Page 1

HORNADY

366 AUTO

AUTOMATIC SHOTSHELL RELOADER

OPERATION MANUAL

Page 2

Table of Contents

Steps: Page

Overview......................................................................................3

Standard Loads and Bushings......................................................3

Setting up your 366 Auto.............................................................4

Function and Adjustment.............................................................5

1. Resize and De-Prime (Station 1A) ........................................6

2. De-Prime Only (Station 1) ....................................................7

3. Prime (Station 2) ...................................................................8

4. Powder Drop (Station 3)........................................................9

5. Wad Seating (Station 4) ........................................................10

6. Shot Drop (Station 5) ............................................................11

7. Crimp Starter (Station 6) .......................................................12

8. Crimp (Station 7)...................................................................13

9. Crimp Taper (Station 8) ........................................................14

Adjustment of Auto Advance ......................................................15

Trouble Shooting .........................................................................16

Converting to another Gauge.......................................................19

List of Illustrations

Figures:

1. Function and Adjustment......................................................5

2. Resize and De-Prime.............................................................6

3. De-Prime...............................................................................7

4. Prime.....................................................................................8

5. Powder Drop .........................................................................9

6. Wad Seating..........................................................................10

7. Shot Drop..............................................................................11

8. Crimp Start............................................................................12

9. Crimp ....................................................................................13

10. Taper Crimp.........................................................................14

11. Adjustment of Auto Advanced ............................................15

12. Exploded View.....................................................................23

List of Charts

Charts:

1. Powder Bushings ...................................................................20

2. Bill of Materials .....................................................................21

2

Page 3

SHOTSHELL RELOADER INSTRUCTIONS

To help you load completely satisfactory ammunition the first time you operate your 366 Auto,

these instructions have detailed steps of operation and adjustment to help in avoiding problems.

To begin loading shot shells, you will need powder, shot, primers and wads, in addition to empty

hulls. Before purchasing any of these components, first note what charge the standard bushing

furnished with your loader will throw by weighing your charge. Listed on the label on the outside

of the carton is a powder bushing and shot bushing number which is referenced to a powder weight

and brand, as well as shot amount and type.

STANDARD LOADS AND BUSHINGS

If the referenced powder in not available, refer to the recommended load chart furnished with this

loader. This chart will show the other powder weights and brands it will dispense. It is not to be

taken for a reloading manual. Loading data from the major powder manufactures is furnished,

when available, to help you in getting started. Unless you have experience in shot shell reloading,

ask your dealer to help you pick the best starting combination, or contact Hornady’s Reloading

Advisory Center.

IMPORTANT: Never mix powders or use unidentified powder. Do not use smokeless powder

in old firearms until the firearm is certified safe. Do not exceed recommended loads.

Your 366 Auto is a precision machine. It is the only loader to feature full-length resizing with

each stroke, automatic primer feed, swing-out wad guide, three stage crimping with taper-loc for

factory tapered crimp, automatic advance to the next station and automatic ejection with the option

of a gas assisted automatic advance.

This press should give you many years of enjoyable, trouble-free service. Any problems that you

have can generally be corrected by slight adjustments of the dies and punches in each station. If

you are unable to correct the problem, please write us or call:

Hornady Mfg. Co.

PO Box 1848

Grand Island, NE 68802-1848

800-338-3220

DO NOT RETURN THE LOADER TO YOUR DEALER.

3

Page 4

SETTING UP YOUR 366 AUTO

Mount your 366 Auto securely toward the front of a sturdy bench. All operations of the press are

to a full stop, so the operating handle must clear the bench when in the down position. Since the

shells are ejected down a chute, out the back of the loader, you may want to set your loader up on

riser blocks (010060) to provide access to the completed shells. An alternate method to catch

finished shells would be to cut a hole in the bench and place a box underneath.

1. Before filling the shot and powder hoppers, turn the measure assembly upside down and

carefully push the charge bar out and check the powder and shot bushing numbers.

2. Your loader was furnished with standard bushings, 12 GA. 1 ⅛ oz. #7 ½ shot, 468 Powder

Bushing; 20GA. ⅞ oz. #9 shot, 393 Powder Bushing; 28 GA. ¾ oz. #9 shot, 303 Powder

Bushing; 410 GA. ½ oz. #9 shot, 291 Powder Bushing but double check to insure you will

dispense the correct weight of powder and shot.

3. While the charge bar is removed or pushed back, check that the measure casting seals

(rubber washers) are in the recess in the measure casting.

4. Reinstall the bushings and push the charge bar back in place. If the powder slide should

drop out of the measure assembly, do not disassemble the measure plate.

5. Replace the powder slide by pressing it in from the side against the detent spring, pull

spring back and fit into slot.

6. Reinstall the measure assembly by tilting the casting as you slip the measure plate and shot

rotor spring under the hold down washer, and the charge bar into the slot of the charge bar

cam.

7. Secure assembly in position with measure attaching bolt.

8. Install the primer tube in the die head casting and fill the primer tray according to

instructions furnished with it. Do not fill the tube at this time.

9. Check the individual stations of the loader for alignment to make sure nothing has loosened

during shipping. Shut off the powder slide (push in) and the shot rotor (pull forward) while

checking each station.

READ THIS SECTION BEFORE ATTEMPTING TO LOAD AMMUNITION!

