AFG Service Seminar

Horizon Fitness

Models

1.0AT, 2.0AT, 2.0AT,

4.0AT, 5.0AT, 13.0AT,

14.0At

Models

2.0AE, 3.0AE, 4.0AE,

14.0AE, 18.0AE

Models

2.0AR, 3.0AR, 4.0AR,

3.0AH, 4.0AH

Models

2.0AS

Table of Contents

>> Table of Contents

Section One Section Two

Warranty

Service and Billing Information

Safety Instructions Resetting the Incline Motor

3

4

-Treadmill 6

-Elliptical | Bike 8

-Gym 10

Recommended Tools

Parts Diagrams

12 -Treadmill 44

-Treadmill 13

-Elliptical 14

-Bike 15

-Gym 16 -Treadmill 48

Maintenance

-Treadmill 17 -Gym 69

>> Lubrication 18

>> Tensioning & Alignment 19

-Elliptical 20

-Bike 21

-Gym 22

Proper Heart Rate Usage

23

Horizon Fitness “5-Step” Diagnostic Process

Wiring Diagrams and Schematics

Adjusting the Magnetic Break

Voltage Checks

Engineering Mode

-Elliptical | Bike 45

Section Three

Troubleshooting

-Elliptical | Bike 61

Known Issues

25

27

30

31

32

71

2 | 2008 AFG Service Seminar [rev 1.3]

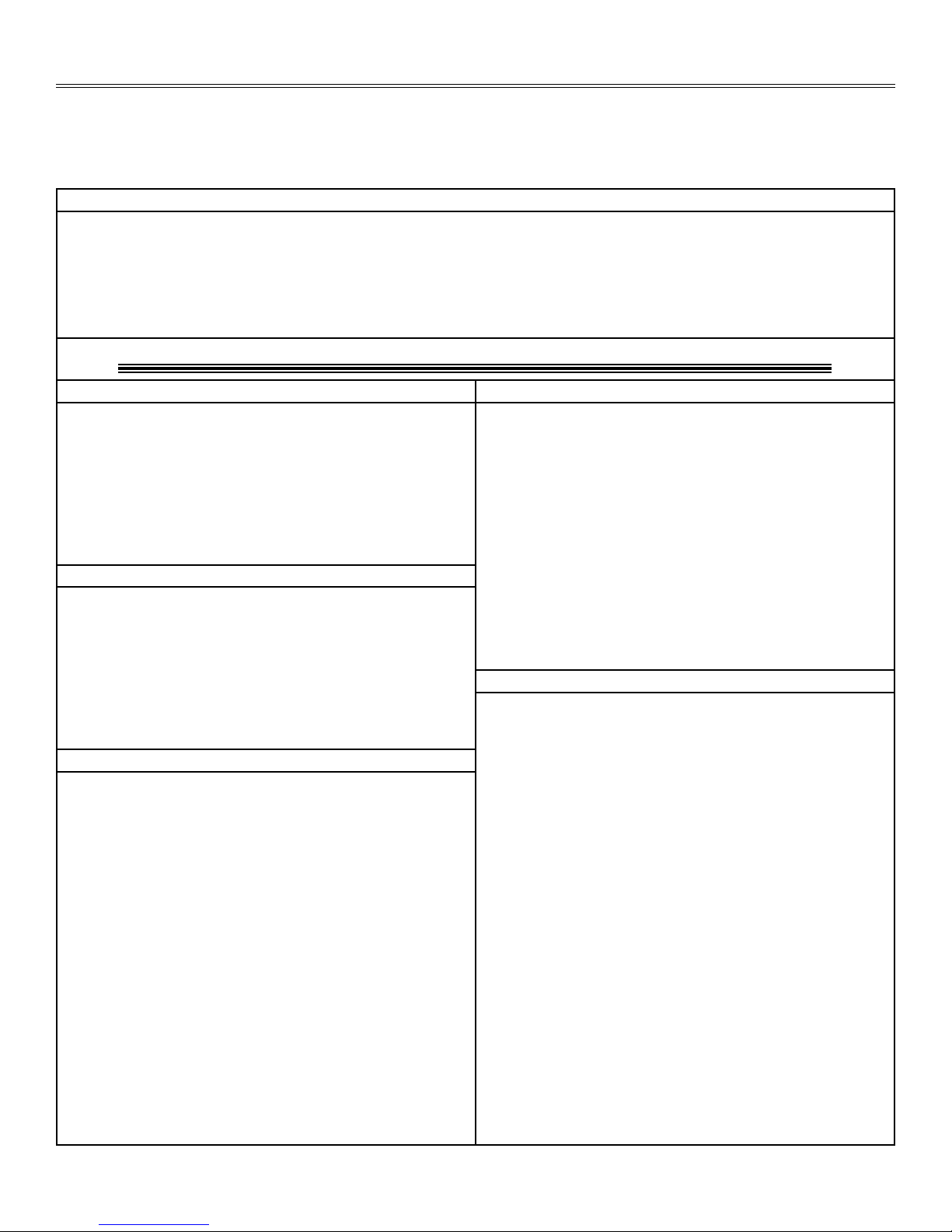

>> Limited Home-Use Warranty

Section One | Warranty Information

AFG extends the following exclusive, limited warranty, which shall apply to the use of the device in the home, for

residential, non-commercial purposes only. Any other use shall void this warranty. AFG hereby offers the following

limited warranties for the following components of the device, for the time period indicated:

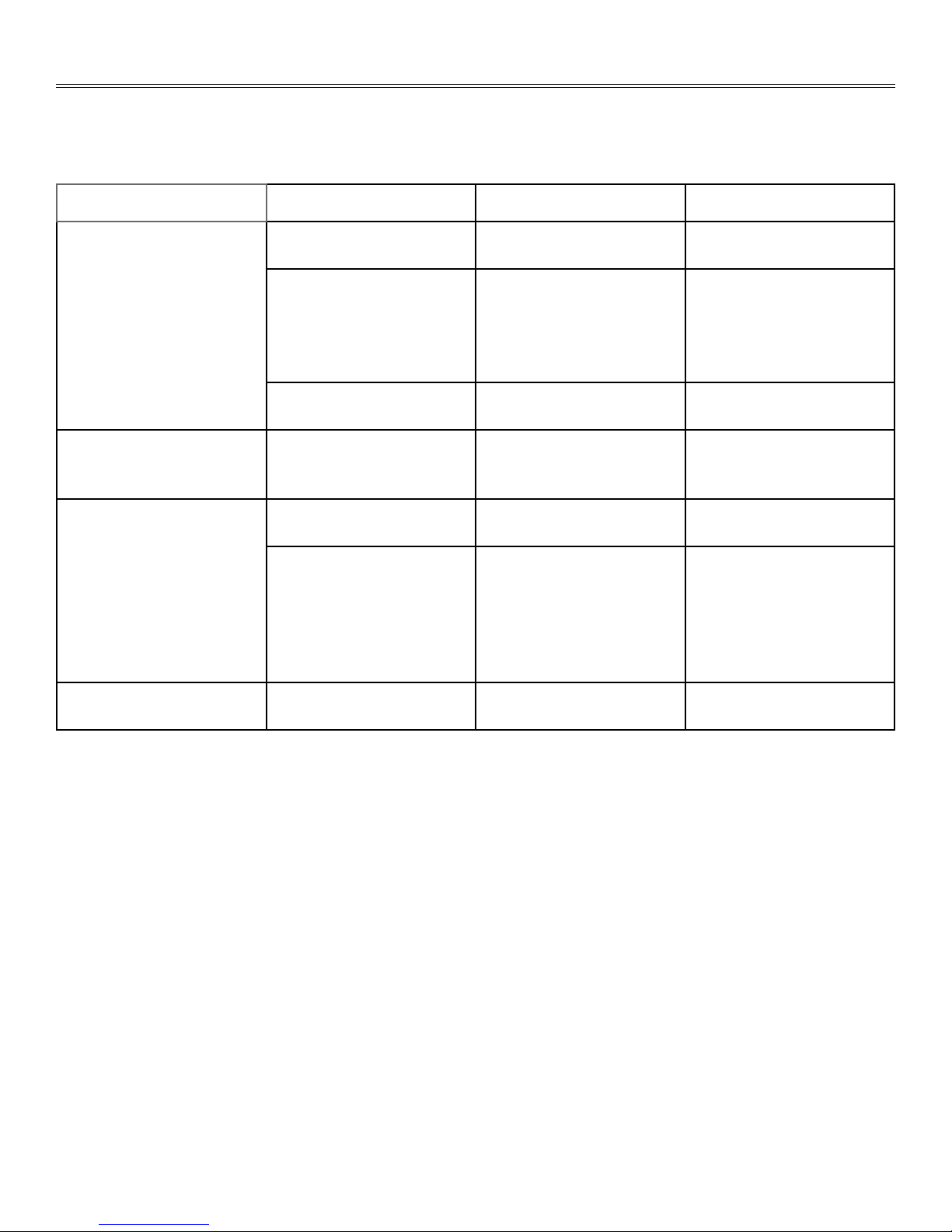

Model Labor Parts Motor Elevation Break Frame

1.0AT 1 Year 3 Years Lifetime Lifetime NA Lifetime

2.0AT 1 Year 3 Years Lifetime Lifetime NA Lifetime

3.0AT 1 Year 3 Years Lifetime Lifetime NA Lifetime

4.0AT 1 Year 3-5 Years Lifetime Lifetime NA Lifetime

5.0AT 1 Year 3-5 Years Lifetime Lifetime NA Lifetime

13.0AT 1 Year 3-5 Years Lifetime Lifetime NA Lifetime

14.0AT 1 Year 3-5 Years Lifetime Lifetime NA Lifetime

2.0AE 1 Year 2 Years NA NA Lifetime Lifetime

3.0AE 1 Year 2 Years NA NA Lifetime Lifetime

4.0AE 1 Year 3 Years NA 2 Years Lifetime Lifetime

14.0AE 1 Year 3 Years NA NA Lifetime Lifetime

18.0AE 1 Year 3 Years NA 2 Years Lifetime Lifetime

2.0AR 1 Year 3 Years NA NA Lifetime Lifetime

3.0AR 1 Year 3 Years NA NA Lifetime Lifetime

4.0AR 1 Year 3-5 Years NA NA Lifetime Lifetime

3.0AH 1 Year 3-5 Years NA NA Lifetime Lifetime

4.0AH 1 Year 3-5 Years NA NA Lifetime Lifetime

2.0AS 1 Year 10 Years NA NA NA Lifetime

AFG warranties the frame, electronics, and parts against defects in workmanship and materials for the above

warranty periods, so long as it remains in the possession of the original owner.

