Page 1

ASSEMBLY INSTRUCTIONS

Vibe 500e Specications

Overall Length ........................33.25 in (844.55mm)

Height ........................................11.75 in (298.45mm)

Main Rotor Diameter ...........37.75 in (958.85mm)

Tail Rotor Diameter ..........................7.3 in (185mm)

Main Gear Ratio ................................7.08:1 or 6.54:1

Tail Gear Ratio ........................................................ 4.5:1

Weight (without battery) ............... 3.9 lb (1800 g)

Control System ............................................120 CCPM

Page 2

2

TABLE OF CONTENTS

Introduction .........................................................................3

Key Features .........................................................................3

Preassembly Warning .......................................................4

Recommended Radio System ........................................4

Items Required to Complete Assembly ......................5

1-1A Attaching the Servo Adapters ............................6

1-1B Assembling the Guide Roller ..............................6

1-2 Attaching the Guide Roller ..................................7

1-3 Attaching the Bearing Case and

Frame Support .........................................................7

1-4 Attaching the Body Catch ....................................8

1-5 Attaching the Frame Bridge ................................8

1-6 Attaching the Radius Support ...........................9

1-7 Attaching the Battery Mount .............................9

1-8 Attaching the Landing Gear ............................10

2-1 Attaching the Tail Pulley Case .........................10

2-2 Attaching the Tail Output Shaft ...................... 11

2-3 Assembling the Tail Pitch Control Lever ...... 11

2-4 Attaching the Tail Pitch Control Lever 1 ......12

2-5 Attaching the Tail Pitch Control Lever 2 ......12

2-6 Attaching the Tail Rotor Grip ...........................13

2-7 Attaching the Tail Rotor Blade .........................13

2-8 Attaching the Horizontal Stabilizer and

Vertical Fin ..............................................................14

2-9 Installing the Tail Boom .....................................14

3-1 Attaching the Gyro Mount ...............................15

3-2 Assembling the Boom Supports ....................15

3-3 Attaching the Boom Supports ........................16

3-4 Assembling the Main Drive Gear ...................16

3-5 Attaching the Main Drive Gear and

Front Pulley ............................................................ 17

4-1 Assembling the Swashplate and

Washout Assembly ..............................................18

4-2 Attaching the Swashplate and

Washout Assembly ..............................................18

4-3 Assembling the Main Blade

Holder and Rotor Hub Part 1 ...........................19

4-4 Assembling the Main Blade Holder and

Rotor Hub Part 2 ...................................................19

4-5 Attaching the Seesaw ........................................20

4-6 Attaching the Seesaw Arm ...............................20

4-7 Attaching the Main Rotor Head ......................21

4-8 Attaching the Stabilizer Arm ...........................21

4-9 Attaching the Paddle Decals ...........................22

4-10 Attaching the Paddle ..........................................22

4-11 Installing Main Rotor Head Linkages ............23

5-1 Assembling the Motor and Motor Mount ...23

5-2 Attaching the Motor ........................................... 24

5-3A Installing Mini Servos Part 1.............................24

5-3B Installing Mini Servos Part 2............................. 25

5-4A Installing Standard Servos Part 1 ...................25

5-4B Installing Standard Servos Part 2 ...................26

5-5 Preparing the Servo Arms .................................26

Radio System Preparation ............................................ 27

Understanding CCPM Control Systems ...................28

Important CCPM Programming

Do’s and Don’ts ..................................................... 30

CCPM Software Initial Adjustments ..........................31

JR 12X Programming ......................................................32

JR X9303 2.4 and XP9303: Programming ................36

JR 7202 and Spektrum DX7se and DX7:

Programming ........................................................ 40

5-6 Installing the Servo Arms .................................. 44

5-7 Installing Swash Servo Linkages ....................45

5-8 Assembling the Tail Control Rod ....................46

5-9 Attaching the Tail Control Rod ........................46

6-1 Installing the Speed Controller .......................47

6-2 Installing the Receiver and Gyro ....................47

6-3 Fixing the Wiring .................................................. 48

6-4 Installing the Battery ..........................................48

6-5 Installing the Body ..............................................49

Basic Adjustment After Assembly .............................50

6-6 Balancing the Main Rotor Blades ...................51

6-7 Attaching the Main Rotor Blades ...................51

Leveling the Swashplate ............................................... 52

Pitch-to-Aileron Mixing Adjustment ........................53

Pitch-to-Elevator Mixing ............................................... 54

Tail Servo Adjustment .................................................... 55

Final Servo Adjustment and Radio Setup ............... 56

Pitch Range and Curve Settings ................................. 57

Pitch Adjustment Linkages .......................................... 58

Conrmation of Proper Blade Direction..................59

Final Preight Check .......................................................59

Blade Tracking Adjustment .......................................... 60

General Maintenance ..................................................... 61

Repair of Assemblies ......................................................62

Repair of Assemblies ......................................................63

Replacement Parts Listing ............................................ 64

Page 3

3

INTRODUCTION

KEY FEATURES

To say electric helis are everywhere these days is a bit of an understatement. Electric helicopter performance and

popularity is on a level now that is unprecedented in the history of RC. And with the demand for more power

and potential comes the demand for a heli platform that can handle it.

Enter the Vibe 500e. JR’s latest foray into electric helicopter design has the benet of drawing on years of glow

heli development, producing a platform built from the ground up to dominate. The design is all new, and was

conceived with one goal in mind—being the smoothest, most precise electric helicopter available. Features like

the belt-driven tail, aluminum head and tail assemblies plus more, make precision and smoothness a possible

reality. The result is a connection between you and your heli that feels like nothing you’ve ever own before.

• 120CCPM

• Belt-driventail

• Fullaluminumheadandtailassemblies

• Designedfor6SLi-Popower(2200or2600mAhThunderPowerorsimilar)

• DesignedforE-itePower251000Kvhighpowerhelimotorsystemforaggressive3Dperformance

• UsesE-ite60-AmpProESC

• Requires425–430mmmainblades

• Constantdriventailrotor

Page 4

4

PREASSEMBLY WARNING

RECOMMENDED RADIO SYSTEM

When rst opening your helicopter, you will notice that all of the parts are packaged and numbered to

coordinate with the assembly step numbers of this instruction manual. All small hardware (nuts, bolts, washers,

etc.) for each step is separated and packaged separately within the main parts bags. When beginning a section,

you will need to open only the bag with the corresponding number to the section you are going to start. It is

suggested that you place all of the hardware in an open container (e.g., coee can) during assembly so as not

to lose any of the small parts. It may also be helpful to familiarize yourself with the various sizes of screws, bolts,

nuts, etc., as illustrated in the appropriate assembly section before you begin assembly. At the end of each

assembly, in most cases, there should be no parts remaining.

NOTE: Your kit also includes JR® red and green threadlock. Unlike conventional U.S.-made

threadlock, JR red is the U.S. equivalent of blue. JR green is the equivalent of U.S. red.

Great care has been taken in lling the bags with the correct quantity of parts and hardware for each section.

However, occasionally mistakes do happen. In the event that you nd a parts shortage or are in need of

technical assistance, please contact your local JR Heli Division parts dealer or contact the Horizon Service Center

directly.

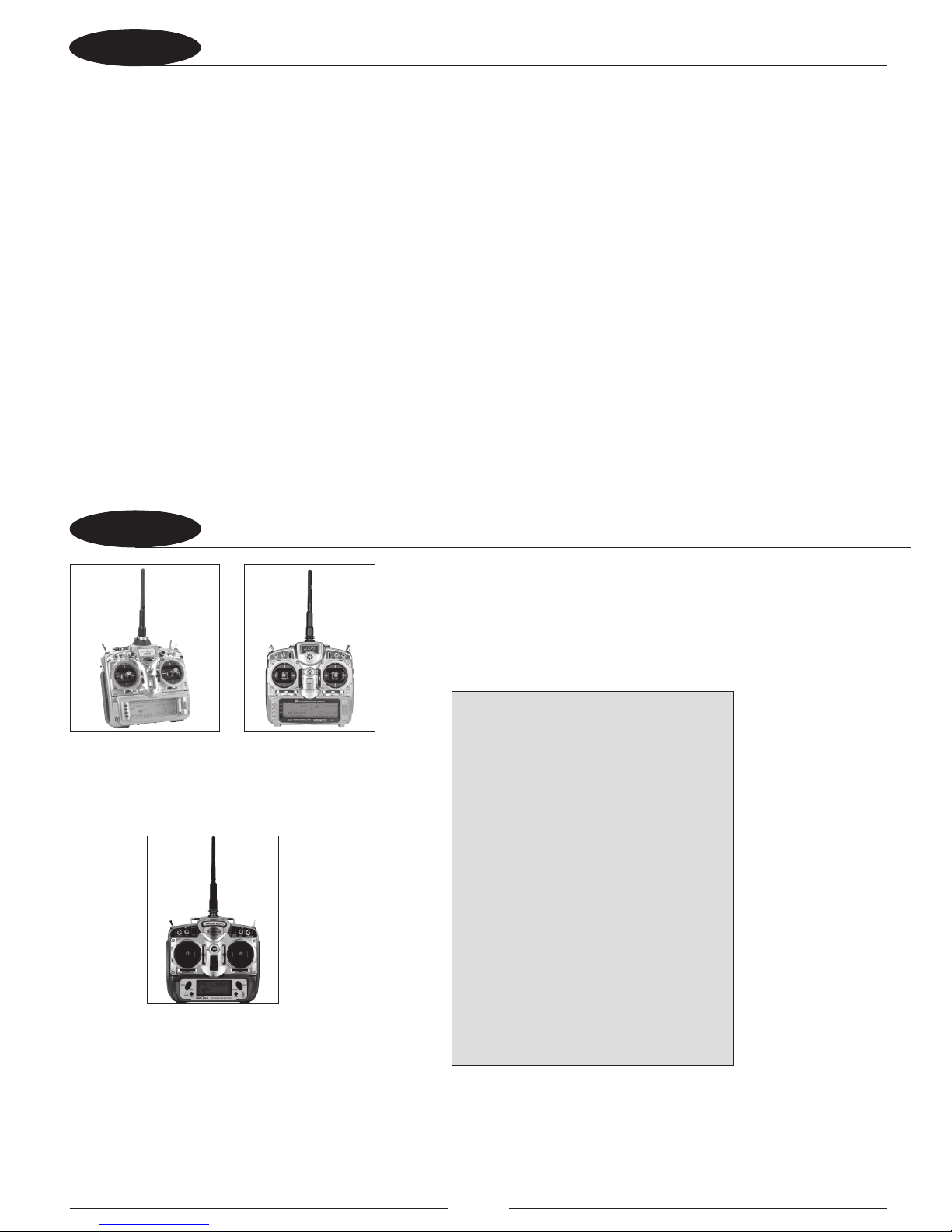

JR 12X 2.4

(JRP1200)

JR X9303 2.4

(JRP2925)

Spektrum DX7se

(SPM2731)

CCPM-Ready JR Radio Systems

Most current JR and Spektrum heli radio

systems (12X, XP9303, X9303 2.4, DX7se,

DX7 and DX6i) are equipped with 120° CCPM

electronics for use with JR CCPM machines.

Radios you may be ying now, like the X347,

X388S, XP783 and XP8103* have 120° CCPM

capability built in but require activation by

the Horizon Service Department. For details,

please call (877) 504-0233.

*Please note that many XP8103 systems

have the CCPM function already activated.

Please check with the Horizon Service

Center for details.

Spektrum is used with permission of

Bachmann Industries, Inc.

Page 5

5

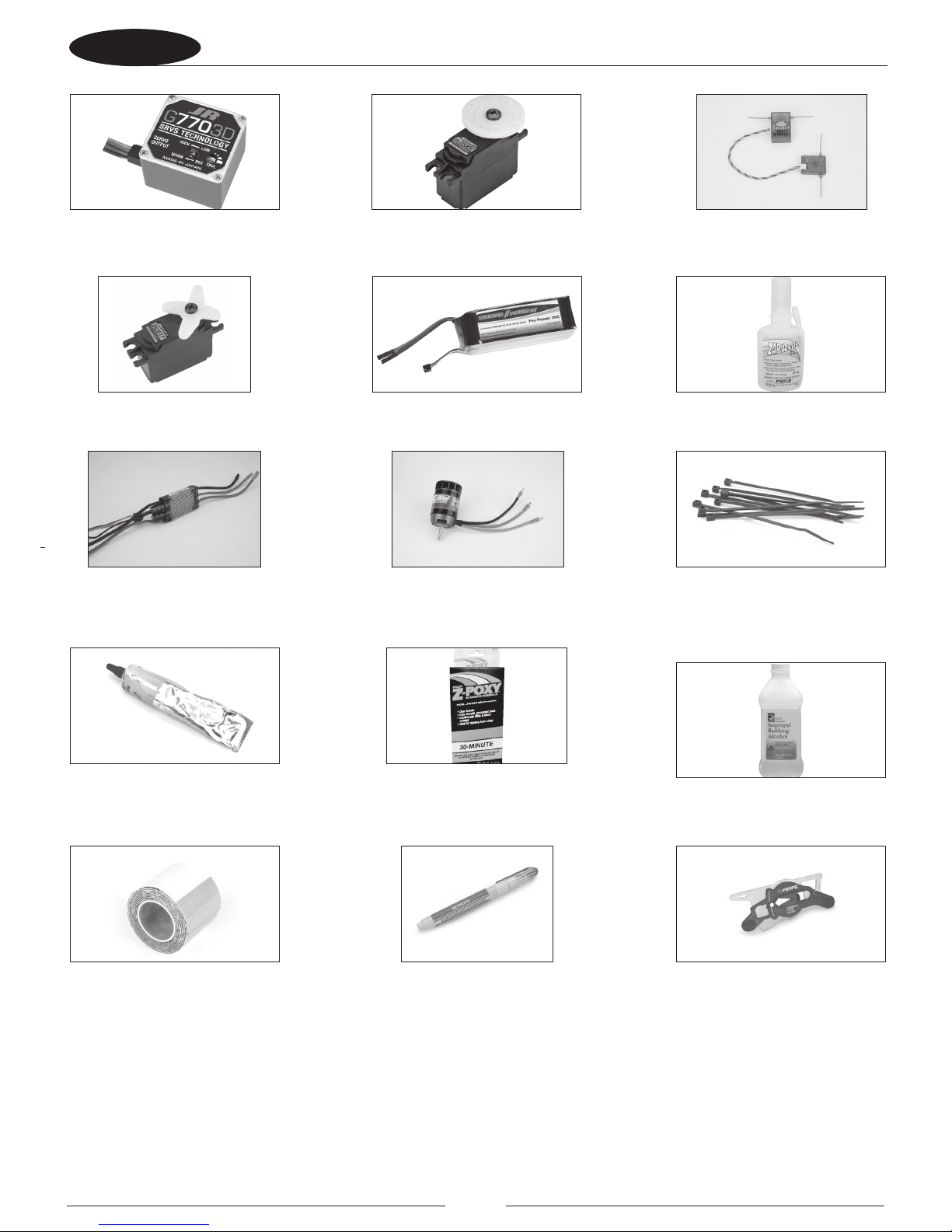

ITEMS REQUIRED TO COMPLETE ASSEMBLY

G770 3D Gyro (JRPG7703D)

E-ite Power 25 Heli BL

Outrunner Motor,1000KV

(EFLM4025H)

Oil Touch Pen

(JRP961296)

2200mAh–2600mAh

(6S Battery) (THP27006SP30)

PAAPT39

30-Minute Z-Poxy

3500G Gyro Servo (JRPG3500G)

PAAPT02

Zap-A-Gap CA+

Rubbing Alcohol

Nylon Wire Ties (ASC7709)

E-ite 60-AMP PRO SB

Brushless ESC (EFLA1060)

Double-Sided Servo Tape

(BRP7541)

DS3517 High-Speed Mini Servo

(x3)

Grease

Spektrum AR6200, AR7000 or JR

R921 Receiver

(SPMAR6200)

