Page 1

ASH 31 6.4M

Instruction Manual

Bedienungsanleitung

Manuel d’utilisation

Manuale di Istruzioni

Page 2

2

EN

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon

Hobby, LLC. For up-to-date product literature, visit horizonhobby.com and click on the support tab for this product.

Age Recommendation: Not For Children Under 14 Years. This Is Not A Toy.

SAFETY WARNINGS AND PRECAUTIONS

Read and follow all instructions and safety precautions before use. Improper use can result in fire, serious injury and

damage to property.

Components

Use only with compatible components. Should any compatibility questions exist, please refer to the product

instructions, component instructions or contact the appropriate Horizon Hobby office.

Flight

Fly only in open areas to ensure safety. It is recommended flying be done at radio control flying fields. Consult local

ordinances before choosing a flying location.

Propeller

If using the motor powered option, always keep loose items that can become entangled in the propeller away from the

prop. This includes loose clothing or other objects such as pencils and screwdrivers. Keep your hands away from the

propeller as injury can occur.

Batteries

Always follow the manufacturer’s instructions when using and disposing of any batteries. Mishandling of Li-Po

batteries can result in fire causing serious injury and damage.

Small Parts

This kit includes small parts and should not be left unattended near children as choking and serious injury could result.

MEANING OF SPECIAL LANGUAGE

The following terms are used throughout the product literature to indicate various levels of potential harm when

operating this product:

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage,

and serious injury OR create a high probability of superficial injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a

possibility of serious injury.

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND a little or

no possibility of injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before

operating. Failure to operate the product correctly can result in damage to the product, personal property and

cause serious injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic

mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury or damage

to the product or other property. This product is not intended for use by children without direct adult supervision. Do

not attempt disassembly, use with incompatible components or augment product in any way without the approval of

Horizon Hobby, LLC. This manual contains instructions for safety, operation and maintenance. It is essential to read and

follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and

avoid damage or serious injury.

SAFE OPERATING RECOMMENDATIONS

• Inspect your model before every flight to ensure it is airworthy.

• Be aware of any other radio frequency user who may present an interference problem.

• Always be courteous and respectful of other users in your selected flight area.

• Choose an area clear of obstacles and large enough to safely accomodate your flying activity.

• Make sure this area is clear of friends and spectators prior to launching your aircraft.

• Be aware of other activities in the vicinity of your flight path that could cause potential conflict.

• Carefully plan your flight path prior to launch.

• Abide by any and all established AMA National Model Aircraft Safety Code.

BEFORE STARTING ASSEMBLY

• Remove parts from bag.

• Inspect fuselage, wing panels, rudder and stabilizer for damage.

• If you find damaged or missing parts, contact your place of purchase.

• Charge transmitter and receiver batteries.

• Center trims and sticks on your transmitter.

• For a computer radio, create a model memory for this particular model.

• Bind your transmitter and receiver, using your radio system’s instructions.

NOTICE: Rebind the radio system once all control throws are set. This will keep the servos from moving to their

endpoints until the transmitter and receiver connect. It will also guarantee the servo reversal settings are saved in

the radio system.

FAA INFORMATION

If you own this product, you may be required to register with the FAA.

For up-to-date information on how to register with the FAA, please visit https://registermyuas.faa.gov/.

For additional assistance on regulations and guidance on UAS usage, visit knowbeforeyoufly.org/.

Page 3

3

EN

ASH 31 6.4M ARF

SPECIFICATIONS LARGE PARTS LAYOUT

252 in (6.4m)

1920 sq in (123.87 dm2)

88 in (2.2m)

26 lbs (11.8 kg)

6-channel (or greater) with 7 servos

Notice ......................................................................................................................................................................2

Meaning of Special Language ..................................................................................................................................2

Safety Warnings and Precautions .............................................................................................................................2

Safe Operating Recommendations ...........................................................................................................................2

Before Starting Assembly .........................................................................................................................................2

FAA INFORMATION ...................................................................................................................................................2

Specifications ..........................................................................................................................................................3

Large Parts Layout ...................................................................................................................................................3

Required for Completion ..........................................................................................................................................4

Optional Parts ..........................................................................................................................................................4

Additional Items Required ........................................................................................................................................4

Tools Required .........................................................................................................................................................4

Building Precautions ................................................................................................................................................5

Transportation and Storage ......................................................................................................................................5

Fluorescent Color Care .............................................................................................................................................5

Outer Wing Panels ...................................................................................................................................................5

Inner Wing Panels ....................................................................................................................................................7

Winglet Installation ................................................................................................................................................10

Rudder Installation .................................................................................................................................................10

Elevator Installation ...............................................................................................................................................12

Tow Release Installation.........................................................................................................................................13

Radio Installation ...................................................................................................................................................13

Cockpit Installation ................................................................................................................................................14

Optional Electric Power System Installation ............................................................................................................14

Final Assembly .......................................................................................................................................................17

Balancing the Aircraft.............................................................................................................................................18

Control Throws ......................................................................................................................................................19

Preflight Checklist ..................................................................................................................................................19

Daily Flight Checks ................................................................................................................................................19

Limited Warranty ...................................................................................................................................................19

Warranty and Service Contact Information .............................................................................................................20

Compliance Information for the European Union .....................................................................................................20

Instructions for Disposal of WEEE by Users in the European Union ..........................................................................20

AMA National Model Aircraft Safety Code ..............................................................................................................21

Replacement Parts .................................................................................................................................................22

Recommended Parts ..............................................................................................................................................22

Optional Parts ........................................................................................................................................................22

