Horizon FIREPLACES CANTLEVER 700, CANTLEVER 1500, CANTLEVER 1100, LOW LINE 850, LOW LINE 1100 Installation Instructions Manual

...

----FIREPLACES----

Installation Instructions

Horizon Power Flue Gas Fireplaces

28/02/2019 Ver. 25

1

SINGLE SIDED MODELS

SUITABLE GAS BURNER OPTION

CANTILEVER

700 Cantilever 700 Mk2Pebble

700 Mk2Coal

700 Ironbark LogMk4

1100 Cantilever 1000 Mk2 Pebble

1000 Mk2Coal

850 Ironbark Log Mk4

1500 Low Line 1400 Mk2 Pebble

1400 Mk2Coal

DOUBLE SIDED MODELS

Power Flue approved for the

following models:

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

Location Requirements

Power flue systems utilizes a fan assisted draft to

ensure products of combustion are exited through a

flue terminal either horizontally or vertically

terminated.

The following A.G.A location requirements for flues

are to be observed when installing a powered flue

system.

SEE NEXT PAGE FOR LOCATION EQUIREMENTS

Ventilation Requirements:

Rooms with gas open fireplaces require as per

clause 6.10.9.5 in AS/NZS5601.1:2013, one or more

ventilation openings with a combined free ventilation

area of not less than the equivalent cross sectional

area of the flue cowl shall be provided for each

decorative flame effect fire and calculations based

on clause 6.4.4

Model Type 2: Power Flue

Decorative Gas Fireplace

DATA PLATE: Refer to information on page 16 of this

Instruction booklet in respect to gas pressure,

consumption and gas type, Natural, ULPG or LPG.

Data Plate is located under the gas burner and is

accessed by lifting front access panel or removing

base plate.

700 Low Line 700 Mk2Pebble

700 Mk2Coal

700 Ironbark LogMk4

850 Low Line 800 Mk2 Pebble

800 Mk2Coal

850 Ironbark Mk4

1100 Low Line 1000 Mk2Pebble

1000 Mk2Coal

850 Ironbark LogMk4

1500 Low Line 1400 Mk2 Pebble

1400 Mk2Coal

2000 Low Line 1800 Mk2 Pebble

1800 Mk2Coal

700 Low Line 700 Mk2Pebble

700 Mk2Coal

700 Ironbark LogMk4

850 Low Line 800 Mk2 Pebble

800 Mk2Coal

850 Ironbark Mk4

1100 Low Line 1000 Mk2Pebble

1000 Mk2Coal

850 Ironbark LogMk4

1500 Low Line 1400 Mk2 Pebble

1400 Mk2Coal

2000 Low Line 1800 Mk2 Pebble

1800 Mk2Coal

28/02/2019 Ver. 25

NOTE: The chimney in which the appliance is installed

is not to be considered as a ventilation opening.

PLEASE NOTE:

All power flue external joints (inc. flue joints,

attenuator, Fan, etc.) must be sealed with

approved heat rated (149°C minimum

continuous exposure rating) foil tape

after joining sections! Internal flues do not

need to be sealed with foil tape.

2

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

T=flue terminal

I =Mechanical air inlet

M=Gas meter

P = Electricity meter or fuse

box

Shading indicates

prohibited

areas for flue terminals

a

Below eaves, balconies or other projections:

Appliances up to 50 MJ/h input

Appliancesover 50 MJ/h input

From the ground or above a balcony

From a return wall or external corner

From a gas meter (M)

From an electricity meter or fuse box (P)

From a drain or soil pipe

Horizontally from any building structure (unless appliance

approved for closer installation) or obstruction facinga terminal

From any other flue terminal, cowl, or combustion air intake

Horizontally from an openable window, door, non-mechanical air

inlet, or any other opening intoa building, with the exception of sub-floor ventilation:

Appliances up to 150 MJ/h input

Appliances over 150 MJ/h input

From a mechanical air inlet, including a spa blower

MIN. CLEARANCE(mm)

300

500

300

500

1000

500

150

g

500

500

h

j

500

150

150

k

Vertically below an openable window, non-mechanical air inlet

or any other opening into a building, with the exception of sub-

floor ventilation

See table below

NOTES:

I. All distances are measured vertically or horizontally along the wall to a point

in line with the nearest part of the terminal.