Pitch Gauge w/Case

JRP960326

Page 6

6

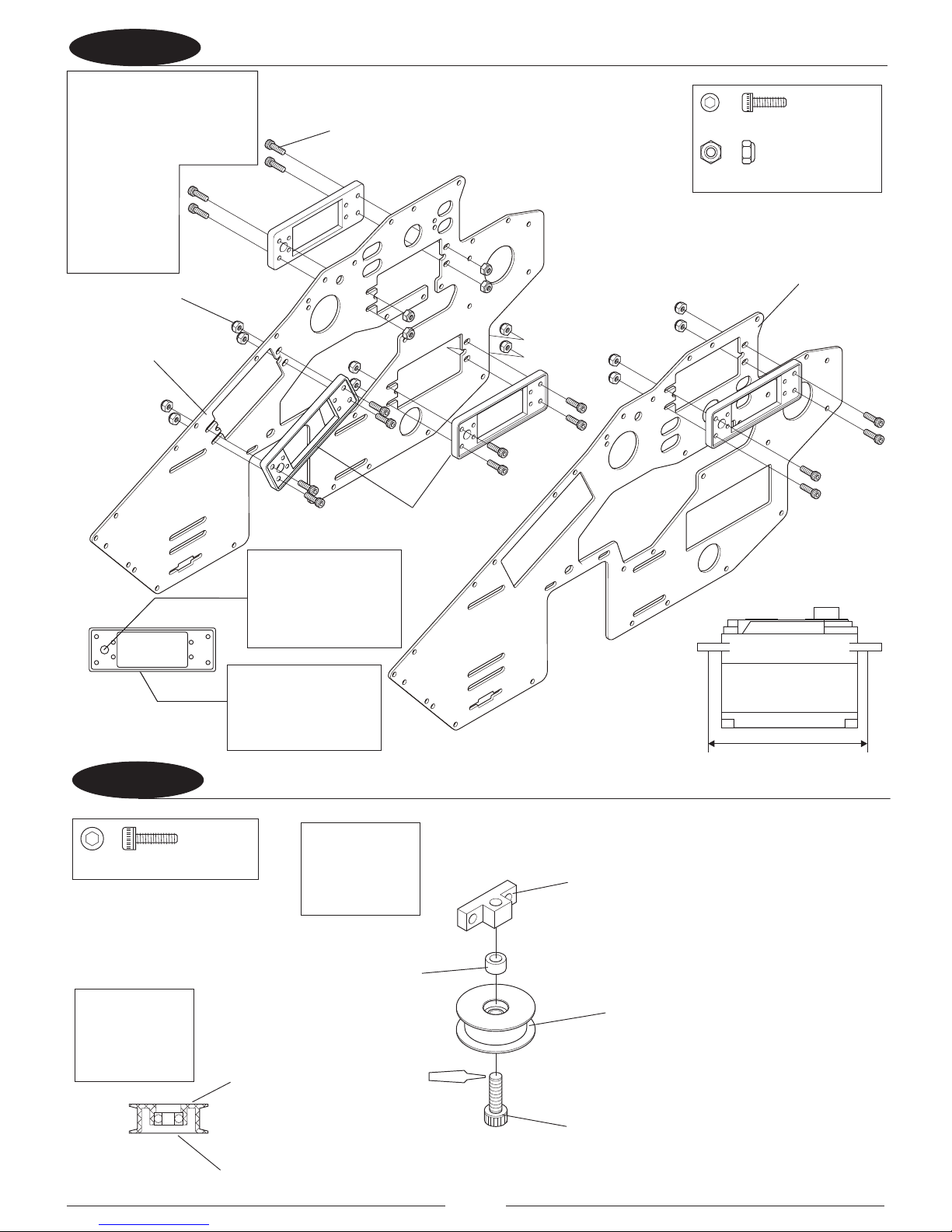

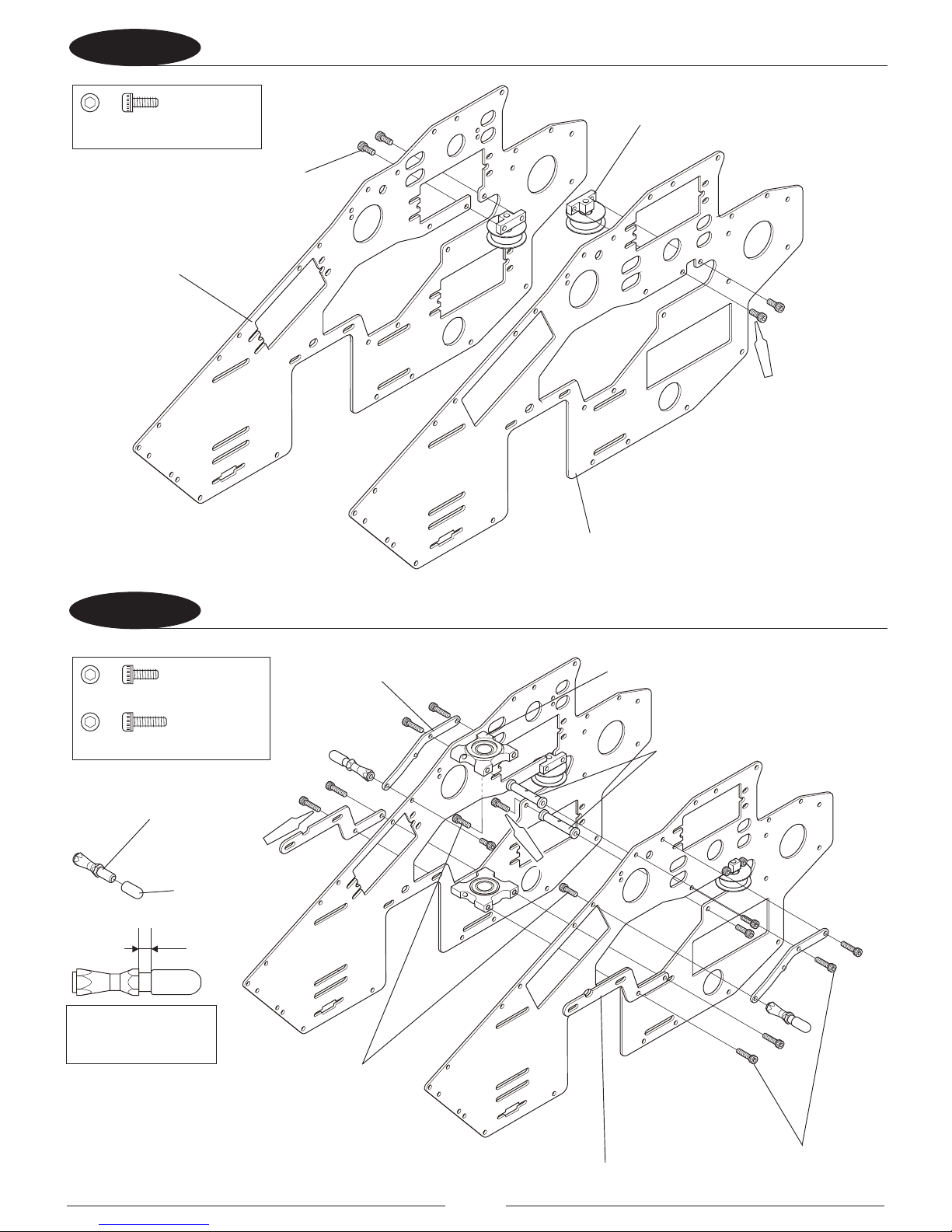

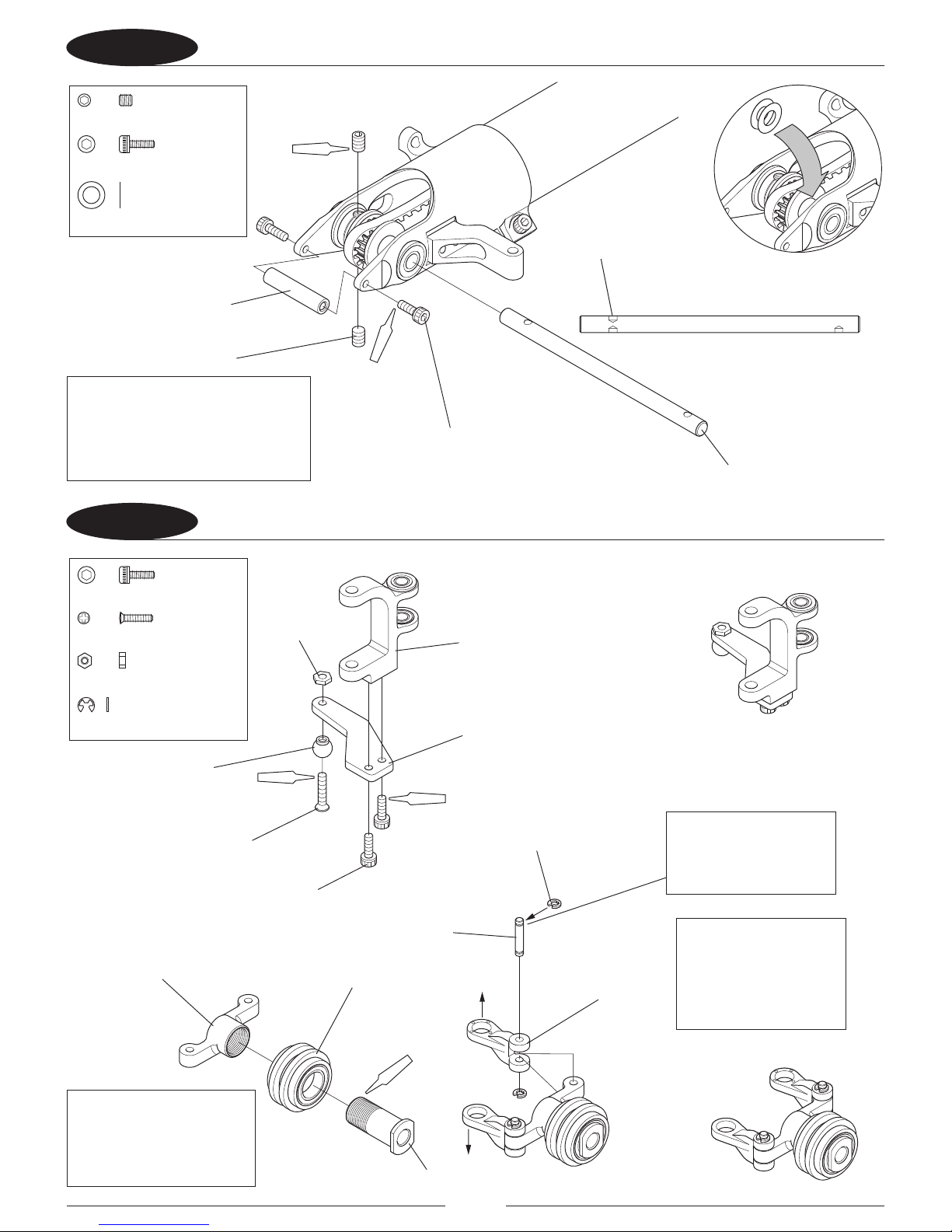

11A ATTACHING THE SERVO ADAPTERS

11B ASSEMBLING THE GUIDE ROLLER

SocketHeadBolt,M3×10

………×2

SocketHeadBolt,M2.6×8

………×16

NylonLockNut,M2.6

………………×16

Red

(×2)

Socket Head Bolt, M2.6 x 8 (16 Pcs)

Socket Head Bolt, M3 x 10 (2 Pcs)

Nylon Lock Nut, M2.6 (16 Pcs)

Guide Roller Block (2 Pcs)

Guide Roller (2 Pcs)

Top

Bottom

Guide Roller Spacer (2 Pcs)

Main Frame L

Main Frame R

Mini Servo

38.5mm

Servo Adapters (4 Pcs)

Prepare 2 sets of

the Guide Roller

assembly.

Note the proper

direction of the

Guide Roller.

Install the servo

adapter in the direction

shown noting the

direction of the hole in

the adapter.

Note: Either Mini Servos

such as the DS3517 or

Standard Servos such as the

DS821 can be installed. If

using Mini Servos, install the

servo adapters

as shown. If

using Standard

Servos, skip

ahead to step

1-1B.

The at edge of the

adapter should be

installed toward the

frame.

Page 7

7

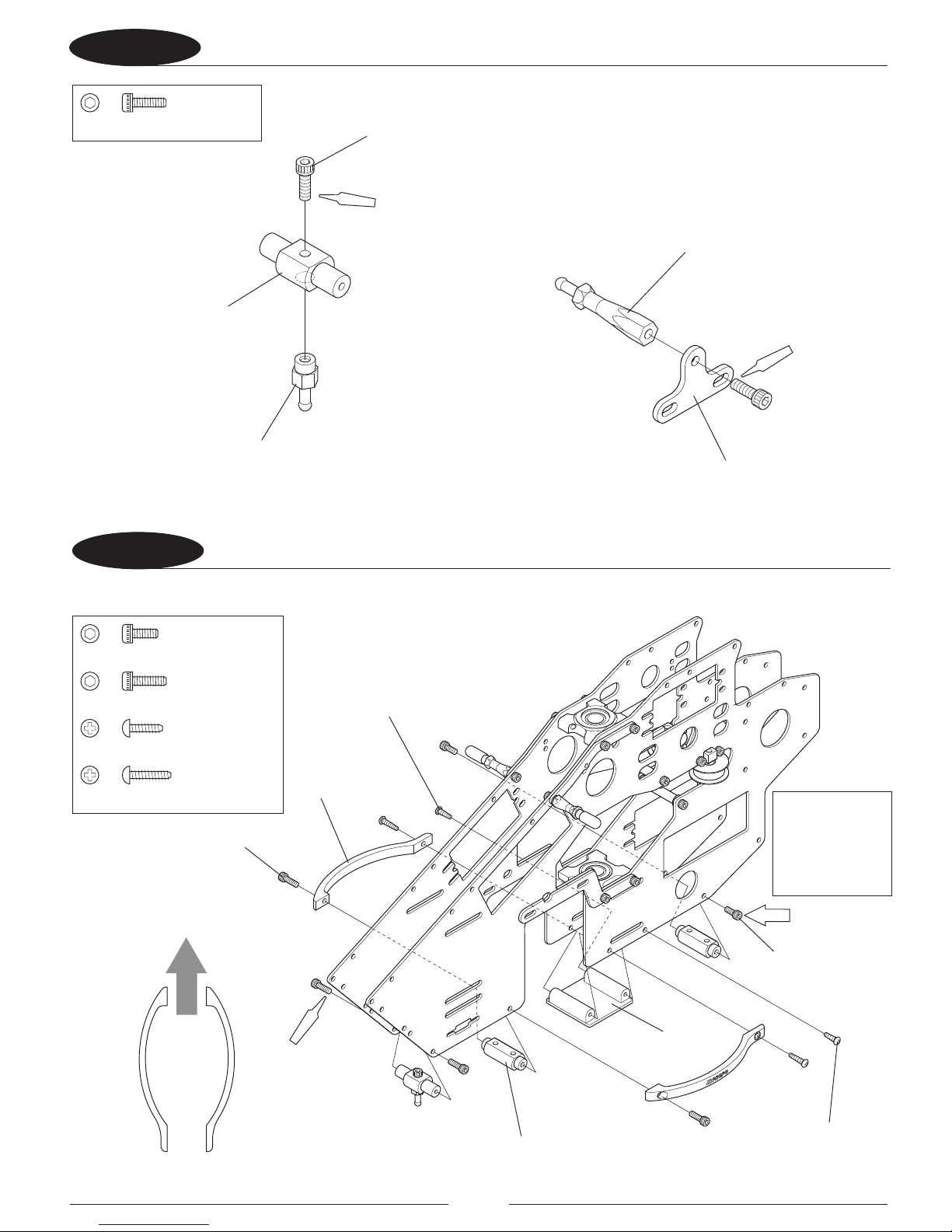

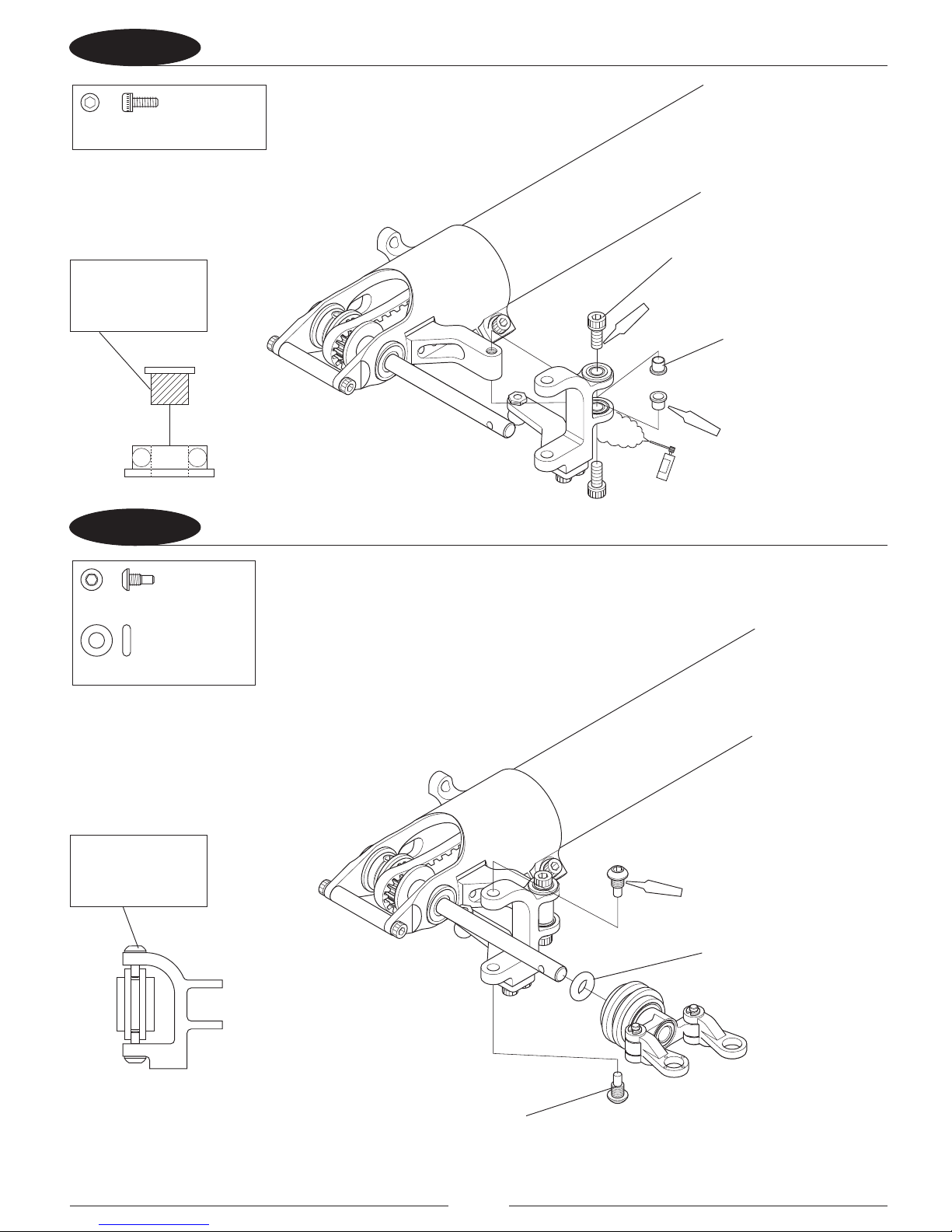

12 ATTACHING THE GUIDE ROLLER

13 ATTACHING THE BEARING CASE AND FRAME SUPPORT

SocketHeadBolt,M2.6×6

……………×4

SocketHeadBolt,M2.6×8

……………×6

SocketHeadBolt,M2.6×10

……………×8

Red(×8)

