Page 1

COLLATOR

VAC-100

Important Information

- This manual is designed to help you to install, operate and maintain Collator, VAC-100.

Read, understand and keep this manual in a safe and convenient place.

- Do not operate VAC-100 until you read and understand the instructions in this manual.

- Horizon International Inc. shall not be liable for incidental consequential damages

resulting from : improper or inadequate maintenance by customer; unauthorized modification or misuse; operation outside of the environmental specifications for the product.

- Horizon International Inc. pursues a policy of continuing improvement in design and

performance of the product. Therefore, the product design and specifications are subject to

change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or

translated to another language without the prior written consent of Horizon International Inc.

020702/VAC100/09E/DV

I

UM201050-09

Page 2

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in damage on machines. It may also be used to alert against unsafe

practices.

- Read and understand all safety instructions with signal word such as WARNING and

CAUTION. If safety instructions are ignored, personal injury may result.

- Horizon International Inc. cannot anticipate every possible situation that might involve

a potential hazard. The instructions in this manual and warning labels on the machine are

therefore not all inclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation when such operation could cause injury to personnel. Do not attempt to

operate any switch, valve, or other energy isolating device where it is locked or tagged out.

- Do not operate the machines when any covers are removed.

- Some of the drawings in this manual show the machine uncovered for explaining the

detail or inside of machine.

II

Page 3

CONTENTS

Important Information ............................................................................................I

Safety Precautions .................................................................................................... II

1. Before You Begin

1-1 Specifications ...................................................................................................... 2

1-1-1 VAC Series Specifications .............................................................................2

1-1-2 Receiving Tray (Option) Specifications ......................................................... 3

1-2 Machine Descriptions ........................................................................................ 4

1-2-1 Overview ........................................................................................................ 4

1-2-2 Feed Section ................................................................................................... 5

1-2-3 Operation Panel ..............................................................................................6

[1] Main Page.......................................................................................................6

[2] Set 1 Page ....................................................................................................... 8

[3] Set 2 Page ....................................................................................................... 9

[4] Program Page ................................................................................................. 10

[5] Memory Page ................................................................................................. 11

[6] Preset Input Page ............................................................................................ 12

1-2-4 Remote Controller ..........................................................................................13

1-2-5 Receiving Tray (CCR)....................................................................................14

1-2-6 Receiving Tray (CCR-DX) ............................................................................ 15

1-2-7 Stacker (ST-20) .............................................................................................. 16

1-2-8 Stacker (ST-20R)............................................................................................ 17

1-2-9 Stacker (ST-40) .............................................................................................. 18

1-2-10 Stacker (ST-60) ............................................................................................ 19

1-2-11 Hand Marry Unit (HMU-100) ...................................................................... 21

1-3 Accessories .......................................................................................................... 22

1-4 Consumables and Options ................................................................................ 24

2. Operation Procedures

2-1 Power ON ........................................................................................................... 26

2-2 Preparation for Operation ................................................................................27

2-2-1 Tower ON/OFF and Delivery Direction Setup .............................................. 27

2-2-2 Collating Sheet Preparation ............................................................................ 28

2-2-3 Small Size Sheet Setup ................................................................................... 30

2-2-4 Feed Height Adjustment ................................................................................. 32

2-2-5 Blower Adjustment.........................................................................................32

III

Page 4

2-2-6 Double Feed Stop Plate Height Adjustment...................................................33

2-2-7 Separate Nose Adjustments ............................................................................33

2-2-8 Delivery Section Setup ...................................................................................34

[1] Bulging Nose and Delivery Roller Setup ....................................................... 34

[2] Weight Setup ..................................................................................................35

[3] Delivery Air Adjustment ................................................................................36

2-2-9 Tray Unit Setup .............................................................................................. 37

[1] When CCR or CCR-DX Is Used .................................................................... 37

[2] When ST-20/ST-20R Is Used ........................................................................40

2-2-10 Setup in Main Page.......................................................................................41

2-2-11 Hand Marry Unit Setup (HMU-100: Accessary) ......................................... 42

2-3 Collating Operation ...........................................................................................43

2-3-1 Sheet Thickness Calibration ...........................................................................43

2-3-2 Collating Operation ........................................................................................44

2-4 Feed Error Indication and Remedy .................................................................45

2-5 Program Collation ............................................................................................. 47

2-5-1 Double Cycle ..................................................................................................47

2-5-2 Dual Cover Feed ............................................................................................. 49

2-5-3 Tab Insert ........................................................................................................ 51

2-6 Job Memory ....................................................................................................... 53

2-7 Right Side Delivery ............................................................................................54

2-8 Hand Marry ....................................................................................................... 55

3. Troubleshooting

3-1 Error Indication and Remedy .......................................................................... 58

3-2 When Misfeeding Occurs ..................................................................................59

3-3 When Double Feeding Occurs ..........................................................................59

3-4 Sheets Are Fed on the Skew ..............................................................................60

3-5 Paper Jam in Transport Conveyor .................................................................. 60

3-6 Sheet from Hand Marry Unit Is Jammed ....................................................... 61

3-7 Collating Operation Does Not Start Even If Pressing Start Buttom ............ 61

3-8 Fuse and Breaker Check ...................................................................................62

3-9 Pump Does Not Work ........................................................................................ 65

IV

Page 5

4. Maintenance

4-1 Daily Cleaning ....................................................................................................68

4-1-1 Feed Ring .......................................................................................................68

4-1-2 Transport Belt .................................................................................................69

4-2 Monthly Cleaning .............................................................................................. 70

4-2-1 Bin Sensor ...................................................................................................... 70

4-2-2 Delivery Sensor ..............................................................................................70

4-3 Double Feed Stop Plate Replacement .............................................................. 71

4-4 Feed Error Sensor Cleaning ............................................................................. 72

5. Move and Installation

5-1 Collator Installation ...........................................................................................74

5-2 Blower Box Installation .....................................................................................75

5-3 System Switch Set Up ........................................................................................77

5-4 Cable Connection ...............................................................................................78

5-5 Receiving Tray Installation ............................................................................... 79

5-5-1 CCR/CCR-DX ................................................................................................ 79

5-5-2 ST-20/ST20R..................................................................................................80

5-6 EAB-100 Extra Air Blower (Option) Installation ...........................................82

5-7 VAC-100a Right Side Unit (Option) Attachment ...........................................87

5-7-1 Accessories .....................................................................................................87

5-7-2 How to Attach ................................................................................................89

5-8 HMU-100 Hand Marry Unit (Option) Installation .........................................97

5-8-1 Accessories .....................................................................................................97

5-8-2 Hand Marry Unit (HMU-100) Installation .....................................................98

5-8-3 Cable Connection ........................................................................................... 101

V

Page 6

VI

Page 7

1. Before You Begin

1. Before You Begin

1-1 Specifications ........................................................................................... 2

1-2 Machine Descriptions .............................................................................. 4

1-3 Accessories ............................................................................................... 22

1-4 Consumables and Options ...................................................................... 24

1

Page 8

1. Before You Begin

1-1 Specifications

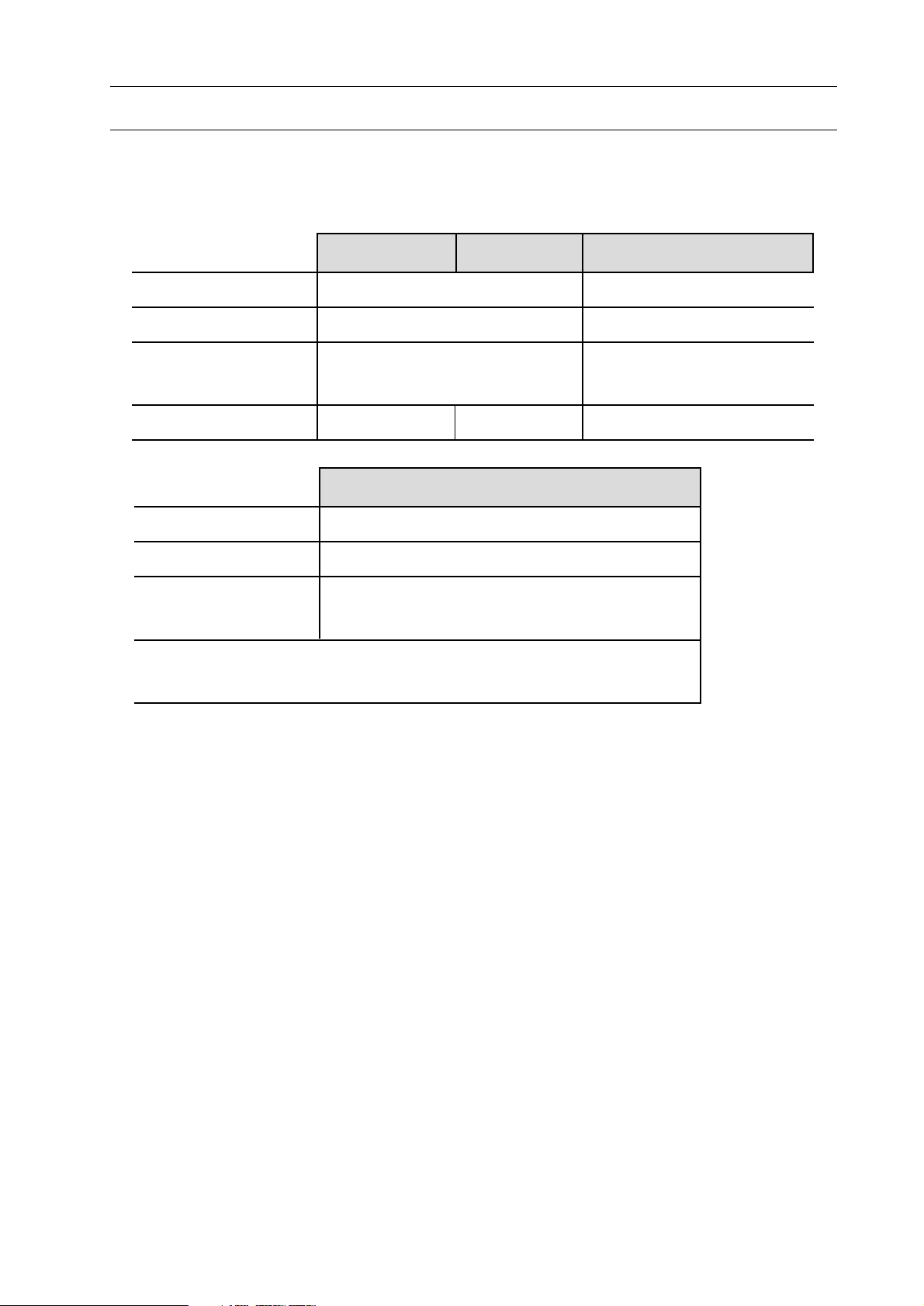

1-1-1 VAC Series Specifications

Module Type VAC-100a (Main Module)

