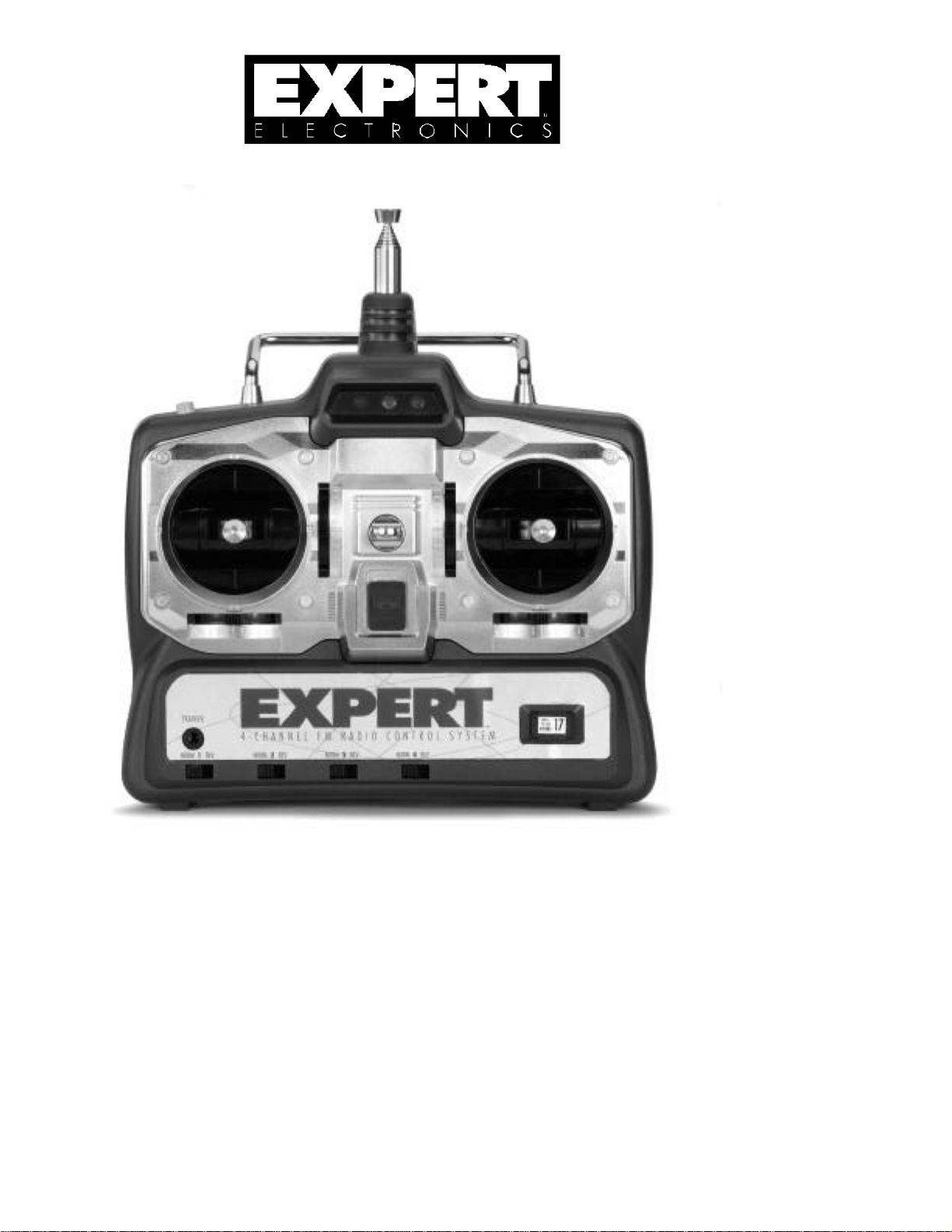

E X P E RT

4-Channel Radio System

I n s t ruction Manual

2

EXPERT Manual

INTRODUCTION TO THE EXPERT RADIO SYSTEM

Thank you for purchasing the EXPERT 4-Channel Radio System.

This unit has been designed to provide the modeler with a user

friendly radio system that can be depended upon for years to

come.

