Page 1

ASSEMBLY INSTRUCTIONS

VENTURE SPECIFICATIONS

Overall Length 47.32''

Overall Height 16.29''

Main Rotor Diameter 52.63''

Tail Rotor Diameter 9.17''

Gear Ratio 9.78:1: 5.18

Gross Weight 7.0–7.5 lb

ARF

™

Page 2

2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Venture 50 3D ARF Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Radio System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Engine Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Building Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required Field Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hardware Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-1 Tail Boom Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2 Drive Belt Connection and Adjustment. . . . . . . . . . . . . . . . . . . . . . . 8

1-3 Tail Boom Brace Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4 Tail Fin Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5 Tail Control Rod Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-6 Tail Control Rod Installation/Horizontal Fin Attachment. . . . . . . . . 10

2-1 Engine Mount/Cooling Fan Installation. . . . . . . . . . . . . . . . . . . . . . 11

2-2 Clutch Assembly Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . 11–12

2-3 Starter Shaft/Hex Adapter Installation . . . . . . . . . . . . . . . . . . . . . . 12

2-4 Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-5 Muffler Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-1 Servo Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-2 Gyro/Receiver/Switch Harness/Battery Installation . . . . . . . . . 15–16

Understanding Swashplate Control Systems. . . . . . . . . . . . . . . . . . . . . . . 17–18

How JR 120 CCPM Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Radio System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CCPM Software Activation and Initial Adjustment . . . . . . . . . . . . . . . . . . . 20-23

Important CCPM Programming Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-3 CCPM Servo Arm Preparation and Installation. . . . . . . . . . . . . . . . 25

3-4 CCPM Servo Centering with the Sub-Trim Function. . . . . . . . . 26–27

3-5 CCPM Linkage Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-6 Checking the Swashplate for Level. . . . . . . . . . . . . . . . . . . . . . . . . 29

3-7 Pitch-to-Aileron Mixing Adjustment with Travel Adjust . . . . . . . . . 30

3-8 Pitch-to-Elevator Mixing Adjustment with Travel Adjust . . . . . . . . 31

3-9 Tail Control Rod Servo Connection . . . . . . . . . . . . . . . . . . . . . . . . 32

3-10 Throttle Linkage Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-1 Body Assembly/Canopy Attachment . . . . . . . . . . . . . . . . . . . . . . . 34

4-2 Decal Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-3 Main Rotor Blade Balancing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-4 Main Rotor Blade Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-5 Optional 3D Control System Setup. . . . . . . . . . . . . . . . . . . . . . 37–38

Radio Data Sheet: XP662 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Radio Data Sheet: XP662 3D Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Radio Data Sheet: X-378 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Radio Data Sheet: X-378 3D Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Radio Data Sheet: XP8103 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Radio Data Sheet: XP8103 3D Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Radio Data Sheet: PCM10X 3D Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45–46

Final Servo Adjustment and Radio Setup. . . . . . . . . . . . . . . . . . . . . . . . . . 47–49

Final Preflight Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Blade Tracking Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Blade Tracking Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Advice and Basic Hover Training Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Preassembled Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1-1 Clutch Bell Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1-2 Tail Drive Pinion/Bearing Assembly . . . . . . . . . . . . . . . . . . . . . . . . 54

1-3 Elevator Arm Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1-4 Fuel Tank Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2-1 Main Frame Section Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2-2 Main Frame Clutch/Tail Pinion/Elevator/Fuel Tank . . . . . . . . . . . . . 57

2-3 Front Radio Bed/Cooling Shroud Installation. . . . . . . . . . . . . . . . . 58

3-1 Main Drive Gear/Autorotation Assembly Installation . . . . . . . . . . . 59

3-2 Landing Gear Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . 60

4-1 FlyBar Control Arm/Seesaw Arm Assembly . . . . . . . . . . . . . . . . . . 61

4-2 Main Blade Holder Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4-3 Main Blade Holder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4-4 Washout Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4-5 Swashplate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4-6 Tail Pitch Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4-7 Swashplate/Washout Assembly Installation . . . . . . . . . . . . . . . . . 64

4-8 Rotor Head Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-9 Flybar Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-10 Flybar Paddle Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-11 Rotor Head/Swashplate Control Rod Installation. . . . . . . . . . . . . . 66

5-1 Tail Gear Case Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5-2 Tail Gear Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5-3 Tail Center Hub Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5-4 Tail Blade Holder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5-5 Tail Pitch Control Lever Installation . . . . . . . . . . . . . . . . . . . . . . . . 69

5-6 Tail Boom Brace Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Parts Diagrams/Parts Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70–83

TABLE OF CONTENTS

Section Description Page

Section Description Page

Page 3

INTRODUCTION

Thank you for purchasing the JR Venture™ 50 3D ARF helicopter. The

Venture 50 has been designed to provide the aspiring 3D Heli pilot with a model

that is very reliable and durable, while featuring outstanding 3D performance and

affordability. Featuring full ball bearings at all critical locations and a high quality

Swashplate, the Venture 50 will retain its precision and reliability through many

flights. The Venture's unique two-piece box frame design adds rigidity to the

model, while keeping the weight and parts count to a minimum. The Venture is

equally suited for both the aspiring and accomplished 3D pilot, thanks to the

optional 3D control system parts and instructions included with each kit. In its

stock form, the Venture is very smooth and predictable, giving the aspiring 3D

pilot an additional step to success.

JR CCPM

To take the Venture's design to the next level, JR’s designers turned to CCPM

(Cyclic/Collective Pitch Mixing). CCPM is a unique control system that mounts

three servos below the swashplate with short, straight linkages directly to the

swashplate at 120 degree intervals. With CCPM, complex collective and cyclic

mixing is accomplished electronically, rather than mechanically. As a result,

many parts are eliminated, along with excessive control system play, not to

mention quicker building and lower maintenance.

What’s more, you get more servo power from CCPM. That’s because instead of

one servo moving the collective, you now have three. Instead of one servo moving

the cyclic, you have two.

Before you begin the assembly of your Venture 30 CP, we suggest that you first

review the entire instruction manual to become familiar with the assembly

sequences and parts layout.

Warning

The radio controlled model helicopter contained in this kit is not a toy but a

sophisticated piece of equipment. This product is not recommended for use

by children. Radio controlled models such as this are capable of causing both

property damage and/or bodily harm to both the operator/assembler and/or

spectator if not properly assembled and operated. Horizon Hobby, Inc. assumes

no liability for damage that could occur from the assembly and/or use/misuse of

this product.

AMA Information

We strongly encourage all prospective and current R/C aircraft pilots to join the

Academy of Model Aeronautics. The AMA is a non-profit organization that provides

services to model aircraft pilots. As an AMA member, you will receive a monthly

magazine entitled Model Aviation, as well as a liability insurance plan to cover

against possible accident or injury. All AMA charter aircraft clubs require

individuals to hold a current AMA sporting license prior to operation of their

models. For further information, contact the AMA.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(317) 287-1256

Preassembly Information

All small hardware (nuts, bolts, washers, etc.) for each step are separated and

packaged separately within the main parts bags. It is suggested that you place all of

the hardware in an open container (e.g., coffee can) during assembly so as not to

lose any of the small parts. It may also be helpful to familiarize yourself with the

various sizes of screws, bolts, nuts, etc., as illustrated in the appropriate assembly

section before you begin assembly. In most cases, at the end of each assembly

section, there should be no parts remaining.

Great care has been taken in filling the bags with the correct quantity of parts and

hardware for each section. However, occasionally mistakes do happen. In the event

that you find a parts shortage or are in need of technical assistance, please contact

your local JR heli division parts dealer or the Horizon Service Center directly.

Horizon Service Center

4105 Fieldstone Road

Champaign, IL 61822

Venture Helplines

(217) 355-9511 (9a.m. to 5p.m. CST)

E-mail: venturehelp@horizonhobby.com

3

™

Page 4

ADDITIONAL ITEMS REQUIRED TO COMPLETE THE VENTURE 30CP

1. RADIO SYSTEM REQUIREMENTS (NOT INCLUDED):

6-channel or greater R/C helicopter system with 120° CCPM function (see list below), 5 servos, 1000mAh receiver battery, and gyro

VENTURE™50 3D ARF FEATURES

CCPM (Cyclic/Collective Pitch Mixing):

More Accurate: Control system play is totally eliminated thanks to full ball bearings

and a high-grade swashplate

Simpler: Fewer links to set up and maintain

More Powerful: Collective has three times the servo power, cyclic has double

Special 3D Rotor Head Design

The Venture 50's updated 3D rotor head features an aluminum center hub, heavy

duty spindle shaft, 3D dampener set, and main blade holder thrust bearings to

handle the rigors of 3D flight like never before

High Quality Aluminum/Composite Swashplate

Improves control accuracy, eliminates the need for expensive Swashplate upgrades

Two-Piece Box Frame System

Provides excellent rigidity and vibration absorption

One-Way Hex Start Shaft System

Provides positive starting, starter shaft utilizes a one-way bearing that allows the

shaft to stop after the engine is started

Belt-Driven Tail Rotor Design with LSD Slipper Clutch

Provides easy adjustment and low maintenance, eliminates the need for

optional/expensive tube drive shafts. The added LSD clutch allows the Ventures tail

to be partially driven for aerobatic autorotations

Precision Ball Bearings at All Critical Locations

Provide low wear, high precision and reduced maintenance

Ultra-Low Parts Count

Adds reliability and ease of maintenance

Self-Aligning One-Piece Heavy Duty Steel Clutch System

Offers easy installation and adjustment with exceptional reliability

Rearward-Facing Engine Design

Provides easy access to the glow plug for starting, engine slips easily through the

main frame for trouble free engine maintenance

Dual Boom Braces

Offers increased rigidity of the tail assembly for increased gyro holding power. Also

eases glow plug access and replacement

Included Header Tank System

An industry First! Improves engine performance and consistency throughout the

entire flight. Increases flight times, and provided a fuel level visual during flight

Superior Parts Fit and Finish

Make assembly trouble-free and enjoyable

Optional 3D Control System Setup Included

Converts the Venture(tm) from a smooth and predictable 3D trainer to an all out

extreme 3D machine with the use of the included aggressive 3D paddles and

Swashplate ball spacers for ultra aggressive 3D flight

4

CCPM-Ready JR Radio Systems

Most current JR Heli radio systems (XP662,

XP8103 w/digital trims, 10X, as well as older

10 series systems) are equipped with 120°

CCPM electronics for use with the JR CCPM

machines. Radios you may be flying now, like

the X347, X388S, XP783, and XP8103* have

CCPM capability built in, but require

activation by the Horizon Service Department.

Please call (217) 355-9511 for details.

*Please note that many XP8103 systems have the CCPM

function already activated. Please check with the Horizon

Service Center for details.

CURRENT RADIO SYSTEMS

JRP1656** PCM 10X, 5-8231 Servos (50/53/72 MHz)

JRP165TX PCM 10X, Transmitter Only (50/53/72 MHz)

JRP8622** XP8103FM, 5-517 Servos (50/53/72 MHz)

JRP8653** XP8103PCM, 5-531 Servos (50/53/72 MHz)

JRP7425** X-378 FM 5-537 Servos (72MHz)

JRP6822** XP662 FM, 5-537 Servos (72MHz)

3'' Servo Extensions (2)G500T Gyro JR AirPac

™

JR XP662 JR X-378

JR 10X JR XP8103 DT

Page 5

5

Double-Sided Servo Mounting Tape

Threadlock

(blue required)

Nylon Wire Ties (secure radio

wires)

2' Silicone Fuel Tubing

Fuel Filter Glow Plugs

2. ENGINE REQUIREMENTS (NOT INCLUDED):

3. BUILDING SUPPLIES (NOT INCLUDED):

The following items are needed to complete the assembly of the JR Venture™:

A .46–.52 R/C helicopter engine

A special helicopter-type muffler is also required.

Webra Speed .52 AAR HELI (WEBE520)

Revolution .50 Heli Muffler (RVO1150)

NOH600RP Razor Pro Symmetrical, 600mm

Page 6

6

Needle-Nose Pliers

Drill and Drill Bits

Allen Wrenches:

1.5, 2.0, 2.5, 3.0 mm

Ball Link Pliers

JR Ball Link Sizing Tool

(JRP960219)

(optional)

Universal Blade Balancer

(KSJ528)

Crankshaft Locking Tool

(RVO1007)

X-ACTO Knife

Metric Ruler

Scissors

(DYN2511)

12-Volt Electric Starter

(HAN110)

12-Volt Starting Battery

(HAN102)

Long Reach 1.5-Volt Glow

Plug Battery (DYN1960)

Long Reach Remote Glow Plug

Adaptor (HAN121)

Helicopter Fuel, 15%–30%

Pitch Gauge

(JRP960326)

Fuel Pump (KSJ860)

Hex Starting Shaft (JRP960090)

Phillips Screwdriver

Nut Drivers: 4, 5, 7 mm

4. REQUIRED TOOLS (NOT INCLUDED):

5. REQUIRED FIELD EQUIPMENT (NOT INCLUDED):

or

Page 7

7

Socket Head Bolt

Tapping Screw

Flat Washer

.05mm

.05mm

Flat Head Screw

Lock Nut

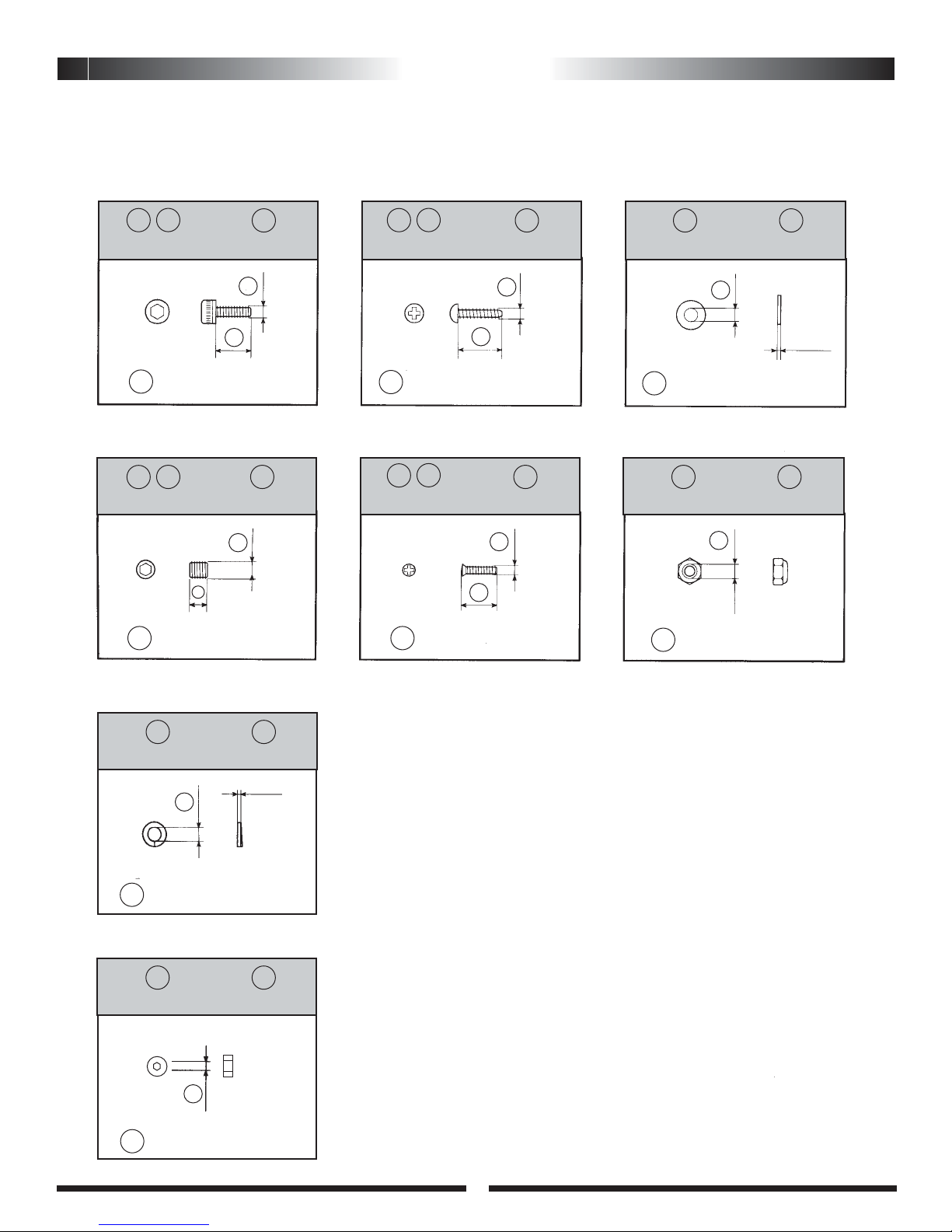

There are many various sizes and shapes of hardware included in this kit. Prior to

assembly, please be careful to identify each screw by matching it to the full size

screw outlines included in each step.

