Page 1

6-CHANNEL COMPUTER RADIO

Page 2

Page 3

3

XF631 MANUAL • Table of Contents

QUICK START

4

I. INTRODUCTION

1. Using This Manual 6

2. Features 6

2.1 Transmitter Features 6

2.2 Receiver Features 6

2.3 Servo Features 7

2.4 Servo Layout 7

3. Specifications 8

3.1 System Specifications 8

3.2 Transmitter Specifications 8

3.3 Servo Specifications 8

3.4 Receiver Specifications 9

3.5 Charger Specifications 9

3.6 Airborne Battery Pack 9

4. Battery Charging 10

4.1 Transmitter/Receiver 10

4.2 Charger 10

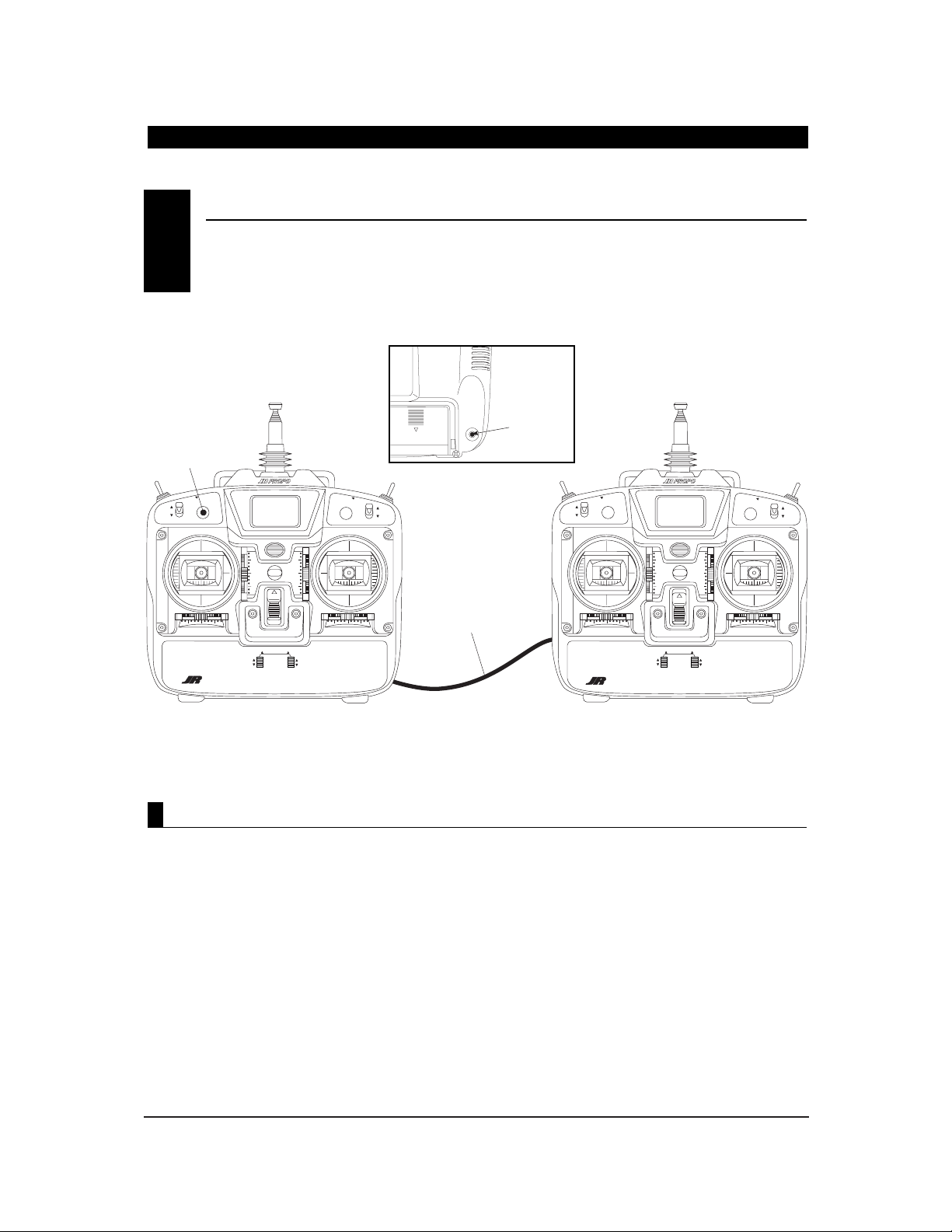

5. Trainer System 11

II. XF631 MANUAL

1. Transmitter Controls 12

1.1 Control Identification and Location 12

1.2

Receiver Channel Assignment/

Transmitter Throttle ALT

12

1.3 Transmitter Rear 13

1.4 Control Stick Length Adjustment 13

1.5 Direct Servo Control (DSC) 14

1.6 Neck Strap Attachment 14

2. Connections 15

2.1 Installation Requirements 15

2.2 Connections 15

3. Key Input and Display 16

4. Battery Alarm and Display 16

5. Input Mode and Functions 17

5.1 Normal Display 17

5.2 Direct Trim Access Display 17

5.3 Mode Types 17

5.4 Throttle Cut 17

5.5 System Mode 18

5.6 Function Mode 18

6. Functions (System Mode) 19

6.1 Data Reset 19

6.2 Model Selection 20

6.3 Wing Type Selection 20

6.4 Model Name Entry 23

7. Functions (Function Mode) 24

7.1 Servo Reversing 24

7.2 Dual Rate 25

7.3 Sub Trim 26

7.4 Travel Adjustment 27

8. Data Sheets 28

III. IMPORTANT INFORMATION

1. General Notes 31

2. Daily Flight Checks 31

3. Warranty Coverage 32

4. Repair Service Instructions 32

5. Frequency Chart 33

TABLE OF CONTENTS

We strongly encourage all prospective and current R/C

aircraft pilots to join the Academy of Model Aeronautics.

The AMA is a non-profit organization that provides

services to model aircraft pilots. As an AMA member you

will receive a monthly magazine entitled Model Aviation, as

well as a liability insurance plan to cover against possible

accident or injury. All AMA charter aircraft clubs require

individuals to hold a current AMA membership prior to

operation of their models. For further information you can

contact the AMA at:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(317) 287-1256

Thank you for purchasing the JR XF631 6-Channel Radio

System. This unit has been designed to provide the

modeler with a high-quality, user-friendly radio system

that can be depended upon for years to come.

It’s important that you carefully read this manual before

attempting to operate your system. Please pay particular

attention to Page 10, Introduction 4, “Battery Charging.”

AMA INFORMATION

INTRODUCTION TO THE XF631 RADIO SYSTEM

Page 4

4

XF631 MANUAL Quick Start

XF631 QUICK START

In this manual you will find in-depth instructions that

detail all the steps and procedures you should follow in

order to program each of the XF631’s features. For

modelers who want to get into the air fast, we have

provided Quick Start. Quick Start covers the basic

programming information necessary to get you airborne.

Later, when you want to learn more about specific features

of the XF631, turn to the appropriate pages(s) in this

manual for more detailed programming information.

Note: Please charge the system batteries as indicated

in step 4.1 before attempting the Quick Start setup

and again before flying the model.

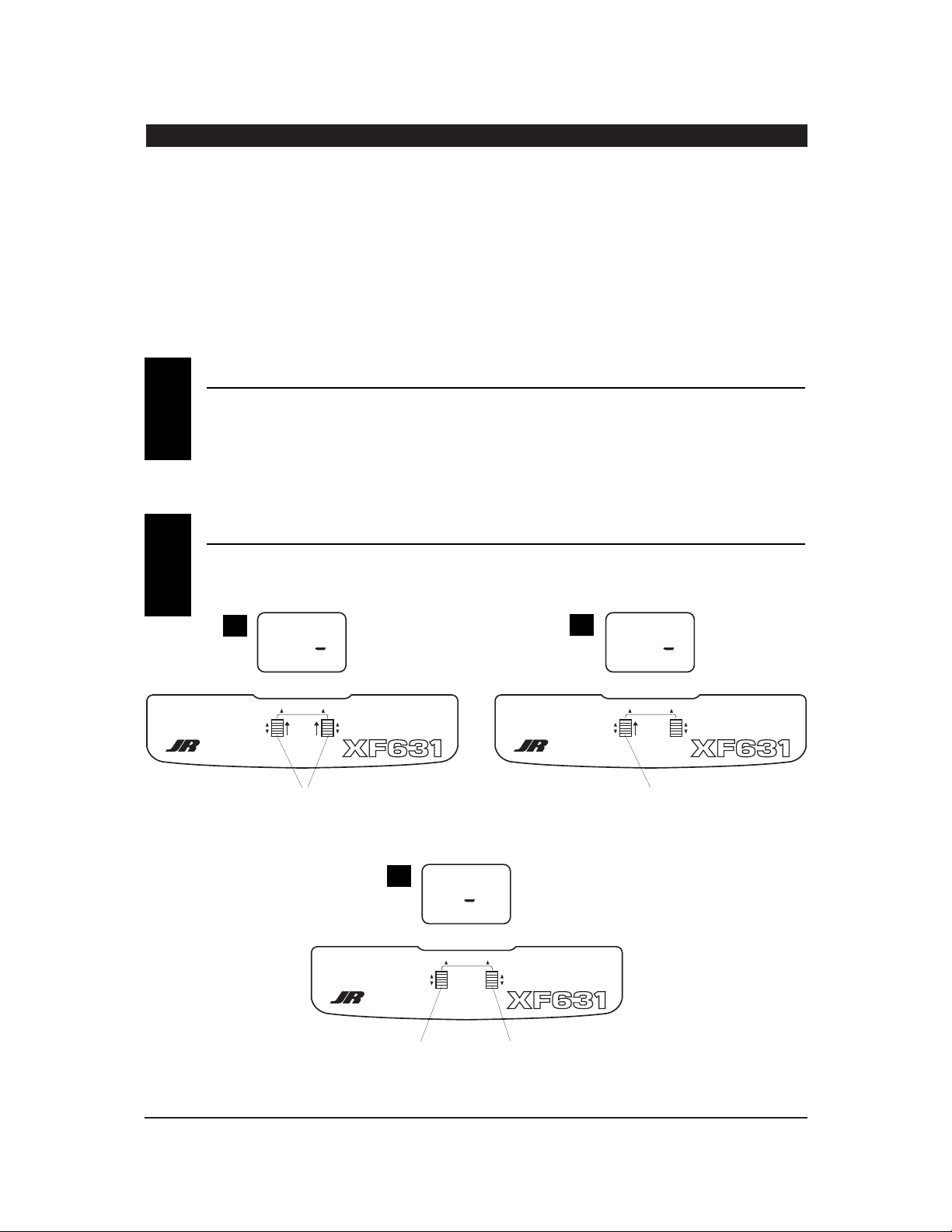

Turn on the transmitter and check to ensure that the

aileron, elevator, and rudder trim valves are set to the

0 (neutral) position.