TABLE OF CONTENTS

Introduction to the EXPERT Radio System . . . . . . . 3

1. System Specifications . . . . . . . . . . . . . . . . . . . . 4

2. EXPERT Transmitter

2.1 Transmitter Features/Specifications . . . . . . . . . . 4

2.2 Transmitter Layout. . . . . . . . . . . . . . . . . . . . . . 5

2.3 Control Stick Length Adjustment. . . . . . . . . . . . . 6

2.4 Neck Strap Attachment. . . . . . . . . . . . . . . . . . . 6

3. RF600 Receiver

3.1 Receiver Features/Specifications . . . . . . . . . . . . 6

3.2 Receiver Layout. . . . . . . . . . . . . . . . . . . . . . . . 6

4. SL500 Servo

4.1 Servo Features Specifications. . . . . . . . . . . . . . . 7

5. Airborne (Receiver) Battery Pack . . . . . . . . . . . 7

6. Charger Specifications. . . . . . . . . . . . . . . . . . . . . 8

7. Charging Your EXPERT Radio System

Prior to Installation

7.1 Battery Charger. . . . . . . . . . . . . . . . . . . . . . . . 8

It is important that you carefully read this manual before

attempting to operate your EXPERT System. Please pay

particular attention to Section 8, Charging Your EXPERT Radio

System Prior to Installing.

8. Pre-Installation System Preparation

8.1 Flight Pack Connections. . . . . . . . . . . . . . . . . . . 9

8.2 SL500 Servo Preparation . . . . . . . . . . . . . . . . . 9

8.3 Transmitter Preparation . . . . . . . . . . . . . . . . . 10

8.4 System Check. . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Flight Pack Installation

9.1 Installation Suggestions. . . . . . . . . . . . . . . . . . 11

9.2 Servo Reversing/Setting Reversing Switches . . . 12

9.3 Adjusting Control Surface Travel. . . . . . . . . . . . 13

10. Pre-Flight Information

10.1 EXPERT Trainer System . . . . . . . . . . . . . . . . . 14

10.2 Operating the Trainer System . . . . . . . . . . . . 14

10.3 Range Testing Your Model . . . . . . . . . . . . . . 14

General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Daily Flight Checks . . . . . . . . . . . . . . . . . . . . . . . . . 15

Warranty and Service Information

Warranty Coverage . . . . . . . . . . . . . . . . . . . . . . . 16

Repair Service Instructions . . . . . . . . . . . . . . . . . . 16

Frequency Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EXPERT Manual

3

1. SYSTEM SPECIFICAT I O N S

System Name EXPERT

Receiver RF600

Airborne Battery 4.8V 600mAh

Servos 4 – SL500

2. EXPERT TRANSMITTER

2.1

TRANSMITTER FEAT U R E S / S P E C I F I C AT I O N S

• Computer-designed, ergonomically styled case

• Servo reversing on all four channels (page 12)

• Adjustable control stick length (page 6)

• Trainer system feature compatible with Expert and JR

radio systems

Accessories Mini Switch

Servo Accessories

12" Aileron Extension

Instruction Manual

Charger

• Easy-to-read transmitter battery voltage LED readout

• 9.6V 600mAh transmitter Ni-Cad battery pack

• Power output approximately 500mw

TRANSMITTER SPECIFICAT I O N S

Encoder 4-Channel Analog System

RF 72 MHz

Modulation PPM (FM)

Output Power Approximately 500mw

Current Drain 150mAh

Power Source 1.2V x 8 Ni-Cad (9.6V 600mAh)