All of the hardware, screws, nuts, etc., contained in the Venture™kit are described

in the following A, B, C manner:

C

C

C

A

B

A

A

B

B

C

3x8 mm Socket Head Bolt

Set Screw

C

A

B

C

C

A

A

A

2x8 mm Flat Head Screw

2.6x10 mm Self-Tapping Screw

A

B

B

3 mm Flat Washer

A

B

B

3 mm Lock Nut

Spring Washer

A

B

B

3 mm Spring Washer

A

Hex Nut

A

B

B

2 mm Hex Nut

C

4x4 mm Set Screw

HARDWARE IDENTIFICA TION

A

B

A

B

A

B

A

B

Page 8

8

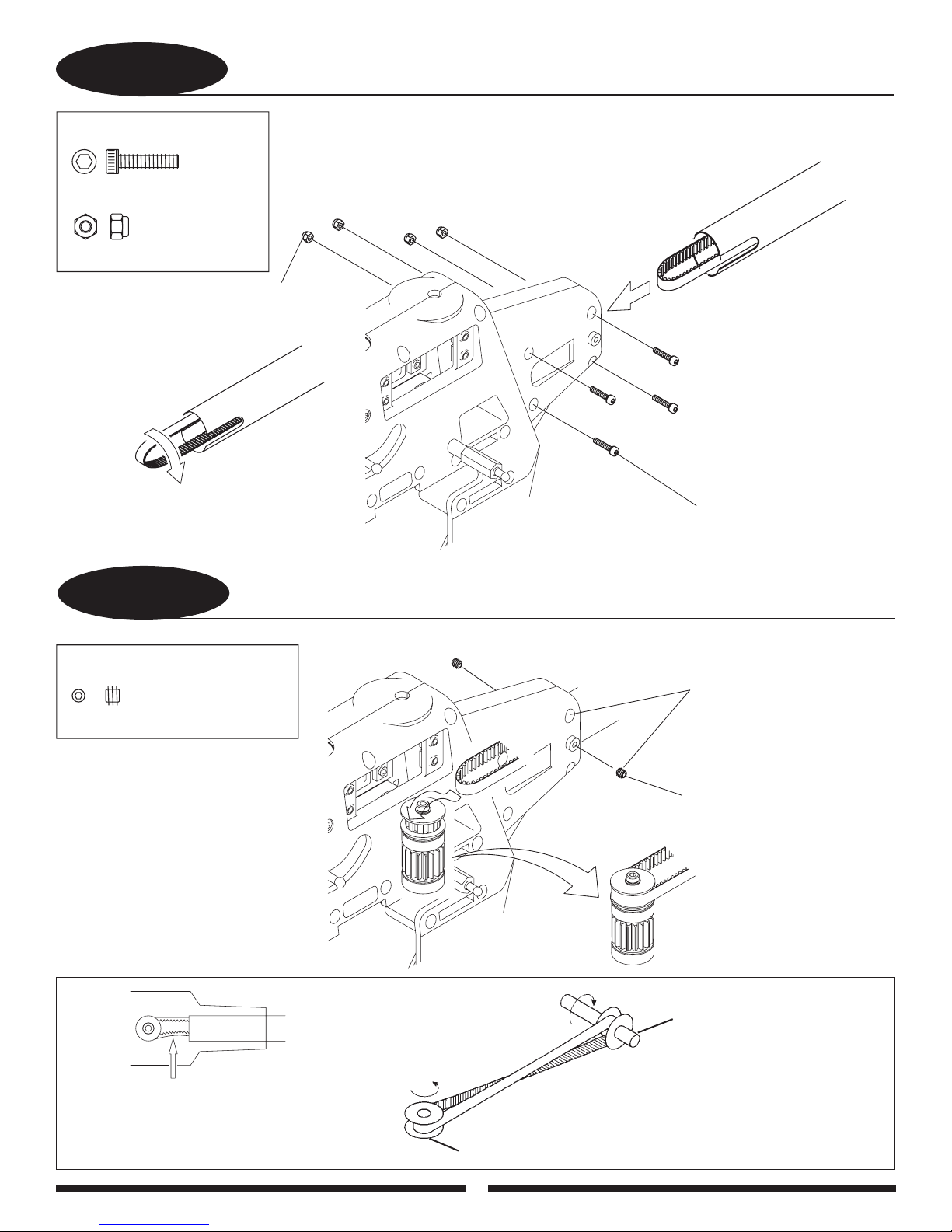

1-1

TAIL BOOM INSTALLATION

1-2

TAIL DRIVE BEL T CONNECTION AND ADJUSTMENT

Engage the tail drive belt over the front pulley. Be

certain to note the correct rotation (shown below).

Set the belt tension per the directions below.

Secure bolts completly after adjusting the tail

belt, making sure that the tail output shaft is

exactly 90° to the main rotor shaft.

Rotate the tail drive belt in the direction shown before

installing it onto the front pulley. It is extremely

important to install the belt in the proper direction to

insure correct rotation of the tail rotor blades.

Belt tension should be set so when pressing with your

finger, the sides of the belt do

not come in contact with

each other. If unsure, it is always better to set the belt

tension too tight than too loose.

Insert the tail boom assembly into

the rear of the frame as shown.

Note: Check to make sure that

the belt is not twisted inside the

boom prior to insertion.

Do not fully tighten bolts at this time.

These will be tightened in Step 1-2.

Preinstalled

3x3 mm Set Screw (2)

3x3 mm Set Screw (preinstalled)

Tail Output Shaft

Front Pulley

3x15 mm Socket Head Bolt (4)

3x15 mm Socket Head Bolt (4) (preinstalled)

Preinstalled

3 mm Lock Nut (4)

3 mm Lock Nut (4)

Twist the tail drive belt 90°.

Page 9

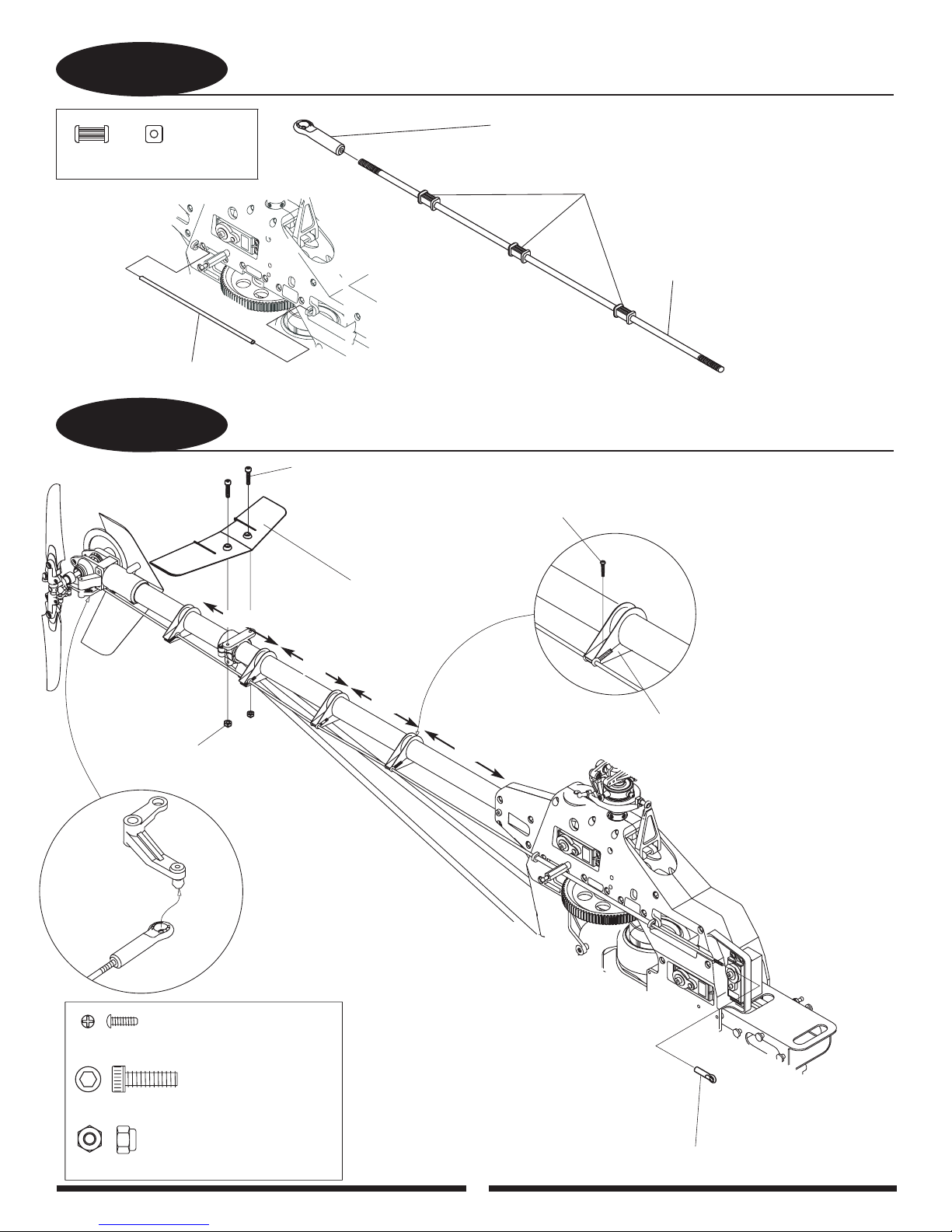

1-3

TAIL BOOM BRACE INSTALLATION

9

Connect the tail braces

end to the rear of the

frame as shown.

Tighten this bolt after the brace

has been connected to the rear

of the frame.

It may be neccessary to loosen these

bolts to reposition the tail brace

clamp as needed.

3x15 mm Socket Head Bolt (1)

3x15 mm Socket Head Bolt (2)

Tail Brace Clamp U/D

Preassembled

3x15 mm Socket Head Bolt

3x25 mm Socket Head Bolt

3 mm Lock Nut (1)

3 mm Lock Nut

3 mm Lock Nut

3 mm Flat Washer (2)

3 mm Lock Nut (2)

3x8 mm Socket Head Bolt (2)

3x8 mm Socket Head Bolt (2)

Vertical Fin

3 mm Flat Washer (2)

1-4

TAIL FIN ATTACHMENT

3x25 mm Socket Head Bolt (1)

3mm Lock Nut (5)

3mm Flat Washer (4)

3x7x3 mm Spacer

Page 10

1-5

TAIL CONTROL ROD ASSEMBLY

10

1-6

TAIL CONTROL ROD INSTALLATION/HORIZONT AL FIN A TTACHMENT

Insert the tail control rod assembly into

the four guides through the inner

holes. Adjust the spacing of the

guides as shown below and secure

using the four 2x8 mm self-tapping

screws as shown. Rotate each tail

guide as needed to align the tail

control rod so it will move easily,

with little resistance.

Thread link 8 mm onto

the end of the control rod.

63/4''

5''

51/4''

Tail Control Rod Bushings (3)

Tail Control Rod Bushings (3)

Tail Control Rod 965 mm

Tail Control Rod Tube

Universal Link

3x10 mm Socket Head Bolt (2)

Horizontal Fin

3 mm Lock Nut (2)

3 mm Lock Nut (2)

3x10 mm Socket Head Bolt (2)

2x8 mm Self-Tapping Screw (3)

2x8 mm Self-Tapping Screw (3)

Tail Control Guide

Universal Link

Thread link 8 mm onto

the end of the control rod.

21/2''

Page 11

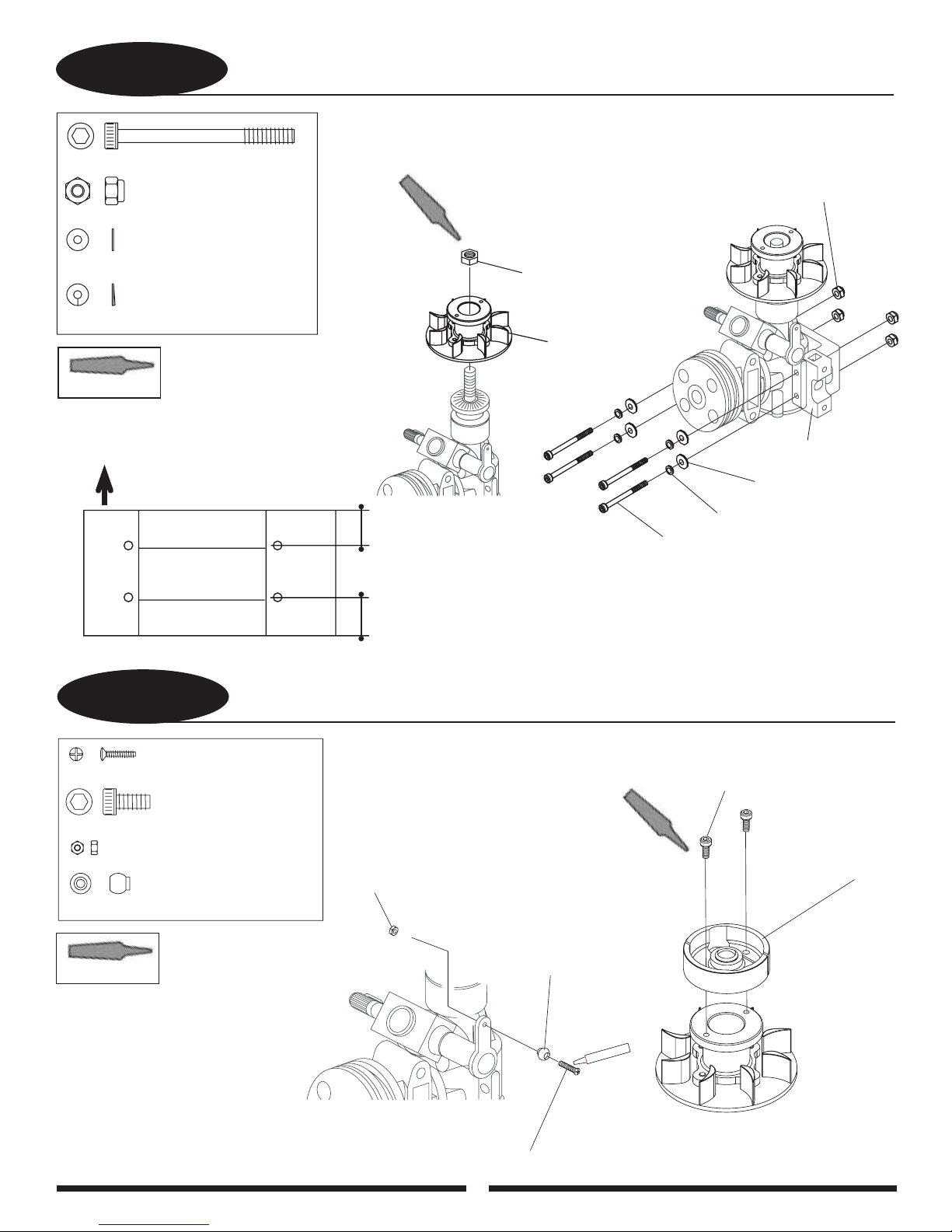

2-1

ENGINE MOUNT/COOLING FAN INSTALLA TION

11

2-2

CLUTCH ASSEMBLY A TT ACHMENT

Longer Distance

Shorter Distance

*It is recommended that a crankshaft locking tool be used

to properly secure the cooling fan assembly to the engine.