TABLE OF CONTENTS

Page 4

4

EN

REQUIRED FOR COMPLETION

ADDITIONAL ITEMS REQUIRED

TOOLS REQUIRED

# Required Part # Description

1 SPMAR12310T AR12310T 12CH PowerSafe Tele RX

4 SPMSA5060 A5060 H-T / H-S Mini Metal HV Servo

2 SPMSA7050 A7050 HV Thin Wing Hi Torq MG

3 SPMA3003 Heavy-Duty Servo Extension 12-inch

8 SPMA3004 Heavy-Duty Servo Extension 18-inch

5 SPMA3005 Heavy-Duty Servo Extension 24-inch

4 SPMA3007 Heavy-Duty Servo Extension 48-inch

1 SPMA3008 Heavy-Duty Y-Harness 6-inch

2 SPMB4000LPRX 4000mAh 2S 7.4V LiPo Rx Battery

1 SPMA3054 Servo Connector Clips (25)

1 SPMVR5203 VR5203 Dual Output Regulator

Description

6+ channel transmitter

LiPo battery charger

All Versions

Unpowered, Tow-Launched Version

Electric Powered Version

# Required Part # Description

1 SPMSA7040 A7040 HV Retract Servo

DLMBD38 Liquid Gravity; Weight System

# Required Part # Description

1 CSE010009700 Talon 90 Heli ESC 010-0097-00

1 EFLM4060B Power 60 BLOutrunner Mtr, 470Kv

1 EFLP16080FA Spinner, 45mm: ASW 20 4.7m

1 HAN495512 Propeller 16 x 10: ASW 20 4.7m

1 KXSB40006S40 F-Tek 4000mAh 6S 40C, EC5, LED

Description

Balancing stand

Box wrench: 17mm

Clamps

Clear tape

Crimping tool

Cyanoacrylate (CA) glue, thin and medium

Drill with various size bits

Epoxy

Epoxy brushes

Felt-tipped pen

Isopropyl alcohol

Hemostat

Hex drivers, metric, various sizes

Hobby knife

Long plastic pushrod

Low-tack masking tape

Medium grit sandpaper

Metric ruler

Microballoons

Mixing cups and sticks

Paper towels

Pencil

Phillips screwdriver: #1, #2

Pin vise

Pliers

Rotary tool with cutting disk, drum sander, carbide cutter, grinding stone

Soldering iron and solder

String

Part # Description

SPMA3008 Heavy-Duty Y-Harness 6 inch

SPMAS3000 AS3000 AS3X Stabilization Module

TAM85013 Spray Lacquer TS-13 Clear

TAM86024 PS-24 Fluor Org 100ml Spray Can

TAM87044 Primer White 180ml

OPTIONAL PARTS

Page 5

5

EN

ASH 31 6.4M ARF

1. Remove packing tape, clean and polish the wing surface.

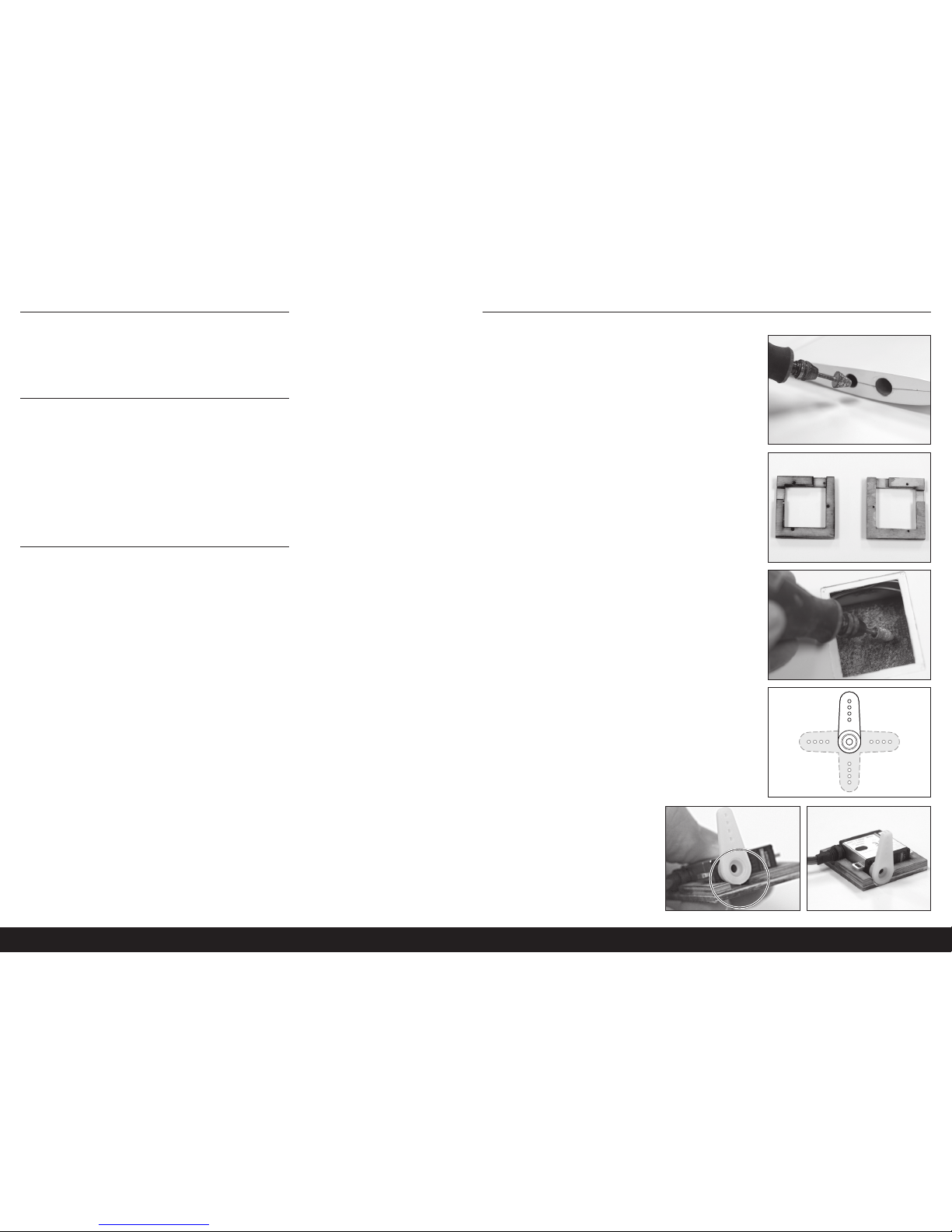

3. Find the short servo mounts. Drill pilot holes for the servo mounting

screws.

4. Carefully roughen the wing servo mounting surface for the servo

mount using either a rotary tool on low speed or 80 grit sandpaper.

Only lightly scuff the inner surface of the wing panel to give the

epoxy something to grip. DO NOT sand through the surface of the

wing panel. Clean the mounting surface thoroughly with denatured

alcohol or 91% IPA.

5. Cut 3 arms from a 4 arm servo horn.

6. Test fit the servo with the servo arm

installed. Enlarge the opening in the mount

as necessary to allow the servo to sit fully

in the mount.

Test fit the servo mount screws as well to

ensure they do not protrude through the

mount and damage the wing surface. If

the screws protrude, cut them off so they

are below the surface of the mount.

BUILDING PRECAUTIONS

Prepare the work surface prior to beginning the build. The surface

should be soft and free of any sharp objects. We recommend resting

the airframe parts on a soft towel or pit mat to prevent scratching or

denting the surface of the aircraft.

TRANSPORTATION AND STORAGE

When transporting and storing your model, you will need a minimum

of 80 inches (2m) in length, and 18 inches (46cm) in height to

accommodate the size of the fuselage. We also recommend the use of

wing and stabilizer bags to help protect these surfaces during transport

and storage. The control horns and linkages can cause damage to

other surfaces even when placed in storage bags. Always transport

and store the wings and stabilizer so the linkages do not contact other

panels to prevent damage.

FLUORESCENT COLOR CARE

The fluorescent color used on your model can fade with exposure to

direct sunlight over time. To increase the longevity of the fluorescent

color on the aircraft, limit the exposure to direct sunlight when not flying.

If repairs become necessary or if you decide to color optional parts

to match the fuselage color, Tamiya spray color, PS-24, Fluorescent

Orange is a close match to the color used on the model. For best

results, PS-24 needs to be sprayed over Tamiya Fine White Primer

(TAM87044) and clearcoated with Tamiya TS-13, Clear.

OUTER WING PANELS

2. Cut an access hole in the root end of the outer wing panel using a

rotary tool.

TIP: Make the hole just large enough for the servo connector to fit

through. If the hole is too big, the extension will fall back into the

wing panel when disconnected.

Page 6

6

EN

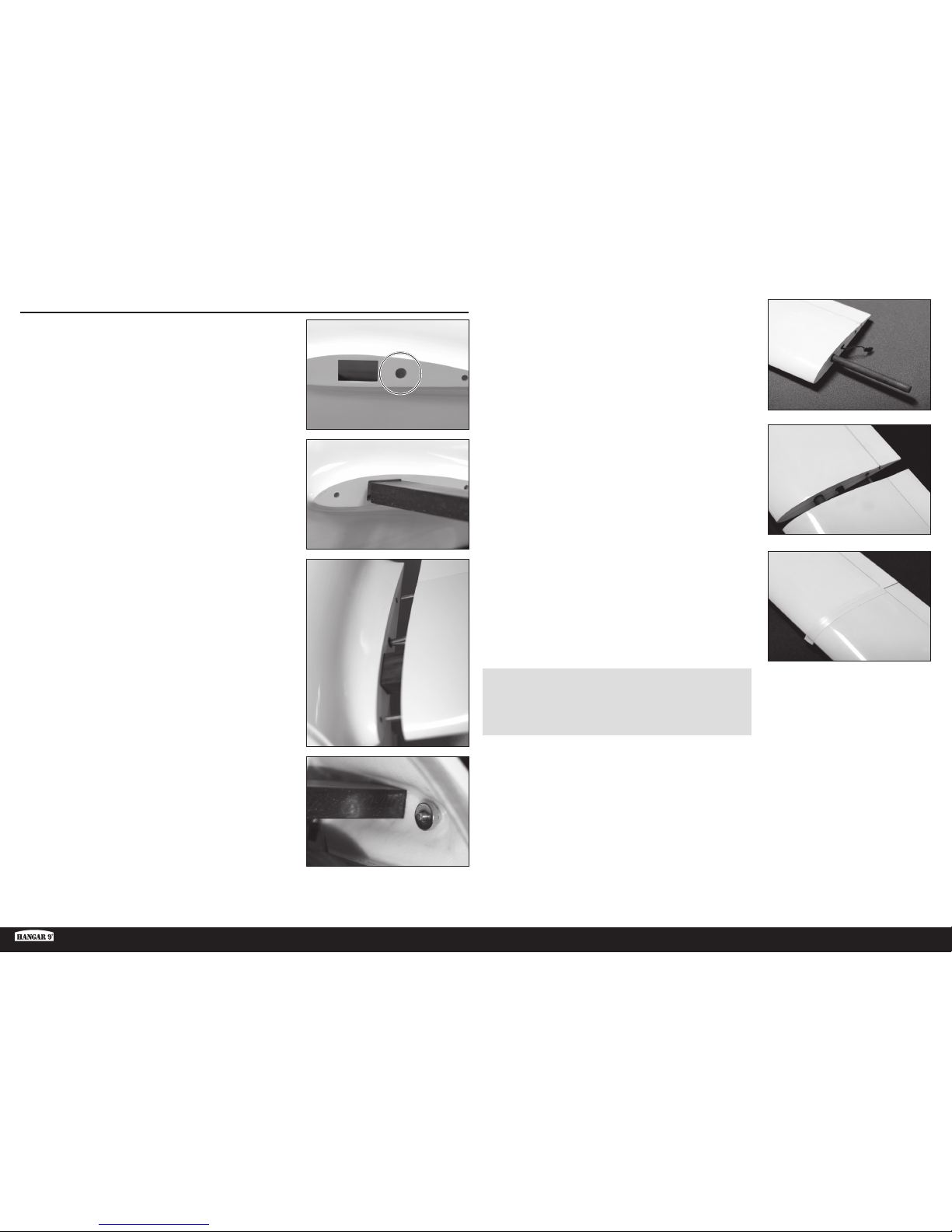

7. Measure and mark the wing panel at the servo hatch; 10mm from

raised outer hatch edge and 45mm from rear raised edge.

When mounting the frame in the wing, the edge of the frame lines

up with the front and back marks, and the servo output lines up

with the 45mm mark.

8. Using epoxy (DLMAD64), install the servo mount to the wing panel.

Ensure the servo arm will align with the surface control horn.

The arm clearance notch should face the wingtip and the servo

lead notch should face forward. Clean any epoxy from the servo

mounting area, which may interfere with the servo fitting into the

mount, with paper towel and alcohol. Allow the epoxy to cure fully.

9. Install anti-rotation pins in the root end with epoxy. Do not push the

pin in past half the length of the pin. Wipe away any excess epoxy

with paper towel and alcohol.

10. Connect a 12” servo lead extension to the aileron servo. Secure the

extension with a servo connector clip (SPMA3054) or heat shrink

tubing.

11. Use either a string with a weight attached or a long plastic pushrod

to thread the assembled servo extension through the wing panel

and out the previously cut access hole.

TIP: Feed the string or plastic rod through the access hole to the

servo hatch and attach the servo lead to the end. Pull the servo

lead end back through the access hole.

12. Install the servo arm. Install the servo in the mount using short

servo screws (2 x 8mm).

13. Carefully measure and cut the hole in the hatch for the servo arm

using a rotary tool or hobby knife. Test fit the hatch often to ensure

adequate clearance of the servo arm through full travel of the

servo. Round the outside corners of the hatch to fully fit into the

recessed mounting area of the wing panel.

14. Cut a piece of white UltraTrim (HANU80000) adhesive film about

3cm larger than the size of the servo hatch.

15. Peel and stick the adhesive film to the finished side of the servo hatch.

TIP: Start at the center of the hatch and carefully press any air

bubbles and wrinkles out of the film as you work your way to the

edges.

Cut and remove the hole for the servo arm. Trim the film to

approximately 10mm past the edge of the hatch and ease the

corners as shown to help prevent the corners from lifting after use.

16. Carefully install the servo hatch to the wing panel by placing the

hatch in the recess of the wing panel and pressing the film to the

wing panel around the perimeter of the hatch. Work outward from

the hatch to remove any air bubbles or wrinkles.