Output Pulse 1.0 –2.0ms

4

EXPERT Manual

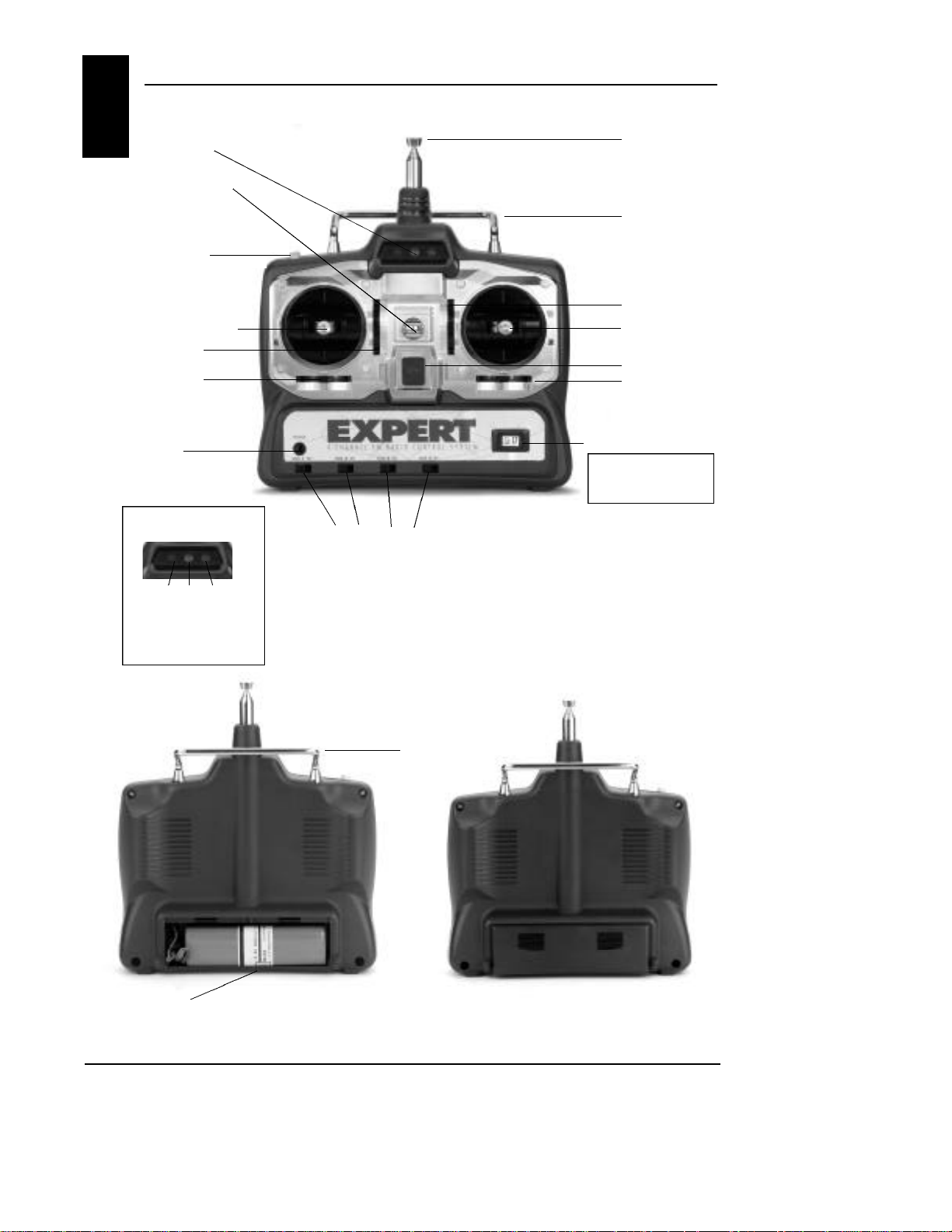

2.2

TRANSMITTER LAY O U T

Transmitter Battery

Voltage LED

Neck Strap Attachment

Trainer Button

Throttle/Rudder Stick

Throttle Trim

Rudder Trim

Trainer Cord Jack

(Cord not included,

order EXRA400.)

IMPORTANT

Transmiter Battery Voltage LED Indicator

Transmitter Antenna

Carrying Bar

Elevator Trim

Elevator/Aileron Stick

Power Switch

Aileron Trim

Transmitter Crystal

JR brand replacement crystals

recommended order JRPXF**

Replace ** with channel number

Servo Reversing Switches

Low Mid Full

Red Orange Green

Low: Do not fly

Mid: System should be recharged

Full: System ok to fly

9.6V 600mAh

Ni-Cad Transmitter Battery Pack

Carrying Bar

EXPERT Manual

5

2.3

CONTROL STICK LENGTH ADJUSTMENT

To adjust the control stick length, use a 2mm Allen wrench to unlock

the set screw located inside the end of the control stick. Turn the set

screw counterclockwise to loosen it, then turn the knurled portion of the

stick to adjust the length. Counterclockwise will lengthen the stick and

clockwise will shorten it. After the control stick(s) has been adjusted to

suit your flying style, tighten the set screw.

2.4

NECK STRAP AT TA C H M E N T

There is an eye hook on the front of the transmitter for attaching an

optional neck strap. The eye hook is precisely positioned (see Section

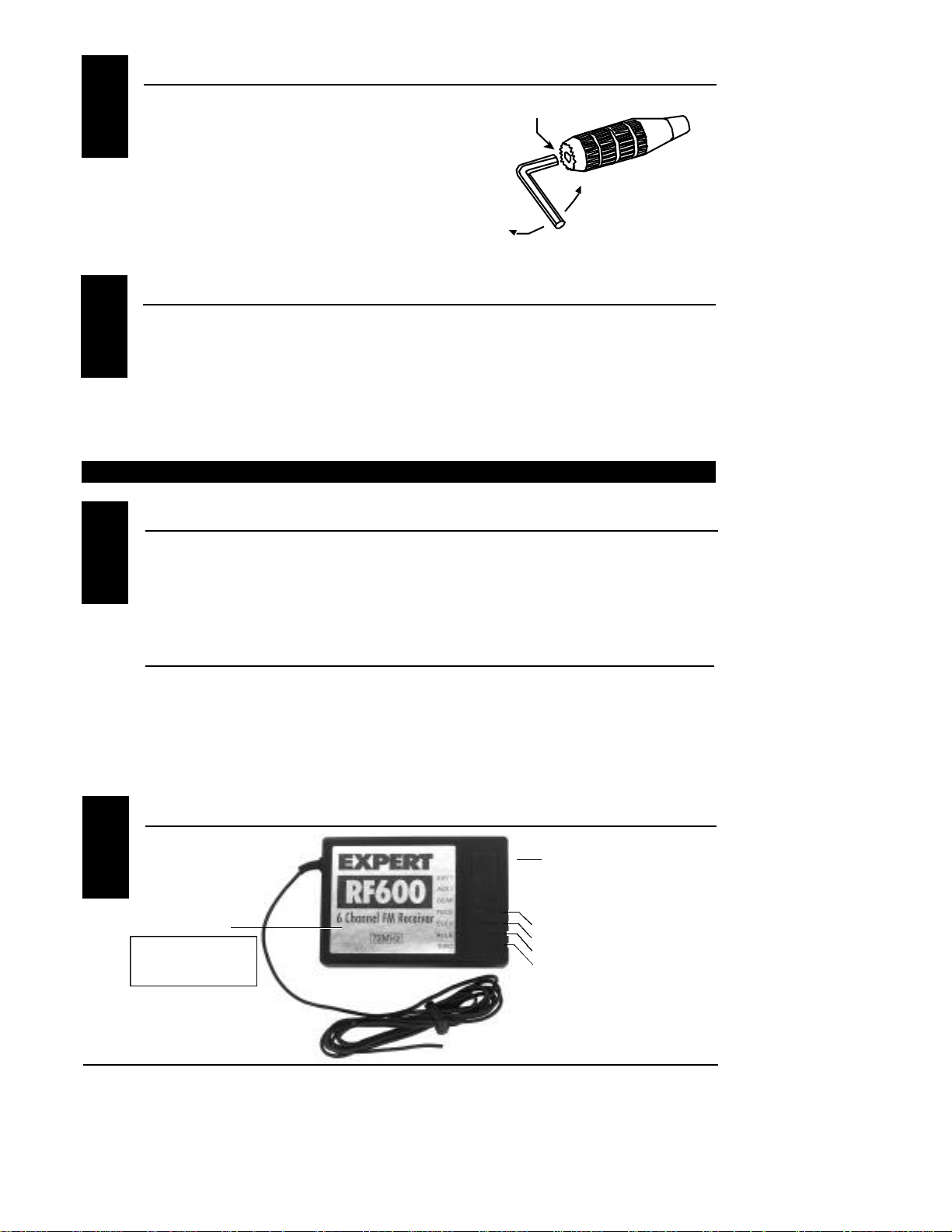

3. RF600 RECEIVER

3.1

RECEIVER FEAT U R E S / S P E C I F I C AT I O N S

• Patented noise rejection system for excellent interference

protection

Set Screw

SET SCREW

LOOSEN

Loosen

TIGHTEN

Tighten

3.2) so that the transmitter will be perfectly balanced when a neck

strap is used.

• Compact, lightweight design provides easy installation into most

model designs

• State-of-the-art surface mount technology (SMT) design

6

RECEIVER SPECIFICAT I O N S

Model Number RF600

Type 6-Channel FM

Frequency 72 MHz

Sensitivity

3.2

RECEIVER LAY O U T

Receiver Frequency Crystal

JR brand replacement crystals

recommended order JRPXF**

Replace ** with channel number

(Microseconds

)

5µs Minimum

RF600 Receiver

Selectivity 8KHz/50db

Weight (oz.) 1 oz.

Size (W x L x H) 1.43" x 2.06" x .55"

Receiver Antenna 39" for all Aircraft Frequencies

Battery (Switch Harness)

Rudder

Elevator

Aileron

Throttle (Engine)

Antenna

EXPERT Manual

4. SL500 SERV O

4.1

S E RVO FEAT U R E S / S P E I C I F I C AT I O N S

• Low current drain

• An indirect drive feedback potentiometer gives additional

protection from vibration

SL500 SERVO SPECIFICAT I O N S

Torque (oz/in) 43

Speed(sec./60°) .25

Weight (oz.) 1.47

5. AIRBORNE (RECEIVER) BAT T E RY PA C K

Type 4.8V, 600mAh

Voltage 1.2V x 4 Ni-Cad (4.8V 600mAh)

• State-of-the-art surface mount technology (SMT)

• The SL500 features a 3-pole ferrite cored motor for reliability

Size (WxLxH) 0.73" x 1.52" x 1.32"

Motor 3-Pole Ferrite

Size (WxLxH) 2.24" x .59" x 2.05"

Weight(oz.) 3.3

6. CHARGER SPECIFICAT I O N S

Input Voltage AC 100-120V

Output Current 50mAh Transmitter/

50mAh Receiver

EXPERT Manual

Charging Time 15 Hours

7

7. CHARGING YOUR EXPERT RADIO SYSTEM PRIOR TO INSTA L L AT I O N

Your EXPERT Radio System is shipped from the factory with both the

transmitter and receiver NiCad batteries in a discharged state. Before

attempting to install/operate your EXPERT system, it is important that

Under normal conditions, subsequent recharging of your EXPERT system

will require only an overnight charge (approximately 16 hours) to

attain peak charge capacity.

the system be charged for approximately 24 hours to ensure that both

transmitter and receiver packs are at peak capacity.

The charger supplied with this system is designed to recharge your

transmitter and receiver battery packs at a rate of 50mAh.

Special note on EXPERT transmitter charge polarity:

The center pin of the charge receptacle on this radio system is Negative

polarity. Therefore, the center pin is negative, not positive. Your radio

system’s charge polarity is reversed from many other manufacturers

chargers. Beware of improper polarity connections based on “color

code” wire leads as they DO NOT APPLY in this instance.

You must always be certain that the center pin on any charger used

with this system is wired for negative polarity, otherwise damage will

occur to the charge circuit of the EXPERT. The Expert warranty does not

cover any system that is damaged by reverse polarity charging.

Right Side of Transmitter

Charging Jack

Center Pin

Is Negative

Outside Is Positive

Charger Pigtail For Transmitter

Black To Positive

Red To Negative

7.1

B AT T E RY CHARGER

The pilot lamps on the battery charger should always be on during the

charging operation. If they are not, check to make sure you have

turned off both the transmitter and receiver.

Do not use the charger for equipment other than this system. The

charging plug polarity may not be the same and equipment damage

may result. Do not use other manufacturers’ after-market accessories

that plug into the transmitter’s charging jack. If you do, any damage

that results will not be covered by the warranty. If you are unsure of

compatibilities with your radio, seek expert advice before doing anything to avoid possible damage. During the charging operation, the

charger’s temperature is slightly elevated. This is normal.

Charger Pigtail For Receiver

Red-Positive/Black-Negative/Grey-Signal

8

EXPERT Manual

8. PRE-INSTA L L ATION SYSTEM PREPA R AT I O N

8.1

FLIGHT PACK CONNECTIONS

Connect all flight pack components of your EXPERT system as outlined in the diagram below:

Connect to Charger for

Charging

RF600 Receiver

Receiver Battery

4.8V 600ma

On/Off Switch Harness

(EXRA050)

Not Used With

4-Channel System

Not Used With

4-Channel System

Elevator

Rudder

Aileron

Note: On some types

of 2 and 3 channel

aircraft, the rudder

servo is plugged

in here.

8.2

SL500 SERVO PREPA R AT I O N

Using a Phillips screwdriver, remove the servo arm retaining screws from each of the SL500 servos as shown in Figure 1.

Next, install 4 servo grommets and 4 servo eyelets to each SL500 servo as shown in Figure 2.

Servo Mounting Flange

Rubber Grommet

Servo Eyelet

EXPERT Manual

Antenna

Throttle

Servo Arm Retaining

Screw (Phillips Head).

Figure 1

Servo Arm Retaining Screw

Servo Arm/Horn

Servo Output Shaft

Servo Case

Servo Lead w/Connector

Figure 2

9

8.3

TRANSMITTER PREPA R AT I O N

Adjust each of the 4 trim levers (aileron, elevator, rudder, and throttle) to the center position.

8.4

Gimble

SYSTEM CHECK

Slide the power on/off switch on your EXPERT Transmitter to the

“on” position.

Next, slide the on/off switch on your flight pack switch harness to the

“on” position.

Throttle

Rudder

Rudder

By moving each of the two transmitter sticks in a fore-aft, left-right

motion, the corresponding throttle, rudder, elevator, and aileron

(optional) servo arm/wheel will rotate. Please refer to the transmitter

stick function chart below for clarification.

Aileron

(w/optional servo)

Gimble

Elevator

Aileron

(w/optional servo)

1 0

Throttle

With the system still activated (on), move the throttle stick to the

neutral (center) position. Double check to be sure that the four

doing this, the SL500 servos will be left in their neutral position, and

they are now ready to be installed into your model.

transmitter trim levers are still in their neutral position.

NOTE: Save the servo arms/horns; they will be reattached to the

Next, with the power still activated to the transmitter and flight pack,

remove the servo arm/horn from each of the SL500 servos, and then

turn the power “off” to the flight pack first, then the transmitter. By

Elevator

servos after installation.

EXPERT Manual

9. FLIGHT PACK INSTA L L AT I O N

Flight pack installation varies greatly from one model to another. For

your convenience, we have included the photograph below outlining a

Fuselage Servo, Receiver, Battery Installation

9.1

I N S TA L L ATION SUGGESTIONS

It is important to correctly install the radio system in your model.

Please read and carefully follow the suggestions listed below:

1. For added protection, wrap the receiver and the receiver NiCad in

foam rubber that is at least 1/4" thick.

2. Run the receiver antenna through the fuselage and make sure it is

fully extended. Never cut or bundle your receiver antenna —

this will decrease range and performance.

3. Rubber servo grommets are included with your radio system and

should be installed in the servo flanges. The servos should then be

mounted on either hardwood rails or a plywood tray with the

mounting screws provided. Do not overtighten the mounting screws.

The flange of the brass eyelets should face down (toward the

wood). See Section 9.3.

typical flight pack installation in a standard 4-channel trainer type

model airplane.

Aileron (Wing) Servo Installation

4. With the servo at neutral, install the required servo arm/horn

exactly 90 degrees to the servo case as shown in the diagram

below.

5. Before installing the servo output arms, make sure the servo is in

its neutral position.

6. All servos must be able to move freely over the full range of their

travel. Make sure the linkages do not impede servo travel. A stalled

servo will drain the battery pack within a few minutes.

7. In the case of gas-powered model aircraft, mount the receiver

power switch on the side of the fuselage opposite the muffler to

protect the switch from exhaust residue. With other types of models,

mount the switch in the most convenient place. Make sure the

switch operates freely and is capable of traveling its full distance.

EXPERT Manual

Control Rod

Servo Horn

90° with Servo at

Neutral/Center Position

1 1

9.2

S E RVO REVERSING/SETTING REVERSING SWITCHES

After radio installation, it is imperative that the proper servo/control

system direction be established. Servo reversing allows you to alter the

of the transmitter stick. Please refer to the chart in the following section

below to determine the proper control surface direction.

direction of the servo/control surface movement to match the direction

1. Connect all control linkages and check to see that all servos

move freely.

2. While standing directly behind the airplane, go through the steps

3. Using the Servo Reversing Switches located on the front of the

transmitter, adjust the direction of each servo as necessary for

proper operation.

shown in the charts below to check proper direction of the

control surface.

Full Throttle

Full Throttle Down Elevator

Left

Left

Rudder

Rudder

Right

Right

Rudder

Rudder

Left

Left

Aileron

Aileron

Down Elevator

Right

Right

Aileron

Aileron

Up Elevator

Elevator

Idle

Idle

RudderElevatorAileronThrottle

Servo Reversing Switches

High (Full)

Aileron Down

Carburetor

Low (Idle)

1/16"

Throttle Right Aileron

Up Elevator

Up Elevator

Aileron Up

Rudder

Right Rudder

1 2

EXPERT Manual

9.3

ADJUSTING CONTROL SURFACE TRAV E L

Servo Arm

The final step in your flight pack installation will be to determine the

amount each control surface will move on your model at full transmitter stick deflection. Please refer to your aircraft’s instruction manual

for suggested travel limits.

It is possible to increase/decrease the amount that your control surface

moves at full stick deflection by mechanical adjustments.

more quickly from your flight pack battery, thereby reducing your

usable flying time. Fortunately, servo “stalling” is usually easy to

detect by either a “buzzing” or “humming” sound which comes from

the stalled servo.

The following diagram is designed to help clarify how to increase or

decrease control surface travel mechanically to eliminate control sur-

face “binding” and servo “stalling”.

It is imperative that the servo does not attempt to push/pull the control surface past its mechanical limits. This condition is called “binding.”

When a servo moves a control surface into a “binding” position, the

servo itself then becomes “stalled,” unable to reach its full deflection.

This condition is both harmful to your control linkage and to your

servo. This “stalled” condition will also force the servo to drain power

Figure 1 Normal (Linear)

Linkage Set Up

Control Rod

Control Surface Arm

(Horn)

Figure 2 Increased Control

Surface Movement

Control Rod

Servo Arm Servo Arm

Control Surface Arm

(Horn)

Figure 3 Reduced Control

Surface Movement

Control Rod

Control Surface Arm

(Horn)

To increase control surface travel, select a linkage attachment point further outward on the servo arm or further inward on the control horn

closer to the control surface (Figure 2).

To reduce control surface travel, select the linkage attachment point

close to the center of the servo area or further out on the control horn

on the control surface (Figure 3).

Quite simply, by moving the control rod in on the servo arm/wheel,

control surface travel will be reduced, and by moving the control rod

out on the servo arm, the control surface travel will be increased. The

opposite holds true for the control surface arm (horn) as well. You may

EXPERT Manual

also use any combination of these positions to achieve proper control

surface/servo travel.

NOTE:Once the appropriate servo arm/wheel and control rod location

has been established, be certain that you have secured the

servo arm to the servo output shaft using the original servo

horn screw.

1 3

10. PRE-FLIGHT INFORMAT I O N

10.1

10.2

E X P E RT TRAINER SYSTEM

The EXPERT features a built-in trainer system. The transmitter can be

used as either a master (trainer) or as a slave (trainee). The EXPERT is

compatible with all other current PPM selectable (FM) EXPERT or JR

Trainer Button

Optional

Trainer Cord

(EXRA400)

Master Transmitter

Power Switch On

radios that have built-in trainer systems. An optional trainer cord is

needed (EXRA400).

Trainer Button

O P E R ATING THE TRAINER SYSTEM

Slave Transmitter

Power Switch Off

10.3

1. Match the servo reversing and trims of both radios.

Special Note to Beginners: We strongly suggest that you seek the

2. Plug the optional trainer cord into both transmitters.

3. Turn on the master transmitter.

NOTE: The slave radio must be left off.

4. Test all the control functions on your aircraft with the master radio.

5. Push the trainer button on the master transmitter and check all the

control functions with the slave radio.

RANGE TESTING YOUR MODEL

We suggest that before the initial flight of your model, you first

perform a ground range test to ensure that the transmitting/receiving

abilities of your EXPERT perform properly. Conduct the range test

as follows:

Do not extend the transmitter antenna at this time. Turn your EXPERT

transmitter “on.” Next, turn the model switch “on.” Slowly walk away

from the model while moving the control surfaces. The system should

function properly to a distance of approximately 60-65 feet.

NOTE: If your test falls short of the described range, confirm that your

help of an experienced model airplane

pilot prior to flying your new model.

NiCad batteries are fully charged. If this situation remains

unchanged, please contact the Horizon Service Center (address

and phone number at the back of this manual) before attempting to fly your model.

1 4

EXPERT Manual

GENERAL NOTES

Radio controlled models are a great source of pleasure. Unfortunately,

they can also pose a potential hazard if not maintained and operated

properly. It is imperative that you install your radio control system correctly. Additionally, your level of piloting competency must be high

enough to ensure that you are able to control your aircraft under all

conditions. If you are a newcomer to radio controlled flying, please

seek help from an experience pilot or your local hobby shop.

Listed below are some safety Do’s and Don’ts that must be followed by

all pilots.

• Ensure that your batteries have been properly charged prior to

initial flight.

• Keep track of the time that the system is turned on so that you will

have an idea of how long you can safely operate your system.

• Perform a ground range check prior to the initial flight of the day.

See the “Daily Flight Checks” section for information on how to do so.

• Check all control surfaces prior to each take off.

• Use frequency flags.

• Do not fly your model near spectators, parking areas, or at any other

area that could result in injury to people or damage of property.

• Do not fly during adverse weather conditions. Poor visibility can

cause disorientation and loss of control of your aircraft. Strong winds

can cause similar problems.

• Do not fly unless your frequency is clear.

Warning:Only one transmitter at a time can operate on a given

• Do not point the transmitter antenna directly toward the model.

The radiation pattern from the tip of the antenna is inherently low.

• Do not take chances. If at any time during flight you observe any

erratic or abnormal operation, land immediately, and do not

resume flight until the cause of the problem has been ascertained

and corrected.

frequency. If you turn on your transmitter while someone

else is operating a model on your frequency, both pilots will

lose control of their models. Only one person can use a

given frequency at a time. It does not matter if it is AM, FM

or PCM — only one frequency at a time.

D A I LY FLIGHT CHECKS

1. Check the battery voltage on both the transmitter and the receiver

battery packs. Don’t fly below 9.0 volts on the transmitter (orange

and red lights on only) or below 4.7 volts on the receiver. To do so

can cause a crash of your aircraft.

NOTE: When you check the receiver battery, be sure that you

have polarities correct on your expanded scale

voltmeter (optional).

2. Check all hardware (linkages, screws, nuts, bolts) prior to each

day’s flight. Be sure that binding does not occur, and that everything is properly secured.

3. Ensure that all surfaces are moving in the proper manner.

EXPERT Manual

4. Perform a ground range check before each day’s flying session.

The range check should be as follows:

• Do not extend the transmitter antenna at this time. Turn the

transmitter “on.”

• Turn the model “on.”

• Slowly walk away from the model while moving the control

surfaces. The aircraft should function properly at a distance of

60-75 feet.

5. Ensure that all trim levers are in the proper location.

6. Check to be sure that all servo pigtails and switch harness plugs

are secure in the receiver. Also, make sure that the switch harness

moves completely in both directions.

1 5

WARRANTY AND SERVICE INFORMAT I O N

WARRANTY COVERAGE

Your new equipment is warranted to the original purchaser against manufacturer defects in material and workmanship for 1 year from the date

of purchase. During this period, Horizon Service Center will repair or

replace, at our discretion, any component that is found to be factory

defective at no cost to the purchaser. This warranty is limited to the orig-

inal purchaser of the unit and is not transferable.

This warranty does not apply to any unit which has been improperly

installed, mishandled, abused, or damaged in a crash, or to any unit

R E PAIR SERVICE INSTRUCTIONS

In the event that your equipment needs service, please follow the

instructions listed below:

1. Check all on/off switches to be sure they are off. This will speed the

repair process of checking battery condition.

2. R e t u rn your system components only (transmitter, re c e i v e r,

servos, etc.). Do not return your system installed in a model car,

boat, plane, etc.

3. Use the original carton/packaging (molded foam container), or

equivalent, to ship your unit. Do not use the carton itself as a

shipping carton; you should package the equipment carton within a

sturdy shipping container using additional packing material to safeguard against damage during transit. Include complete name and

a d d ress information inside the carton, as well as writing it

clearly on the outer label/re t u rn address are a . Ship your

equipment fully insured and prepaid. Horizon Service Center is not

responsible for any damages incurred during shipping.

which has been repaired or altered by any unauthorized agencies. Under

no circumstances will the buyer be entitled to consequential or incidental

damages. This limited warranty gives you specific legal rights; you also

have other rights which may vary from state to state.

As with all fine electronic equipment, do not subject your unit to extreme

temperatures, humidity or moisture. Do not leave it in direct sunlight for

long periods of time.

5. Warranty Repairs. To receive warranty service, you must include a

legible photocopy of your original dated sales receipt to verify your

proof-of-purchase date. Providing that warranty conditions have

been met, your radio will be repaired without charge.

6. Normal Non-Warranty Repairs. Should your repair cost exceed 50%

of the retail purchase cost, you will be provided with an estimate

advising you of your options.

Mail your system to:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

(217) 355-9511

1 6

4. Include detailed information explaining your operation of the equipment and problem(s) encountered. Provide an itemized list of equipment enclosed and identify any particular area/function which may

better assist our technicians in addressing your concerns. Date your

c o rrespondence and include your name, mailing address, and

a phone number where you can be reached during the business day. Within your letter, advise us of the payment method you

prefer to use. Horizon Service Center accepts VISA or MasterCard, or

we can return the equipment C.O.D. cash-only. If you prefer to use a

credit card, include your card number and expiration date.

EXPERT Manual

FREQUENCY CHART/REPLACEMENT CRY S TA L S

72 MHz requires no special license to operate.

* It is important that you attach the enclosed frequency ID plates/flag to your EXPERT transmitter antenna.

7 2 M H z 7 2 M H z

CH.NO. FREQUENCY

15 72.090

16 72.110

17 72.130

18 72.150

19 72.170

20 72.190

21 72.210

22 72.230

23 72.250

24 72.270

25 72.290

26 72.310

27 72.330

28 72.350

29 72.370

30 72.390

31 72.410

32 72.430

33 72.450

34 72.470

35 72.490

36 72.510

37 72.530

CH.NO. FREQUENCY

38 72.550

39 72.570

40 72.590

41 72.610

42 72.630

43 72.650

44 72.670

45 72.690

46 72.710

47 72.730

48 72.750

49 72.770

50 72.790

51 72.810

52 72.830

53 72.850

54 72.870

55 72.890

56 72.910

57 72.930

58 72.950

59 72.970

60 72.990

REPLACEMENT CRY S TA L S

Your EXPERT system has been designed to use the standard “JR” type FM crystals. As replacement crystal sets are not available through Expert,

please use JR brand crystals for replacements (part number JRPXF**).

Replace ** with channel number

EXPERT Manual

1 7

1 8

EXPERT Manual

EXPERT Manual

1 9

Distributed exclusively by Horizon Hobby, Inc. Champaign, IL 61822

www.horizonhobby.com

2 0

EXPERT Manual

Loading...

Loading...