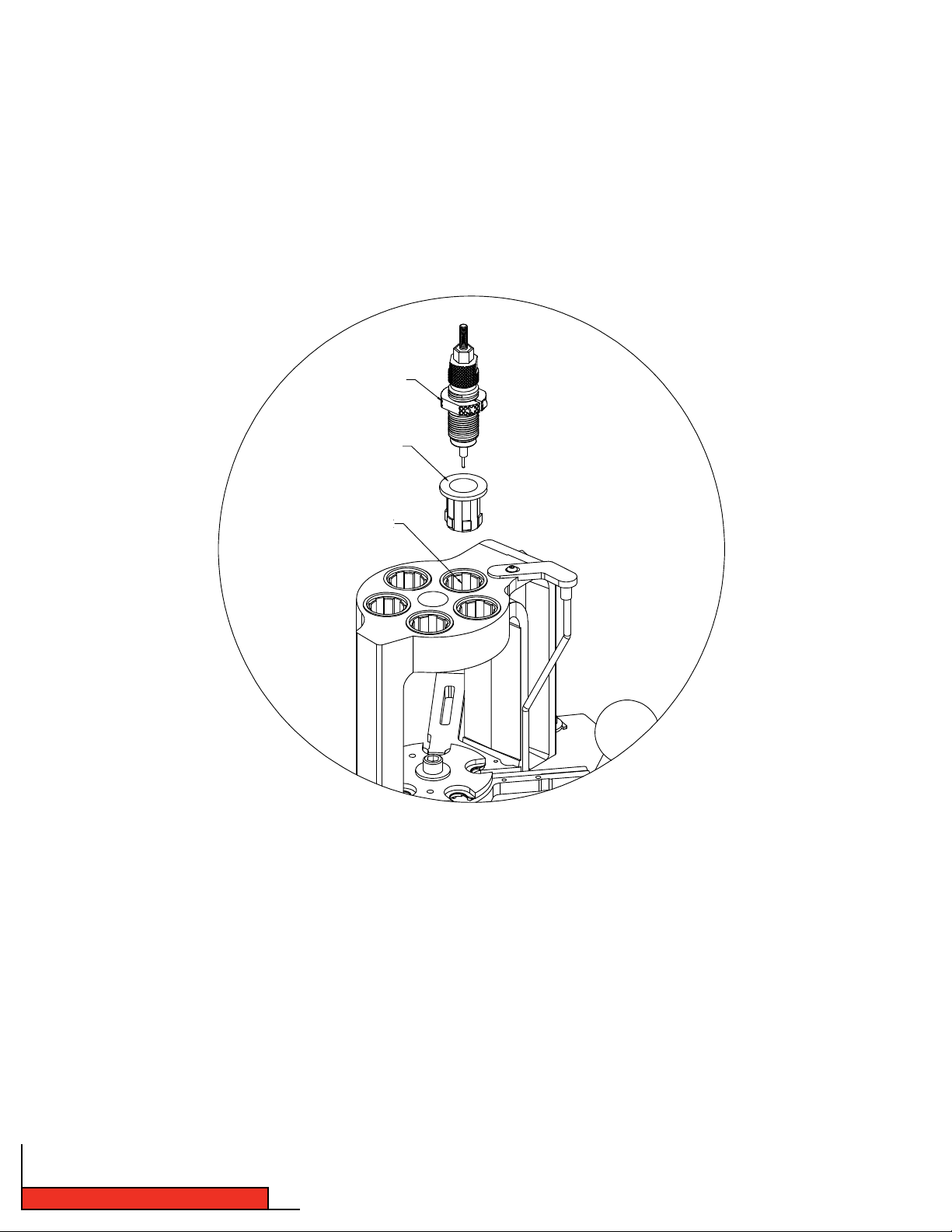

Step 4: Automatic Primer Feed Assembly

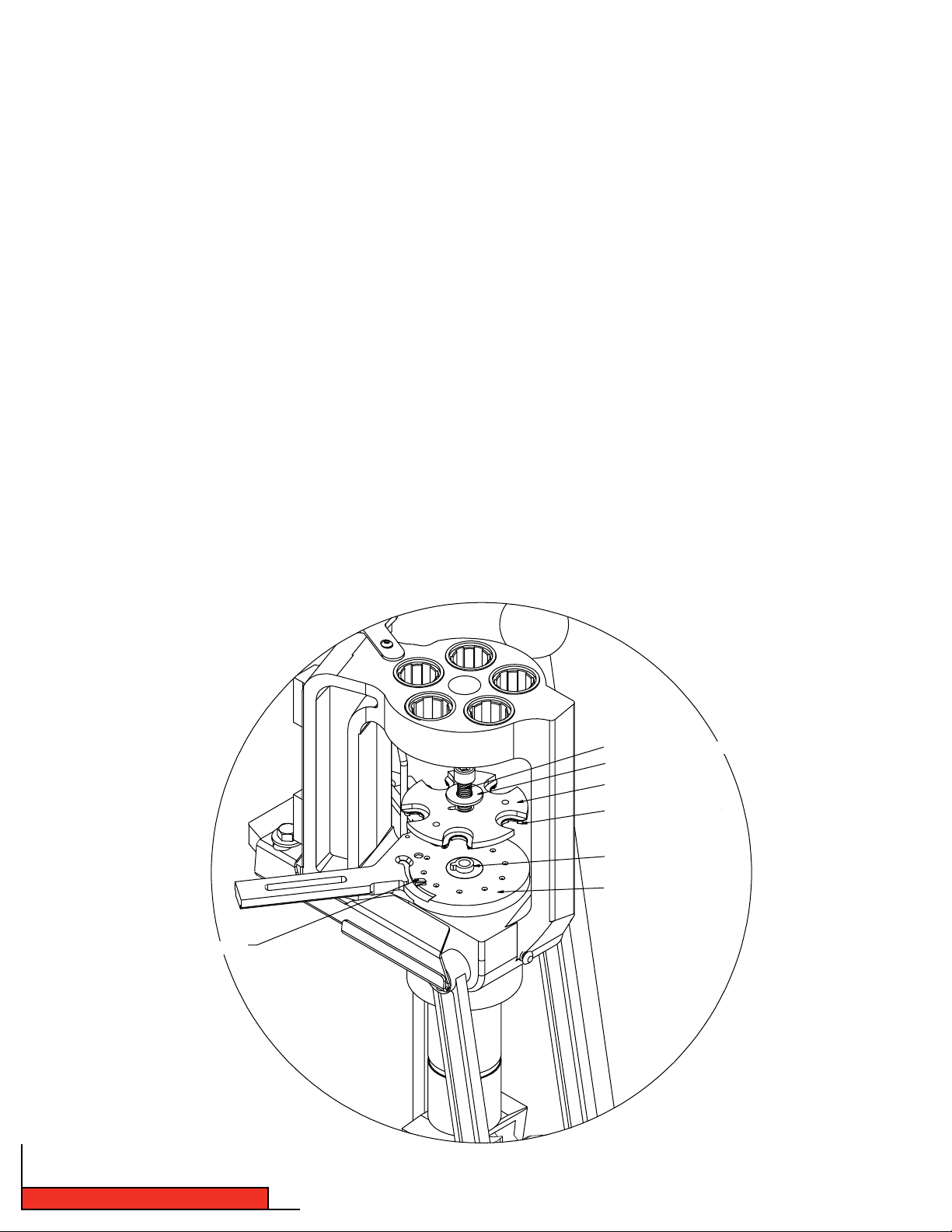

4A: Installing the Primer Body (see drawing on next page

•Place the aligning pin, located on the underside of the Primer Body (14) in the hole on the Sub-Plate (24) located next to

the Primer Slide (15).

•Insert the Cap Screw (11) thru the hole of the Primer Body (14) and screw it into the Sub-Plate (24).

•Rotate the Primer Body (14) counterclockwise towards the loader against the bolt and tighten the bolt.

4B: Installing the Primer Slide, Large or Small

•Lower the handle (44).

•Place a 2" spacer under the Sub-Plate (24); a 4" section of a 2" wide wooden block works well.

•Place the Primer Slide (15) flat side up in the groove on the Sub-Plate (24) and slide forward. The bump on the bottom

side of the slide is the travel stop as well as an alignment guide while the slide is in the retracted position.