It is important to note the proper direction for the motor mount

installation for achieving the correct alignment of the engine.

Top

Bottom

Motor Mount Direction

*

Use Threadlock

Use Threadlock

3x30 mm Socket Head Bolt (4)

3x30 mm Socket Head Bolt (4)

3 mm Lock Nut (4)

3 mm Lock Nut (4)

3 mm Flat Washer (4)

3 mm Flat Washer (4)

3 mm Spring Washer (4)

3 mm Spring Washer (4)

Engine Nut

Engine Mount*

Cooling Fan Assembly

2x8 mm Flat Head Screw (1)

2x8 mm Flat Head Screw

3x5 mm Socket Head Bolt (2)

3x5 mm Socket Head Bolt (2)

2 mm Hex Nut (1)

2 mm Hex Nut

Steel Joint Ball (1)

Steel Joint Ball

Clutch Assembly

Page 12

2-2

CLUTCH ASSEMBLY A TT ACHMENT

12

2-3

ST AR TER SHAFT/HEX ADAPTER INST ALLATION

To insure smooth operation, it is suggested that the clutch assembly

be checked for trueness (runout) prior to final attachment. Place the

engine assembly on a flat surface using the engine mount to steady

the engine. While viewing the assembly straight on, rotate the

fan/clutch assembly while watching the 1-way bearing located in

the center of the clutch. Note the side-to-side movement (wobble or

run-out). Next loosen the two 3x5 mm clutchbolts and rotate the

clutch 180° on the fan. Re-test and note the runout in this position.

Choose the position that shows the least amount of visual runout and

secure the clutch using the two 3x5 mm bolts (use threadlock).

Use Threadlock

4x4 mm Set Screw (1)

Engine

Fan

1-Way Bearing (watch for runout)

3x5 mm Socket Head Bolts

Table Surface

Rotate

Clutch Assembly

Continued

Hex Adaptor

Remove protective bag or blue

cap from top of rotor head.

4x4 mm Set Screw

Starter Shaft

Insert the start shaft as shown and

secure the hex adaptor to the shaft using

the 4x4 mm set screw. Position the start

shaft so that there is no up/down play.

Page 13

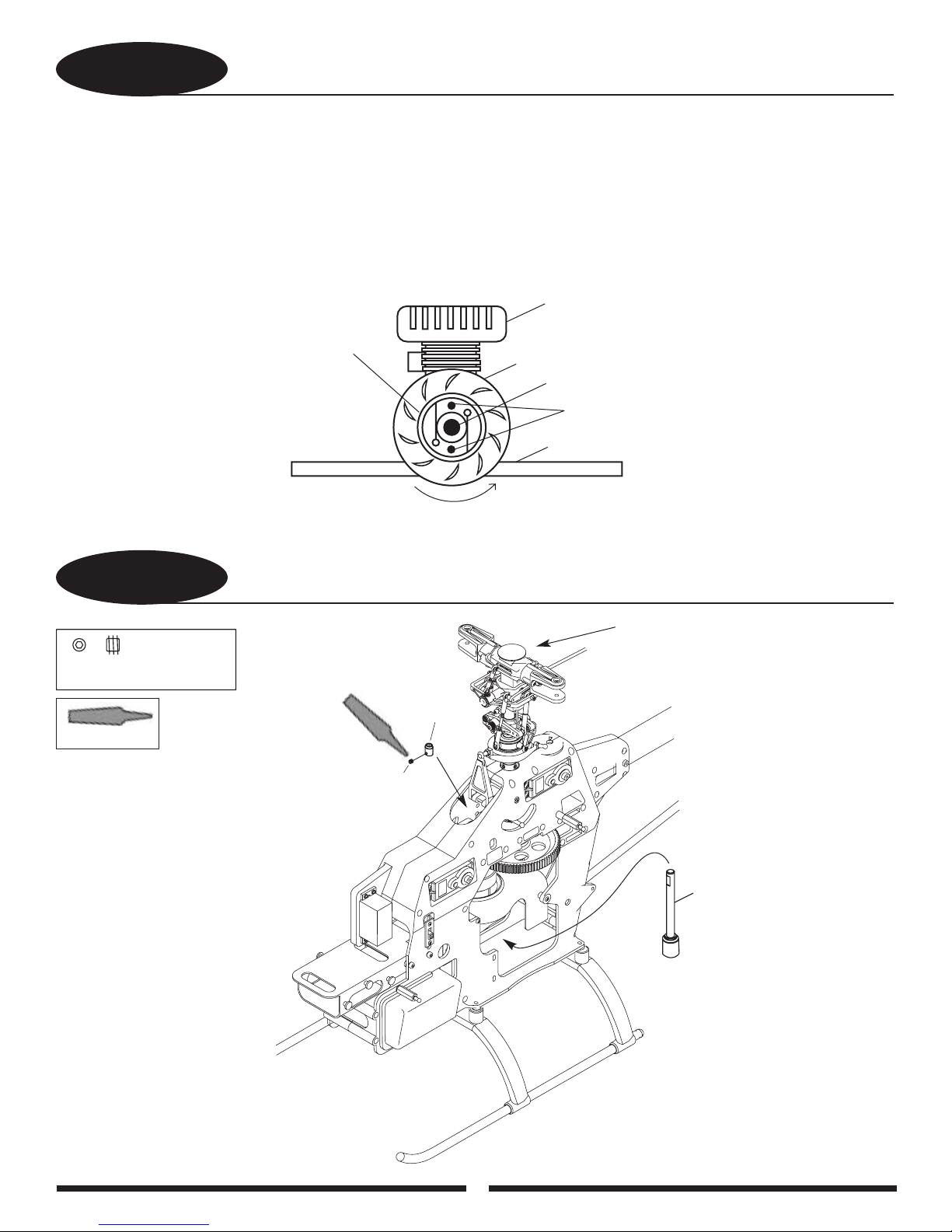

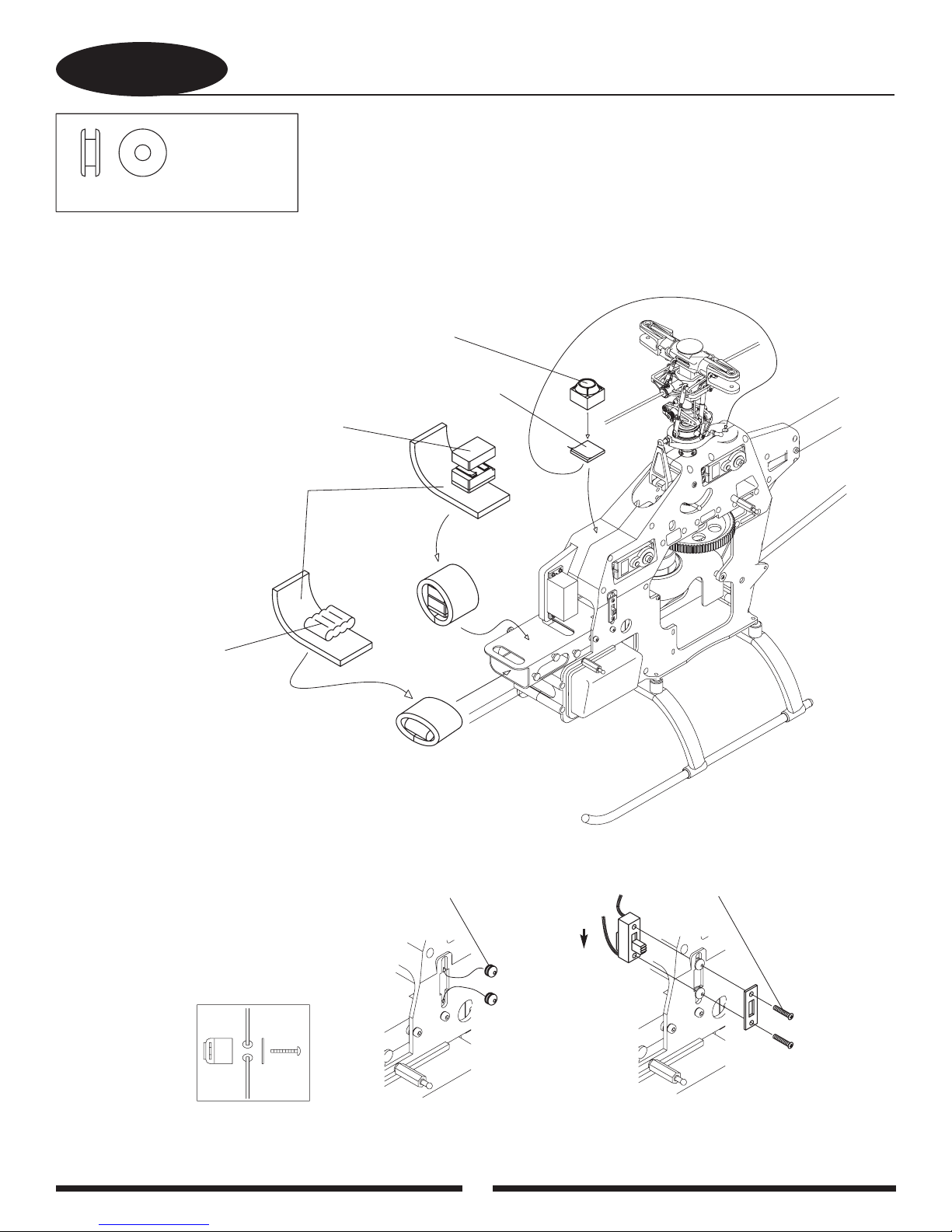

2-4

ENGINE INST ALLATION

13

2-5

MUFFLER/HEADER T ANK INSTALLATION

Adjust the height and position of the

engine as shown so the bottom of the clutch

assembly is flush with the bottom of the

clutch bell. Also check to insure that the

engine and clutch bell are parallel.

*It is highly recommended that you insert

the muffler bolts into the engine case prior

to installing the engine in the frame.

3x15 mm Socket Head Bolt (4)

3x15 mm Socket Head Bolt (4)

Engine Mount/Frame Washers

Pressure Fuel Line Attachment

Fuel Filter

(not included)

Revolution .50 Heli Muffler

Shown (RVO1150)

(purchased separately)

Please refer to the photo

for proper Header Tank

plumbing and attachment

Fuel line connections:

• Main tank pickup line

to top nipple of

Header tank

• Header tank pickup line

to carburetor nipple

• Main tank overflow to

muffler pressure nipple

Main Tank Pickup Line Header Tank Pickup Line Header Tank Nipple

Page 14

14

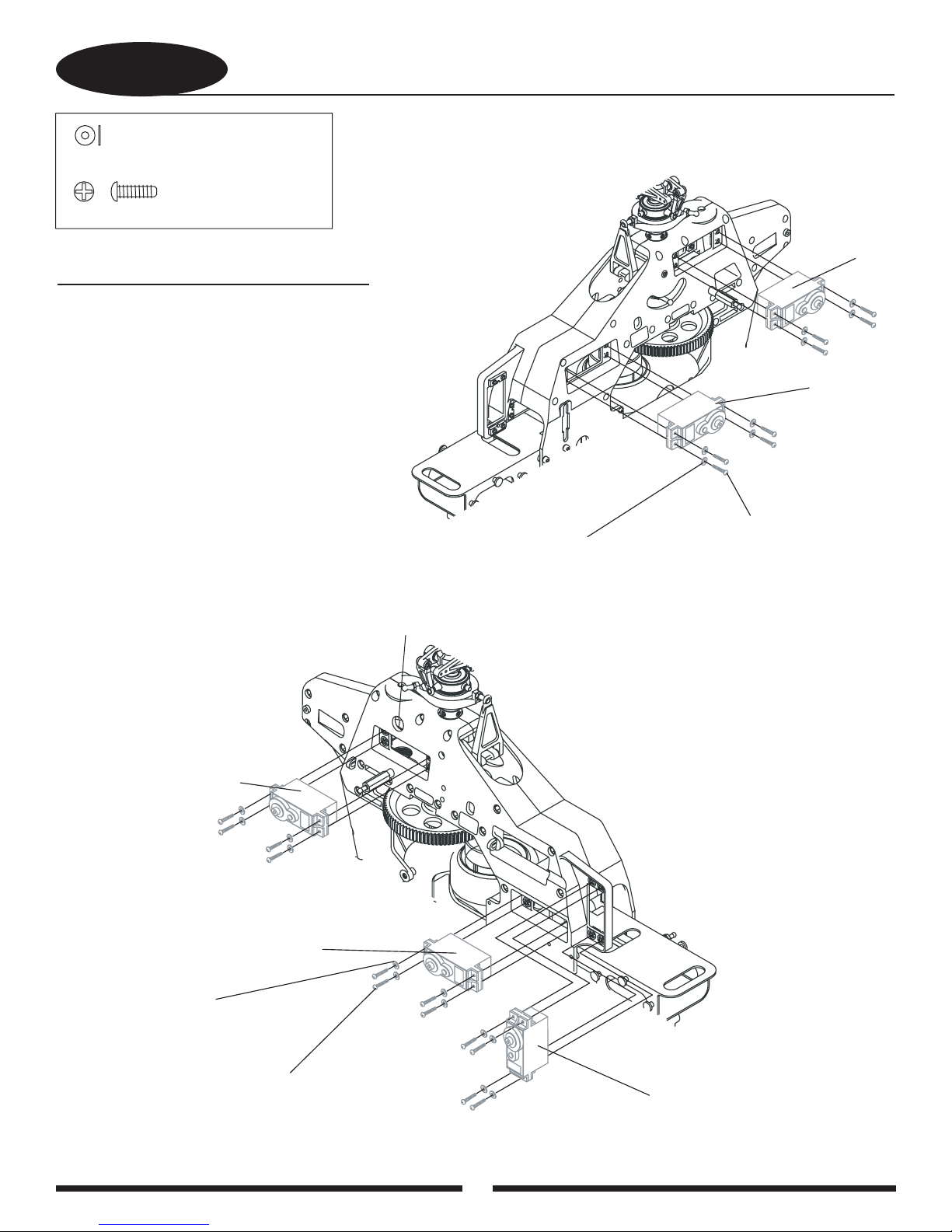

3-1

SERVO INST ALLATION

RADIO INSTALLATION SUGGESTIONS

Be sure to install four rubber servo grommets and eyelets to

each servo prior to installation.