VAC-100m (Extension Module)

VAC-100c (Rear Delivery Module)

Number of Bins 10, 20, 30, 40, 50, 60

Sheet Size 148 x 148 mm to 350 x 500 mm

(5.8" x 5.8" to 13.8" x 19.7')

Bin Pile Height 55 mm (2.2")

Paper Weight Range 52 gsm to 208 gsm

Collating Speed 8,000 sets/hr (Single or 2 to 3 towers installation and Straight Receiving)

5,000 sets/hr (4 towers installation and Straight Receiving)

4,500 sets/hr (5 towers installation and Straight Receiving)

4,000 sets/hr (6 towers installation and Straight Receiving)

Error Detection Miss, Double and Jam detection system (Photocell)

Error Monitor Eight sets of Feed Error Monitors

Power 3-Phase 200 V 50/60 Hz

3-Phase 220 V 60 Hz 10.4A

Single Phase 230 V 50 Hz 10.4A

Power Consumption 200 V 1,500 W / 220 V 1,700 W / 230 V 1,800 W

Motors 1,200 W x 1 / 400 W x 1 / 200 W x 1 / 100 W x 1

60 W x 1 (only a, c towers)

Machine Weight VAC-100a : 290 kg (639.5 lb)

VAC-100m : 290 kg (639.5 lb)

VAC-100c : 290 kg (639.5 lb)

The machine design and specifications are subject change without any notice.

2

Page 9

1. Before You Begin

1-1 Specifications

1-1-2 Receiving Tray (Option) Specifications

Model CCR CCR-DX ST-20 and ST-20R

Max. Sheet Size 318 x 470 mm (12.5" x 18.5") 320 x 450 mm (12.6" x 17.7")

Min. Sheet Size 148 x 210 mm (5.9" x 8.3") 128 x 185 mm (5.1" x 7.3")

Max. Pile Height A5 to A4 : 170 mm (6.7") 320 mm (12.6")

A4 to A3 : 100 mm (3.9")

Machine Weight 56 kg (123.5 lb) 64 kg (141.2 lb) 56 kg (123.5 lb)

Model HMU-100

Max. Sheet Size 350 x 500 mm (14" x 20")

Min. Sheet Size 120 x 148 mm (4.7" x 5.8")

Max. Sheet Height 80 gsm (21.3 lb) 50 sheets (5 mm)

Min. Sheet Height 80 gsm (21.3 lb) 1 sheets (0.1 mm)

The HMU-100 can be used with maximum of two-tower VAC-100.

The HMU-100 can not be connected with c-tower VAC-100.

The machine design and specifications are subject change without any notice.

3

Page 10

1. Before You Begin

1-2 Machine Descriptions

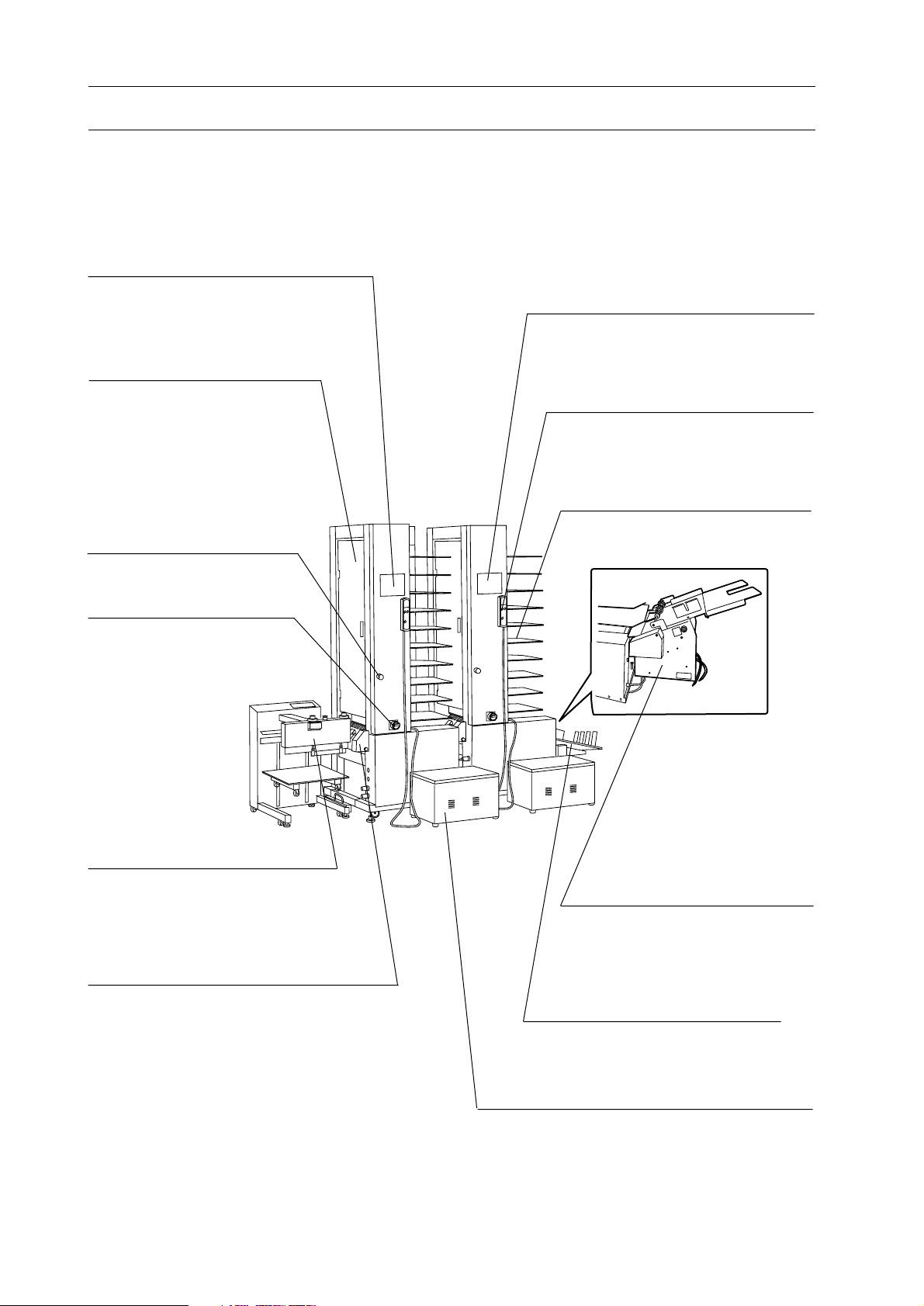

1-2-1 Overview

Operation Panel (a-Tower)

This panel is used to operate or setup

collator. Feed errors and troubles are

indicated on this panel.

Transport Door

Belts, which transports sheets

from each bin, are provided

inside this door. This door can

be opened or removed.

Stop Button

Operation Panel (c-Tower)

Sheets can be delivered to the right by

setting with this panel. Feed errors and

troubles are indicated on this panel.

Remote Controller

Main operation can be performed

with this remote controller.

Bin

Sheets are loaded on this bin.

Power Switch

Accessories

Receiving tray or stitcher & folder

(option) can be connected as

finishing device.

Delivery Section

Sheets are transported from this section to

the accessory.

Hand Marry Unit (Option)

This unit is used to insert a sheet

on or under the collated sheets in

VAC-100. It can be attached to a tower or m-tower.

Accessories (Option)

Receiving tray can be connected

as finishing device.

Stool

This stool is used to load sheets on the upper

bin. This stool is equipped with blower.