10mm

45mm

Page 7

7

EN

ASH 31 6.4M ARF

17. With the aileron held at center, measure between the holes of the

servo arm and the control horn.

18. Set the length of the aileron pushrod to the measurement above by

turning in or out on the clevis at either end of the pushrod. When

the correct length is achieved, apply thread locking compound and

tighten the nuts against the clevis. Try to center the threaded rod

between the two clevises.

TIP: The excess threaded rod may be cut off, if desired. Leave

enough of the rod that at least 3 threads are visible on the inside of

the clevis, as shown.

19. Install the pushrod to the servo and control surface horns. Ensure

the control surface is centered when the servo is at neutral.

20. Repeat steps 1–19 for the opposite outer wing panel.

2. Lay the finished outer wing panel next to the inner wing panel as

shown. Mark the location of the outer wing access hole on the

inner wing panel.

4. Connect a 48” and 24” servo extension together to create an inner

aileron extension. Secure with a clip or heat shrink tubing.

3. Cut access holes in both the outer and root ends of the inner

wing panel. The holes should be just large enough to fit the servo

connectors through to keep the ends from falling back into the

wing.

5. Insert a long plastic pushrod or weighted string through the cut

access hole in either end of the panel and out the flap servo hatch.

Attach one end of the assembled aileron servo extension to the

pushrod. Pull the extension end through the wing panel and out the

access hole. Tape the extension end to the end of the wing panel.

Repeat the procedure from the other end of the panel to pull the

opposite end of the aileron servo extension through the access

hole in the other end of the wing panel.

INNER WING PANELS

1. Remove packing tape, clean and polish the wing surface.

Page 8

8

EN

10mm

6. Connect an 18” servo extension to the spoiler lead and secure it

with a clip or heat shrink tubing. Thread the extension through the

inner end of the wing panel as before.

11. Install the flap servo mount using epoxy. Align the mount with the

marks made in the previous step. Remove any epoxy that squeezes

into the mounting lug slots or the inner base of the mount which

may interfere with the servo. Ensure the mount bonds to the wing

spar as well as the surface and that the servo arm will align with

the flap control horn. Allow epoxy to fully cure.

8. Carefully trim the webs from the servo mounting lugs. Test fit the

servo in the servo mount. The servo should be a very snug fit in the

mount.

13. Center the servo and install the control horn angled slightly toward

the trailing edge of the wing.

14. Slide the servo into the mount as shown.

7. Using hot glue or contact adhesive, such as Deluxe Systems

Foam2Foam (DLMAD34), secure the aileron and spoiler leads to

the spar at the front of the servo hatch. Doing so will keep the leads

from shifting and interfering with the flap servo arm and pushrod.

12. Cut the flap servo arm to length.

9. Carefully scuff the wing flap servo mounting surface for the servo

mount using either a rotary tool on low speed or 80 grit sandpaper.

Only lightly scuff the inner surface of the wing panel to give the

epoxy something to grip. DO NOT sand through the surface of the

wing panel. Clean the mounting surface thoroughly with denatured

alcohol or IPA.

15. Using the acetate template provided, create a servo retention plate

using 1/8” and 1/16” ply.

10. Measure and mark the flap servo hatch opening, 12mm from the

rear recess line and 17mm from the outer recess line, as shown in

the illustration.

17mm

12mm

Page 9

9

EN

ASH 31 6.4M ARF

79mm

16. Secure the servo in the mount with the servo retention plate and

two screws. Ensure the screw heads sit below the servo hatch

mounting surface and the screws don’t damage the outer surface

of the wing panel.

17. Connect a 24” servo extension to the servo lead and secure with

a clip or heat shrink tubing. Thread the extension through the

wing root end of the wing panel, using a long plastic pushrod or

weighted string as before.

18. Cut the pushrods to 79mm length.

19. Install the pushrod to the flap horn and servo arm. Deflect the flap

down and insert one end of the pushrod through the hole in the

trailing edge of the wing and connect it to the servo arm. Connect

the other end of the pushrod to the flap control horn.

20. Install the servo hatch to the wing with tape as done on the outer

wing panel.

21. Install anti-rotation pins in the root end of the panel with epoxy.

Wipe away any excess epoxy with paper towel and alcohol.

22. Trim and attach the flap pushrod exit cover to the top of the wing

using contact cement.

23. Repeat steps 1–22 for the opposite inner wing panel.

Page 10

10

EN

13mm

1. Clean and polish the fuselage.

2. Remove the tailwheel using a 2.5mm hex driver.

3. Feed a weighted string or long flexible pushrod through the elevator

servo opening, through the vertical fin, through the small hole in

front of the rudder servo opening and up through the fuselage

tail. This will be used later to pull the rudder and elevator servo

extensions through the fuselage.

4. Trim a servo arm to 13mm.

5. Center the rudder servo and install the servo arm.

6. A 60” servo extension is required for the rudder servo. Connect a

48” and a 12” extension to the rudder servo. Secure all connections

with servo extension clips or heat shrink tubing.

RUDDER INSTALLATION

1. Slide the winglet blade into the winglet slot.

2. Slide the assembly into the slot in the outer wing panel tip.

3. Trim the winglet blade to length, if necessary, to achieve a tight fit

of the winglet against the wing panel. There should not be a gap

between the panel and the winglet.

4. The blade should be a tight fit in both the winglet and the outer

wing panel. The winglet should be taped in place for added

security.

WINGLET INSTALLATION

5. Using epoxy, attach a wing tip wheel to the outer wing panel

bottom, near the tip.

TIP: Use fine grit sandpaper or a scouring pad to very lightly scuff

the surface of the wing panel where the wheel will be attached to

give the epoxy something to grip.

Repeat steps 1-5 for the opposite wingtip.

Page 11

11

EN

ASH 31 6.4M ARF

12. Push the rudder over the hinge points in the fin.

13. Carefully insert the rudder hinge pin through the hole in the top of

the rudder and feed it fully through each of the hinge points until it

exits through the bottom of the rudder.

TIP: The hinge pin is a tight friction fit. It may be necessary to lightly

push or pull on the rudder as the pin is inserted to get the pin to

seat fully. Do not force the pin through. If you feel resistance, move

the rudder slightly and continue to insert the pin.

14. When fully inserted, the hinge pin may be taped at the top of the

rudder if desired or if the hinge pin is excessively loose.

95mm

7. Trim the rudder pushrod so the finished length is 95mm between

the clevis pins. Attach one end of the pushrod to the rudder servo

arm.

8. With the fuselage upside down in a stand, feed the servo extension

through the rudder servo cutout and out the elevator servo cutout at

the top of the fin. This extension will be pulled through the fuselage

with the elevator servo extension later.

9. Install the rudder servo through the tailwheel opening and into the

servo mount. The servo is installed with the output shaft toward

the front of the aircraft and the servo arm toward the left side of

the fuselage. Feed the open end of the pushrod through the molded

opening in the tail as you fit the servo into place. Keep some tension

on the servo lead to ensure the lead is not pinched in the opening.

TIP: Use a magnetic screwdriver or attach a small magnet to a

regular screwdriver to install the servo screws.

10. Rotate the servo horn so the pushrod extends out the back of the fin.

11. Attach the rudder control horn to the pushrod.

Page 12

12

EN

53mm

10mm

1. A 72” servo extension is required for the elevator servo. Connect

a 48” and a 24” extension together and connect to the elevator

servo. Secure all connections with clips or heat shrink tubing.

2. Tape the ends of the rudder and elevator servo extensions to

the end of the flexible pushrod or string that was inserted in the

fuselage earlier. Carefully pull the servo extensions through the

fuselage and up to the cockpit.

3. Fit the elevator servo into place with the output shaft toward the

front of the aircraft. Ensure the servo lead is not pinched.

4. Trim the elevator pushrod so the finished length is 53mm between

the clevis pins. The clevises should be at 90° to each other.

5. Trim the elevator servo arm to 10mm.

6. Attach one end of the pushrod to the elevator servo arm and the

other end to the elevator control horn.

7. Feed the elevator pushrod with the servo arm attached through the

top of the fin. Center the elevator servo. Attach the servo horn to

the servo output shaft at 90° as shown in the illustration.

8. Attach the horizontal stab to the fin using two M4 X 20mm flathead

screws.

ELEVATOR INSTALLATION

Page 13

13

EN

ASH 31 6.4M ARF

2. Install the tow release servo into the nose of the fuselage. Slide

the release wire through the small hole in the front of the cockpit.

Attach the arm to the servo, ensuring the wire fully opens at one end

of the servo travel and fully closes at the opposite end of travel.

IMPORTANT: While the spoilers and retract will operate on 7.2V, for increased longevity and reliability, we recommend

regulating the power input of these components to 5.2V with the use of an inline voltage regulator, such as SPMVR5203.

If the retract is slow to operate or does not retract to the fully locked position at the regulated voltage, run the retract

directly to the receiver at 7.2V.

IMPORTANT: If you are installing the electric power option, skip this

section and see the optional electric power installation secton.

1. Carefully cut the rear of the cockpit floor in the area shown.

2. Connect the gear and spoiler channels from the receiver to the

input ports of the regulator.

3. Connect the output ports of the regulator to the gear lead and the

spoiler y-harness.

4. Route all servo leads from the tail to the forward fuselage, keeping

them as organized as possible. Use wire ties or hook and loop tape

to secure the leads in the fuselage.

5. Prepare six 18-inch servo leads; two for ailerons, two for flaps and

two for spoilers.

TIP: Use different colored tape wrapped around the ends of the

leads to differentiate which leads go to which control surface.

6. Connect all servo leads to the appropriate receiver ports.

7. Mount the receiver under the rear of the cockpit floor as shown. If

necessary, use small pieces of foam or hook and loop tape to hold

the receiver in place.

TIP: If desired, cut holes in the rear of the cockpit floor and route

the servo leads to the receiver.

8. Temporarily mount the receiver batteries as far forward in the

cockpit as possible. The battery location will be finalized after the

correct center of gravity has been established. The unpowered, glider version will have the batteries mounted as

far forward as possible, along with additional nose weight.