When adjusting control rods, be sure to adjust each universal

link the same amount so as not to unthread one link too far.

Be sure to keep all servo lead wires, etc., away from all servo

arms, rods, and sharp edges of the helicopter’s mechanics.

After final installation, group these wires together as indicated

using the small nylon wire ties and the nylon spiral tubing

included with this kit.

Note: It is suggested that the switch harness be

installed prior to installation of the rudder servo.

Note: Once the servos are installed, check to see if

the servos can be moved in the mounts. If the

servos can be moved slightly, tighten the servo

mounting screws until the servos remain in position.

2.6 mm Flat Washer (20)

2.6 mm Flat Washer (8)

Left Servo (C)

Front Servo (A)

2.6x12 mm Self-Tapping Screw (20)

2.6x10 mm Self-Tapping Screw (8)

Right Servo (B)

Throttle Servo

2.6 mm Flat Washer (12)

2.6x12 mm Self-Tapping Screw (12)

Rudder Servo

Route Servo B and C wires

through this hole.

Page 15

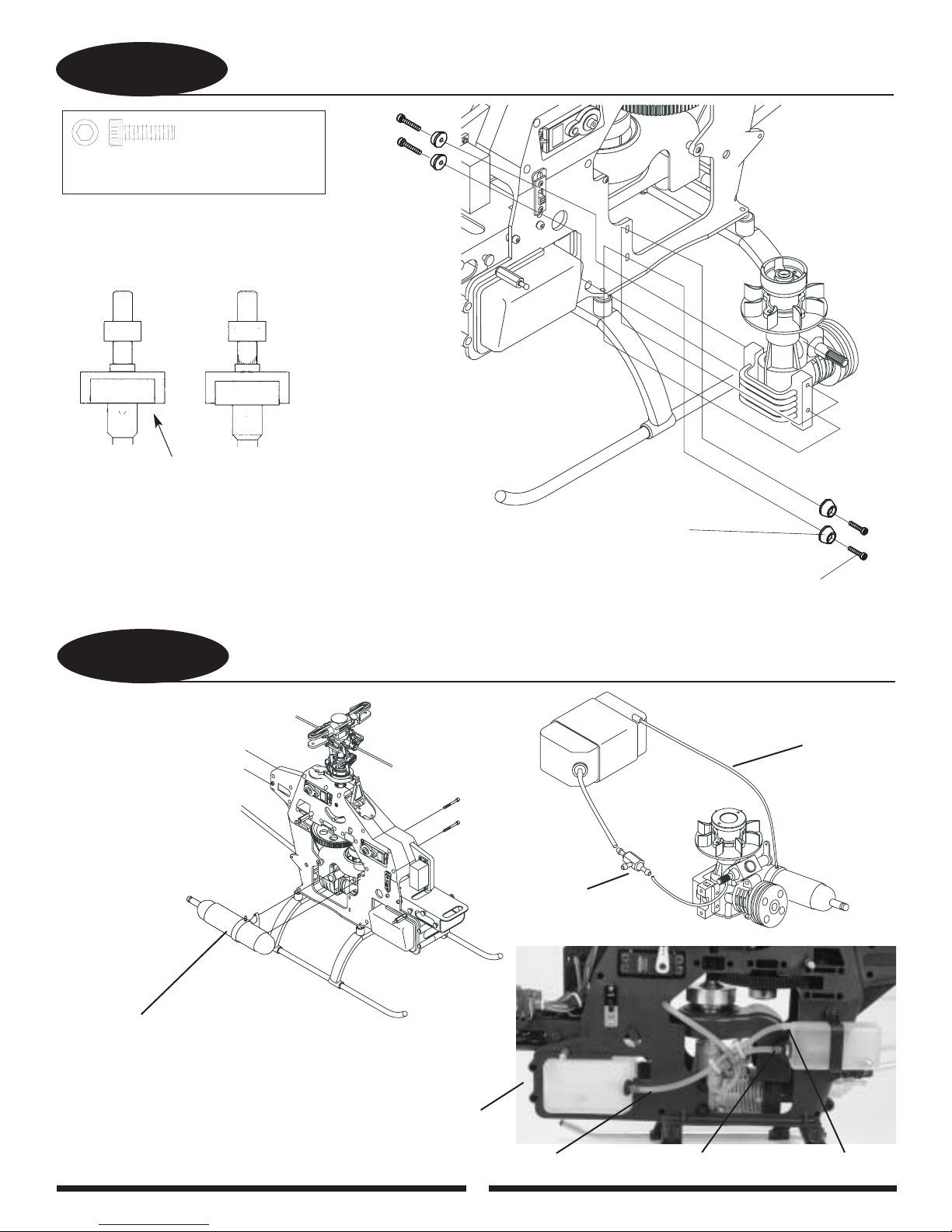

3-2

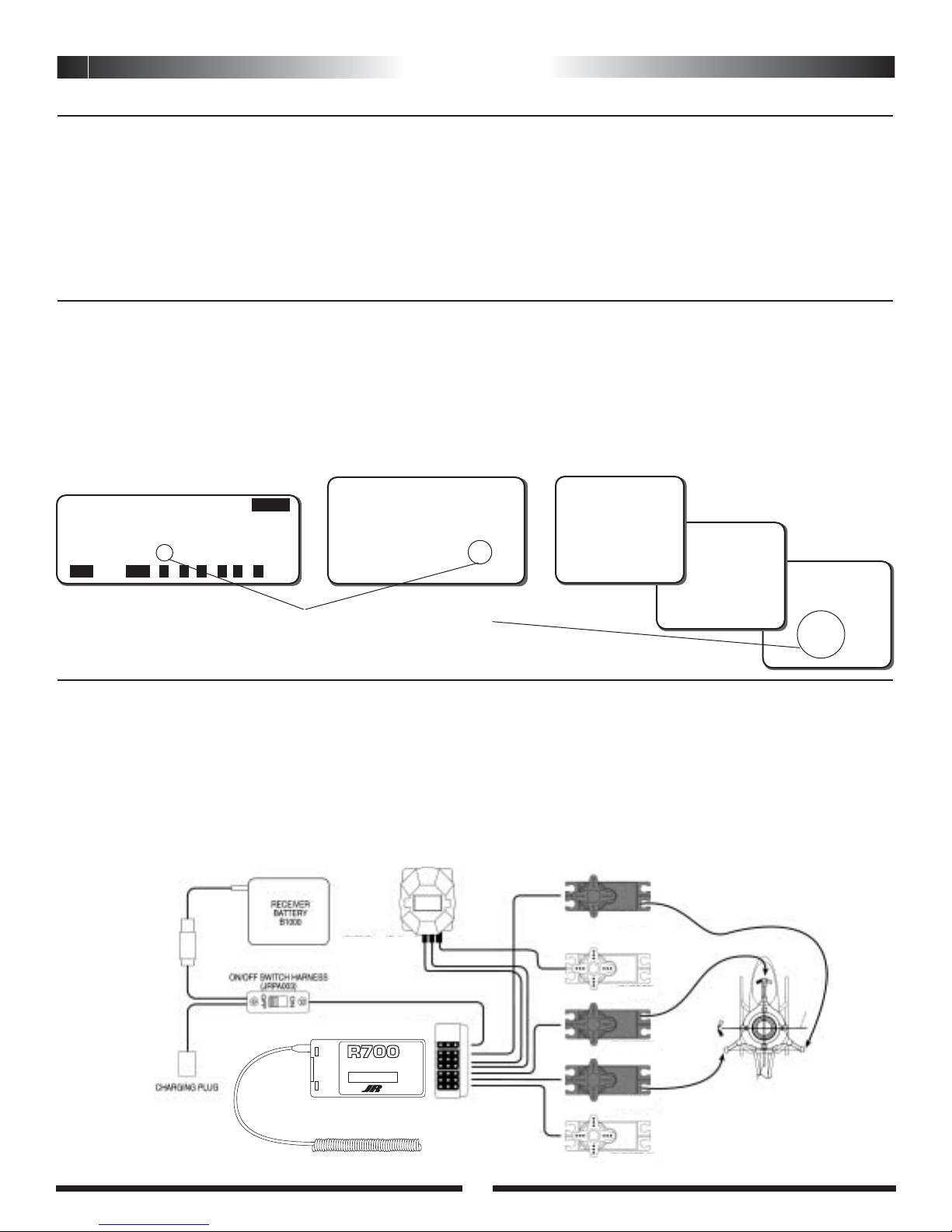

GYRO/RECEIVER/SWITCH HARNESS/BA TTER Y INST ALLATION

15

It is suggested that both the receiver and gyro amplifier be isolated from

vibration by wrapping them in foam, then securing them to the model using

double-sided servo tape.

Be certain when installing the gyro to the gyro mounting plate that it does not

come in contact with the frame of the helicopter and that the mounting surfaces

are free from oil, residue, etc. Clean if necessary to ensure proper adhesion.

Install the switch harness with the switch plate screws through the round rubber

grommets before the servos are installed.

Round Rubber Grommets (2)

Note: With some smaller switch harnesses, it will be necessary

to omit the rubber grommets for proper installation.

Gyro Sensor

Receiver/Gyro Amplifier

(not included)

Thin Gyro Mounting Tape

(not included; supplied

with the gyro)

Round Rubber

Grommets (2)

(included with switch)

Do not overtighten

the screws.

Direction

Off

On

Foam or Sponge Rubber

(not included)

Battery Pack

(not included)

Page 16

Continued

16

3-2

GYRO/RECEIVER/SWITCH HARNESS/BA TTER Y INST ALLATION

R700 Receiver

Antenna

G460T Gyro (Optional)

(JRPG460T)

Wrap the servo leads with the included servo spiral

wrap and route as shown.

G500T

Right Pitch (B)

Rudder

Front Elevator (A)

Left Aileron (C)

Throttle

7 CH 72MHz FM SLIMLINE

RECEIVER

ABC&W INTERFERENCE

PROTECTION SYSTEM

AUX1

GEAR

BATT

RUDD

ELEV

AILE

THRO

Page 17

17

UNDERSTANDING SW ASHPLATE CONTROL SYSTEMS

Currently, there are several different types of control systems available on the market. Although the mechanical methods for

transferring control to the swashplate vary, the different control systems can be broken down into two categories:

One-Servo (Conventional)

CCPM (Cyclic/Collective Pitch Mixing)

The following is an explanation of the two most popular types of swashplate control.

One-Servo Standard Swashplate Control (Conventional Helicopter)

The One-Servo standard system is found in a wide variety of radio

controlled helicopters. The term “One-Servo” means that the control

system requires one servo to operate each separate swashplate

function. With this system, a total of three servos is required to operate

the three main swashplate functions, which are aileron (roll), elevator

(pitch), and collective functions. With this type of control system, each

servo works independently and is assigned to a specific function. In

other words, the aileron (roll) servo is assigned to move only the aileron

(roll) function, as is the elevator (pitch) servo, etc. Since these servos

operate completely independently of each other, the servo torque to

each control surface is limited to the maximum torque rating of the

servos used.

The One-Servo standard system swashplate is designed so that the

lower swashplate ring control balls are spaced at 90° to each other. This

system is also most commonly arranged so that the aileron (roll) axis of

the swashplate is positioned at 90° to the main mechanics of the

helicopter, and the elevator (pitch) axis is parallel to the mechanics.

Please refer to the diagram at right for clarification.

With this type of system, it is necessary for the helicopter to be designed using an intermediate mechanical mixing system so that

the control inputs can be transferred from the three independent servos to the swashplate in such a manner that the three controls can

be achieved. This mechanical mixing system allows the swashplate to both roll (aileron) and pitch (elevator), as well as slide up and

down the main rotor shaft for collective pitch inputs. These mechanical mixing systems generally require the use of many ball bearings

and control rods to achieve this result.