AFG shall cover the labor cost for the repair of the device for the above warranty periods, so long as the device

remains in the possession of the original owner.

EXCLUSIONS AND LIMITATIONS

This warranty applies only to the original owner and is not transferable. This warranty is expressly limited to the

repair or replacement of a defective frame, electronic component, or defective part. The warranty does not cover

normal wear and tear, improper assembly or maintenance, or installation of parts or accessories not originally

intended or compatible with the Unit as sold. The warranty does not apply to damage or failure due to accident,

abuse, corrosion, discoloration of paint or plastic, or neglect. AFG shall not be responsible for incidental or

consequential damages. All returns must be pre-authorized by AFG. AFG’s obligation under this warranty is

limited to replacing or repairing, at AFG’s option, the product at one of its authorized service centers. An AFG

authorized service center must receive all products for which a warranty claim is made. These products must be

received with all freight and other transportation charges prepaid, accompanied by sufficient proof of purchase.

Parts and electronic components reconditioned to “As New” Condition by AFG or its vendors may

sometimes be supplied as warranty replacement parts and constitute fulfillment of warranty terms. This warranty

gives you specific legal rights, and your rights may vary from state to state.

WARRANTY REGISTRATION

Your warranty card must be completed and sent to AFG or register on line at www.advancedfitnessgroup.com,

before a warranty claim can be processed.

2008 AFG Service Seminar [rev 1.3] | 3

Section One | Service and Billing Information

>> Service and Billing Information

AFG IS YOUR TOTAL SOLUTIONS PROVIDER

ServiceBench is a web-based system that will allow you to create parts orders, submit labor credits and

to track the process of each. Know instantly if a part is in stock! Have exploded diagram and parts list at

your disposal to use when it is convenient for you, not just when the Tech Support department is open.

You can access this site at www.servicebench.com. On the Left side of the screen are 3 boxes

(ServiceBench ID, User ID, and Password from top to bottom). The initial User ID is the word User. Your

ServiceBench ID and initial Password are available from Alan at 800-244-4192 ext. 3240 or

alan@horizonfitness.com.

Once logged in, you will need to answer a few one time only questions. You will also be asked for bank

account information. You do not have fill out the bank information, as we will not be sending out

electronic payments, we will continue to credit your account.

After answering these questions, you will go to the Main Menu for ServiceBench. From here the most

useful links will be the Claims Tab and the Dispatch Tab.

Claims Tab – used to track payment.

• Use the Claim Review to track the status of a particular claim number

• From the Claim Inbox you will be able to track the process of the submitted claim and verify

payment.

4 | 2008 AFG Service Seminar [rev 1.3]

Section One | Service and Billing Information

Dispatch Tab – Used to store and locate work orders (Dispatches) from Horizon Fitness.

• If you have a paper copy of the customer information, click Dispatch (it will be written in white

against dark blue background). Click Dispatch Review, type in the dispatch number and click

Search.

• If you do not have a paper copy of the customer information, click Dispatch (it will be written in white

against dark blue background). Click Dispatch Inbox, this will display all dispatches received in the

past week. If you have already accepted the dispatch, change Received to Accepted by clicking the

down arrow next to Received.

• Location E-mail Maintenance allows you to set e-mail addresses to receive notification when new

dispatches are received. Availability Maintenance allows you to set a number of dispatches that

you can receive on a certain day. This is not a scheduled appointment with a customer, but rather

allows you to adjust for vacation (keep zeroes in availability), or allow for more work orders

(set a maximum number of work orders that can be sent to you for a certain day). It is still up to you to

set an appointment with the customer depending on your schedule.

Business Management Systems - is the link which will allow any business software you currently use

to synchronize with ServiceBench.

If you have any questions please contact Alan with Horizon Fitness at 800-244-4192 ext. 3240 or

ServiceBench phone support at 877-472-3624 for technical assistance.

2008 AFG Service Seminar [rev 1.3] | 5

Section One | Safety Instructions

Safety Instructions

>> Treadmills

WARNING STATEMENTS INDICATE A PARTICULARLY DANGEROUS ACTIVITY.

YOU SHOULD BE EXTREMELY CAUTIOUS WHEN DOING THE FOLLOWING:

• Removing power from the treadmill, or removing the power cord from the wall outlet. Always ensure

that the treadmill is unplugged from the wall outlet when you inspect or adjust the treadmill, or when

you isolate, remove, or replace a treadmill component.

• Removing the motor cover exposes high voltage components and potentially dangerous machinery.

Exercise extreme caution when you perform maintenance procedures with the motor cover removed.

• During service operations you will be very close to moving machinery and high voltage components.

When you perform maintenance procedures with the hood removed, remove jewelry (especially from

ears and neck), tie up long hair, remove neckties, and do not wear loose clothing.

• When the treadmill is operating, the capacitor will hold a lethal amount of charge. Do not touch the

capacitor as serious injury or death might result.

• When the treadmill is turned off and the power cord is removed from the wall outlet, the capacitor will

hold voltage for 30-60 seconds. Allow the capacitor to discharge for a period of one minute before you

touch or work near the capacitor. Do not attempt to discharge the capacitor by any other means.

• Exercise caution when touching any wire or electrical component during treadmill operation.

• When it is necessary to lift the treadmill, ensure that the treadmill has adequate support. Do not lift the

treadmill by the front.

SAFETY GUIDELINES YOU SHOULD KNOW AND FOLLOW INCLUDE:

• Read the owner’s manual and follow all operation instructions.

• Operate the treadmill on a solid, level surface. Locate the rear of the treadmill at least four feet from

walls or furniture. Keep the area behind the treadmill clear.

• Visually check the treadmill before beginning service or maintenance operations. If it is not completely

assembled or is damaged in any way, exercise extreme caution while operating and checking the

treadmill.

• When operating the treadmill, do not wear loose clothing. Do not wear shoes with heels or leather soles.

Check the soles of your shoes and remove any embedded stones. Tie long hair back.

• Use care when getting on or off the treadmill. Use the handrails whenever possible. Do not get on or off

the treadmill when the running belt is moving.

• Before starting the running belt, straddle the belt by placing your feet firmly on the guiderails of the

treadmill. You should also step off the belt and onto the guiderails of the treadmill after turning off the

running belt.

• Do not rock the unit. Do not stand or climb on the handrails, electronic console, or motor cover.

• Do not set anything on the handrails, electronic console, or motor cover. Never place liquids on any part

of the treadmill.

• To prevent electrical shock, keep all electrical components, such as the drive motor, power cord, and

circuit breaker away from water and other liquids.

• Do not use accessory attachments that are not recommended by the manufacturer-such attachments

might cause injuries.

• Turn off the treadmill when adjusting or working near the rear roller. Do not make any adjustments to

the running belt when someone is standing on the machine.

• Keep all loose items away from the treadmill running surface. A treadmill running belt will not stop

immediately if an object becomes caught in the belt or rollers.

6 | 2008 AFG Service Seminar [rev 1.3]

Section One | Safety Instructions

WA RN IN G

WA RN IN G

Connect this unit to a properly grounded, dedicated 20-amp outlet only.

See grounding instructions.

GROUNDING INSTRUCTIONS

This product must be grounded. If a treadmill should malfunction or breakdown, grounding provide

a path of least resistance for electrical current to reduce the risk of electrical shock. This product is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly installed and grounded in accordance with local

codes and ordinances.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. Check with a qualied electrician if you are in doubt as to whether the product is

properlygrounded. Do not modify the plug provided with the product, if it will t in the

outlet; have a proper outlet installed by a qualied electrician.

Grounded Outlet

Grounding Pin

Grounded Outlet Box

SAFETY TIPS

Adapter

Metal Screw

TAS For

Grounding Screw

• Never use the treadmill before securing the safety tether clip to your clothing.

• If you experience chest pains, nausea, dizziness, or shortness of breath, stop exercising

immediately and consult your physician before continuing.

• Do not wear clothes that might catch on any part of the treadmill.

• Keep power cord away from heated surfaces.

• Keep children off of treadmill at all times.

• Do not use treadmill outdoors.

• Unplug treadmill before moving it.

• Do not remove the treadmill motor cover or roller covers.

• Treadmill should be plugged into a dedicated 20 amp circuit for optimal performance.

2008 AFG Service Seminar [rev 1.3] | 7

Section One | Safety Instructions

WA RN IN G

Safety Instructions

>> Ellipticals/Bikes

SAVE THESE INSTRUCTIONS

Read all instructions before using this Elliptical/Bike. When using an electrical product, basic

precautions should always be followed, including the following: Read all instructions before using this

Elliptical/Bike. It is the responsibility of the owner to ensure that all users of this Elliptical/Bike are

adequately informed of all warnings and precautions. If you have any questions after reading this

manual, contact Customer Tech Support at the number listed on the back panel of this manual.