Red (×6)

Red

(×4)

Socket Head Bolt, M2.6 x 6 (4 Pcs)

Socket Head Bolt, M2.6 x 8 (6 Pcs)

Socket Head Bolt,

M2.6 x 10 (8 Pcs)

Guide Roller Assembly (2 Pcs)

SG Twist Support, Upper (2 Pcs)

Absorber Post(2 Pcs)

Absorber Cap (2 Pcs)

3mm

HG Bearing Case (2 Pcs)

HG Cross Member (2 Pcs)

Frame Support Plate, Lower (2 Pcs)

Main Frame R

Main Frame L

Prepare 2 sets of

the Absorber Post

assembly.

Page 8

8

14 ATTACHING THE BODY CATCH

15 ATTACHING THE FRAME BRIDGE

SocketHeadBolt,M2.6×8

…………×3

SocketHeadBolt,M2.6×8

……………×4

SocketHeadBolt,M2.6×6

……………×2

……………×2

Self-TappingScrew,M2.6×8

……………×2

Self-TappingScrew,M2.6×10

Red (×2)

Red

Temp.

(×4)

Red(×2)

Socket Head Bolt, M2.6 x 8 (3 Pcs)

Socket Head Bolt, M2.6 x 8 (4 Pcs)

Socket Head Bolt,

M2.6 x 6 (2 Pcs)

Frame Stando

Block

Self-Tapping Screw, M2.6 x 10 (2 Pcs)

Self-Tapping Screw,

M2.6 x 8 (2 Pcs)

Frame Bridge R/L

Brace Mount(2Pcs)

Front

Body Catch 23mm (2 Pcs)

SG Body Mount Plate (Rear) (2 Pcs)

Body Catch 4mm

Body Catch Mount

Do not fully

tighten M2.6 x 6

screws until the

landing gear is

installed later.

Page 9

9

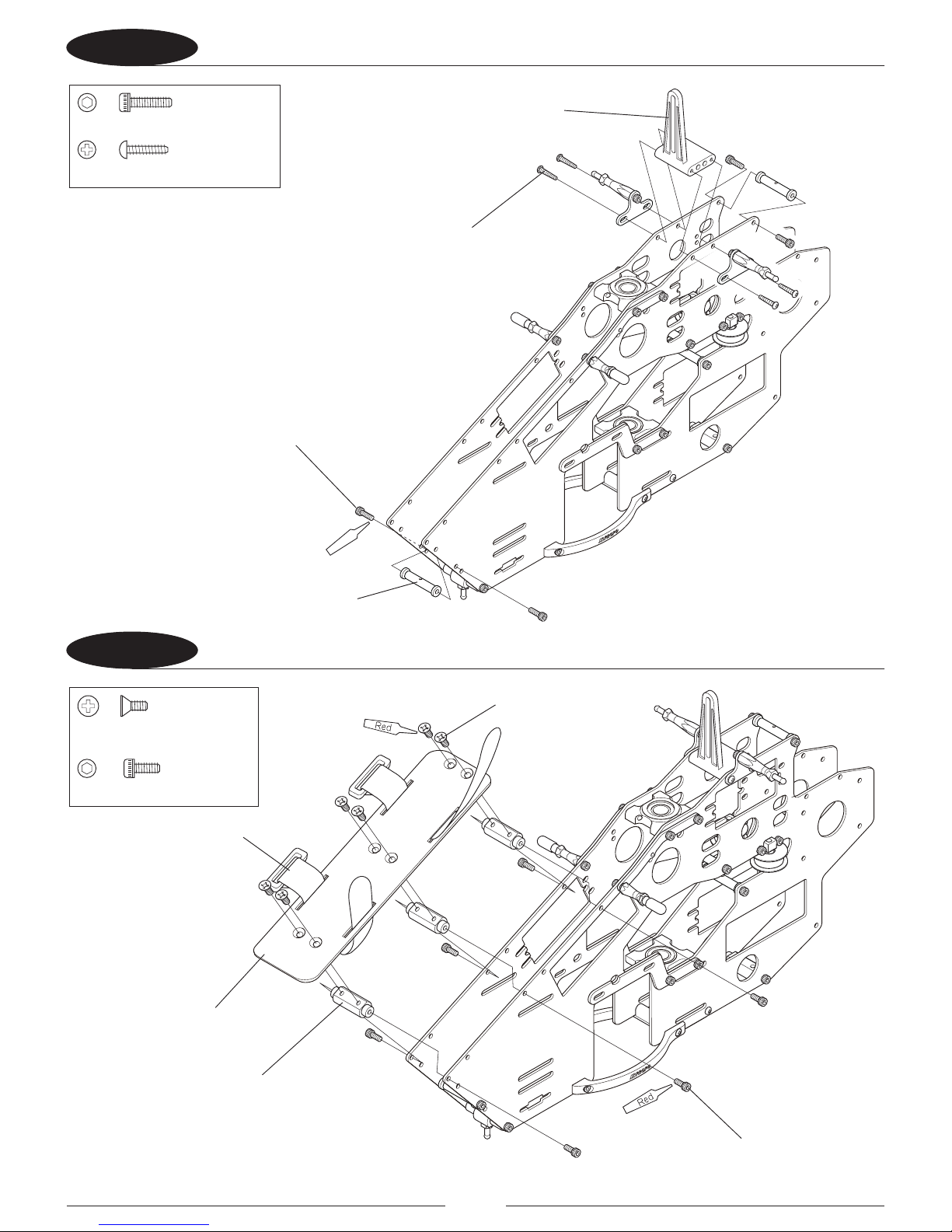

16 ATTACHING THE RADIUS SUPPORT

17 ATTACHING THE BATTERY MOUNT

Soft(×6)

Soft(×6 )

Red(×4)

SocketHeadBolt,M2.6×8

……………×4

……………×4

Self-TappingScrew,M2.6×10

……………×6

FlatHeadScrew,M2.6×5

SocketHeadBolt,M2.6×6

…………×6

Socket Head Bolt, M2.6 x 8 (4 Pcs)

Socket Head Bolt, M2.6 x 6 (6 Pcs)

Self-Tapping Screw, M2.6 x 10 (4 Pcs)

Flat Head Screw, M2.6 x 5 (6 Pcs)

Brace Mount (3 Pcs)

Carbon Battery Mount

HG Cross Member 25mm (2 Pcs)

Radius Support

Hook and Loop Strap M (2 Pcs)

Page 10

10

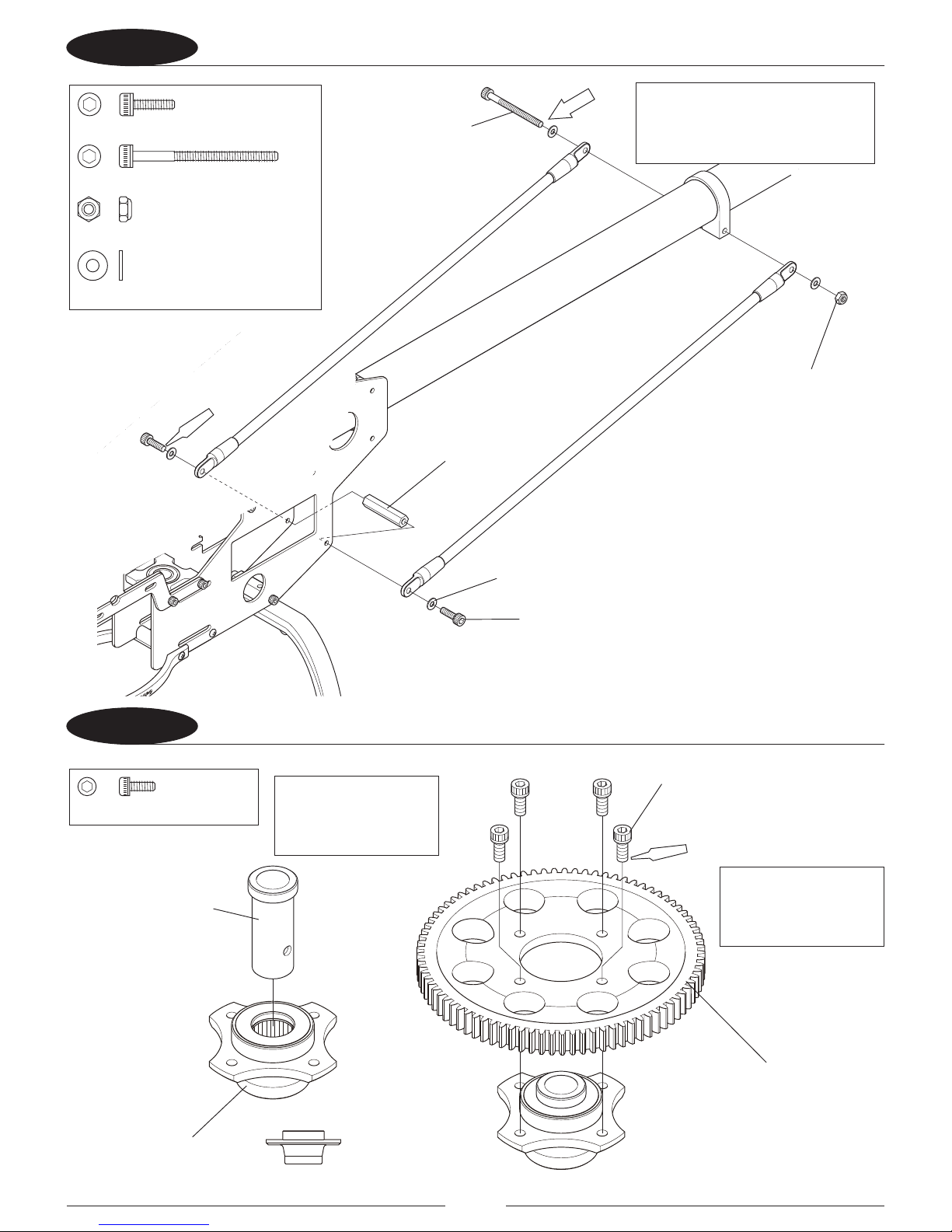

18 ATTACHING THE LANDING GEAR

21 ATTACHING THE TAIL PULLEY CASE

SocketHeadBolt,M2.6×12

………×4

FlatWasher,M2.6

…………………×4

Soft(×4 )

SocketHeadBolt,M2×5

……………×2

SocketHeadBolt,M2.6×6

……………×1

Red

(×2)

Red

0.5mm

Socket Head Bolt, M2.6 x 12 (4 Pcs)

Socket Head Bolt,

M2.6 x 6

Socket Head Bolt, M2 x 5 (2 Pcs)

Tail Pitch Control Base

Clear Tape

Tail Pulley Case

Tail Pulley

Tail Drive Belt

Tail Boom L470

Flat Washer, M2.6 (4 Pcs)

Landing Gear

Note: After the

landing gear is

installed, fully

tighten the bolts

left loose from

Step 1-5.

Note: To easily pull the tail drive

belt through the tail boom, wrap a

small piece of tape around the belt

using great care to not pinch the

belt at the bend and weakening

the belt. Caution: If the belt is bent

or kinked during assembly it will

damage the belt and cause a failure

resulting in loss of tail control.

Note: Tighten the M2.6 x 6 socket

head bolt carefully when tightening

on the Tail Boom, the Tail Boom will

be damaged if overtightened. There

should be a gap remaining in the

clamp when fully tightened.

Note: The notched end of the tail boom

installs into the Tail Pulley Case. Insert the

Tail Boom as deeply as possible.

Page 11

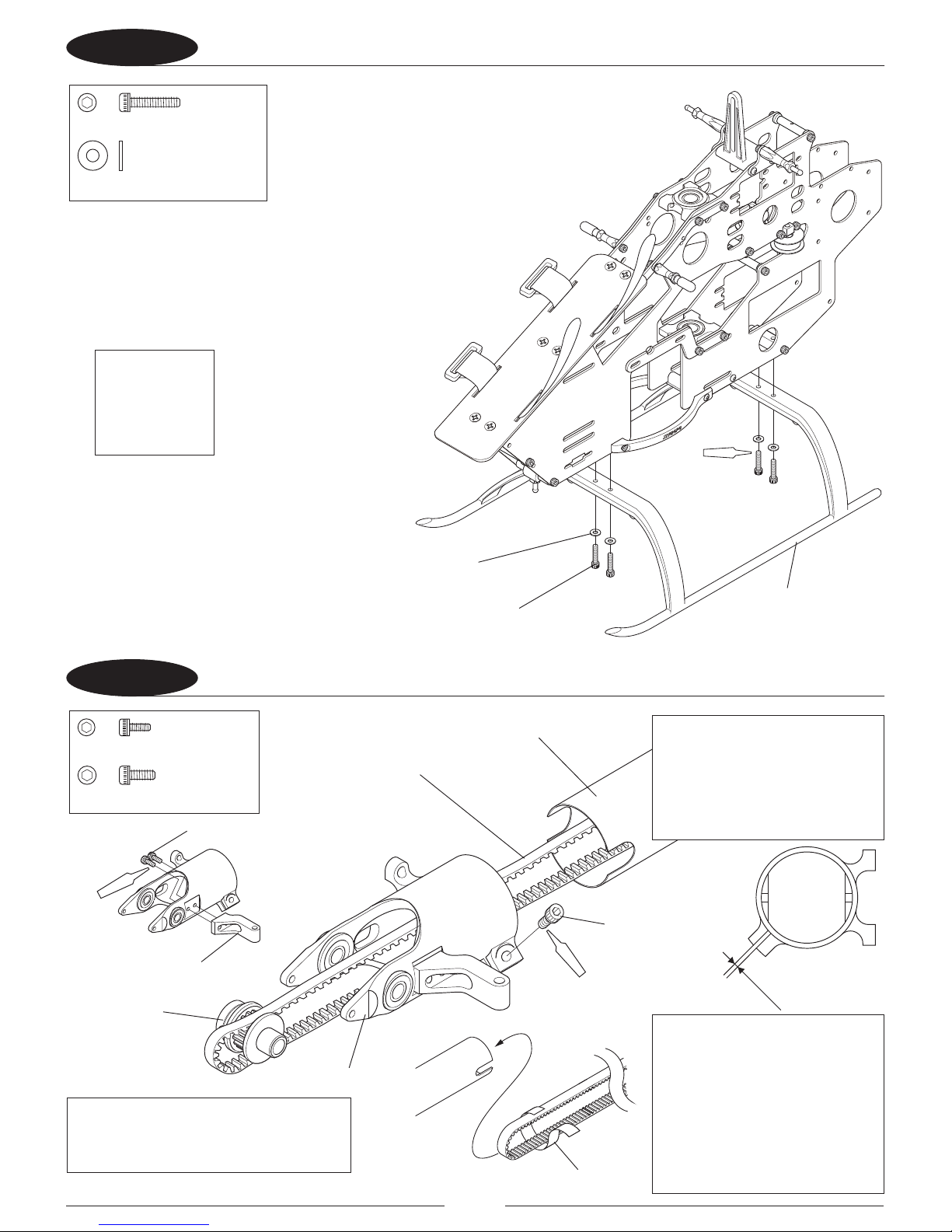

11

22 ATTACHING THE TAIL OUTPUT SHAFT

23 ASSEMBLING THE TAIL PITCH CONTROL LEVER

Red

(×2)

Red

(×2)

……………×2

Setscrew,M3×4

SocketHeadBolt,M2×6

…………×2

Polysliderwasher4.1×6.5×0.13

………………×2

SocketHeadBolt,M2×6

…………×2

FlatHeadScrew,M2×8

…………×1

Nut,M2

………………×1

ERetainingRing,M1.5

………×5(1spare)

Red

Red (×2)

Red

Tail Case Cross Member

Joint Ball

Nut, M2

Tail Output Shaft

Tail Pulley Side

Setscrew, M3 x 4 (2 Pcs)

Socket Head Screw, M2 x 6 (2 Pcs)

Flat Head Screw, M2 x 8

Tail Slide Ring

Tail PC Plate

Tail PC Link (2 Pcs)

Tail Pitch Control Arm

HG Tail PC Link Pin(2 Pcs)

Tail Pitch Control Lever

E Retaining Ring, M1.5 (4 Pcs)

Tail Slide Ring Sleeve

Socket Head Bolt, M2 x 6 (2 Pcs)

If the Tail Pulley has too much play (to

the left and right) install the included

Polyslider washers to adjust. Install

the washers as necessary to eliminate

any free play in the tail pulley.