The electric powered version does not require additional nose weight to balance, and depending on the motor

battery used, may require the receiver batteries to be moved rearward.

1. Install the tow release wire to the servo arm.

TOW RELEASE INSTALLATION RADIO INSTALLATION

Page 14

14

EN

COCKPIT INSTALLATION

1. Install the fiberglass cockpit tub. Squeeze gently on the sides of

the tub to fit it between and under the molded fuselage sides.

The holes in the tub should line up with the holes in the fuselage.

It is not necessary to secure the tub to the fuselage. The tub is

removable to allow for access to the rear of the fuselage and the

lower cockpit area.

2. Install an optional pilot into the tub for added scale realism if

desired. It is not necessary to secure the pilot to the tub.

TIP: Hangar 9 has partnered with two companies who offer

custom pilots; www.warbirdpilots.com in the United States and

www.tailoredpilots.com in the United Kingdom offer very detailed

pilot figures to suit the ASH 31.

3. Install the canopy to the fuselage by inserting the pin at the front

of the canopy into the hole at the front of the fuselage and rotating

the back of the canopy down against the fuselage, ensuring the

side alignment lugs insert into the holes in the fuselage.

4. Slide the wire canopy lock, located under the left wing root, in until

the canopy is secured. It may be necessary to press gently on the

back of the canopy to get it to latch fully. The wire lock is purposely

a tight fit to prevent coming loose in flight.

OPTIONAL ELECTRIC POWER SYSTEM INSTALLATION

1. Roughen one side of each of the motor mount pieces using 80 grit

sandpaper.

2. Using 5-minute epoxy, glue the roughened sides of the two motor

mount pieces together, ensuring the holes line up accurately. Clean

up any excess epoxy with alcohol and a paper towel. Clamp the

pieces together until the epoxy fully cures.

3. Trace a line around one side of the mount approximately 1.5mm

from the outer edge, as shown.

4. Using the line as a guide, sand a bevel on the edge of the mount by

sanding across the edge, from the back corner to the line.

5. Using 1/8” tape, mark a line 25mm back from the nose of the

fuselage.

Page 15

15

EN

ASH 31 6.4M ARF

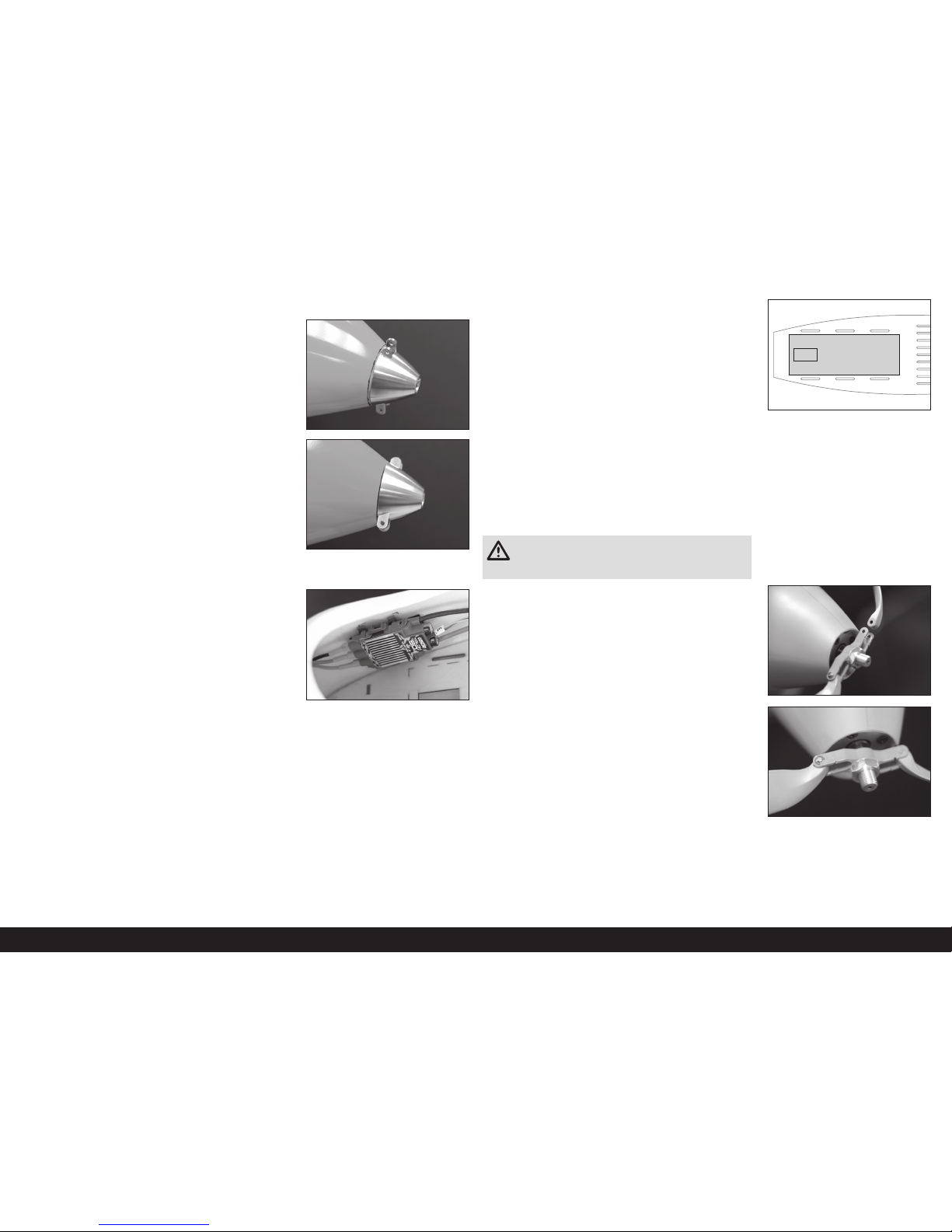

6. Carefully cut the nose away from the fuselage using a rotary tool

with a cutoff disk. Do not cut all the way to the tape. Leave some

excess to be sanded away later.

7. Following the instructions included with the motor, change the

motor shaft orientation for mounting the motor to the back of the

mount.

8. Attach the motor mount to the motor using screws provided with

the motor. If necessary, use a countersink to bevel the holes in

the mounting plate. Ensure the narrow side of the edge bevel

previously sanded into the mount is facing away from the motor.

9. Insert the motor and mount into the nose of the fuselage from the

inside.

10. Press the propeller adapter onto the motor shaft and loosely install

the propeller nut. Install the spinner over the propeller adapter.

Ensure the spinner is fully seated over the adapter. Install the

spinner center screw.

11. Press the motor forward and tighten the spinner center screw

while pressing against the motor. Tighten the screw just enough

to hold the motor in place but still allow for adjusting the spinner

placement against the fuselage.

12. Use the spinner to correctly align the motor with the nose of the

fuselage.

13. When the alignment is correct, hold the motor steady from the

inside of the fuselage and carefully remove the spinner assembly

by loosening the spinner center screw, being careful to not move

the motor. Slide the spinner assembly off of the motor shaft.

14. With the spinner removed, temporarily tack the motor mount to the

fuselage with a couple drops of medium CA and accelerator around

the mounting ring.

15. Remove the motor mount screws and remove the motor, being

careful not to break the motor mount loose from the fuselage.

16. DO NOT SKIP THIS STEP. Apply a generous bead of epoxy around

the joint between the mount and fuselage, both in front of and

behind the motor mount. Press the epoxy into the joint and smooth

it to form a fillet. Allow the epoxy to fully cure before continuing.

Page 16

16

EN

17. Temporarily install the motor and spinner assembly.

18. Measure and mark 1mm back from the spinner around the

fuselage.

19. Remove the spinner assembly and motor and sand the front of the

fuselage back to the line.

TIP: Use a sanding block to keep the front of the fuselage straight.

Remove material slowly and check the progress often. The goal is

to get a perfectly straight line that is parallel with the back of the

spinner around the circumference of the fuselage.

20. Mount the motor to the motor mount using medium thread locking

compound.

21. Use hook and loop tape or servo tape to install the ESC in the

cockpit.

22. Connect the motor leads to the ESC following the instructions

included with the motor and ESC.

23. Connect the ESC throttle lead to the appropriate reciever port.

24. Cut and remove the section of the cockpit floor shown.

25. Mount the motor battery in the cockpit floor and secure using hook

and loop straps through the pre-cut holes in the cockpit floor.

26. Mount the receiver batteries at the rear of the cockpit. The receiver

batteries can be moved accordingly to adjust the balance of the

aircraft. When using the recommended optional power system

components no additional ballast should be required. However,

proceed to the Balancing the Aircraft section to confirm the correct

center of gravity.

CAUTION: Never attempt to fly without properly balancing the

aircraft. An un-balanced aircraft will be extremely unstable and

may cause a crash. Crash damage is not covered under warranty.

27. Prepare the spinner yoke by installing the tapered shaft and nut.

Do not tighten the nut at this time.

28. Check the fit of the propeller blades to the yoke. The blade should

move freely when the pin is installed. If not, lightly sand the blades

where they contact the yoke to allow free movement.

29. Once the blades fit the yoke, use the pins and clips to secure the

blades to the yoke. Ensure the front of the blades are facing toward

the notched side of the yoke.

30. Fit the assembly to the motor shaft. Check that the yoke can rotate

freely and not contact the front of the fuselage through its full

rotation. Use a 12mm wrench to tighten the nut, securing the yoke

and adapter.

31. Install the spinner, making sure it fits into the notches in the

propeller yoke. Use the screw provided with the spinner and a

#1Phillips screwdriver to secure the spinner to the adapter.

TIP: The spinner and propeller blades may be painted to match

the fluorescent orange of the aircraft nose, using the products

mentioned in the Fluorescent Color Care section, making the

spinner and propeller almost invisible during flight.

Page 17

17

EN

ASH 31 6.4M ARF

1. Cut a hole in the wing root of the fuselage for the various servo leads

from the wing. Ensure the hole aligns with the hole previously cut in

the root of the inner wing panel and it is large enough to allow the

servo lead connectors to pass through. Use sandpaper to remove

any sharp edges around the hole.