•Attach the Spring (16) to the Sub-Plate (24) with the open end up (you may need to use needle nose pliers).

Attach the other end of the Spring to the pin on the Primer Slide.

4C: Installing the Primer Punch Assembly, Large or Small

•Raise the Ram (37) to the top of the stroke.

•Screw the Primer Seater Punch (26) into the Sub-Plate (24) from the bottom side.

•Tighten the Primer Seater Punch assembly (26) until it is snug using a wrench. (Do not over tighten the Primer Punch)

4D: Installing the Primer Tubes

•Place the tube of your choice (large or small primers) (4 or 5) in the center hole of the Primer Body (14) with the shoulder

section of the tube facing down. Make sure the tube is fully seated in the Primer Body.

4E: Installing the Primer Tube Housing

•Slip the threaded end of the Primer Tube Housing (6) over the Primer tube (4 or 5) and onto the Primer Body (14).

•Screw the Primer Tube Housing (6) on to the Primer Body (14) clockwise. Snug the tube by hand.

- 11 -

Lock-N-Load® AP Reloading Press

Page 12

SPRING (16)

SUB-PLATE (24)

Figure 4: Primer Feed System

PRIMER BODY (14)

(10)

PRIMER TUBE SUPPORT (1)

PRIMER FEED TUBE (4 or 5)

“SHOULDERED END DOWN”

PRIMER FEED TUBE (4 or 5)

“SHOULDERED END DOWN”

PRIMER SLIDE (15)

ALIGNING PIN

CAP SCREW (11)

PRIMER SLIDE (15)

PRIMER BODY (14)

SUB-PLATE (24)

PRIMER FEED TUBE (4 or 5)

“SHOULDERED END DOWN”

4F: Primer Tube Support installation

•

Place the Primer Tube Support (1) over the Primer Feed Tube (4 or 5) and slip the three tapered “fingers”

inside the Primer Tube Housing (6). This will create a recess that allows the Primer Filler Tube (2 or 3) to

properly align with the Primer Feed tube during refillings.

Lock-N-Load® AP Reloading Press

PRIMER BODY (14)

PRIMER SEATER PUNCH (26)

- 12 -

Page 13

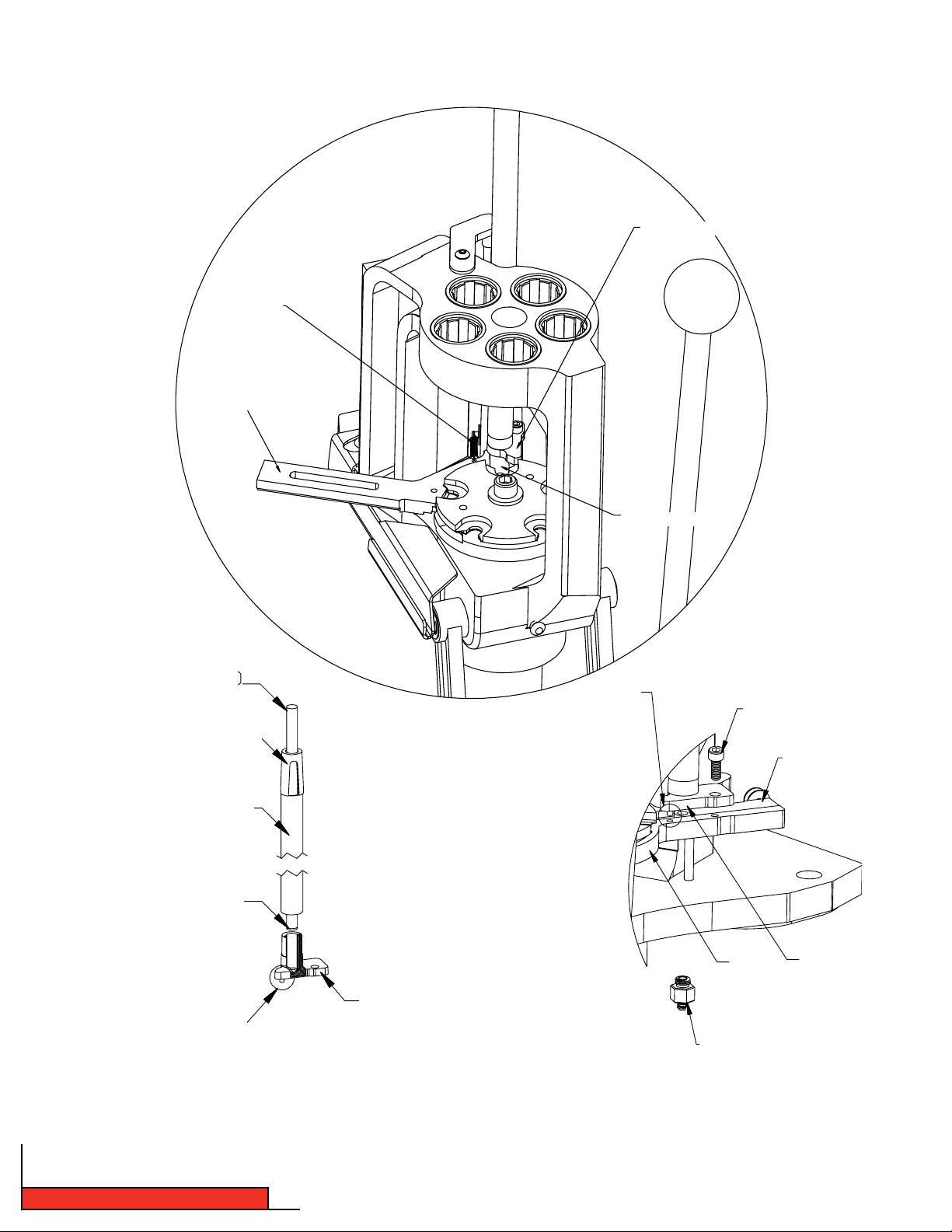

Step 5: Loading the Primer Tube

Refer to Step 4D for Primer Tube installation instructions.

PRIMER FILLER TUBE (2 or 3)

PRIMER FILLER TUBE (2 or 3)

PRIMER TUBE SUPPORT (1)

PRIMER TUBE HOUSING (6)

Figure 5: Filling the Priming System

PRIMER FEED TUBE (4 OR 5)

14

4

24

Carefully transfer the primers out of their factory package into a Hornady Primer Turning Plate and orientate them

shiny side up. Then holding the Primer Filler Tube (2 or 3) like a pencil, bring the plastic primer pick up tip over each

primer and gently press it over the primers. The primers will be pushed into the filler tube one on top of another.

Continue loading the primer filler tube until you have picked up approximately 100 primers.

Make sure the cotter pin is in place; turn the Primer Filler Tube (2 or 3) upside down. At the top of the exposed

Primer Filler Tube, there may be several primers still held and visible. Gently shake the tube to release the primers.

Align the Primer Filler Tube (2 or 3) to the Primer Feed Tube (4 or 5) using the Primer Tube Support (1). Remove the

cotter pin from the Primer Filler Tube (2 or 3) and fill the Primer Feed Tube (4 or 5). The primer tube has a 100

primer capacity. Do not over fill the primer tube.

Insert the Primer Fouler (10) into the Primer Feed Tube (4 or 5). This will help the primers feed more reliably.

- 13 -

Lock-N-Load® AP Reloading Press

Page 14

Step 6: Changing Primer Tubes

When changing to a different size of primer, you need to change the Primer Feed Tube ( 4 or 5), Primer Slide (15) and Punch

Assembly (26).

If there are primers in the Primer Feed Tube (4 or 5), you will need to empty it before changing the tubes. Remove the Cap

Screw (11), cup your hand under the Primer Tube and rotate the Primer Feed Body Assembly clockwise to catch the primers.

After the tube is empty, rotate the body back in place and re-install the mounting screw. Refer to Step 4 for more details.

Disconnect the Spring (16) from the roller pin and remove the Primer Slide (15). Remove the Primer Tube Support (1) and the

Primer Feed Tube (4 or 5).

If the primer tube is empty, there is no need to take the primer feed assembly off of the sub-plate. Remove the Primer

Feed Support (1), Primer Tube (4 or 5), disconnect the Spring (16) and remove the Primer Slide (15) and Punch Assembly

(26). Reinstall the primer system for your application (Refer to Step 4). Fill the primer tube as previously described (Refer to

Step 5).