4

Page 5

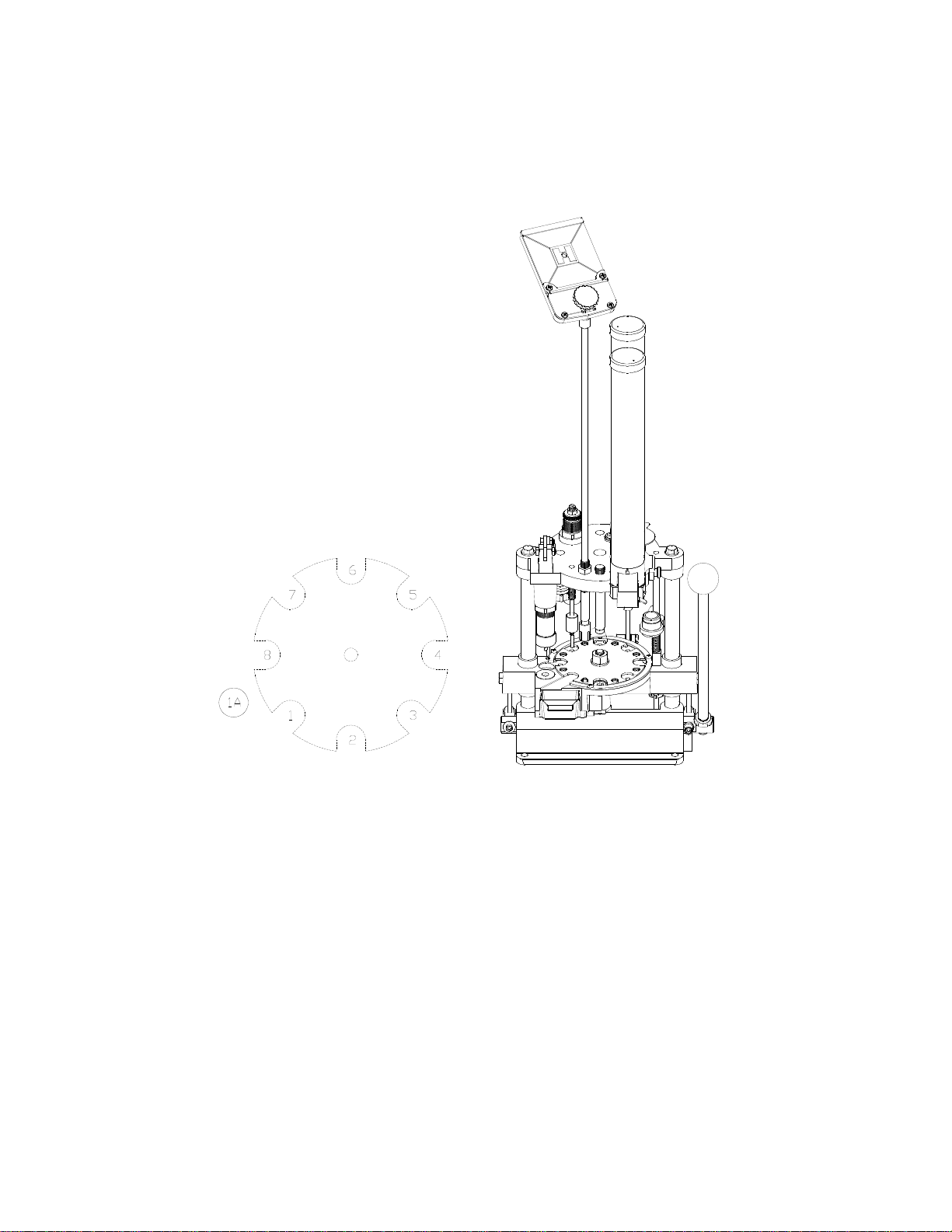

FUNCTION AND ADJUSTMENT

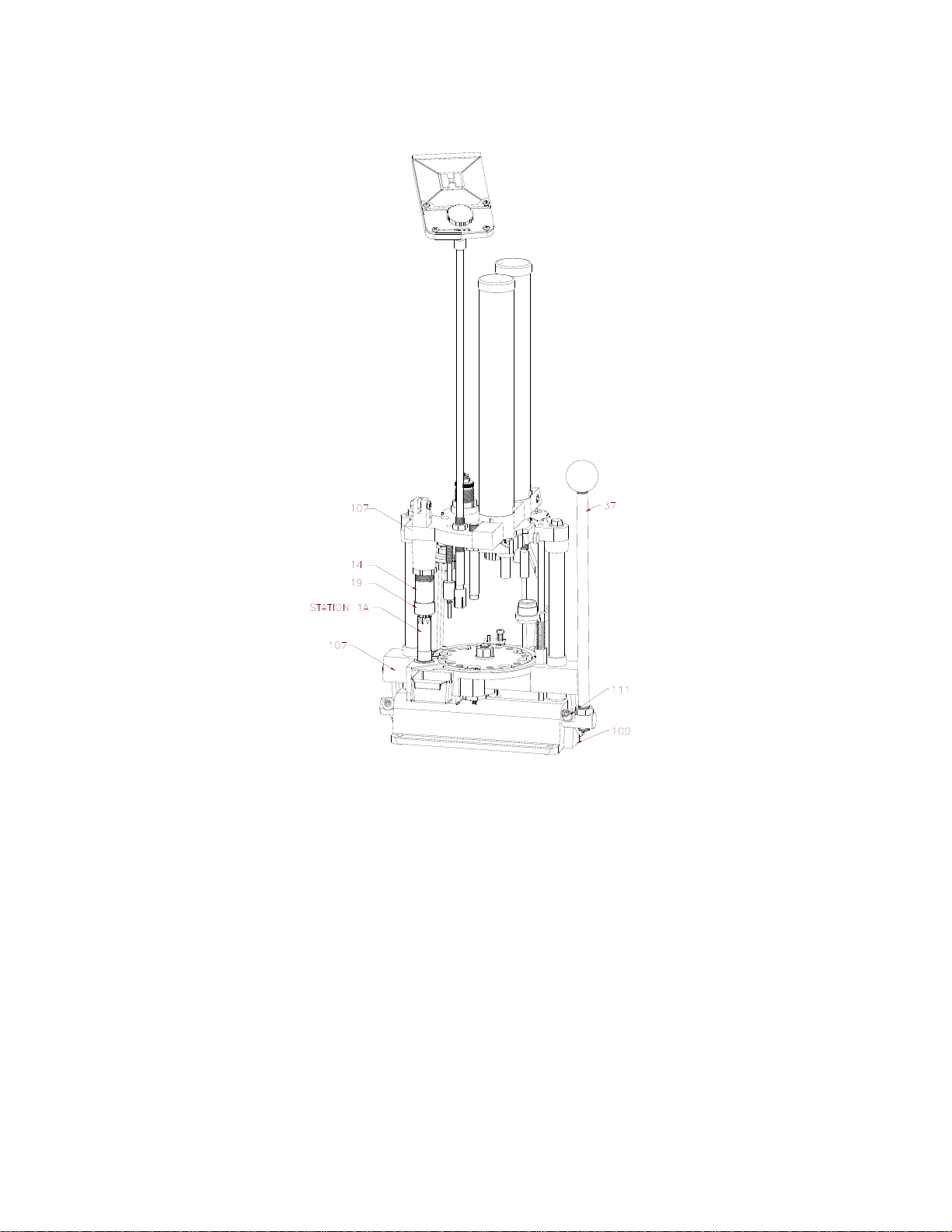

Fig. 1: Function and Adjustment

The following is a detailed description of the operation and adjustment of the 366 Auto