2. Insert the wing joiner into the fuselage. The joiner should be a snug

fit in the fuselage opening. Ensure the joiner is centered in the

fuselage.

3. Slide the inner wing panels over the ends of the wing joiner,

connecting the servo leads and inserting the wing alignment pin in

the fuselage as you slide the panel on.

4. Thread the wing retention nut onto the threaded wing stud from

the inside of the fuselage. Hand tighten the retention nut, ensuring

the various servo leads are not pinched between the wing and the

fuselage.

5. Slide an outer wing tube into the outer end of the inner wing panel.

FINAL ASSEMBLY

NOTICE: Always ensure the wing is clean, dry and free from any dust or

debris prior to installing the tape.

NOTICE: Do not re-use the tape after disassembling the wing. Use new

tape every time the wing is reassembled.

6. Slide the outer wing panels over the wingtube until the outer panel

contacts the inner panel. Ensure the wing alignment pin is inserted

into the wing alignment hole.

7. Wrap the seam between the inner and outer panel with tape. Ensure

the tape does not interfere with the operation of the wing control

surfaces. White PVC electrical tape is recommended. We have found

this tape to be more than sufficient to retain the outer wing panels in

flight, even during aggressive aerobatic maneuvers.

8. Install the tip winglet as described in the Winglet Installation section.

9. Repeat steps 1-8 for the opposite wing.

10. Install the cockpit shell, pilot and canopy to the fuselage.

Page 18

18

EN

2. The recommended center of gravity (CG) location for your model

is 2

3

/8–35/16 inches (60–85 mm) back from the leading edge of

the wing at the root. Mark the CG location on the wings with tape

or a marker. Balance your model upright with your fingers or a

balancing stand supporting the model at the marks made on the

bottom of the wing.

3. Support the aircraft upright at the marks made on the wing with

your fingers or a commercially available balancing stand.

If you are building the unpowered, tow launch version, proceed to

step 5.

4. If you are building the electric powered version, move the receiver

batteries forward or backward in the cockpit until the aircraft sits

level or slightly nose down on the balancing stand. When the proper

center of gravity is achieved, mount the receiver batteries to the

fuselage using hook and loop tape.

Proceed to the Control Throws section.

TIP: If the proper balance point cannot be achieved with the receiver

batteries fully forward, add self-adhesive weight until the aircraft

balances.

BALANCING THE AIRCRAFT

CAUTION: DO NOT SKIP THIS STEP. Never attempt to fly

without properly balancing the aircraft. An un-balanced aircraft

will be extremely unstable and may cause a crash. Crash damage is

not covered under warranty.

1. Attach the wing panels, canopy and tail surfaces to the fuselage.

Make sure to connect the leads from the aileron, flaps and spoilers

to the appropriate leads from the receiver. Make sure the leads are

not exposed outside the fuselage before tightening the wing bolts.

Your model should be powered OFF, in an otherwise flight-ready

state prior to balancing.

Add ballast to the nose of the aircraft until the fuselage sits level

or slightly nose-down on the balancing stand.

TIP: Tape a plastic bag to the outside of the nose of the fuselage

and add weight, such as lead shot or Deluxe Materials Liquid

Gravity (DLMBD38) to the bag until the aircraft balances.

5. Remove the wings, canopy and flight batteries from the fuselage,

and carefully stand the fuselage up on its nose.

6. Mix the ballast from step 5 with epoxy and micro balloons and add to

the inside of the nose of the fuselage. Allow the mixture to fully cure.

TIP: An alternative to adding the ballast directly to the fuselage

is to use the spinner from the Hangar 9 RV-4 (HAN488509) as a

mold to hold the epoxy/ballast mixture until it cures. This spinner

is an almost perfect match to the shape of the ASH nose. Pour the

ballast mixture into the spinner. After fully curing, the mixture can

be removed from the spinner and securely mounted in the nose of

the fuselage with epoxy.

Return the flight batteries to their position in the cockpit and

secure their location.

23/8–35/16 inches

(60–85 mm)

Page 19

19

EN

ASH 31 6.4M ARF

PREFLIGHT CHECKLIST

• Charge the transmitter, receiver and motor batteries. Follow the instructions provided with the charger. Follow all

manufacturer’s instructions for your electronic components.

• Check the radio installation and make sure all control surfaces (aileron, elevator, rudder, flaps and spoilers) move

correctly (i.e., the correct direction and with the recommended throws).

• Check all the hardware (control horns, servo horns, and clevises) to make sure they are secure and in good condition.

• Prior to each flying session (and especially with a new model), perform a range check of your radio system. See your

radio manual for the recommended range and instructions for your particular radio system.

DAILY FLIGHT CHECKS

• Check the battery voltage of the transmitter battery. Do not fly below the manufacturer’s recommended voltage.

Doing so can cause your aircraft to crash.

• Check all hardware (linkages, screws, nuts, and bolts) prior to each day’s flight. Ensure that binding does not occur

and that all parts are properly secured.

• Ensure all surfaces are moving in the proper manner.

• Perform a ground range check before each day’s flying session.

• All servo leads and switch harness plugs should be secured in the receiver.

LIMITED WARRANTY

What this Warranty Covers

Horizon Hobby, LLC, (Horizon) warrants to the original purchaser that the product purchased (the “Product”) will be free from

defects in materials and workmanship at the date of purchase.

What is Not Covered

This warranty is not transferable and does not cover (i) cosmetic damage, (ii) damage due to acts of God, accident, misuse,

abuse, negligence, commercial use, or due to improper use, installation, operation or maintenance, (iii) modification of or to

any part of the Product, (iv) attempted service by anyone other than a Horizon Hobby authorized service center, (v) Product

not purchased from an authorized Horizon dealer, (vi) Product not compliant with applicable technical regulations, or (vii) use

that violates any applicable laws, rules, or regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE, HORIZON MAKES NO OTHER WARRANTY OR REPRESENTATION,

AND HEREBY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED

WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS

OF THE PURCHASER’S INTENDED USE.

Purchaser’s Remedy

Horizon’s sole obligation and purchaser’s sole and exclusive remedy shall be that Horizon will, at its option, either (i) service,

or (ii) replace, any Product determined by Horizon to be defective. Horizon reserves the right to inspect any and all Product(s)

involved in a warranty claim. Service or replacement decisions are at the sole discretion of Horizon. Proof of purchase is

required for all warranty claims. SERVICE OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE PURCHASER’S

SOLE AND EXCLUSIVE REMEDY.

CONTROL THROWS

1. Turn on the transmitter and receiver of your model. Check the movement of the rudder using the transmitter.

When the stick is moved to the right, the rudder should also move right. Reverse the direction of the servo at the

transmitter if necessary.

2. Check the movement of the elevator with the radio system. Moving the elevator stick toward the bottom of the

transmitter will make the airplane elevator move up.

3. Check the movement of the ailerons with the radio system. Moving the aileron stick to the right will make the right

aileron move up and the left aileron move down.

4. Use a ruler to adjust the throw of the elevator, ailerons and rudder.

• In Landing or Soaring Mode, the ailerons will move independent from the flaperons.

• In Landing or Soaring Mode, droop the entire trailing edge (flaperons and ailerons) down 1/8–5/32 inches (3–4mm).

• In Cruise or Launch Mode, couple the ailerons and flaperons for full roll control.

• In Cruise or Launch Mode, reflex the entire trailing edge (flaperons and ailerons) up 1/8–5/32 inches (3–4mm).

• Use a slider to control the flaperon throw so the amount of travel can be varied.

• We recommend lowering the flaperons 3/8 inches (10mm) during Rise-Off-Ground (ROG) takeoffs and

during aero-tow.

• Set the rudder throw to an amount that will not bind the servo.

• Set the maximum flaperon throw to an amount that will not bind the servo.

These are general guidelines measured from our own flight tests. You can experiment with higher rates to match your

preferred style of flying.

Travel Adjust and Sub-Trims are not listed and should be adjusted according to each individual model and preference.

Always install the control horns 90 degrees to the servo center line. Use sub-trim as a last resort to center the servos.

Always re-binding the radio system once all of the control throws are set to keep the servos from moving to their

endpoints until the transmitter and receiver connect.

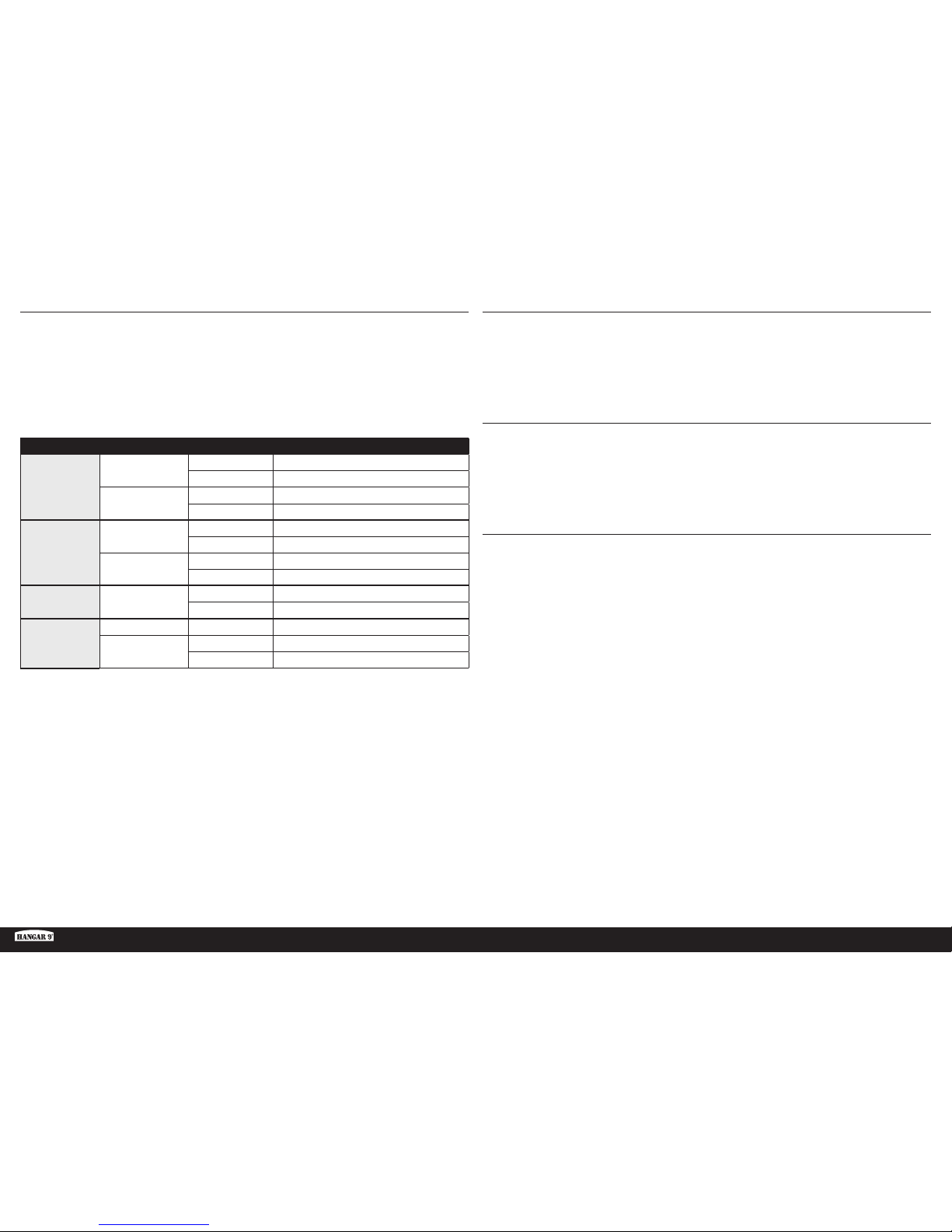

Surface Rate Direction Throw

Aileron

Landing/Soaring

Up 5/8 inches (16mm)

Down 15/32 inches (12mm)

Cruise/Launch

Up

11/16–13/16 inches (18–20mm)

Down 17/32 inches (14mm)

Elevator

High

Up 11/32 inches (9mm)

Down 9/32 inches (7mm)

Low

Up 9/32 inches (7mm)

Down 3/16 inches (5mm)

Rudder High

Right

1

1

/8–19/32 inches (35–45mm)

Left

1

1

/8–19/32 inches (35–45mm)

Flaperon

Landing Down

1–1

3

/16 inches (25–30mm)

Cruise/Launch

Up

11/16–13/16 inches (18–20mm)

Down 17/32 inches (14mm)

Page 20

20

EN

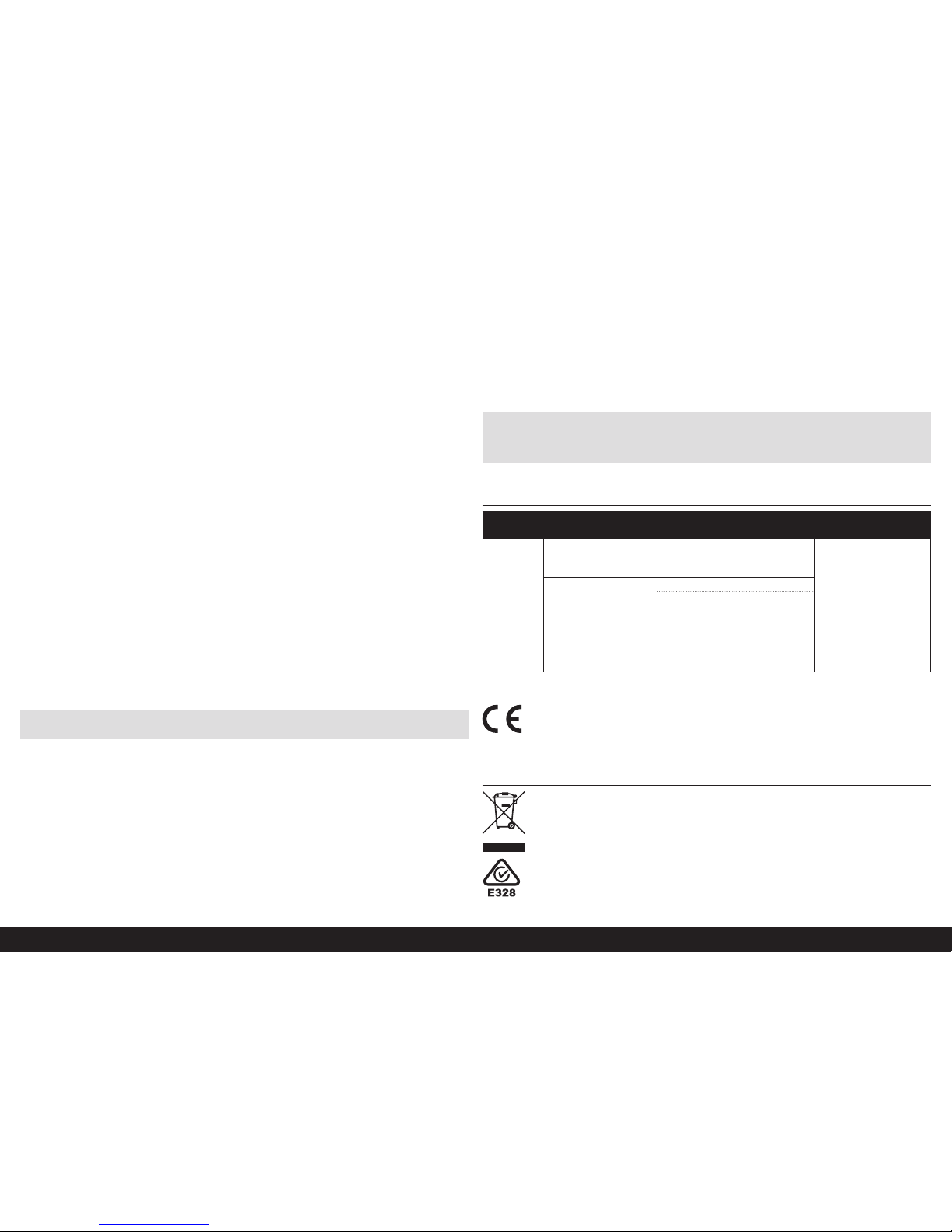

WARRANTY AND SERVICE CONTACT INFORMATION

Country of

Purchase

Horizon Hobby Contact Information Address

United States

of America

Horizon Service Center

(Repairs and Repair

Requests)

servicecenter.horizonhobby.com/

RequestForm/

2904 Research Road

Champaign, IL 61822

Horizon Product Support

(Product Technical

Assistance)

productsupport@horizonhobby.com

877-504-0233

Sales

websales@horizonhobby.com

800-338-4639

European

Union

Horizon Technischer Service service@horizonhobby.eu

Hanskampring 9

D 22885 Barsbüttel, Germany

Sales: Horizon Hobby GmbH +49 (0) 4121 2655 100

INSTRUCTIONS FOR DISPOSAL OF WEEE BY USERS IN THE EUROPEAN UNION

This product must not be disposed of with other waste. Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated collections point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling of your waste equipment at the time of disposal

will help to conserve natural resources and ensure that it is recycled in a manner that protects human health

and the environment. For more information about where you can drop off your waste equipment for recycling,

please contact your local city office, your household waste disposal service or where you purchased the

product.

COMPLIANCE INFORMATION FOR THE EUROPEAN UNION

EU Compliance Statement: Horizon Hobby, LLC hereby declares that this product is in compliance with the

essential requirements and other relevant provisions of the EMC Directive.

A copy of the EU Declaration of Conformity is available online at:

http://www.horizonhobby.com/content/support-render-compliance.

Non-Warranty Service

Should your service not be covered by warranty, service will be completed and payment will be required without notification or

estimate of the expense unless the expense exceeds 50% of the retail purchase cost. By submitting the item for service you

are agreeing to payment of the service without notification. Service estimates are available upon request. You must include this

request with your item submitted for service. Non-warranty service estimates will be billed a minimum of ½ hour of labor. In

addition you will be billed for return freight. Horizon accepts money orders and cashier’s checks, as well as Visa, MasterCard,

American Express, and Discover cards. By submitting any item to Horizon for service, you are agreeing to Horizon’s Terms and

Conditions found on our website http://www.horizonhobby.com/content/service-center_render-service-center.

ATTENTION: Horizon service is limited to Product compliant in the country of use and ownership. If received, a

non-compliant Product will not be serviced. Further, the sender will be responsible for arranging return shipment

of the un-serviced Product, through a carrier of the sender’s choice and at the sender’s expense. Horizon will hold

non-compliant Product for a period of 60 days from notification, after which it will be discarded.

10/15

Limitation of Liability

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS

OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, TORT, NEGLIGENCE, STRICT LIABILITY OR ANY OTHER THEORY OF LIABILITY, EVEN IF HORIZON HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Further, in no event shall the liability of Horizon exceed the individual price

of the Product on which liability is asserted. As Horizon has no control over use, setup, final assembly, modification or misuse,

no liability shall be assumed nor accepted for any resulting damage or injury. By the act of use, setup or assembly, the user

accepts all resulting liability. If you as the purchaser or user are not prepared to accept the liability associated with the use of

the Product, purchaser is advised to return the Product immediately in new and unused condition to the place of purchase.

Law

These terms are governed by Illinois law (without regard to conflict of law principals). This warranty gives you specific legal

rights, and you may also have other rights which vary from state to state. Horizon reserves the right to change or modify

this warranty at any time without notice.

WARRANTY SERVICES

Questions, Assistance, and Services

Your local hobby store and/or place of purchase cannot provide warranty support or service. Once assembly, setup or

use of the Product has been started, you must contact your local distributor or Horizon directly. This will enable Horizon to

better answer your questions and service you in the event that you may need any assistance. For questions or assistance,

please visit our website at www.horizonhobby.com, submit a Product Support Inquiry, or call the toll free telephone number

referenced in the Warranty and Service Contact Information section to speak with a Product Support representative.

Inspection or Services

If this Product needs to be inspected or serviced and is compliant in the country you live and use the Product in, please use

the Horizon Online Service Request submission process found on our website or call Horizon to obtain a Return Merchandise

Authorization (RMA) number. Pack the Product securely using a shipping carton. Please note that original boxes may be

included, but are not designed to withstand the rigors of shipping without additional protection. Ship via a carrier that

provides tracking and insurance for lost or damaged parcels, as Horizon is not responsible for merchandise until it arrives

and is accepted at our facility. An Online Service Request is available at http://www.horizonhobby.com/content/servicecenter_render-service-center. If you do not have internet access, please contact Horizon Product Support to obtain a RMA

number along with instructions for submitting your product for service. When calling Horizon, you will be asked to provide

your complete name, street address, email address and phone number where you can be reached during business hours.

When sending product into Horizon, please include your RMA number, a list of the included items, and a brief summary of

the problem. A copy of your original sales receipt must be included for warranty consideration. Be sure your name, address,

and RMA number are clearly written on the outside of the shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If you have any issue with a LiPo battery, please contact the

appropriate Horizon Product Support office.

Warranty Requirements

For Warranty consideration, you must include your original sales receipt verifying the proof-of-purchase date. Provided

warranty conditions have been met, your Product will be serviced or replaced free of charge. Service or replacement

decisions are at the sole discretion of Horizon.

Page 21

21

EN

ASH 31 6.4M ARF

AMA NATIONAL MODEL AIRCRAFT SAFETY CODE

Effective January 1, 2014

A. GENERAL

A model aircraft is a non-human-carrying aircraft capable of sustained flight in the atmosphere. It may not exceed

limitations of this code and is intended exclusively for sport, recreation, education and/or competition. All model flights must

be conducted in accordance with this safety code and any additional rules specific to the flying site.

1. Model aircraft will not be flown:

(a) In a careless or reckless manner.

(b) At a location where model aircraft activities are prohibited.

2. Model aircraft pilots will:

(a) Yield the right of way to all man carrying aircraft.

(b) See and avoid all aircraft and a spotter must be used when appropriate. (AMA Document #540-D.)

(c) Not fly higher than approximately 400 feet above ground level within three (3) miles of an airport, without notifying the

airport operator.

(d) Not interfere with operations and traffic patterns at any airport, heliport or seaplane base except where there is a

mixed use agreement.

(e) Not exceed a takeoff weight, including fuel, of 55 pounds unless in compliance with the AMA Large Model Aircraft

program. (AMA Document 520-A.)

(f) Ensure the aircraft is identified with the name and address or AMA number of the owner on the inside or affixed to the

outside of the model aircraft. (This does not apply to model aircraft flown indoors).

(g) Not operate aircraft with metal-blade propellers or with gaseous boosts except for helicopters operated under the

provisions of AMA Document #555.

(h) Not operate model aircraft while under the influence of alcohol or while using any drug which could adversely affect

the pilot’s ability to safely control the model.

(i) Not operate model aircraft carrying pyrotechnic devices which explode or burn, or any device which propels a projectile

or drops any object that creates a hazard to persons or property.

Exceptions:

• Free Flight fuses or devices that burn producing smoke and are securely attached to the model aircraft during flight.

• Rocket motors (using solid propellant) up to a G-series size may be used provided they remain attached to the model

during flight. Model rockets may be flown in accordance with the National Model Rocketry Safety Code but may not be

launched from model aircraft.

• Officially designated AMA Air Show Teams (AST) are authorized to use devices and practices as defined within the

Team AMA Program Document (AMA Document #718).

(j) Not operate a turbine-powered aircraft, unless in compliance with the

AMA turbine regulations. (AMA Document #510-A).

3. Model aircraft will not be flown in AMA sanctioned events, air shows or model demonstrations unless:

(a) The aircraft, control system and pilot skills have successfully demonstrated all maneuvers intended or anticipated prior

to the specific event.

(b) An inexperienced pilot is assisted by an experienced pilot.

4. When and where required by rule, helmets must be properly worn and fastened. They must be OSHA, DOT, ANSI, SNELL

or NOCSAE approved or comply with comparable standards.

B. RADIO CONTROL

1. All pilots shall avoid flying directly over unprotected people, vessels, vehicles or structures and shall avoid endangerment

of life and property of others.

2. A successful radio equipment ground-range check in accordance with manufacturer’s recommendations will be

completed before the first flight of a new or repaired model aircraft.

3. At all flying sites a safety line(s) must be established in front of which all flying takes place (AMA Document #706.)

(a) Only personnel associated with flying the model aircraft are allowed at or in front of the safety line.

(b) At air shows or demonstrations, a straight safety line must be established.

(c) An area away from the safety line must be maintained for spectators.

(d) Intentional flying behind the safety line is prohibited.

4. RC model aircraft must use the radio-control frequencies currently allowed by the Federal Communications Commission

(FCC). Only individuals properly licensed by the FCC are authorized to operate equipment on Amateur Band frequencies.

5. RC model aircraft will not operate within three (3) miles of any pre-existing flying site without a frequency-management

agreement (AMA Documents #922 and #923.)

6. With the exception of events flown under official AMA Competition Regulations, excluding takeoff and landing, no powered

model may be flown outdoors closer than 25 feet to any individual, except for the pilot and the pilot’s helper(s) located at the

flight line.

7. Under no circumstances may a pilot or other person touch a model aircraft in flight while it is still under power, except to

divert it from striking an individual.

8. RC night flying requires a lighting system providing the pilot with a clear view of the model’s attitude and orientation at all

times. Hand-held illumination systems are inadequate for night flying operations.

9. The pilot of a RC model aircraft shall:

(a) Maintain control during the entire flight, maintaining visual contact without enhancement other than by corrective

lenses prescribed for the pilot.

(b) Fly using the assistance of a camera or First-Person View (FPV) only in accordance with the procedures outlined in

AMA Document #550.

(c) Fly using the assistance of autopilot or stabilization system only in accordance with the procedures outlined in AMA

Document #560.

Please see your local or regional modeling association’s guidelines for proper, safe operation of your model aircraft.

Page 22

22

EN

Part # Description

EFLG630S Electric Retract

HAN318501 Fuselage

HAN318502 Left-Hand Wing Inner Panel

HAN318503 Right-Hand Wing Inner Panel

HAN318504 Left-Hand Wing Outer Panel

HAN318505 Right-Hand Wing Outer Panel

HAN318506 Left-Hand Winglet

HAN318507 Right-Hand Winglet

HAN318508 Wingtip Wheels

HAN318509 Horizontal Stab

HAN318510 Carbon Wing Joiner

HAN318511 Outer Wing Rods

HAN318512 Winglet Joiners

HAN318513 Servo Covers (6)

HAN318514 Cockpit

HAN318515 Seat

HAN318516 Rudder

HAN318517 Landing Gear Parts

HAN318518 Landing Gear Doors

HAN318519 Tailwheel

HAN318520 Hinges (4)

HAN318521 Airbrake Covers (2)

HAN318522 Wing Retainers (2)

REPLACEMENT PARTS

Part # Description

CSE010009700 Talon 90 Heli ESC 010-0097-00

EFLM4060B Power 60 BLOutrunner Mtr, 470Kv

EFLP16080FA Spinner, 45mm: ASW 20 4.7m

HAN495512 Prop 16 x 10: ASW 20 4.7m

KXSB40006S40 F-Tek 4000mAh 6S 40C, EC5, LED

DLMBD38 Liquid Gravity; Weight System

SPMSA7040 A7040 HV Retract Servo

SPMA3005 Heavy-Duty Servo Extension 24-inch

SPMA3004 Heavy-Duty Servo Extension 18-inch

SPMA3006 Heavy-Duty Servo Extension 36-inch

SPMA3007 Heavy-Duty Servo Extension 48-inch

SPMA3054 Servo Connector Clips (25)

SPMAR12310T AR12310T 12CH PowerSafe Tele RX

SPMB4000LPRX 4000mAh 2S 7.4V LiPo Rx Battery

SPMSA5060 A5060 H-T / H-S Mini Metal HV Servo

SPMSA7050 A7050 HV Thin Wing Hi Torq MG

SPMVR5203 VR5203 Dual Output Regulator

Part # Description

SPMA3008 Heavy-Duty Y-Harness 6 inch

SPMAS3000 AS3000 AS3X Stabilization Module

TAM85013 Spray Lacquer TS-13 Clear

TAM86024 PS-24 Fluor Org 100ml Spray Can

TAM87044 Primer White 180ml

RECOMMENDED PARTS

OPTIONAL PARTS

Page 23

23

DE

ASH 31 6,4M ARF

HINWEIS

Alle Anweisungen, Garantien und anderen zugehörigen Dokumente können im eigenen Ermessen von Horizon Hobby,

LLC. jederzeit geändert werden Die aktuelle Produktliteratur finden Sie auf horizonhobby.com unter der Registerkarte

„Support“ für das betreffende Produkt.

NICHT GEEIGNET FÜR KINDER UNTER 14 JAHREN. DIES IST KEIN SPIELZEUG.

WARNUNGEN UND SICHERHEITS-VORKEHRUNGEN

Bitte lesen und befolgen Sie alle Anweisungen und Sicherheitsvorkehrungen vor dem Gebrauch. Falscher, nicht

sachgemäßer Gebrauch kann Feuer, ernsthafte Verletzungen und Sachbeschädigungen zur Folge haben.

Komponenten

Verwenden Sie mit dem Produkt nur kompatible Komponenten. Sollten Fragen zur Kompatibilität auftreten, lesen Sie

bitte die Produkt- oder Bedienungsanweisung oder kontaktieren den Service von Horizon Hobby.

Fliegen

Fliegen Sie um Sicherheit garantieren zu können, nur in weiten offenen Gegenden. Wir empfehlen hier den Betrieb auf

zugelassenen Modellflugplätzen. Bitte beachten Sie lokale Vorschriften und Gesetze, bevor Sie einen Platz zum Fliegen

wählen.