Note: Be certain the

e-clips are fully installed

in the groove in the pin.

Note: Be sure to note the

proper tightening direction

for the Tail Slide Ring Sleeve,

it is reverse threaded.

Note: Be sure to install

the Tail PC Link in the

correct direction. The side

with the circular marks

should be in the direction

of the arrow.

Page 12

12

24 ATTACHING THE TAIL PITCH CONTROL LEVER 1

25 ATTACHING THE TAIL PITCH CONTROL LEVER 2

SocketHeadBolt,M2.6×6

……………×2

Red

(×2)

Red

(×2)

Degrease

Red

(×2)

TailPCSlideBolt

…………×2

O-Ring3.8×7.6×1.9(90°)

……………×1

Socket Head Bolt, M2.6 x 6 (2 Pcs)

O-ring 3.8 x 7.6 x 1.9 (90°)

Tail PC Slide Bolt (2 Pcs)

Tail Pitch Control

Bearing Collar(2 Pcs)

Apply a thin and

even layer of red

threadlock to adhere

Tighten the Tail PC

Slide Bolts, tting

them in the groove

in the tail slide ring.

Page 13

13

26 ATTACHING THE TAIL ROTOR GRIP

27 ATTACHING THE TAIL ROTOR BLADE

FlatHeadScrew,M2×7

……………×2

SocketHeadBolt,M3×10

………×2

Washer,03×4.5×0.4

…………………×2

………………×1

Setscrew,M3×4

O-Ring3.5×5.5×1

…………………×2

Red(×2)

Red

SocketHeadBolt,M2.6×12

………×2

NylonLockNut,M2.6

…………………×2

Red

(×2)

O-ring 3.5 x 5.5 x 1 (2 Pcs)

Washer, 3 x 4.5 x .04 (2 Pcs)

Socket Head Bolt, M3 x 10 (2 Pcs)

Flat Head Screw, M2 x 7 (2 Pcs)

Nylon Lock Nut, M2.6 (2 Pcs)

Long Tail Rotor Blade (2 Pcs)

Socket Head Bolt, M2.6 x 12 (2 Pcs)

Joint Ball (2 Pcs)

Tail Rotor Grip (2 Pcs)

Setscrew, M3 x 4

Tail Center Hub

Note: Clamp the Tail Rotor Blades

uniformly to an extent that the tail

blade will move back and forth

when a slight force is applied to

them by hand.

Page 14

14

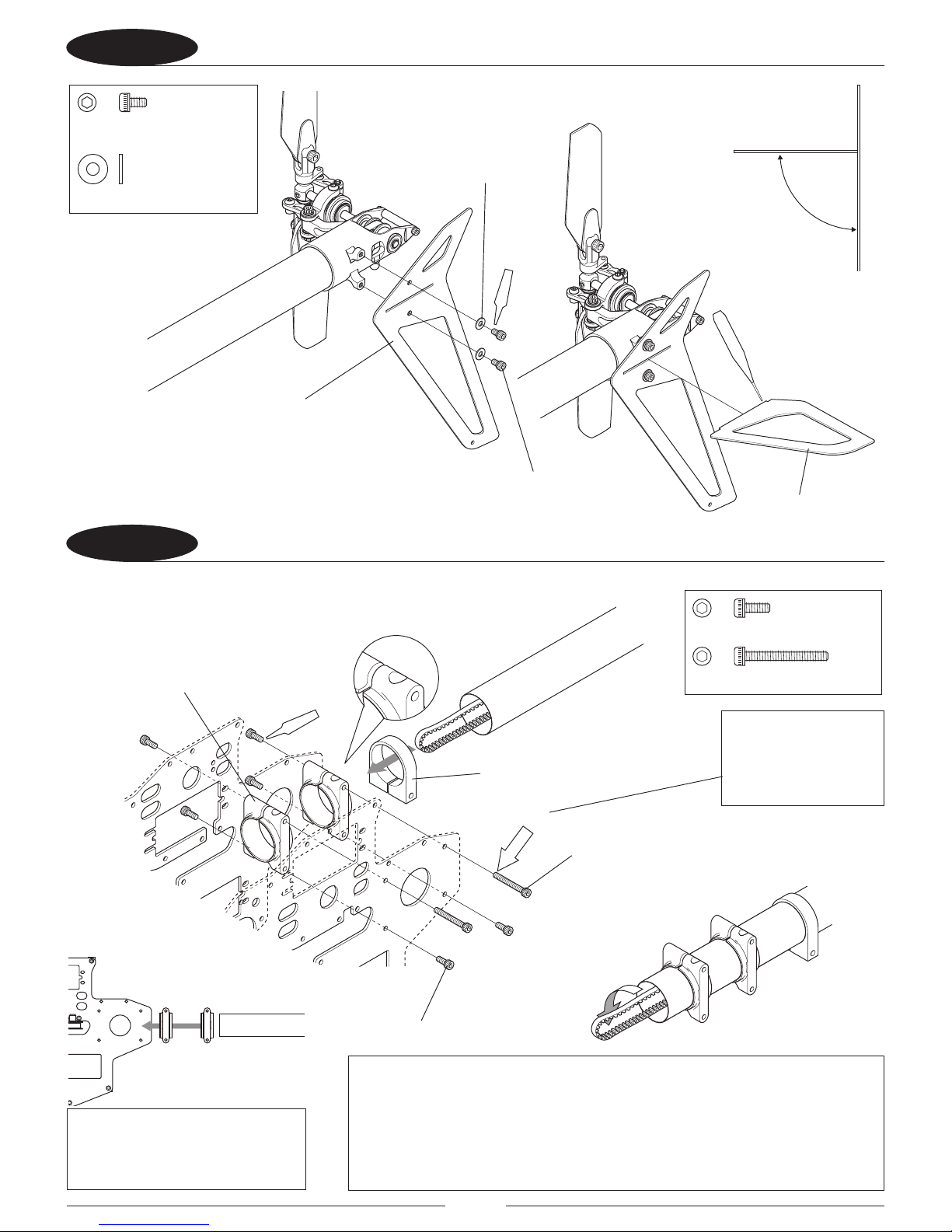

28 ATTACHING THE HORIZONTAL STABILIZER AND VERTICAL FIN

29 INSTALLING THE TAIL BOOM

Temp.

(×2)

Red (×6)

FlatWasher,M2.6

…………………×2

SocketHeadBolt,M2.6×4

……………×2

90°

CA

Red

(×2)

SocketHeadBolt,M2.6×6

……………×6

SocketHeadBolt,M2.6×20

…×2

Socket Head Bolt,

M2.6 x 4 (2 Pcs)

Flat Washer, M2.6 (2 Pcs)

HG Tail Boom Holder (2 Pcs)

Tail Support Clamp

Horizontal Stabilizer

Vertical Fin

Socket Head Bolt, M2.6 x 20 (2 Pcs)

Socket Head Bolt, M2.6 x 6 (6 Pcs)

Note: Do not fully

tighten the M2.6x20

socket head bolts until

the belt tension is set in

a later step.

Note: Insert the tail boom as far

forward as it will go into the tail

boom holders; belt tension will be set

later in the assembly.

Note: Pay close attention to the direction of rotation of the belt. With the belt

installed as shown, sight down the tube to ensure that the belt is not twisted down

the length of the boom, then rotate the belt 90 degrees in the direction of the arrow to

ensure the tail blades rotate the proper direction and the belt is not twisted or kinked.

The tail blade rotation direction will be veried later in step 3-5.

Caution: If the belt is twisted or kinked it will cause premature wear and failure of the

belt which will cause loss of tail control.

Page 15

15

31 ATTACHING THE GYRO MOUNT

32 ASSEMBLING THE BOOM SUPPORTS

EPOXYA+B(×)4

Self-TappingScrew,2.6×8

…………×4

Self-Tapping Screw, M2.6 x 8 (4 Pcs)

Boom Support End (4 Pcs)

Carbon Tail Boom Support L275(2 Pcs)

Gyro Mount

Note: Prior to assembly, lightly sand

the ends of the carbon boom supports

to ensure a good bond with the boom

support ends.

Note: Adhere the Boom Support

ends carefully in alignment with

each other as shown.

Assemble 2 Boom

Supports

Page 16

16

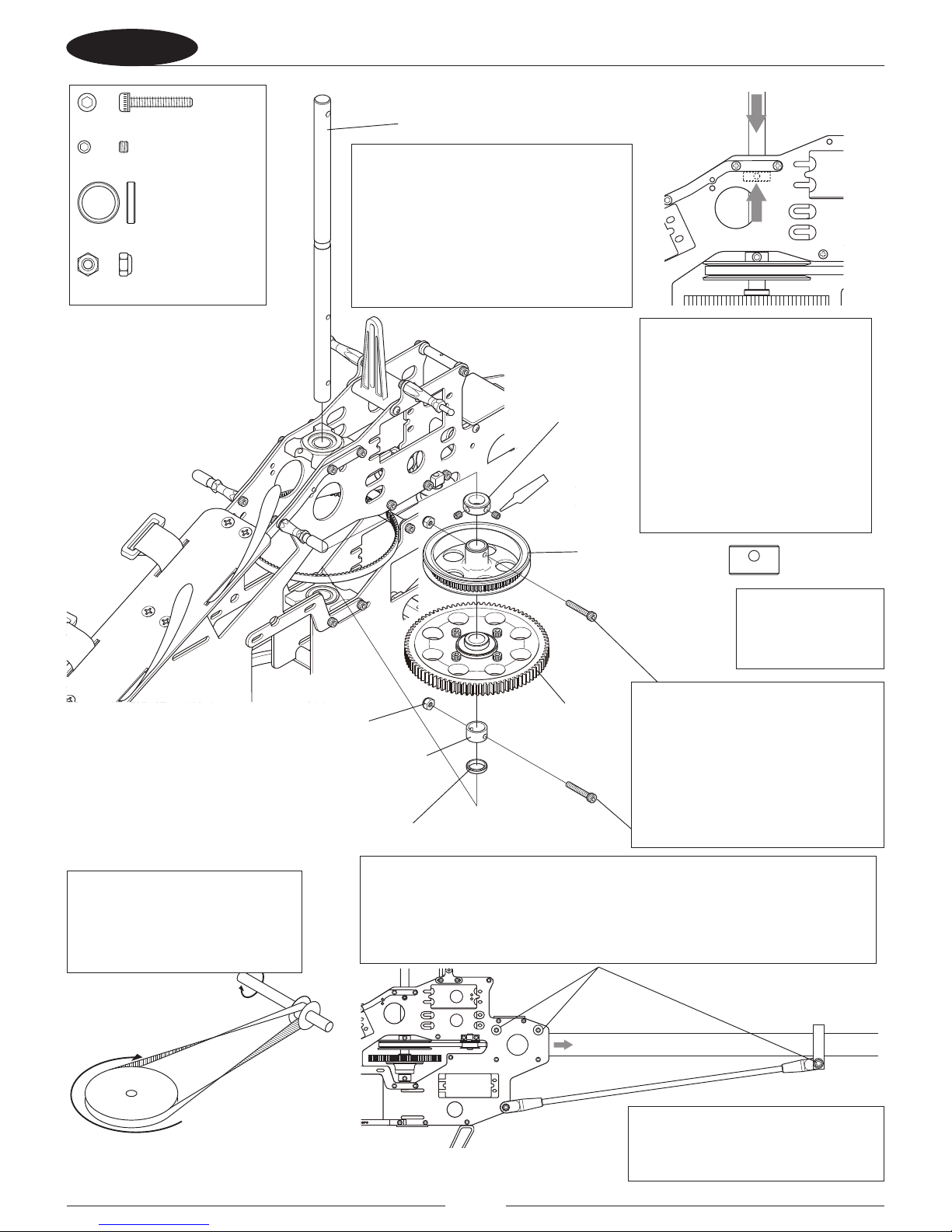

33 ATTACHING THE BOOM SUPPORTS

34 ASSEMBLING THE MAIN DRIVE GEAR

Red

(×2)

Temp.

SocketHeadBolt,M2.6×6

…………×4

FlatWasher,M3

……………………………×4

NylonLockNut,M3

……………………………×1

SocketHeadBolt,M3×35

…×1

SocketHeadBolt,M3×10

……………………×2

Red (×4)

Socket Head Bolt,

M3 x 35

Socket Head Bolt, M3 x 10 (2 Pcs)

Socket Head Bolt, M2.6 x 6 (4 Pcs)

Cross Member 25mm

(Black)

Nylon Lock Nut, M3

Flat Washer, M3 (4 Pcs)

Autorotation Sleeve

T85 Main Drive Gear

Autorotation Unit

Top

Bottom

Note: Do not fully tighten M3 x 35

socket head bolt at this time. This

bolt will be tightened in step 3-5

when the belt tension has been set.

Note: Insert the

Autorotation Sleeve into

the Autorotation Unit.

Note: Tighten the bolts

for the main gear equally

to prevent warping.

Page 17

17

35 ATTACHING THE MAIN DRIVE GEAR FRONT PULLEY

Soft (×2)

SocketHeadBolt,M2.6×15

………×2

NylonLockNut,M2.6

…………………×2

…………………×2

Setscrew,M3×3

MainShaftSpacer

…………………×1

Main Shaft

Main Shaft Collar

Front Pulley

Main Drive Gear

Assembly

Autorotation Collar

Nylon Lock Nut, M2.6 (2 Pcs)

Main Shaft Spacer

Note: After installing the Front

Pulley and Auto Rotation Assembly,

push down on the Main Shaft, and

pull up on the Main Shaft Collar

until it is against the top Main

Shaft Bearing Block. Tighten the

M3 x 3 Setscrews in the Collar

while holding the Main Shaft Collar

against the Bearing Block and the

Main Shaft pressed down against

the lower Main Shaft Bearing Block.

Note: The proper

direction to install the

Auto Rotation Collar is

as shown.

Note: If the Tail Boom is stuck and

cannot easily be moved, loosen the Gyro

Mount attachment screws.

Check that the Tail Drive Belt

direction rotation is correct as shown

and there are no twists in the belt.

Ensure the Tail Blades rotate in the

proper direction prior to ight.

Note: After the direction of the Tail Drive Belt has been conrmed, set the belt

tension. The belt tension should be set by pulling out on the Tail Boom so that

the belt will remain in contact with the Guide Roller when pressed with a nger

between the Front Pulley and Guide Roller. When the belt tension is set properly,

tighten the bolts left loose previously in step 3-3.

Note: After installing the Main Shaft

through the bottom Main Shaft Bearing

Block, install the M2.6 x 15 socket head

bolts through the Front Pulley and

Main Shaft and then through the Auto

Rotation Assembly and Auto Rotation

Collar by aligning the holes in each

assembly with the corresponding holes

in the Main Shaft.

Note: Install the Main Shaft in the proper

direction as shown through the top bearing

block, then through the Main Shaft Collar,

Front Pulley, Main Drive Gear Assembly,

Auto Rotation Collar, Main Shaft Spacer, and

nally the bottom Main Shaft Bearing Block.

Be sure to loop the Tail Drive Belt around

the Front Pulley in the direction shown

previously in step 2-9.