To reduce the risk of burns, fire, electrical shock or injury follow the instructions below.

• If you experience any kind of pain, including, but not limited to chest pains, nausea, dizziness, or

shortness of breath, stop exercising immediately and consult your physician before continuing.

• Maintain a comfortable pace. Do not sprint above 80 rpms on this machine.

• To maintain balance, it is recommended to keep a grip on the handlebars while exercising, mounting

or dismounting the machine.

• Do not wear clothes that might catch on any part of the Elliptical/Bike.

• Do not turn pedal arms by hand.

• Make sure handlebars are secure before each use.

• Do not insert or drop any object into any opening.

• Unplug Elliptical/Bike before moving or cleaning it. To clean, wipe surfaces down with soap and

slightly damp cloth only; never use solvents. (See MAINTENANCE)

• This elliptical should not be used by persons weighing more than the weight limit stated in the owners

manual. Failure to comply will void the warranty.

• This elliptical is intended for in-home use only. Do not use this elliptical in any commercial, rental,

school or institutional setting. Failure to comply will void the warranty.

• Do not use elliptical in any location that is not temperature controlled, such as but not limited to

garages, porches, pool rooms, bathrooms, car ports or outdoors. Failure to comply may void the

warranty.

• Use the elliptical only as described in this manual.

• Keep the topside of the foot support clean and dry.

• Care should be taken when mounting or dismounting the equipment. Before mounting or dismounting

move the pedal on the mounting or dismounting side to its lowest position and bring the machine to a

complete stop.

• Disconnect all power before servicing the equipment.

At NO time should pets or children under the age of 12 be closer to the Elliptical/Bike

than 10 feet.

At NO time should children under the age of 12 use the Elliptical/Bike.

Children over the age of 12 should not use the Elliptical/Bike without adult supervision.

It is essential that your Elliptical/Bike is used only indoors, in a climate controlled room. If your

Elliptical/Bike has been exposed to colder temperatures or high moisture climates, it is strongly

recommended that the Elliptical/Bike is warmed up to room temperature before first time use.

Failure to do so may cause premature electronic failure.

8 | 2008 AFG Service Seminar [rev 1.3]

Section One | Safety Instructions

WA RN IN G

WA RN IN G

Safety Instructions

>> Elliptical | Bike Continued

Connect this exercise product to a properly grounded outlet only.

See grounding instructions.

GROUNDING INSTRUCTIONS-Inclining Ellipticals Only

This product must be grounded. If a Elliptical/Bike should malfunction or breakdown, grounding

provides a path of least resistance for electrical current to reduce the risk of electrical shock. This

product is equipped with a cord having an equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with local codes and ordinances.

There are several areas during the assembly process of an elliptical that special

attention must be paid. It is very important to follow the assembly instructions correctly

and to make sure all parts are firmly tightened. If the assembly instructions are not

followed correctly, the elliptical could have frame parts that are not tightened and will

seem loose and may cause irritating noises. To prevent damage to the elliptical, the

assembly instructions must be reviewed and corrective actions should be taken.

UNPACKING

Unpack the product where you will be using it. Place the product on a level flat surface. It is

recommended that you place a protective covering on your floor. During each assembly step, ensure that

ALL nuts and bolts are in place and partially threaded in before completely tightening any ONE bolt.

NOTE: A light application of grease may aid in the installation of hardware. Any grease, such as lithium

bike grease is recommended.

2008 AFG Service Seminar [rev 1.3] | 9

Section One | Safety Instructions

WA RN IN G

Safety Instructions

>> Gym

FOR HOUSEHOLD USE ONLY

Read all instructions before using this home gym. Basic precautions should always be followed,

including the following: Read all instructions before using this home gym. It is the responsibility of the

owner to ensure that all users of this home gym are adequately informed of all warnings and precautions.

If you have any questions after reading this manual, contact AFG at the number listed on the back cover

of this manual.

TO REDUCE THE RISK OF INJURY FOLLOW THE INSTRUCTIONS BELOW

• Close supervision is necessary when this home gym is used by, on, or near children or

disabled persons.

At NO time should pets or children under the age of 12 be closer to the home gym than 10

• Use this appliance (or home gym) only for its intended use as described in this manual.

Do not use attachments not recommended by the manufacturer.

• Never drop or insert any object into any opening.

• If you experience any kind of pain, including but not limited to chest pains, nausea, dizziness, or

shortness of breath, stop exercising immediately and consult your physician before continuing.

• Do not wear clothes that might catch on any part of the home gym.

• Always wear athletic shoes while using this equipment.

• Do not jump on the home gym.

• At no time should more than one person be on home gym while in operation.

• The home gym should not be used by persons weighing more than 300 pounds.

Failure to comply will void the warranty.

• The home gym is intended for in-home use only. Do not use this home gym in any commercial, rental,

school or institutional setting. Failure to comply will void the warranty.

• Do not use outdoors.

feet. At NO time should children under the age of 12 use the home gym.

Children over the age of 12 should not use the home gym without adult supervision.

10 | 2008 AFG Service Seminar [rev 1.3]

Section One | Safety Instructions

WA RN IN G

WA RN IN G

Safety Instructions

>> Gym Continued

During the assembly process there are several areas that special attention must be paid. It is very

important to follow the assembly instructions correctly and to make sure all parts are firmly tightened. If

the assembly instructions are not followed correctly, the home gym could have frame parts that are not

tightened and will seem loose and may cause irritating noises. There should be no side-to-side play in

the frame uprights. If there is any play in these areas, the home gym has not been properly assembled.

To prevent damage to the home gym, the assembly instructions must be reviewed and corrective actions

should be taken.

UNPACKING

Unpack the unit where it will be used. Place the home gym carton on a level flat surface.

It is recommended that you place a protective covering on your floor. Take CAUTION when handling and

transporting this unit. Never open box when it is on its side.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN INJURY!

SEAT ASSEMBLY PIN

Ensure that the seat assembly safety pin is fully inserted before using the home gym.

Failure to do so may result in injury!

PROPER USAGE

Make sure to follow the MAINTENANCE schedule in this manual. Stop your workout immediately if you

feel pain, faint, dizzy or are short of breath. Reference Home Gym Maintenance p22.

Do not operate the home gym if there is any noticeable damage to the cables or pulleys.

If any damage is noticeable, contact AFG at the number located on the back panel of

this manual.

2008 AFG Service Seminar [rev 1.3] | 11

Section One | Recommended Tools

>> Recommended Tools and Equipment

The following list is a summary of the tools and equipment required by the procedures in this manual.

Tools are not supplied by Horizon Fitness.

• Phillips screwdrivers

• Anti-static wrist strap (when handling electronic parts)

• Flat-head screwdrivers

• Digital multi-meter

• Drive belt tension gauge

• Allen wrench set (Metric)

• Open-end wrenches of assorted sizes (Metric)

• Clamp-on amp meter

• 1/2” drive ratchet and sockets of assorted sizes

• Blue Thread Lock

• Cable ties

•

• Needle nose pliers

• Damp cloth

• Rubber mallet

• Hammer

• Drop cloth

• Ruler

• Snap ring pliers

• Wire cutters

•

*Motor commutator stone

*Crank Puller (Park Tool CCP-2, 22mm)

•

*Crank Puller (26mm)

*Available through Horizon Fitness at Cost.

12 | 2008 AFG Service Seminar [rev 1.3]

>> Treadmill Parts Diagram

WATERBOTTLE HOLDER

TOUCHPAD PANEL WITH LED WINDOWS

READING RACK

GRIP PULSE HAND RAILS

SAFETY KEY PLACEMENT

HAND RAILS

MOTOR COVER

SIDE RAIL

ROLLER END CAP

REAR ROLLER ADJUSTMENT BOLTS

P6:

G

O

L

F

COUR

S

E

P7:

P

A

CER

P8

: THR

ZONE

P10: CUS

TOM 2

P9

: CUS

TOM 1

P1:

MA

NUAL

P2:

I

NTERVALS

P3:

MTN C

LI

MB

P4:

WEIGH

T LOSS

P5:

PEA

K

INTERVALS

1

2

1

1

1

0

9

8

7

6

5

4

3

2

1

1

2

1

1

1

0

9

8

7

6

5

4

3

2

1

DISTANC

E

TIME

IN

C

L

INE

HE

ART RATE

S

PEED

CALORI

ES

8

6

4

2

+

1

%

%

%

%

1

0

%

1

2

%

%

1

0

8

6

4

2

MPH

1

2

MPH

MPH

MPH

MPH

MPH

+

1

MPH

CHANGE

DIS

P

L

A

Y

S

TAR

T

QUICK

STA

RT

STO P

HOLD T

O RESET

PRES

S

T

O

CO

NFIRM

INCLI

NE

PR

ESS T

O

CO

N

F

IRM

SPEED

ENT

ER

BACK

CONSOLE

CONSOLE SKIRT

CONSOLE MAST

CIRCUIT BREAKER

ON/OFF SWITCH

POWER CORD

WHEEL LOCKS

SIDE COVER

TRANSPORT WHEEL

RUNNING BELT / RUNNING DECK

Section Three | Parts Diagrams >>Treadmill

Console

Console Skirt

Console Mast

Circuit Breaker

ON | OFF Switch

Power Cord

Wheel Locks

Side Cover

Transport Wheel

Running Belt | Running Deck

Water Bottle Holder

Touch Panel with LED Window

Reading Rack

Grip Pulse Hand Rails

Safety Key Placement

Hand Rails

Motor Cover

Side Rail

Roller End Caps

Rear Roller Adjustment Bolts

2008 AFG Service Seminar [rev 1.3] | 13

Section Three | Parts Diagrams >>Elliptical

CONSOLE

RIGHT HANDLEBAR

LOWER LINK ARM

ELBOW COVER

PULSE GRIP

CONSOLE MAST

DISPLAY

FOOT PAD

PEDAL ARM

BOTTLE HOLDER

POWER ADAPTOR SOCKET

HANDLEBAR COVERS

FOOT LEVELER

FRONT STABILIZER TUBE

CONSOLE MAST BOOT

TOP CAP

LEFT HANDLEBAR

>> Elliptical Parts Diagram

Display

Left Handlebar

Console Mast Boot

Top Cap

Pulse Grip

Bottle Holder

Console Mast

Foot Pad

Pedal Arm

Console

Right Handlebar

Handlebar Covers

Power Adaptor Socket

Elbow Cover

Front Stabilizer Tube

Lower Link Arm

Foot Leveler

14 | 2008 AFG Service Seminar [rev 1.3]