2. Prohibited area below electricity meter or fuse box extends to ground level.

3. See clause 5.13.6.6 for restrictions on a flue terminal under a roofed area.

4. See Appendix J, Figure JI (a) and J2(a) for clearances required from a flue

terminal to a LP Gas cylinder. A flue terminal is considered to be a source of ignition.

MINIMUM CLEARANCES REQUIRED FOR BALANCED FLUE TERMINALS

OR THE FLUE TERMINALS OF OUTDOOR APPLIANCES

CLEARANCES 'n' (mm)

Space heaters

All other appliances

Up to 50

MJ/h

Input

UP to 50 MJ/h

input

Over 50 MJ/h& up

To 150 MJ/h

Over 150 MJ/h

input

150

500

1000

1500

b

c

d

e

f

28/02/2019

Ver. 25

n

3

Before Installation

The Power flue system shall be installed by authorized

personnel in accordance with the manufacturer’s

installation instructions, local gas fitting regulations,

municipal building codes, electrical wiring regulations,

and any other statutory regulations. Contact your local

building authorities about restrictions and installation

inspections that may be required. If in doubt contact

your local dealer or Kemlan’s Head office.

IMPORTANT AUSTRALIAN CODES:

• Australian Standards AS 5601 Gas Installation

• Australian Standards AS 3000 Electrical

Important Safety Notes

• Comply with all instructions in manual

including clearances to combustible material.

• Do not operate without fully assembling

all components.

• All open gas fires require ventilation in the

room.

• Do not connect to any other air distribution duct or

system.

• An A.G.A approved cowl is required at flue terminal.

• Refer to the table below for flue diameter and flue

cowl size.

• Air movement of systems- A decorative gas log fire

must not be installed where the operation of any

ventilation system, fan or air blower could in any

circumstances cause the air pressure to be less than

atmospheric at the appliance.

• Do not block or restrict chimney.

• After installing appliance check that the flue draws

well with smoke pellet.

• Kemlan recommends that all gas fires be serviced

every year.

• All gas units must be fitted by a licensed gas fitter.

• It is the responsibility of the gas fitter to follow the

regulations set out in the Gas Code that dictate the

procedures to follow when installing a gas appliance,

particularly regarding gas pipe sizing and checking of

pressures.

Installation

1 The Power flue system is supplied with all

required electrical fittings. Work needs to be

undertaken by a licensed electrician if extending

wiring. Wiring requires clearance of minimum

100mm to flues and fireplace body due to heat. See

Wiring diagram page15. Wiring must be positively

secured away from heat source.

2 An isolation switch needs to be provided if

connecting within fireplace framework.

3 Build frame to specifications provided. Note: 80mm

clearance above fireplace and 5mm to front surface

of firebox.

4 Unit located on 10mm fiber cement sheeting.

Sheeting required for access to gas burner.

5 Unit and flues to be installed prior to plastering.

6 Gas line run to desired position prior to plastering.

7 Clearance of 25mm to vertical flue.

8 Allow for a minimum flue height of 3.6m.

9 All flue components to be riveted together.

10 Rooms with Gas Open Fires require fresh air vents,

refer to page 2 , Ventilation Requirements, for each

Decorative Gas and Coal Fire.

11 Important: Both caps to stay off if heat zone is not

used.

12 Important: if a heat zone kit with fan is used, the

unused outlet must remain uncapped.