Page 18

18

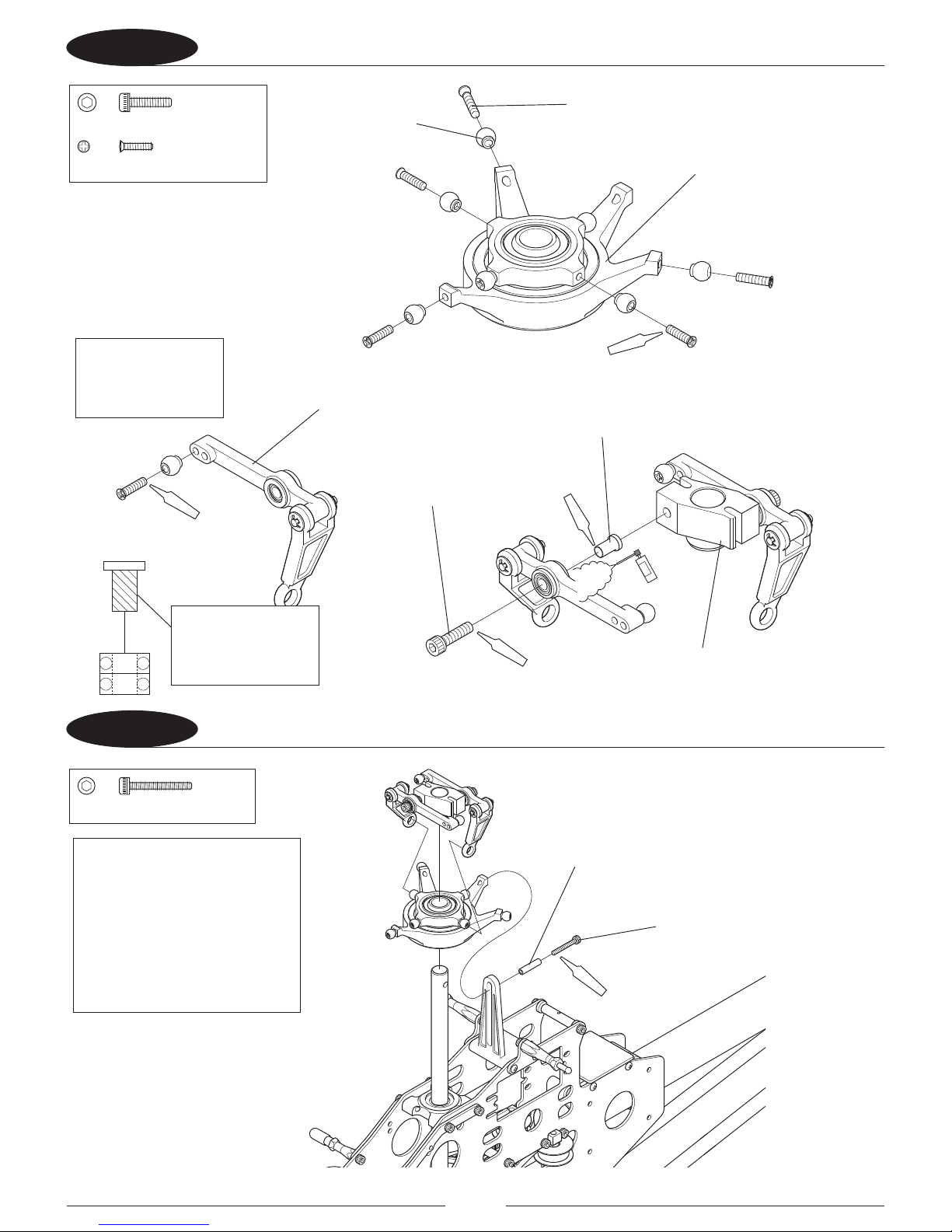

41 ASSEMBLING THE SWASHPLATE AND WASHOUT ASSEMBLY

42 ATTACHING THE SWASHPLATE AND WASHOUT ASSEMBLY

Red(×7)

Red (×2)

Red(×2)

Degrease

Red (×2)

SocketHeadBolt,M2×15

……×1

Red

FlatHeadScrew,M2×8

……………×9

SocketHeadBolt,M2.6×10

…………×2

Flat Head Screw, M2 x 8 (9 Pcs)

Socket Head Screw,

M2.6 x 10 (2 Pcs)

Socket Head Bolt, M2 x 15

120° Swashplate Assembly

Washout Arm Collar (2 Pcs)

Washout Arm (2 Pcs)

Washout Base

Swash Pin

Joint Ball (9 Pcs)

Note: Assemble

2 Washout Arm

Assemblies

Apply a light even

coat of red threadlock

to uniformly adhere

Note: Slide the Swashplate onto

the Main Shaft. Install the M2 x 15

and Swash Pin onto the Swashplate

going through the Radius Support

as shown. Next install the Washout

Assembly onto the Main Shaft and

install the Washout links onto the

Joint balls on the Swashplate as

shown.

Page 19

19

43 ASSEMBLING THE MAIN BLADE HOLDER AND ROTOR HUB 1

44 ASSEMBLING THE MAIN BLADE HOLDER AND ROTOR HUB 2

Red

Red(×2)

SocketHeadBolt,M3×6

…………×1

O-Ring5.2×10.4×2.6

…………×4

SocketHeadBolt,M3×10

………×2

FlatWasher,M3

………………×2

GripSpacer

…×2

SpindleWasher

…×2

Red (×2)

(×2)

Grease

Socket Head Bolt, M3 x 6

Socket Head Bolt,

M3 x 10 (2 Pcs)

Head Button

O-ring 5.2 x 10.4 x 2.6 (4 Pcs)

Main Blade Holder Assembly (2 Pcs)

Ball Arm (2 Pcs)

Main Rotor Hub

Smaller I.D.

Larger I.D.

Spindle Shaft

Grip Spacer (2 Pcs)

Thrust Bearing T5-10 (2 Pcs)

Spindle Washer (2 Pcs)

Flat Washer, M3 (2 Pcs)

Parts Bags 1=50°

2=70°

For 3D performance

install 70° O-rings

Note:

Assemble 2

Main Blade

Holder sets.

Note: Apply a small amount of Thrust Bearing

Grease to the Thrust Bearing

Note: If it is dicult to install the Spindle Shaft

through the O-ring dampeners, apply a small

amount of O-ring lubricant.

Note: The larger and smaller inner diameter Thrust

Bearing must be installed as shown.

Install the thrust BB CAGE toward the Main Shaft,

exposed balls to the Blade side of the grip. (The

thrust race will keep grease in, and positioning

the cage this way will prevent any possible cage

deformation from balls jamming on the cage that will

be thrown outward during use.)

Page 20

20

45 ATTACHING THE SEESAW

46 ATTACHING THE SEESAW ARM

ButtonHeadBolt,M2.5×6

……………×2

SeesawcenterCollar

………………×2

Degrease

Red(×2)

Red(×2)

Red (×4 )

Red(×2)

Degrease

FlatHeadScrew,M2×8

……………×4

SocketHeadBolt,M2.6×14

………×2

FlatWasher,2.6×4.5×0.5

…………………×2

Seesaw Center Collar (2 Pcs)

Joint Ball (4 Pcs)

Flange

Inner Hole

Flat Head Screw, M2 x 8 (4 Pcs)

Socket Head Bolt, M2.6 x 14 (2 Pcs)

Washer, 2.6 x 4.5 x 0.5 (2 Pcs)

Seesaw Arm Collar (2 Pcs)

Button Head Bolt, M2.5 x 6 (2 Pcs)

Seesaw Assembly

3D

Seesaw Arm(2 Pcs)

Apply a light, even

coat of red threadlock

to uniformly adhere.

Apply a light, even

coat of red threadlock

to uniformly adhere.

Note: The Seesaw Arm is installed

with the bearing retaining ange

toward the Seesaw Arm. For 3D

ight attach the joint ball to the

outer hole.

Page 21

21

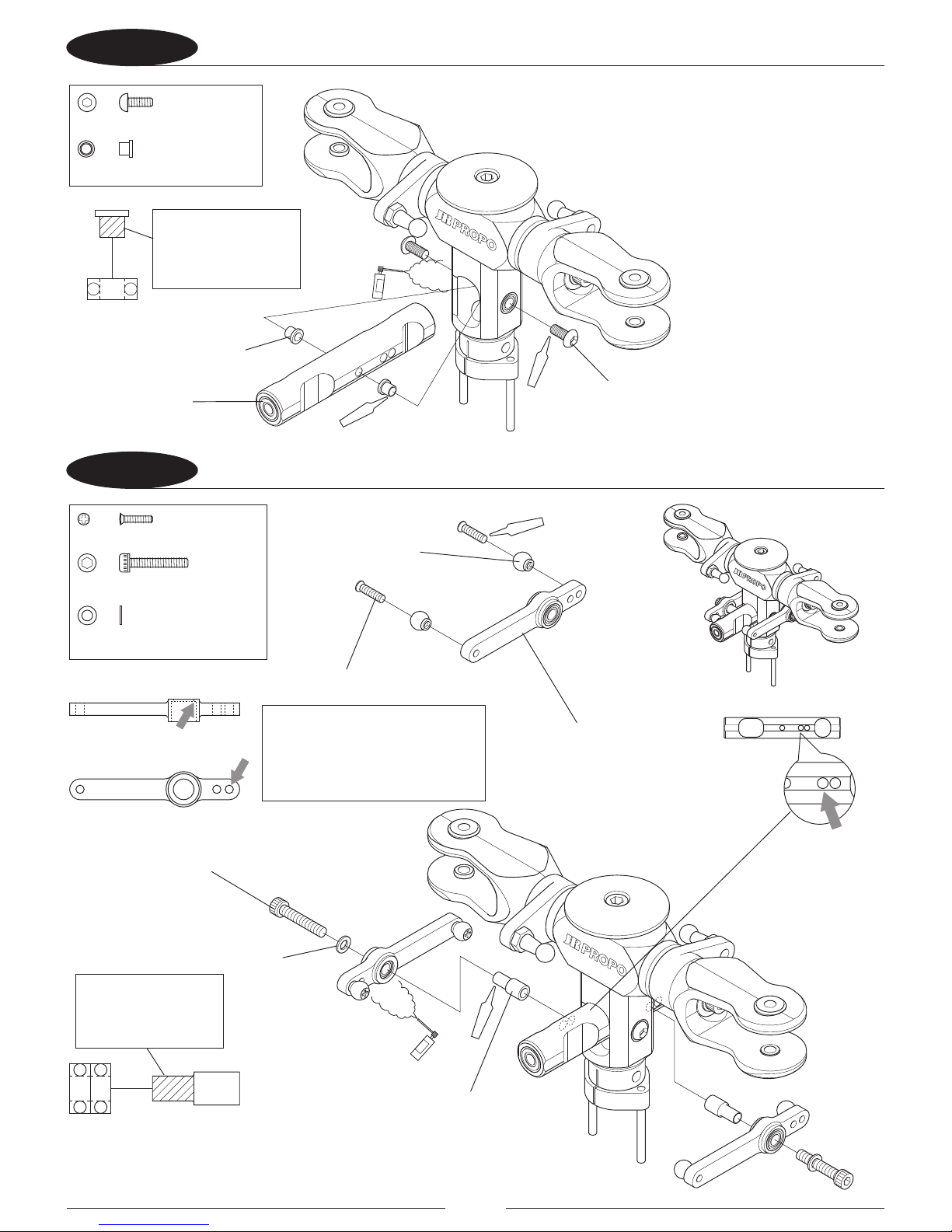

47 ATTACHING THE MAIN ROTOR HEAD

48 ATTACHING THE STABILIZER ARM

SpecilSocketHeadBolt,M3×18

…………×1

NylonLockNut,M3

………………………×1

137mm A=B

A B

SocketHeadBolt,M2×8

………×4

ScrewRod,M2.3×20

………×2

……………×2

Setscrew,M3×4

8mm

Red (×2 )

Red (×4)

Nylon Lock Nut, M3

Flybar 340mm

Setscrew, M3 x 4 (2 Pcs)

Screw Rod, M2.3 x 20 (2 Pcs)

Universal Link S (4 Pcs)

Stabilizer Arm A (2 Pcs)

This side to inside.

Socket Head Bolt, M2 x 8 (4 Pcs)

Stabilizer Arm B (2 Pcs)

Special Socket Head Bolt, M3 x 18

Note: Be certain that the washout

pins engage in the slots in the

Washout Base to ensure the phase

is correct.

Caution: Be certain to check that

the washout pins remain in the

slots in the Washout Base prior to

every ight. If the washout pins

are not engaged properly in the

Washout Base, the CCPM controls

will be out of phase, causing

incorrect cyclic response in ight

and will potentially cause a crash.

Page 22

22

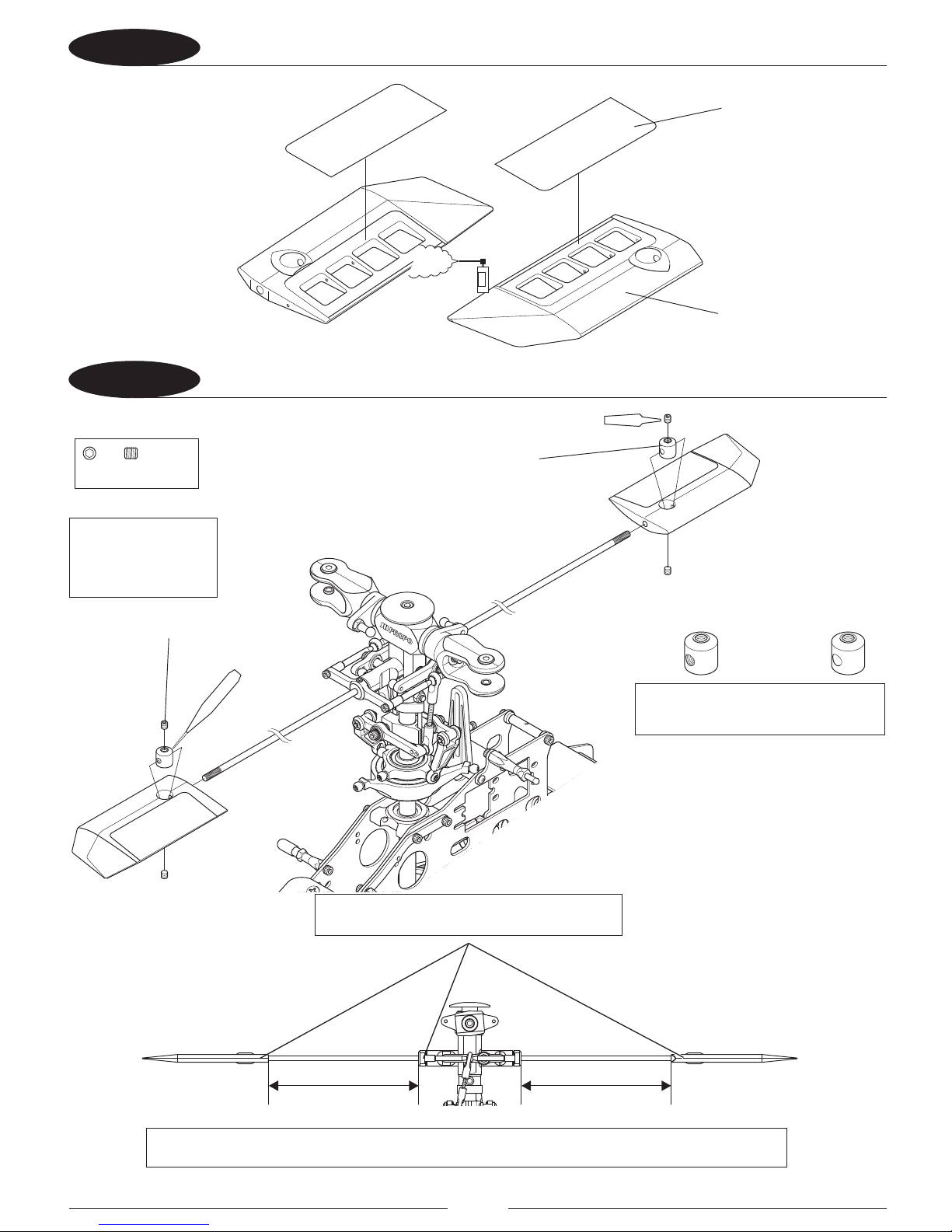

49 ATTACHING THE PADDLE DECALS

410 ATTACHING THE PADDLE

111.5mm

A

A=B

B

Degrease

Red

(×4)

(×2)

CAG

……×4

Setscrew,M3×4

Setscrew, M3 x 4 (4 Pcs)

This side to inside.This side to outside.

Paddle Stopper (2 Pcs)

Paddle (2 Pcs)

Paddle Decal (4 Pcs)

Install the paddles so they are even and parallel

with each other and the ybar cage.

Note: Ensure that A and B are equal in length.

Apply a small amount

of CA glue when

installing the Paddle

Stopper.

Note: Install the threaded side of the

Paddle Stopper to the outside.