>> Bike Parts Diagram

CONSOLE

MAIN FRAME

WATER BOTTLE HOLDER

SEAT BACK

SEAT BASE

PULSE GRIP HANDLEBARS

PEDALS WITH FOOT STRAPS

SEAT FRAME

REAR PLASTIC CAP

SEAT BACK COVER

REAR STABILIZER TUBE

Section Three | Parts Diagrams >>Bike

Console

Pulse Grip Handlebars

Seat Back

Seat Base

Main Frame

Pedals with Foot Straps

Seat Back Cover

Water Bottle Holder

Rear Plastic Cap

Seat Frame

Rear Stabilizer Tube

2008 AFG Service Seminar [rev 1.3] | 15

Section Three | Parts Diagrams >>Gym

LAT PULLDOWN BAR

LAT BAR BRACKET ASSEMBLY

MAIN SUPPORT FRAME (RIGHT)

CENTER SUPPORT FRAME

CABLE “C”

RADIAL ARM ADJUSTMENT PIN

SEAT BACK PAD

SEAT BOTTOM PAD

SEAT ASSEMBLY

SEAT HEIGHT ADJUSTMENT KNOB

FOAM LEGROLLERS

ADJUSTABLE FOOTPLATE CABLE “B”

BASE FRAME

SEAT ASSEMBLY SAFETY PIN

MAIN SUPPORT FRAME (LEFT)

SINGLE FLOATING PULLEY BRACKET

WEIGHT SELECTION PIN

WEIGHT SHIELD

DUAL FLOATING PULLEY BRACKET

GUIDE ROD

UPPER PULLEY ASSEMBLY

RADIAL ARM ASSEMBLY

CABLE “A”

>> Gym Parts Diagram

Cable A

LAT Pulldown Bar

LAT Bar Bracket Assembly

Center Support Frame

Main Support Frame (Right)

Cable C

Upper Pulley Assembly

Dual Floating Pulley Bracket

Weight Shield

Guide Rod

Radial Arm Assembly

Radian Arm Adjustment Pin

Seat Back Pad

Seat Bottom Pad

Seat Assembly

Seat Height Adjustment Knob

Foam Legrollers

Adjustable Footplate

Weight Selection Pin

Main Support Frame (Left)

Single Floating Pulley Bracket

Seat Assembly Safety Pin

Base Frame

Cable B

16 | 2008 AFG Service Seminar [rev 1.3]

Section One | Maintenance

Maintenance

>> Treadmill Preventative Maintenance Procedures

Cleanliness of your treadmill and its operation environment will keep maintenance problems and service

calls to a minimum. For this reason, we recommend that the following preventive maintenance schedule

be followed.

AFTER EACH USE (DAILY)

Clean and inspect, following these steps:

• Turn off the treadmill with the on/off switch, then unplug the power cord at the wall outlet.

• Wipe down the running belt, deck, motor cover, and console casing with a damp cloth. Never use

solvents, as they can cause damage to the treadmill.

• Inspect the power cord. If the power cord is damaged, contact AFG.

• Make sure the power cord is not underneath the treadmill or in any other area where it can become

pinched or cut.

• Check the tension and alignment of the running belt. Make sure that the treadmill belt will not damage

any other components on the treadmill by being misaligned.

EVERY WEEK

Clean underneath the treadmill, following these steps:

• Turn off the treadmill with the on/off switch, then unplug the power cord at the wall outlet.

• Fold the treadmill into the upright position, making sure that the lock latch is secure.

• Move the treadmill to a remote location.

• Wipe or vacuum any dust particles or other objects that may have accumulated underneath the

treadmill.

• Return the treadmill to its previous position.

EVERY MONTH - IMPORTANT!

• Turn off the treadmill with the on/off switch, then unplug the power cord at the wall outlet.

• Inspect all assembly bolts of the machine for proper tightness.

• Turn off the treadmill and wait 60 seconds.

• Remove the motor cover. Wait until ALL LED lights turn off.

• Clean the motor and lower board area to eliminate any lint or dust particles that may have

accumulated. Failure to do so may result in premature failure of key electrical components.

• Vacuum and wipe down the belt with a damp cloth. Vacuum any black/white particles that may

accumulate around the unit. These particles may accumulate from normal treadmill use.

Note: Maintenance is NOT covered under manufacturer’s warranty.

2008 AFG Service Seminar [rev 1.3] | 17

Section One | Maintenance

Maintenance

>> Treadmill Lubrication

EVERY 6 MONTHS OR 150 MILES

It is necessary to lubricate your treadmill running deck every six months or 150 miles to maintain optimal

performance of your treadmill. Once the treadmill reaches 150 miles, the console will prompt you to

lubricate the treadmill. Only use lubricant provided by AFG!

• Turn off the treadmill with the on/off switch, then unplug the power cord at the wall outlet.

• Loosen both the rear roller bolts. (For best results, place two removable marks on both sides of the

frame and note roller position). Once the belt is loosened, take the bottle of lubricant and apply it to the

entire top surface of the running deck. Tighten both rear roller bolts (matching up the marks for proper

position) to original position. After you have applied lubricant, plug in the power cord, insert the safety

key, start the treadmill and walk on the belt for two minutes to spread the lubricant.

• Lubricate the air shocks with Teon based spray.

• Once lubrication is complete, reset the console by pressing and holding ‘STOP’ and Speed (s) buttons

for 5 seconds.

LUBRICATION

Running Belt

Running Deck

18 | 2008 AFG Service Seminar [rev 1.3]

Section One | Maintenance

Maintenance

>> Tensioning and Aligning the Running Belt

If you can feel a slipping sensation when running on the treadmill, the running belt must be tightened.

In most cases, the belt has stretched from use, causing the belt to slip. This is a normal and common

adjustment. Make sure that the unit is turned off and not running. To eliminate this slipping, tension

both the rear roller bolts with the appropriate sized Allen wrench, turning both the left and right bolt 1/4

TURN as shown below. Try the treadmill again to check for slipping. Repeat if necessary, but NEVER

TURN the roller bolts more than 1/4 turn at a time.

Belt is too far to the left side. Belt is too far to the right side.

1 | If the running belt moves rapidly to one side when performing the next step, press the Stop button

immediately.

• Turn on the treadmill. With the treadmill speed between 3-4mph, stand behind the treadmill and

watch the movement of the running belt. DO NOT STAND ON THE TREADMILL AND DO NOT

TOUCH THE TREADMILL WHILE PERFORMING THIS PROCEDURE. As you watch the running belt,

make sure that the belt runs without moving from one side to the other and that the belt is centered

between the side rails.

If the running belt is not tracking properly, follow the procedures below:

2 |

• If the running belt tracks to the left, turn the left roller bolt clockwise 1/4 of a turn, keeping the belt

tension in mind. Over-tightening the running belt may cause damage to the running belt and roller

bearings.

• If the running belt tracks to the right, turn the right roller bolt clockwise 1/4 of a turn, keeping the belt

tension in mind. Over-tightening the running belt may cause damage to the running belt and roller

bearings.

2008 AFG Service Seminar [rev 1.3] | 19

Section One | Maintenance

WA RN IN G

Maintenance

>> Elliptical Preventative Maintenance Procedures

WHAT KIND OF ROUTINE MAINTENANCE IS REQUIRED?

We use sealed bearings throughout our ellipticals so lubrication is not needed. The most important

maintenance steps are to wipe perspiration off the unit after each use and periodically checking the

assembly bolts for tightness.

HOW DO I CLEAN MY ELLIPTICAL?

Clean with soap and water cleaners only. Never use solvents on plastic parts.

Cleanliness of your elliptical and its operating environment will keep maintenance problems and service

calls to a minimum. For this reason, AFG recommends that the following preventive maintenance

schedule be followed.

AFTER EACH USE (DAILY)

Turn off the elliptical by unplugging the power cord from the wall outlet

• Wipe down the elliptical with a damp cloth. Never use solvents, as they can cause damage to the

elliptical.

• Inspect the power cord. If the power cord is damaged, contact AFG.

• Make sure the power cord is not underneath the elliptical or in any other area where it can become

pinched or cut.

To remove power from the elliptical, the power cord must be disconnected from the wall

outlet.

WEEKLY

Clean underneath the elliptical, following these steps:

• Turn off the elliptical.

• Move the elliptical to a remote location.

• Wipe or vacuum any dust particles or other objects that may have accumulated underneath the

elliptical.

• Return the elliptical to its previous position.

EVERY MONTH

• Inspect all assembly bolts and pedals on the machine for proper tightness.

• Clean any debris off of the pedal arm wheels and guide rails.