4

Page 11

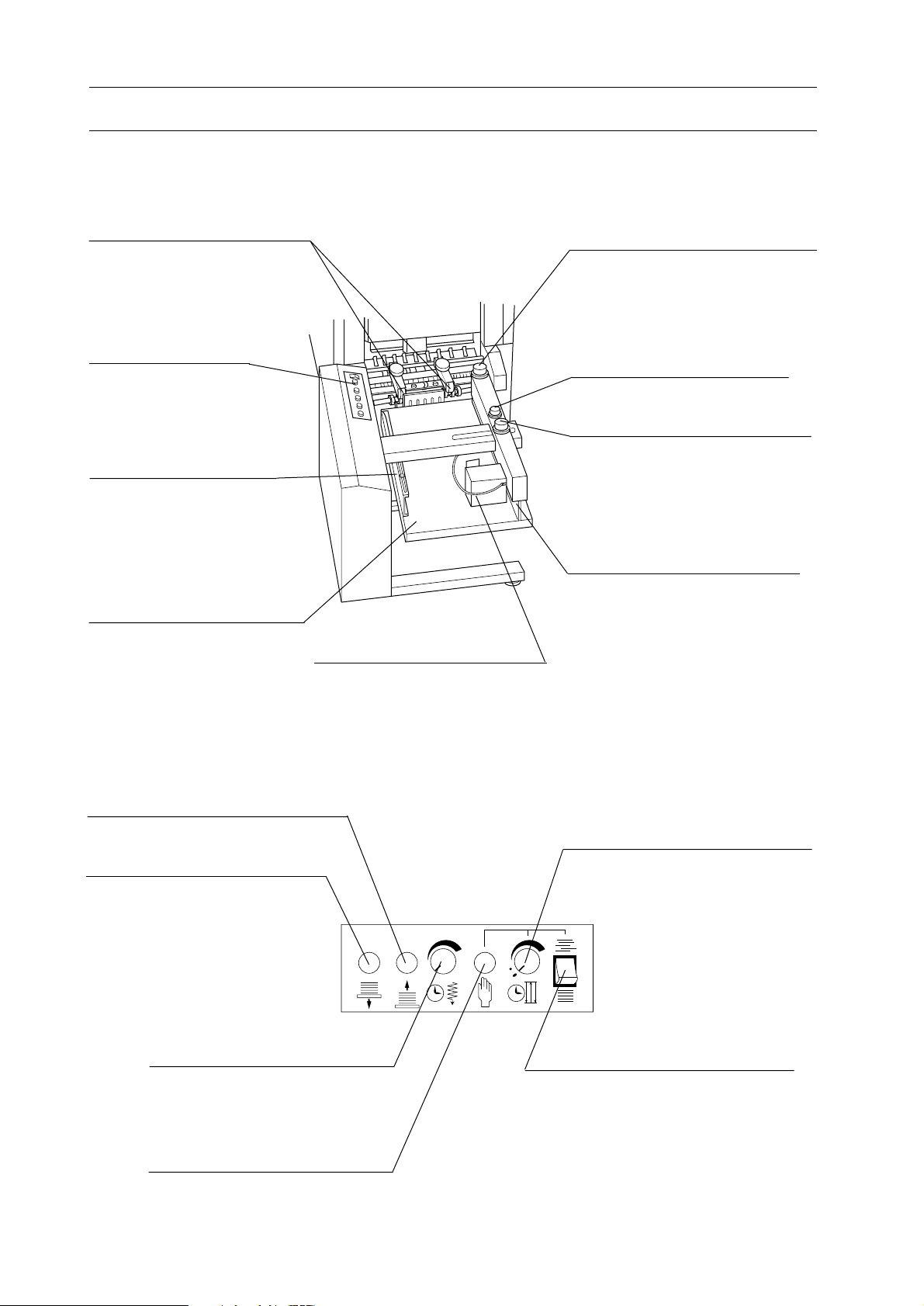

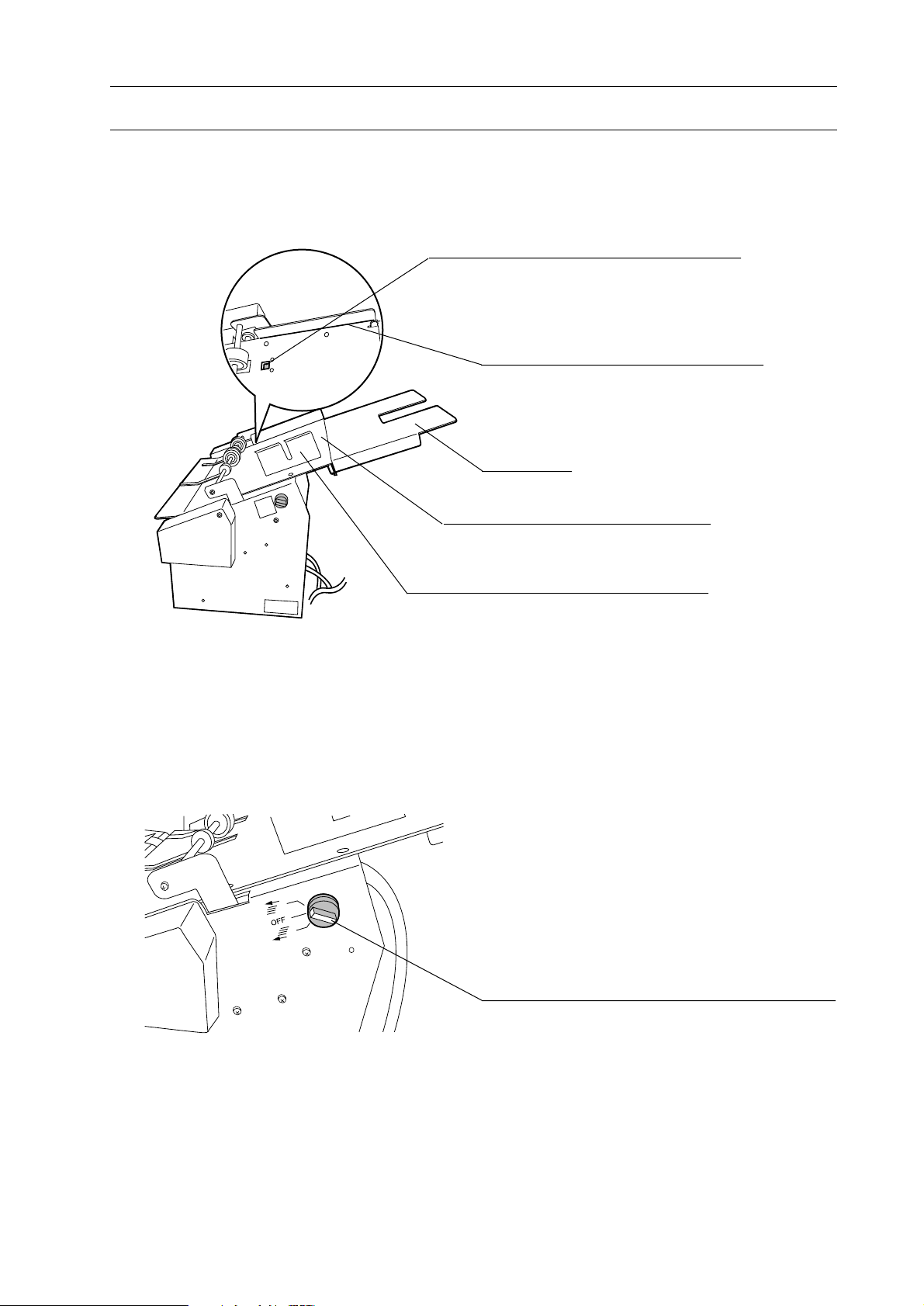

1-2 Machine Descriptions

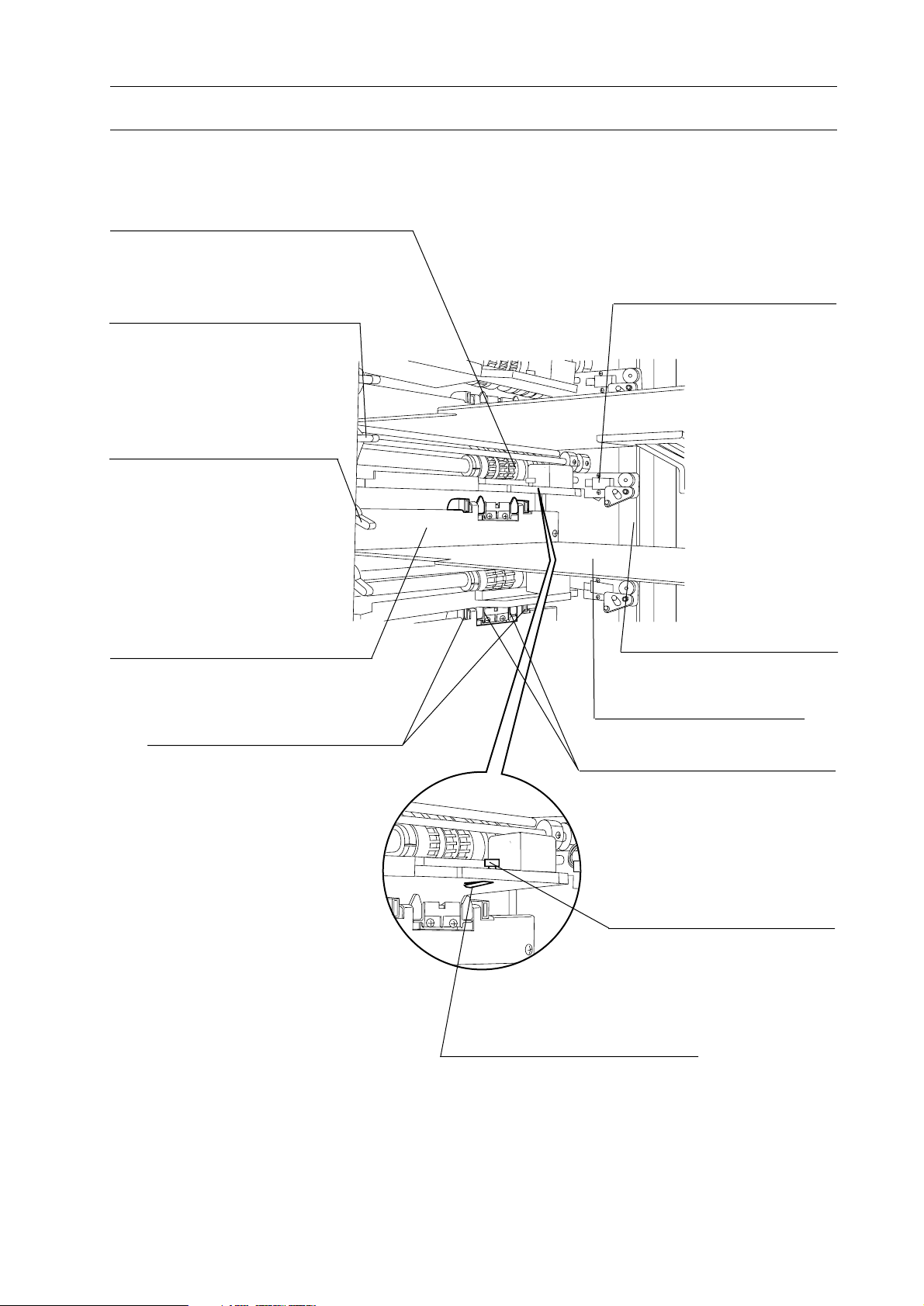

1-2-2 Feed Section

Feed Rotor

This rotor sucks and feed sheets.