The Primer Seater Punches (26) are installed from the bottom side of the Sub-Plate (24). Raise the Ram (37) to the top of

the stroke. Use a wrench to loosen the Primer Seater Punch (26) and unscrew it from the Sub-Plate (24). When installing a

new Primer Seater Punch (26), tighten it snug with a wrench. Do not over tighten the Primer Punch.

(10)

PRIMER TUBE SUPPORT (1)

PRIMER FEED TUBE (4 or 5)

“SHOULDERED END DOWN”

PRIMER FEED TUBE (4 or 5)

“SHOULDERED END DOWN”

SPRING (16)

SUB-PLATE (24)

PRIMER BODY (14)

PRIMER SLIDE (15)

ALIGNING PIN

CAP SCREW (11)

SUB-PLATE (24)

PRIMER SLIDE (15)

PRIMER

BODY (14)

PRIMER FEED TUBE (4 or 5)

“SHOULDERED END DOWN”

Lock-N-Load® AP Reloading Press

PRIMER BODY (14)

PRIMER SEATER PUNCH (26)

- 14 -

Page 15

Step 7: Automatic Primer Feed Inspection

It is not necessary to install the primer tubes at this time to test your loader, but you must install the Primer Body (14).

Lower the Primer Slide (15) so that is stays in place. See step 4A for instructions on installing the Primer Body (14).

At this point you should have installed a Shell Plate and the corresponding Primer Seater Punch (26) and Primer Slide (15)

for the cartridge you are loading.

Step 8: Installing the Lock-N-Load® Powder Measure with Case Activated Powder Drop.

Figure 6: Lock-N-Load Powder Measure

UPPER ASSEMBLY

MEASURE ADAPTER

STATION 1

STATION 2

The Lock-N-Load Powder Measure combines with the Case Activated Powder Drop to mount on-top of the Lock-N-Load AP in

station 2 or 3. The Lock-N-Load Powder Measure that was shipped with the press has been factory fitted with the case

activiated

Powder Drop.

* This press comes packaged with the Standard Rotor & Standard Metering Insert and the Pistol Rotor & Pistol Metering Insert.

Refer to the Lock-N-Load Powder Measure and Case Activated Powder Drop instructions for cleaning and functionality.

(These instructions are included).

- 15 -

Lock-N-Load® AP Reloading Press

Page 16

Step 9: Lock-N-Load® quick change bushing system

The Lock-N-Load system is based on the positive locking action of the bolt action rifle. Just like the bolt action rifle,

the locking action is incredibly strong and simple.

Once the dies and the powder measure are adjusted for loading, these settings are locked in place by tightening

the Lock Ring that is provided with all Hornady dies and powder measures.

How the Lock-N-Load® works:

LOCK-N-LOAD BUSHING

BUSHING/RECPTACLE

Figure 7: Hornady Lock-N-Load System

LOCK RING

LOCK-N-LOAD

LOCK-N-LOAD BUSHING THREADS

ONTO STANDARD 7/8"-14 TPI

RELOADING DIES.

•Insert the Lock-N-Load bushing into the press and turn it clock wise to lock it in place.

•Adjust the die to the desired position and lock the setting in place with the die’s lock ring.

Once Lock-N-Load bushings are installed, Dies and Powder Drop can be removed from the press with a quick

counterclockwise turn. Since the Lock-N-Load bushing is locked in place, the dies and the Powder Drop remain set

exactly as you left them.

For added speed and convenience, Hornady offers inexpensive Quick Change Powder Dies for use with the Case

Activated Powder Drop.

Step 10: Die Mounting Instructions

For initial die cleaning and set-up instructions, please refer to the instruction sheet that came with your die set.

Please Note: The Hornady Lock-N-Load Auto Progressive with EZject™ System can use any brand of die.

Lock-N-Load® AP Reloading Press

- 16 -

Page 17

Step 11: Preparing to Load

Start with a single empty cartridge case and run it through all the loading stations (see Step 3 for details). This will

allow you to check your adjustments. Refer to instructions provided with the die set for set up and proper adjustment.

• Sizing a case.

n

Make sure the sizing die is adjusted properly, and the de-priming pin knocks out the old primer.

• Seating a primer.

n

Check and make sure the Primer Slide (15) picked up a primer from the Primer Feed Tube (4 or 5).

n

When you cycle the press and the handle comes to a stop, you will have to push the handle away from you past

the stop to seat the primer. Push until it stops but don’t force it. Seating the primer requires a firm push.

n

Lower the handle of the press slowly to rotate the shell plate to start the next operation. If there is resistance on

the shell plate, the primer is improperly seated and not allowing the Shell Plate to rotate.

• Drop powder in the case using the case activated powder drop.

n

Verify the weight on a properly calibrated scale.

• Seat a bullet in the powder charged case.

n

Begin lowering the handle to rotate the shell plate to this station.

n

Place a bullet on top of the case and lower the handle the rest of the way. (You may need to position the bullet

over the case neck between your thumb and forefinger until the bullet enters the alignment sleeve).

• Station 5. (Refer to illustration on page 6)

n

This station is used for a Taper Crimp Die when reloading pistol cartridges that headspace off the case mouth.

* Any manufacturer’s Taper Crimp Die will work in Station 5 with the AP’s EZject™ System.

n

Properly adjusted, a taper crimp die removes all case-flare from the expander die without damaging or

squeezing into the bullet.

Lower the handler to advance the shell plate to the next station. The loaded round will rotate and contact the EZject

System underneath the shell plate. This EZject™ System will automatically eject the loaded round from the press.

Never force the handle. Measure the case for proper length and check the data in your reloading book.

When you are satisfied with the first completed cartridge, repeat the process with another single case, advancing

slowly from station to station until you eject the finished cartridge from the press with the case ejector.

After you are comfortable with the process, load the press with consecutive cases for reloading. Do not rush! After

you advance the cases through each station, inspect everything to insure proper function. If anything looks out of

place, or if you lose track of what you are doing, STOP! It’s safer to begin slowly than it is to assume you need to

reload a large number of cartridges during each session. Don’t force the handle at any time, and be sure that all

mechanical parts are properly lubed.

SAFETY NOTE: Be safe! Double check your powder loads at frequent intervals to insure the powder charge is

working properly.

™

- 17 -

Lock-N-Load® AP Reloading Press

Page 18

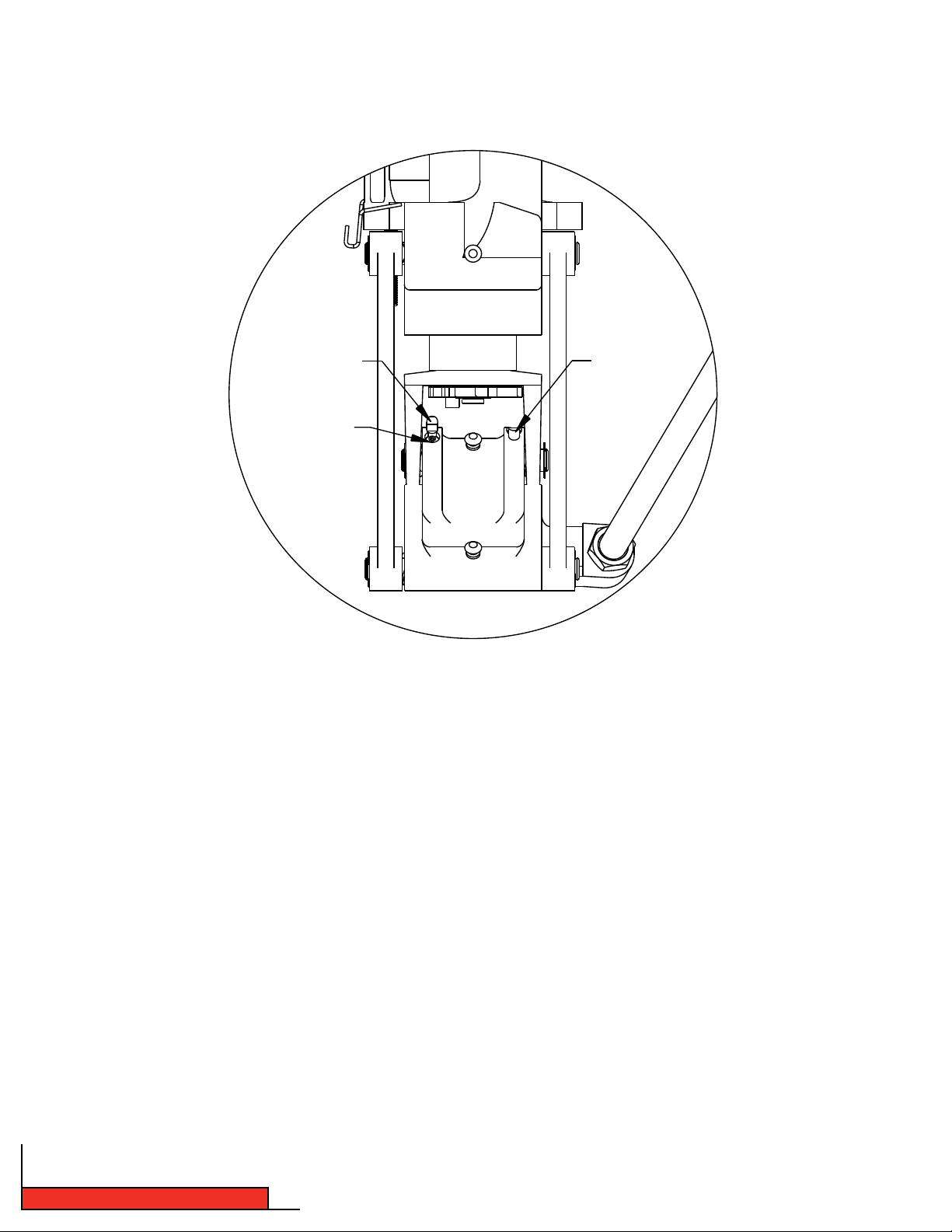

Step 12: Adjusting the Auto Advance Mechanism

Figure 8: Pawl Adjustment

LEFT PAWL (32)

PAWL ADJUSTMENT

SCREW

RIGHT PAWL (32)

The Auto Advance Mechanism is fully adjusted at the Hornady factory and should not require further adjustment. If you

feel your shell plate is not advancing properly, check all other options listed in this manual before attempting to adjust

the mechanism’s pawls.

All adjustments should be made in extremely small increments.

Through everyday use, the pawls on your press may gradually wear and may need to be adjusted. Before making

adjustments you should understand what each pawl does.

As the operating handle is lowered and raised through a complete cycle, each pawl engages the index wheel at the

bottom of the press. The index wheel is connected through the driveshaft to the shell plate. As each pawl engages the

index wheel it advances the shell plate either at the top or bottom of the cycle.

The right pawl (as you face the press) advances the shell plate as the ram travels up when the handle is pulled down.

The left pawl advances the wheel on the down stroke of the handle and should advance the shell plate to the detent

holes in the sub-plate. If the shell plate doesn’t advance enough on the down stroke of the ram, only the left pawl needs

adjustment.

Lock-N-Load® AP Reloading Press

- 18 -

Page 19

The right pawl is too low if the shell plate stops short of the detent, which can be felt as you rotate the shell

plate into place by hand in a clockwise direction. If the pawl is too high, you will feel a slight double click on the

handle as the pawl disengages and the shell plate is locked into place by the detents.

The same is true for the left pawl which indexes on the up stroke of the handle (down stroke of the ram.)

Likewise, if the plate doesn’t advance far enough on the up stroke of the ram, only the right pawl needs to be

adjusted. Don’t assume that both pawls need adjusting.

Do only one pawl at a time to keep from becoming confused.

The height of each pawl determines how far the shell plate will advance when that pawl comes in contact with

the indexing wheel. To adjust the pawls, increase the height of the chosen pawl to increase the advancement of

the shell plate in that direction or decrease the height of the pawl to decrease the shell plate advancement in

that direction.

There is a set screw on each pawl, refer to (Figure 8).

•Turnthesetscrewclockwisetolowerthepawl.

•Turnthesetscrewcounterclockwisetoraisethepawl.

Become familiar with these pawls from the onset and see how they operate. You will then find it much easier

to adjust the pawls, should you need to do so in the future.

MAINTENANCE OF THE LOCK-N-LOAD® AP

As with all machinery, proper routine maintenance will provide smooth operation and a longer life for your

reloading press. Check all moving parts for dirt or spilled powder and remove with a clean shop rag.

Remove the primer slide, shell plate and clean the spilled powder under it. After cleaning, lubricate the

sub-plate in the area of the detents, drive hub and sub-plate with one or two drops of light grade machine oil or

Hornady One Shot Gun Cleaner and Dry Lube. The primer slide is permanently lubricated and needs no oil.

Lightly lube the index wheel and pawls. Hornady One Shot Gun Cleaner and Dry Lube is excellent to use here. It is

a dry lube, so stray powder won’t stick to it while you’re reloading.

- 19 -

Lock-N-Load® AP Reloading Press

Page 20

TIPS FOR TROUBLE-FREE OPERATION

PROBLEMS SOLUTIONS

Powder dropping around case Correct bushing in place?

Powder drop tube and measure adapter clean?

Bushing installed deep counter sink side up?

No primer in case Primer slide properly adjusted?

Correct primer punch installed?

Primer slide spring in place?

Correct primer slide installed?

Primer body rotated counterclockwise when installed?

Shell Plate will not advance or does

not index on station

Primer not fully seated?

Pawls correctly adjusted?

Make sure you have the latest shell plate version with the

groove on the bottom side.

Cases do not feed into Dies Die mouths beveled? (If not, return to manufacturer for repair.)

Pawls timed correctly?

Gun powder is sticking in the

powder measure, or inconsistent

charge weights

Is the inside surface dry and clean?

Try pouring a little powdered graphite thru the powder measure for

lubricant. Rub the outside of the powder hopper with a dryer sheet

to eliminate static.

Case retainer spring won’t fall off

the shell plate or it is getting kinked

Is there a burr on the shell plate where the spring groove and the

case location meet?

Is there a burr on the sides of the slot on the sub-plate? (With a

casefeeder, when you are setting up the timing, do not run the case

into the spring if the spring is up on the shell plate.)

Lock-N-Load® AP Reloading Press

- 20 -

Page 21

TABLE OF CONTENTS

Steps Page

Overview........................................................22

1: Disassemble ...........................................22

2: Assemble ................................................23

3: Operate and Adjustment.........................23

4: Precautions ............................................23

BILL OF MATERIALS

Item

(*)’s are for 50 BMG Powder Measure

Production

No.

Part Number

1 170405 1 HOPPER CAP

2 398520 1 HOPPER

3 392740 1 BODY

4 392719 2 SCREW BHSCS 10-32 X 3/8

5 392752 1 HANDLE ASSEMBLY

6 392741 1 ROTOR

7 392743 1 METERING PLUNGER

8 392742 1 SLEEVE

9 480083 1 O-RING 1/2 ID X 11/16 OD

10 392764 1 NUT LOCK METERING UNIT

11 392766 1 O-RING 1 1/2 ID X 1 5/8 OD

12 390702 1 SMALL DROP TUBE

13 390701 1 LARGE DROP TUBE

14 392760 1 MOUNTING BRACKET

15 390656 1 3/32” HEX WRENCH

16 O44000 1 LOCK RING

17 390653 1 1/8” HEX WRENCH

1* 392779 1 BODY 165-265

2* 392780 1 PLUNGER, HIGH CAPACITY

3* 480083 1 O-RING 1/2 ID X 11/16 OD

4* 392764 1 NUT LOCK METERING UNIT

5* 392777 1 ADAPTER

6* 392775 1 TUBE DROP

7* 398521 1 HOPPER

8* 390653 1 1/8” HEX WRENCH

9* 390656 1 3/32” HEX WRENCH

10* 390036 1 5/32” HEX WRENCH

Qty. Description

Lock-N-Load

®

Powder Measure

Charts

1. Bill of Materials of

Lock-N-Load Powder Measure ................21

2. Exploded view of

Lock-N-Load Powder Measure ................21

- 21 -

Lock-N-Load® Powder Measure

Page 22

OVERVIEW: LOCK-N-LOAD® POWDER MEASURE

Your Powder Measure has been treated with a rust preventative which must be removed before use. We

recommend that you clean and degrease all metal parts with Hornady One-Shot Cleaner and Dry Lube.

TO DISASSEMBLE:

•Set the Rotor with the Metering Unit perpendicular to the axis

of the Body, press the Push Button and hold it down while

removing the Metering Unit.

NOTE: Do NOT remove push button. It is permanently installed

and does not need cleaning.

•Remove the Handle, or Rotating Arm from the Powder Measure, by removing the two attaching screws with a 1/8” hex

wrench.

•Slide the Rotor out of the Body by pressing gently on the

handle side of the Rotor.

Be careful not to drop or otherwise damage the Rotor while

it is out of the Body.

•Remove the Lock Nut, O-Ring and Sleeve from the Metering

Plunger. Spray all metal parts liberally with Hornady One ShotGun Cleaner and Dry Lube. Be sure all rust preventatives are

removed.

•Allow it to dry thoroughly before reassembling.

Lock-N-Load® Powder Measure

- 22 -

Page 23

TO ASSEMBLE:

Reverse the procedure in the first five steps above.

The Rotor and Body are very closely fit and must be properly aligned to reassemble.

DO NOT FORCE IT OR IRREPAIRABLE DAMAGE WILL OCCUR.

TO OPERATE AND ADJUST:

•

Attach the Mounting Bracket to your bench or shelf using (2) #14 Binding Head Sheet Metal Screws or other suitable

hardware. The screws should be approximately _” back from the edge of the bench, and the smaller of the two large holes

should be suspended off of the bench.

•Place the Powder Measure in the hole of the Mounting Plate, thread the Lock Ring onto the Powder Measure, tighten the

Lock Ring to the Mounting Plate and lock it in place with the 3/32” hex wrench, if desired.

•Select the appropriate Drop Tube (The smaller for 20 and 25 caliber, the larger for 6.5 mm and up) and thread it into the

bottom of the Powder Measure until it is secure against the internal shoulder. (Finger tight is all that is required.)

•The Lock Nut and O-ring on the Metering Unit may be adjusted to provide tension on the thread of the Plunger, so as to

allow setting it while not allowing unintentional movement in operation. It may be locked in place by tightening when

adjustment is achieved.

One revolution of the plunger is .05” travel. With the plunger all the way in, or the capacity set to near zero, the end of

the thread and the outer surface of the Lock Nut should be approximately flush.

With the plunger all the way out (roughly 20 turns, 1”), the maximum capacity is approximately 100 grains or 5 grains

per turn.

•Once your Metering Unit is set, lock it, label it and store it with the die set, for the fastest possible return to the present

setting in future loading sessions.

PRECAUTIONS:

Always change the metering units with the handle and the metering unit in the horizontal position, and after you

have dropped the charge. If you allow the Handle to fall while changing units, you will drain the Hopper.

Be sure that you have the proper “Lock-N-Load” device locked in place, before operating.

Always verify your charges with a scale before loading.

Any moisture in the unit will cause powder to stick, and charge weights will vary dramatically.

- 23 -

Lock-N-Load® Powder Measure

Page 24

TABLE OF CONTENTS

Lock-N-Load

Case Activated Powder Drop

Steps Page

Overview............................................................................ 25

1: Assembling the Case Activated

Powder Drop Rotor Arm ................................................. 25

2: Upper Bracket Assembly ............................................... 26

3: Drop Tube Installation...................................................27

4: Installing the Case ActivatedPowder Drop .................... 27

(Lower Assembly)

5: Final Powder Measure Assembly ................................... 28

6: Case Activated Powder Drop Adjustment ...................... 28

BILL OF MATERIALS

®

Figures

1. Attaching the Case Activated Powder Drop Rotor Arm ..10

2. Upper Bracket Assembly ............................................... 11

3. Drop Tube Installation...................................................12

4. Installation for the Case Activated Powder Drop ........... 14

(Lower Assembly)

5. Final Powder Measure Assembly ................................... 15

Charts

1. Bill of Materials for Case Activated Powder Drop .......... 24

2. Exploded view for Case Activated Powder Drop ............. 24

6

5

Item

* (Sold Separately)

Production

No.

Part Number

1 392721 4 BHSCS 10-32 X 1.00

2 392708 2 MOUNTING CLAMP

3 392710 1 ROTOR ARM

4 392719 5 BHSCS 10-32 X 3/8

5 392715 2 SHOULDER NUT

6 398735 1 PIVOT

7 398737 1 DRIVE LINK

8 398736 1 MEASURE LINK

9 398742 2 BHSCS 10-32 X 1.25

10 392717 1 GROOVE PIN 3/16 X 7/8

11 392718 1 SPRING PIN 1/8 X 3/8

12 392707 1 UPPER BRACKET

13 398739 2 SPRING NUT

14 391008 1 RETURN SPRING

15 392705 1 DROP TUBE

16* 392703 1 17 CAL. SLEEVE

17 392701 1 #1 POWDER SLEEVE

18 392702 1 #2 POWDER SLEEVE

19 392700 1 PISTOL POWDER SLEEVE

20* 290040 1 .355 POWDER THRU EXPANDER

20* 290041 1 .357 POWDER THRU EXPANDER

20* 290042 1 .400 POWDER THRU EXPANDER

20* 290043 1 .430 POWDER THRU EXPANDER

20* 290044 1 .451/.452 POWDER THRU EXPANDER

20* 290045 1 .475 POWDER THRU EXPANDER

20* 290048 1 .500 POWDER THRU EXPANDER

21 392704 1 MEASURE ADAPTER

22 392706 1 LOWER BRACKET

23 398741 1 LOCKING BOLT

24 392722 1 RETAINING RING

25 O44000 1 LOCK RING

26 392302 1 LOCK -N-LOAD BUSHING

Qty. Description

12

4

7

8

10

13

14

15

20

22

13

11

4

23

1

9

16*

1

9

2

17

25

26

24

21

2

18

3

19

Lock-N-Load® Powder Measure

- 24 -

Page 25

OVERVIEW: CASE ACTIVATED POWDER DROP

The Case Activated Powder Drop helps make reloading faster

and easier than ever before. It automatically activates

and dispenses a charge with every pull of the handle,

but only when a case is present in the station. Plus, it

works with Lock-N-Load bushings. (You can remove

and change Hornady powder measures with a quick

turn, without changing adjustments.) The Case

Activated Powder Drop unit can be used ONLY on

the Hornady Lock-N-Load Powder Measure.

Before using, disassemble and carefully clean

the inside surfaces of the drop tube, measure

adapter and powder sleeves. Rust preventative oil

was applied at the factory to protect the parts during

shipment and must be removed before reloading.

Brake cleaner works well to remove the oil.

Step 1: Assembling the Case Activated

Powder Drop Rotor Arm

Reinstall the Rotor with the handle side to the

right (metering opening facing you).

Place the Metering Unit back into the Rotor.

Attach the Case Activated Powder Drop Rotor

Arm (#3) to the right side of the Rotor using

two Button Head Cap Screws (#4).

L-N-L POWDER MEASURE

Fig. 1: Attaching the Case Activated

Powder Drop Rotor Arm

- 25 -

Lock-N-Load® Case Activated Power Drop

Page 26

Step 2: Upper Bracket Assembly

Slide the Upper Bracket Assembly onto the Powder Measure.

Engage Drive Link Pin (#10) into the Rotor Arm Slot.

Adjust the position of the Upper Assembly so that the drive link pivot is across from the centerline.

Tighten the two Button Head Cap Screws (#1) and (#9). The longest screw 10-32 X 1.25 goes in the front hole. Screw

on the Spring Nut (#13) to the end of the 10-32 X 1.25 screw.

Figure 2: Upper Bracket Assembly

ROTOR

ARM SLOT

DRIVE LINK PIN

9

2

UPPER ASSEMBLY

L-N-L POWDER MEASURE

ROTOR “CENTERED”

PIVOT LOCATED

ACROSS FROM

ROTOR CENTERLINE

Lock-N-Load® Case Activated Power Drop

- 26 -

Page 27

Step 3: Drop Tube Installation

Screw the Drop Tube (#16) into the bottom of

the Powder Measure.

Lubricate the exterior of the Drop Tube (#16)

with Hornady One Shot Gun Cleaner and Dry

Lube or other similar dry lubricant.

L-N-L POWDER MEASURE

ROTOR “CENTERED”

Figure 3: Drop Tube Installation

16

PIVOT LOCATED

ACROSS FROM

ROTOR CENTERLINE

Step 4: Installing the Case Activated Powder Drop (Lower Assembly)

Screw the Measure Adapter (Lower Assembly) into the reloading press a couple of turns.

Select the appropriate powder bushing sleeve for your application. (Each sleeve has a shallow countersink on one side,

and a deep counter sink on the other.) Insert the bushing, with the deep counter sink facing up, into the top of the measure adapter.

If using a Drop Thru Expander Powder Sleeve, insert the Expander with the deep countersink facing up, into the top of the

Measure Adapter.

The Case Activated Powder Drop comes with three internal powder bushing sleeves. The longest is the pistol powder sleeve

(#20). Powder sleeve (#19) has the smallest inside diameter and works for loading 20 to 270 caliber rifle cases. The third

and shortest powder sleeve is for loading 7MM to 45 caliber rifle cases.

Figure 4: Installation for the Case

Activated Powder Drop (Lower Assembly)

POWDER BUSHING

MEASURE ADAPTER

- 27 -

MEASURE ADAPTER

Lock-N-Load® Case Activated Power Drop

Page 28

Step 5: Final Powder Measure Assembly

Insert the Powder Drop Tube (#16) into the lower assembly. (Refer to pg. 13)

Connect the slot on the Measure Link (#8), (Refer to pgs. 17 & 18 for more details).

UPPER ASSEMBLY

Figure 5: Final Powder Measure Assembly

MEASURE ADAPTER

Step 6: Case Activated Powder Drop Adjustments

Insert a case into the shell plate at station 3 of your Lock-N-Load AP and operate the handle to raise the ram to its highest

position. (refer to pg. 13 in your Lock-N-Load AP manual)

Lower the Powder Measure by rotating it Clock-Wise (CW) into the press until the Powder Measure Rotor is fully rotated,

but not contacting the end of the slot in the Powder Measure Body.

Lower the Ram and attach the Return Spring (#14) between the two Spring Pins (#13).

Check the adjustment for correct positioning and secure the adjustment with the lock ring.

Clean the Case Activated Powder Drop at the end of each reloading session with a clean dry cloth to prevent a build up of

excess powder. This helps prevent the internal sleeve from sticking and spilling powder around the cartridge cases as they

are loaded.

Lock-N-Load® Case Activated Power Drop

- 28 -

Page 29

TABLE OF CONTENTS

Lock-N-Load

Auto Progressive Case Feeder

Steps

Overview........................................................................32

List of required hand tools ............................................32

1: Mounting the Lock-N-Load Auto Progressive

with Case Feeder ..................................................33

2: Changing the sub-plate .........................................34

3: Assemble the square tubing brackets ....................35

4: Placing the square tubing brackets

onto the square tubing ...........................................35

5: Assemble the square tubing and brackets

to the frame of the AP Press ...................................36

6: Assemble the square tubing to the frame

of the AP Press .......................................................37

7: Adding the case slide onto the sub-plate ...............37

8: Inserting the cam wire into the assembly ...............39

9: Case escapement bracket assembly ......................40

10: Mounting the Feed tube bracket to

the square tubing ...................................................41

Page

®

11: Determine which caliber you are going

to be loading ..........................................................42

12: Installing the V-block to the case slide ..................43

13: Changing and installing the shell plate .................43

14: Set the timing of the cam wire ...............................44

15: Assembling the feed tube end and pivot ................46

16: Placing the feed tube end on the assembly ............47

17: Selecting the case feed plate for

your application......................................................48

18: Adjusting the push rod ...........................................50

Single case operation ....................................................50

Fail-safe mechanism ....................................................50

Maintenance of the Lock-N-Load AP Case Feeder .........51

Trouble free operation....................................................51

List of Illustrations

Figures

1. AP with main bracket .............................................33

2. Spent primer tube dismantle/assembly ..................34

3. Square tubing brackets with set screws .................35

4. Square tubing brackets with square tubing ...........35

5. Square tubing brackets to AP Frame ......................36

6. Square tubing to AP Frame .....................................37

7a. Case slide assembly ...............................................37

7b. Case slide and sub-plate assembly .......................38

8. Assembly of cam wire .............................................39

9. Assembling case escapement bracket

on square tubing ...................................................40

Charts

1. Caliber change over chart .......................................42

2. Shell plate selection chart ........................................7

3. Case feed wheel selection chart .............................50

10. Feed tube mounting bracket to square tubing ........41

11. V-block selection ....................................................42

12. Inserting the V-block ..............................................43

13. Adjusting the V-block .............................................44

14. Feeding a case .......................................................44

15. Cam rod adjustment...............................................45

16. Pivot assembly .......................................................46

17a. Setting the feed tube end (most cases) ..............47

17b. Setting the feed tube end (357 Mag., etc.) ..........47

18. Case feed bowl door adjustment ............................49

19. Push rod adjustment ..............................................50

4. Trouble free operation .............................................51

5. Bill of Materials ......................................................30

6. Exploded view .........................................................31

- 29 -

Lock-N-Load® AP Case Feeder

Page 30

BILL OF MATERIALS: LOCK-N-LOAD® AP CASE FEEDER

Production

Item No.

1 398327 1 Case Feed Bowl

2 398313 4 10-32 x ¾ FHSCS

3 398374 8 10-24 “U” Nut

4 398415 8 #8 x 1/2 Sheet Metal Screw Pan Head Philips

5 398326 1 Motor Housing

6 398375 2 4-40 Hex Head Lock Nut

7 398333 1 Micro Switch

8 398369 1 Case Feed Funnel Assembly

9 398376 1 4-40 x 5/8 B HSCS

10 398332 2 Rocker Switch

11 398331 1 Motor

12 398328 1 Motor Cover

13 398320 1 Feed Tube-Large

14 398321 1 Feed Tube-Small

15 398303 1 Feed Tube End-Large

16 398286 1 Feed Tube Mounting Bracket

17 396440 2 Lock Ring

18 398298 1 Pivot Adapter

19 398290 1 Pivot

20 398310 1 1/4 - 3/4 Shoulder Bolt

21 398 311 1 3/0 x 3/4 Tper Pin

22 398305 1 Drop Tube-Large

23 398288 1 Spring, Tor sion

24 398317 1 Push Rod

25 398371 1 Push Rod Tip

26 390178 2 1/4-20 Hex Head Nut

27 398349 1 Push Rod Bushing

28 398364 1 10 x 1/2 Sheet Metal Screw Pan Head Philips

29 398344 1 Pivot Body

30 398363 1 Push Rod Spring

31 398343 1 Cam Wire Support

32 398425 1 E Clip 1/4

33 398373 1 Push Rod Nut

34 398372 1 Push Rod Lower

35 398314 2 5/16-18 x 5/8 Set Screw Cup

36 39 8315 2 5/16-18 x 5/8 Set Screw Cone Point (45 Deg.)

Part No. Qty. Description

Production

Item No.

37 398285 1 Case Feed Door Adjustment

38 398291 1 Case Slide

39 398307 1 Case Slide Rod Guide

40 398308 1 Case Slide Rod Guide Spring

41 39 2011 2 10-32 Hex Head Nut

42 398289 1 Main Bracket

43 398299 1 Cam Wire

44 398309R 1 Sub-Plate (on press or with retrofit kit)

45 398287 2 Bracket, Sq. Tubing

46 398345 1 Eject Wire (pre 7000 SER #)

47 398321 2 1/4-20 x 125SHCS

48 390128 4 1-4 Flaat Washer Zinc Plated

49 398284 1 Case Feed Stand

50 398304 1 Feed Tube End-Small

51 398300 1 Pivot Adapter Bushing

52 398301 1 Pivot Bushing

53 398306 1 Drop Tube-Small

54 095310 OPT Case Feed Plate-Small Pistol

55 095312 OPT Case Feed Plate-Large Pistol

56 095314 OPT Case Feed Plate-Small Rifle

57 0 95316 OPT Case Feed Plate-Large Rifle

58 059100 OPT AP Press

59 398346 1 10-24 x 1/2 SHCS

60 398293 1 V-Block #1

61 398297 1 V-Block #2

62 398294 1 V-Block #3

63 398292 1 V-Block #4

64 398295 1 V-Block # 5

65 398296 1 V-Block #6

66 398324 1 Plastic Feed Tube Small Bushing

67 390651 2 3/16" Flat Washer SAE

68 398362 1 10-24 x 5/16 B HSCS

69 398 370 1 Case Feed Bowl Bushing

70 398388 2 1/4-20 x 150 SHCS

71 398416 1 O-Ring 7/8 OD, 11/16 ID

72 398550 6 Rivet Poly Black

73 398302 OPT Intermediate Drop Tube

Part No. Qty. Description

Lock-N-Load® AP Case Feeder

Chart 5: Bill of Materials

(“*” Sold Separately) (“Italics” Pre Assembled)

OPT = Optional Accessory Sold Separately

- 30 -

Page 31

EXPLODED VIEW: LOCK-N-LOAD® AP CASE FEEDER

- 31 -

Lock-N-Load® AP Case Feeder

Page 32

OVERVIEW ON LOCK-N-LOAD

®

AUTO PROGRESSIVE (AP) CASE FEEDER

Your new AP Case Feeder has been packaged to insure minimal

vibration and damage during transportation.

Remove all the parts from the packing box and spread them out over

a large flat surface. Refer to the parts list on pages 26-27 to make

sure all necessary parts are identified.

The manual provides step-by-step instructions and suggestions that

make set-up and operation easy and understandable.

•Remember, everything is designed and machined to fit easily

together without modification. If you find that it is necessary

to force parts together, stop and check the instructions and

illustrations we have provided.

List of needed hand tools:

•3/8" wrench

•7/16" wrench

•9 /16" wrench

•1/8" Allen wrench

•5/32" Allen wrench

•3/16" Allen wrench

•Pliers or vise grips

•Small hammer

Lock-N-Load® AP Case Feeder

- 32 -

Page 33

INSTRUCTIONS ON LOCK-N-LOAD® AUTO PROGRESSIVE (AP) CASE FEEDER

Step 1: Mounting the Lock-N-Load® Auto Progressive with Case Feeder

Figure 1: AP with main bracket

•Your work area should be well lit and have plenty of room for your reloading accessories. Your Hornady Lock-N-Load AP should

be mounted securely to the edge of a solid level bench approximately 2 ¼" from the center of holes to the front edge of the

table when using the optional case feeder.

•While facing the bench and using the Main Bracket (#42) for a pattern, mark and drill the mounting holes. Mount the press

using (2) 5/16" bolts that are long enough to secure the press to the bench with plenty of clearance for the nuts. (Due to

variations of benches we have chosen to not provide these items.) We also recommend using 5/16" flat washers at both ends

of the bolts with lock washers on the bottom side. Washers are required on the two mounting bolts if using the case feeder

system.

•Place the Main Bracket (#42) on the bench and verify that the mounting holes line up with the holes. Place the Bracket on

the underside of the Press Frame. Place one of the 5/16" bolts through the mounting hole from the top. Place the unit on the

bench, and run the bolt down through the appropriate hole and secure it to the bench with a nut and washer assembly (finger

tight is good for now). Align the second hole, and using the second bolt, secure it to the bench. Check that the linkage of the

press is free to operate and that no part of the bench interferes. If everything is proper, tighten the nuts on the bolts to finish

securing the press and mounting plate to the bench.

See Figure 1 for details.

- 33 -

Lock-N-Load® AP Case Feeder

Page 34

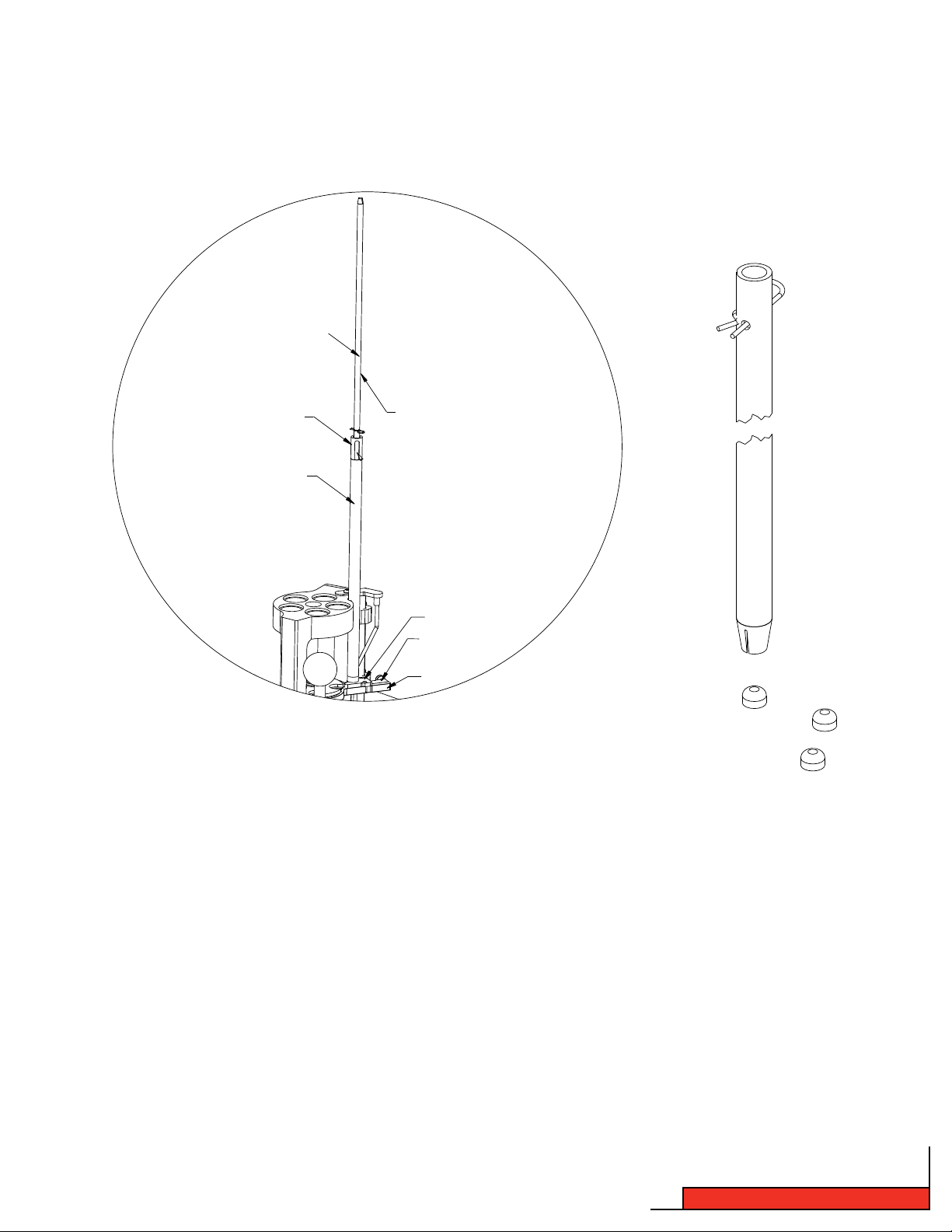

Step 2: Changing the Sub-Plate.

(This step is necessary only if you are installing the case feeder to an existing press, with a serial number lower than

07000.) The new Sub-Plate (Part Number 398309) is sold separately. The new priming system (Part Number 095210) is

also sold separately for presses with serial number prior to 07000.

•Raise the Eject Wire (E46) to move it out of the way.

•Use a 9/16" end wrench to remove the bolt holding down the shell plate and remove the shell plate.

•Remove the case retainer spring.

•Remove the primer feed assembly.

•Unhook the extension spring from the primer slide and remove it from the Sub-Plate (#44).

•Remove the primer slide from the Sub-Plate.

•Place the spent primer assembly tool in the bottom of the spent primer tube. Take a pair of pliers or vise grips and clamp

onto the spent primer tube approximately ¼" from the end and tap the pliers with a hammer to remove the spent primer

tube. Be careful not to lose the Counter Balance spring.

See Figure 2 for more details.

•Raise the ram to the top of the stroke and “Block” it into place

•The Ram can be blocked into place by inserting the handle of a medium sized screw driver between the “Toggle” and the

“Yoke” near the pawls. Be careful not to put extreme pressure on the Index wheel as you may damage it.

•Use a 5/32" Allen wrench to remove the two screws that secure the Sub-Plate onto the ram.

•Remove the “Block” and lower the ram and remove the “Sub-Plate”.

•Install the new “Sub-Plate”, raise the ram and replace the “Block” before installing the screws and tightening them very

tight. (Be careful not to strip the socket or damage the threads.)

•Once again, remove the “Block”, lower the ram and replace all parts in the reverse order that you removed them.

The instructions thru Step 5 are for a Lock-N-Load Auto Progressive Frame without the new machined bosses on the frame,

serial # 07279 and later.

Lock-N-Load® AP Case Feeder

Figure 2: Spent primer tubes dismantle / assembly

- 34 -

Page 35

Step 3: Assemble the square tubing brackets (NOTE: #45 is used on pre 7000 serial number Lock-N-Load AP)

See Figure 3 for more details.

Figure 3: Square tubing bracket with set screws

•Lay the two Brackets (#45) in front of you along with two 5/16-18 x 5/8 Cup Set Screws (#35) and two 5/16-18 x 5/8 Cone

Point Set Screws (#36).

•Place one Cone Point Set Screw (#36) into the side of the Square Tubing Bracket (#45) until the point is just flush with the

inside surface of the Bracket.

•Place one (#35) Cup Set Screw in the back of the Bracket until the cup point is just flush with the inside of the Bracket.

•Repeat these steps for the second Bracket.

Step 4: Mounting the square tubing brackets on to the square tubing.

See Figure 4 for more details.

Figure 4: Square tubing brackets with square tubing.

•Place the ¼" Flat Washers (#48) on the ¼-20 x 1 ¼" Socket Head Cap Screw (SHCS) (#47).

•Place one SHCS thru the Square Tubing (#49) and into one of the Square Tubing Brackets (#45) as shown and tighten finger tight.

•Repeat for the second Bracket.

¼-20 1 ¼” Cap Screw (Full Size)

- 35 -

Lock-N-Load® AP Case Feeder

Page 36

Step 5: Assemble the square tubing and brackets to the frame of the AP Press. (For serial numbers pre 7000)

(This step is a preliminary adjustment and will be completed later in the assembly.)

See Figure 5 for more details.

Figure 5: Square tubing brackets to the frame

•While standing to the left side of the press (your left), hook the v-section of bracket to the rib on the corner of the frame.

•Rotate the square tubing with the brackets counter clockwise around the corner of the press. Make sure that the tube

rests on the tab of the mounting bracket.

•Tighten the two (Cone Point) set screws (#36) until about half of the angled point is past the corner of the rib on the

press.

•Tighten the two (Cup Point) set screws (#35) until the square tubing assembly is secure.

•Finish by tightening the screws (#47) on the Square tubing and bracket assembly.

•The back of the square tubing should be parallel to the back edge of the frame. If it is not, you will need to readjust it

using the set screws.

•The assembly can be rotated clockwise by loosening the Cone Point screws (#36) and tightening the Cup Points (#35)

and visa versa to rotate it counterclockwise. Complete the installation by tightening the Cup Point Set Screws (#35).

Lock-N-Load® AP Case Feeder

- 36 -

Page 37

Step 6: Assemble the square tubing to the frame of the AP Press.

(For serial numbers post 7000)

Figure 6: Square tubing to the frame

• Place the ¼" Flat Washers (#48) on the ¼-20 x 1 ¼" Socket Head Cap Screw (SHCS) (#47).

• Place one SHCS thru the Square Tubing (#49) and thread into the Frame.

• Repeat for the second Bracket.

• Tighten both screws down using a 3/16" Allen wrench.

¼-20 1 ¼” Cap Screw (Full Size)

Step 7: Adding the case slide on to the sub-plate.

See Figure 7b for more details.

Figure 7a: Case slide assembly

- 37 -

Lock-N-Load® AP Case Feeder

Page 38

•Whileholdingthecaseslide(#38)upsidedowninonehand,pullthecardboardpackagingrearwardtillthe

front edge bi-sects the foot at the front of the slide.

See Figure 7a for more details.

Figure 7b: Case slide and sub-plate assembly

•Turn the Case Slide (#38) right side up and start the slide onto the rail of the sub-plate. While holding the end of

the cardboard, push the slide onto the rail. You may need to push up on the bottom of the cardboard while you

are pushing it on the sub-plate.

•If now, or anytime in the future, the guide and spring come out of the slide, they can be assembled by placing

the spring in the relief of the slide and hooking the relief of the guide onto the end of the spring. Slide the guide

forward and compress the spring until the guide fits into the pocket. You may need to hold the guide and spring

into the Slide with your finger as you slide the assembly back onto the “Sub-Plate.”

Lock-N-Load® AP Case Feeder

- 38 -

Page 39

Step 8: Inserting the cam wire into the assembly.

See figure 8 for more details.

Figure 8: Assembly of cam wire

•Raise the ram to the top of the stroke.

•Screw one #10-32 Hex Nut (#41) onto the Cam Wire (#43) approximately 1" from the end.

•Place one of the #10 Flat Washers (#67) onto the Cam Wire (#43).

•From the bottom of the Sub-Plate (#44), slide the non-threaded end of the Cam Wire (#43) through the slot of the

Sub-Plate (#44) and through the Case Slide (#38).

•Place the threaded end of the Cam Wire through the hole of the tab on the Main Bracket (#42).

•Place the other Flat Washer (#67) and Hex Nut (#41) onto the bottom of the Cam Wire (#43) and tighten finger tight.

•Lower the ram.

- 39 -

Lock-N-Load® AP Case Feeder

Page 40

Step 9: Case escapement bracket assembly.

See Figure 9 for details.

Figure 9: Assembling Case escapement bracket on square tubing

•Put a ¼" Flat Washer (#48) on the ¼-20 X 1 ½" Cap Screw (#70).

•Place the Cap Screw (#70) thru the Square Tubing and thread the Hex Nut (#26) the length of the nut.

•Slip the Case Escapement Body (#29) over the Cap Screw so the Hex Nut (#26) is in the slot on the back of the Case

Escapement Body. (#29)

•Slip the Cam Wire (#43) into the Cam Wire Support (#31).

•Tighten the Cap Screw (#70) while holding the Bracket level with the top of the frame.

¼-20 x 1 ½" Cap Screw (Full Size)

Lock-N-Load® AP Case Feeder

- 40 -

Page 41

Step 10: Feed Tube Mounting Bracket to the square tubing.

See Figure 10 for more details.

Figure 10: Feed Tube Mounting Bracket with square tubing

•Put a ¼" Flat Washer (#48) on a ¼-20 X 1 ½" Cap Screw (#70).

•Place the Cap Screw (#70) thru the Square Tubing and place the Feed Tube Mounting Bracket (#16) over the Cap Screw

(#70), then insert the Hex Nut (#26) on the Cap Screw and tighten. Be certain that the top of the Feed Tube Mounting

Bracket (#16) is level. A small level may be used to check it, if you desire, but should appear level to the eye.

¼-20 x 1 ½" Cap Screw (Full Size)

- 41 -

Lock-N-Load® AP Case Feeder

Page 42

Step 11: Determine which cartridge case you are going to be loading.

Chart 1: Cartridge Case change over chart.

Cases Item Numbers Required Pg. 22 Notes

Small Pistol (9 mm, 40 S&W, etc.) 14, 50, 52, 53, 66 Cases smaller than .43" maximum diameters

Large Pistol (.357 Mag., .44 Mag, etc.) 13, 15, 22 Cases larger than .43" maximum diameters

Small Rifle (.223, 22 Hornet) 14, 18, 50, 51, 52, 53, 66 Cases smaller than .43" maximum diameters

Large Rifle (243 Win., 45-70 Govt., etc.) 13, 15, 18, 22 Cases larger than .43" maximum diameters

If you find that some cases such as the 40 S&W are tight in the Feed Tube – Small (#14), you may need to use the part

of both the large and small feed tubes. For example, 40 S&W could use item numbers 13, 15, 19 and 53.

See figure 11 for more details on selecting the V-Block.

Lock-N-Load® AP Case Feeder

Figure 11: V-Block selection chart

- 42 -

Page 43

Step 12: Installing the V-Block onto the case slide.

Figure 12: Inserting the V-block

•With the ram at the bottom of the stroke (idle position), set the V-Block (item #60-#65) onto the Case Slide (#38).

•Place the #10-24 X 1/2 Cap Screw (#59) through the hole of the V-Block and screw it into the Case Slide. Before you