20 | 2008 AFG Service Seminar [rev 1.3]

Section One | Maintenance

WA RN IN G

Maintenance

>> Bike Preventative Maintenance Procedures

WHAT KIND OF ROUTINE MAINTENANCE IS REQUIRED?

We use sealed bearings throughout our bikes so lubrication is not needed. The most important

maintenance step is to simply wipe your perspiration off the bike after each use.

HOW DO I CLEAN MY Bike?

Clean with soap and water cleaners only. Never use solvents on plastic parts.

Cleanliness of your bike and its operating environment will keep maintenance problems and service calls

to a minimum. For this reason, AFG recommends that the following preventive maintenance schedule

be followed.

AFTER EACH USE (DAILY)

Turn off the bike by unplugging the power cord from the wall outlet.

• Wipe down the bike with a damp cloth. Never use solvents, as they can cause damage to the bike.

• Inspect the power cord. If the power cord is damaged, contact AFG.

• Make sure the power cord is not underneath the bike or in any other area where it can become

pinched or cut.

To remove power from the bike, the power cord must be disconnected from the wall

outlet.

WEEKLY

Clean underneath the bike, following these steps:

• Turn off the bike.

• Move the bike to a remote location.

• Wipe or vacuum any dust particles or other objects that may have accumulated underneath the bike.

• Return the bike to its previous position.

EVERY MONTH

• Inspect all assembly bolts and pedals on the machine for proper tightness.

• Clean any debris off of the seat guide rail.

2008 AFG Service Seminar [rev 1.3] | 21

Section One | Maintenance

Maintenance

>> Gym Preventative Maintenance Procedures

Cleanliness of your home gym and its operation environment will keep maintenance problems and

service calls to a minimum. For this reason, we recommend that the following preventive maintenance

schedule be followed.

AFTER EACH USE (DAILY)

• Wipe upholstery, handles, bars, and frame (if needed) with a soap and water cleaning solution.

EVERY WEEK

• Lubricate guide rods with a spray or silicone gel lubricant.

• Inspect cable ends and cable insulation for damage.

EVERY MONTH - IMPORTANT!

• Inspect all frame bolts and tighten as needed.

ADJUSTING CABLE TENSION

Regularly check the cable tension of your home gym. If

excessive slack exists adjust cable tension by removing

the pulley bolts and moving one or both pulleys to the inner

mounting position in the dual oating pulley bracket and

then reinstalling the pulley bolts. Cable tension may also

be adjusted using the threaded cable end on single pulley

bracket and weight stack. Twist threaded end to adjust

tension and then tighten lock nut.

NOTE: Always maintain at least ½˝ of threaded bolt in

bayonet.

Inner

Mounting

Positions

Twist Screw to

Adjust Tension,

Then Tighten

Lock Nut

Single pulley

Bracket Thread

22 | 2008 AFG Service Seminar [rev 1.3]

Twist Screw to

Adjust Tension,

Then Tighten

Cable Screw

And Nut

Bayonet

Lock Nut

Cable Screw

And Nut

Weight Plates

Section One | Proper Heart Rate Usage

WA RN IN G

>> Proper Heart Rate Usage

HAND GRIPS

Place the palm of you hands directly on the grip pulse handlebars. Both hands must grip the bars for your

heart rate to register. It takes 5 consecutive heartbeats (15-20 seconds) for your heart rate to register

accuratly. When gripping the pulse handlebars, do not grip tightly. Holding the grips tightly may elevate

your blood pressure. Keep a loose, cupping hold. You may experience an erratic readout if consistently

holding the grip pulse handlebars. Make sure to clean the pulse sensors to ensure proper contact can be

maintained.

WIRELESS CHEST TRANSMITTER 4.0AR, 4.0AH, 4.0AE, 14.0AT, 14.0AE, 5.0AT, 18.0AE

(3.0AE, 13.0AT, 4.0AT sold separately)

Prior to wearing the wireless chest transmitter, moisten the two rubber electrodes with water. Center the

chest strap just below the breast or pectoral muscles, directly over your sternum, with the logo facing

out. *Verify the chest strap is the Polar brand chest strap.

The chest strap must be tight and properly placed to receive an accurate and consistent

readout. If the chest strap is too loose, or positioned improperly, you may receive an

erratic or inconsistent heart rate readout.

The heart rate function is not a medical device. Various factors may affect the accuracy

of your heart rate reading. The heart rate reading is intended only as an exercise aid.

Backside of Chest Transmitter

Apply Moisture Here

TROUBLESHOOTING-HEART RATE

Check your exercise environment for sources of interference such as uorescent lights, computers,

underground fencing, home security systems or appliances containing large motors. These items may

cause erratic heart rate readouts.

You may experience an erratic readout under the following conditions:

• Gripping the heart rate handlebars too tight. Try to maintain moderate pressure while holding onto the

heart rate handlebars.

• Constant movement and vibration due to constantly holding the heart rate handlebars while

exercising. If you are receiving erratic heart rate readouts, try to only hold the grips long enough to

monitor your heart rate.

• When you are breathing heavily during a workout.

• When your hands are constricted by wearing a ring.

• When your hands are dry or cold. Try to moisten your palms by rubbing them together to warm them.

• Anyone with heavy arrhythmia.

• Anyone with arteriosclerosis or peripheral circulation disorder.

• Anyone whose skin on the measuring palm is especially thick.

2008 AFG Service Seminar [rev 1.3] | 23

Table of Contents

>> Section Two

Horizon Fitness “5-Step” Diagnostic Process 25

Wiring Diagrams and Schematics 27

Resetting the Incline Motor 30

Adjusting the Magnetic Break 31

Voltage Checks

-Treadmills 32

>>No Motor Movement 34

>>Motor | AC Wire 34

>>Console Cable 35

>>Speaker Amp Board 35

>>9 Wire Console Cable 36

>>12 Wire Console Cable 37

>>Incline Wire 38

-Ellipticals | Bikes

>>Incline Motor 39

>>Resistance Motor 40

>>Resistance Motor Cable 41

>>10 WireConsole Cable 42

>>Incline Console Cable 43

Engineering Mode

-Treadmill 44

-Elliptical | Bike 45

24 | 2008 AFG Service Seminar [rev 1.3]

Section Two | Voltage Checks

120 VAC

WA RN IN G

>> Horizon Fitness “5-Step” Treadmill Diagnostic Process

The following steps are provided as routine checkpoints when diagnosing problems on

a Horizon Fitness treadmill. If followed correctly, these checkpoints should help diagnos

the majority of problems that may be encountered.

1 | Proper supplying power to treadmill.

• Make sure the treadmill is not on an extension cord, surge protector or GFCI circuit. Extension

cords and surge protectors create energy loss, which prevents proper voltage from being

supplied to the treadmill.

• Make sure the treadmill is on a dedicated circuit. Horizon Fitness recommends a 20 amp

dedicated circuit, but a 15 amp dedicated circuit may be sufcient.

• Make sure that proper voltage is being supplied from the wall outlet.

Hazardous voltages will be tested in the following procedure. Exercise extreme caution

when performing these procedures. Do not connect or disconnect any wiring,

connectors, or other components with the power applied to the treadmill.

• Disconnect the treadmill power cord from the wall outlet. Using an AC voltmeter, verify that the

proper AC voltage is present at the wall outlet. Nominal 120 volts AC may vary between

approximately 105 volts AC and 135 volts AC. If the AC voltage is missing or incorrect, check

the AC service or consult an electrician.

2 | Proper Wiring

• Verify that all wires are secure and attached in the correct position.

(Reference Wiring Diagrams and Scematics section p27.)

• Verify that there aren’t any pinches or cuts in any of the wires, especially the console cable

connecting from the motor control board to the upper board. Replace any wires that are

pinched or cut.

2008 AFG Service Seminar [rev 1.3] | 25

Section Two | Horizon Fitness “5-Step” Diagnostic Process

NTC

C1

30A 120/240V AC

JQX-15FS-A

COIL 12 VDC

C US

CQC

CHINA

30A 120/240V AC

JQX-15FS-A

COIL 12VDC

C US

CQC

CHINA

DLS2

D1

NTC

D6

C8

D3

FZ

ZJ

DW

R6

R8

Q1

Q2

Q3

R7

R9

Q4

UP

D5

R5

TP1

R14

C9

D9

R17

TP2

BL

R29

TP4

JOHNSONFITNESS

D10

SGND

R35

Q9

D17

C34

R27

R26

R28

JP5

C30

U3

U1

D18

D20

R32

R33

C33

07

08

D19

R18

D21

DLS3

R24

Q10

C20

L3

12

C14

R10

C15

R11

C16

R12

C17

R13

SJED08043EE

R19

LED2

LED3

LED4

LED5

WJ28025T

04 08

02.31

3 | Proper Motor Function

• Verify that the treadmill is properly lubricated (Reference Maintenance Section p17.) and drive

motor is operating at the proper amperage rating. To verify the current draw, place a clamp

meter around the red motor wire. If a clamp meter is not available, an additional wire harness

can be produced to measure amperage with a standard voltmeter.

Red Motor

Black Motor Connection

Connection

Black

Motor Wire

Red Motor

Wire

• Remove the brush covers on the drive motor and inspect the brushes and the motor commutator

for any uneven wear. If the surface of the motor brush is pitted, rough, has burn marks, or the

commutator has a black residue on it, replace the motor.

4 | Proper Speed Calibration

• To ensure proper belt speed and proper calibration use engineering mode to verify that machine

is running in MPH not KM (all models). (Reference Engineering Mode Section p44.)

• Auto-calibrate the machine from engineering mode if the belt speed is erratic or the belt speed

does not correspond to what is displayed on the console.

(Reference Engineering Mode Section p44.)