Reloading Press. This press has been pre-adjusted at the factory for Remington STS cases, but

every person has a preference about how the finished product should look, so some changes might

be necessary. The reloader should begin by advancing a single shell through each station to

familiarize himself with the operation and adjustment of each position. The illustrated

discussion which follows shows the 366 with all eight stations filled. Since your first shell will be

the only one in the loader, be sure the shot and powder slides are off at the beginning of the

sequence.

Sort your shot shells by brand and type. Refer to the loading manuals provided for

recommended loads for your shot shells.

5

Page 6

Step 1: STATION 1A (Resize and Deprime)

Fig. 2: Resize and De-Prime

Place an empty shell in Station 1A, making sure the deprime punch enters the case mouth

and the shell is reasonably centered under the size die (#14). Pull the operating handle (#37) to the

bottom of the stroke. Make sure nothing interferes with the handle reaching bottom. When the

operating handle is pulled, the platen casting (#107) rises until the eccentric arm stop (#111)

contacts the base casting (#100). At this point, the shell should be completely enclosed in the size

die (#14) and there should be no gap between the size die ring cap (#19) and the platen casting

(#107). When the handle (#37) is returned, the de-prime punch guide (#8) pushes the case from the

die. The expander (#8) is threaded on the deprime bolt (#62) which is forced down by the clevis

link (#13) attached to the head casting (#7). The size die (#14) should size the brass head and rim

to permit the chambering of that shell in any firearm. Properly adjusted, the size die (#14) just

contacts the platen casting (#107). All other dies are set from this adjustment point, but are

designed with all stations full. Interference with the handle (#37) can cause light powder charges

or primers not seated properly. The size die (#14) and the size die ring cap (#19) must be kept tight

at all times.

6

Page 7

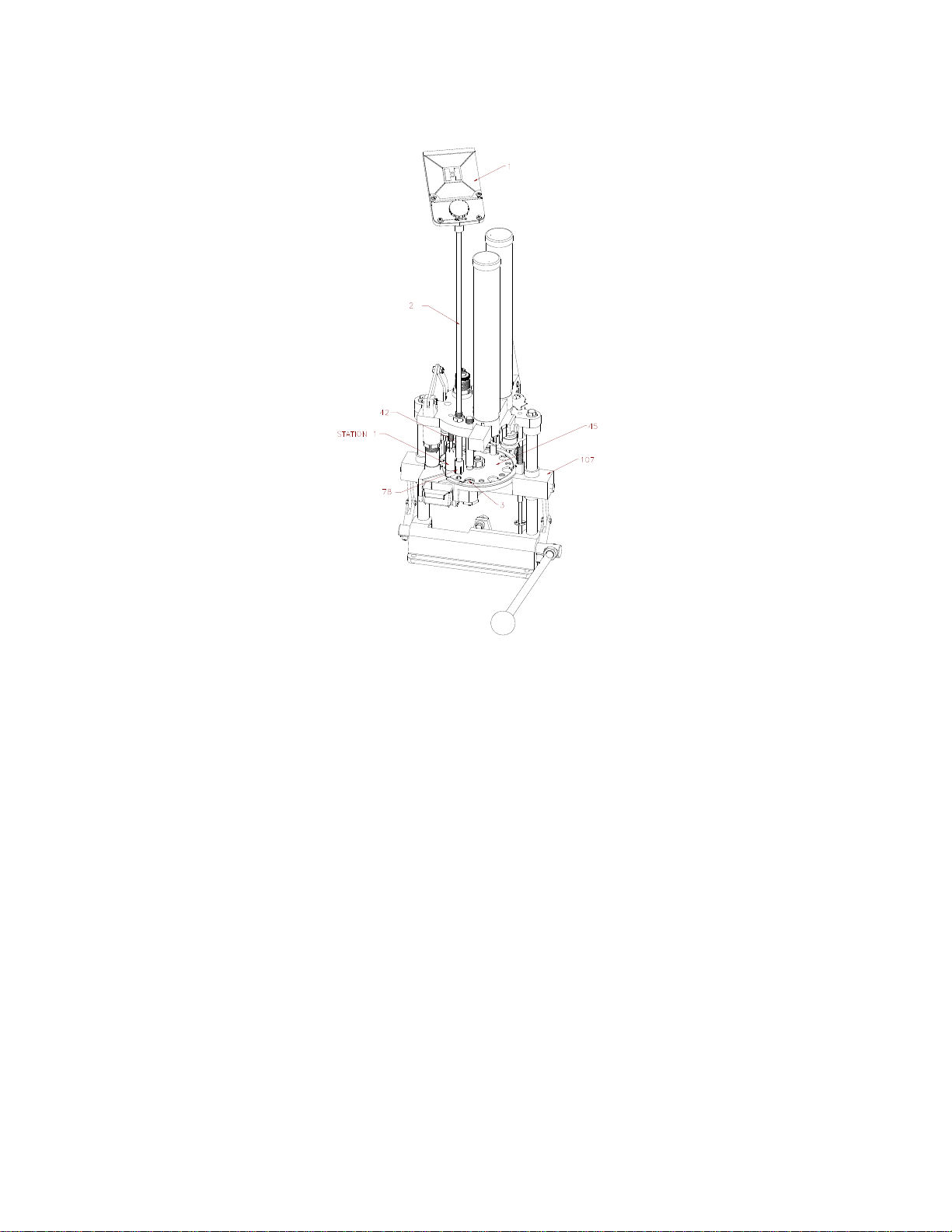

Step 2: STATION ONE (De-prime Only)

Fig. 3: De-Prime

Insert the case in station.

1. Normally, at this time, we would fill the primer tube (#2), but since we are working with a

single shell, drop only one primer from the tray (#1) into the primer tube (#2). Now pull the

handle (#37). As the handle (#37) makes a complete cycle, the shell will automatically

advance to the next station also dropping the primer into the hole in the primer seat pad

(#3). Some individuals may wish to bypass Station 1A but a shell must be in place in

Station 1 before pulling the handle (#37). The shell automatically advances on the return

stroke and if Station 1 is empty, there will be a gap in the reloading sequence.

Primer Drop: Until you are more familiar with your reloader, always return the handle

smoothly and, at first slowly. The primer is dropped when the shell plate (#45) contacts the

plastic primer drop stop unit (#78) at the bottom of the down stroke, and spreads the fingers of

this unit, allowing the primer to slip into the hole provided in the shell plate (#45). At this

point, make sure that the metal portion of the primer feed body (#42) does not make contact

with the shell plate. Such contact will turn a burr on the inside and prevent primers from

falling.

The primer seat pad (#3) is notched to improve the primer drop, but the primer only falls at

the speed of gravity, so the handle (#37) must not be raised too rapidly, or the primer could be

jammed between the shell plate (#45) and the platen casting (#107). Therefore, operate the

handle smoothly, and only as fast as primers will reliably drop into the primer seater pad (#3).

7

Page 8

Step 3: STATION TW0 (Prime)

Fig. 4: Prime

Pull the handle (#37) through a complete stroke. The primer seating punch (#20) or the

optional spring loaded primer seater punch (010051) will enter the case and push the case

down, over the primer in the primer seating pad (#3). On the return stroke, the primer seating

pad (#3) will push the case back up into position and the shell plate (#45) will advance to the

next position. Before continuing the loading sequence, remove the primed case, to inspect the

primer seat depth. To remove, lift the pawl (#94) from the indexing position and rotate the

shell plate (#45) back to station one and inspect the seated primer. The primer should be flush

with the case head. If the primer is not fully seated, the primer seater punch (#20) must be

adjusted. Different brands of cases have different base wad heights. Replace the case in

position at Station Two. Loosen the primer punch lock nut (#23). Pull the handle (#37) down,

and steadily lower the primer seater punch until you feel the punch start to interfere with the

handle (#37). The primer seating punch (#20) should then be backed up just enough to

eliminate any interference. Your loader was factory set to load the low base wad of the modern

compression formed type cases and may not need any adjustment. The primer seater pad notch

should be on your right as you face the loader.

8

Page 9

Step 4: STATION THREE (Drop Powder)

Fig. 5: Powder Drop

Before pulling the handle (#37), pull the powder slide (#69) toward you. The spring (#71)

will lock the slide in place in the second slot of powder slide (#69). The powder drop is now

on. During the stroke, the powder bushing will advance to the Powder Drop station.

Normally, we would leave the powder slide on, but since we are taking one shell through each

step, push the powder slide back and shut off the powder. (Do this before pulling the handle

again.)

There is no adjustment to the powder drop, but the drop tube should be kept clean and dry and

must be able to float freely in the head casting. To clean the drop tube, use brake cleaner to

remove all oils.

9

Page 10

Step 5: STATION FOUR (Wad Seating)

Fig. 6: Wad Seating

Insert a wad in the wad guide (#106A). Pull the operating handle (#37) through a complete

stroke. When the handle (#37) is pulled, the spring (#106B) around the wad guide rod (#105)

turns the wad guide bracket (#101) to align the wad with the case. The unit then rises until the

wad is stopped with the platen casting (#107) by the wad ram (#48). The case continues

upward until the spring fingers (#77) have entered the case mouth, and then pushes the wad

guide (#101) upward until the wad is seated in the case. The spring fingers (#77) have enough

resistance to prevent the wad from going through until the spring fingers (#77) are in the case.

At the completion of the return stroke, the wad guide bracket (#101) will swing forward for the

next wad to be inserted. The wad guide bracket should have 1/8” clearance above the

shells. The empty shells vary in length so a closer setting would not be beneficial. Be sure the

wad seating ram (#48) is set high enough for the wad to swing into position with out being

folded by early contact with the wad seating ram (#48). Wad pressure is adjusted by raising

or lowering the wad seating ram (#48). Most one-piece plastic wads today will self-adjust

when the shell is crimped. Generally, the wad should be seated to allow 5/8” clearance

between the case mouth and the shot.

10

Page 11

Step 6: STATION FIVE (Shot Drop)

Fig. 7: Shot Drop

Before pulling the handle (#37), rotate the shot shut-off (#70) backward, turning on the

shot. Now, lower the handle (#37). The shot drop tube (#47) enters the case mouth and then

both case and shot drop tube (#47) rise together to the top of the stroke. In this fashion, all the

shot enters the case without being spilled. No adjustment of this station is possible. Upon

completion of the stroke, the shells will advance to the next station. Normally, we would leave

the shot drop on, but since we are taking a single shell through the sequence, rotate the shot

rotor (#70) forward to shut off the shot.

11

Page 12

Step 7: STATION SIX (Crimp Start)

Fig. 8: Crimp Start

As you lower the handle (#37), the shell at Station Six enters the crimp starter (#82). The

plastic body has ridges on the inside to align with the old crimp and restart the folds. The

outside of each crimp starter (#82) has a ridge corresponding with the inside, so if manual

alignment is necessary with damaged crimps, follow these ridges. A hole in the case mouth of

¼” should be left when the shell completes this station. Hornady loaders come with eight

point crimp starter installed, but if you are using another crimp, substitute with either smooth

for paper or six point plastic, included with your loader. The plastic starter unit unthreads from

the rod (#65) extending through the main body. The amount of “start” may be adjusted, but too

much can cause the wall of the case to collapse, producing a defective shell.

12

Page 13

Step 8: STATION SEVEN (Crimp)

Fig. 9: Crimp

As you pull the handle (#37), the shell in Station Seven will enter the crimp die (#59). The

shell will contact the inside of the die and raise the die body (#59) as it goes up. It will then

contact the crimp plunger (#58) and the crimp will be closed. On the return stroke, the shell

will be pulled from the crimp plunger (#58) but the crimp die (#59) will keep pressure on the

case to retain the proper shape. Since different manufactures’ cases have varying types of

construction, different settings are required for best results. The two-stage die enables the user

to create a reloaded round that has approximately the same tapered mouth as a factory shell.

There are two adjustments to the crimp die assembly (#57, #58, and #59); the larger outer

position adjusts the die body (#59), the threaded bolt through the center of the die adjusts the

crimp plunger (#58). To adjust the die, refer to the number of threads exposed above the large

die body locking nut (#15) as reference points for each brand of case. For Winchester AA type

shells, ten to ten and one half threads should remain above the locking ring (#15); for

Remington Blue Magic and Federal Gold Metal Cases, eleven to thirteen threads should be

exposed. These measurements are approximate and may need adjustment up or down,

depending on the plastic and components, but should be correct in most situations. Before

adjusting the crimp the crimp die (#59), the crimp plunger (#58) should be raised a few turns

by loosening lock nut (#15) and turning the crimp die bushing (#57) clock wise. Then, make

the necessary die body (#59) adjustments, and follow by crimping the case. At this point, the

case mouth will not be closed. Lower the crimp plunger (#58) in small increments, each time

recrimping the shell until the final desired crimp depth is obtained. The crimp depth is up to

you, but excessive depth shortens case life, while a crimp that is too shallow will not yield

uniform velocity or good patterns. A good practice is to keep a factory round on hand for

reference

13

Page 14

Step 9: STATION EIGHT (Taper Crimp)

Fig. 10: Taper Crimp

The taper crimp is a smooth crimp starter (#82) and will taper the finished case better than

factory loads. As the shell at Station Eight enters the taper crimp die (#59), the mouth of the

shell will be “rolled.” On the return stroke, the shells advance, but the shell in Station Eight

contacts a cam in the platen casting (#107), moves to the left, and drops through a hole in the

platen casting (#107) down the chute (#108) to the back.

Adjustment of the taper crimp (#82) is done by loosening the lock nut (#29) and raising or

lowering the taper crimp starter (#82) to obtain the desired taper on the case mouth.

At this point in a normal reloading sequence, you would have a completed shell at each

station. To begin reloading, go back to the beginning and follow instructions for Step 1

and Step 2, but this time fill the primer tube (#2) when you insert a shell in Station One.

As the shells advance around the loader, remember to turn on the powder and shot when

the shells advance to the positions, and to reinsert a shell at Station One and a wad in the

wad guide after each pull of the handle. You can continue the sequence until all your

empty shells have been reloaded but always remember to check the powder and shot

hoppers (#80) and make sure a primer drops on each stroke. If you refill the primers,

shot and powder after each 100 rounds, you will never load shells without components.

14

Page 15

ADJUSTMENT OF AUTO ADVANCE

Fig. 11: Adjustment of Auto Advance

When the operating handle (#37) is pulled all the way up, a spring (#98) swings the pivot

arm (#85) and the advance pawl (#94) to your right. The hook of the pawl rides in the gap

between the shell plate (#45) and the shell plate ring (#110). On the return stroke, the roller on

the base casting (#100) contacts the curve on the pivot arm (#85) and the entire unit is cammed

toward the left, advancing the shells to the next position. The cam bearing (#12) is mounted

off-center on the bolt (#25) so when it is turned, the cam bearing is shifted right or left. If an

adjustment is necessary, loosen the lock nut (#28) and turn the eccentric bolt (#93) with a

screwdriver. It is necessary to hold the eccentric bolt (#93) with the screwdriver when

tightening the nut (#28).

15

Page 16

TROUBLESHOOTING

Handle will not come to bottom of stroke

Do not force the handle (#37). If you meet with any resistance, shut off the shot and powder

and slowly return the handle (#37) back to normal while unlatching the rotating pawl (#94).

1. Check to see the loader is mounted near the front of the bench, allowing the handle (#37) to

come completely down.

2. Check to see if the size die body (#14) adjustment has changed or if the size die ring cap

(#19) has loosened.

3. Check that the de-prime punch guide (#8) is threaded all the way up on the size die ejector

bolt (#62).

4. Check to see that you are not seating a second primer on top of an already primed case.

5. Check the primer seater punch (#20) to see if it is adjusted too low. Readjust to seat the

primer when the handle (#37) is depressed.

6. Check to see that you aren’t trying to seat a second wad on top of another and the wad

entered the shell correctly.

7. Check to see that shells are in alignment and the correct shell is in each station.

8. Check for an obstruction inside the shell which would prevent you from depriming or

repriming the case.

9. Check to see that you aren’t trying to load a high base wad shell when you are set up for

low base wads.

10. Check to see if a loaded shell has rolled underneath one of the eccentric arms.

Handle will not turn to normal position on backstroke.

DO NOT FORCE THE HANDLE. Shut off the powder and shot and unlatch the rotating

pawl (#94).

1. Check the clevis link (#13) to see if it is bent and hanging up on the size die eject bolt

(#62). Replace if necessary.

2. Check the primer seater station to see that the primer was fully seated. If not, lower the

primer seater punch (#20).

3. Check to see that the wad is being fully seated and not pulling back up into the wad guide

bracket (#101).

16

Page 17

4. Check the wad guide bracket (#101) to see that the wad guide return spring (#106B) is

attached and that the bracket is fastened to the wad guide rod (#105).

5. Check the charge bar cam (#9) adjustment to see that it hasn’t slipped.

6. Check for an obstruction, spilled shot, etc., between the shell plate ring (#110) and the

platen casting (#107). If there is, you may need to rotate the pawl (#94) clock wise and

take the shell plate nut (#91) off and lift the shell plate (#45) off the platen (#107) and clean

out the shot. When the shot is cleaned out, replace the components in reverse order as you

took them off.

7. Lift each shell up against the shell plate (#45) to see if a primer flange may be catching in a

platen casting (#107) indention.

8. Check to see if the shell plate (#45) is dragging on the shell retainer spring (#63).

9. Check to make sure the primer was fully removed at Station One.

Primers do not drop or drop erratically.

If primers do not drop into the shell plate (#45), or drop erratically, shut off the shot and

powder and unlatch the rotating pawl (#94).

1. Make sure the primer feed body (#42) is adjusted low enough to open the primer stop unit

(#78) which allows a primer to drop.

2. Check alignment of primer feed body (#42) with the shell plate (#45). The taper of the

primer feed body (#42) should enter the chamfer in the shell plate (#45), but not touch.

When there are no shells in the crimp die (#59), pressure on the size die (#14) may tip the

platen casting (#107) enough to cause erratic drop. When possible, make adjustments with

all stations full.

3. Check that the auto advance unit (#83) is fully advancing and stopping in the correct

location.

4. See that the primer feed body (#42) is not burred on the inside, preventing the primers from

dropping freely. If burred, remove with small file.

5. Check the primer feed body (#42) to see that it is not burred on the ends and that it is

straight.

6. Inspect the plastic primer top unit (#78) for flash around the fingers and make sure that the

foot moves freely on the body.

Wads are not seating properly, tearing or tipping.

Shut off the powder and shot and detach the rotating pawl (#94) and return the handle (#37) to

normal position. DO NOT force the handle (#37) back, as it may not be able to move due to the

17

Page 18

swinging wad guide (#101). You may have to cut the wad in half if it cannot be pushed through

into the case.

1. Check your operation of the tool, making sure you allow enough time for the wad to

correctly align with the ram. The wad guide (#106) should be set to swing out just far

enough for easy insertion of the wad; swinging too far will delay the bracket.

2. Make sure the wad guide bracket (#101) clears the shell by about 1/8” so the spring fingers

(#77) enter the case mouth before the wad starts through.

3. Check shell length; variations may cause the case mouth to catch on the bottom of the wad

guide (#106); preventing it from aligning correctly.

4. Check the E clip (#104), which is about 3” from the bottom of the wad guide rod (#105), to

see if it has slipped or broken off the wad guide rod (#105); it could allow the wad to move

through the spring fingers (#77) before they enter the case mouth.

5. Check the spring fingers (#77) to see if they are broken or weak.

6. Check the shells to see that the case mouth is opened up enough to allow the wad to be

seated. Case mouths which are too tight must be flared open, either by hand or with an

expander in the size die (#14) or de-prime station (#1A).

Crimp is concave or opens after being ejected from die. Crimp not satisfactory in

appearance. Detach the rotating pawl, shut off the powder and shot.

1. If the crimp is concave (sinks):

a. Reduce the wad seating depth to see that the shot comes to about 5/8” from the case

mouth in the crimp starter station.

b. Check to see if powder slide is turned on.

c. See if you have correct powder bushing.

d. Make sure the wad length is correct for the case you are loading.

e. Check to see if the shot bushing is correct. Adjust the crimp plunger (#58).

2. If the crimp is bulging open:

a. Check to see if you have seated the wad deep enough.

b. Inspect powder bushing to insure correct powder charge used.

c. Check shot bushing for shot size used.

d. Make sure you have the correct wad length for load being used

18

Page 19

e. Double-check all components to make sure they are the correct ones for the specific

load.

f. Check adjustment of crimp plunger (#58).

3. If the finished shell does not have enough taper in the end or is flared, lower the taper

crimp die (#82) (Station Eight).

4. If crimp isn’t deep enough, turn the crimp plunger (#58) in the final crimp down.

5. If the shell swirls in the center, the plastic shell has elongated or stretched. No adjustment

is generally possible to remove the swirl. This is common, and was probably in the factory

shell.

6. Check to see that you have the proper crimp starter (#82) installed. Eight point for most

plastic target cases, six point for most plastic hunting loads and smooth for paper cases. If

the case buckles at the mouth or wrinkles after final crimp or during the crimp start, raise

the crimp starter. Also check to insure you have the correct components.

Converting to another gauge.

If you purchase a die set for a different gauge, always remember to start installation by

adjusting the full length size die (#14) FIRST! When adjusted properly, the size die should just

contact the platen (#107) at the top of the stroke. Then, install other dies and punches using the

size die (#14) as a guide. Stations should be adjusted by actually reloading a shell. The exception is

the primer seating pad (#3) to ensure seating the primer to the full depth of the primer pocket.

Adjust the wad ram (#46) to provide best crimp (except as noted in sinking crimps or bulging).

By showing you how to “fine tune” and troubleshoot the 366 Auto, we hope to save you

downtime and maximize your reloading enjoyment. Your 366 Auto is a fine progressive

reloader…once the first cycle is completed; it kicks out a finished shell with every stroke.

ABOUT WADS AND WAD PRESSURE: We recommend the use of 1-piece plastic wads. They

are more convenient, and do not require any specific wad pressure. They need to be seated only

deep enough to obtain a satisfactory crimp.

PLEASE NOTE: Normally, few problems are encountered when reloading shot shells. However,

variations in the powder lot, different brands of primers and other components can cause

substantial changes in pressure. Hornady Mfg Company has no control over the components and

equipment which may be used with this published information; no responsibility is implied or

assumed for modern firearms and does not exceed manufacturer’s pressure recommendations.

Further data may be obtained from:

Hercules Powder Company Dupont Explosive Products Winchester Division

Mr. Don Burton Mr. Don Wenner Mr. Ted Henshaw

910 Market Street Wilmington, DE 1938 Olin Corp.

Wilmington, DE 1939 Shamrock St.

East Alton, IL 62024

19

Page 20

Powder Bushing Chart

Grains

Powder/

Accurate Nitro 100

IMR 700-X

IMR PB

IMR SR 7625

IMR 800-X

IMR SR 4756

IMR MR 4227

Alliant American Select

Alliant Red Dot

Alliant Green Dot

Alliant Unique

Alliant Herco

Alliant Blue Dot

Alliant 2400

Alliant E-3

Alliant 410

Hodgdon Clays

Hodgdon International

Hodgdon Universal

Hodgdon HS-6

Hodgdon HS-7

Hodgdon H110

Hodgdon Titewad

Hodgdon Lil' Gun

Hodgdon LGSH

Hodgdon Titegroup

Scot 1000

Solo 1250

Win. 540

Win. 571

Win. 296

Win. Super Target

10 330 256

11 256 266

12 384 363 266 291 250

13 336 393 378 342 357 - 300 363 330 256 259 363 256

14 366 345 363 405 390 354 369 291 266 300 266

15 402 372 366 303 423 405 369 381 300 426 390 354 - 384 309 324

16 414 390 390 438 420 381 393 312 438 429 402 366 303 291 396 318 330 330

17 420 429 402 381 402 423 453 435 393 405 324 450 441 414 312 300 408 330 342 447 300 345

18 432 441 414 390 414 432 468 447 405 414 366 330 465 456 423 390 318 309 420 339 351 456 420 309 417 354

19 444 453 426 402 423 408 447 480 456 414 426 372 339 477 468 435 402 327 318 315 432 348 360 468 432 318 318 429 363

20 456 465 435 414 429 417 456 489 468 423 438 381 483 447 336 330 324 441 357 369 480 444 327 330 438 372

21 468 447 426 438 426 357 468 498 480 435 450 390 459 420 345 339 453 366 378 456 336 339 450 381

22 486 456 438 447 435 366 510 492 444 462 396 471 429 354 348 462 372 387 504 468 345 348 459 390

23 498 465 444 459 447 519 501 453 471 408 438 363 357 474 381 396 480 351 357 471 402

24 474 453 468 459 513 465 477 414 447 369 363 486 390 405 489 360 363 480

25 486 462 480 471 390 522 474 489 423 507 456 378 369 492 396 498 366 369

26 474 489 480 534 483 498 435 468 387 378 405 375 378 420

27 486 489 408 - 492 - 441 480 393 384 414 381 384 426

28 507 414 549 501 513 447 489 402 390 423 387 390 432

29 525 420 558 - 522 459 408 396 429 393 396 441

30 426 510 531 468 414 405 435 402 405 450

31 534 435 - 474 420 411 444 408 411 456

32 525 441 549 483 429 417 450 414 417 462

33 549 534 447 558 489 435 423 459 423 423

34 558 543 453 564 495 441 429 465 429 429

35 549 462 573 501 447 438 471 435 438

36 558 468 - 510 453 444 480 441 444

37 474 588 516 459 450 486 444 450

38 480 594 522 465 492 450 456

39 580 486 531 471 498 459 462

40 588 534 465 468

41 498 534 471 474

42 549 477 480

43 555 483 486

44 561 489 492

Win. Super Lite

Win. Super Field

20

Page 21

Item# Qty Part #

r

M

Measure Plate Hold-Down

410/28 Ga. Powder Drop

D

D

Detent Ball & Spri

Wad Rod Spri

10-32

3/8 S

(12 G

Set Screw 10-32 5/8 (410

410/28 Ga. Crimp Die

410 Ga. Primer Seater

20 G

3/4" Cri

y

11

21

31

4

5 1 190003

6 1 190007

7 1 190008

8 1 190033

9 1 190049

10

11 1 380050

12 2 380100

13 1 390014

14 1 390019

15 2 390020

16 1 390021

17

18

19 1 390029

20 1 390038

21

22

23 3 390087

24 2 390089

25 2 390092

26 3 390093

27 4 390098

28 2 390096

29 3 390097

020003

1 480032

1 398415

1 480034

1 480031

1 390633

1 480030

1 480033

050025

1 390180

1 290001

050040

1 370047

1 390069

1 390068

1 390065

1 392011

1 390086

OBSOLETE

1 190035

1 190036

1 190037

OBSOLETE

OBSOLETE

OBSOLETE

1 390031

1 390032

1 390033

1 390040

1 390041

1 392076

OBSOLETE

OBSOLETE

390178

Description

Bill of Material

Assembly

Movable Lid

Panhead Screw

Knob

Fixed Lid

Spring

Body

Roto

Primer Tube Assembly

Ferrule

Ferrule Tube

Primer Seater Assembly

Spring

Screw 10-32 x 1 1/2

Primer Pad

Well Nut

Hex Nut 10-32

Locating Pin

Measure Casting

Charge Bar

Die Head Casting

Deprime Punch Guide, 12

Ga.

eprime Punch Guide, 20

Ga.

Deprime Punch 28 Ga.

Deprimer Punch 410 Ga.

Charge Bar Cam

Assembly

Cam Bearing

Clevis Link

Shotshell Size Die Body

Die Body Lock Nut

Ga. & 410 Ga.

Size Die Ring Cap 12 Ga.

Size Die Ring Cap 20 Ga.

Size Die Ring Cap 28 Ga.

Size Die Ring Cap 410 Ga.

12/16 ga. Primer Seater

Punch

20 Ga. Primer Seater Punch

28 Ga. Primer Seater Punch

Punch

9/16-18 Lock Nut

1/4-20 Hex Lock Nut

1/2-20 x 5/8" Bolt

Clevis & Cam Bolt

Poly Hopper Rivet

1/2-20 Jam Nut

Lock Nut 3/8-16

Lock Nut 28/410 1/4-20

ng

ng 20 Ga., 28

Item# Qty Part #

30 2 390100

31 4 390101

32 1 398120

33 2 398121

34 2 390105

35 2 390106

36 2 390107

37 1 390657

38 1 390027

39 1 390119

40 1 390124

41 2 390125

42 1 390126

43 1 390127

44 1 390128

45 1 390129

1 390141

1 390147

1 392078

46 1 390132

1 390144

1 390156

47 1 390133

1 390145

1 390157

47A 1 390155

1 390134

48 1 390146

1 390158

1 390152

49 1 390179

50 1 390186

51 2 390187

52 1 390188

53 3 390095

53 1 390190

54 2 390196

55 1 390198

1 392080

56 2 390201

57 1 390202

390203

58 1 390204

390206

390207

390208

59 1 390212

390213

390215

390216

390217

392075

60 1 390633

61 2 390066

Description

Guide Post

Guide Post Bolt

Pivot Shaft

Eccentric Arm

Drive Link

Drive Link Roll Pin

Platen Drive Bolt

Operating Handle

5/8-18 Jam Nut

Bearing Pin

Clevis Rod

Clevis Rod Bushing

Primer Feed Body

easure Plate Hold-Down

Screw

Washer

12 Ga. Shell Plate

20 Ga. Shell Plate

28 Ga. Shell Plate

410 Ga. Shell Plate

12/16 ga. Powder Drop Tube

20 Ga. Powder Drop Tube

Tube

12/16 ga. Shot Drop Tube

20 Ga. Shot Drop Tube

410/28 Ga. Shot Drop Tube

eprime Punch 20 Ga., 28

Ga., & 410 Ga.

Deprime Punch 12 Ga.

12/16 Ga. Wad Ram

20 Ga., 28 Ga., Wad Ram

410 Ga. Wad Ram

Shell Plate Washer

Clevis Rod Bolt

Set Screw

Measure Attaching Bolt

x

20 Ga. & 28 Ga.)

Ga. Qty. 3)

Split Washer 3/8

Crimp Die Spring

410/28 Ga. Crimp Die Spring

Bearing Pin E Clip 7/32

Crimp Die Bushing 12 Ga., &

20 Ga.

Bushing

Crimp Plunger 12 ga.

20 Ga. Crimp Plunger

28 Ga. Crimp Plunger

410 Ga. Crimp Plunger

12 Ga. 2 3/4" Crimp Die

Body

12 Ga. 3" Crimp Die Body

Body

20 Ga. 3" Crimp Die Body

28 Ga. Crimp Die Body

410 Ga. Crimp Die Bod

Primer Tube Filler Spring

Push Nut

crew

a. 2

a.,

mp Die

21

Page 22

Item# Qty Part #

62 1 392053

63 1 392054

64 2 392055

65 2 392101

66 2 392102

67 1 392103

68 1 392104

69 1 392105

70 1 392106

71 1 392107

72 1 392108

73 4 392109

74 2 480001

75 1 480003

76 1 480006

77 1 480007

78 1 480028

79

80 2 490002

81 2 490003

82 1 490500

A

TO-ADVANCE PARTS

U

83 1 O50034

84 1 O50041

85 1 190043

86 1 380100

87 1 390081

88 1 390084

89 3 390093

90 1 390191

91

92 2 390125

93 1 390777

94 1 392027

95 1 392026

96

97 1 392029

98 1 392030

4

480010

480011

490501

490313

490503

490504

490319

4

490321

490511

490323

490512

390115

1

1 392440

2 392081

1 392083

1 392082

1

392028

Bill of Material

Description

Size Die Eject Bolt

Shell Retainer Spring

3/8 Flat Washer

Crimp Starter Rod

Crimp Starter Bushing

Measure Plate

Measure Plate Spacer

Powder Slide

Shot Rotor Slide

Powder Slide Spring

Shot Rotor Slide Spring

Roll Pin 1/8 X 1/4

M

easure S

eals

Plastic Handle Ball

Primer Catcher

12 Ga. Spring Finger

20 Ga. Spring Finger

80009

28 Ga. Spring Finger

410 Ga. Spring Finger

Stop Unit

See Accessories

Shot/Powder Hopper Tube

Hopper Cap

t. Crimp Starter

12 Ga. 8p

12 Ga. 6pt. Crimp Starter

12 Ga. Paper Crimp Starter

p

t. Crimp Starter

20 Ga. 8

20 Ga. 6pt. Crimp Starter

aper Crimp Starter

20 Ga. P

28 Ga. 6pt. Crimp Starter

90509

28Ga. Paper Crimper Starter

410 Ga. 6pt. Crimp Starter

410 Ga. Paper Crimp Starter

10 Ga. 6pt. Crimp Stater

Auto-Advance Assembly

Pawl Assembly

Pivot Arm

SAME AS 12

1/2" E Clip

Slotted Pin 1/8 x 1

Clevis & Cam Bolt

6-32 X 3/4 FH SLTD (410

Ga.)

Shell Plate Bolt Nut (elastic)

Shell Plate Bolt Nut 410 Ga.

Clevis Rod Bushing

Spacer 410 Ga.

Eccentric Bolt

New Styl e Pa wl

Pawl 410 Ga.

Shoulder Bolt

Shoulder Bolt 410 Ga. 1/4 x

3/4

Shell Plate Bolt

Pawl Spring

Return Spring

Item# Qty Part #

SWING OUT WAD GUIDE PARTS

O50036

100 1 190050

101 1 190038

102 1 190045

103 1 390167

104 1 390120

105 1 392035

106 1 390048

390050

390051

390052

106A 1 392041

392043

392044

390047

106B 1 392046

SHELL DROP PARTS

O50035

107 1 190046

108 1 392052

109 3 390182

110 1 392047

1 392049

1 392050

1 392079

111 1 392038

112 1 3901

113 1 3901

114 2 398323

Additional Parts for 410 Ga. Loader Only

1 190060

1 190061

1 392077

1 390710

1 480081

1 480085

1 390157

Description

Assembly (factory installed)

Base

Swing Out Wad Guide

Br

cket

a

Return Spring Retainer

Primer Feed Rod Roll Pin 1/8

2

x 1/

E Clip 1/4

Wad Guide Rod

12 Ga. Wad Guide Body

20 Ga. Wad Guide Body

28 Ga. Wad Guide Body

410 Ga. Wad Guide Body

12 ga. Wad Guide Cap

20 Ga. Wad Guide Cap

28 Ga. Wad Guide Cap

410 Ga. W

ad Guide Cap

Wad Guide Return Spring

Shell Drop Assembly (factory

inst

alled)

Platen

Shell Chute

Chute Screw 6-32 x 1/4 Pan

Hea

d

12 Ga. Shell Plate Ring

20 Ga. Shell Plate Ring

28 Ga. Shell Plate Ring

410 Ga. S

Eccentric Arm Stop

/4 x 20 by 3/4

1

99

1/4 x 20 by 1/2

75

#10 FLAT

Hull Guide (Primer) 410 Ga.

Hull Guide (Powder) 410 Ga.

Flaring Sleeve, 410 Ga. & 28

Ga.

Nylon Tip Set Screw 410 Ga.

O-Ring (Primer) 410 Ga.

O-Ring (Powder) 410 Ga.

Shot Drop Tube 410 Ga.

late Ring

hell P

WASHER

22

Page 23

23

Loading...

Loading...