Elevator control ball is in

line with helicopter frame

Aileron Axis

Elevator Axis

Aileron control ball is 90°

to elevator control ball

and helicopter frame

Standard “One-Servo” Swashplate System

90°

Page 18

18

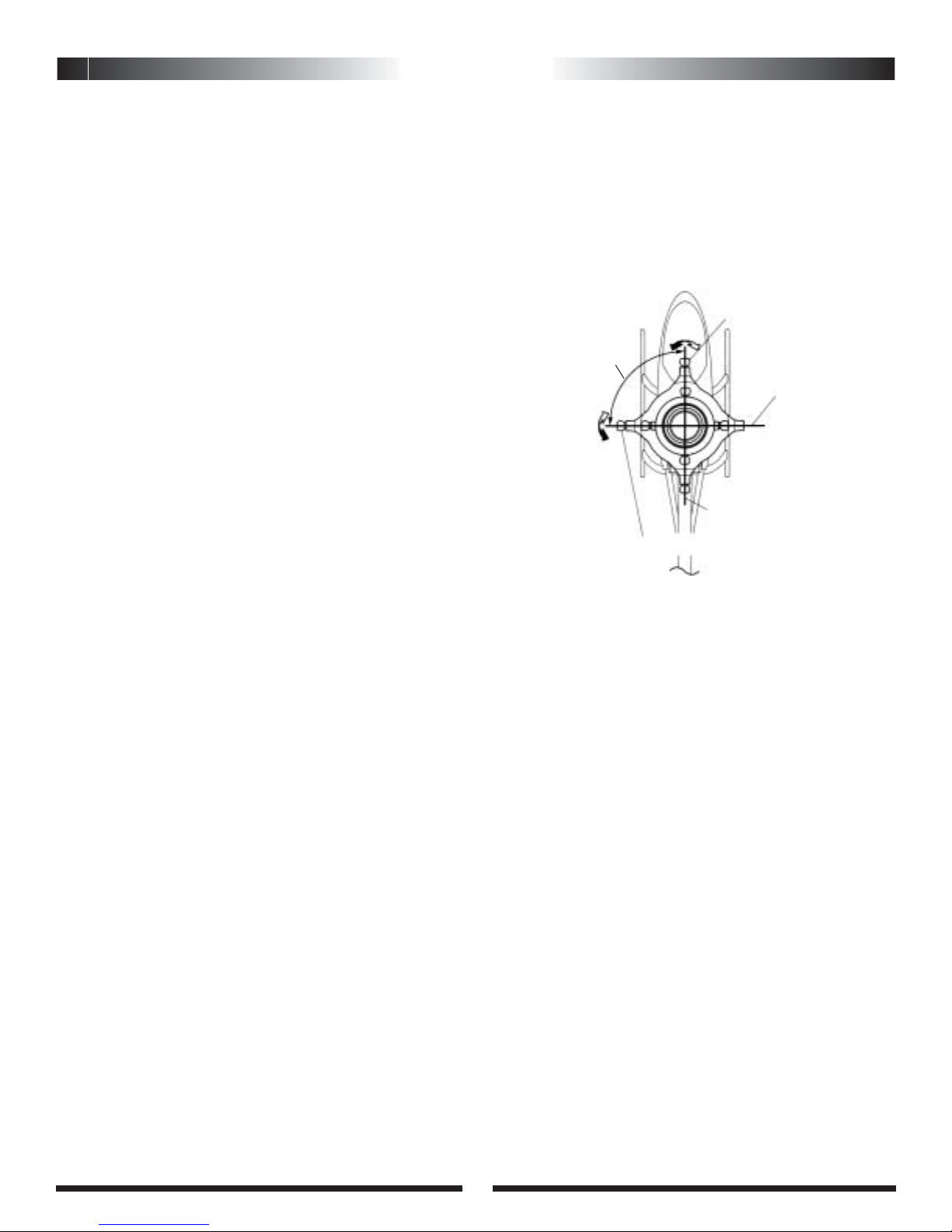

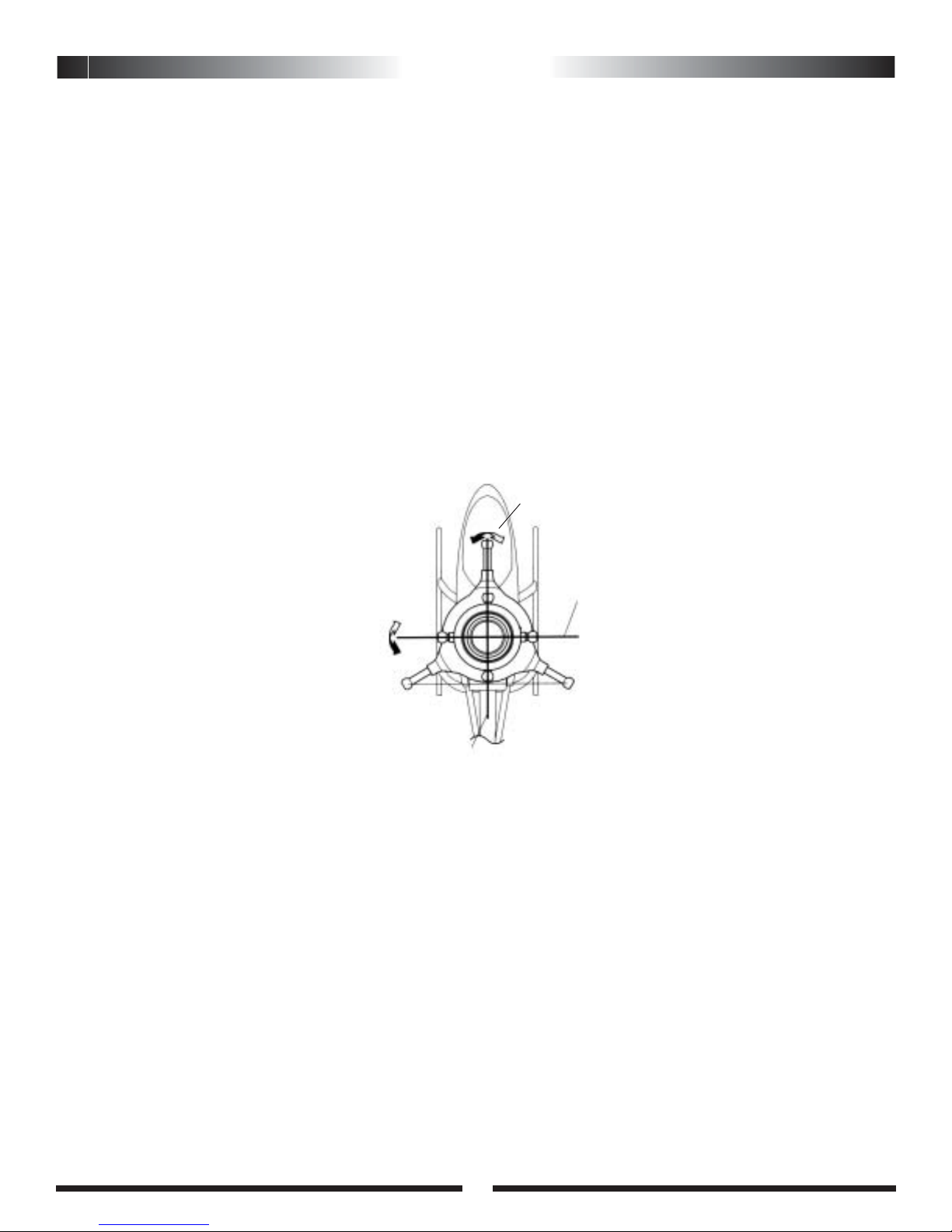

120 Three-Servo CCPM Swashplate Mixing (Venture 30 CP)

The JR 120° CCPM or Cyclic/Collective Pitch Mixing, system offers the user a control system that can accomplish the same control

inputs as the One-Servo standard system mentioned above, but with increased precision and reduced complexity.

As with the One-Servo system, the JR CCPM system utilizes three servos for the three main controls: aileron (roll), elevator(pitch) and

collective. The CCPM lower swashplate ring is designed with only three control balls, spaced at 120° from each other, hence the 120° CCPM

designation. Although the control balls are not at 90° as in the standard system, the aileron (roll) axis is still parallel to the main mechanics

of the helicopter, and the elevator (pitch) axis still functions at 90° to the mechanics as does the One-Servo system. Please refer to the

diagram below for clarification.

The main and important difference in the way that these two systems operate is that unlike the One-Servo system where the three

servos work completely independent from each other, the CCPM systems work as a team to achieve the same control inputs. For example, if

an aileron (roll) input is given, two servos work together to move the swashplate left and right. If an elevator (pitch) input is given, all three

servos work together to move the swashplate fore and aft. For collective, it’s also the strength of three servos that will move the swashplate

up and down the main rotor shaft. With two to three servos working at the same time during any given control input, servo torque is

maximized and servo centering is also increased. In addition to these benefits, CCPM achieves these control responses without the need

for complex mechanical mixing systems that require many more control rods and parts to set up.

This amazing CCPM control is achieved through special CCPM swashplate mixing that is preprogrammed into many of today’s popular

radio systems. Since the 120° CCPM function is preprogrammed, CCPM is no more complicated to set up than a conventional one-servo

standard system. When you factor in the reduced parts count and easy programming, CCPM is actually easier to set up and operate than

many conventional systems.

For JR radio owners, please refer to the radio information contained at the front of this manual or on the following page to determine if

your radio system has the CCPM function. For other brands of radio systems, please contact the radio manufacturer for CCPM information.

Please note that it is not possible to program a non-CCPM radio system for CCPM operation.

UNDERSTANDING SW ASHPLATE CONTROL SYSTEMS (CONTINUED)

Elevator Axis

120°

JR 120° 3 Servo CCPM Control System

Aileron Axis

(A)

(B)

(C)

Page 19

19

JR 120° Three-Servo CCPM relies on the radio’s special CCPM swashplate mixing, rather than a conventional mechanical mixer that is

utilized to achieve the same results.

The radio’s 120°Three-Servo CCPM function automatically mixes the three servos to provide the correct mixing inputs for aileron

(roll), elevator (pitch), and collective. The following is an example of how each control input affects the servo’s movement:

1. Collective

When a collective pitch input is given, all three servos (A, B, and C) move together in the same direction, at equal amounts, to raise

and lower the swashplate while keeping the swashplate level. During this function, all three servos travel at the same value (100%) so

that the swashplate can remain level during the increase and decrease in pitch. This mixing of the three servos is achieved through the

radio’s CCPM program.

2. Elevator (Pitch)

When an elevator input is given, all three servos must move to tilt the swashplate

fore and aft, but their directions vary. The two rear servos (B and C) move together in

the same direction, while the front servo (A) moves in the opposite direction. For

example, when an up elevator (back cyclic) command is given, the two rear servos (B

and C) will move downward, while the front servo (A) moves upward so that the

swashplate will tilt aft. During this function, the front servo (A) travels at 100%, while

the two rear servos (B and C) travel at 50% (1/2 the travel value) of the front servo.

This difference in travel is necessary due to the fact that the position of the front

control ball is two times the distance of the two rear control ball position as measured

from the center of the swashplate. As mentioned, this mixing of the three servos is

also achieved through the radio’s CCPM program.

3. Aileron (Roll)

When an aileron (roll) input is given, the two rear servos (B and C) travel in opposite directions, while the front servo (A) remains

motionless. For example, when a left aileron (roll) command is given, the left rear servo (C) will move downward, while the right rear

servo (B) will move upward to tilt the swashplate to the left. As mentioned, the front servo (A) will remain motionless. The travel value

for each of the two rear servos is 100%.

HOW JR 120 CCPM WORKS

Front of Helicopter

Elevator Axis

JR 120° CCPM Control System

RADIO SYSTEM REQUIREMENTS (NOT INCLUDED):

6-channel or greater R/C helicopter system with 120° CCPM function (see list below), 5 servos, 1000mAh receiver battery, and gyro

XP662

10X

XP8103 DT

X-378

CCPM-Ready JR Radio Systems

Most current JR Heli radio systems (XP662,

XP8103 w/digital trims, 10X, as well as older

10 series systems) are equipped with 120°

CCPM electronics for use with the JR CCPM

machines. Radios you may be flying now, like

the X347, X388S, XP783, and XP8103* have

CCPM capability built in, but require

activation by the Horizon Service Department.

Please call (217) 355-9511 for details.

*Please note that many XP8103 systems have the CCPM

function already activated. Please check with the Horizon

Service Center for details.

CURRENT RADIO SYSTEMS

JRP1656** PCM 10X, 5-8231 Servos (50/53/72 MHz)

JRP165TX PCM 10X, Transmitter Only (50/53/72 MHz)

JRP8622** XP8103FM, 5-517 Servos (50/53/72 MHz)

JRP8653** XP8103PCM, 5-531 Servos (50/53/72 MHz)

JRP7425** X-378 FM 5-537 Servos (72MHz)

JRP6822** XP662 FM, 5-537 Servos (72MHz)

Page 20

20

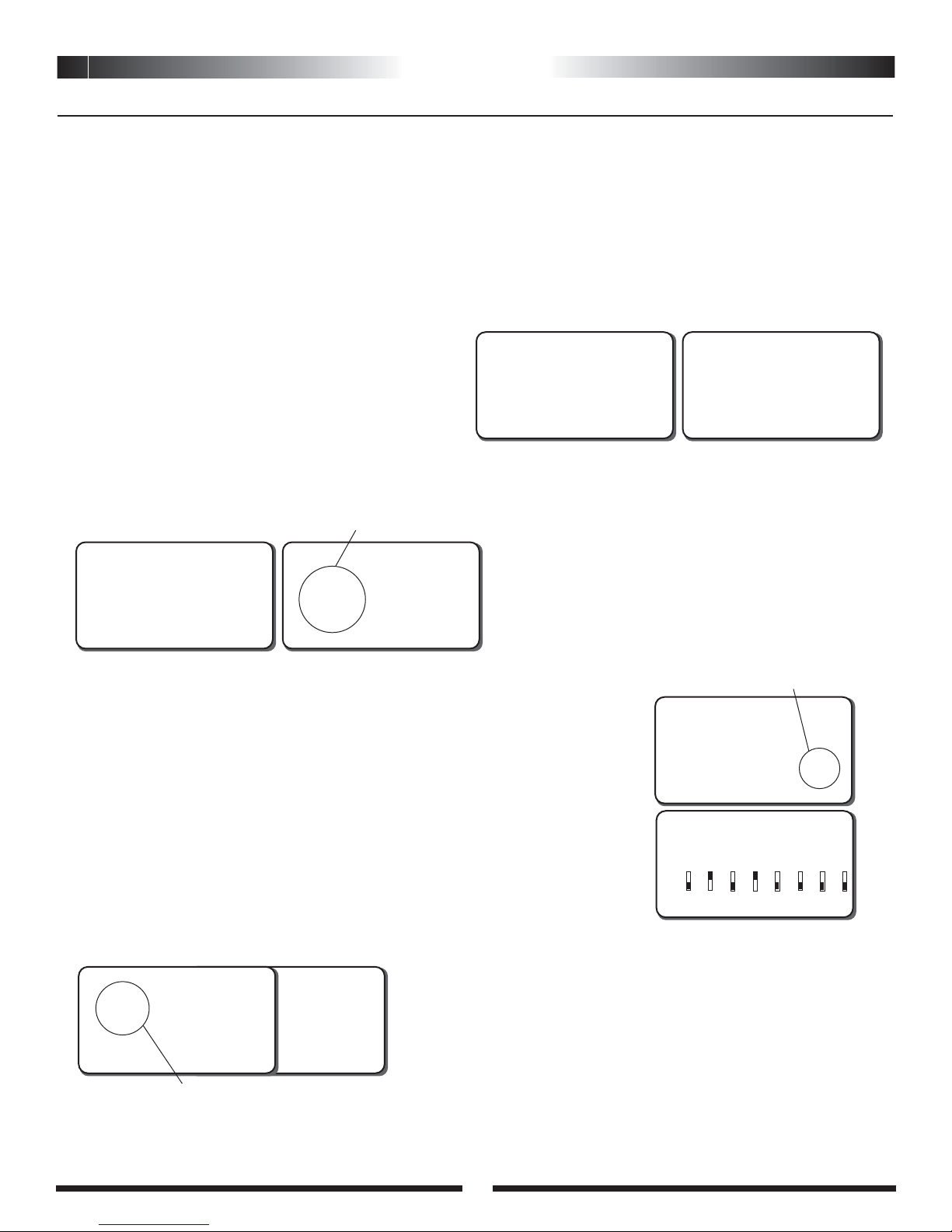

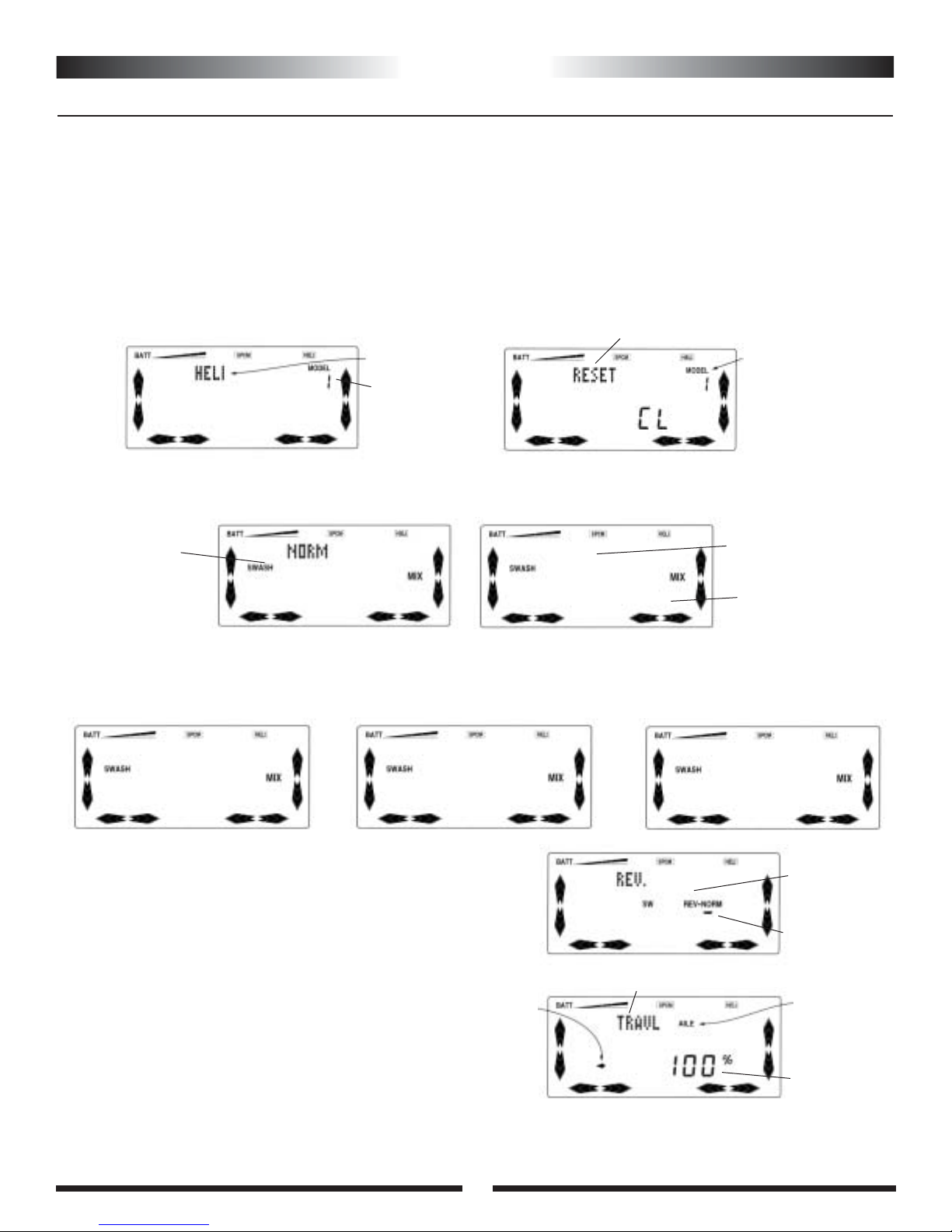

CCPM SOFTWARE ACTIVATION AND INITIAL ADJUSTMENT

The following activation and setup procedure should be used for all JR XP652 and XP662 systems. Please note that the XF622 and XP642

6-channel systems do not have the required CCPM software and therefore cannot be activated by the Horizon Service Center.

Prior to activating the CCPM function, it is first suggested that the Data Reset function be performed to reset the desired model number to

be used back to the factory default settings. If you are using a new radio system, proceed to Step C.

Caution: Prior to performing the Data Reset function, it will be necessary to select the desired model number to be used.

A) Press the Mode (scroll) and Channel keys simultaneously while turning the power

switch on to enter the System Mode. Next, press the

Channel key until “MDL” (Model

Select) appears on the screen, and choose the desired model number to be used.

B) Press the Mode (scroll) key until “RST” (Data Reset) appears on the screen. Press the

(+) and (-) keys simultaneously to reset the current model. A high-pitched beep will

indicate that the reset was successful. Press the

Mode and Channel keys

simultaneously to exit the system mode.

C) With the power switch still on, press the Mode (scroll) and Channel keys

simultaneously to enter the function mode. Press the

Mode key until “MIX CCP”

(CCPM mixing) appears on the screen. Press the (+) or (-) keys to activate the CCPM

function. “MIX CP2” should appear on the screen. It will be necessary to change the value of CP2, CP3, and CP6 to the

values as shown below.

D) Press the Mode (scroll) key until the servo reversing screen appears on the screen. Next, reverse the aileron (AIL) and rudder (RUD)

channels by pressing the

Channel key to select the desired channel, and then the (+) or (-) keys to set the servo direction.

E) Press the Mode (scroll) key until “TRV ADJ” (Travel Adjust) appears on the screen, and adjust the travel values as shown by pressing

the

Channel key to select the desired channel, and then the (+) or (-) key to set the desired travel value. Press the Mode (scroll) and

Channel keys simultaneously or turn the power switch off to exit the function mode. Please note that the throttle travel values may vary

based upon the type of engine used. This value can be fine tuned once the throttle linkage has been installed.

Note: The travel values shown for the rudder function are for use with Piezo gyros, like the JR G410T and G460T type gyros.

Proceed to page 24.

1. JR XP652/XP662 SYSTEMS

mdl

1

Model Select

Current Model

rst

he

Data Reset

Model Type

mixCCP

of

CCPM Mixing

Inhibited

ail

rev.norm

rud

rev.norm

mixCP2

+ 70

%

mixCP3

+ 70

%

mixCP6

— 65

%

Channel 2

Reversed

Channel 4

Reversed

thro

trv adj

-120

ail

-100

ele

-100

rud

-150

pit

-100

Ch Ch

Ch Ch

Page 21

21

The following activation and setup procedure should be used for all JR XP8103 and XP8103DT (digital trim) systems.

Note: Some early XP8103 systems will require the activation of the CCPM software through the Horizon Service Center. It’s easy to

identify if your system has the CCPM function activated by identifying if the “SWASH TYP” function appears in the System mode as

shown in Section A below. Please refer to Section A to access the System mode.

Prior to activating the CCPM function, it is first suggested that the Data Reset function be performed to reset the desired model number to

be used back to the factory default settings. If you are using a new radio system, proceed to Step B.

Caution: Prior to performing the Data Reset function, it will be necessary to select the desired model number to be used.

A) Press the Up and Down keys simultaneously while turning the

power switch on to enter the system mode. Next, press the

Up or

Down keys to move the cursor to the Model Select function. Press

the

Up and Down keys simultaneously to enter the Model Select

Function. Select the desired model number to be used, then press

the

Clear key to reset the current model to the factory default

settings. Press the

Up and Down keys simultaneously to exit the

Model Select function.

B) Press the Up or Down keys to move the cursor to the Swash Type function, then press the Up and Down keys simultaneously to access the

Swashplate Type function.

Note: If the Swashplate Type function is not present, it

can be activated by the Horizon Service Center. Please call

for details.

Press the

Up or Down keys until “3 servo 120°” appears on the

screen. Press the

Up and Down keys simultaneously two times

to exit the Swashplate Type function and the System mode.

C) Turn the power switch on, then press the Up and Down keys simultaneously to enter the function

mode. Press the

Up key until “SWASH MIX” appears on the screen. Once this has been completed,

it will be necessary to change the values as shown using the (+) and (-) keys.

D) Press the Up key until “REV. SW.” (Servo Reversing) appears on the screen. Next, reverse

Channels 2 and 4 by moving the cursor with the

CH key, then pressing the (+) and (-) keys.

E) Press the Up key until “TRVL. ADJ.” (Travel Adjust) appears on the screen. Adjust the values as

shown using the channel key to move the cursor, and the (+) and (-) keys to set the value. Press

the

Sel key to access the pitch channel values and set as indicated. Please note that the required

travel values will vary based on the type of servo selected. Please also note that the throttle travel

values may vary based on the type of engine used. This value can be fine tuned once the throttle

linkage has been installed.

Proceed to page 24.

CCPM SOFTWARE ACTIVATION AND INITIAL ADJUSTMENT (CONTINUED)

2. JR XP8103/XP8103DT SYSTEMS

[SYSTEM M.]

• INFO-DISP

•Model SEL

• MDL Name

• Type SEL

• MDL Reset

• MODULAT

•TRANSFER

• INPUT SEL

• SWASH TYP

[MDL Reset]

MODEL 1

HELI SPCM

PIT.

£H 100%

L 100%

AUX3

+ 100%

- 100%

[TRVL ADJ.]

£THRO

H 120%

L 120%

AILE

£L 100%

R 100%

ELEV

D 100%

U 100%

RUDD

£L 150%

R 150%

[SWASH TYP]

1servo

NORM

[SWASH MIX]

3servos

120

•

[SWASH TYP]

3servos

120

•

3servos 120°

AILE +70%

ELEV +70%

∞ PIT. -65%

Adjust Pitch Value to -65%

Throttle travel values may vary,

depending upon engine used.

[REV.SW]

1

2345678

ch

REV.

NORM.

Note: The travel values shown for the

rudder function are for use with Piezo type

gyros, like the JR G410T and G460T.

Page 22

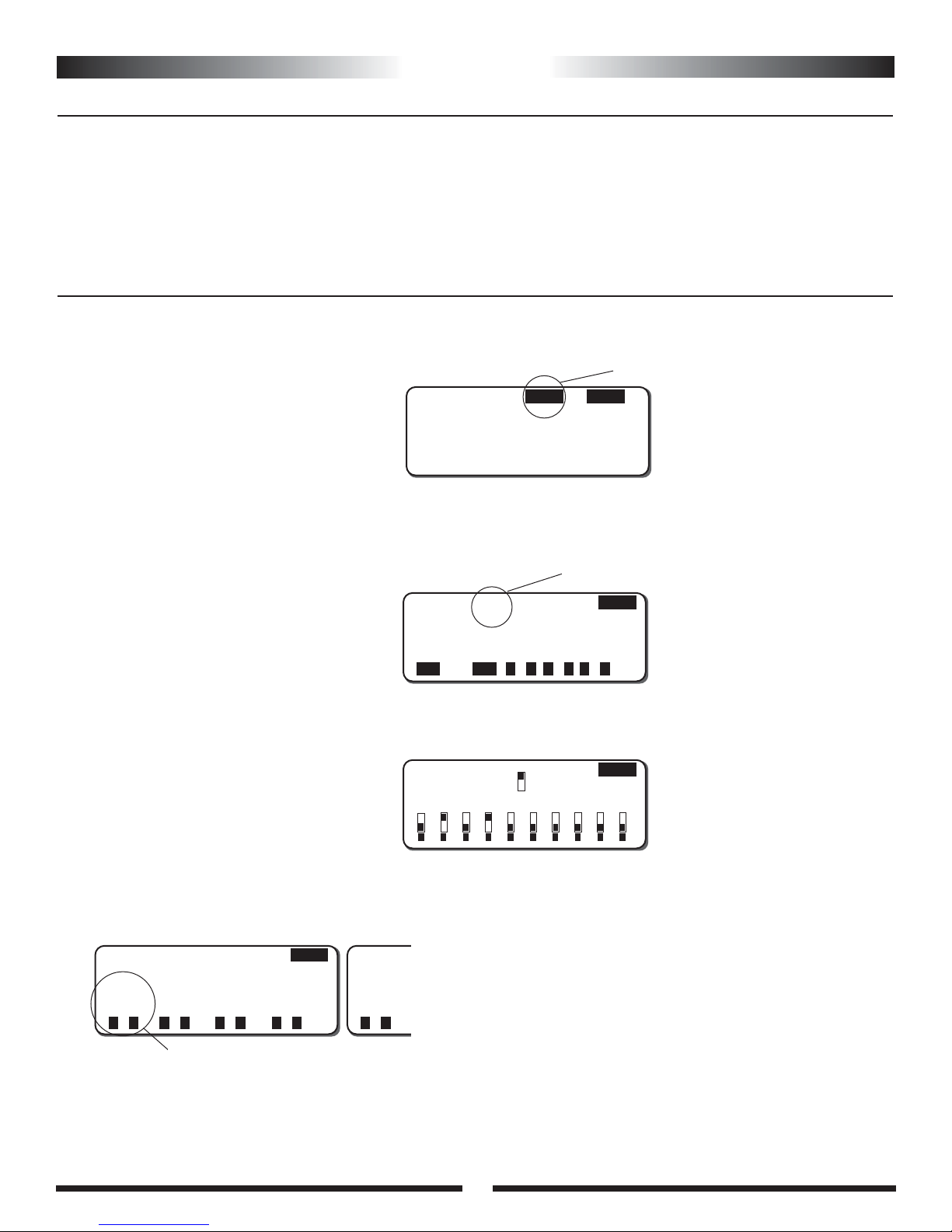

CCPM SOFTWARE ACTIVATION AND INITIAL ADJUSTMENT (CONTINUED)

22

The following activation and setup procedure should be used for all JR PCM10, 10S, 10SX, 10SXI, and 10X systems.

Prior to activating the CCPM function, it is first suggested that a Data Reset function be performed to reset the desired model number to

be used back to the factory default settings. If you are using a new radio system, proceed to Step B.

Caution: prior to performing the Data Reset function, it will be necessary to select the desired model number to be used. Access the

Model Select function (Code 84) and select the desired model to be used.

A) Access the Data Reset function (Code 28) once the correct model number has been established. Next, press the

Clear key to reset the

current model. Press the

Enter key to exit the Data Reset function.

B) Access the Swash Type function (Code 65). Next, press the

Sel key until “3 SERVOS” (120°) appear on the screen. Once this is complete,

it will be necessary to change the value of the functions from the factory default setting to the values as shown using the (+) and (-) keys

below. Press

Enter to exit the Swash Type function.

C) Access the Servo Reversing function (Code 11). Next, reverse channels 1, 2, and 4 by pressing the desired channel number. The screen

should appear as shown. Press

Enter to exit the Servo Reversing function.

D) Access the Travel Adjust function (Code 12) and adjust the servo travel values as shown. Please note that the required travel values will

vary based on the type of servo selected. Press

Enter to exit the Travel Adjust function.

Note: The travel values shown for the rudder function are for use with Piezo type gyros, like the JR NEJ-900, NEJ-400, NEJ-450, or

NEJ-3000 type gyros. If a conventional mechanical type gyro is used (JR 120, 130, etc.), then the travel value of the rudder channel

will need to be reduced to approximately 100%.

3. JR 10 SERIES SYSTEMS

SET-UP PROCEDURE

[DATA RESET]

MODEL 1 SPCM

CLEAR ENTER

[SWASH TYPE]

3SERVOS(120•)

FXP AILE ELEV PITCH

[NH +70% +70% -65%

ENTER

SEL ACT + –CL+ –CL+ –

CL

[REVERSE SW]

REVERSE

NORMAL

ENTER

1 2 3 4 5 6 7 8 9 10

[TRAVEL ADJUST]

THRO AILE ELEV RUDD

H120% L100% D100% L150%

L120% R100% U100% R150%

PAGE

+ –CL+ –CL+ –CL+ –

CL

[TRAVEL ADJUST]

PITCH

+100%

-100%

+ –CL+ –CL+ –

CL

[CLEAR]

SELECT 3 SERVOS(120°)

Standard Servos

Throttle travel values may vary,

depending upon engine used.

Proceed to page 24.

Page 23

CCPM SOFTWARE ACTIVATION AND INITIAL ADJUSTMENT (CONTINUED)

4. JR X-378 SYSTEMS

23

The following activation and setup procedures should be used for all JR X-378 systems.

Prior to activating the CCPM function, it is first suggested that the Data Reset function be performed to reset the desired model number to be used

back to the factory default settings. If you are using a new radio system, proceed to Step B.

Caution: Prior to performing the Data Reset function, it will be necessary to select the desired model number to be used.

A) Press the Down and Channel keys simultaneously while turning the power switch on to enter the system mode. Next, press the Up key until the word

“Model” flashes on the top right portion of the screen. Press the (+) or (-) keys to select the desired model number to be used. Press the Up key until

“RESET” appears on the screen. Next, press the Clear key to reset the data for this model. A “beep” will be heard and the letters “CL” will flash when the

Clear key is pressed, indicating that the data has been reset successfully.

B) Press the Up key until the word “SWASH” appears on the left side of the screen. Next, press the (+) or (-) keys until the word “3SERV” appears on the

screen. This would indicate the selection of Three-Servo 120 Degree CCPM. Press the Down and Channel keys simultaneously to store this data and exit

the System mode.

C) Press the Down and Channel keys simultaneously to enter the Function mode. Next, Press the Up or Down keys until the words “SWASH” and “3S120”

appear on the screen. Once at this screen, it will be necessary to change the values for each of the three CCPM channels as shown using the Channel

key to select the desired channel, and the (+) and (-) keys to alter the values.

D) Press the Upor Down keys until the word “REV.” appears on the top left portion of th e

screen. Next, reverse the rudder and aileron channels by using the Channel key to select the

desired channel and the (+) or (-) keys to change the servo direction from NORM to REV .

E) Press the Up or Down keys until the word “TRAVL” appears on the top left portion of

the screen. Adjust the servo travel values as shown using the Channel key to select

the desired channel to be adjusted, and the (+) or (-) keys to increase or decrease the

travel value as needed. Please note that the required travel values can vary slightly

based on the type of servo selected. Please also note that the throttle travel values

may vary based on the type of engine used. This value can be fine tuned once the

throttle linkage has been installed.

Note: The travel values shown for the rudder function are for use with Piezo-type

gyros like the JR G410T and G460T.

Proceed to page 24.

Model Type

Model Number

Model Number

Data Reset

Indicates

Swashplate Type

Indicates 3-Servo CCPM

Indicates 120° CCPM

3SERV

120

AILE

+70

∞

ELEV

+70

∞

PIT.

-65

∞

RUDD

Rudder Channel

Direction

(normal or reverse)

Aileron Channel

Travel Adjust Function

Travel Value

Travel Values:

Throttle: 120/120

Aileron: 100/100

Elevator: 100/100

Rudder: 150/150

Gear: 100/100

Pitch: 100/100

Aux2: 100/100

Page 24

IMPORT ANT CCPM PROGRAMMING GUIDELINES

It is extremely important that the travel adjustment values for the three CCPM servos (aileron, elevator, AUX1) be initially set to exactly the

same travel value. If the travel value is not similar for each servo, it will create unwanted pitching and rolling of the swashplate during collective

pitch inputs. The travel values for each servo will be adjusted in Steps 3-7 and 3-8 to remove any minor pitch and roll coupling during pitch, roll,

and collective movements.

Minor travel value adjustments are necessary due to slight variations in servo travel and centering. Although the three servos may appear to

travel at the same amounts in each direction, in reality the servos can vary slightly. This variation is more common in analog type servos. If JR’s

new digital servos are used, the travel adjustment values will generally not need to be altered.

A. TRAVEL ADJUST

B. SERVO REVERSING

[SWASH TYPE]

3SERVOS(120•)

EXP AILE ELEV PITCH

[NH +70% +70% -65%

ENTER

SEL ACT + –CL+ –CL+ –

CL

To reverse the direction of a CCPM control function it’s neccessary

to change the value from + to – or – to + as needed.

[SWASH MIX]

3servos

120

•

AILE +70%

ELEV +70%

∞ PIT. -65%

24

It is also extremely important that the servo reversing directions for the three CCPM servos (aileron, elevator, AUX 1) be set as indicated in the

previous radio programming steps. If one or more servos is not set to the correct direction, the CCPM function will be out of synchronization, and

the three control functions (aileron, elevator, collective) will not move properly. In the event that a control surface is working in the wrong

direction, the control function can only be reversed by changing the desired CCPM value for that function from a + to a - value or vise versa.

Example: If, when you increase the collective pitch, the pitch of the main blades actually decreases, it will be necessary to access the CCPM

function and change the travel value for this function from + to - or - to +. This will reverse the direction of the collective pitch function without

affecting the movement of the aileron and elevator functions.

mixCP6

- 65

%

mixCP3

+ 70

%

mixCP2

+ 70

%

The JR 120° CCPM system requires the use of three servos to operate, aileron, elevator, and AUX 1(Pitch). The labeling of these servos can

become quite confusing because with the CCPM function, the three servos no longer work independently but rather as a team, and their functions

are now combined. For this reason, we will refer to the three servos in the following manner:

Aileron Servo: “Left” servo (C); the channel number is CH2 when using a JR radio

Elevator Servo: “Front” servo (A); the channel number is CH3 when using a JR radio

AUX 1 (Pitch) Servo: “Right” servo (B); the channel number is CH6 when using a JR radio

Please refer to the CCPM connections chart below for clarification. For non-JR radios, please consult your radio instructions for proper connection.

C. CCPM SERVO CONNECTIONS

JR 10 Series

JR 8103

JR 652

R700 Receiver

Antenna

G460T Gyro (Optional)

(JRPG460T)

G500T

Right Pitch (B)

Rudder

Front Elevator (A)

Left Aileron (C)

Throttle

7 CH 72MHz FM SLIMLINE

RECEIVER

ABC&W INTERFERENCE

PROTECTION SYSTEM

AUX1

GEAR

BATT

RUDD

ELEV

AILE

THRO

Page 25

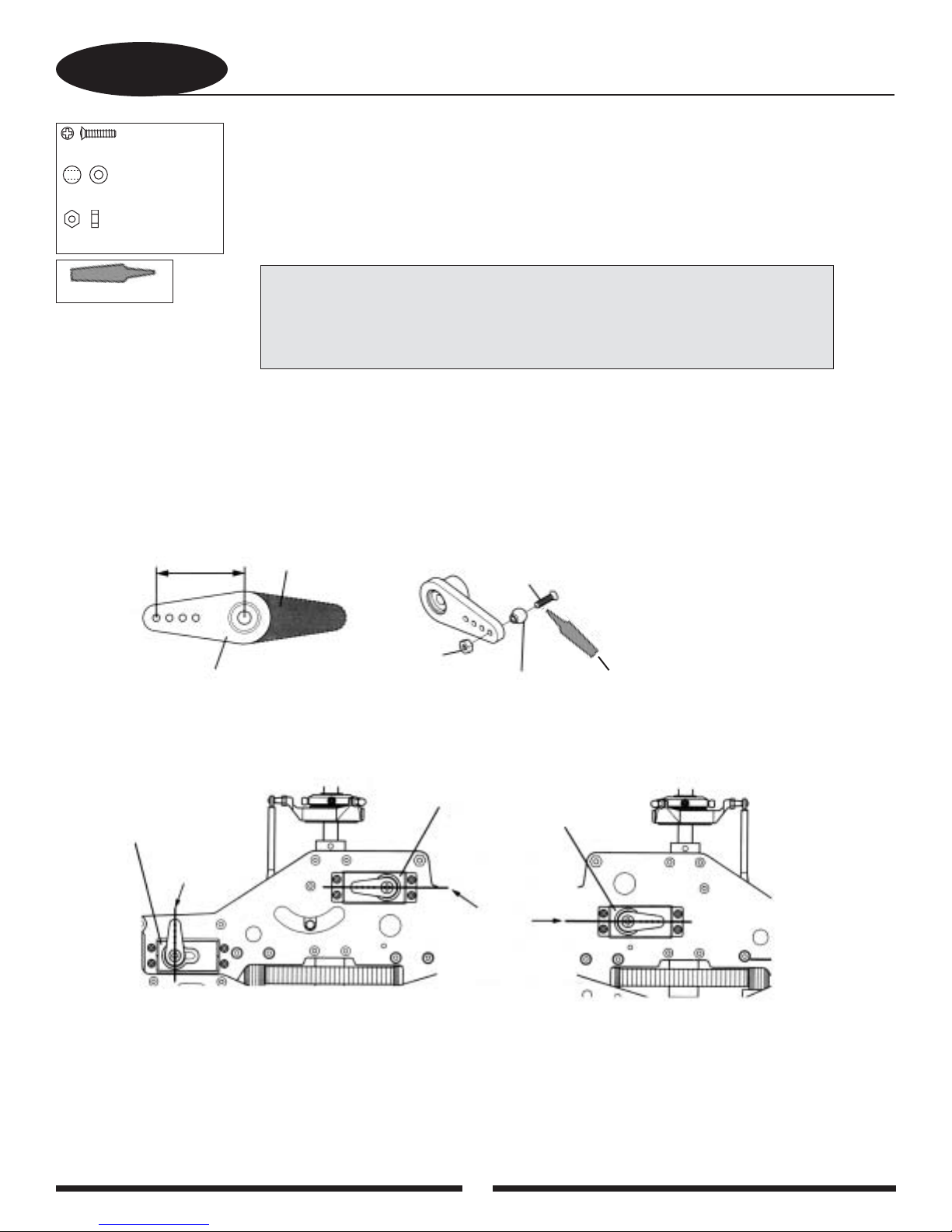

3-3

CCPM SERVO ARM PREPARATION AND INST ALLA TION

25

2x10 mm Flat Head Screw (3)

Steel Joint Ball (3)

2 mm Hex Nut (3)

It will be necessary to prepare three servo arms as shown in the diagram below. Prior to

assembling the servo arms, the servos should be centered as indicated below, and the servo arms

test fitted to the servo to insure that the arms will attach to the servo as indicated. Since the JR

servo arm spline uses an odd number of teeth, it is sometimes possible to rotate the servo arm

180° to achieve a more correct positioning.

Once the best direction for the servo arm has been decided, mark the servo arm with the servo

it is to be connected to (F, R, or L), as well as the side of the servo arm that needs to be removed.

It is

very important that a heavy-duty type servo arm be used with the control ball location

placed at exactly 20 mm as shown. For JR radio users, we recommend the JRPA215 Heavy-Duty

Servo Arms included for this use. If a control ball position other than the specified 20 mm is used,

this will create an adverse affect as to the travel of the swashplate, as well as unwanted control

differential and interaction.

Prior to attaching the servo arm to the servo, it will be necessary to first turn on the radio

system to center each of the three CCPM servos. It is important that the radio’s collective pitch

stick be set at the center position. If your radio is equipped with a hover pitch knob, please check

to make sure that this knob is also in the center position at this time.

Connect the three servo arms to the three CCPM servos as shown. It is important that the

servo arms be positioned parallel to the servos as shown. If the servo arm is not parallel as

shown, minor centering adjustments can be made using the radio’s Sub-Trim function. Please

refer to Section 3-4 for more information.

Use Blue Threadlock

Steel Joint Ball

2 mm Hex Nut

Front Servo

Left Servo

Right Servo

Servo Arm

Must Be Parallel

to Servo

2x10 mm Flat Head Screw

Remove this section.

JRPA215 Heavy-Duty Servo Arm

(included in kit)

20 mm

Use Blue Threadlock

Page 26

26

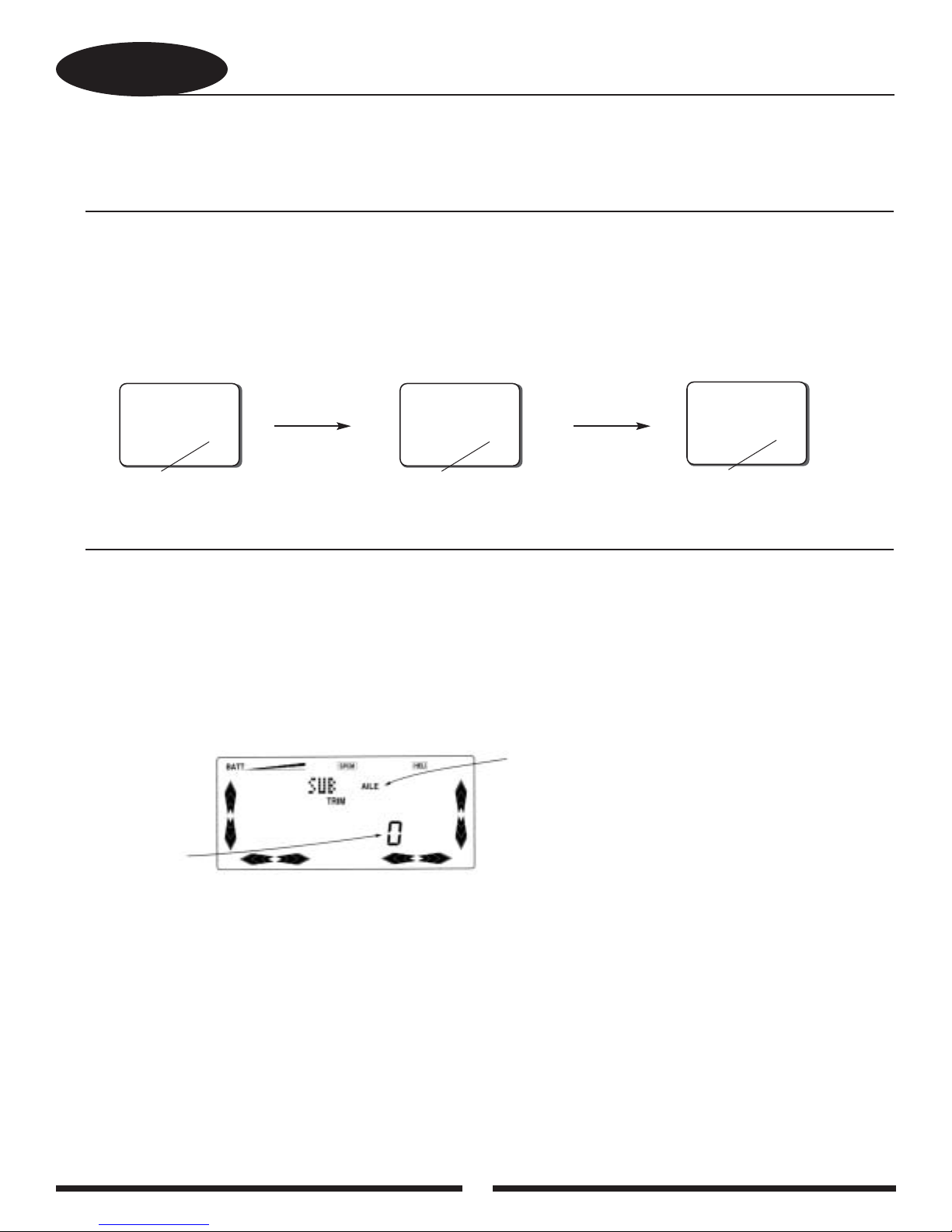

3-4

CCPM SERVO CENTERING WITH THE SUB-TRIM FUNCTION

As mentioned in the previous step, it may be necessary to make minor servo centering adjustments with the use of the Sub-Trim function to

achieve the desired servo arm positions. Please refer to your particular radio’s section as listed below or consult your radio instruction

manual for more information.

XP652/XP662 SYSTEM

1) With the radio power switch on, press the Mode and Channel keys simultaneously to enter the Function mode.

2) Press the

Mode key until “SB-TRIM” (sub-trim) appears on the screen.

3) Adjust the left (aileron), right (AUX 1), and front (elevator) servos as needed until the servo arm is exactly parallel to the servo as shown when

the collective stick is in the center position. It will be necessary to press the

Channel key to access the necessary channels to be adjusted.

4) Press the

Mode and Channel keys simultaneously to exit the Function mode.

CHANNEL CHANNEL

sb-trim ail

0

Increase or decrease value

to center the left servo.

sb-trim ele

0

Increase or decrease value

to center the front servo.

sb-trim pit

0

Increase or decrease value

to center the right servo.

X-378 SYSTEM

1) With the radio power switch on, press the Down and Channel keys simultaneously to enter the Function mode.

2) Press the

Up key until “SUB” appears on the screen.

3) Adjust the left (aileron), right (Aux1) and front (elevator) servos as needed until the servo arm is exactly parallel to the servo as shown

when the collective stick is in the center position. Use the

Channel key to select the desired channel to be adjusted, and the (+) and (-)

keys to set the sub-trim value for each servo.

4) Press the

Down and Channel keys simultaneously to exit the Function mode.

Current Channel

Sub-Trim Value

Page 27

3-4

CCPM SERVO CENTERING WITH THE SUB-TRIM FUNCTION

27

JR PCM10, 10S, 10SX, 10SXII, 10X SYSTEMS

1) Enter the Sub-Trim function (Code 15).

2) Adjust the left (aileron), right (AUX 1) and front (elevator) servos as needed until the servo arm is exactly parallel to the servo as shown when

the collective stick is in the center position. It will be necessary to press the

Page button to access the right servo (AUX 1) sub-trim value.

3) Press

Enter to exit the Sub-Trim function.

XP8103, XP8103 WITH DIGTIAL TRIMS

1) With the radio power switch on, press the Up and Down keys simultaneously to enter the Function mode.

2) Press the

Up key until “Sub Trim” appears on the screen.

3) Adjust the left (aileron), right (AUX 1), and front (elevator) servos as needed until the servo arm is exactly parallel to the servo as shown when

the collective stick is in the center position. It will be necessary to press the

Sel key once to access the right servo (AUX 1) sub-trim.

4) Press the

Up and Down keys simultaneously to exit the Function mode.

[SUB TRIM]

THRO AILE ELEV RUDD GEAR

00000

ENTERPAGE

+ –CL+ –CL+ –CL+ –CL+ –

CL

Press Page to access

the second screen.

Increase or decrease

value to center the

left servo.

Increase or decrease

value to center the

front servo.

[SUB TRIM]

PIT. AUX2 AUX3 AUX4 AUX5

00000

ENTERPAGE

+ –CL+ –CL+ –CL+ –CL+ –

CL

Increase or decrease value

to center the right servo.

[Sub Trim]

£THRO ∞AILE

00

ELEV RUDD

00

[Sub Trim]

£GEAR ∞ PIT.

00

AUX2 AUX3

00

Increase or decrease

value to center the

front servo.

Increase or decrease

value to center the

right servo.

Increase or decrease

value to center the

left servo.

SEL

Continued

Page 28

28

3-5

CCPM LINKAGE CONNECTION

Attach the three CCPM servo linkages as shown below. It is important that the exact distances specified below be maintained for each linkage as

this is critical to the alignment and neutral position of the swashplate. Please also note the direction of the ball links as shown by the “JR Propo”

name imprinted on each ball link. “JR Propo” is imprinted on the front of each ball link. When attaching the control rods, it is important to make

sure that “JR Propo” faces outward as the links are attached to the control balls.

Please also note that when attaching control linkages B and C, it will be necessary to rotate the link that attaches to the swashplate slightly so

that it is parallel to the rear mounting surface of the ball link. This will allow the control linkage to rotate slightly on the two control balls.

Option: For smooth operation,

pre-size the ball links with the

JR Ball Link Sizing Tool

(JRP960219) prior to attachment.

Rotate link slightly so

it’s parallel to the rear

mounting surface of

each control ball.

Rotate link slightly so it’s

parallel to the rear mounting

surface of the control ball.

Front Servo to Elevator Arm Linkage

(2.3x65 mm threaded rod)

Left Servo to Swashplate Linkage

(2.3x30 mm threaded rod)

Right Servo to Swashplate Linkage

(2.3x40 mm threaded rod)

40.5 mm

9.5 mm

29.5 mm

A

A

C

C

B

B

Page 29

3-6

CHECKING THE SWASHPLATE FOR LEVEL

29

Upper Swashplate Ring

Left Servo

Left

Servo

Right Servo

Right

Servo

Left Side View

(Fore/AFT Axis)

Rear View of Left

& Right Servo

(Left/Right Axis)

Front Servo

Control Rod

Make sure the servo arms are parallel

as shown when the swashplate is level;

adjust the three servos linkages as

needed.

Front Servo

After the three control linkages have been attached to the swashplate, it will be necessary to check the swashplate to ensure that it is level.

To do this, turn on the radio system and place the collective stick in the center position as before. Next, check to make sure that all trim

levers and knobs are also in their center position.

Check to insure that the servo arms are parallel to the servos as adjusted in the previous step. If the servos are not parallel, please refer

to the Sub-Trim section on page 26 and re-adjust as necessary. Once it’s determined that the servo arms are parallel to the servos as

required, it will now be necessary to check the swashplate to insure that it is also level or neutral in this position.

It is suggested that the swashplate first be checked from the rear of the model to insure that it’s level from left to right. If the swashplate

is not level as compared to the frame of the model, adjust either the left or right servo control rod as needed. To determine which rod needs

adjustment, it may be helpful to view the swashplate from the left and right side view of the model to determine which side is high or low.

Once this left-to-right adjustment is completed, it will now be necessary to check the fore/aft position of the swashplate to insure that it is

also level on this axis. If the swashplate is not level in the fore/aft axis, it is suggested that the adjustment be made to the front servo control

linkage as needed. If you are unsure as to which linkage needs adjustment or are having difficulty obtaining the correct adjustment, please

check the length of each control rod to insure that it is adjusted to the correct length as outlined in Step 3-5.

Note: If care was taken in the linkage attachment in Step 3-5, little or no adjustment should be required in this step. Only minor

adjustments should be made to the lengths of the control linkages at this time. Any major adjustments indicates either incorrect

linkage lengths or incorrect servo arm positioning. If the control linkage lengths are altered from the recommended lengths more

that one or two turns, this will have a great effect on the range and settings of the collective pitch in later steps.

Page 30

30

3-7

ADVANCED SETUP: PITCH-TO-AILERON MIXING ADJUSTMENT

WITH TRAVEL ADJUST (OPTIONAL)

It is very possible that the travel of each servo varies slightly, which can cause the swashplate to be tilted to the left or right when the

collective is moved to the extreme high and low pitch positions. This condition is generally more common when standard type servos are

used. If JR digital servos are used, the adjustment required is generally very small, if any. These variations in travel can be corrected by

altering the travel value of each servo slightly through the TravelAdjustment function.

To check the pitch-to-aileron mixing, it will first be necessary to position the collective stick in the center position as in the previous

steps. Next, move the collective stick from the center position to the high pitch position while viewing the swashplate from the rear of the

model as shown in the diagram below. While moving the swashplate, look for any tendency for the swashplate to roll to the left or right as it

reaches the high pitch position. Repeat this procedure several times to be sure that your observations are correct. If no rolling tendency is

found, it will now be necessary to repeat this procedure from the center collective stick position to full low pitch. If no rolling tendency is

found, proceed to Step 3-8.

In our example, we have shown that the swashplate has been tilted to the right as the collective has been increased to full pitch. This

would indicate that the left servo’s maximum travel is greater than the right servo’s maximum travel.

In this condition, we suggest that the travel value for the left servo be reduced slightly (5–10%). Repeat the procedure above. If the same

condition occurs, but to a lesser degree, then the travel value of the right servo should be increased slightly and retest. In most cases, it will

require only the adjustment of the left or right servo to correct this situation.

For information on the Travel Adjustment function, please refer to your radio instruction manual for details. Once this condition has been

corrected, repeat this procedure for the center to low collective pitch position and adjust as needed.

Beginners can proceed to step 3-9.

View is shown from the rear of the

model. Notice how in this example,

the swashplate has tilted to the right

as the collective has moved from

center to full high pitch position.

High Low

AILE= Left Servo (C)

ELEV= Front Servo (A)

AUX1= Right Servo (B)

Page 31

3-8

ADVANCED SETUP: PITCH-TO-ELEVATOR MIXING

ADJUSTMENT WITH TRAVEL ADJUST (OPTIONAL)

31

The total travel of each servo can vary slightly, which can also cause the swashplate to be tilted fore and aft when the collective is moved

to the extreme high and low pitch positions. This situation can also be corrected if necessary through the use of the Travel Adjustment function.

To check pitch-to-elevator mixing, it will first be necessary to position the collective stick in the center position as in the previous steps.

Next, move the collective stick from the center to the high pitch position while viewing the swashplate from the left side of the model. While

moving the swashplate, look for any tendencies for the swashplate to tilt fore or aft as it reaches the high pitch positions. Repeat this

procedure several times to be sure that your observations are correct. If no fore or aft tilting tendencies are found, it will now be necessary to

repeat this procedure from the center collective stick position to full low pitch. If no tilting tendency is found, proceed to the next step.

In our example, we have shown that the swashplate has be tilted forward as the collective has been increased to full high pitch. This would

indicate that the front servo’s maximum travel is now more than that of the two rear servos (left and right).

In this condition, we suggest that the travel value for the front servo be increased slightly (5–10%). Repeat the above procedure and

increase the value as needed until the tilting tendency is eliminated.

For information on the Travel Adjustment function, please refer to your radio instruction manual for details. Once this condition has been

corrected, repeat this procedure for the center to low collective pitch position and adjust as needed.

Note: It is very important that during this step, only the travel value for the front servo (elevator) be adjusted to correct any pitch-toelevator tendencies. If the travel value of the left or right servo changes, this will affect the pitch-to-aileron tendencies corrected in the

previous step. If you feel that readjustment of the left and right servo travel is necessary, then it is suggested that the travel for each

servo be increased or decreased at the same amount, and the pitch-to-aileron procedure be re-tested.

Beginners can proceed to step 3-9.

View is shown from the left side

of the model. Notice how in this

example the swashplate has tilted

forward as the collective has moved

from the center to the full high pitch

position.

High

Low

Page 32

32

3-9

TAIL CONTROL ROD SERVO CONNECTION

Use Blue Threadlock

Note: Check to ensure the tail control rod can slide through the tail control rod guides

smoothly before connecting it to the servo. If resistance is felt, rotate the tail control rod

guides slightly until the control rod slides smoothly. Once the system is adjusted to

move freely, it is suggested that a small amount of CA adhesive glue be applied to

secure each tail control rod guide to the tail boom in the proper location.

Adjust the length of the tail control rod by

turning the universal link until both of them

are at 90° as shown below.

Please refer to your

gyro’s instructions for

recommended distance.

Note: The 4th HD servo arm

included in the kit can be

used for the rudder servo.

2x8 mm Flat Head Screw (1)

2 mm Hex Nut (1)

Steel Joint Ball (1)

2 mm Hex Nut

Steel Joint Ball

12.5mm -18mm

2x8 mm Flat Head Screw

90°

90°

Page 33

3-10

THROTTLE LINKAGE INST ALLATION

33

Use Blue Threadlock

High Low

Throttle

THROTTLE ARM/SERVO HORN POSITIONS

*To avoid differential throttle travel, make certain both the throttle arm and the servo horn are positioned as shown in the above diagrams.

1/2 Stick (Throttle) Position

(Throttle Barrel 1/2 open)

Low Stick (Throttle) Position

(Throttle Barrel Fully Closed)

High Stick (Throttle) Position

(Throttle Barrel Fully Open)

To achieve the correct position of the throttle/servo arm, it may be

necessary to re-position the throttle arm on the carburetor and to adjust the

length of the throttle linkage slightly to achieve full open and closed positions

of the carburetor.

It is also possible to increase/reduce the travel of the throttle servo through

the Travel Adjust function found in most computer radio systems. If this

function is used, make sure the values for the high and low positions remain

equal (same value for high/low). If these values are not equal, this will create a

differential or uneven movement of the throttle, making rotor rpm adjustment

and fine tuning more difficult.

90°

2x8 mm Flat Head Screw

2x8 mm Flat Head Screw

2 mm Hex Nut

2 mm Hex Nut

Steel Joint Ball

Steel Joint Ball

2.3x85 mm Threaded Rod

62.5 mm–65.5 mm

High

Low

High

Low

Neutral

Low

High

Page 34

34

4-1

BODY ASSEMBLY/CANOPY A TT ACHMENT

After trimming, attach the windshild to the body

temporarily with tape. Next, drill four 1/16" holes

through both the windshield and the body and

secure using the 2.3x8 mm screws provided.

Slide the completed body over the mechanics and secure

through the four canopy mount standoffs as shown.

Note: Check to insure that the

body does not come contact with

any portion of the main frame,

muffler, servo/servo horns, etc.

Trim for clearance if necessary.

Rubber Grommet (4)

Preinstalled

Rubber Grommet (4)

Body

Canopy

2.3x8 mm Self Tapping Screw (4)

2.3x8 mm Self-Tapping Screw (4)

Trim the shaded area from

the windshield as shown.

Page 35

35

4-2

DECAL A TTACHMENT

Attach the decals as shown. It is suggested that

the parts be cleaned with rubbing alcohol prior to

decal attachment.

Page 36

36

4-3

MAIN ROTOR BALANCING (ROTOR BLADES NOT INCLUDED)

4-4

MAIN ROTOR BLADE A TTACHMENT

4 mm Lock Nut (2)

4 mm Lock Nut

Firmly secure the main rotor blades to the rotor head as

shown above. Be certain to note the proper direction of

the rotor blades when assembling (clockwise rotation).

Main blades should be tightened so they can pivot when

moderate pressure is applied. Do not allow the main

blades to swing freely within the main blade holders.

Spanwise C.G. Balancing

Place each rotor blade on a sharp edge of a table as

shown and adjust so each rotor blade “teeters” on the

edge of the table. If the blades are correctly balanced, they

should be at an equal distance to the edge of the table. If

they are not, apply tape to the center of the light or short

blade until equal distance can be achieved.

Final Static Balancing

To static balance the main rotor blades, either attach each blade to a

“seesaw” type Blade Balancer (KSJ528) or bolt each of the two blades

together through the blade mounting holes shown and suspend this

unit between two drinking glasses. Add blade tracking tape (from

decal sheet) to the tip of the light or high blade until they each

become level to the table surface.

Step 1

Step 2

Drinking Glass (2 pcs)

Main Rotor Blades

4x30 mm Socket Head Bolt (2)

4x30 mm Socket Head Bolt

Main Rotor Blade (Optional)

Page 37

4-5

OPTIONAL 3D CONTROL SYSTEM SETUP

37

For advanced pilots wanting the best 3D performance from the Venture™, 50 3D please perform the following changes as shown.

Remove the two short control balls from the upper

swashplate ring as shown.

Re-install the control balls using the two ball spacers and

two 2x12 mm flat head screws.

This change will allow for increased control to the rotor head

for 3D flying.

To achieve 0° pitch at 1/2 stick for 3D flight, it will be

necessary to change the length of the swashplate to seesaw

rods to a length of 17 mm as shown.

A. SWASHPLA TE MODIFICATION

Remove

B. CONTROL ROD ADJUSTMENT

2x12 mm Flat Head Screw (2)

Ball Spacers (2)

Swashplate Seesaw Arm (2)

(2.3x40 mm threaded rod)

17 mm

Ball Spacer

Control Ball

2x12 mm Flat Head Screw

Page 38

38

4-5

OPTIONAL AGGRESSIVE 3D CONTROL SYSTEM SETUP

C. 3D FLYBAR/PADDLE INSTALLATION

Remove the current flybar and paddles by removing one paddle and loosening the two 4 mm flybar

control arm screws.

Install the special 410 mm 3D flybar and paddles as shown. Check to make sure that the flybar is

centered before attaching the paddles.

Thread the 3D paddles onto the flybar through the front hole in the paddles. It is not recommended

that the paddles be used in the rear hole, as they will make the control overly aggresssive.

Use Blue Threadlock

Align paddles so they

are parallel to each

other and to the flybar

control arm.

Flybar Control Arm

Adjust so that A and B are