5 | Voltage Checkpoints

• Verify that proper voltage is being transferred through the console cable.

(Reference Voltage Checks p35.)

If the techniques described in the ve-step diagnostic process did not resolve the

problem, reference the symptoms in the table of contents and review other possible

causes in the troubleshooting section.

26 | 2008 AFG Service Seminar [rev 1.3]

MCB

WHITE

BLACK

BLACK

RED

WHITE

BLACK

WHITE

GREEN

Power Cord

110-120 VAC

GREEN

+2.5vdc

EL - Vcc (+2.5v)

EL - Pot

Gnd

Digital Ground

RPM

Power Voltage (+15V)

Power Voltage (+15V)

Speed Command pwr

RELAY

DOWN Incline

UP Incline

Optic Speed Sensor

Speed Sensor

BLACK +GND

WHITE PULSE

RED +5V

BLUE GND

BLACK GND

GREEN

Drive Motor

0-90 VDC

BLACK

RED

BREAKER

Digital Ground

EL. Pol

EL. GND

Incline Motor

>> Digital Drive Wiring Diagram

Section Two | Wiring Diagrams and Schematics

2008 AFG Service Seminar [rev 1.3] | 27

Section Two | Wiring Diagrams and Schematics

>> Elliptical Wiring Diagram Schematics

28 | 2008 AFG Service Seminar [rev 1.3]

>> Power Source Wiring Diagram

Section Two | Wiring Diagrams and Schematics

To Motor Control Board

A

B

C

A – Socket wire to breaker or on/off switch.

D

A F

E

C

BreakerOn | Off SwitchSocket

F

Wire Length will determine connection point.

B – Ground

C – Socket wire to breaker or on/off switch.

Wire Length will determine connection point.

D – On/Off switch to motor control board.

E – On/Off switch to motor control board.

F – On/Off switch to breaker.

Note: Wires A & C are interchangeable.

2008 AFG Service Seminar [rev 1.3] | 29

Section Two | Resetting The Incline Motor

>> Resetting the Incline Motor after replacing the Motor Control Board

Tools Required:

• Philips Screwdriver

• 17mm Socket

• 17mm Combination Wrench

Procedure:

1 | Turn off power to the treadmill and unplug power cord from wall outlet.

2 | Replace the Motor Control Board.

3 | Fold treadmill into locked position.

4 | Undo bolt that attaches the elevation tube to the bottom of the machine (F1)

F2

F1

17 mm Nut

17 mm Bolt

Proper Zero

Shaft Position

5 | Power up the machine and let the incline spin freely in the tube until it reaches its “zero” position,

and then turn power off.

6 | Spin shaft manually until it is almost ush with the incline motor casing and only about 1 thread is

visible (F2).

7 | Reinsert bolt and power up the machine.

8 | Test the incline function and calibrate the unit.

30 | 2008 AFG Service Seminar [rev 1.3]

Section Two | Adjusting the Magnetic Break

>> Adjusting the Magnetic Break

Tools Required:

• Phillips Screwdriver

• 8mm, 13mm, 17mm Socket and Combination Wrenches

• 5mm Allen Wrench

• Crank Puller

Procedure:

1 | Turn on unit and Press start.

2 | Set resistance highest level and power off unit.

3 | Remove side covers.

4 | Loosen the short nut (A), and adjust the long nut (B) clockwise to reduce the brake resistance and

counterclockwise to increase the brake resistance.

The correct position for the ywheel/brake assembly is 1-2 mm from the ywheel at the

highest resistance level.

A

B

2008 AFG Service Seminar [rev 1.3] | 31

Section Two | Voltage Checks

>> No Motor Movement Voltage Checkpoints

Upper Board Checkpoints

Procedures:

Using a dc volt meter (if non-auto ranging set for the 20vdc range), test the voltage at the grey and again at the

white console cable connections using the yellow, orange or red wires as ground. Two tests are to be performed;

test once with power on before the treadmill is started and again after Start is pressed.

Desired Results:

The voltage charts contain typical desired results on a fully functional system. A variance from the norm would

indicate a defective component.

Checkpoint Voltage Before Start Volatge After Start

Console Cable Grey to Yellow (Gnd) 0.0 vdc 0.3 +/- .3 vdc, increases as speed increases.

(as shown on console)

Console Cable White to Yellow (Gnd) 4.3 +/- .3 vdc 0.0 vdc

Lower Board Checkpoints

Console Cable Connection

Procedures:

Using a dc volt meter (if non-auto ranging set for the 20vdc range), test the voltage at the grey and again at the

white console cable connections using the yellow, orange or red wires as ground. Two tests are to be performed;

test once with power on before the treadmill is started and again after Start is pressed. Note: this is the same

procedure as the upper board console cable connection. If results vary from the upper board, the console cable is

the likely cause and a continuity check should be performed.

Desired Results:

The voltage charts contain typical desired results on a fully functional system. A variance from the norm would

indicate a defective component.

Checkpoint Voltage Before Start Volatge After Start

Console Cable Grey to Yellow (Gnd) 0.0 vdc 0.3 vdc, increases as speed increases.

(as shown on console)

Console Cable White to Yellow (Gnd) 4.3 vdc 0.0 vdc

Note: 2.75 Hp motors and higher: the reading on the console cable -white to yellow (gnd) is 1.6 + or - .3vdc

Digital Speed Sensor Connection

Procedures:

Using a dc volt meter (if non-auto ranging set for the 20vdc range); test the voltage at the red wire and again at

the yellow wire using the blue, black or black as ground. The yellow wire should be measure twice, once with the

optic speed sensor obstructed and once not obstructed.This can be done by slowly turning the motor and aligning

the tines or open spaces of the optic disk with the sensor.

Desired Results:

The voltage charts contain typical desired results on a fully functional system. A variance from the norm would

indicate a defective component.

Checkpoint Voltage With Sensor

Volatge With Sensor Not Obstructed

Obstructed

Yellow Digital Speed Sensor 5.0 +/- 0.4 vdc 0.3 vdc

Red Digital Speed Sensor 5.0 +/- 0.4 vdc 5.0 +/- 0.4 vdc

32 | 2008 AFG Service Seminar [rev 1.3]

Section Two | Voltage Checks

>> No Motor Movement Voltage Checkpoints Continued

Drive Motor Connection

Procedures:

Using a dc volt meter (if non-auto ranging set for the 200vdc range), test the voltage at the red and black motor

leads with the motor still attached.

Note: This should be tested after the console cable and optic sensor points because they can give the same

results as a defective lower board.

Note: A non-functional system may still have a voltage present with no motor attached. For accurate results, the

motor must be attached when the voltage is checked.

Desired Results:

The voltage charts contain typical desired results on a fully functional system. A variance from the norm would

indicate a defective component.

Checkpoint Voltage Before Start Voltage After Start @

Volatge After Start @ 10.0mph

0.5mph

Across Motor Out,

0.0-22.5 vdc 0.0-22.5 vdc 0.0-22.5 vdc

No Motor

Attached

Across Motor Out,

0.0 vdc 2.5- 0 vdc 80-100.0 vdc

W/ Motor

Attached

Drive Motor Checkpoints

Procedures:

Unplug the motor from the lower board. Using a dc volt meter (if non-auto ranging set for the 20vdc range), attach

volt meter leads directly into the motor leads and turn the running belt.

Desired Results:

The motor should generate 5-15 vdc depending on the speed it is turned.

Procedures:

Unplug the motor from the lower board. Using an ohm meter (if non-auto ranging set for the 200 ohm range),

attach ohm meter leads directly into the motor leads.

Desired Results:

The motor should read approximately 1.0-1.5 ohms.

2008 AFG Service Seminar [rev 1.3] | 33

Section Two | Voltage Checks

1.20

V DC

"$8JSFT

7"$

>> Motor Voltage Check | Spin motor ywheel to produce voltage

>>

AC Wire Voltage Check

34 | 2008 AFG Service Seminar [rev 1.3]

V DC

GND

GND

UP

Dow

Mo

P

VD

M

>> Console Cable Voltage Check

JOHNSON

Acepower

CON2

D12

Section Two | Voltage Checks

To check the voltage of a specic function (i.e. elevation, motor control, etc), place the negative lead of

your multi-meter on pin B3, B4 or B5, and place the positive lead on the desired pin. Follow the voltage

charts on p37 (12pin) and p36 (9pin).

Note | 1: Wire colors are subject to change.

Note | 2: It may be necessary to remove the glue from the console cable to access the pins.

>> Speaker Amp Board Voltage

Voltage In Voltage Out

120v 12v

2008 AFG Service Seminar [rev 1.3] | 35

Section Two | Voltage Checks

P7: Incline Pot/VREF+

P2: Incline Down

P3: GND

P5: Drive Motor Relay

P4: Power Voltage (to UCB)

P6: Stop

P1: Incline Up

P8: Incline VCC/ELE

P9: RPM

Polarity tab will face User

Polarity tab will face User

>> 9 Wire Console Cable Voltage Chart (DC Volts)

P1: Incline Up

P2: Incline Down

P3: GND

P4: Power Voltage (to UCB)

P5: Drive Motor Relay

P6: Stop

P7: Incline Pot | VREF+

P8: Incline VCC | ELE

P9: RPM

Polarity tab will face

User

Wire

Color

1 Red Incline Up 0.0 vdc before started, +1.9

2 Brown Incline Down 0.0 vdc before started, 0.0

3 Orange GND n/a ground 0.0 vdc 0.0 vdc

4 Yellow Power

5 Green Drive Motor

6 Blue Stop Constantr 0.53 vdc-0.69

7 Purple Incline Pot/

Function Console Cable Voltage

no wires cut

vdc while inclining, 0.0 vdc

while declining. Voltage

constant while inclining/

declining.

vdc while inclining, +1.9

vdc while declining. Voltage

constant while inclining/

declining.