Next, set the throttle trim valve to the full low (-40)

position by pressing the throttle trim lever down.

DIGITAL TRIM SETTINGS

1

SERVO REVERSING

2

REV◆NORM

THR

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

REV◆NORM

THR

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

With the transmitter on, press the Scroll and Increase

buttons upward simultaneously until a beep is heard.

Press the Channel button to select

the channel you want to reverse.

Press the Increase or Decrease button

to reverse the direction of the

channel you selected.

REV◆NORM

THR

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

Press the Scroll button (if necessary) until

“REVERSE-NORM” appears on the screen.

A

B

C

Page 5

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

TRV ADJ.

AIL

+I00

%

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

TRV ADJ.

AIL

+I07

%

5

XF631 MANUAL Quick Start

XF631 QUICK START

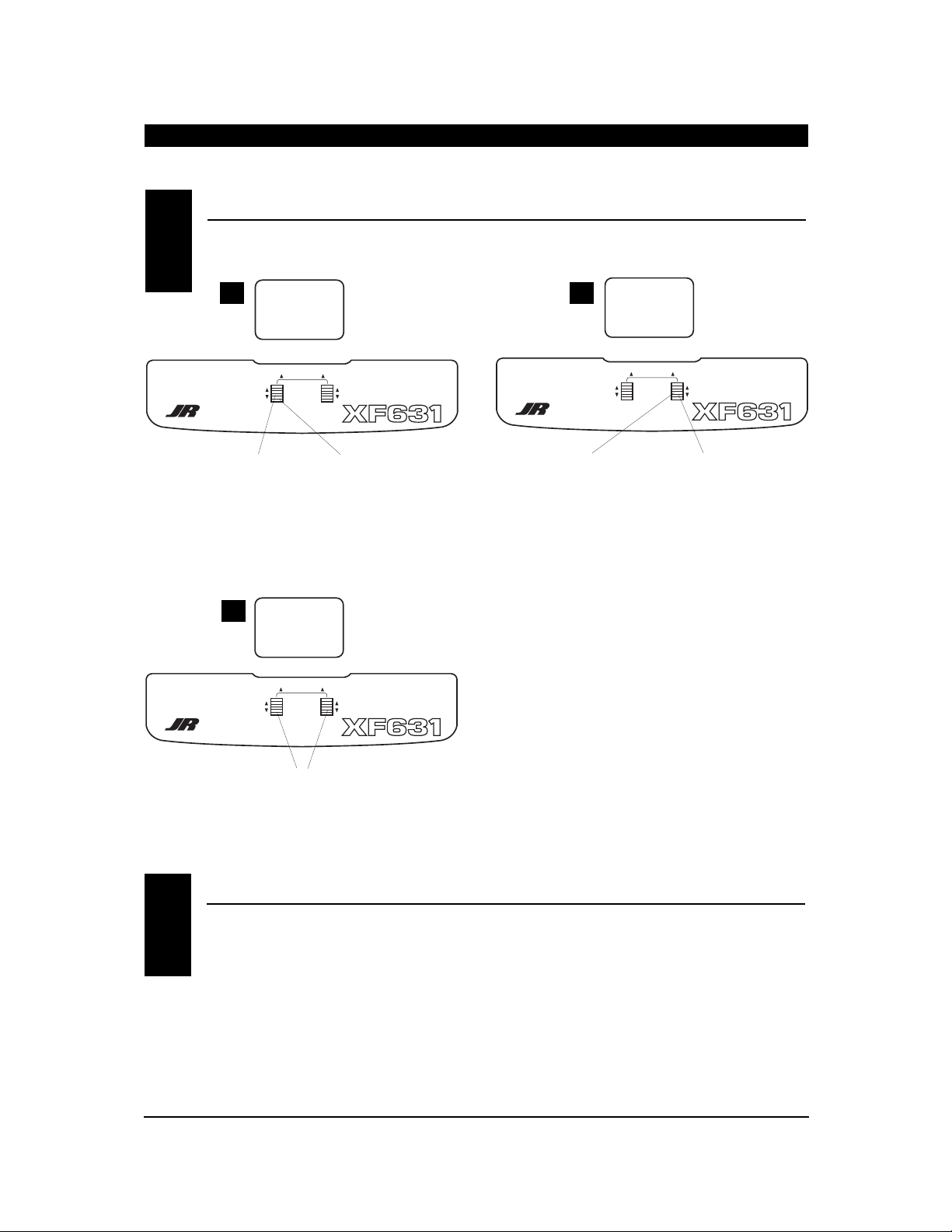

Press the Scroll

button until

“TRV ADJ”appears

on the screen.

Press the Channel button

to select the channel on

which you want the travel

adjusted.

INCREASE

To increase the travel,

move the stick (i.e.aileron)

to the right then press the

Increase button to adjust

the right travel.Release

the Increase button and

move the same stick to

the left. Press the

Increase button to adjust

the left travel.

DECREASE

To decrease the travel,

move the stick (i.e.aileron)

to the right then press the

Decrease button to adjust

the right travel.Release

the Decrease button and

move the same stick to the

left. Press the Decrease

button to adjust the

left travel.

A

B

C

TRAVEL ADJUSTMENT

3

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

I0.4

V

AC I

Press the Scroll and Increase buttons upwards

simultaneously to return to the main screen and exit

the Function mode.

Note: Before flying, check that the direction and travel

of all control surfaces move correctly.

Before the initial start of your model, please check

to ensure that when the Throttle Cut button is pressed,

the engine’s carburetor barrel will move to the fully

closed (engine off) position.

This safety feature ensures that the engine can

be shut off immediately in case of a problem or

safety concern.

THROTTLE AUTO CUT

4

Page 6

6

XF631 MANUAL • INTRODUCTION 1: Using This Manual / INTRODUCTION 2: Features

The XF631 is a full feature introductory computer

radio that can be used for airplanes.

A blank data sheet is included at the end of this

manual. Once you have input all the necessary data

into your transmitter for a particular model, we

strongly recommend that you write that information

down on a copy of the data sheet provided. This is to

ensure that, in the rare case of a memory failure, you

will not lose your data.

INTRODUCTION 1: Using This Manual

USING THIS MANUAL

1

•

Easy-to-read LCD screen

•

3-model memory

•

Trainer system compatible with most other JR

FM radios

•

2 conveniently mounted direct-access

programming levers

•

Computer designed ergonomically styled case

•

Adjustable stick length

•

Dual rates for aileron and elevator

•

Digital trims with Direct Access feature

•

Throttle trim only affects idle position

•

Two-speed scrolling—press and hold the

appropriate button to scroll quickly or press and

release to scroll in steps

•

Flaperons mixing

•

Delta wing mixing

•

V-tail mixing

•

Throttle cut safety feature

R700 Slimline Receiver

•

The R700’s extremely compact “slimline” design

allows it to fit easily in limited spaces.

•

An independent laboratory ranked the R700

receiver with JR’s patented ABC&W circuitry as

one of the best receivers ever tested in terms of

3IM, 2IM, adjacent channel rejection, signal-tonoise ratio, and on-channel capture point.

•

A special “unwanted interference limiter” ignores

signals outside of the R700’s band width when

the receiver is on and the transmitter is off.

The limiter also prevents servos from random

glitching when other transmitters are operating

in close proximity.

•

The electrical circuitry in the R700 is state-of-theart surface mount technology (SMT). These SMT

components draw less current, thus increasing

flying time. Flush mounting of these components

also reduces the risk of vibration, wear, and

damage.

•

The R700 is compatible with all JR FMtransmitting radios.