13 Vent (240mm x 90mm) supplied by Kemlan is

required to ventilate chase to room

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

28/02/2019 Ver. 25

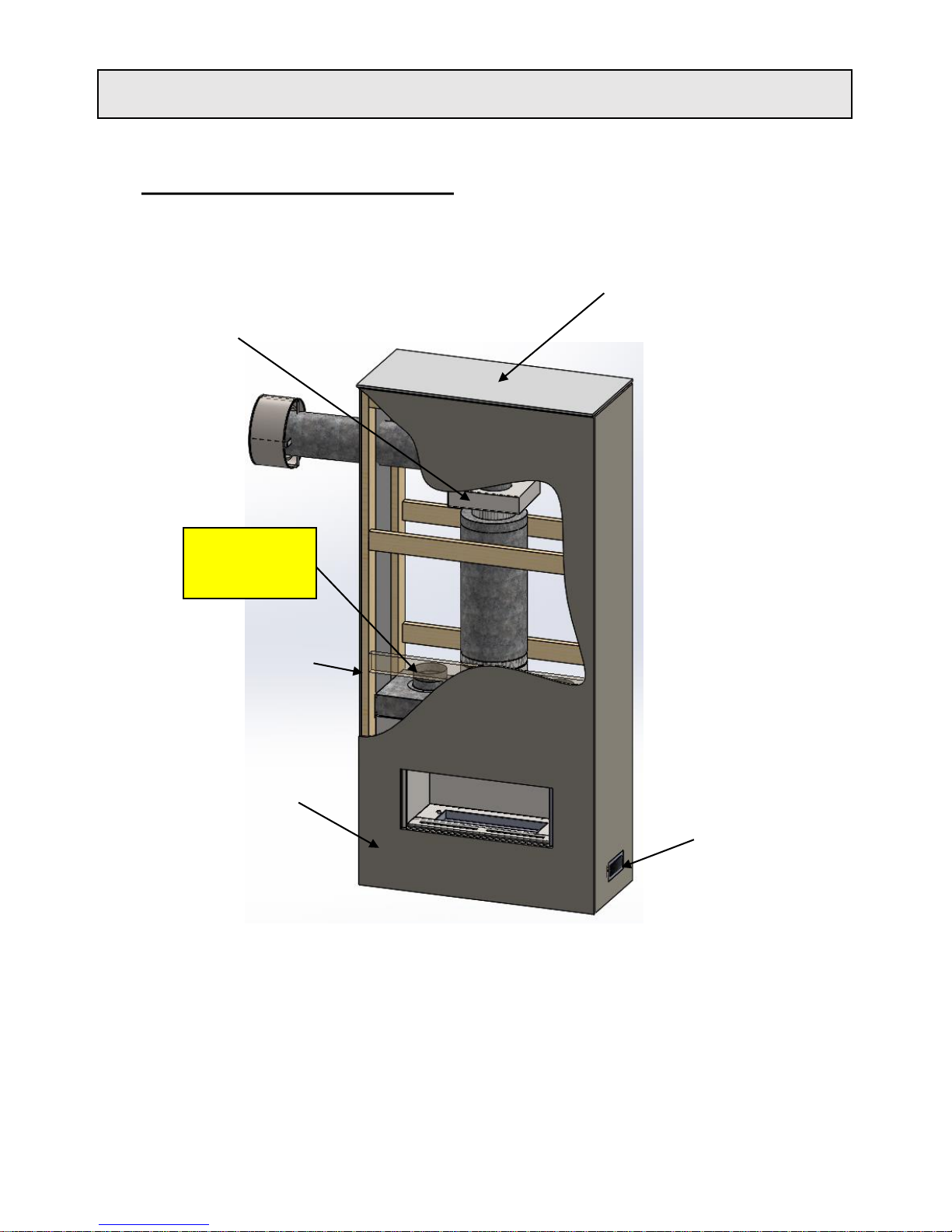

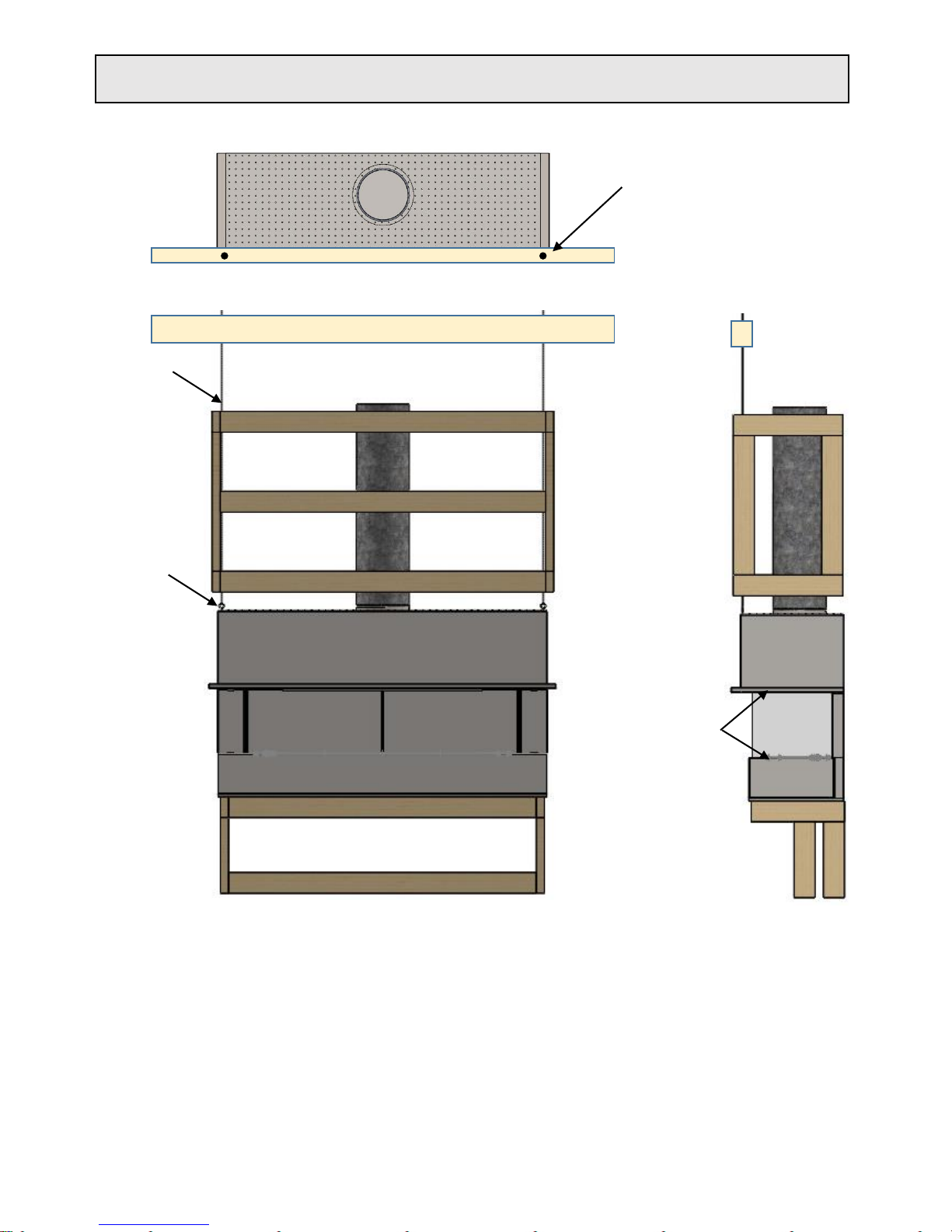

Rear clearances to

combustible material

Cantilever : 0mm

Low line: 25mm

4

28/02/2019 Ver. 25

WALL LININGS BY

INSTALLER

COMBUSTIBLE

FRAMING

ASSEMBLY REQUIREMENTS : LOWLINE SINGLE SIDED MODEL SHOWN

CEILING

IMPORTANT:

VENTILATION INTO

CHASE FROM VENT

240MM X 90MM

(SUPPLIED)

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

INTERNAL FAN

ASSEMBLY

IMPORTANT: BOTH

CAPS NEEDS TO STAY

OFF, IF HEAT ZONE IS

NOT USED

5

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

B*

D

* TO UNDERSIDE OF FLUE WITH EXTERNAL FAN (1300mm)

** TO UNDERSIDE OF FLUE WITH INTERNAL FAN (1010mm)

+ BOX SIZE ONLY NOT INCLUDING LIP FRAME

EXTERNAL FAN

CASING

3 PIN PLUG

240 VOLT

10 AMP