Page 23

23

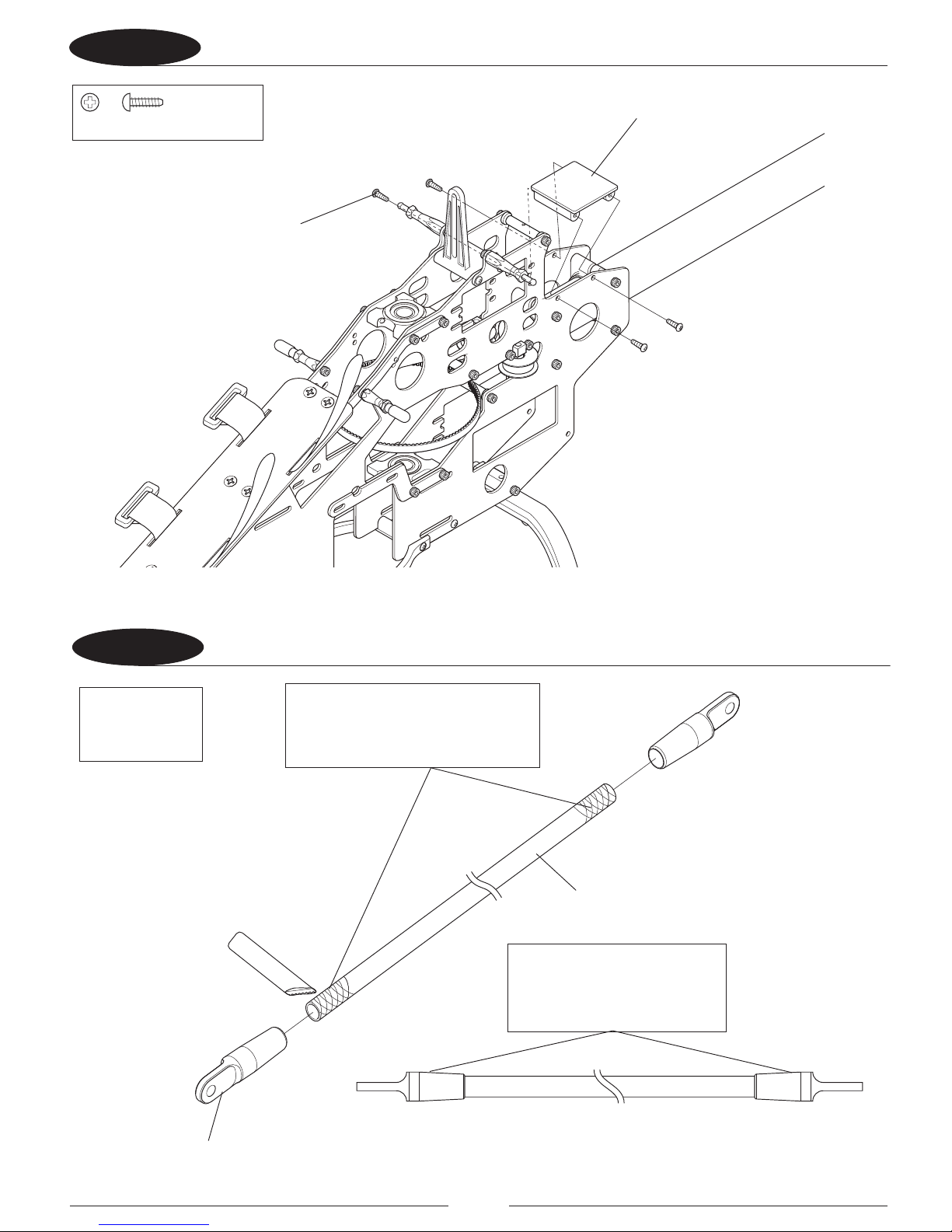

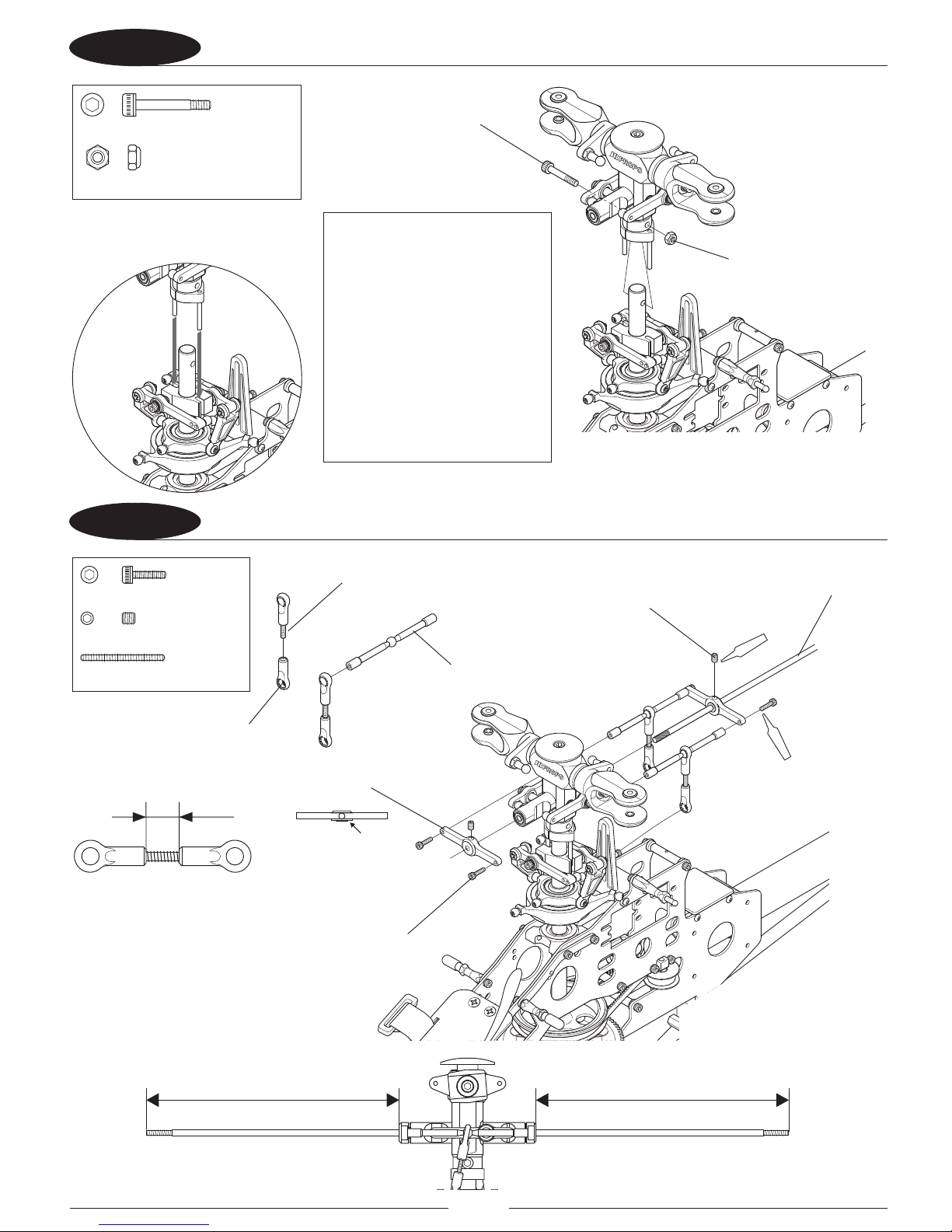

411 INSTALLING MAIN ROTOR HEAD LINKAGES

51 ASSEMBLING THE MOTOR AND MOTOR MOUNT

ScrewRod,M2.3×12

………………×2

ScrewRod,M2.3×30

…×2

JRPROPO

14mm

31mm

A

or

B

JRPROPO

SocketHeadBolt,M3×6

…………×2

FlatWasher,M3

………………×2

……………×1

Setscrew,M4×4

Temp

Red

(×2)

Double Link A (2 Pcs)

A

A

B

B

Screw Rod, M2.3 x 12 (2 Pcs)

Screw Rod, M2.3 x 30 (2 Pcs)

Setscrew, M4 x 4

Motor Mount

Motor (not included), E-ite

Power 25 Heli Outrunner Motor

(EFLM4025H)

T12 or T13 Pinion

Socket Head Bolt,

M3 x 6 (2 Pcs)

Flat Washer

M3 (2 Pcs)

Cut Universal Link (4 Pcs)

Universal Link (4 Pcs)

Parts Bags

T12 Pinion ③

T13 Pinion ④

If a replacement Universal Link

S is purchased for repair, cut it

by 3mm for this assembly.

Note: For 3D

ight, use the cut

Universal Link S

for rod A.

Note: Install the T12 pinion gear for sport

3D ight. Install the T13 pinion gear for

aggressive 3D performance. Using the

T13 pinion will result in less ight time

per charge, but higher power for more

aggressive performance.

Note: Do not fully tighten Setscrew,

M4 x 4 at this time. Fully tighten later

when the proper height position on

the Motor Shaft to line up with the

Main Gear is determined.

Page 24

24

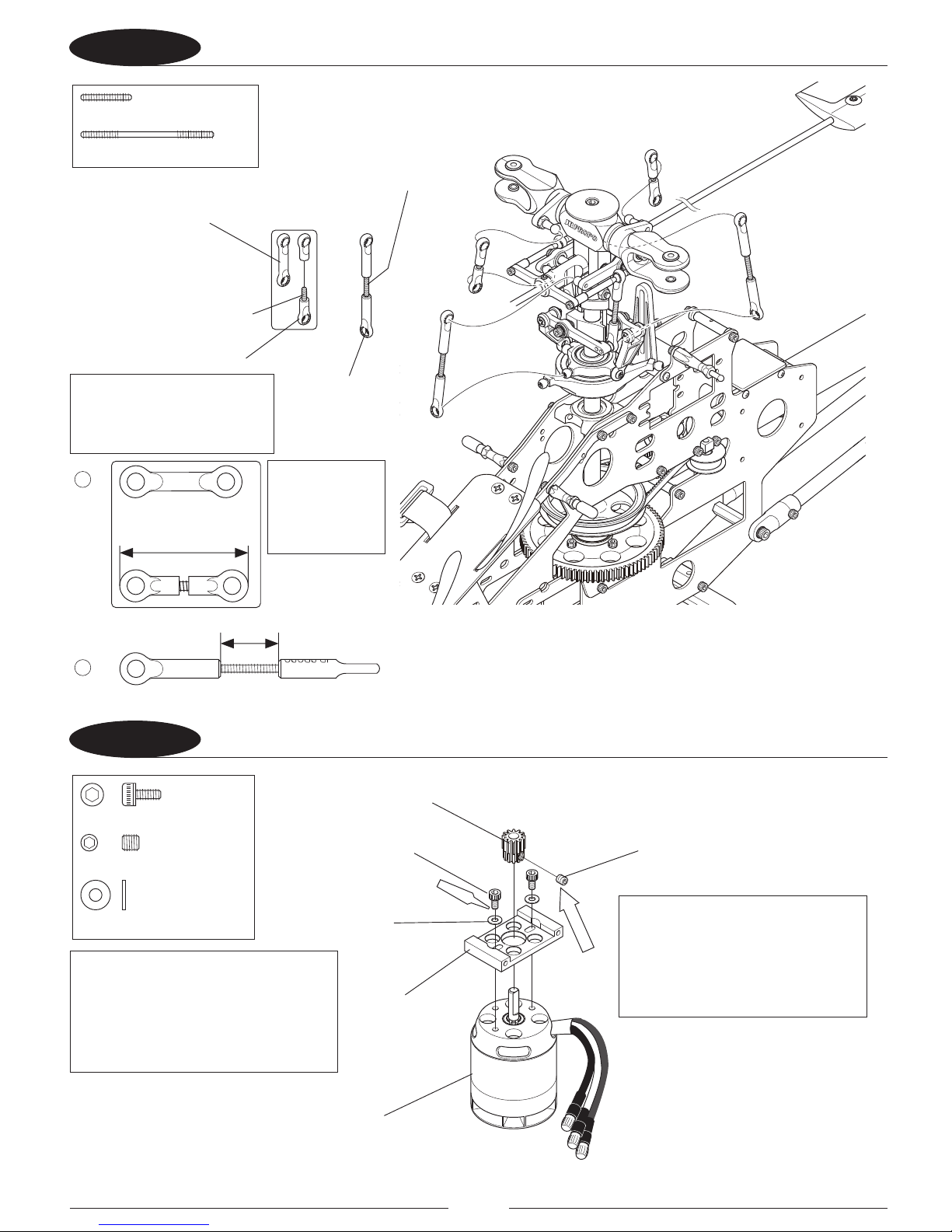

52 ATTACHING THE MOTOR

53A INSTALLING MINI SERVOS PART 1

Red (×4)

FlatWasher,M2.6

…………………×4

SocketHeadBolt,M2.6×10

…………×4

22

…………×12

Self-TappingScrew,M2.6×10

FlatWasher,M2.6

…………………×12

Self-Tapping Screw,

M2.6 x 10 (12 Pcs)

Swash Servo L

Flat Washer,

M2.6 (12 Pcs)

Rudder/Tail Servo

Swash Servo F

Flat Washer, M2.6 (4 Pcs)

Socket Head Bolt, M2.6 x 10 (4 Pcs)

Note: Either Mini Servos

such as the DS3517 or

Standard Servos such

as the DS821 can be

installed. Follow the

directions for the type

you will install.

Note: Align pinion

gear of motor with

spur gear as shown.

Page 25

25

53B INSTALLING MINI SERVOS PART 2

54A INSTALLING STANDARD SERVOS PART 1

22

…………×12

Self-TappingScrew,M2.6×12

FlatWasher,M2.6

……………………×12

22

……………×4

Self-TappingScrew,M2.6×10

FlatWasher,M2.6

……………………×4

Self-Tapping Screw,

M2.6 x 10 (4 Pcs)

Self-Tapping Screw,

M2.6 x 12 (12 Pcs)

Swash Servo R

Swash Servo L

Swash Servo F

Servo Plate B(6Pcs)

Rudder/Tail Servo

Flat Washer, M2.6 (4 Pcs)

Flat Washer, M2.6 (12 Pcs)

Page 26

26

54B INSTALLING STANDARD SERVOS PART 2

55 PREPARING THE SERVO ARMS

Red (×4)

…………×4

Self-TappingScrew,M2.6×12

FlatWasher,M2.6

……………………×4

22

Nuts,M2

………………×4

FlatHeadScrew,M2×10

………×4

Flat Washer, M2.6 (4 Pcs)

Self-Tapping Screw,

M2.6 x 12 (4 Pcs)

Swash Servo R

Servo Plate B (2 Pcs)

Joint Ball (4 Pcs)

Rudder/Tail Servo Arm,

Prepare 1 Set

Nut, M2 (4 Pcs)

Swash Servo Arm,

Prepare 3 Sets

Flat Head Screw, M2 x 10 (4 Pcs)

20mm

12–14mm

Page 27

27

RADIO SYSTEM PREPARATION

The following preparations are suggested for use with JR® radio systems. However, these procedures are

applicable to most other brand radio systems. These suggested adjustments are necessary to ensure correct

installation and attachment of the control linkages and servo horns.

TRANSMITTER PREPARATION

1. Set all trim levers, knobs, and switches to the neutral or zero positions.

2. Turn the transmitter power switch to the “On” position.

3. Reset all functions and input values of your computer radio system to the factory preset position.

4. Move the throttle/collective control stick to the center or half stick position. Next slide the throttle

trim lever to the full low position.

RECEIVER FLIGHT PACK PREPARATION

1. With the transmitter still on, slide the receiver switch to its “On” position. All servos should move to

the neutral or center position.

2. Check that all servos operate with the appropriate control stick.

3. Reset the throttle stick to the center position, making sure the throttle trim is still at low.

4. Turn o the receiver switch rst, followed by the transmitter. For proper operation, it’s important that

the servo horns are positioned on the servos in the “exact” neutral position. Although most computer

radio systems oer a sub-trim feature, it is suggested that the servo horns be manipulated on the

servos to achieve the “exact” neutral settings.

SERVO HORN INSTALLATION SUGGESTIONS

Since the servo output spline on a JR system has an odd number of teeth (23), it’s possible to reposition the

servo arm on the servo at 90° intervals to achieve the proper neutral attachment of the servo horn.

Once the correct arm of the servo horn has been established, it’s suggested that the remaining unused arms be

removed from the servo horn as shown in the installation diagrams in the following section.

It will also be necessary to enlarge the appropriate hole in the servo horn slightly to allow correct installation of

the steel control balls to the servo horn.

Page 28

28

UNDERSTANDING CCPM CONTROL SYSTEMS

120 3-SERVO CCPM SWASHPLATE MIXING

The JR® 120° CCPM or Cyclic Collective Pitch Mixing system oers the user a control system that can accomplish

the same control inputs as a one-servo standard system, but with increased precision and reduced complexity.