Voltage (to

UCB)

Relay

VREF+

+15 vdc constant range. 0.0 vdc 14.55 vdc Console will not turn on.

+1.6 vdc before started, 0.0

vdc after started.

vdc 3.6 vdcwhen the safety

key is removed. Will remain

at 3.6 vdc untill Start is

pressed.

+2.5 vdc at 0.0% incline,

+0.5 vdc at max incline.

Voltage changes with each

change in incline.

Voltage at UCB

after wire’s cut

2.5 vdc b/f start,

5.0 vdc after start.

2.5 vdc b/f start,

0.8 vdc after start.

1.4 vdc b/f start

0.8 vdc after start

5.0 vdc safe off

1.3 vdc safe on

1.7 vdc running

1.9 vdc paused

2.5 vdc 3.7 vdc b/f start,

Voltage at MCB

after wire’s cut

3.7 vdc b/f start,

0.0 vdc after start.

0.0 vdc b/f start,

0.1 vdc after start.

0.0 vdc b/f start

1.4 vdc after start

16.6 vdc safe off

0.0 vdc safe on

and running

5.0 vdc after start.

Physical Symptoms-If Wire Cut

Incline motor will go up but not down.

Incline motor will go down but not up.

Console will not turn on.

No belt movement.

No physical symptoms were noticed when

this wire was removed.

If the incline is changed from 0.0%, the

motor will move constant up untill the incline on the console is returned to 0.0%. it

will then stop in place and NOT go down.

8 Grey Incline VCC/

ELE

9 White RPM When the speed sensor is

+2.5 vdc constant. 3.8 vdc b/f start

aligned to the magnet; short,

0.0vdc. When the speed

sensor is not aligned: open,

+5.0 vdc.

Note: Wire colors are subject to change.

36 | 2008 AFG Service Seminar [rev 1.3]

4.8 vdc after start

5.0 vdc 0.0 vdc Console will use default PWM value or

2.5 vdc Incline constant up as soon as start is

pressed. Incline will work in Hardware

test.

auto-cal values. Will not auto-cal, will not

show speed in Hardware Test.

B7: Power Voltage (to UCB)

B2: Incline Pot

B3: Incline GND

B5: Digital GND

B4: Digital GND

B6: RPM

B1: Incline VCC

B8: Power Voltage (to UCB)

B9: Speed Command (PWM)

B10: Drive Motor Relay

B11: Incline Down

B12: Incline Up

>> 12 Wire Console Cable Voltage Chart (DC Volts)

B1: Incline VCC

B2: Incline POT

B3: Incline GND

B4: Digital GND

B5: Digital GND

B6: RPM

B7: Power Voltage (to UCB)

B8: Power Voltage (to UCB)

B9: Speed Command (PWM)

B10: Drive Motor Relay

B11: Incline Down

B12: Incline Up

Section Two | Voltage Checks

Wire

Color

Function Console Cable

Voltage

no wires cut

Voltage at

UCB

no wires cut

Voltage at MCB

after wire’s cut

Physical Symptoms-If Wire Cut

1 Black Incline VCC 2.5 vdc 0.0 vdc 2.5 vdc After Start pressed constant down incline, down LED

constant on. In Hardware Test the motor moves down

but not up, value always at maximum.

2 Brown Incline Pot 2.5 vdc at 0.0% incline,

0.5 vdc at max incline.

Voltage changes with

2.5 vdc 0.0 vdc After Start pressed constant down incline, down LED

constant on. In Hardware Test the motor moves down

but not up, value always at maximum.

each change in incline.

3 Red Incline

GND

n/a ground 2.5 vdc, grounded

at MCB not UCB.

0.0 vdc, grounded at

MCB not UCB.

Constant up incline. In Hardware Test, motor moves

up and down. Incline value started low and went

down to 0 but not up past 10. Value changes very

slowly.

4 Orange Digital

GND

5 Yellow Digital

GND

6 Green RPM When speed sensor

n/a ground 0.0 vdc 0.0 vdc If one removed, no issues. If both removed: UCB does

not turn on. Both incline lights are on and incline mo-

n/a ground 0.0 vdc 0.0 vdc

tor hums and gets hot quickly. See below for voltage

chart if both grounds removed.

5.0 vdc 0.0 vdc Everything works in normal mode but the console

aligned to

magnet: short, 0.0vdc.

does not register a speed in Hardware Test or Auto

Calibration

When sensor not

aligned:open,5.0 vdc

7 Blue Power

Voltage

8 Purple 15 vdc constant

(to UCB)

15 vdc constant

Range=15 to 17 vdc

0.0 vdc 17 vdc If one removed, no issues. If both removed: UCB does

not turn on. At UCB green measures 0.46 vdc, white

0.0 vdc 17 vdc

1.4 vdc, all others 0.0 vdc.

Range=15 to 17 vdc

9 Grey Speed

Command

(PWM)

10 White Drive Motor

Relay

0.0 vdc before started,

0.5 vdc at 0.5 mph, 4

vdc at 10 mph. Voltage changes as speed

changes.

4.3 vdc before started

0.0 vdc after started

“0.0 vdc b/f start

0.36vdc aft start

increases as

console speed

increased”

“5.0 vdc b/f start

0.0 vdc aft start”

“0.8 vdc b/f start

0.7 vdc aft start no

change as console

speed increased”

“1.4 vdc b/f start

1.4 vdc aft start”

No belt movement, MCB relay clicks. LCD 1 lights.

When measuring MCB voltage, there is a slight belt

movement, then stops

No belt movement, no click from MCB relay. LED 1

does not light.

11 Pink Incline

Down

0.0 vdc before started,

0.0 vdc while inclining,

1.9 vdc while declining.

Voltage constant while

inclining/declining.

12 Light

Blue

Incline Up 0.0 vdc before started,

1.9 vdc while inclining,

0.0 vdc while declining.

Note: Wire colors are subject to change.

“0.0 vdc b/f start

5.0 vdc if press

incline down”

“0.0 vdc if at 0%

5.0 vdc if not at

0% or at console

height”

0.0 vdc Up incline functions, no down incline, LED’s function

for up, not for down. If incline then decline, motor

does not move again until past incline point. Ex. If incline to 2.0 % then back down to 0%, the motor will not

move until 2.5 %. In Hardware Test, on;ly up incline,

value increases, does not decrease.

0.0 vdc Down incline functions, no up incline, LED’s function

for down but not up. In Hardware Test, down incline

functions until value at 0, no up incline. Similar phenomenon to cut Pink wire if incline stopped not at 0%.

2008 AFG Service Seminar [rev 1.3] | 37

Section Two | Voltage Checks

>> Incline Wire Voltage Chart

Small Connector

Wire

Color

Blue Ground n/a Ground n/a Ground n/a Ground Constant up incline,

Function Before Start At 0.0% At 10% Physical

Symptoms-If Wire

Cut

no down incline.

ENG 1 Test Results

Incline value 0, no down incline.

Brown Incline Pot 2.3 vdc* 0.6 vdc* 0.6 vdc* Constant down in-

cline, no up incline.

Orange VCC 2.4 vdc

constant

* The voltage changes as the incline changes

2.4 vdc constant 2.4 vdc constant Constant down incline, no up incline.

Large Quick Connects

Wire

Color

Black

w/white

as

ground

Red

w/white

as

ground

Red

w/black

as

ground

Function Before

Start

Incline Up 0.15 vac 0.15 vac 171 vac 120 vac Up incline works, no down

Incline

Down

Ground 0.03 vac 0.03 vac 219 vac 228 vac Neither up nor down func-

0.15 vac 0.15 vac 120 vac 186 vac Down incline works, no up

After Start,

Not Inclining

Or

Declining

While

Inclining

While

Declining

Physical

Symptoms-If Wire

Cut

incline.

incline.

tion.

Incline value at max, no up

incline.

Incline value started one less

than max, pressed up once and

value maxed out, thereafter no

up incline.

ENG 1 Test Results

Up incline works, down does not.

Value increases, does not decrease.

Down incline works (until value 0), up

does not. Value decreases to 0 then

no down incline, does not increase.

Neither up nor down function. Value

does not change.

Parameter: Use functioning incline motor and remove one wire at a time to observe malfunction

38 | 2008 AFG Service Seminar [rev 1.3]

Section Two | Voltage Checks

>> Elliptical Incline Motor Voltage Checks

DC

Wire Color Function Voltage at Zero Voltage

w/ Increase

1 Brown Voltage in

(VCC)

2 Orange POT Sensor

(ADC)

3 Blue Ground n/a n/a n/a Normal: Upon start-up incline continuously goes

5V 5V 5V Normal: After start and pressing incline up and down

4.2V Deacreases to 1.7V Increases to 4.2V Normal: After pressing incline- no incline movement.

Voltage

w/ Decrease

Physical Symptoms-If Wire Cut

value is displayed, but there is no incline function.

Eng4: When pressing incline up no motor movement,

Incline - functions normally

Eng4: Incline + functions normal, no movement with

incline - .

down. Eng4: When pressing up incline does not go up

distance value ickers at max value.

AC

Wire Color Function Voltage at Zero Voltage

1 Black Incline Up 0-1 VAC 171 VAC 120 VAC Normal: No incline function and value is displayed

2 Red Incline Down 0-1 VAC 120 VAC 172 VAC Normal: Incline is at a constant down upon start-up.

3 White NC n/a n/a n/a Normal: after pressing start and incline up and down

w/ Increase

Voltage

w/ Decrease

Physical Symptoms-If Wire Cut

Eng4: Incline + functions normal, no movement with

incline - .