ISOLATING

SWITCH

3 PIN PLUG

240 VOLT

10 AMP

ISOLATING

SWITCH

ON/OFF SWITCH

TO BURNER

A*

D

INTERNAL FAN

REAR EXIT

EXTERNAL FAN

SIDE EXIT

ON/OFF SWITCH

TO BURNER

GAS INLET

CONNECTION UNDER

BURNER TYP.

ELECTRICAL LOOM

CONNECTOR BURNER

TO FAN

ELECTRICAL LOOM

CONNECTOR BURNER

TO FAN

REMOVABLE GAS

BURNER

AGA APPROVED

GAS COWL

INTERNAL FAN

CASING

A*

B*

F

K

K

SPIGGOT TYP. DETAIL

G

* TO UNDERSIDE OF FLUE WITH EXTERNAL FAN (1300mm)

** TO UNDERSIDE OF FLUE WITH INTERNAL FAN (1010mm)

+ BOX SIZE ONLY NOT INCLUDING LIP FRAME

I

FRONT OF

FIREPLACE

SECTION VIEW

Z-Z

Y

DETAIL Y -

LIP TRIM ASSEMBLY

Z

Z

Measurement and Specifications of P.F: LOWLINE

PLASTER TRIM 50mm,

100mm &150mm

TRIMS OPTIONAL FOR

BOTH MODELS

IMPORTANT: BOTH

CAPS NEEDS TO STAY

OFF, IF HEAT ZONE IS

NOT USED

Z

NOTE: THE “J” MEASUIREMENT IS TO THE UNDERSIDE OF AN 8” FLUE , THE DIAMETER OF THE 8” INCH FLUE IS 203mm.