As with the one servo system, the JR CCPM system utilizes three servos for the three main controls:

aileron (roll), elevator (pitch), and collective. The CCPM lower swashplate ring is designed with only three control

balls, spaced at 120° from each other, hence the 120° CCPM designation. Although the control balls are not at

90° as in the standard system, the aileron (roll) axis is still parallel to the main mechanics of the helicopter, and

the elevator (pitch) axis still functions at 90° to the mechanics as does the one-servo system.

The main dierence in the way that these two systems operate is that unlike the one servo system where the

three servos work completely independently from each other, the CCPM systems work as a team to achieve

the same control inputs. For example, if an aileron (roll) input is given, two servos work together to move

the swashplate left and right. If an elevator (pitch) input is given, all three servos work together to move the

swashplate fore and aft. For collective, it’s also the strength of three servos that will move the swashplate up and

down the main rotor shaft. With two or three servos working at the same time during any given control input,

servo torque is maximized and servo centering is also increased. In addition to these benets, CCPM achieves

these control responses without the need for complex mechanical mixing systems that require many more

control rods and parts to set up.

This amazing CCPM control is achieved through special CCPM swashplate mixing that is preprogrammed into

many of today’s popular radio systems. Since the 120° CCPM function is preprogrammed, CCPM is no more

complicated to set up than a conventional one-servo standard system. When you factor in the reduced parts

count and easy programming, CCPM is actually easier to set up and operate than many conventional systems.

For JR radio owners, please refer to the radio information contained at the front of this manual or on the

following pages to determine if your radio system has the CCPM function. For other brands of radio systems,

please contact the radio manufacturer for CCPM information. Please note that it is not possible to program a

non-CCPM radio system for CCPM operation.

Page 29

29

UNDERSTANDING CCPM CONTROL SYSTEMS

The JR 120° three servo CCPM relies on the radio’s special CCPM swashplate mixing, rather than a conventional

mechanical mixer that is utilized to achieve the same results.

The radio’s 120° 3-servo CCPM function automatically mixes the three servos to provide the correct mixing

inputs for aileron (roll), elevator (pitch), and collective. The following is an example of how each control input

aects the servo’s movement.

1. COLLECTIVE

When a collective pitch input is given, all three servos move together in the same direction, at equal amounts, to

raise and lower the swashplate while keeping the swashplate level. During this function, all three servos travel

at the same value (100%) so that the swashplate can remain level during the increase and decrease in pitch. As

mentioned, this mixing of the three servos is achieved through the radio’s CCPM program.

2. ELEVATOR (PITCH)

When an elevator input is given, all three servos must move to tilt the swashplate fore and aft, but their

directions vary. The servos move together in the same direction, while the rear swashplate servo moves in the

opposite direction. For example, when a down elevator (forward cyclic) command is given, the front swashplate

servos will move the swashplate down, while the rear swashplate servo moves so that the swashplate will

tilt forward. During this function with 120° CCPM, the rear swashplate servo travels at 100%, while the front

swashplate servos travel at 50% (1/2 the travel value). This dierence in travel is necessary due to the fact that

the position of the 120 CCPM rear control ball is two times the distance of the two front control ball positions as

measured from the center of the swashplate.

3. AILERON (ROLL)

When an aileron (roll) input is given, the front swashplate servos travel in opposite directions, while the rear

swashplate servo remains motionless, such as, when a right aileron command is given.

Page 30

30

IMPORTANT CCPM PROGRAMMING DO’S AND DON’TS

A. TRAVEL ADJUST

It is extremely important that the travel adjustment values for the three CCPM servos (aileron, elevator and

Aux1) be initially set to exactly the same travel value. If the travel value is not similar for each servo, it will create

unwanted pitching and rolling of the swashplate during collective pitch inputs. The travel values for each servo

will be adjusted in the nal radio setup to remove any minor pitch and roll coupling during pitch, roll and

collective movements.

Minor travel value adjustments are necessary due to slight variations in servo travel and centering. Although the

three servos may appear to travel at the same amounts in each direction, in reality the servos can vary slightly.

This variation is more common in analog-type servos. If JR’s new digital servos are used, the travel adjustment

values will generally not need to be altered.

B. SERVO REVERSING

It is also extremely important that the servo reversing directions for the three CCPM servos (aileron, elevator,

Aux 1) be set as indicated in the upcoming radio programming steps. If one or more servos is not set to the

correct direction, the CCPM function will be out of synchronization, and the three control functions (Aileron,

Elevator, Collective) will not move properly. In the event that a control surface is working in the wrong direction,

the control function can only be reversed by changing the desired CCPM value for that function from a (+) to a

(-) value or vice versa.

Example: If when you increase the collective pitch, the pitch of the main blades actually

decreases, it will be necessary to access the CCPM function and change the travel value for this

function from (+) to (-), or (-) to (+). This will reverse the direction of the collective pitch function

without aecting the movement of the aileron and elevator functions.

C. CCPM SERVO CONNECTIONS

The JR® 120° CCPM system requires the use of three servos to operate Aileron, Elevator and Aux1(Pitch). The

labeling of these servos can become quite confusing because, with the CCPM function, the three servos no

longer work independently, but rather as a team, and their functions are now combined. For this reason, we will

refer to the three servos in the following manner:

Elevator Servo: This is the front CCPM servo. The channel number for this servo when using a JR radio is CH3.

Aileron Servo: This is the top left CCPM servo. The channel number for this servo when using a JR radio is CH2.

Aux 1 (Pitch) Servo: This is the right CCPM servo. The channel number for this servo when using a JR radio is CH6.

Please refer to the CCPM connections chart below for clarication. For non-JR radios, please consult your radio

instructions for proper connection.

Page 31

31

CCPM SOFTWARE INITIAL ADJUSTMENTS

RADIO SYSTEM REQUIREMENTS (NOT INCLUDED)

6-channel or greater RC helicopter system with 120° CCPM function

CCPM-Ready JR Radio Systems

Most current JR and Spektrum heli radio systems (12X, X9303 2.4, XP9303, DX7se, DX7, DX6i, as well as older 10

series systems) are equipped with 120° CCPM electronics for use with JR CCPM machines. Radios you may be

ying now, like the X347, X388S, XP783 and XP8103 have 120° CCPM capability built in but require activation by

the Horizon Service Department. Please call 877-504-0233 for details.

*Please note that many XP8103 systems have the CCPM function already activated. Please check

with the Horizon Service Center for details.

Page 32

32

JR 12X PROGRAMMING

The following activation and setup procedure should be used for JR 12X systems. Prior to activating the CCPM

function, it is rst suggested that the data reset function be performed to reset the desired model number to be

used back to the factory default settings.

Caution: Prior to performing the data reset function, it will be necessary to select the desired

model number to be used.

A) Model Select/Data Reset

Press the ENT key while turning the power switch on to enter the system mode. Next, move the cursor to the

MODEL SEL function. Press the roll selector to enter the model select function. Select the desired model number

to be used, then press the roll selector. Next, move the roll selector to highlight LST, and press the roll selector.

Move the roll selector to highlight MDL RESET, then press the roll selector. Press the CLEAR key, then press YES to

reset the data of the current model selected.

B) Device Select

Move the roll selector to highlight the Device SEL function, then press the roll selector to access the Device

Select function. Next, move the cursor to the OUT: column in the GEAR row and select the GYR setting.

Page 33

33

C) CCPM Activation

Move the roll selector to highlight the SWASH TYP function, then press the roll selector to access the swashplate

type function. Press the roll selector to access the variations of CCPM mixing, then move the roll selector to

select the CCPM type (120). Move the roll selector to highlight LST and press the roll selector to exit the system

mode.

D) D/R and EXPO Selection

Turn the power switch on, then press the ENT key to enter function mode. Move the roll selector to highlight the

D/R and EXPO function, then press the roll selector to enter the function. Set the Dual Rate and Expo values as

desired, below are suggested settings. Press the LST key to return to the menu.

Page 34

34

E) Servo Reversing

Move the roll selector and highlight REV.SW on the screen, then press the roll selector to enter the function.

Next, reverse channel 2 by moving the roll selector, and pressing as needed to change from NORM to REV. Press

the LST key to return to the menu.

F) Travel Adjustment

Move the roll selector until TRVL ADJ is highlighted on the screen, then press the roll selector to enter the

function. Adjust the values as shown by moving the roll selector to highlight the desired channel, while using

the control stick to select up/down, or left/right values to be adjusted. Please note that the required travel values

will vary based on the type of servo selected. Press the LST key to return to the menu.

G) CCPM Settings

Move the roll selector to highlight the SWASH MIX function, then press the roll selector to enter the function. Set

the value of the aileron, elevator, and pitch functions from the factory default setting using the rolling selector.

Press the LST key to return to the menu.

Page 35

35

H) Throttle Hold Setting

Move the roll selector to highlight the THRO HOLD function, then press the roll selector to enter the function.

Activate the throttle hold function. Set the hold position in this function so that when the throttle hold switch

is pulled, the motor does not run with the throttle stick at idle and throttle trim set at the idle position. Press the

LST key to return to the menu.

I) Gyro Sensitivity Selection

Move the roll selector to highlight the GYRO function, then press the roll selector to enter the function. Set the

gyro gain as shown as a starting point for the G770 3D gyro. Adjust the percentage as necessary when ying the

heli. Other gyros may require dierent settings, consult your gyro manual for further information on setting the

gain. Press the LST key to return to the menu.

J) Mix to Throttle

Move the roll selector to highlight the MIX -> THRO function, then press the roll selector to enter thefunction.

Begin by selecting SW SEL for both Aileron to Throttle and Elevator to Throttle, and set to on when in ST-1 and

ST-2. Set the Aileron to Throttle and Elevator to Throttle mixing as shown. This function is used to prevent the

head speed from sagging during aerobatics. Adjust these values as needed in ight. This function is not required

if using a governor. Press the LST key to return to the menu.

Page 36

36

JR X9303 2.4 AND XP9303: PROGRAMMING

The following activation and setup procedure should be used for the JR 9303 systems. Prior to activating the

CCPM function, it is rst suggested that the data reset function be performed to reset the desired model number

to be used back to the factory default settings.

Caution: Prior to performing the data reset function, it will be necessary to select the desired

model number to be used.

A) Model Select/Data Reset

Press the ENT key while turning the power switch on to enter the system mode. Next, move the cursor to the

MODEL SEL function. Press the roll selector to enter the model select function. Select the desired model number

to be used, then press the roll selector. Next, move the roll selector to highlight LST, and press the roll selector.

Move the roll selector to highlight MDL RESET, then press the roll selector. Press the CLEAR key, then press YES to

reset the data of the current model selected.

B) Device Select

Move the roll selector to highlight the Device SEL function, then press the roll selector to access the Device

Select function. The GYR setting for channel AUX2 will be set when the gyro function is activated in a following

step. Note: When using a 6-channel receiver, it will be necessary to use the travel adjust function or a program

mix to set the Gyro gain instead of the built-in Gyro function.

Page 37

37

C) CCPM Activation

Move the roll selector to highlight the SWASH TYP function, then press the roll selector to access the swashplate

type function. Press the roll selector to access the variations of CCPM mixing, then move the roll selector to

select the desired CCPM type (120). Move the roll selector to highlight LST and press the roll selector to exit the

system mode.

D) D/R and EXPO Selection

Turn the power switch on, then press the ENT key to enter function mode. Move the roll selector to highlight the

D/R and EXPO function, then press the roll selector to enter the function. Set the Dual Rate and Expo values as

desired (below are suggested settings). Press the LST key to return to the menu.

Page 38

38

E) Servo Reversing

Move the roll selector and highlight REV.SW on the screen, then press the roll selector to enter the function.

Next, reverse channel 2 by moving the Roll selector, and pressing as needed to change from NORM to REV. Press

the LST key to return to the menu.

F) Travel Adjustment

Move the roll selector until TRVL.ADJ is highlighted on the screen, then press the roll selector to enter the

function. Adjust the values as shown by moving the roll selector to highlight the desired channel, while using

the control stick to select up/down, or left/right values to be adjusted. Please note that the required travel values

will vary based on the type of servo selected. Press the LST key to return to the menu.

G) CCPM Settings

Move the roll selector to highlight the SWASH MIX function, then press the roll selector to enter the function.

Set the value of the aileron, elevator, and pitch functions from the factory default setting using the + and - keys.

Press the LST key to return to the menu.

Page 39

39

H) Throttle Hold Setting

Move the roll selector to highlight the THRO HOLD function, then press the roll selector to enter the function.

Activate the throttle hold function. Set the hold position in this function so that when the throttle hold switch

is pulled, the motor does not run with the throttle stick at idle and throttle trim set at the idle position. Press the

LST key to return to the menu.

I) Gyro Sensitivity Selection

Move the roll selector to highlight the GYRO function, then press the roll selector to enter the function. Set the

gyro gain as shown as a starting point for the G770 3D gyro. Adjust the percentage as necessary when ying the

heli. Other gyros may require dierent settings; consult your gyro manual for further information on setting the

gain. Press the LST key to return to the menu. Note: When using a 6-channel receiver, it will be necessary to use

the travel adjust function or a program mix to set the Gyro gain instead of the built in Gyro function.

J) Mix to Throttle

Move the roll selector to highlight the MIX -> THRO function, then press the roll selector to enter the function.

Begin by selecting SW SEL for both Aileron to Throttle and Elevator to Throttle, and set to on when in ST-1 and

ST-2. Set the Aileron to Throttle and Elevator to Throttle mixing as shown. This function is used to prevent the

head speed from sagging during aerobatics. Adjust these values as needed in ight. This function is not required

if using a governor. Press the LST key to return to the menu.

Page 40

40

JR 7202 AND SPEKTRUM DX7se AND DX7: PROGRAMMING

The following activation and setup procedure should be used for the JR 7202, Spektrum DX7se and DX7 systems.

Prior to activating the CCPM function, it is rst suggested that the data reset function be performed to reset the

desired model number to be used back to the factory default settings.

Caution: Prior to performing the data reset function, it will be necessary to select the desired

model number to be used.

A) Model Select/Data Reset

Press the Down and Select keys while turning the power switch on to enter the system mode. Next, move

the cursor to the MODEL SEL function with the UP key. Select the desired model number to be used with the

increase or decrease key. Next, press the UP key until MODEL RESET is displayed. Press the CLEAR key, then press

YES to reset the data of the current model selected.

B) CCPM Activation

Press the UP key until the SWASH TYPE function is displayed, then press the INCREASE key to select 120 CCPM

type as shown.

Page 41

41

C) Input Select function

Press the DOWN key until the INPUT SELECT function is displayed, then set AUX 2 or GEAR to GYRO. If using a 7

channel receiver, either the Gear or Aux 2 channels can be used for the Gyro gain. If using a 6-channel receiver,

use the Gear channel press the down and select keys together to exit the system menu.

D) D/R and EXPO Selection

Turn the power switch on, then press the DOWN and SELECT keys together to enter the function mode. Press the

UP key to select the D/R and EXPO function. Set the Dual Rate and Expo values as desired, below are suggested

settings.

Page 42

42

E) Servo Reversing

Press the UP key to select the REVERSING function. Next, reverse channel 2 by selecting the channel with the

SELECT key, and pressing the INCREASE key as needed to change from NORM to REV.

F) Travel Adjustment

Press the UP key to select the TRAVEL ADJUST function. Set the Travel Adjust values as shown as initial settings,

while using the control stick to select up/down, or left/right values to be adjusted. Please note that the required

travel values will vary based on the type of servo selected.

Page 43

43

G) CCPM Settings

Press the UP key to select the SWASH MIX function. Change the value of the aileron, elevator, and pitch functions

from the factory default setting using the INCREASE key and selecting the channel with the select key to the

values as shown.

H) Throttle Hold Setting

Press the UP key to select the THRO HOLD function. Press the INCREASE key to activate the function.

Set the hold position in this function so that when the throttle hold switch is pulled, the motor does not run

with the throttle stick at idle and throttle trim set at the idle position.

I) Gyro Sensitivity Selection

Press the UP key to select the GYRO SENS function. Set the gyro gain as shown as a starting point for the G770

3D gyro. Adjust the percentage as necessary when ying the heli. Other gyros may require dierent settings;

consult your gyro manual for further information on setting the gain.

Page 44

44

56 INSTALLING THE SERVO ARMS

22

22

90°

90°

90°

Caution: Unplug at least one of the 3 brushless

motor leads from the speed control to the

motor to prevent the motor from arming

and running while setting up the servos and

linkages. Failure to do this can lead to the

motor running, possibly causing bodily injury

and property damage.

Install the servo arms on the servos

as shown with the arms at the angles

shown with the transmitter and

receiver turned on, and throttle/pitch

stick in the center.

Page 45

45

57 INSTALLING SWASH SERVO LINKAGES

ScrewRod,M2.3×25

……………………×1

ScrewRod,M2.3×40

………×1

…×1

ScrewRod,M2.3×50

22

22

21mm

JRPROPO

C

32mm

B

6.5mm

A

JRPROPO

JRPROPO

Universal Link (5 Pcs)

Universal Link S

Screw Rod, M2.3 x 25

Screw Rod, M2.3 x 50

Screw Rod, M2.3 x 40

A

B

C

Page 46

46

58 ASSEMBLING THE TAIL CONTROL ROD

59 ATTACHING THE TAIL CONTROL ROD

12mm

12mm

JRPROPO

160mmApprox. 190mmApprox.

Self-TappingScrew,M 2×8

…………×2

Logo “JR PROPO”

Logo “JR PROPO”

Tail Control Rod L460

Self-Tapping Screw, M2 x 8 (2 Pcs)

Tail Control Rod

Guide B (2 Pcs)

Universal Link (2 Pcs)

Tail Control Rod Guide

Collar B (2 Pcs)

Page 47

47

61 INSTALLING THE SPEED CONTROLLER

62 INSTALLING THE RECEIVER AND GYRO

22

22

Page 48

48

63 FIXING THE WIRING

64 INSTALLING THE BATTERY

22

6S Li-Po Battery, Not Included

Page 49

49

65 INSTALLING THE BODY

22

Body

Rubber Grommet (3 Pcs)

Page 50

50

BASIC ADJUSTMENT AFTER ASSEMBLY

JRPROPO

JRPROPO

Horizontal

The following information is very important and has a great e ect on ight performance. Read it thoroughly to fully understand

the contents.

The Helicopter does not work properly without rst performing basic settings in the Radio and of the helicopter mechanics.

Optimum settings of each helicopter can only be made following a test ight. The following provides information only

for initial settings. Note that this is not nal and the best setting for your Radio and helicopter can only be determined

following test ights.

1. Initial Setting of Radio System

Using the Radio Set Up Sheets earlier in this manual and the instruction manual for the Radio used, make the initial

settings for the Radio.

2. Wiring to the Receiver

See the wiring diagram earlier in the manual and the instruction manual for the gyro, speed control, and motor used, to

connect each servo, speed control and gyro.

The three servos to be linked to the JR CCPM will now be called the “swash servo F (Front),” “swash servo R (Right)” and

“swash servo L (Left)” for convenience sake.

The tail rotor servo will be called the “rudder servo.” Check the connections of each servo for any error. If they are not

correctly connected, subsequent adjustments cannot be properly made. Basic connections are the same for both JRmade and Futaba-made servos, but channel arrangement on the receiver di ers between them.

3.ServoNeutralAdjustment–1

Turn on the Radio and the receiver (switch on the helicopter) to con rm that all the servos function properly ( rst

disconnect the wiring to the motor so that the main rotor will not run). Next, adjust the neutral position of the swash

servos F, R and L. (for the Radio’s aileron and elevator, set the trim to the neutral position. If the Radio has hovering pitch

and pitch trim adjusting functions, set them to the center also).

Enter the pitch curve function of the Radio and nd out the neutral position of the pitch (throttle) stick by seeing an input

value in the middle of the travel (the spot indicating the input value “50” is the neutral position). The servo angle at this

time serves as a reference. THIS IS VERY IMPORTANT.

Next, check in this state whether or not the F, R and L swash servos are at the reference positions shown in the gure

below. For the rudder servo, check whether or not it is positioned as indicated in each assembly process.

If the servo horn is not appropriately angled, remove and re-attach it so that it will be aligned with the reference

positions.

4.ServoNeutralAdjustment–2

Use the sub-trim function to adjust any slight misalignment between the neutral position of the Radio and that of each

servo (this function provides adjustment for individual servos. For the swash servos F, R and L, this is not a steering

adjustment. Do not confuse it with each trim function for the aileron, elevator and pitch on the front of the Radio.)

Futaba is a registered trademark of Futaba Denshi Kogyo Kabushiki Kaisha Corporation of Japan

Page 51

51

66 BALANCING THE MAIN ROTOR BLADES

67 ATTACHING THE MAIN ROTOR BLADES

SpecialSocketHeadBolt,M3×22

………×2

NylonLockNut,M3

………………………×2

Special Socket Head Bolt, M3 x 22 (2 Pcs)

Rotor Spacer t1 (4 Pcs)

Install spacers as required to make the thickness

11mm and then install into the Blade Grip.

Main Rotor Blades (2 Pcs)

Not Included

Nylon Lock Nut, M3 (2 Pcs)

Parts Bags

Rotor Spacer t1 ①

Rotor Spacer t0.5 ②

Longitudinal Balance

Place the rotor blades on a desk edge or a

mast-like object. Mark the center of gravity

position of each rotor blade itself. Wrap tape

at the tip of one blade so the center of gravity

position of the two blades is within 5mm.

Note: Screw in the Special Cap Bolts until they have fully engaged with the nylon area of

the Nylon Lock Nuts, and tighten them rmly so that they will not be loosened when the

Motor starts running. The blade should be able to be rotated freely when pressed with a

nger, but not loose enough to move freely when the heli is held on its side.

Static Balance

After adjusting the longitudinal

balance, adjust the balance of the

two rotors together (static balance).

Bolt the blades together and hang

from some light string. If one blade

drops and the other rises, wrap tape

around the center of gravity (position

of longitudinal balance) of the lighter

blade until the blades hang level.

Page 52

52

LEVELING THE SWASHPLATE

Evenifslightlymisaligned

Canbeaccuratelyadjustedwiththe

sub-trimfunction

JRPROPO

CCPM SERVO CENTERING WITH THE SUB-TRIM FUNCTION

It may be necessary to make minor servo centering adjustments with the use of the sub-trim function to achieve

the desired servo arm positions. Adjust the sub-trim percentages through the radio system as necessary to make

the servo wheels center properly. With proper servo arm positioning, little to no sub trim will be required.

After the control linkages have been attached to the swashplate, it will be necessary to check the swashplate to ensure that it is

level. To do this, turn on the radio system and place the collective stick in the center position as before. Next, check to make sure

that all trim levers and knobs are also in their center position. Check to ensure that the servo wheels are centered as shown. If the

servos are not centered as shown, please adjust the sub trim function in the radio system as necessary. Once it’s determined that the

servo wheels are centered properly, it will now be necessary to check the swashplate to ensure that it is also level or neutral in this

position. It is suggested that the swashplate rst be checked from the rear of the model to ensure that it’s level from left to right. If

the swashplate is not level as compared to the frame of the model, adjust either the left or right servo control rod as needed.

Once the left to right adjustment is completed, it will now be necessary to check the fore/aft position of the swashplate to ensure

that it is also level on this axis. If the swashplate is not level in the fore/aft axis, it is suggested that the adjustment be made to the

front servo control linkage as needed. If you are unsure as to which linkage needs adjustment or are having diculty obtaining

the correct adjustment, please check the length of each control rod to ensure that it is adjusted to the correct length. Only minor

adjustments should be made to the lengths of the control linkages at this time. Any major adjustments indicate either incorrect

linkage lengths or incorrect servo arm positioning. If the control linkage lengths are altered from the recommended lengths more

than one or two turns, this will have a great eect on the range and settings of the collective pitch in later steps. If required, use sub

trims of each servo to ne-tune 90-degree positions of the linkages. No more than 15 points should ever be required, since the servo

arm can be ipped and a dierent spline can be used.

Page 53

53

PITCHTOAILERON MIXING ADJUSTMENT

PITCH-TO-AILERON MIXING ADJUSTMENT WITH TRAVEL ADJUST

It is very possible that the travel of each servo varies slightly, which can cause the

swashplate to be tilted to the left or right when the collective is moved to the extreme high

and low pitch positions. This condition is generally more common when standard-type

servos are used. If JR® digital servos are used, the adjustment required is generally very

small, if any. These variations in travel can be corrected by altering the travel value of each

servo slightly through the travel adjustment function. To check the pitch-to-aileron mixing,

it will rst be necessary to position the collective stick in the center position and make sure

the swashplate is level.

Next, move the collective stick from the center position to the high pitch position while

viewing the swashplate from the rear of the model as shown in the diagram below. While

moving the swashplate, look for any tendency for the swashplate to roll to the left or right

as it reaches the high pitch position. Repeat this procedure several times to be sure that

your observations are correct. If no rolling tendency is found, it will now be necessary to

repeat this procedure from the center collective stick position to full low pitch. If no rolling

tendency is found, proceed to the next step.

In our example, we have shown that the swashplate has been tilted to the right as the

collective has been increased to full pitch. This would indicate that the right servo’s

maximum travel is less than the left servo’s maximum travel.

In this condition, we suggest that the travel value for the right servo be increased slightly

(5–10%).Repeattheprocedureaboveifthesameconditionoccurs,buttoalesserdegree.

The travel value of the right servo should be increased slightly and retested. In most cases,

it will require only the adjustment of the left or right servo to correct this situation. Once

this condition has been corrected, repeat this procedure for the center-to-low collective

pitch position and adjust as needed.

Page 54

54

PITCHTOELEVATOR MIXING

JRPROPO

PITCH-TO-ELEVATOR MIXING ADJUSTMENT WITH TRAVEL ADJUST

The total travel of each servo can vary slightly, which can also cause the swashplate to be tilted fore and aft when the collective is

moved to the extreme high and low pitch positions. This situation can also be corrected if necessary through the use of the travel

adjustment function. To check pitch-to-elevator mixing, it will rst be necessary to position the collective stick in the center position

as in the previous step. Next, move the collective stick from the center to the high pitch position while viewing the swashplate from

the left side of the model. While moving the swashplate, look for any tendencies for the swashplate to tilt fore or aft as it reaches

the high pitch positions. Repeat this procedure several times to be sure that your observations are correct. If no tilting tendency is

found, proceed to the next step. In our example, we have shown that the swashplate has tilted forward as the collective has been

increased to full high pitch. This would indicate that the front servo’s maximum travel is less than that of the two left/right servos. In

thiscondition,wesuggestthatthetravelvalueforthefrontservobeincreasedslightly(5–10%).Repeattheaboveprocedureand

decrease the value as needed until the tilting tendency is eliminated. For information on the travel adjustment function, please refer

to your radio’s instruction manual for details. Once this condition has been corrected, repeat this procedure for the center-to-low

collective pitch position and adjust as needed. Note: It is very important that during this step, only the travel value for the front servo

(elevator) be adjusted to correct any pitch-to-elevator tendencies. If the travel value of the left or right servo changes, this will the

pitch-to-aileron tendencies corrected in the previous step. If you feel that readjustment of the left and right servo travel is necessary,

then it is suggested that the travel for each servo be increased or decreased at the same amount and the pitch-to-aileron procedure

be retested.

Page 55

55

TAIL SERVO ADJUSTMENT

TAIL ROTOR SERVO SETTINGS

Note: Please refer to the instructions for your gyro in addition to these notes. Please have your gyro connected to the receiver

and the tail rotor servo plugged into the gyro while performing these checks.

Servo Horn: The servo horn needs to be attached so that there is an angle of 90° between the linkage rod and the servo horn’s

arm with the servo at neutral as shown in the gure below. It is best to install the arm on the servo with the gyro in rate or

normal gain mode so that the servo is centered properly. After the servo arm is installed and the tail control rod set, the gyro can

then be set to tail lock mode as desired. The tail rotor linkage rod should now be adjusted in length so the tail rotor pitch slider is

in the middle of its travel.

Reverse Switch (servo direction): The direction of the tail rotor servo movement is set in the Radio using the servo reversing

function. To check if the servo moves in the correct direction move the rudder (tail rotor control) stick on the Radio to the left.

The servo arm should move toward the rear of the helicopter. Moving the Radio stick to the right should move the servo arm

toward the front of the helicopter. The gyro’s direction of response to rotation of the helicopter is discussed and set on page 50

of these instructions.

Travel Adjust (right and left angle adjustment): The Radio travel adjust setting for the tail rotor (rudder) channel will generally

control yaw rate. The physical servo limits for left and right are set on the gyro. Please refer to your gyros instructions.

Sub-trim (Radio’s internal rudder trim): Generally this should remain at zero but may require adjustment depending on your

make and model of gyro. Please refer to your gyro’s instructions for further information about its setup.

Page 56

56

Now that the radio system is completely installed into the helicopter, it’s necessary to check and adjust the

following:

1. Servo Direction (Servo Reversing)

Check to ensure that all servos have been set to the correct direction.

2. Sub-Trim Settings

It’s suggested that the correct neutral settings be achieved without the use of the Sub-Trim function, as this

will aect the neutral position of the servos. Adjust the cyclic trim using the control rods until a neutral hover is

achieved.

3. Pitch/Throttle Curve Adjustment

It is very important that the throttle and pitch curves are adjusted properly to achieve the best performance

from your helicopter. When properly adjusted, the main rotor head rpm should remain consistent throughout all

maneuvers and throttle stick positions. A constant rpm will also help to improve the eectiveness and accuracy

of the tail rotor and gyro systems.

A) Pitch Curve

It will now be necessary to establish the maximum pitch value required for your application prior to adjustment.

For example, if you are a 3D pilot, then your maximum negative pitch will be -12, and your maximum positive

pitch will be +12.

The maximum pitch range that you will require will be 24° total. The maximum pitch range

mentioned above must be established through the use of the pitch travel value in the CCPM function.

As mentioned previously, do not try to establish the maximum pitch curve values through adjustment

of the travel adjustment function, as this will alter the pitch-to-aileron and pitch-to-elevator travel

values established earlier.

Please refer to the CCPM activation section for information on how to access the CCPM function. Once the CCPM

function has been activated, set the maximum positive pitch settings as mentioned above. Since the CCPM

function does not allow for independent travel settings for positive and negative pitch, it will be necessary to

establish the maximum positive pitch, since this is generally the largest degree of pitch in the pitch range. Once

the maximum positive pitch range is set, the maximum pitch range positive and negative can be reduced as

needed through the pitch curve function. Set the main rotor pitch gauge to the desired maximum pitch setting,

then increase or decrease the CCPM pitch travel (labeled Pitch or Ch 6) as needed until this pitch setting is

achieved.

Once this procedure has been completed, the positive and negative pitch settings for each ight mode

can be adjusted through the radio’s pitch curve function. Please refer to your radio’s instruction manual

for more information.

FINAL SERVO ADJUSTMENT AND RADIO SETUP

Page 57

57

Note: Flight modes #1 and #2 are

duplicated for safety.

Throttle Curve Settings

Below are examples of possible throttle curves during

various ight conditions.

It will be necessary to ne-tune and adjust these

values during test ights to achieve a constant main

rotor rpm.

Gyro Gain Adjustment (All Gyros)

Please refer to your Gyro’s instruction manual for

proper gain settings.

Gyro Direction

It will also be necessary to conrm the direction the

gyro compensates when the body of the helicopter

is rotated. To do this, turn the radio system on and

suspend the helicopter by the main rotor head. Next,

move the rudder stick to the right and watch the

direction that the tail rotor servo arm travels. Now

while watching the tail rotor servo arm, rotate the

body of the helicopter counterclockwise. The servo

arm should move in the same direction as when the

rudder stick was moved to the right. If the arm moves

in the opposite direction, reverse the gyro and re-test.

Generally with the G770 3D Gyro, the gyro reversing

switch will be left set to NORM on the gyro.

Normal

(Hover)

Stick Position

Pitch Range

Flight Mode 1

3D Stunt 1

Stick Position

Pitch Range

Stick Position

Pitch Range

Flight Mode 2

3D Stunt 2

(Duplicate of #1)

Autorotation

(Throttle Hold)

Stick Position

Pitch Range

+12º

0º

-12º

Low 1/4 1/2 3/4 High

+12º

0º

-12º -9º

+12º

0º

-12º -9º

Low 1/4 1/2 3/4 High

Low 1/4 1/2 3/4 High

+12º

0º

-12º

Low 1/4 1/2 3/4 High

Pitch Curve Settings

N

1

*2

H

Hovering

3D Flight #1

3D Flight #2

Autorotation

-12º

-12º

-12º

-12º

0º

0º

0º

0º

+12º

+12º

+12º

+12º

Flight

Mode

Application

Low Pitch

(Low Stick)

Hovering Pitch

(Half Stick)

High Pitch

(High Stick)

Pitch Range Settings

Hovering

Stick Position

Power Output

Normal Mode

Flight Mode N

3D Flight Stunt 1 and 2

Stick Position

Power Output

Flight Mode 1

100%

50%

0% (Idle)

40%

60%

1

2

3

4

Low 1/4 1/2 3/4 High

100%

50%

80%

0% (Idle)

40%

Low 1/4 1/2 3/4 High

Throttle Curve Settings

PITCH RANGE AND CURVE SETTINGS

Page 58

58

CONFIRMATION OF PROPER BLADE DIRECTION

PITCH ADJUSTMENT LINKAGES

RotorPitchAdjustingRod

RotorPitchAdjustingRod

FINAL PREFLIGHT CHECK

Once all assemblies have been completed, please review the following suggestions before

attempting initial ights.