TRANSMITTER FEATURES

2.1

RECEIVER FEATURES

2.2

INTRODUCTION 2: Features

Page 7

7

XF631 MANUAL • INTRODUCTION 2: Features

INTRODUCTION 2: Features continued

537 Servo

•

An ultra-tight deadband amplifier ensures

accurate neutral centering

•

Low current drain

•

Ball bearing supported ouput shaft with new

wide spacing for improved precision

•

An indirect drive feedback potentiometer gives

additional protection from vibration

SERVO FEATURES2.3

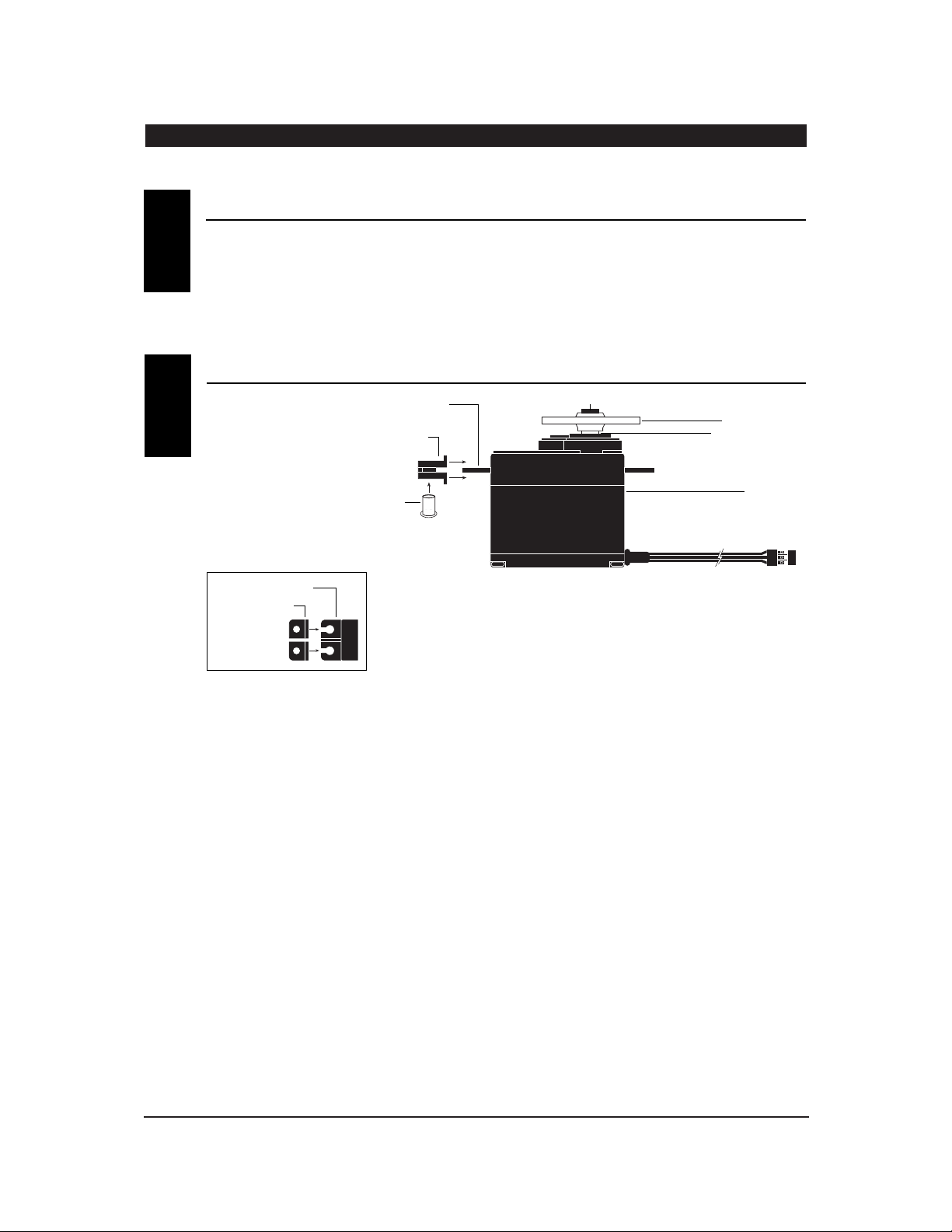

SERVO LAYOUT

2.4

Servo Mounting Flange

Rubber Grommets

Rubber Grommets

Servo Case

Servo Lead w/Connector

Servo Output Shaft

Servo Mounting Flange

Servo Arm/Horn

Servo Arm Retaining Screw

Servo Eyelet

Top View

Page 8

8

XF631 MANUAL • INTRODUCTION 3: Specifications

INTRODUCTION 3: Specifications

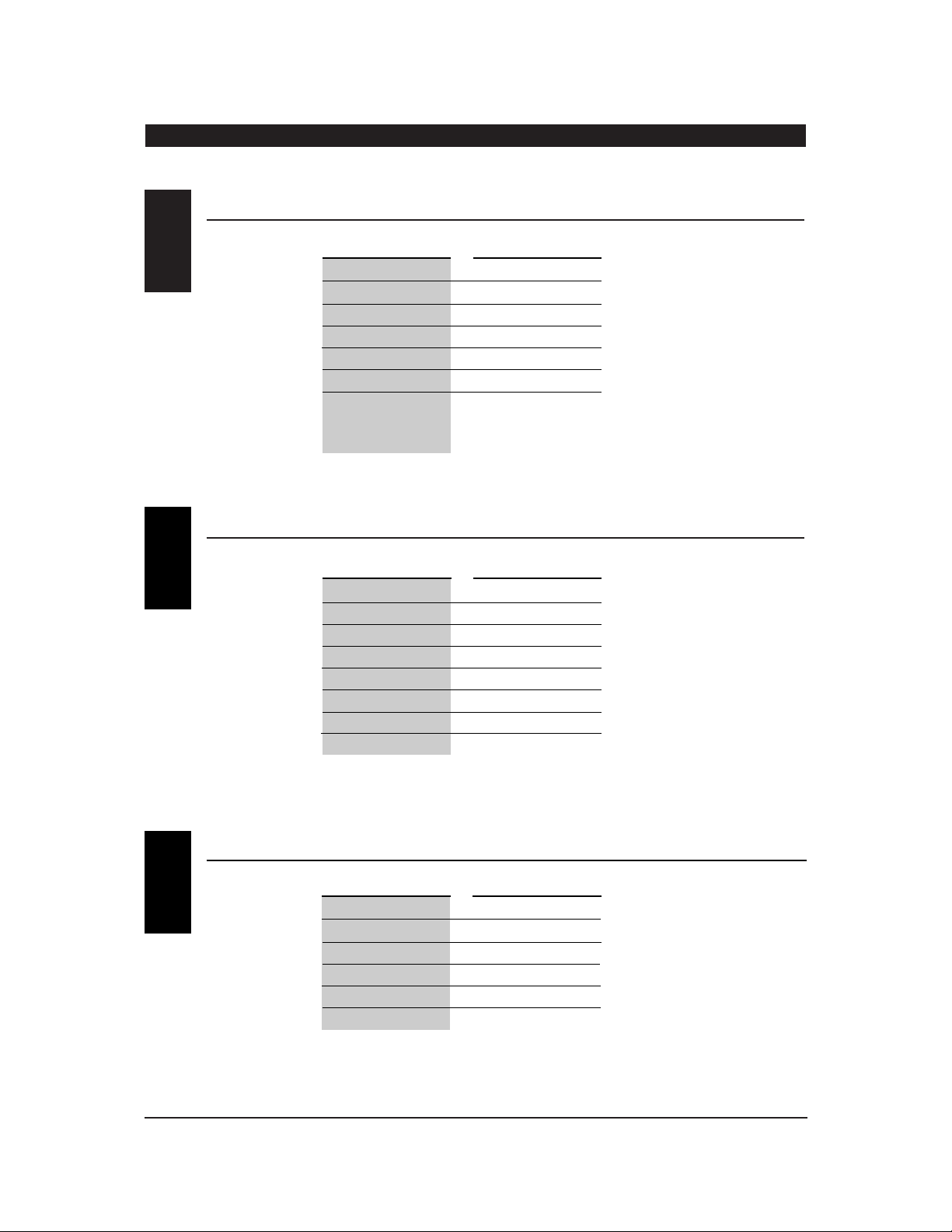

SYSTEM SPECIFICATIONS

TRANSMITTER SPECIFICATIONS

3.1

3.2

SYSTEM NAME XF631

TRANSMITTER BODY XF631

RECEIVER R700

CHARGER NEC-221

AIRBORNE BATTERY 4N-600

SERVOS NES-537BB x 4

ACCESSORIES Mini Switch

12" Aileron Extension

Servo Accessories

Instruction Manual

TYPE AIRPLANE

MODEL NUMBER XF631

ENCODER 6-Channel Computer System

RF 72 MHz

MODULATION PPM (FM)

OUTPUT POWER Approximately 1 Watt

CURRENT DRAIN 200mA

POWER SOURCE 1.2V x 8 NiCad (9.6V) 600mAh

OUTPUT PULSE 1000-2000 (1500 Neutral)

TYPE AIRPLANE

SERVO SPECIFICATIONS3.3

TORQUE (oz/in) 43

SPEED (sec/60°) .25

WEIGHT (oz) 1.37

SIZE (in) (W x L x H) 0.73 x 1.52 x 1.32

BB YES

MOTOR 3-Pole Ferite

TYPE 537BB

Page 9

9

XF631 MANUAL • INTRODUCTION 3: Specifications

RECEIVER SPECIFICATIONS

3.4

CHARGER SPECIFICATIONS

AIRBORNE BATTERY PACK

3.5

3.6

MODEL NUMBER NER-700

TYPE 7-Ch/FM Slimline w/ABC Circuitry

FREQUENCY 50/53/72MHz

SENSITIVITY (Microseconds) 5µs Minimum

SELECTIVITY 8KHz/50dB

WEIGHT (oz) .64 oz

SIZE (in) (W x L x H) 1.84 x 0.98 x 0.61

RECEIVER ANTENNA 39" For All Aircraft Frequencies

TYPE R700 FM

MODEL NUMBER NEC-221

INPUT VOLTAGE AC 100-120V

OUTPUT CURRENT 50mAh TX/50mAh RX

CHARGING TIME 15 Hours

TYPE AIRPLANE

MODEL NUMBER 4N-600

VOLTAGE 4.8V

SIZE (in) (W x L x H) 2.24 x 0.59 x 2.05

WEIGHT (oz) 3.3

TYPE AIRPLANE

INTRODUCTION 3: Specifications continued

Page 10

10

XF631 MANUAL • INTRODUCTION 4: Battery Charging

INTRODUCTION 4: Battery Charging

The pilot lamps should always be on during the

charging operation. If they are not, make sure you

have turned off both the transmitter and receiver.

Do not use the charger for equipment other than JR.

The charging plug polarity may not be the same, and

equipment damage may result.

Do not use other manufacturers’ after-market

accessories that plug into the transmitter’s charging

jack. If you do, any damage that results will not be

covered by warranty. If you are unsure of

compatibilities with your radio, seek expert advice

before doing anything to avoid possible damage.

During the charging operation, the charger’s

temperature is slightly elevated. This is normal.

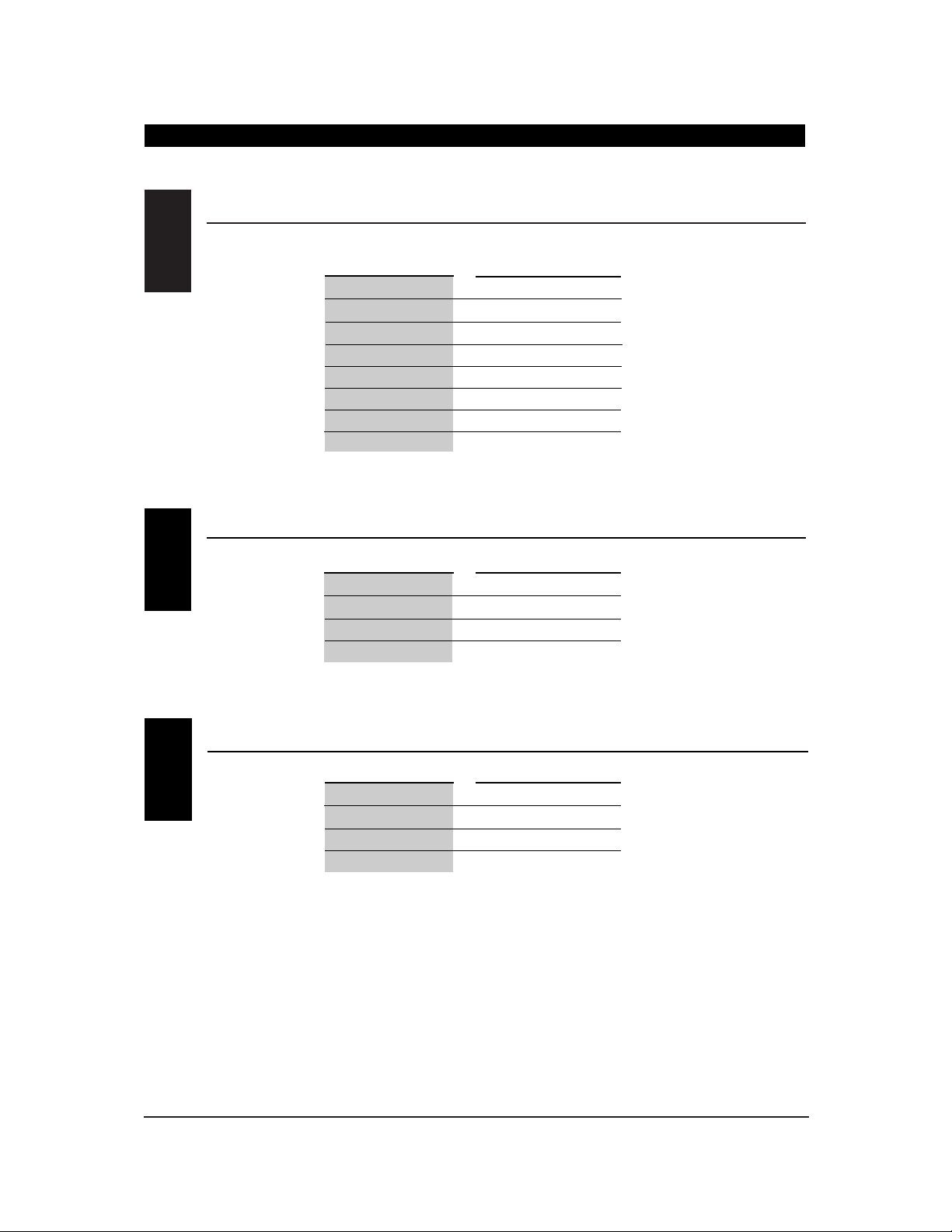

CHARGER4.2

It is imperative that you fully charge both the

transmitter and the receiver battery packs prior to

each day of flying. For the initial charge, leave the

charger and batteries hooked up for 20-24 hours in

order to fully charge both battery packs to peak

capacity. For subsequent charges, leave the charger

and batteries hooked up overnight (approximately

16 hours).

The charger supplied with this system is designed to

recharge your transmitter battery at a rate of 50mA.

The receiver battery pack will charge at 50mA for the

600mAh battery pack.

Transmitter Only

The center pin on all JR remote control systems is

negative. Therefore, the center pin on all JR

chargers is negative, not positive. This is different

from any other manufacturers’ chargers and radio

systems. Beware of improper connections based

on “color code” wire leads as they do not apply

in this instance. You must make certain that the

center pin of your JR transmitter is always

connected to the negative voltage for correct

polarity hookup.

CENTER

PIN IS

NEGATIVE

OUTSIDE IS POSITIVE

RIGHT SIDE OF TRANSMITTER

CHARGER PIGTAIL FOR RECEIVER

CHARGER PIGTAIL FOR TRANSMITTER

BLACK TO POSITIVE

RED TO NEGATIVE

RED–POSITIVE / BROWN–NEGATIVE / ORANGE–SIGNAL

TRANSMITTER / RECEIVER4.1

Page 11

11

XF631 MANUAL • INTRODUCTION 5: Trainer System

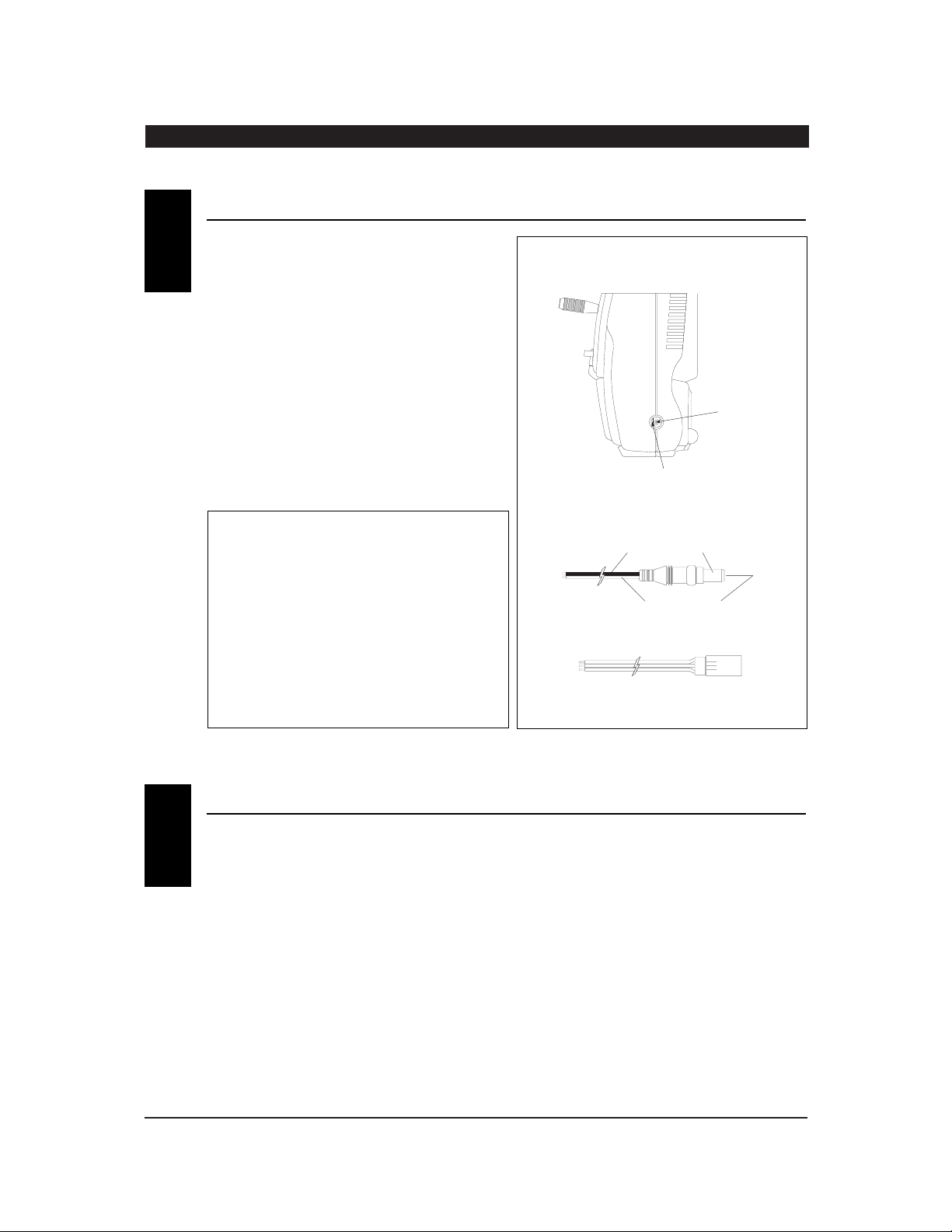

The XF631 features a built-in trainer system. The

transmitter can be used as either a master (trainer) or

as a slave (trainee). The XF631 is compatible with all

other current JR radios that have built-in trainer

systems. An optional trainer cord (JRPA130)

is needed .

1. Match the servo reversing, sub-trims, travel

adjust, and trims of both radios.

2. Plug the optional trainer cord into both

transmitters.

3. Turn on the master transmitter.

Note: The slave radio must be left off.

4. Test all the control functions on your aircraft with

the master radio.

5. Push the Trainer button on the master transmitter

and check all the control functions with the

slave radio.

INTRODUCTION 5: Trainer System

TRAINER SYSTEM5

D.S.C.

TRAINER

CORD INPUT

ON

TRAINERELEVATOR D/R

0

1

0

1

AILERON D/R

SCROLL

CHANNEL

INCREASE

DECREASE

XF622

FUNCTION 3-4 1-4 FUNCTION 1-2 2-3

MULTI

DATA

DISPLAY

VOLTAGE

INDICATOR

ON

TRAINERELEVATOR D/R

GEAR

0

1

FLAP

0

1

AILERON D/R

SCROLL

CHANNEL

INCREASE

DECREASE

XF622

XF631

FUNCTION 3-4 1-4 FUNCTION 1-2 2-3

MULTI

DATA

DISPLAY

VOLTAGE

INDICATOR

TRAINER

BUTTON

OPTIONAL

TRAINER CORD

(JRPA130)

MASTER TX

POWER SWITCH ON

SLAVE TX

POWER SWITCH OFF

THROTTLE CUT

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA DISPLAY SYSTEM

ENTER

ENTER

XF631

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA DISPLAY SYSTEM

GEAR

FLAP

THROTTLE CUT

Operating the Trainer System

Page 12

12

XF631 MANUAL • CHAPTER 1: Transmitter Controls

1. THRO: Throttle Channel

2. AILE: Aileron Channel

3. ELEV: Elevator Channel

4. RUDD: Rudder Channel

5. GEAR: Gear Channel

6. AUX 1: Flap Channel

Transmitter Throttle ALT

The throttle ALT function makes the throttle

stick trim active only when the throttle stick is less

than half throttle. This gives easy, accurate idle

adjustments without affecting the high

throttle position.

RECEIVER CHANNEL ASSIGNMENT/TRANSMITTER THROTTLE ALT1.2

CHANNEL 6 (GEAR) SWITCH

ELEVATOR DUAL RATE

ANTENNA

LCD SCREEN

CHANNEL 5 (GEAR) SWITCH

AILERON DUAL RATE

AILERON/ELEVATOR STICK

THROTTLE/RUDDER STICK

POWER SWITCH

DIGITAL AILERON TRIM

DIGITAL ELEVATOR TRIM

DIGITAL THROTTLE TRIM

DIGITAL RUDDER TRIM

NECK STRAP EYELET

CARRYING HANDLE

TRAINER SWITCH

THROTTLE CUT BUTTON

PROGRAMMING INPUT LEVERS

CONTROL IDENTIFICATION AND LOCATION• Mode II

CHAPTER 1: Transmitter Controls

1.1

Page 13

13

XF631 MANUAL • CHAPTER 1: Transmitter Controls

To adjust the control stick length, use a 2 mm Allen

wrench to unlock the set screw located inside the

end of the control stick. Turn the set screw counterclockwise to loosen it, then turn the knurled portion

of the stick to adjust the length. Counterclockwise

will lengthen the stick and clockwise will shorten it.

After the control stick(s) has been adjusted to suit

your flying style, tighten the set screw.

CONTROL STICK LENGTH ADJUSTMENT1.4

CHAPTER 1: Transmitter Controls continued

TRANSMITTER REAR1.3

Note: Your transmitter has a 5-year lithium battery

to protect your preprogrammed data against main

transmitter battery failure. If your system reads 0.0V

or has an unfamiliar display (service mode), or your

data resets to the factory defaults, return your

transmitter to Horizon Service Center (see page 28)

for a lithium battery replacement.

BATTERY CONNECTOR

Use caution when disconnecting/removing the

transmitter battery pack. If the connector is not

properly disconnected, damage to the connector

and/or the radio system can result.

CRYSTAL

(Factory installed)

SET SCREW

LOOSEN

TIGHTEN

Page 14

14

XF631 MANUAL • CHAPTER 1: Transmitter Controls

CHAPTER 1: Transmitter Controls continued

For proper DSC hook-up and operation:

1. Leave the transmitter power switch off. The

transmitter will not transmit any radio

frequency (RF) in this position.

2. Plug the optional DSC cord (JRPA132) into

the DSC port in the rear of the transmitter.

3. The encoder section of the transmitter will now

be operational and the LCD display will be lit.

4. Plug the other end of the DSC cord into

the receiver charge receptacle. Turn on the

switch harness.

Note: When installing the optional charging

jack (JRPA024), be sure to hook the charging jack

receptacle securely into the switch harness

charge cord.

Why you should use the DSC function:

1. The DSC enables you to check the control

surfaces of your airplane without drawing the

fully operational 200mAh from your transmitter

battery pack. Instead, you will only draw 70mAh

when using the DSC function.

Note: You will need to purchase (separately)

both the DSC cord (JRPA132) and the JR Deluxe

Switch Harness (JRPA001) to make use of the

XF631 DSC function.

2. The DSC function allows you to make final

adjustments to your airplane without

transmitting any radio signals. Therefore, if

another pilot is flying on your frequency, you

can still adjust your aircraft and not interfere

with the other aircraft.

Note: Under no circumstances should you

attempt to fly your aircraft with the DSC cord

plugged in! This feature is for bench checking

your aircraft only.

There is an eye hook on the front of the transmitter

for attaching an optional neck strap (JRPA023). The

eye hook is precisely positioned (see Section 1.1)

so that the transmitter will be perfectly balanced when

a neck strap is used.

DIRECT SERVO CONTROL (DSC)1.5

A

B

C

A - Charge Cord/DSC Receptacle

B - Switch Harness Lead

C - Charger/DCS Cord

NECK STRAP ATTACHMENT1.6

Page 15

15

XF631 MANUAL • CHAPTER 2: Connections

It is important to correctly install the radio system in

your model. Please read and carefully follow the

suggestions listed below.

1. For added protection, wrap the RX and the RX

NiCad in foam rubber that is at least 1/4” thick.

2. Run the RX antenna through the fuselage and

make sure it is fully extended. Never cut or

bundle your RX antenna — this will decrease

range and performance.

3. Rubber servo grommets are included with your

radio system and should be installed in the servo

flanges. The servos should then be mounted on

either hardwood rails or a plywood tray with the

mounting screws provided. Do not overtighten

the mounting screws. The flange of the brass

eyelets should face down (toward the wood).

4. All servos must be able to move freely over the

full range of their travel. Make sure the linkages

do not impede servo travel. A stalled servo will

drain the battery pack within a few minutes.

5. Before installing servo output arms, make sure

the servo is in its neutral position.

6. In the case of gas-powered model aircraft, mount

the receiver power switch on the side of the

fuselage opposite the muffler to protect the

switch from exhaust residue. With other types of

models, mount the switch in the most convenient

place. Make sure that the switch operates freely

and is capable of traveling its full distance.

7. With your model sitting on the ground and the

transmitter antenna collapsed, check that your

system works at a distance of 75 to 100 feet.

If your system stops functioning at a distance that

is shorter than listed above, please contact the

Horizon Service Center for further information

prior to flying your model.

INSTALLATION REQUIREMENTS

CHAPTER 2: Connections

CONNECTIONS2.2

2.1

FLAP

Optional

Optional

R700 RECEIVER

ANTENNA

RECEIVER BATTERY

4N-600

ON/OFF SWITCH HARNESS

NEW ABC & W SYSTEM

6 CHANNEL RECEIVER

7 CH 72MHz FM SLIMLINE

RECEIVER

7

ABC&W INTERFERENCE

PROTECTION SYSTEM

NER-226X

JAPAN REMOTE CONTROL CO., LTD

MADE IN JAPAN

226X RECEIVER

ANTENNA

AUX 1

GEAR

RUDD

ELEV

THRO

BATT

AILE

OFF

(JRPA003)

AUX1

GEAR

BATT

RUDD

ELEV

AILE

THRO

ON

GEAR

RUDDER

ELEVATOR

AILERON

THROTTLE

Page 16

16

XF631 MANUAL • CHAPTER 3: Key Input and Display / CHAPTER 4: Battery Alarm and Display

Two input keys are located at the lower right and left

faceplate of the XF631 transmitter. The keys are used

to access and program the transmitter. Each key can

be moved up or down using your thumbs.

CHAPTER 4: Battery Alarm and Display

CHAPTER 3: Key Input and Display

KEY INPUT AND DISPLAY3

When the transmitter battery drops below 9.0 volts,

the display will start to flash BAT and an audible

alarm will sound for 8 beeps. These warnings mean

you should land your aircraft immediately.

Note: During the period that the battery alarm

is flashing, the input buttons will not

function. If you are currently in the

function mode, the transmitter will exit

automatically and return to the normal

display (see Section 5.1).

BATTERY ALARM AND DISPLAY4

Left button up........Scroll — Used to advance

through the menus.

Left button down...Channel — Used to advance

through the channels or features

in a given function.

Right button up........Increase— Increases value or

changes setting

(e.g., Reverse Normal).

Left button down......Decrease — Decreases value

or changes setting.

(e.g., Reverse Normal).

BAT

8.9

V

FLASHING

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

SCROLL

CHANNEL

ENTER

INCREASE

DECREASE

Page 17

17

XF631 MANUAL • CHAPTER 5: Input Mode and Functions

When the power switch is turned on, the

screen will read as shown here in the

diagram. This screen is referred to as the

normal display.

CHAPTER 5: Input Mode and Functions

NORMAL DISPLAY5.1

The Direct Trim function of the XF631 can be

accessed through the use of any of the 4 digital trims

levers (throttle, aileron, elevator, or rudder).

When a trim input is given, the screen will

automatically change to show the trim value for

that particular channel. Once the trim adjustment

has been made, the screen will automatically return

to the previous screen setting after 2-3 seconds. The

maximum trim value for each channel is +/- 40 in

increments of 2.

DIRECT TRIM ACCESS DISPLAY5.2

The XF631 features two types of programming paths.

System mode includes programming functions that

are initially adjusted when the model is first set up,

like selecting wing type or the model, and is seldom

accessed after the initial setup. System modes

include:

MODEL RESET

MODEL SELECT

WING TYPE MIXING

V-TAIL MIXING

MODEL NAME

Function mode includes programming that is more

frequently changed, sometimes at the flying field.

Function Modes include:

SERVO REVERSING

DUAL RATES

SUB-TRIM

TRAVEL ADJUST

MODE TYPES5.3

THROTTLE CUT5.4

Your XF631 incorporates a special Throttle Cut button

located on the upper right face of the transmitter.

This feature is designed to immediately override any

current throttle/trim position and will immediately

return the throttle servo to the full low position. This

feature will allow the engine to be automatically

stopped in case of emergency, or in the event of a

crash. When adjusting your throttle linkage, please

check to ensure that when the Throttle Cut button is

pushed, the throttle servo will move the carburetor

barrel to the full closed position.

Note: In some cases it will be necessary to

adjust the engines barrel stop screw so that the

carburetor can be fully closed. Please refer to

your engine instructions for more detail.

MDI

10.4V

MODEL NAME

BA TTER Y V OLTAGE

AIL

- 2

INDICATES CHANNEL

INDICATES CURRENT

TRIM VALUE (+ OR --)

Page 18

To enter System Setup mode,

press both programming

levers up and turn on the

Power switch.

Power Switch

Programming Levers

RST

I

To enter Function mode,

turn on the Power switch

and then press both

programming levers up.

Power Switch

THR

-

REV•NORM

18

XF631 MANUAL • CHAPTER 5: Input Mode and Functions

To enter the Function mode, turn on the transmitter. Press the Scroll

and Increase buttons up simultaneously until a beep is heard. The

display will change accordingly and show the last active function.

Press the Scroll button up to scroll down through the functions one by

one as shown in the flowchart at left. Once the appropriate function is

selected, use the Channel button to select the appropriate channel.

Use the Increase and Decrease buttons to adjust the values displayed on

the screen.

CHAPTER 5: Input Mode and Functions continued

FUNCTION MODE5.6

THR

-

REV•NORM

SERVO REVERSING

Page 24

SUB-TRIM

Page 26

TRAVEL ADJUSTMENT

Page 27

DUAL RATES

Page 25

0

THR

SB-TRIM

+I00

%

THR

TRV ADJ

+I00

%

AI0

To enter the System mode, press the Scroll and Increase buttons up

simultaneously while you turn on the transmitter. You can now select

any of four system mode functions shown here in the flow chart. To

exit the System mode, press the Scroll and Increase buttons

simultaneously or turn off the transmitter. Press up the Scroll button

to move through the System mode functions. Information for each

function is located on the page number listed next to the

function name.

SYSTEM MODE5.5

MODEL NAME ENTRY

Page 22

WING TYPE

SELECTION

FPR FLAPERON

DELTA

V-TAIL

Page 20–21

RST

DATA RESET

Page 18

MODEL SELECTION

Page 19

I

MDL

OF

WNG

MIX

I

I

MDI

MIX

Programming Levers

D/R

ON

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ENTER

INCREASE

DECREASE

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ON

ENTER

INCREASE

DECREASE

Page 19

19

XF631 MANUAL • CHAPTER 6: Functions (System Mode)

Accessing the Data Reset Function

CHAPTER 6: Functions (System Mode)

The data reset function allows you to reset all the

programming in the selected model (1,2, or 3) to the

factory settings. Before using the data reset function,

it’s important to enter the model selection function

and select the desired model number (1,2, or 3) for

which you want to reprogram to the factory settings.

The model selection function is described in

Section 6.2.

1. Press the Scroll and Increase buttons up

simultaneously and hold.

2. Turn on the transmitter to enter the

System mode.

3. Press the Scroll button up until “RST” appears

on the screen.

4. Press the Channel and Increase buttons

simultaneously to reset the data. (To confirm that

the selected model's programming has been

reset, a beep will sound and the model number

will momentarily disappear from the screen.)

5. Press the Scroll button to access the model

select function.

6. To exit, press the Scroll and Increase buttons up

simultaneously.

DATA RESET• System Mode

6.1

RST

I

Programming Levers

In System Setup mode,

press the Scroll button up

until “RST”appears on

the screen.

Press the Channel button down and

Increase button up simultaneously

to reset the data (a beep will sound).

RST

1

INDICATES DATA RESET FUNCTION

MODEL NUMBER TO RESET

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ENTER

INCREASE

DECREASE

Page 20

20

XF631 MANUAL • CHAPTER 6: Functions (System Mode)

The XF631 has memory for 3 models.

1. Press the Scroll and Increase buttons up

simultaneously and hold.

2. Turn on the transmitter to enter the

System mode.

3. Press the Scroll button until “MDL”

appears on the screen.

4. Press the Increase or Decrease button to select

model number 1,2, or 3.

5. Press the Scroll button to access the wing type

entry function.

6. To exit, press the Scroll and Increase buttons up

simultaneously.

Accessing the Model Selection Function

MODEL SELECTION• System Mode

6.2

CHAPTER 6: Functions (System Mode) continued

MDL

I

Programming Levers

In System Setup mode,

press the Scroll button

until “MDL”appears on

the screen.

Press the Increase or

Decrease button to select

model number 1, 2, OR 3.

MDL

1

INDICATES MODEL SELECTION FUNCTION

MODEL NUMBER 1, 2, OR 3

ENTER

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

INCREASE

DECREASE

Page 21

21

XF631 MANUAL • CHAPTER 6: Functions (System Mode)

CHAPTER 6: Functions (System Mode) continued

OF

MIX

Press the Scroll

button until

“MIX WING” appears

on the screen.

Press the Channel

button to select

Wing Type (WNG) or

V-tail (VTL) mixing.

Press the Increase or

Decrease button to turn the

flaperon (FPR), Delta (DLT) or

V-tail (VTL) mixing on or off.

OF = OFF

ON = ON

INDICA TES WING TYPE FUNCTION

FPR = FLAPERON

VTL = V-TAIL

DLT = DELTA

WING = WING TYPE SELECTION

MIX

OF

Accessing the Wing Type Selection Function

1. Press the Scroll and Increase buttons up

simultaneously and hold.

2. Turn on the transmitter to enter the

System mode.

3. Press the Scroll button until the “MIX WNG”

appears on the screen.

4. Press the Channel button to select either the wing

type (WNG) or V-tail (VTL) mode.

5. Press the Scroll button to access the model

name function.

6. To exit, press the Scroll and Increase buttons

up simultaneously.

Flaperon, V-tail, and Delta mixing are available for

specialty aircraft that require those functions. The

flaperon feature mixes flaps with ailerons so the

ailerons can be drooped for takeoffs and landings

while still functioning fully as ailerons. V-tail mixing

combines rudder and elevator for V-tail operations.

The Delta wing function allows the aileron to also act

as the elevator, while retaining independent use of

both functions. The Delta wing function allows the

ailerons to also act as the elevator, while retaining

independent use of both functions.

Flaperon Setup

When using flaperon mixing, two servos (one for

each aileron) must be used. Connect the left aileron

servo to channel #6 (Flp/Aux 1) and the right aileron

servo to channel #2 (Aile) in the receiver. Individual

functions (e.g., servo reversing, sub-trims, etc.) are

still available for each of the channels. Use sub-trims

for individual neutral adjustment.

Note: When flaperon is selected, it is necessary

to reduce the travel adjust values of channel #6

0% in each direction to prevent servo over-travel

(binding). Please refer to section 7.3 for travel

adjust information.

V-Tail

V-Tail mixing requires two servos. Connect the left

tail servo to channel #3 (Elev) and the right tail servo

to channel #4 (Rudd) in the receiver. Individual

functions (e.g., servo reversing, sub-trims, etc.) are

available for each servo. Use sub-trims for individual

neutral adjustments described in Section 7.2. V-Tail

elevator travel is adjusted by elevator and rudder

travel adjust.

Delta Wing Mixing

Delta or elevon mixing, as it is commonly known, is

the final wing mixing selection in your XF631. This

style of aircraft also employs two wing servos.

However, in essence, there is not an elevator present.

Instead, at an elevator stick input, the two wing

servos function in conjunction with one another in

the same direction to create an up/down movement

of the aircraft. Also, when an aileron control is given,

the two wing servos move in opposite directions to

function as ailerons as well.

WING TYPE SELECTION• System Mode

6.3

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ENTER

INCREASE

DECREASE

Page 22

22

XF631 MANUAL • CHAPTER 6: Functions (System Mode)

CHAPTER 6: Functions (System Mode) continued

To Activate Flaperon (FPR) Mixing (Wing Type Mode)

To Activate Delta Wing (DLT) Mixing (Wing Type Mode)

1.In System Setup mode, press

the Scroll button until “MIX

WNG” appears on the screen.

2.Press the Increase button to

activate Flaperon mixing.

OF

FPR

MIX

OF = MIX OF

ON = MIX ON

OF

ON

DLT

MIX

MIX

2.Press the Channel

button once to access

the V-tail mixing screen.

DEL TA WING

MIX ON

OF

ON

VTL

MIX

MIX

To Activate V-Tail (VTL) Mixing

Note: It is also possible to

activate both the flaperon (FPR)

and V-tail (VTL) functions to

work simultaneously.

WING TYPE SELECTION• System Mode (continued)

6.3

1.In System Setup mode, press

the Scroll button until “MIX

WNG” appears on the screen.

2.Press the Decrease button to

activate Delta wing mixing.

1.In System Setup mode,

press the Scroll button

until “MIX WNG”appears

on the screen.

3.Next press either the Increase or

Decrease buttons once to activate

V-tail mixing.

OK

WNG

MIX

OK

WNG

MIX

OK

WNG

MIX

SCROLL

ENTER

INCREASE

DECREASE

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

CHANNEL

SCROLL

ENTER

INCREASE

DECREASE

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ENTER

SCROLL

CHANNEL

INCREASE

DECREASE

Page 23

23

XF631 MANUAL • CHAPTER 6: Functions (System Mode)

CHAPTER 6: Functions (System Mode) continued

1. Press the Scroll and Increase buttons

up simultaneously and hold.

2. Turn on the transmitter to enter the

System mode.

3. Press the Scroll button until “MD1” appears

on the screen.

4. Press the Increase or Decrease buttons to

select the correct letter/number for the first

character (flashing).

5. To adjust the remaining 2 characters, press the

Channel button until the desired character to be

adjusted is flashing.

6. Press the Scroll button to access the modulation

select function.

7. To exit, press the Scroll and Increase buttons up

simultaneously.

Accessing the Model Name Entry Function

Press the Channel

button to select the

character to be

changed (flashing).

Press the Increase or

Decrease buttons to

select the desired

character (A-Z, 1-9, etc.).

Flashing Character includes

character to be adjusted

CURRENT MODEL

NUMBER

I

ACI

In System Setup mode,

press the Scroll button

until “MD1”appears on

the screen.

The XF631 allows a 3-character name to be input for

each of the 3 models available. The current model

will be displayed in the normal display. This feature

is useful to help identify different aircraft types or

model setups.

MODEL NAME ENTRY• System Mode

6.4

MDI

I

CHANNEL

SCROLL

INCREASE

DECREASE

ENTER

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

Page 24

24

XF631 MANUAL • CHAPTER 7: Functions (Function Mode)

CHAPTER 7: Functions (Function Mode)

Servo reversing is a very convenient function used in

the setup of a new aircraft. It is used to change the

direction of servo rotation in relation to the

corresponding stick movement. Servo reversing is

available for all channels.

1. Turn on the transmitter.

2. Press the Scroll and Increase buttons up

simultaneously to enter the Function mode.

3. Press the Scroll button until “REV/NORM” appears

on the screen.

4. Press the Channel button until the desired channel

appears on the screen.

5. Press the Increase or Decrease button to change the

servo direction.

6. Press the Scroll button to access the sub-trim

function.

7. To exit, press the Scroll and Increase buttons up

simultaneously.

Accessing the Servo Reversing Function

SERVO REVERSING• Function Mode

7.1

1 THR:THROTTLE

2 AIL: AILERON

3 ELE: ELEVATOR

4 RUD:RUDDER

5 GER: LANDING GEAR

6 FLP: FLAP (AUX 1)

Press the Increase or

Decrease button to change the

servo direction

Press the Channel

button until the desired

channel appears on

the screen.

Press the Scroll button

until “REV/NORM”

appears on the screen.

THR

REV+NORM

–

CHANNEL

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ENTER

INCREASE

DECREASE

Page 25

25

XF631 MANUAL • CHAPTER 7: Functions (Function Mode)

CHAPTER 7: Functions (Function Mode) continued

Dual rate is available for the aileron and elevator

channels. The purpose of this function is to allow for

in-flight selection of two preset servo travels for each

of these channels. The amount of travel is adjustable

from 0-125%. The factory settings for both switch

positions (0 and 1) is 100%. Either position may be

selected as the low or high rate by placing the

switches in the desired position and adjusting the

value for that position. Different types of maneuvers

require varying amounts of control movements. Snap

rolls require large control movements, while smooth

maneuvers like long slow rolls are best performed

with smaller control movements. Dual rates allow

you to change the control movements in flight at the

flip of a switch. This allows you to execute maneuvers

requiring both radical control movements and small

control movements during a single flight.

DUAL RATE• Function Mode

7.2

1. Turn on the transmitter.

2. Press the Scroll and Increase buttons

simultaneously to enter the Function mode.

3. Press the Scroll button until “D/R” appears on

the screen.

4. Press the Channel button until the desired

channel appears on the screen. (AI = aileron or

EL = elevator).

5. The number that appears directly to the right of

the selected channel is the switch position.

There are two switch positions, 0 and 1, for each

of the channels. A “0” will appear when the

selected dual rate switch is in the uppermost

position and a “1” when the selected switch is in

the lower position.

6. The number in the center of the screen indicates

the current dual rate value for the selected switch

position and channel. Press the Increase or Decrease

button to adjust the dual rate value (0-125%).

7. After adjusting the value for the 0 switch position,

change to the 1 switch position and adjust

the rates.

8. Press the Channel button to select the other

channel and adjust the dual rate value for both

switch positions.

9. To exit, press the Scroll and Increase buttons

simultaneously.

Accessing the Servo Reversing Function

Press the Scroll button

until “D/R”appears on

the screen.

Press the Channel

button until “AI”or “EL”

appears on the screen.

Press the Increase or

Decrease button to adjust

the dual rate value.

AIO

100

%

MODEL NAME

CHANNEL

AI: AILERON

EL: ELEVATOR

DUAL RATE VALUE

INDICATES THE DUAL RATE FUNCTION

D/R

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

SCROLL

CHANNEL

ENTER

INCREASE

DECREASE

Page 26

26

XF631 MANUAL • CHAPTER 7: Functions (Function Mode)

CHAPTER 7: Functions (Function Mode) continued

Accessing the Sub-Trim Function

Sub-trim is an electronic trim that is available for

each of the 6 channels. Sub-trim is particularly useful

as it allows the digital trim levers to be returned to

their neutral positions by adjusting /changing the

servo’s neutral position electronically, without the

need to mechanically adjust the specific control

linkage. This allows the same digital trim lever

settings between the two models you can control

with this radio system. Sub-trim can also allow

additional trim travel when digital trims do not

provide enough movement.

Note: It is recommended to use as little sub-trim

as possible for adjustment. If more that 20–30

points are required, is it suggested that a

mechanical linkage adjustment be performed.

Note: Prior to making final subtrim adjustments,

please check to make sure that the digital trim

values for aileron, elevator, and rudder are set to

the neutral position. Throttle trim value should

be set to the -40 position.

1. Turn on the transmitter.

2. Press the Scroll and Increase buttons up

simultaneously to enter the Function mode.

3. Press the Scroll button until “SB-TRIM” appears on

the screen.

4. Press the Channel button until the desired

channel appears on the screen.

5. Press the Increase or Decrease button to establish

the desired amount of sub-trim.

6. Press the Scroll button to access the travel

adjustment function.

7. To exit, press the Scroll and Increase buttons up

simultaneously.

SUB-TRIM• Function Mode

7.3

Press the Scroll button

until “SB-TRIM”appears

on the screen.

Press the Channel

button until the desired

channel appears on

the screen.

Press the Increase or

Decrease button to adjust

the sub-trim value.

1 THR:THROTTLE

2 AIL: AILERON

3 ELE: ELEVATOR

4 RUD:RUDDER

5 GER: LANDING GEAR

6 FLP: FLAP (AUX 1)

THR

0

SB-TRIM

CHANNEL

INDICATES

SUB-TRIM FUNCTION

SUB-TRIM VALUE (±125)

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

SCROLL

CHANNEL

ENTER

INCREASE

DECREASE

Page 27

27

XF631 MANUAL • CHAPTER 7: Functions (Function Mode)

CHAPTER 7: Functions (Function Mode) continued

The amount of servo travel is adjustable for each

direction for each of the 6 channels individually. The

adjustment range is from 0% to 150%. Travel

adjustment is factory set at 100% for all channels.

The travel adjustment value displayed on the screen

depends on the position of the stick or switch (e.g.,

flap switch, gear switch). This function is useful either

to maximize control surface travel or to reduce travel

to eliminate servo binding without the need for

mechanical adjustment.

1. Turn on the transmitter.

2. Press the Scroll and Increase buttons up

simultaneously to enter the Function Mode.

3. Press the Scroll button until “TRV ADJ.” appears on

the screen.

4. Press the Channel button until the desired

channel appears on the screen.

5. Move the selected channel stick or switch in the

direction that you want to adjust the travel.

Press the Increase or Decrease button to achieve

the desired travel. Move the stick in the

opposite direction to adjust the travel in the

opposite direction.

6. The same may be done for all channels.

7. Press the Scroll button to access the Servo

Reverse function.

8. To exit, press the Scroll and Increase buttons

up simultaneously.

Accessing the Travel Adjustment Function

TRAVEL ADJUSTMENT• Function Mode

7.4

Press the Scroll button

until “TRV ADJ.” appears

on the screen.

Press the Channel

button until the desired

channel appears on

the screen.

Press the Increase or

Decrease button to adjust

the travel adjustment value.

1 THR:THROTTLE

2 AIL: AILERON

3 ELE: ELEVATOR

4 RUD:RUDDER

5 GER: LANDING GEAR

6 FLP: FLAP (AUX 1)

THR

+I00

%

TRV ADJ.