H

C

C

J

J

E

E

J

SINGLE SIDED A B C+ D E F G H I J K

700 LOW LINE

700

280

365

770

1000

178

225

10 15

157

*/ **

850 LOW LINE

850

286

405

870

1095

225

275

10 15

183

*/ **

1100 LOW LINE

1100

286

405

870

1345

225

275

10 15

202

*/ **

1500 LOW LINE

1500

286

435

1000

1746

250

300

10 15

208

*/ **

2000 LOW LINE

2000

286

435

1000

2246

250

300

10 15

208

*/ **

DOUBLE SIDED

A B C+ D E F G H I J K

700 LOW LINE

700

280

450

770

1000

250

300

10 15

225

*/ **

850 LOW LINE

850

286

450

870

1095

250

300

10 15

225

*/ **

1100 LOW LINE

1100

286

450

870

1345

250

300

10 15

225

*/ **

1500 LOW LINE

1500

286

435

1000

1746

300

350

10 27

218

*/ **

2000 LOW LINE

2000

286

435

1000

2246

300

350

10 27

218

*/ **

28/02/2019

Ver. 25

6

28/02/2019 Ver. 25

ON/OFF

SWITCH TO

BURNER

INTERNAL FAN

CANTILEVER – REAR EXIT

G

F

C

B

3 PIN PLUG 240

VOLT 10 AMP

ISOLATING

SWITCH

ELECTRICAL LOOM

CONNECTOR BURNER

TO FAN

AGA APPROVED

GAS COWL

INTERNAL FAN

CASING

E

I

SPIGGOT TYP. DETAIL

D

X

X

W

42*

FRONT OF

FIREPLACE

SECTION VIEW

X-X

DETAIL W -

LIP TRIM ASSEMBLY

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

Measurement and Specifications of P.F: CANTILEVER

7

SINGLE SIDED A A1 B C D D1 E F G H I

CANTLEVER 700 1190 1270 480 455 228 279 177 405 336 1010 170

CANTLEVER 1100 1420 1505 480 455 228 279 177 405 336 1010 188

CANTLEVER 1500 1850 1930 480 455 254 304 177 405 336 1010 224

CANTILEVER 2000 2203 2283 480 455 254 304 177 405 336 1010 189

A1

A

H

20

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

MODEL A B C D E F G H I * J K L M N O

CANTLEVER 700 1190 1270 480 336 280 177 440 405 1250 150 TBD 80 470 190 215

CANTLEVER 1100 1420 1505 480 336 280 177 440 405 1485 150 TBD 80 470 190 215

CANTLEVER 1500 1850 1930 480 336 280 177 440 405 1910 150 TBD 80 470 190 215

CANTILEVER 2000 2203 2283 480 336 280 177 440 405 2263 150 TBD 80 470 190 215

A

B

K

L

D

F

J

C

M

N

O

E

I *

* FRAME WIDTH

G

H

FRAMING DIMENSIONS: CANTILEVER

28/02/2019 Ver. 25 8

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

• Eyelets on the unit are supplied for attaching a turn buckle system, 6-

8mm threaded rod is required with a nut and washer either side of a

sufficient supporting roof member. Alternatively, a stainless steel wire

with a minimum 1mm diameter or heavier and a minimum break load of

130kg can also be used.

• Once hooks have been attached to the eyelets the turn buckle can then

be simply wound up to take the tension.

• Tighten the turn buckle until both the top and bottom glass runners are

parallel.

• Removable glass panel can now be placed in position allowing an even

gap between glass and underside of channel.

DRILL THROUGH THE

BEAM , RAFTER OR

FRAMING IF REQUIRED

AND PUSH THROUGH

THE THREADED ROD.

EYELET

MAKE SURE THESE

PLANES ARE PARALLEL,

AND MAKE SURE ALL

CORNERS ARE SQUARE

THREADED ROD

28/02/2019 Ver. 25 9

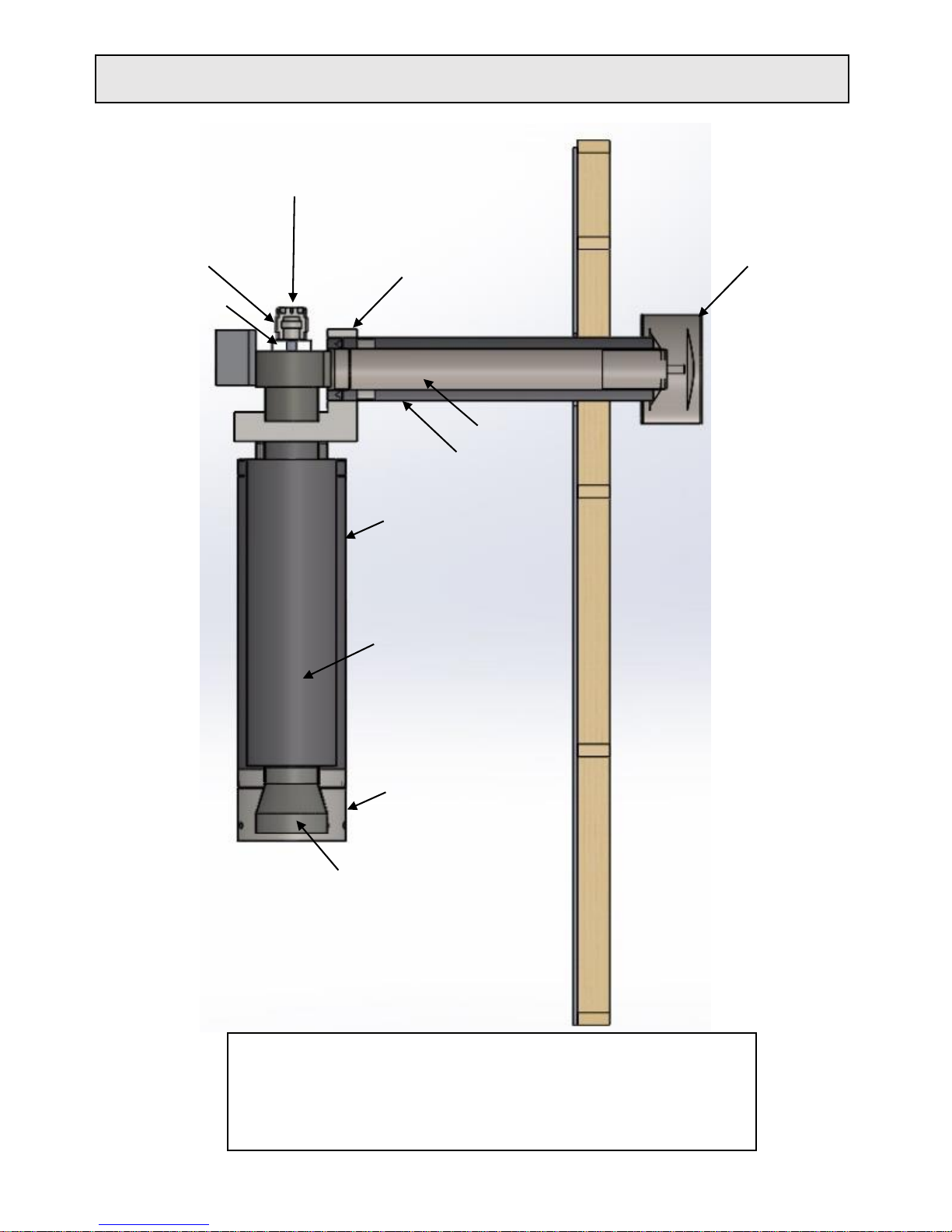

Power Flue with Internal Fan

HEAT TRANSFER

BOX

SILENCER

8” x 900

REDUCER

7” – 6”

8” – 6”

9” – 6”

10” – 6”

12” – 6”

14”-- 6”

GAS COWL

COOLING ROTOR

INBUILT THERMAL

OVERLOAD

COOLING IMPELLER

6” x 900

12.5” x 900

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces

12.5” x 200 VENTED FLUE

Note:

Power flue Horizontal runs greater than 5 meters in length may be compromised by

fluctuations in power. Flue runs greater than 5 meters when tested with underload power

of 15% caused the fan to cut out and burner to turn off and require resetting.

Resetting can be done by turning power off and on. Should power be consistent in supply

then longer flue runs can be recommended and burner will perform correctly.

28/02/2019

Ver. 25

10

Loading...

Loading...