Eng4: Operates normal, value at max

no incline movement. Eng4: no incline movement,

value does not change.

2008 AFG Service Seminar [rev 1.3] | 39

Section Two | Voltage Checks

>> Elliptical | Bike Resistance Motor Voltage Checks

2.0AE | 2.0AR | 3.0AR | 4.0AR |3.0AH | 4.0AH

Wire

Color

1 Red Power to

2 Black Ground

3 Brown Optic

4 Orange Zero

Function

DC Motor

I.C. Board.

-From

Motor

Count

-from

motor

Switch

Sensor

Voltage | Ohm

Readings

+5vdc 5V 5V Normal: After pressing start and resistance+

n/a ground n/a n/a Normal: After pressing start and resistance+

5vdc 180mV 180mV Normal: After pressing start and resistance+

5V 180mV 180mV Normal: After pressing start and

Voltage

w/ Increase

Voltage

w/ Decrease

Physical Symptoms-If Wire Cut

motor continues to rotate upward during

pressingn resistance- motor stops, but does not

zero itself. Eng1:Motor operates but no change

in motor count

motor continues to rotate upward during

pressing resistance- motor stops and does not

zero. Eng1:Motor operates but no change in

motor count.

motor continues to rotate upward during

pressing resistance- motor zeros itself. Eng1:

Motor operates but no change in

motor count.

resistance + motor constantly rotates. If

pressing resistance - motor zeros

itself. Eng1: No motor movement .

Value is displayed and does not change when

pressing resistance +/-.

5 Green Power to

Resistance

up

6 White Power to

Resistance

down

Note: Wire colors are subject to change.

40 | 2008 AFG Service Seminar [rev 1.3]

12mV 8.5-9.7v 110mV Normal: After pressing start and resistance+

12mV 120mV 8.5-9.7v Normal: After pressing start and resistance up

value is displayed and there is no motor

movement.Eng1: No motor movement and

motor count does not change.

value is displayed and there is no motor

movement.Eng1: No motor movement and

motor count does not change.

>> Elliptical Resistance Motor Cable Voltage Checks

3.0AE | 4.0AE | 14.0AE | 18.0AE

Section Two | Voltage Checks

Wire

Color

1 Red Power to

2 Black Ground

3 Brown Optic

4 Orange Zero

Function

DC Motor

I.C. Board.

-From

Motor

Count

-from

motor

Switch

Sensor

Voltage | Ohm

Readings

+5vdc 5V 5V Normal: After pressing start and resistance+

n/a ground n/a n/a Normal: After pressing start and resistance+

5.0vdc 0.0vdc 0.0vdc Normal: After pressing start and resistance+

5V 0.0vdc 0.0vdc Normal: After pressing start and

Voltage

w/ Increase

Voltage

w/ Decrease

Physical Symptoms-If Wire Cut

motor continues to rotate upward during

pressing resistance- motor stops, but does not

zero itself. Eng1:Motor operates but no change

in motor count

motor continues to rotate upward during

pressing resistance- motor stops and does not

zero. Eng1:Motor operates but no change in

motor count.

motor continues to rotate upward during

pressing resistance- motor zeros itself. Eng1:

Motor operates but no change in

motor count.

resistance + motor constantly rotates. If

pressing resistance - motor zeros itself.

Eng1: No motor movement .

Value is displayed and does not change when

pressing resistance +/-.

5 Green Power to

Resistance

up

6 White Power to

Resistance

down

Note: Wire colors are subject to change.

0.0-0.4vdc 8.5-9.7vdc 0.6-2.0vdc Normal: After pressing start and resistance+

0.0-0.4vdc 8.5-9.7vdc 0.6-2.0vdc Normal: After pressing start and resistance up

value is displayed and there is no motor

movement.Eng1: No motor movement and

motor count does not change.

value is displayed and there is no motor

movement.Eng1: No motor movement and

motor count does not change.

2008 AFG Service Seminar [rev 1.3] | 41

Section Two | Voltage Checks

>> 10 Wire Elliptical Console Cable Voltage Chart (DC Volts)

Wire Color Function

1 Purple Ground from

Voltage | Ohm Readings

n/a ground Normal: No speed/ rpm readings.Eng1 No rpm

RPM sensor

2 Black Ground from

n/a ground Normal: After pressing start and resistance+

motor

3 Or-

ange

Zero switch

sensor

If zero switch engaged

(lowest resistance level)

+5.0vdc, open. Any other

resistance position: 0.0vdc,

short.

4 Brown Optic count

from motor

5 Green Power to

resistance

up

+5.0vdc. Ifslot in optic disk

aligned with sensor, 0.0vdc

+0.0 to 0.4vdc if motor idle.

+8.5vdc if resistance

increasing. +0.6 to 2.0vdc if

resistance increasing.

6 White power to

resistance

down

+0.0 to 0.4vdc if motoridle.

+8.5vdc if resistance

decreasing +0.6 to 2.0vdc if

resistance increasing.

7 Yellow RPM sensor If magnet aligned with rpm

sensor: 0.0vdc, short. If

magnet not aligned withrpm

sensor: 5.0vdc, open.

8 Grey Power to

console from

Dependent upon power

supply.

power supply

9 Blue Ground from

n/a ground No power to console

power supply

10 Red Power to

+5.0vdc Normal: After pressing start and resistance+

DC motor

i.c.board

Physical Symptoms-If Wire Cut

readings.

motor continues to rotate upward during

pressing resistance- motor stops and does not

zero. Eng1:Motor operates but no change in

motor count.

Normal: After pressing start and resistance+

motor continues to rotate upward during

pressing resistance- motor stops and does not

zero. Eng1: Motor operates but no change in

motor count.

Normal: After pressing start and resistance+

motor continues to rotate upward during

pressing resistance- motor zeros itself. Eng1:

Motor operates but no change in motor count.

Normal: After pressing start and resistance up

value is displayed and there is no motor

movement.Eng1: No motor movement and

motor count does not change.

Normal: After pressing start and resistance up

value is displayed and there is no motor

movement.Eng1: No motor movement and

motor count does not change.

Normal: No speed/ rpm readings.Eng1 No rpm

readings.

No power to console

motor continues to rotate upward during

pressing resistance- motor stops, but does not

zero itself. Eng1:Motor operates but no change

in motor count.

Note: Wire colors are subject to change.

42 | 2008 AFG Service Seminar [rev 1.3]

>> Elliptical Incline Console Cable Voltage Check

Section Two | Voltage Checks

Wire Color Function

1 White/

Power 12.6VDC If both wires are cut, the console will have no

Orange

Voltage | Ohm Readings

Physical Symptoms-If Wire Cut

power.

2 Orange Power 12.6VDC If both wires are cut, the console will have no

power.

3 White/

Green

Signal

Receive

Receives signals from incline

motor, and resistance

Will give “Connect” error if cut - on select

models.

motor and RPM. 5V

4 Blue Signal

Send

Receives signals from incline

motor, and resistance

If cut there will be no incline or resistance

movement, and no RPM reading.

motor. 0 to .1V before Start | .1

to .2V after start.

5 White/

Blue

Signal

Receive

Receives signals from inclinemotor, resistance motor

Will give “Connect” error if cut - on select

models.

and RPM. 5V

6 Green Signal

Send

Sends signals to incline motor

and resistance motor. 0 to .1V

If cut there will be no incline or resistance

movement, and no RPM reading.

before Start | .1 to .2V after

Start.

7 White/

Brown

Ground n/a Ground If both wires are cut, the console will have no

power.

8 Brown Ground n/a ground If both wires are cut, the console will have no

power.

Note: Wire colors are subject to change.

2008 AFG Service Seminar [rev 1.3] | 43

Section Two | Engineering Mode

Engineering Mode

>> Treadmills

Note: At Any time, Press and hold the STOP button to exit the engineering menu.

1 | Turn the treadmill power to ON.

2 | Place the safety key in position on the console.

3 | Simultaneously press and hold (for about three seconds) the incline “+” (s) and speed “-” (t) buttons.

4 | The console should beep three times and ENG0 (EN90) should be displayed in the time window, “ENGINEERING

MENU” scrolls in matrix or is static in the text box.

Note: To navigate through the engineering menu, use the incline “+” (s) and speed “-” (t) buttons.

Display | Button Test (Eng0)

Eng0 appears in the time window.

DISPLAY TEST will scroll in the matrix or will be static in

text box.

Press ENTER to select .

When selected each display segment should be lit up.

When pressed each button should have a unique display

change.

-Stop button turns off all lights.

-Start button turns all lights on.

Hardware Test (Eng1)

Eng0 appears in the time window.

HARDWARE TEST will scroll in the matrix or will be static

in text box.

Press ENTER to select .

Press START to begin.

-Speed “+” (s) or “-” (t) will change the speed.

-Speed quick keys will change the speed.

Preset to be within 20%.

-Incline “+” (s) or “-” (t) will change the incline.

-Quick incline keys will beep but do not function.

-Incline motor will stop at minimum or maximum incline (not

continue to move) if “+” ((s)or “-” (t) is held.

Auto Calibrate (Eng2)

Eng2

appears in the time window.

AUTO CALIBRATE will scroll in the matrix or will be static

in text box.

Press ENTER to select .

Press START to begin.

-There should be no excessive speed overshoot.

-The engineering menu will be exited upon successful

completion of the auto calibration.

Note: The auto calibration process takes about two minutes to complete.

Switch Function (Eng3)

Eng3 appears in the time window.

SWITCH FUNCTION will scroll in the matrix or will be

static in text box.

Press ENTER to select.

If the treadmill has a Demo Mode then: