Page 1

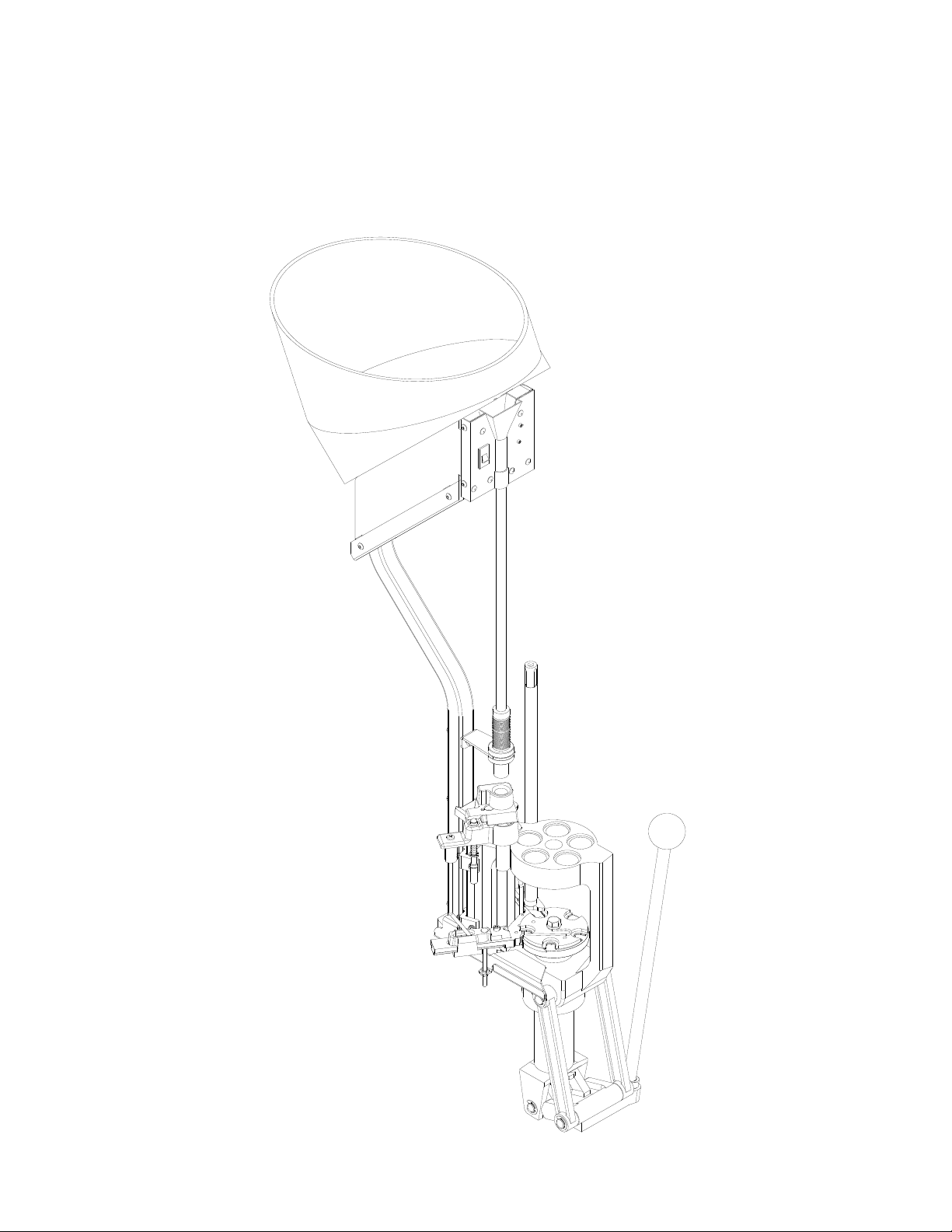

Lock-N-Load

Auto Progressive

Case Feeder

OPERATION MANUAL

Page 2

Table of Contents

Steps Page

Overview.....................................................................................................................4

List of required hand tools..........................................................................................4

1: Mounting the Lock-N-Load Auto Progressive with Case Feeder ........................5

2: Changing the sub-plate ..........................................................................................6

3: Assemble the square tubing brackets.....................................................................8

4: Placing the square tubing brackets onto the square tubing....................................9

5: Assemble the square tubing and brackets to the frame of the AP Press................10

6: Assemble the square tubing to the frame of the AP Press.....................................11

7: Adding the case slide onto the sub-plate ...............................................................12

8: Inserting the cam wire into the assembly...............................................................14

9: Case escapement bracket assembly .......................................................................15

10: Mounting the Feed tube bracket to the square tubing..........................................16

11: Determine which caliber you are going to be loading.........................................17

12: Installing the V-block to the case slide................................................................18

13: Changing and installing the shell plate.................................................................19

14: Set the timing of the cam wire.............................................................................20

15: Assembling the feed tube end and pivot..............................................................22

16: Placing the feed tube end on the assembly..........................................................23

17: Selecting the case feed plate for your application ...............................................24

18: Adjusting the push rod.........................................................................................26

Single case operation ..................................................................................................26

Fail-safe mechanism ...................................................................................................26

Maintenance of the Lock-N-Load A/P Case Feeder...................................................27

Trouble free operation.................................................................................................27

List of Illustrations

Figures

1. AP with main bracket.............................................................................................5

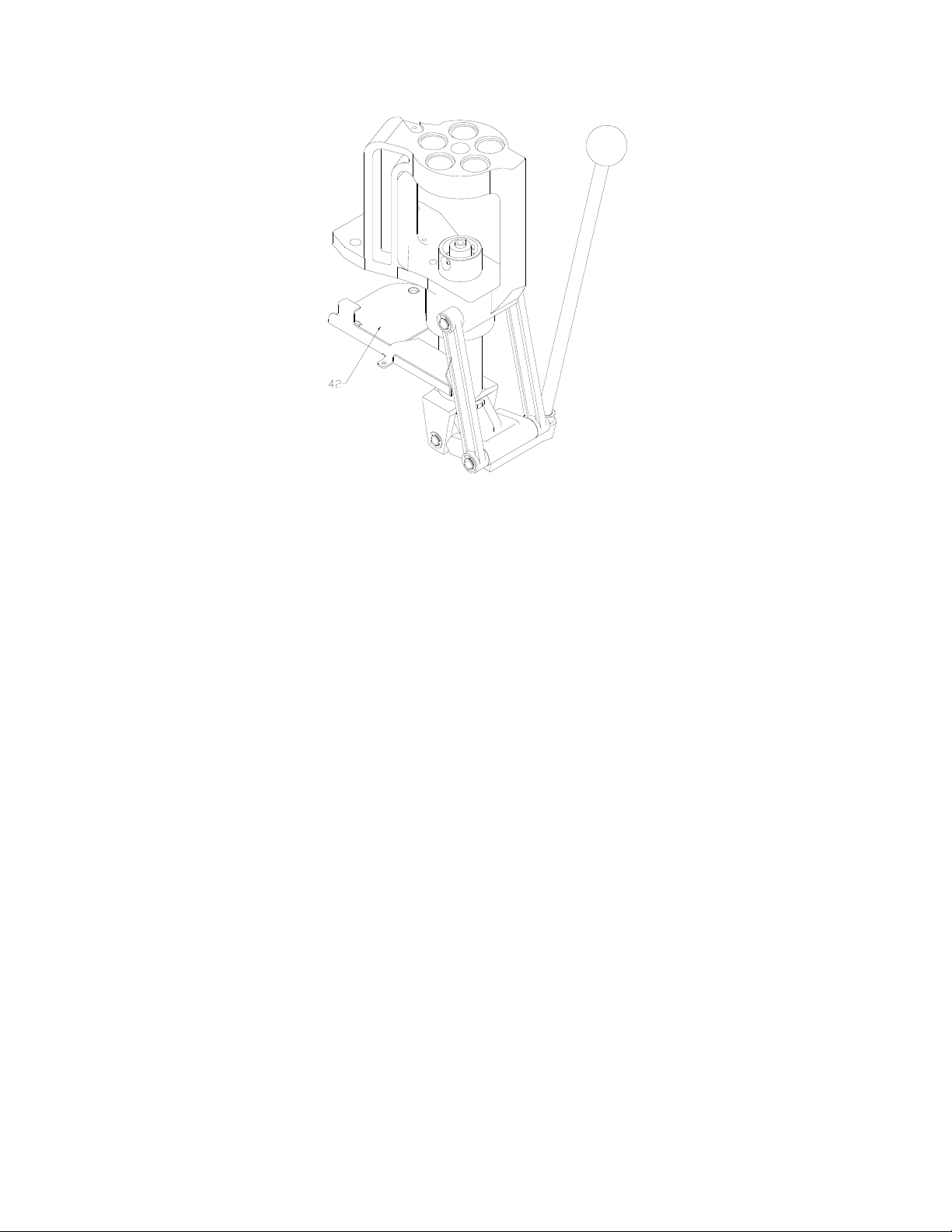

2. Spent primer tube dismantle/assembly..................................................................6

3. Square tubing brackets with set screws .................................................................8

4. Square tubing brackets with square tubing............................................................9

5. Square tubing brackets to AP Frame .....................................................................10

6. Square tubing to AP Frame....................................................................................11

7a. Case slide assembly...............................................................................................12

7b. Case slide and sub-plate assembly........................................................................12

8. Assembly of cam wire ...........................................................................................14

9. Assembling case escapement bracket on square tubing .......................................15

10. Feed tube mounting bracket to square tubing......................................................16

11. V-block selection.................................................................................................17

12. Inserting the V-block ...........................................................................................18

13. Adjusting the V-block..........................................................................................20

14. Feeding a case......................................................................................................20

15. Cam rod adjustment.............................................................................................21

16. Pivot assembly.....................................................................................................22

17a. Setting the feed tube end (most cases) ...............................................................23

17b. Setting the feed tube end (357 Mag., etc.)..........................................................23

18. Case feed bowl door adjustment..........................................................................25

19. Push rod adjustment.............................................................................................26

2

Page 3

Table of Contents Cont.

Charts

1. Caliber change over chart ......................................................................................17

2. Shell plate selection chart ......................................................................................19

3. Case feed wheel selection chart.............................................................................24

4. Trouble free operation............................................................................................27

5. Bill of Materials.....................................................................................................28

6. Exploded view .......................................................................................................29

3

Page 4

Hornady

Lock-N-Load Auto Progressive

Your new AP Case Feeder has been packaged to insure minimal shifting and damage

during transportation.

Remove all the parts from the shipping box and spread them out over a large flat surface.

Refer to the parts list on pages 28-29 to make sure all necessary parts are identified.

The manual provides step-by-step instructions and suggestions that make set-up and

operation easy and understandable.

• Remember, everything is designed and machined to fit easily together without

modification. If you find that it is necessary to force parts together, stop and

check the instructions and illustrations we have provided.

List of needed hand tools:

• 3/8” wrench

• 7/16” wrench

• 9/16” wrench

• 1/8” Allen wrench

• 5/32” Allen wrench

• 3/16” Allen wrench

• Pliers or vise grips

• Small hammer

4

Page 5

Step 1: Mounting the Lock-N-Load Auto Progressive with Case Feeder

Figure 1: AP with main bracket.

• Your work area should be well lit and have plenty of room for your reloading

accessories. Your Hornady Lock-N-Load AP should be mounted securely to the

edge of a solid level bench approximately 2 ¼” from the center of holes to the front

edge of the table when using the optional case feeder.

• While facing the bench and using the Main Bracket (#42) for a pattern, mark and

drill the mounting holes. Mount the press using (2) 5/16” bolts that are long enough

to secure the press to the bench with plenty of clearance for the nuts. (Due to

variations of benches we have chosen to not provide these items) We also

recommend using 5/16” flat washers at both ends of the bolts with lock washers on

the bottom side of the table. Washers are required on the two mounting bolts when

using the case feeder system.

• Place the Main Bracket (#42) on the bench and verify that the mounting holes line

up with the holes. Place the Bracket on the underside of the Press Frame. Place one

of the 5/16 bolts through the mounting hole from the top. Place the press and bracket

on the bench, and run the bolt down through the appropriate hole and secure it to the

bench with a nut and washer assembly (finger tight is good for now). Align the

second hole, and using the second bolt, secure it to the bench. Operate the press; to

make sure that the bench does not interfere with it’s operation. If everything is

functioning proper, tighten the nuts on the bolts to finish securing the press and

mounting plate to the bench.

See Figure 1 for details.

5

Page 6

Step 2: Changing the Sub-Plate.

(This step is necessary only if you are installing the case feeder to an existing

press, with a serial number lower than 07000.) The new Sub-Plate (Part

Number 398309) is sold separately. The new priming system (Part Number

095210) is also sold separately for presses with serial # prior to 07000.

• Raise the Eject Wire (#46) to move it out of the way.

• Use a 9/16” end wrench to remove the bolt holding down the shell plate and

remove the shell plate.

• Remove the case retainer spring.

• Remove the primer feed assembly.

• Unhook the extension spring from the primer slide and remove it from the Sub-

Plate (#44).

• Remove the primer slide from the Sub-Plate.

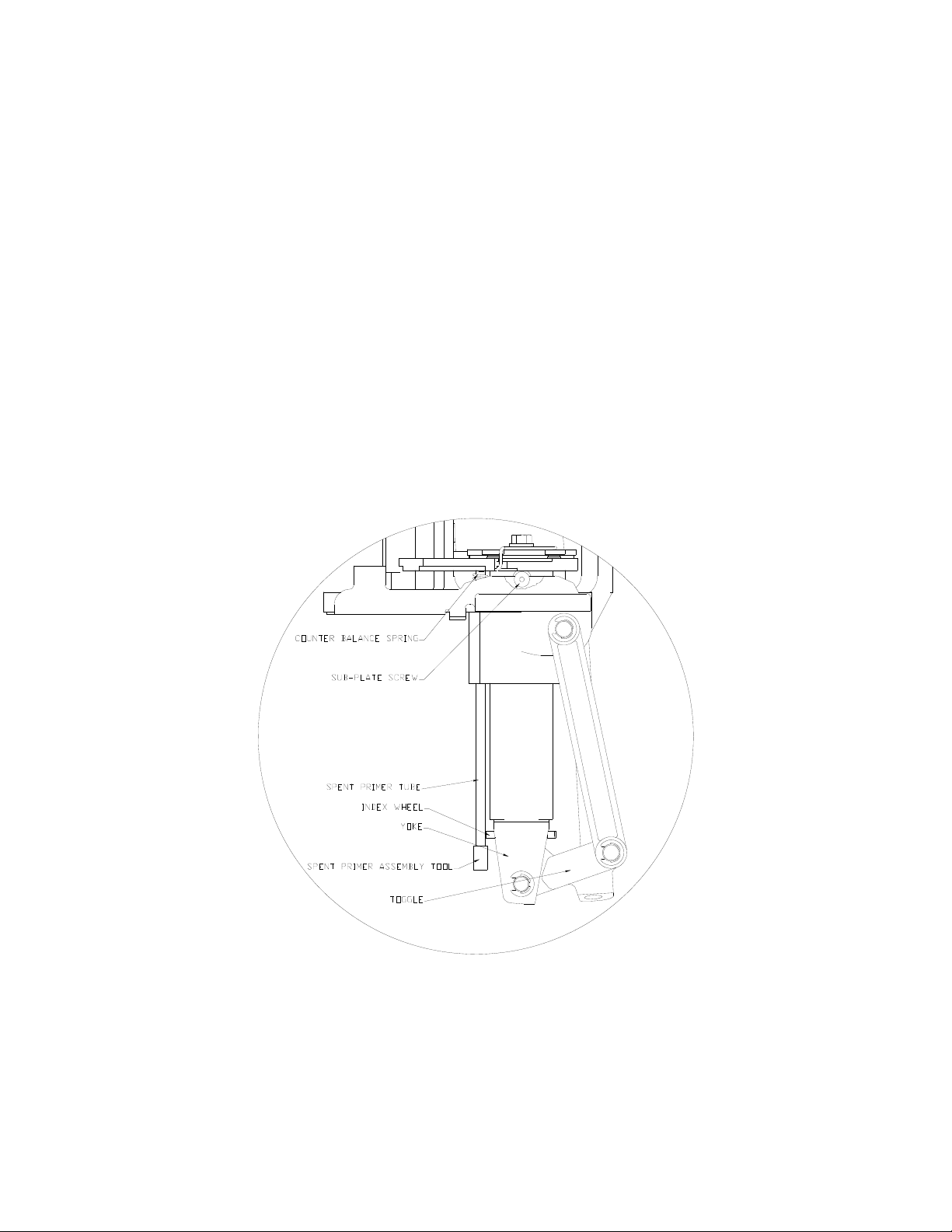

Figure 2: Spent primer tubes dismantle / assembly.

• Place the spent primer assembly tool in the bottom of the spent primer tube. Take

a pair of pliers or vise grips and clamp onto the spent primer tube approximately

¼” from the end and tap the pliers with a hammer to remove the spent primer

tube. Be careful not to lose the Counter Balance spring.

See Figure 2 for more details.

• Raise the ram to the top of the stroke and “Block” it into place

6

Page 7

• The Ram can be blocked into place by inserting the handle of a medium sized

screw driver between the “Toggle” and the “Yoke” near the pawls. Be careful not

to put extreme pressure on the Index wheel as you may damage it.

• Use a 5/32” Allen wrench to remove the two screws that secure the Sub-Plate

onto the ram.

• Remove the “Block” and lower the ram and remove the “Sub-Plate”.

• Install the new “Sub-Plate”, raise the ram and replace the “Block” before

installing the screws and tightening them very tight. (Be careful not to strip the

socket or damage the threads.)

• Once again, remove the “Block”, lower the ram and replace all parts in the reverse

order that you removed them.

The instructions thru Step 5 are for a Lock-N-Load Auto Progressive Frame without

the new machined bosses on the frame, serial # 07279 and later.

7

Page 8

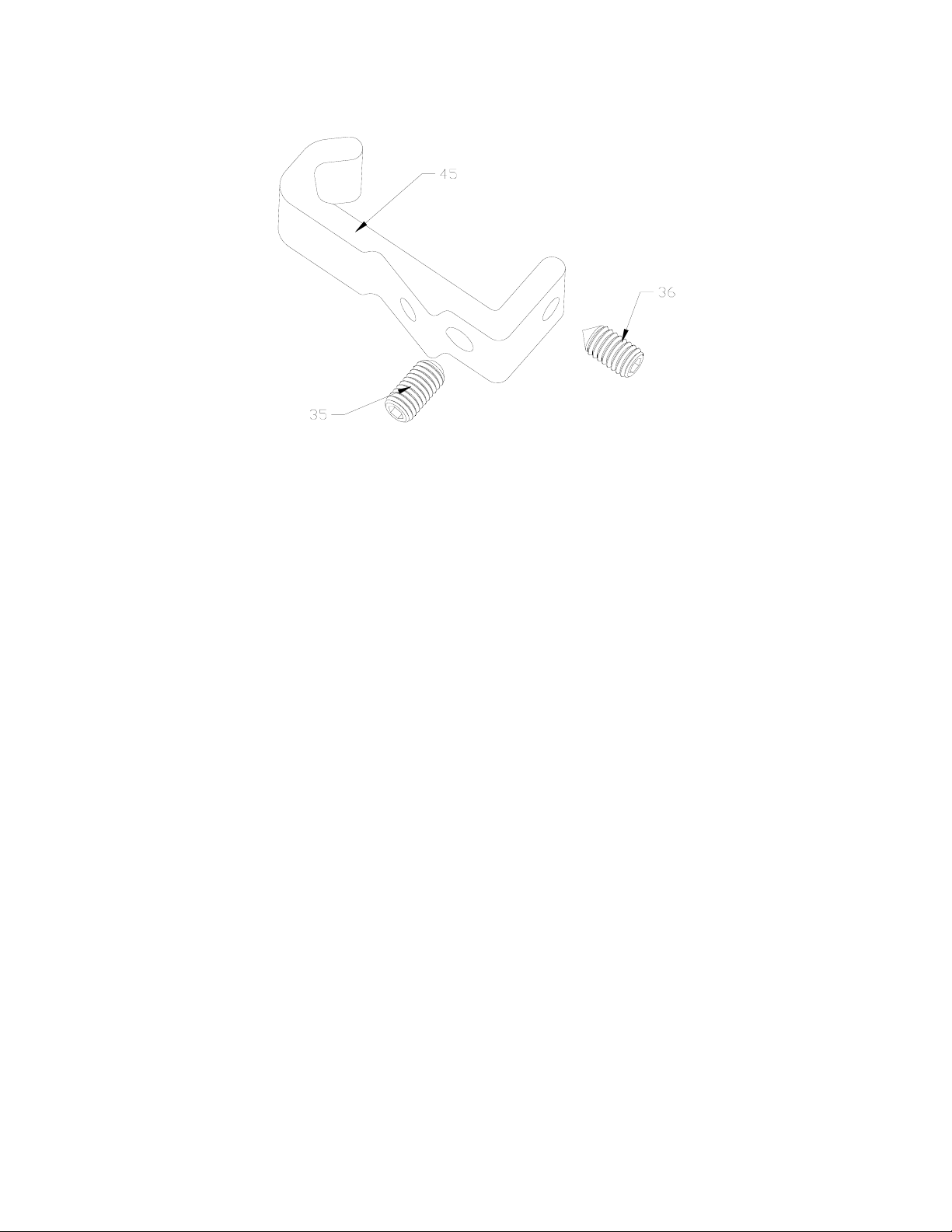

Step 3: Assemble the square tubing brackets.

See Figure 3 for more details.

Figure 3: Square tubing bracket with set screws.

• Lay the two Brackets (#45) in front of you along with two 5/16-18 x 5/8 Cup Set

Screws (#35) and two 5/16-18 x 5/8 Cone Point Set Screws (#36).

• Place one Cone Point Set Screw (#36) into the side of the Square Tubing Bracket

(#45) until the point is just flush with the inside surface of the Bracket.

• Place one (#35) Cup Set Screw in the back of the Bracket until the cup point is

just flush with the inside of the Bracket.

• Repeat these steps for the second Bracket.

8

Page 9

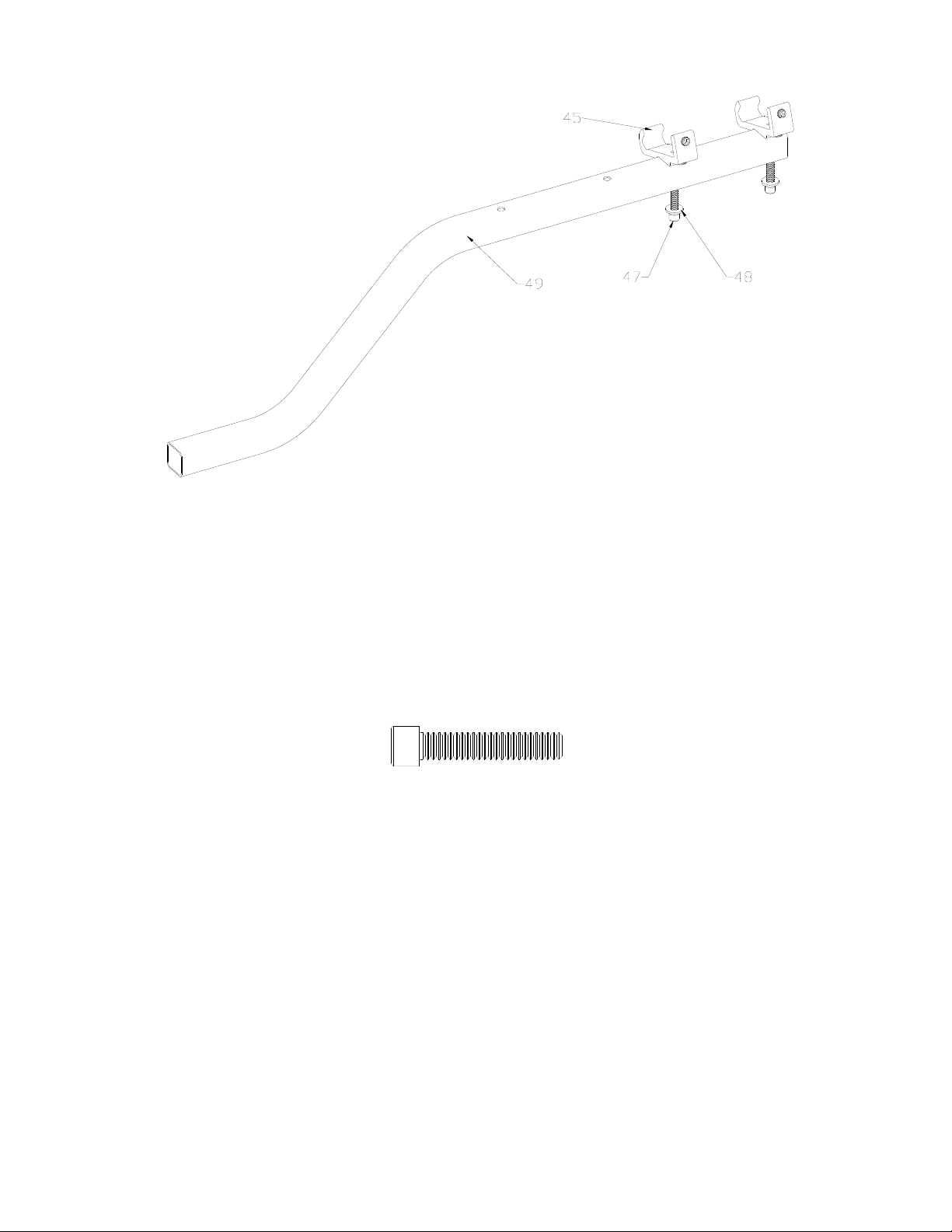

Step 4: Mounting the square tubing brackets on to the square tubing.

See Figure 4 for more details.

Figure 4: Square tubing brackets with square tubing.

• Place the ¼” Flat Washers (#48) on the ¼-20 x 1 ¼” Socket Head Cap Screw

(SHCS) (#47).

• Place one SHCS thru the Square Tubing (#49) and into one of the Square Tubing

Brackets (#45) as shown and tighten finger tight.

• Repeat for the second Bracket.

¼-20 1 ¼” Cap Screw (Full Size)

9

Page 10

Step 5: Assemble the square tubing and brackets to the frame of the AP Press.

(This step is a preliminary adjustment and will be completed later in the assembly.)

See Figure 5 for more details.

Figure 5: Square tubing brackets to the frame.

• While standing to the left side of the press, (your left), hook the v-section of

bracket to the rib on the corner of the frame.

• Rotate the square tubing with the brackets counter clockwise (CCW) around

the corner of the press. Make sure that the tube rests on the tab of the

mounting bracket.

• Tighten the two (Cone Point) set screws (#36) until about half of the angled

point is past the corner of the rib on the press.

• Tighten the two (Cup Point) set screws (#35) until the square tubing assembly

is secure.

• Finish by tightening the screws (#47) on the Square tubing and bracket

assembly.

• The back of the square tubing should be parallel to the back edge of the frame.

If it is not, you will need to readjust it using the set screws.

• The assembly can be rotated clockwise by loosening the Cone Point screws

(#36) and tightening the Cup Points (#35), and visa versa to rotate it Counter

Clockwise. Complete the installation by tightening the Cup Point Set Screws

(#35).

10

Page 11

Step 6: Assemble the square tubing to the frame of the AP Press.

(For serial numbers beyond 07279.)

Figure 6: Square tubing to the frame.

• Place the ¼” Flat Washers (#48) on the ¼-20 x 1 ¼” Socket Head Cap Screw

(SHCS) (#47).

• Place one SHCS thru the Square Tubing (#49) and thread into the Frame.

• Repeat for the second Bracket.

• Tighten both screws down using a 3/16” Allen wrench.

¼-20 1 ¼” Cap Screw (Full Size)

11

Page 12

Step 7: Adding the case slide on to the sub-plate.

See Figure 7b for more details.

Figure 7a: Case slide assembly.

• While holding the case slide (#38) upside down in one hand, pull the

cardboard packaging rearward till the front edge bi-sects the foot at the front

of the slide.

See Figure 7a for more details.

Figure 7b: Case slide and sub-plate assembly.

• Turn the Case Slide (#38) right side up and start the slide onto the rail of the

sub-plate. While holding the end of the cardboard, push the slide onto the rail.

You may need to push up on the bottom of the cardboard while you are

pushing it on the sub-plate.

12

Page 13

• If now or anytime in the future the guide and spring come out of the slide,

they can be assembled by placing the spring in the relief of the slide and

hooking the relief of the guide onto the end of the spring. Slide the guide

forward and compress the spring until the guide fits into the pocket. You may

need to hold the “guide and spring” into the Slide with your finger as you

slide the assembly back onto the “Sub-Plate.”

13

Page 14

Step 8: Inserting the cam wire into the assembly.

See figure 8 for more details.

Figure 8: Assembly of cam wire.

• Raise the ram to the top of the stroke.

• Screw one #10-32 Hex Nut (#41) on to the Cam Wire (#43) approximately 1”

from the end.

• Place one of the #10 Flat Washers (#67) onto the Cam Wire (#43).

• From the bottom of the Sub-Plate (#44), slide the non threaded end of the

Cam Wire (#43) through the slot of the Sub-Plate (#44) and through the Case

Slide (#38).

• Insert the threaded end of the Cam Wire through the hole of the tab on the

Main Bracket (#42).

• Insert the other Flat Washer (#67) and Hex Nut (#41) onto the bottom of the

Cam Wire (#43) and tighten finger tight.

• Lower the ram.

14

Page 15

Step 9: Case escapement bracket assembly.

See Figure 9 for details.

Figure 9: Assembling Case escapement bracket on square tubing.

• Put a ¼” Flat Washer (#48) on the ¼-20 X 1 ½” Cap Screw (#70).

• Slide the Cap Screw (#70) thru the Square Tubing and thread the Hex Nut (#26),

on approximately the length of the nut.

• Slip the Case Escapement Body (#29) over the Cap Screw so the Hex Nut (#26) is

in the slot on the back of the Case Escapement Body. (#29)

• Slip the Cam Wire (#43) into the Cam Wire Support (#31).

• Tighten the Cap Screw (#70) while holding the Bracket level with the top of the

frame.

¼-20 x 1 ½” Cap Screw (Full Size)

15

Page 16

Step 10: Feed Tube Mounting Bracket to the square tubing.

See Figure 10 for more details.

Figure 10: Feed Tube Mounting Bracket with square tubing.

• Put a ¼” Flat Washer (#48) on a ¼-20 X 1 ½” Cap Screw (#70).

• Slide the Cap Screw (#70) thru the Square Tubing and place the Feed Tube

Mounting Bracket (#16) over the Cap Screw (#70), then insert the Hex Nut (#26)

on the Cap Screw and tighten. Make sure that the top of the Feed Tube Mounting

Bracket (#16) is level. Check with a small level if you are unsure.

¼-20 x 1 ½” Cap Screw (Full Size)

16

Page 17

Step 11: Determine which cartridge case you are going to be loading.

Chart 1 below shows what parts are needed for different size of cases.

Cases Item #'s Required Pg. 28 & 29 Notes

Small Pistol (9mm, 40 S&W, etc..)

Large Pistol (.357 Mag., .44 Mag, etc..)

Small Rifle (.223, 22 Hornet)

Large Rifle (243 Win., 45-70 Govt., etc..)

66,14,50,52,53 Cases smaller than .43" maximum diameters

13,15,22 Cases larger than .43" maximum diameters

66,14,50,18,51,52,53 Cases smaller than .43" maximum diameters

13,15,18,22 Cases larger than .43" maximum diameters

Chart 1: Cartridge Case change over chart.

If you find that some cases such as the 40 S&W are tight in the Feed Tube –Small (#14),

you may need to use the part of both the large and small feed tubes. For example, 40

S&W could use item numbers 13, 15, 19 and 53.

See figure 11 for more details on selecting the V-Block.

CASES DIAMETERS "X"V-BLOCK #V-BLOCKS P/N:

22 Hornet .27-.30 1 398292

9mm, .223 .37-.39 2 398293

44 Mag. .35-.38 3 398294

30-06 .42-.47 4 398295

458 Win. Mag. .46-.58 5 398296

10mm .41-.44 6 398297

Figure 11: V-Block selection chart.

17

Page 18

Step 12: Installing the V-Block onto the case slide.

Figure 12: Inserting the V-block.

• With the ram at the bottom of the stroke (idle position), set the V-Block (item

#60-#65) onto the Case Slide (#38).

• Place the #10-24 X 1/2 Cap Screw (#59) through the hole of the V-Block and

screw it into the Case Slide. Before you tighten the Cap Screw, push the V-Block

back into the Case Slide and snug the Cap Screw with your fingers.

18

Page 19

Step 13: Determine which shell plate is required for your application.

See Chart 2 below to help with this selection.

SHELL PLATE NO. 1

Item No. 392601

5.6x57 9.3x62

22/250 44 Auto Mag.

240 Wby. 45 ACP/WM 257 Wby. 6.5 Rem. Mag. 218 Bee 460 Wby. 30 M1 Carbine

243 Win. 260 Rem. 264 Win. Mag. 25/20 Win. 45/70 Govt. 32 ACP

244/6MM 270 Wby. 32/20 Win. 416 Wby.

6MM int.

6MM/284

6MM Br 219 Zi pper 300 H&H

250 Sav. 5.6x52R 300 Win. Mag. 30 Luger

25/06 22 Sav. HP 300 Wby. 9MM Luger 376 Steyr

257 Rbts. 25/35 Win. 300 Re. UI. Mag. 9x18 Makarov

25/284 30/30 Win. 308 Norma Mag. 38 Super Auto

6.5/06 30 Herrett 8MM Rem. Mag. 9x23

6.5 x 57 32 Win. Spl. 338 Win. Mag. 17 Rem.

270 Win. 8.15x46 R 340 Wby.

7x57 (7MM mau.) 357 Herrett 350 Rem. Mag.

7MM/08 375 Win. 358 Norma Mag. 38/40 Win. 221 Rem. 8x68 S

7MM Rem. BR 7x30 Waters 375 H&H 44/40 Win. 222 Rem. 7.5 Swiss 500 S&W

7x64 32/40 416 Rem. Mag. 222 Rem. Mag. 357/44 B&D

7MM Exp/280 458 Win.

284 Win.

300 Sav.

308 Win. 22 Hornet

30/06 22-K Hornet

7.7 Jap. 22 PPC

8MM Mau.

8MM /06

8x60 S 220 Swift 6MM PPC 30/40 Krag 380 Auto

35 Whelen 225 Winchester 7.62x39 6MM TCU 6x61 S&H

358 Win. 7MM Merrill 38/357/357 Max.

9.3x57

SHELL PLATE NO. 5 SHELL PLATE NO. 7

Item No. 392605 Item No. 392607

SHELL PLATE NO. 2

Item No. 392602

SHELL PLATE NO. 3

Item No. 392603

SHELL PLATE NO. 4

Item No. 392304

7MM Rem. Mag. 480/475 Linebaugh

7MM Wby.

450 Marlin

SHELL PLATE NO. 6

Item No. 392606

22 RCFM-Jet

256 Win. 303 British 7x47 Helm

SHELL PLATE NO. 8 Item No. 392626

Item No. 392608 SHELL PLATE NO. 15

SHELL PLATE NO. 9

Item No. 392609

SHELL PLATE NO. 10

Item No. 392610

10MM Auto 6MM/223

40 S&W 6x47 Rem.

SHELL PLATE NO. 11

Item No. 392611

SHELL PLATE NO. 14

Item No. 392614 Item No. 392636

33 Win.

338/378 Wby.

Item No. 392615 Item No. 392641

SHELL PLATE NO. 16

Item No. 392616 Item No. 392643

17/222

17/223 6.5x68

5.6x50 Mag. 44 Spl./44 Mag.

223 Rem.

6.5MM TCU 45 Long colt

7MM TCU 454 Casull

7MM/223 Ingram

204 Ruger

SHELL PLATE NO. 22

Item No. 392622

SHELL PLATE NO. 26

35 Remington

SHELL PLATE NO. 29

Item No. 392629

41 Mag.

SHELL PLATE NO. 30

Item No. 392630

SHELL PLATE NO. 32

Item No. 392632

SHELL PLATE NO. 35

Item No. 392635

SHELL PLATE NO. 36

32 S&W Long/Short/H&R

300 Win. Short Mag

SHELL PLATE NO. 40

Item No. 392640

50 AE

SHELL PLATE NO. 41

45 Schofeild

SHELL PLATE NO. 43

338 Lapua

SHELL PLATE NO. 44

Item No. 392644

Chart 2: Shell Plate selection chart.

Changing and installing the shell plate.

(Refer to the operations manual for the AP Press.)

19

Page 20

Step 14: Setting the timing of the cam wire.

Figure 13: Adjusting the V-block.

• Place a case of the proper size into the shell plate and manually push the Case

Slide (#38) and V-Block into the case. Loosen the Cap Screw (#59) and

continue to push the Case Slide into the case. Tighten the Cap Screw (#59)

with a 3/16” allen wrench.

See Figure 13 for more details.

Figure 14: Feeding a case.

• Raise the ram until the shell plate rotates and place a case (of the proper size)

in-front of the V-Block on the Sub-Plate. Lower the ram so the Case Slide

will advance the case into the shell plate.

20

Page 21

See Figure 13 for more details.

Figure 15: Cam rod adjustment.

If the “Cam Wire” is too high, it will:

1. Not allow the “Shell Plate” to advance. Loosen the upper nut several turns and

pull the wire down.

2. The case will hit the “Shell Plate” before it rotates. Again, loosen the upper nut

and move the wire down, but do this in small increments, as you are close.

If the wire is to low, it will:

1. Not advance the case into the shell plate. Loosen the Lower nut and tighten the

upper one to move the cam down.

Once the timing is correct, snug both nuts to the bracket and make sure the cam is

centered in the Slide. This can be adjusted manually by rotating it around the threaded

end a small amount. Tighten the nuts to complete the timing process. This timing setting

is adequate for all cartridges, and it should not be necessary to make future changes.

21

Page 22

Step 15: Assembling the feed tube end and pivot.

See Figure 15 for more details.

Figure 16: Pivot Assembly.

• If the maximum case diameter is larger than .43 you will need to use the large

tube (#22). If it is smaller, you will need the small tube (#53). Place the correct

one into the pivot block (#29).

• Place the torsion spring (#23) into the slot in the pivot block (#29), leaving the

long leg on the top side. The spring will only fit one way.

• Set the pivot (#19) on top of the pivot block. Make sure you line up the under cut

on the cam with the torsion spring. The leg of the torsion spring will fit into the

slot on the cam.

• When this fits together the pivot should fit on top of the pivot block. The dowel

pin in the cam will fit into the curved slot on the cam block.

• Then insert the shoulder bolt (#20) into the pivot and into the pivot block and

tighten with an allen wrench.

• Actuate the pivot by hand to make sure it will rotate properly.

• For small rifle cases place the pivot adapter bushing (#51) into the hole of the

pivot adapter. See pg. 25 for more details.

• Place the pivot adapter (#18) on top of the pivot for rifle cases (See pg. 25 for

more details).

22

Page 23

Step 16: Placing the Feed tube end on the assembly.

17a. 17b.

Figure 17: Setting the Feed tube end.

• Select the tube for your application (#15 or #50), see pages 25 and 26.

• Screw one lock ring on the tube.

• Place it thru the hole on the feed tube mounting bracket. Adjust the height of the

tube to have approximately 1/16” below the bottom of the tube to the case mouth.

(See Figure 16a for more details.) With some cases such as the 357 Mag. it may

be necessary to adjust the tube to where the case mouth sits up inside of the tube

approximately 3/16”. (See Figure 16b for more details.) These are both starting

points, and for your particular case, it may need to be adjusted a little differently.

(Long skinny cases, which are shorter than 1.50” long will not work with the

Pivot Adapter (#18). They may need to be supported at the mouth of the case by

the Feed Tubes (#15 or #50). This will allow the case to feed down the Drop

Tubes (#22 or #53) with out falling over and causing double or triple feeds.

• Screw on the other lock ring.

• Select the proper “Feed Tube” (#13 or #14) and insert it in the top of the “Feed

Tube End” (#15 or #50). If you select The Small Feed Tube (#14), you will have

to use the Plastic Feed Tube Small Bushing (#66), see pages 25 and 26.

(When feeding some cases (such as the 357 Mag.) you may notice that the base of

the case will not fall into the hole of the pivot every-time. The base will ride on the

radius of the pivot hole. You can operate the press with the cases doing this and

when the push rod (#24) starts to rotate the cam, the case will fall into the hole).

23

Page 24

Step 17: Selecting the case feed wheel for your application.

See Chart 3 for more details.

Small Pistol

Case Feed

Wheel

P/N: 095310 P/N: 095312 P/N: 095314 P/N: 095316

9mm 10mm Auto 7.62 X 39 6mm Rem. .284 Win. .356 Win. .300 Rem . Saum

9 X 21 .357 Mag. .17 Rem. 6.5mm Rem. Mag. .30 Rem. .358 Win. .300 WSM

.38 Super .357 Rem. Max. .218 Bee 6.5 X 55 Swedish Mauser .30-06 Springfild .375 H&H Mag. .300 Dakota

9 X 18 Makarov .38 Long Colt .222 Rem. / Rem Mag. 7mm Mauser (7 X 57) .30-30 Win. .375 Win. .300 Rem. Ultra Mag.

9mm Win Mag .38 Short Colt .223 Rem (5.56mm) 7mm Rem. Mag. .30-40 Krag .38-55 W i n. .338 Rem. Ultra Mag.

.30 Luger .38 S&W .30 Carbine 7mm W BY Mag. .300 H&H Mag. .416 Rem. Mag. . 340 WBY Mag.

32 ACP . 38 S pl. .32-20 Win. 7mm-08 Rem . .300 Savage .416 Rigby .378 WBY Mag.

.32 H&R Mag .41 Rem. Mag. .351 Win Self Loading 7-30 Waters .300 WBY Mag. .444 Marlin .404 Jeffery

.32 Long Colt .44 Spl/Mag. .25-20 Win. 8mm Mauser (8 X 57) .300 Win. Mag. . 45-70 Govt. .460 WBY Mag.

.32 Short Colt .45 A CP 8mm Rem. Mag. .303 British .458 Win. Mag. 500 S&W

.32 S&W .45 Aut o Rim. .22-250 .303 Savage .458 Lott

.32 S&W Long . 45 Colt .220 Swift .307 Win. .450 Marlin

.380 Auto .45 Win. Mag. .225 Win. .308 Win. .376 Steyr

.22 Hornet .454 Casull .243 Win. .32 Rem. .405 Win.

40 S & W 9 X 25 .25-06 .32 Win. Spl. .240 WBY Mag.

Large Pistol

Case Feed

Wheel

.22 Rem. Jet .25-35 Win. .32-40 Win. .257 WBY Mag.

.256 Win. Mag. .250 Savage .338 Win. Mag. .270 WBY Mag.

.475 Linebaugh .257 Roberts .348 W i n. .270 WSM

.480 Ruger .264 Win. Mag. .35 Rem. 7mm Rem Saum

.38-40 Win. .270 Win. .35 Whelen 7mm STW

.44-40 Win. .280 Rem. .350 Rem. 7mm Rem. Ultra Mag.

Small Rifle Case

Feed Wheel

Large Rifle Case Feed

Wheel Large Rifle Cont. Large Rifle Cont. Large Rifle Cont.

Chart 3: Case feed wheel selection chart.

24

Page 25

Figure 18: Case feed bowl door adjustment.

• Select the Case Feed Plate (item #54-57) for your application and place it on the

motor shaft. The clutch on the plate will slip onto the motor shaft fitting flush to

the bottom of the Case Feed Bowl (#1).

• Place the O-Ring onto the Feed Tube Large (#13) approximately 2” from one end.

The O-Ring when pushed down on top of the Feed Tube End (#15) will hold the

feed tube into the funnel on the case feed bowl.

• Set the Case Feed Bowl (#1) on top of the Square Tubing (#49) while inserting

the Feed Tube (#13 or #14) into the Case Feed Funnel Assembly (#8) and plug it

into a power outlet.

• If you are loading rifle cartridges you will need to adjust the Case Feed Door

(#37).

• Loosen the ¼” Button Head Cap Screw (#68) and slide the Case Feed Door

Adjustment (#37) so the opening is approximately ¾ the length of the case. This

is a preliminary setting. Place a hand-full of cases into the Case Feed Bowl (#1).

• Turn the motor on and observe to see if the cases will fall base first. If they do

not, readjust the Case Feed Bowl Door Adjustment (#37) until they do with out

hanging up or getting caught.

• Re-tighten the ¼” Button Head Cap Screw (#68).

• To load pistol cases, completely open the Case Feed Door Adjustment.

See figure 17 for more details.

25

Page 26

Step 18: Adjusting the push rod.

Figure 19: Push Rod adjustment.

• Screw the Push Rod Nut (#33) and the Push Rod Lower (#34) onto the Push Rod

(#24) until the Push Rod Lower (#34) bottoms out on the thread.

• Place a case in the hole of the Pivot (#19) and the Escapement Height adjuster

(#18) (if required).

• Raise the ram to the top of the stroke slowly, so the Case Slide (#38) will actuate

the Push Rod (#24) and Pivot (#19). The Pivot (#19) should rotate far enough to

drop a case down the Feed tube (#13-14). If it does not, lower the ram just far

enough to take the pressure off of the Push rod (#24). Screw the Push Rod Lower

(#34) down a couple of turns and retry. When the Pivot (#19) is dropping a case

thru the Feed Tube, screw the Push Rod Nut (#33) down on top of the Push Rod

Lower (#34) and tighten with your fingers.

• If the case is falling on top of the V-Block, refer to step Step 5.

Single case operation

(To feed cases singly without using the case feeder.)

• Remove the Push Rod Lower (#34).

This will allow the press to be cycled without dropping cases.

Fail-safe mechanism

The Cam Wire (#43) has a fail-safe mechanism at its top (Cam Wire Support #31). The

Cam Wire Support (#31) holds the Cam Wire (#43) in place. If a malfunction occurs, the

Cam Wire (#43) is able to snap out of the support to prevent damage to the Cam Wire.

26

Page 27

Maintenance of the Lock-N-Load A/P Case Feeder

g

g

j

g

As with all equipment, proper and routine maintenance will provide smooth operation

and a longer life for your reloading press and Case Feeder. At the end of each reloading

session, wipe off all spilled powder, any dirt, etc., from the press. Check all moving parts

for dirt or spilled powder and remove with a clean rag.

Tips for trouble-Free operation

Problems Solutions Step

Cases are hitting the back corner

of the shell plate when feeding

into the shell plate.

Slow timing down or Readjust V-Block location 13

Cases are not feeding into the

shell plate far enou

h

Cases are tipping when going into

the shellplate

Cases are falling on top of the VBlock

Drop tube is tight against the AP

Frame; will not allow changing of

tubes

Cases are falling mout h first out

of the bowl

Cases are getting caught in the

open hole on the bowl

The shell plate is hitting the VBlock when it's rotatin

Chart 4: Trouble free operation.

Speed timing up or

Using the wrong V-Block 13

Re-adjust V-Block

location 13

Re-adjust the Bracket,

Square Tubing 5

Re-adjust the Bracket,

Square Tubin

5

Close the door

ad

ustment 16

Open the door

adjustment 16

Lower the Cam Wire 13

27

Page 28

Producti

Producti

Bill of Materials

on Part

Item No.

Number Qty.

1 398327 1 CASE FEED BOWL 37 398285 1 CASE FEED DOOR ADJUSTMENT

2 398313 4

3 398374 8

4 398415 8

5 398326 1 MOTOR HOUSING

6 398375 2

7 398333 1 MICRO SWITCH

8 398369 1

9 398376 1

10 398332 2

11 398331 1 MOTOR

12 398328 1 MOTOR COVER

13 398320 1 FEED TUBE - LARGE 49 398284 1 CASE FEED STAND

14 398321 1 FEED TUBE - SMALL 50 398304 1 FEED TUBE END - SMALL

15 398303 1 FEED TUBE END - LARGE 51 398300 1 PIVOT ADAPTER BUSHING

16 398286 1 FEED TUBE MOUNTING BRACKET 52 398301 1

17 396440 2 LOCK RING 53 398306 1 DROP TUBE - SMALL

18 398298 1 PIVOT ADAPTER 54* O95310 CASE FEED PLATE- SMALL PISTOL

19 398290 1 PIVOT 55* O95312 CASE FEED PLATE - LARGE PISTOL

20 398310 1 1/4-3/4 SHOULDER BOLT 56* O95314 CASE FEED PLATE - SMALL RIFLE

21 398311 1 3/0 X 3/4 TAPER PIN

22 398305 1 DROP TUBE - LARGE 58 O59100

23 398288 1 SPRING, TORSION 59 392338 1 10-24 X 1/2 SHCS

24 398317 1 PUSH ROD

25 398371 1

26 390178 2 1/4-20 HEX HEAD NUT 62 398294 1 V-BLOCK #3

27 398349 1 PUSH ROD BUSHING

28 398364 1

29 398344 1 PIVOT BODY

30 398363 1

31 398343 1 CAM WIRE SUPPORT

32 398425 1 E CLIP 1/4 68 390410 1

33 398373 1

34 398372 1

35 398314 2 5/16 -18 X 5/8 SET SCREW CUP 71 398416 1 O-RING 7/8 OD, 11/16 ID

36 398315 2 5/16 -18 X 5/8 SET SCREW CONE POINT (45 DEG.) 72 398550 6 RIVET POLY BLACK

10-32 x 3/4 FHSCS

10-24 "U" Nut

#8 x 1/2 SHEET METAL SCREW PAN HEAD PHILIPS

4-40 HEX HEAD LOCK NUT

CASE FEED FUNNEL ASSEMBLY

4-40 X 5/8 BHSCS

ROCKER SWITCH

PUSH ROD TIP

10 X 1/2 SHEET METAL SCREW PAN HEAD PHILIPS

PUSH ROD SPRING

PUSH ROD NUT

PUSH ROD LOWER

Description Item No.

38 398291 1 CASE SLIDE

39 398307 1 CASE SLIDE ROD GUIDE

40 398308 1

41 392011 2 10-32 HEX HEAD NUT

42 398289 1 MAIN BRACKET

43 398299 1 CAM WIRE

44 398309R 1 SUB-PLATE (ON PRESS OR WITH RETROFIT KIT)

45 398287 2 BRACKET, SQ. TUBING

46 398345 1 EJECT WIRE (ON SUB-PLATE #44)

47 398312 2 1/4-20 X 1.25 SHCS

48 390128 4 1/4 FLAT WASHER ZINC PLATED

57* O95316 CASE FEED PLATE - LARGE RIFEL

60 398293 1 V-BLOCK #1

61 398297 1 V-BLOCK #2

63 398292 1 V-BLOCK #4

64 398295 1 V-BLOCK #5

65 398296 1 V-BLOCK #6

66 398324 1 PLASTIC FEED TUBE SMALL BUSHING

67 390651 2 3/16" FLAT WASHER SAE

69 398370 1

70 398388 2 1/4-20 X 1.50 SHCS

on Part

Number Qty.

Description

CASE SLIDE ROD GUIDE SPRING

PIVOT BUSHING

AP PRESS

10-24 x 1/4 BHSCS

CASE FEED BOWL BUSHING

Chart 5: Bill of Materials.

(“*” Sold Separately) (“Italics” Pre Assembled)

28

Page 29

29

Page 30

(780308, Original, 09/02/04)

30

Loading...

Loading...