SPEZIELLE BEDEUTUNGEN

Die folgenden Begriffe werden in der gesamten Produktliteratur verwendet, um auf unterschiedlich hohe

Gefahrenrisiken beim Betrieb dieses Produkts hinzuweisen:

WARNUNG: Wenn diese Verfahren nicht korrekt befolgt werden, ergeben sich wahrscheinlich Sachschäden,

Kollateralschäden und schwere Verletzungen ODER mit hoher Wahrscheinlichkeit oberflächliche Verletzungen.

ACHTUNG: Wenn diese Verfahren nicht korrekt befolgt werden, ergeben sich wahrscheinlich Sachschäden UND die

Gefahr von schweren Verletzungen.

HINWEIS: Wenn diese Verfahren nicht korrekt befolgt werden, können sich möglicherweise Sachschäden UND

geringe oder keine Gefahr von Verletzungen ergeben.

WARNUNG: Lesen Sie die GESAMTE Bedienungsanleitung, um sich vor dem Betrieb mit den Produktfunktionen

vertraut zu machen. Wird das Produkt nicht korrekt betrieben, kann dies zu Schäden am Produkt oder persönlichem

Eigentum führen oder schwere Verletzungen verursachen.

Dies ist ein hochentwickeltes Hobby-Produkt. Es muss mit Vorsicht und gesundem Menschenverstand betrieben

werden und benötigt gewisse mechanische Grundfähigkeiten. Wird dieses Produkt nicht auf eine sichere und

verantwortungsvolle Weise betrieben, kann dies zu Verletzungen oder Schäden am Produkt oder anderen Sachwerten

führen. Dieses Produkt eignet sich nicht für die Verwendung durch Kinder ohne direkte Überwachung eines

Erwachsenen. Verwenden Sie das Produkt nicht mit inkompatiblen Komponenten oder verändern es in jedweder Art

ausserhalb der von Horizon Hobby, LLC vorgegebenen Anweisungen. Diese Bedienungsanleitung enthält Anweisungen

für Sicherheit, Betrieb und Wartung. Es ist unbedingt notwendig, vor Zusammenbau, Einrichtung oder Verwendung

alle Anweisungen und Warnhinweise im Handbuch zu lesen und zu befolgen, damit es bestimmungsgemäß betrieben

werden kann und Schäden oder schwere Verletzungen vermieden werden.

Propeller

Halten Sie lose Gegenstände die sich im Propeller verfangen können weg vom Propeller. Dieses gilt auch für Kleidung

oder andere Objekte wie zum Beispiel Stifte oder Schraubendreher.

Halten Sie ihre Hände weg vom Propeller, es besteht akute Verletzungsgefahr.

Akkus

Folgen Sie immer den Herstelleranweisungen bei dem Gebrauch oder Entsorgung von Akkus. Falsche Behandlung von

LiPo Akkus kann zu Feuer mit Körperverletzungen und Sachbeschädigung führen.

Kleinteile

Dieser Baukasten beinhaltet Kleinteile und darf nicht unbeobachtet in der Nähe von Kindern gelassen werden, da die

Teile verschluckt werden könnten mit ernsthaften Verletzung zur Folge.

EMPFEHLUNGEN ZUM SICHEREN BETRIEB

• Überprüfen Sie zur Flugtauglichkeit ihr Modell vor jedem Flug.

• Beachten Sie andere Piloten deren Sendefrequenzen ihre Frequenz stören könnte.

• Begegnen Sie anderen Piloten in ihrem Fluggebiet immer höflich und respektvoll.

• Wählen Sie ein Fluggebiet, dass frei von Hindernissen und groß genug ist.

• Stellen Sie vor dem Start sicher, dass die Fläche frei von Freunden und Zuschauern ist.

• Beobachten Sie den Luftraum und andere Flugzeuge/Objekte die ihren Flugweg kreuzen und zu einem Konflikt

führen könnten.

• Planen Sie sorgfältig ihren Flugweg vor dem Start.

VOR DEM ZUSAMMENBAU

• Entnehmen Sie zur Überprüfung jedes Teil der Verpackung.

• Überprüfen Sie den Rumpf, Tragflächen, Seiten- und Höhenruder auf Beschädigung.

• Sollten Sie beschädigte oder fehlende Teile feststellen, kontaktieren Sie bitte den Verkäufer.

• Laden des Senders und Empfängers.

• Zentrieren der Trimmungen und Sticks auf dem Sender.

• Sollten Sie einen Computersender verwenden, resetten Sie einen Speicherplatz und benennen ihn nach dem Modell.

• Sender und Empfänger jetzt nach den Bindeanweisung des Herstellers zu binden.

HINWEIS: Das Funksystem nach dem Einstellen der Ruderausschläge erneut binden. Damit wird verhindert, dass

sich die Servos auf ihre Endpunkte bewegen, ehe Sender und Empfänger verbunden sind. Außerdem wird garantiert,

dass die Servo-Umkehreinstellungen im Funksystem gespeichert werden.

Page 24

24

DE

SPEZIFIKATIONEN BAUTEILE (OHNE KLEINTEILE)

252 in (6.4m)

1920 sq in (123.87 dm2)

88 in (2.2m)

26 lbs (11.8 kg)

6Kanäle (oder mehr) mit 7Servos

Hinweis .................................................................................................................................................................23

Spezielle Bedeutungen ..........................................................................................................................................23

Vor dem Zusammenbau .........................................................................................................................................23

Spezifikationen ......................................................................................................................................................24

Bauteile (Ohne Kleinteile) .......................................................................................................................................24

Zur Fertigstellung erforderlich ................................................................................................................................25

Optionale Teile .......................................................................................................................................................25

Zusätzliche Teile erforderlich ..................................................................................................................................25

Werkzeuge erforderlich ..........................................................................................................................................25

Vorsichtsmaßnahmen beim Zusammenbau ............................................................................................................26

Transport und Lagerung .........................................................................................................................................26

Pflege der Fluoreszenzfarbe ...................................................................................................................................26

Außentragflächen ..................................................................................................................................................26

Innentragflächen ....................................................................................................................................................28

Montage des Winglets ............................................................................................................................................ 31

Montage des Seitenruders .....................................................................................................................................31

Montage des Höhenruders .....................................................................................................................................33

Montage der Schleppkupplung ..............................................................................................................................34

Montage des Funkgeräts .......................................................................................................................................34

Montage des Cockpits ...........................................................................................................................................35

Montage des optionalen Elektroantriebssystems ....................................................................................................35

Abschließende Montage .........................................................................................................................................38

Ausbalancieren des Flugzeugs ...............................................................................................................................39

Ruderausschlag .....................................................................................................................................................40

Vorflugkontrolle .....................................................................................................................................................40

Täglicher Flug Check ............................................................................................................................................40

Garantie Und Service Informationen .......................................................................................................................40

Garantie und Service Kontaktinformationen............................................................................................................41

Rechtliche Informationen für die Europäische Union ...............................................................................................41

Anweisungen zur Entsorgung von Elektro- und Elektronik-Altgeräten für Benutzer in der Europäischen Union ........41

Ersatzeile ...............................................................................................................................................................42

Zur Fertigstellung erforderlich ................................................................................................................................42

Optionale Teile .......................................................................................................................................................42

INHALTSVERZEICHNIS

Page 25

25

DE

ASH 31 6,4M ARF

ZUR FERTIGSTELLUNG ERFORDERLICH ZUSÄTZLICHE TEILE ERFORDERLICH

WERKZEUGE ERFORDERLICH

Erforderliche

Anz.

Teile-Nr. Beschreibung

1 SPMAR12310T AR12310T PowerSafe Tele RX mit 12 Kanälen

4 SPMSA5060 A5060 H-T/H-S HV-Mini-Metall-Servo

2 SPMSA7050 A7050 HV dünne Tragfläche MG hoher Drehzahl

3 SPMA3003 Servokabelverlängerung 300 mm

8 SPMA3004 Servokabelverlängerung 460 mm

5 SPMA3005 Servokabelverlängerung 600 mm

4 SPMA3007 Servokabelverlängerung 1200 mm

1 SPMA3008 Heavy Duty Y-Kabelbaum, 150 mm

2 SPMB4000LPRX LiPo-Empfängerakku (7,4 V / 4000 mAh)

1 SPMA3054 Servosteckerklemmen (25)

1 SPMVR5203 VR5203 dualer Leistungsregler

Beschreibung

Sender mit 6Kanälen

LiPo-Ladegerät

Alle Versionen

Antriebslose Version für Schleppstart

Elektrisch angetriebene Version

Erforderliche

Anz.

Teile-Nr. Beschreibung

1 SPMSA7040 A7040 HV Einfahr-Servo

DLMBD38 Liquid Gravity-Ballastkugeln; Gewichtssystem

Erforderliche

Anz.

Teile-Nr. Beschreibung

1 CSE010009700 Talon 90 A 25 V bürstenloser Geschwindigkeitsregler mit 20 A BEC

1 EFLM4060B Bürstenloser Außenläufer-Motor Leistung 60, 470Kv

1 EFLP16080FA Spinner, 45mm: ASW 20 4,7m

1 HAN495512 Propeller 16 x 10: ASW 20 4,7m

1 KXSB40006S40 F-Tek 4000mA 6S 40C, EC5, LED

Beschreibung

Balancierständer

Ringschlüssel: 17mm

Klemmen

klares Klebeband

Crimpzange

Cyanacrylat-(CA-)Klebstoff, dünn und mittel

Bohrer mit verschieden großen Aufsätzen

Epoxid

Pinsel

Faserstift

Isopropyl Alkohol

Klemme

Hex drivers, metric, various sizes

Hobbymesser mit # 11 Klinge

Langes Kunststoff-Gestänge

Klebeband mit geringer Klebekraft

Schleifpapier mittel

Metrisches Lineal

Mikroballons

Mischbecher und Rührstäbchen

Papiertücher

Stift

Phillips Schraubendreher: #1,#2

Handbohrer

Zange

Rotationswerkzeug mit Schneidscheibe, Schleifband, Hartmetallschneide, Schleifstein

Lötkolben und Lot

Schnur