CHANNEL

SERVO OPERATING DIRECTION

INDICA TES THE TRA VEL

ADJUSTMENT FUNCTION

TRAVEL ADJUSTMENT V ALUE

SCROLL

CHANNEL

DIGITAL TRIM EQUIPPED 6 CHANNEL

MULTI-DATA COMPUTER DISPLAY SYSTEM

ENTER

INCREASE

DECREASE

Page 28

NORM NORM NORM NORM NORM NORM

••••• •

REV REV REV REV REV REV

SUB TRIM

TRAVEL ADJUST + % + % + % + % + % + %

– % – % – % – % – % – %

28

XF631 MANUAL • CHAPTER 8: DATA SHEET

V-TAIL

ON • OFF

DATA SHEET

CHAPTER 8: Data Sheet

8

REVERSE SW

DIGITAL TRIM

VALUE

CHANNELS THRO (1) AIL (2) ELE (3) RUDD (4) GER (5) FLP (6)

WING TYPE

NORM

•

FLAPERON

•

DELTA

Model Number 1_____________________

Model Name ______________________

– 40% ± % ± % ± %

AILE (AI) ELEV (EL)

D/R % %

D/R % %

DUAL

POS 0

RATE

POS 1

Page 29

29

XF631 MANUAL • CHAMPTER 8: DATA SHEET

CHAPTER 8: Data Sheet

AILE (AI) ELEV (EL)

D/R % %

D/R % %

DUAL

POS 0

RATE

POS 1

NORM NORM NORM NORM NORM NORM

••••• •

REV REV REV REV REV REV

SUB TRIM

TRAVEL ADJUST + % + % + % + % + % + %

– % – % – % – % – % – %

V-TAIL

ON • OFF

DATA SHEET

8

REVERSE SW

DIGITAL TRIM

VALUE

CHANNELS THRO (1) AIL (2) ELE (3) RUDD (4) GER (5) FLP (6)

WING TYPE

NORM

•

FLAPERON

•

DELTA

Model Number 2_____________________

Model Name ______________________

– 40% ± % ± % ± %

Page 30

30

XF631 MANUAL • CHAPTER 8: DATA SHEET

CHAPTER 8: Data Sheet

NORM NORM NORM NORM NORM NORM

••••• •

REV REV REV REV REV REV

SUB TRIM

TRAVEL ADJUST + % + % + % + % + % + %

– % – % – % – % – % – %

V-TAIL

ON • OFF

DATA SHEET

8

REVERSE SW

DIGITAL TRIM

VALUE

CHANNELS THRO (1) AIL (2) ELE (3) RUDD (4) GER (5) FLP (6)

WING TYPE

NORM

•

FLAPERON

•

DELTA

Model Number 3_____________________

Model Name ______________________

– 40% ± % ± % ± %

AILE (AI) ELEV (EL)

D/R % %

D/R % %

DUAL

POS 0

RATE

POS 1

Page 31

31

XF631 MANUAL • IMPORTANT INFORMATION

IMPORTANT INFORMATION

Radio controlled models are a great source of

pleasure. Unfortunately, they can also pose a potential

hazard if not maintained and operated properly. It is

imperative that you install your radio control system

correctly. Additionally, your level of piloting

competency must be high enough to ensure that you

are able to control your aircraft under all conditions. If

you are a newcomer to radio controlled flying, please

seek help from an experienced pilot or your local

hobby shop.

Listed below are some safety “Dos and Don’ts” that

must be followed by all pilots:

• Ensure that your batteries have been properly

charged prior to initial flight.

• Keep track of the time that the system is turned

on so that you will have an idea of how long you

can safely operate your system.

• Perform a ground range check prior to the initial

flight of the day. See the “Daily Flight Checks”

section below for information on how to do so.

• Check all control surfaces prior to each takeoff.

• Use frequency flags.

• Do not fly your model near spectators, parking

areas, or at any other area that could result in

injury to people or damage of property.

• Do not fly during adverse weather conditions.

Poor visibility can cause disorientation and loss

of control of your aircraft. Strong winds can cause

similar problems.

• Do not fly unless your frequency is clear.

Warning: Only one transmitter at a time can

operate on a given frequency. If you turn on your

transmitter while someone else is operating a

model on your frequency, both pilots will lose

control of their models. Only one person can use a

given frequency at a time. It does not matter if it is

AM, FM, or PCM — only one frequency at a time.

• Do not point the transmitter antenna directly

toward the model. The radiation pattern from the

tip of the antenna is inherently low.

• Do not take chances. If at any time during flight

you observe any erratic or abnormal operation,

land immediately and do not resume flight until

the cause of the problem has been ascertained

and corrected.

1. Check the battery voltage on both the transmitter

and the receiver battery packs. Do not fly below

9.0 volts on the transmitter or below 4.7 volts on

the receiver. To do so can cause a crash of your

aircraft.

Note: When you check these batteries, ensure that

you have the polarities correct on your expanded

scale voltmeter.

2. Check all hardware (linkages, screws, nuts, bolts)

prior to each day’s flight. Be sure that binding

does not occur and that everything is properly

secured.

3. Ensure that all surfaces are moving in the proper

manner.

4. Perform a ground range check before each day’s

flying session. The range check should be as

follows:

• Do not extend the transmitter antenna at this

time. Turn the transmitter on.

• Turn the model on.

• Slowly walk away from the model while moving

the control surfaces. The aircraft should function

properly at a distance of 75–100 feet.

5. Just prior to starting your aircraft, turn off your

transmitter and then turn it back on. Do this each

time you start your aircraft. If any critical switches

are on without your knowledge, the transmitter

alarm will warn you at this time.

6. Ensure that all trim levers are in the proper

location.

7. Check to be sure that all servo pigtails and switch

harness plugs are secured in the receiver. Also,

make sure that the switch harness moves

completely in both directions.

GENERAL NOTES

1

DAILY FLIGHT CHECKS

2

Page 32

32

XF631 MANUAL • WARRANTY AND SERVICE INFORMATION

Important Note: Be sure to keep your original dated sales receipt in a safe place as you will be required to provide proof-of-purchase

date for the equipment to be serviced under warranty.

WARRANTY AND SERVICE INFORMATION

WARRANTY COVERAGE

REPAIR SERVICE INSTRUCTIONS

Your new JR Remote Control Radio System is

warranted to the original purchaser against

manufacturer defects in material and workmanship

for one year from the date of purchase. During this

period, Horizon Service Center will repair or replace,

at our discretion and at no cost to the purchaser, any

component that is found to be factory defective. This

warranty is limited to the original purchaser of the

unit and is not transferable.

This warranty does not apply to any unit which has

been improperly installed, mishandled, abused, or

damaged in a crash, or to any unit which has been

repaired or altered by any unauthorized agencies.

Under no circumstances will the buyer be entitled to

consequential or incidental damages. This limited

warranty gives you specific legal rights; you also have

other rights which may vary from state to state. As

with all fine electronic equipment, do not subject

your radio system to extreme temperatures, humidity

or moisture. Do not leave it in direct sunlight for

long periods of time.

In the event that your JR radio needs service, please

follow the instructions listed below:

1. Check all on/off switches to be sure they are off.

This will speed the repair process of checking

battery condition.

2. Return your system components only (transmitter,

receiver, servos, etc). Do not return your system

installed in a model aircraft.

3. Preferably, use the original carton/packaging

(molded foam container), or equivalent, to ship

your system. Do not use the system carton itself as

a shipping carton. You should package the system

carton within a sturdy shipping container using

additional packing material to safeguard against

damage during transit. Include complete name

and address information inside the carton, as well

as clearly writing it on the outer label/return

address area.

4. Include detailed information explaining your

operation of the system and problem(s)

encountered. Provide an itemized list of equipment

enclosed and identify any particular area/function

which may better assist our technicians in

addressing your concerns. Date your

correspondence and be sure your complete name

and address appear on this enclosure.

5. Include your name, mailing address, and a phone

number where you can be reached during the

business day.

6. Warranty Repairs. To receive warranty service, you

must include your original dated sales receipt to

verify your proof-of-purchase date. Providing that

warranty conditions have been met, your radio will

be repaired without charge.

7. Normal Non-Warranty Repairs. Should your repair

cost exceed 50% of the retail purchase cost, you will

be provided with an estimate advising you of your

options.

Within your letter, advise us of the payment method

you prefer to use. Horizon Service Center accepts

VISA or MasterCard. Include your card number and

expiration date. Horizon Service Center also accepts

money orders.

Mail your system to:

Horizon Service Center

4105 Fieldstone Road

Champaign, IL 61822

Phone: (217) 355-9511

www.horizonhobby.com

3

4

Page 33

33

XF631 MANUAL • FREQUENCY CHART

72MHz requires no special license to operate.

50/53MHz requires the operator to have an FCC

amateur radio license (Ham).

CH.NO. FREQUENCY

15 72.090

16 72.110

17 72.130

18 72.150

19 72.170

20 72.190

21 72.210

22 72.230

23 72.250

24 72.270

25 72.290

26 72.310

27 72.330

28 72.350

29 72.370

30 72.390

31 72.410

32 72.430

33 72.450

34 72.470

35 72.490

CH.NO. FREQUENCY

36 72.510

37 72.530

38 72.550

39 72.570

40 72.590

41 72.610

42 72.630

43 72.650

44 72.670

45 72.690

46 72.710

47 72.730

48 72.750

49 72.770

50 72.790

51 72.810

52 72.830

53 72.850

54 72.870

55 72.890

56 72.910

57 72.930

58 72.950

59 72.970

60 72.990

CH.NO. FREQUENCY

00 50.800

01 50.820

02 50.840

03 50.860

04 50.880

05 50.900

06 50.920

07 50.940

08 50.960

09 50.980

72MHz 50MHz

CH. NO. FREQUENCY FLAG COLOR

A1 53.100 Black/Brown

A2 53.200 Black/Red

A3 53.300 Black/Orange

A4 53.400 Black/Yellow

A5 53.500 Black/Green

A6 53.600 Black/Blue

A7 53.700 Black/Purple

A8 53.800 Black/Gray

53MHz

FREQUENCY CHART

5

72MHz

FREQUENCY CHART

*Channels 11–14 are not available

Page 34

NOTES

Page 35

NOTES

Page 36

DISTRIBUTED EXCLUSIVELY BY HORIZON HOBBY DISTRIBUTORS CHAMPAIGN, IL 61822

www.horizonhobby.com

© 1999 Horizon Hobby Distributors, Inc. All Rights Reserved.

®

Loading...

Loading...