1. Before You Begin

Feed Height Adjust Lever

(White)

This lever is used to adjust the

height of feed height sensor.

Separation air Adjust

Lever (Blue)

This lever is used to adjust

separation air.

Front Plate

This plate is the left register when

sheets are loaded on bin.

Blower Nozzle

Blowing air comes out from this

blower nozzle.

Feed Height Sensor

This sensor determines the

sheet feed height.

Side Guide

This guide is the rear register

when sheets are loaded on bin.

Bin

Sheets are loaded on this bin.

Double Feed Stop Plates

These plates prevent double feeding.

Separate Nose Knob

Separate Nose

This separate nose supports to

separate sheets to prevent double

feeding.

5

Page 12

1. Before You Begin

1-2 Machine Descriptions

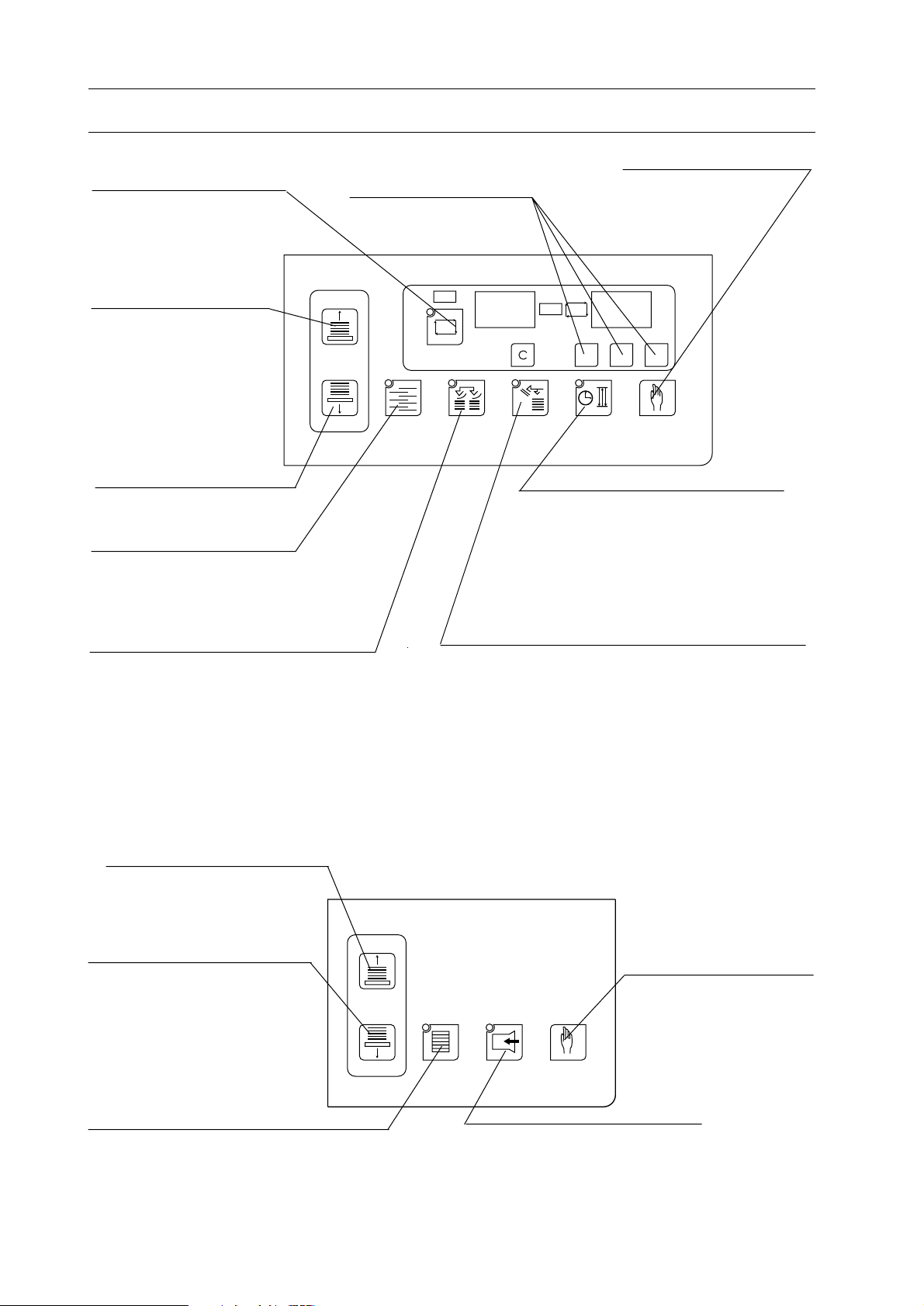

1-2-3 Operation Panel

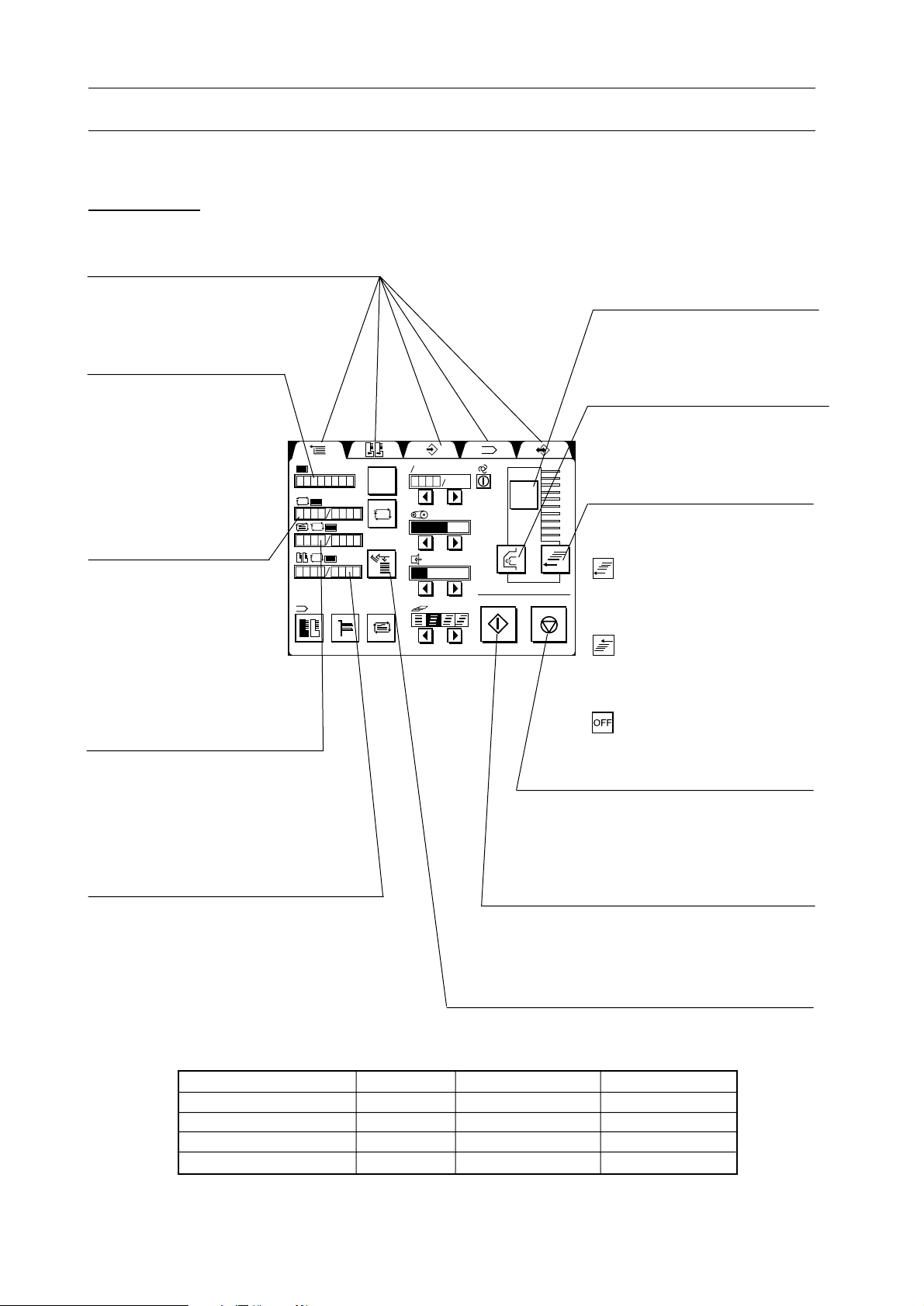

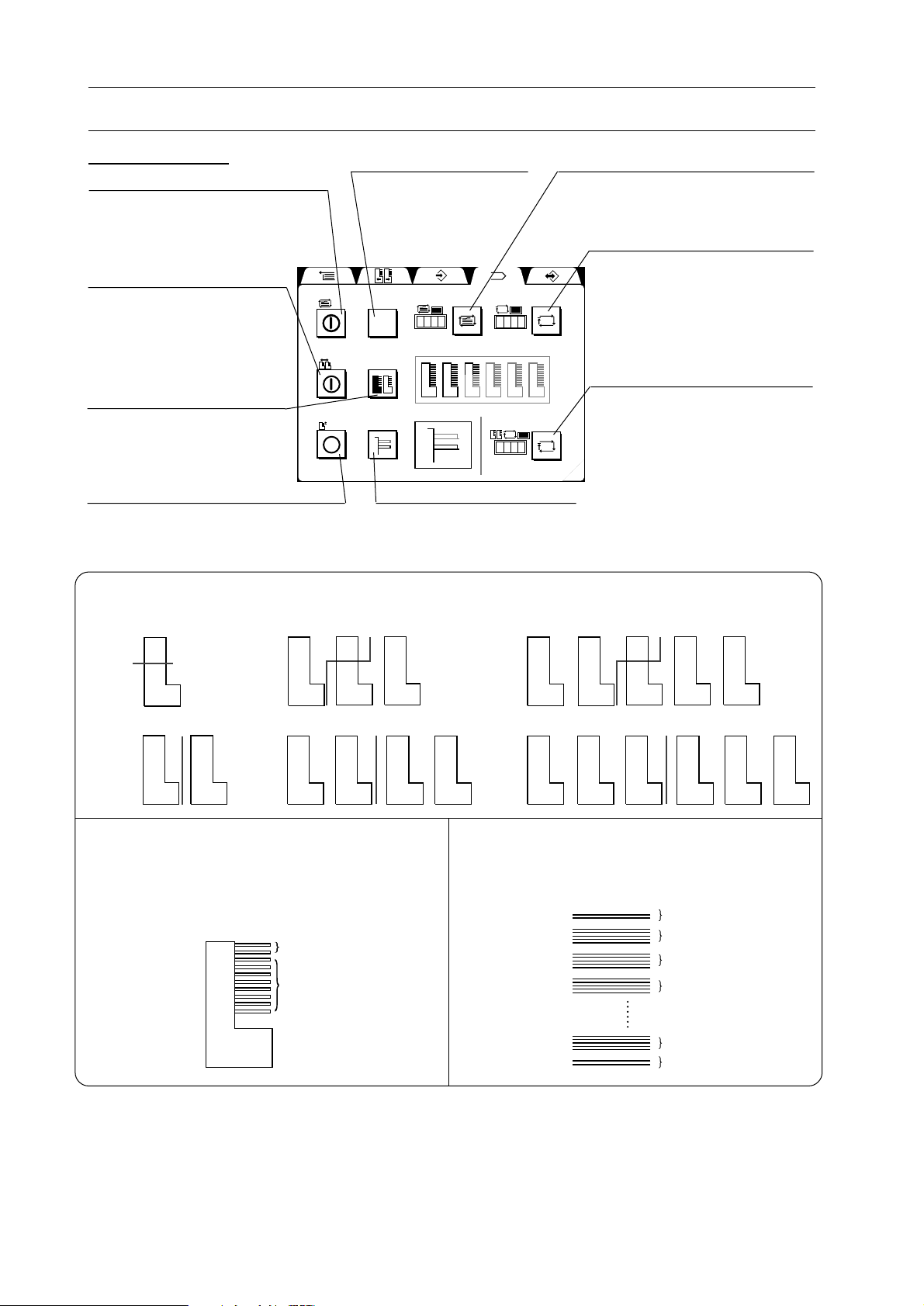

[1] Main Page

Tabs

These tabs are used to select the page

on the screen.

Total Counter

This counter counts sets of

collated sheets. This

counter can be reset with

clear button. When main

power is turned off, this

counter is reset.

Preset Counter

In case the required

number of collated sets is

input in this counter with

the right preset button, the

collation stops when the

number of collated sets

reaches the input number.

Tab Counter

This counter indicates the current

number of times of tab insert and

the preset number of tab insert.

Tab insertion must be set on the

program page.

Double Cycle Preset Counter

In case the double cycle mode is turned

on and the number of double cycle preset

is input in program screen with the

double cycle preset button, the collating

section is automatically switched over

when the number of collated sets reaches

the input number.

123

123

123

123

Error Monitor Button

This button is used to indicate

feed error.

Delivery Air ON/OFF Button

This button is used to turn on/

off delivery air.

60 min.

C

60 min.

?

Hand Marry Mode Indication

These icon indicate the selected mode on HMU-100.

: Sheet(s) from hand marry

unit is inserted under collated

sheets.

: Sheet(s) from hand marry

unit is inserted on collated

sheets.

: Hand marry unit is not

used.

Stop Button

This button is used to stop the operation.

This button must be pressed three times

to stop the collator completely and lower

bins. Refer to the chart below.

Start Button

This button is used to start the operation. The

operation will not start before sheet calibration is performed.

Feed Error Reject Function ON/OFF Button

This button is used to turn ON/OFF the function of

delivering errored sets, to the feed-error tray.

Stop Button Pressing Times

0

1

2

3

Feeding

ON

OFF

OFF

OFF

Motor and Blower

ON

ON

OFF

OFF

6

Bin

Up

UP

UP

DOWN

Page 13

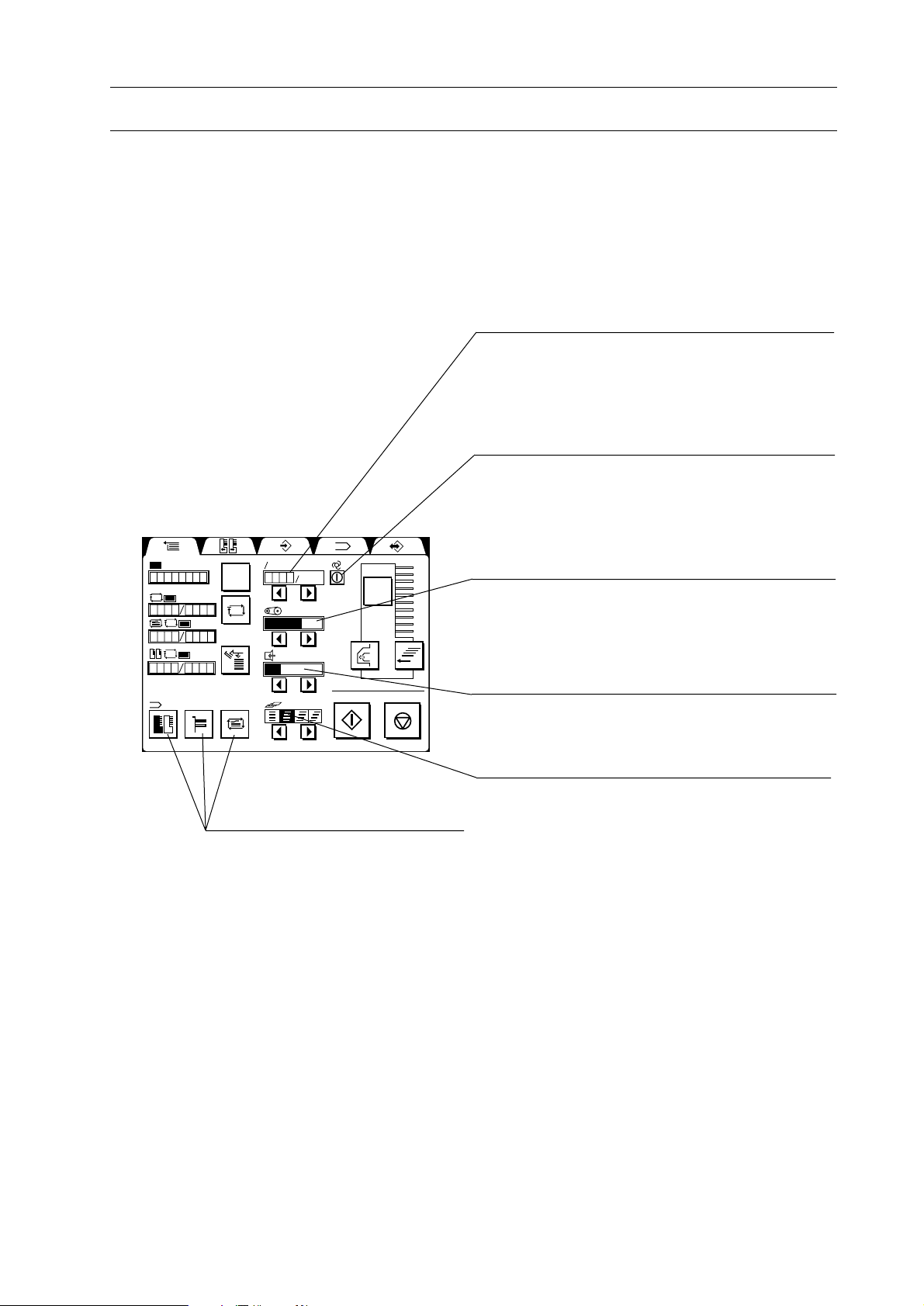

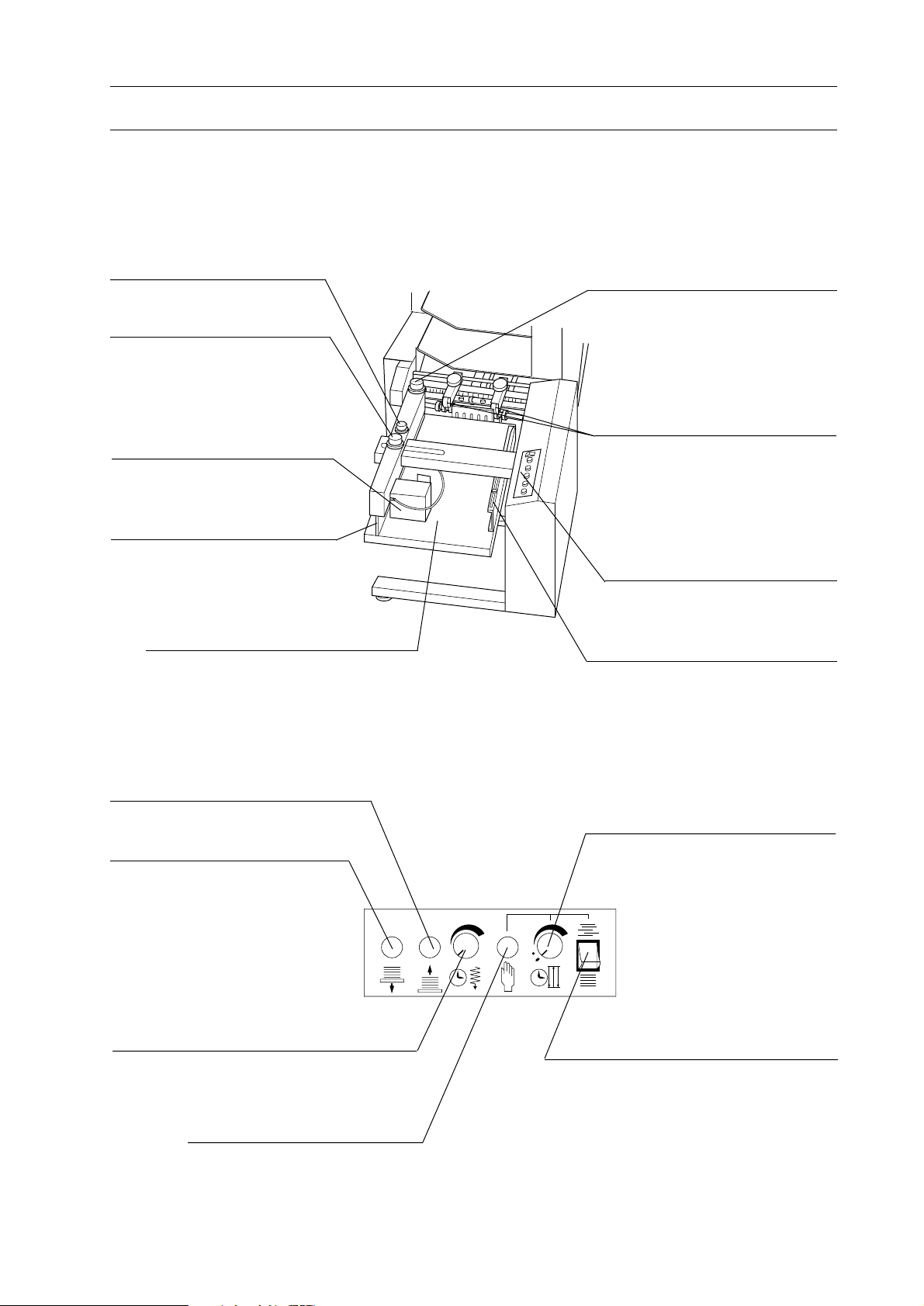

1-2 Machine Descriptions

1. Before You Begin

Feed Speed Indication

Feed speed can be set with triangle buttons

below. The speed can be changed during operation.

Automatic Setup Button

This button is used only when SPF-20A is

combined. When this button is pressed, the

collator speed is adjusted automatically to match

the SPF-20A speed.

123

123

123

123

60 min.

C

60 min.

?

Belt Speed Indication

The belt which transports collated sheets can be

adjusted on three scales with triangle buttons

below.

Suction Air Indication

Suction air power can be adjusted on two scales

with triangle buttons below.

Overlap

The sheet overlap can be adjusted on four scales

Program Indication

with triangle buttons below.

These icons indicate the setup

program function.

7

Page 14

1. Before You Begin

1-2 Machine Descriptions

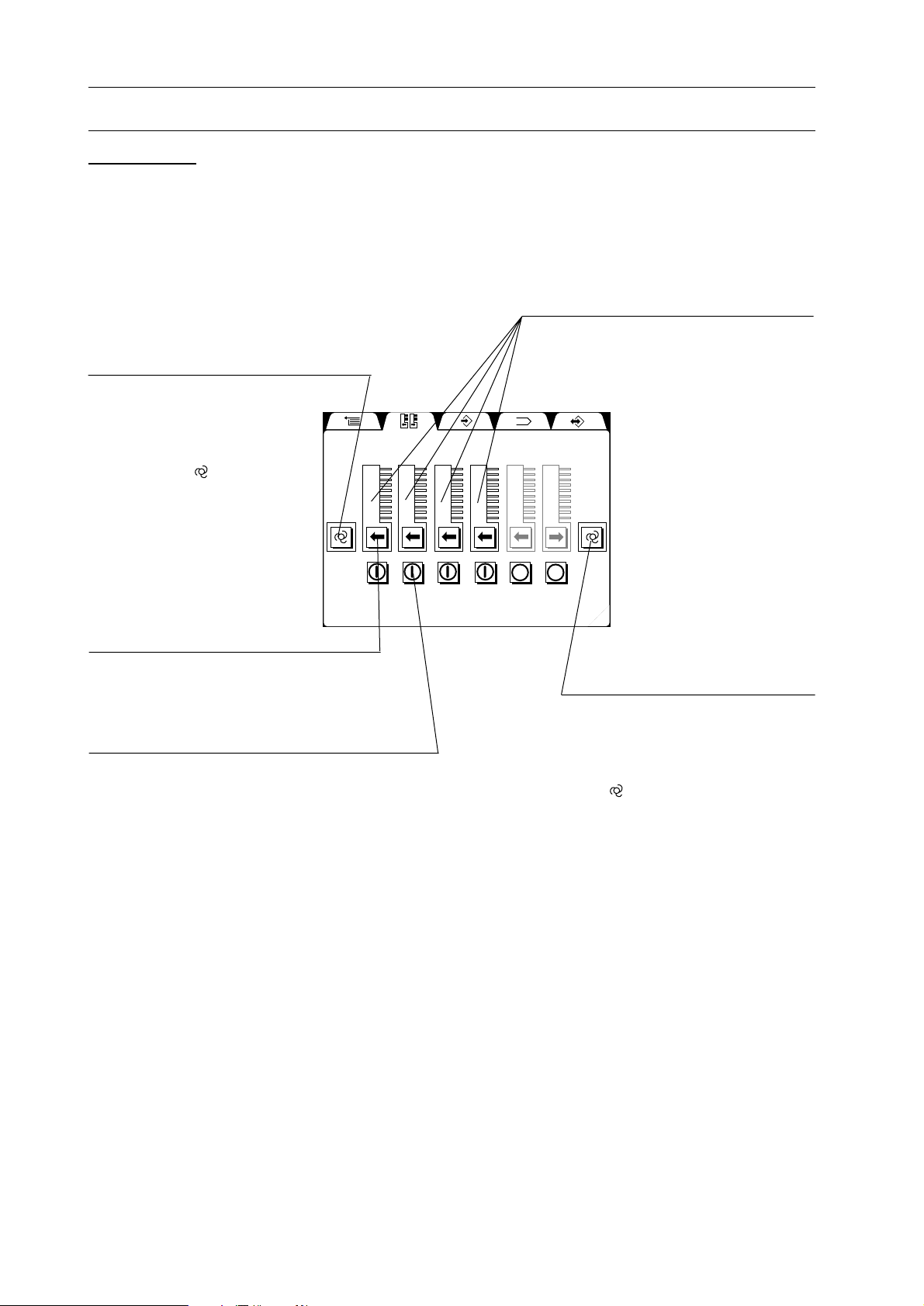

[2] Set 1 Page

Finishing Device Button

This button is used to select

the finishing device combined.

When CCR-DX is used, CCRDX icon must be selected. The

standard icon ( ) must be used

for all the other devices.

Tower Indication

The current used towers (collators) are

highlighted.

1 2 3 4 5 6

Delivery Direction Button

This button is used to select delivery

direction. The c-tower is required to

deliver collated sheets to the right.

Tower Main Power Button

The tower which is not used must be turned off.

Finishing Device Button

This button is used to select the

finishing device combined. When

CCR-DX is used, CCR-DX icon

must be selected. The standard

icon ( ) must be used for all the

other devices.

8

Page 15

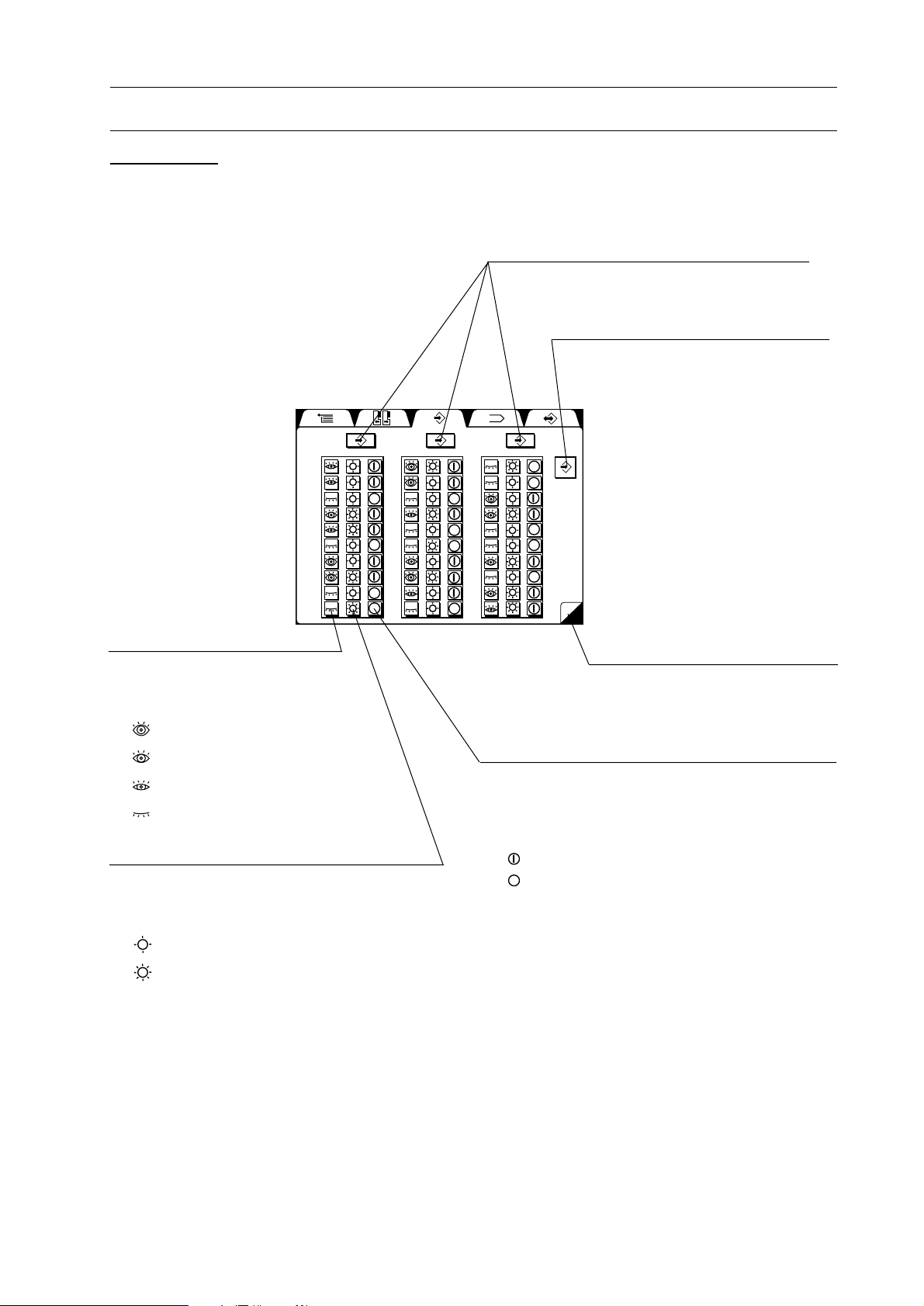

1-2 Machine Descriptions

[3] Set 2 Page

123

1

2

3

4

5

6

7

8

9

10

Sensor Button

This button is used adjust feed

error sensor sensitivity on four

scales.

: High

: Middle

: Low

: Double Feed Detect OFF

Lamp Button

This button is used to adjust the light intensity

on two scales according to the sheet thickness

and print darkness.

: for Normal to Thin

1

2

3

4

5

6

7

8

9

10

1. Before You Begin

Individual Calibration Buttons

These buttons are used to calibrate the sheet

thickness in the individual tower.

All Tower Calibration Button

This button is used to calibrate the

sheet thickness in all towers.

1

2

3

4

5

6

7

8

9

10

1

2

Page UP/DOWN Button

This button is used to see the rest

of tower indication when four

towers or more are combined.

Bin Power Button

This button is used to turn on/off bin. The bin

where sheets are loaded during a sheet calibration is on. If sheets on the particular bin do not

require to be fed, the bin must be turned off.

: ON

: OFF

: for Thick or Dark Print Image

9

Page 16

1. Before You Begin

1-2 Machine Descriptions

[4] Program Page

Tab Insert Button

This button is used to turn on/off

the tab insert.

Double Cycle Select

Button

This button is used to select

which section is started in

the double cycle program.

Double Cycle Button

This button is used to turn

on/off the double cycle

mode.

Dual Cover Feed Button

This button is used to turn on/off the

dual cover feed mode.

Double Cycle :

The VAC-100 system is divided into two sections. When any bin empties, the

VAC-100 immediately switches over to the second section and continues collating.

1

AB

10

1 Tower

1

A

5

6

B

10

3 Towers

Tab Sheet Button

This button is used to

select one tab sheet or

two to be used.

1

Bin Select Button

This button is used to select

which bin is started in the

dual cover feed program.

1

5

6

10

1

A

B

10

123

123

5 Towers

Preset Button

This button is used to set where tab

sheets are inserted.

Stop Button

This button is used to input

number of tab insert to stop

operation when the number of

tab insert reaches the input

number.

Double Cycle Preset Button

In case the number of double

cycle preset is input, the

123

collating section is automatically switched over when the

number of collated sets

reaches the input number.

1

10

1

A

10

1

5

6

AB

10

1

A

B

10

1

B

10

1

2 Towers

10

Dual Cover Feed : When one cover bin

1

AB

10

4 Towers

empties, the VAC-100

automatically switches over

to the other cover bin.

1

10

1

10

Cover Sheets

1

10

1

10

BBAA

6 Towers

1

10

1

A

10

1

10

1

10

1

10

1

BBAA

B

10

Tab Insert : Up to two tab sheets can be

inserted between preset collated

sets.

Tab Sheets

Collated Sets

Collated Sets

Collated Sets

Collated Sets

Collated Sets

Tab Sheets

NOTE

- Double cycle and dual cover feed programs can be operated together. The place of cover

sheets in the second section is the first two bins in the second section.

- Double cycle and tab insert programs can be operated together. The place of tab sheets in the

second section is the first bin in the second section.

10

Page 17

1-2 Machine Descriptions

[5] Memory Page

1. Before You Begin

Job No. Button

Up to nine collating setup patterns can be

stored with these buttons.

Current Setup Button

This button is used to indicate

the current setup condition of

collator.

123

123

Setup Indication

The setup condition is indicated when

current setup button or job No. button is

pressed.

Write Button

This button is used to memorize the collating setup pattern

in the selected job No.

1 2 3 4 5 6 7 8 9

hr.

hr.

Read Button

This button is used to read the memorized setup for the selected job No.

11

Page 18

1. Before You Begin

1-2 Machine Descriptions

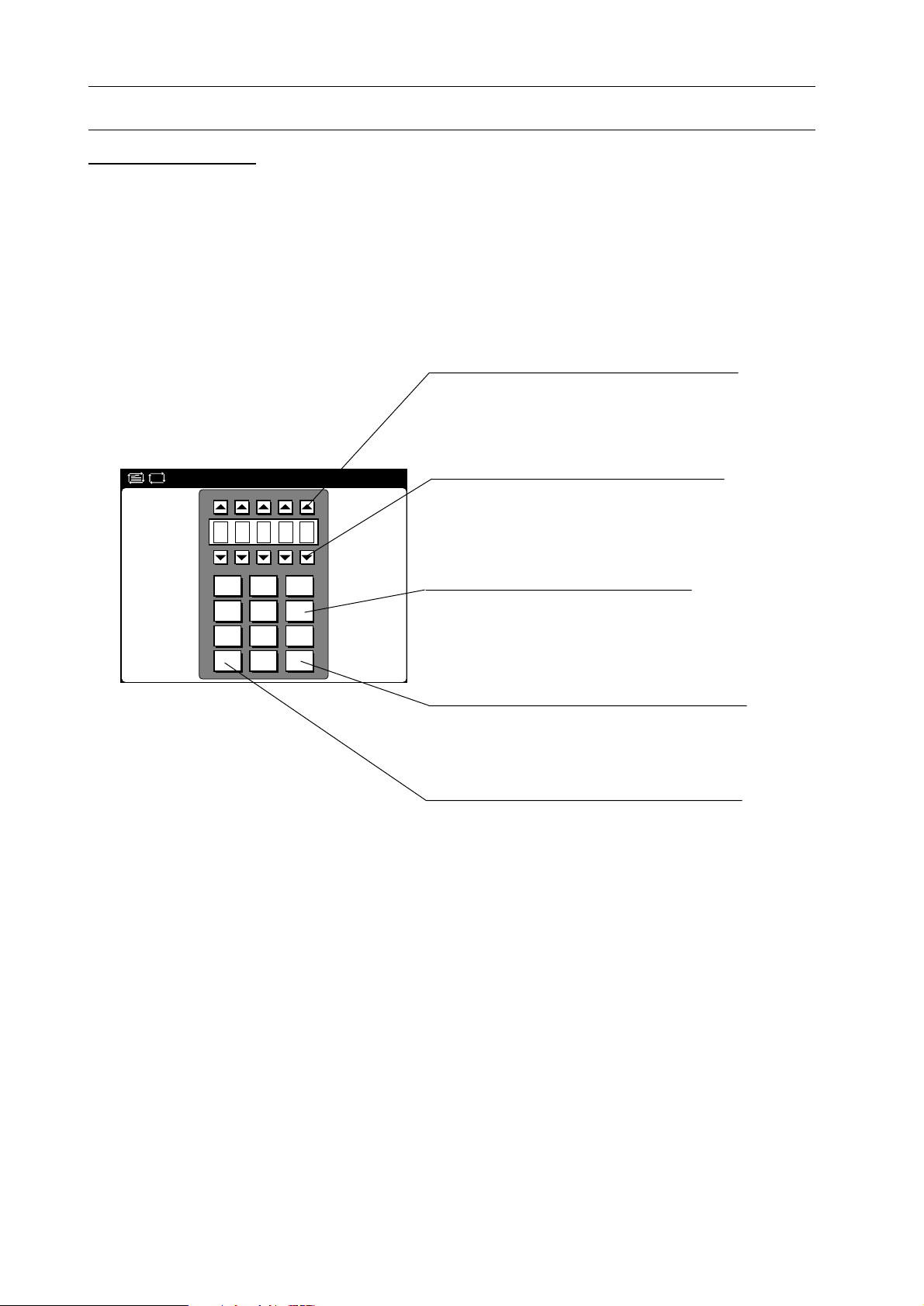

[6] Preset Input Page

The preset input page is shown by pressing preset button on the main page or program page.

UP Key

This key is used to increase the number

indicated.

DOWN Key

This key is used to decrease the number

indicated.

171

141

111

1C1

819

516

213

01E

10-number Keys

The required number can be input

with these keys.

Enter Key

This key is used to enter the number. The

page goes back after pressing this key.

Clear Key

The key is used to clear the input number.

12

Page 19

1-2 Machine Descriptions

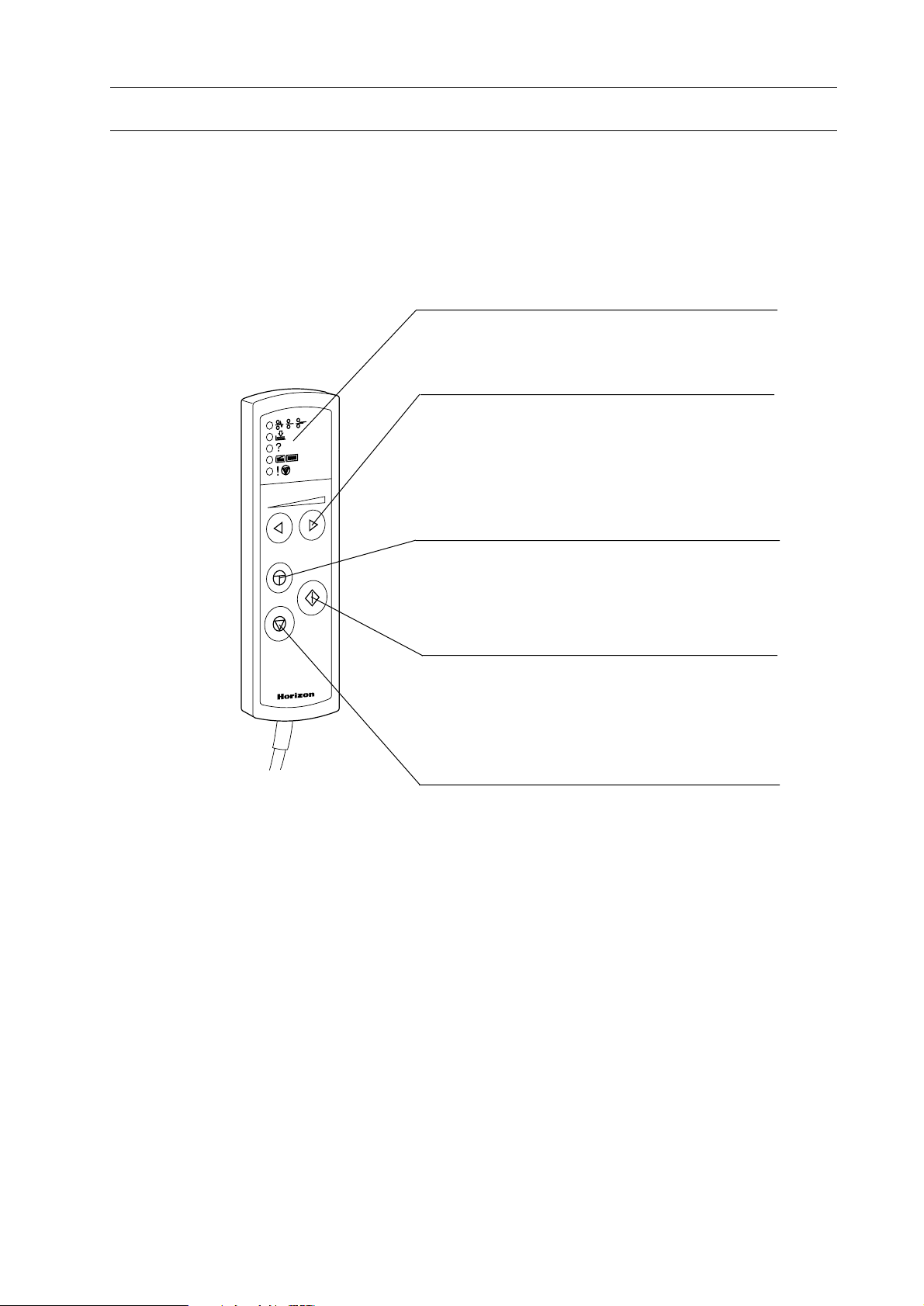

1-2-4 Remote Controller

123

1. Before You Begin

Trouble Monitor

When collating operation stops, this monitor let

the operator know the cause with lamp lighting.

Speed Button

This button is used to adjust the collating speed.

The speed can be adjusted during the operation.

This button has the same function as the one on

the main page. While this button is being

pressed, the speed is increased rapidly.

Inching Button

This button is used to inch roller and belt in the

transport and delivery sections. They can inch

during being pressed this button.

Start Button

This button is used to start the operation. The

operation cannot be started before sheet calibration is performed. This button has the same

function as the one on the main page.

Stop Button

This button is used to stop the operation. This

button has the same function as the one on the

main page. When this button is pressed with

error page shown on the screen, the screen goes

back to the main page. This function is the same

as the OK button in the error page.

13

Page 20

1. Before You Begin

1-2 Machine Descriptions

1-2-5 Receiving Tray (CCR)

Tray

Tray for A5 to A4 sheet size or

for B4 to A3 sheet size can be

selected.

Delivery Rollers

These rollers transport collated

sets to receiving tray. Weights

correct sheet skew.

Air Adjust Knob

This knob is used to adjust the

delivery air.

Stopper

This stopper must be set according to

the sheet size.

Tray Lock Knob

This knob is used to lock tray.

(Operation Panel)

Connecting Cable

This cable must be connected

to the collator connector.

Operation Panel

L

S

Off-set ON/OFF Switch

This switch is used to switch on/off

off-set.

Off-set Timing Knob

This knob is used to adjust the side

guide delay after sheets are delivered

to CCR.

Single Motion Button

Tray rotation can be actuated

with this button.

14

Page 21

1-2 Machine Descriptions

1-2-6 Receiving Tray (CCR-DX)

1. Before You Begin

Tray

Tray for A5 to A4 sheet size or for B4

to A3 sheet size can be selected.

Full Tray Sensor

(Only for Small Receiving Tray)

This sensor detects full tray.

Stopper

This stopper must be set according to

the sheet size.

Tray Lock Knob

This knob is used to lock tray.

Delivery Rollers

These rollers transport collated

sets to receiving tray. Weights

correct sheet skew.

Air Adjust Knob

This knob is used to adjust the

delivery air.

Connecting Cable

This cable must be connected

to the collator connector.

Operation Panel

(Operation Panel)

Full Tray Detection Switch

This switch is used to switch on/off

full tray detection.

Off-set ON/OFF Switch

This switch is used to switch on/off

off-set.

L

S

Off-set Timing Knob

This knob is used to adjust the side

guide delay after sheets are delivered

to CCR-DX.

Single Motion Button

Tray rotation can be actuated

with this button.

15

Page 22

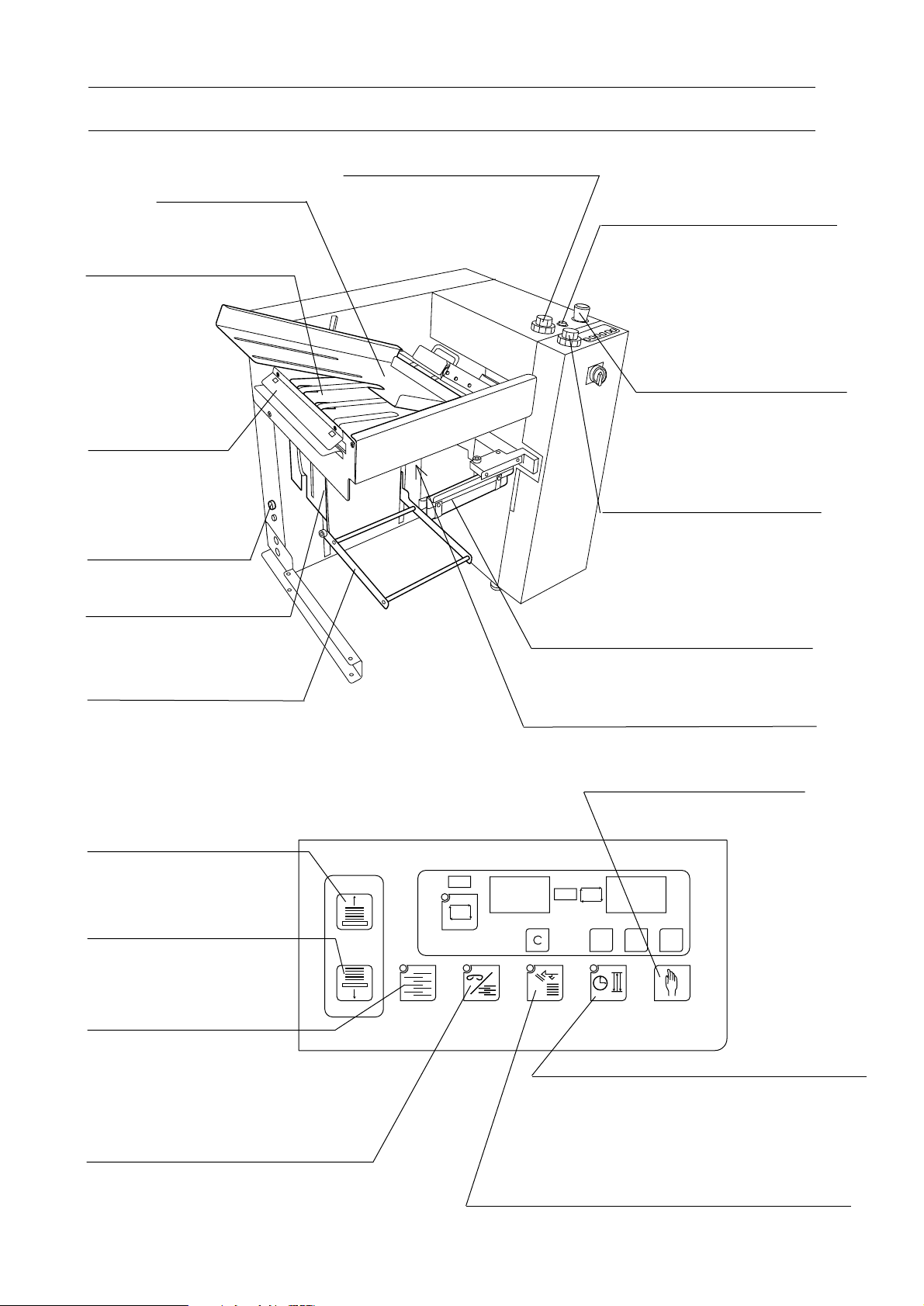

1. Before You Begin

1-2 Machine Descriptions

1-2-7 Stacker (ST-20)

Delivery Rollers

These rollers transport collated

sets to receiving tray. Weights

correct sheet skew.

Operation Panel

Off-set Guide

This guide is for off-set

receiving.

Tray

Collated sets are loaded on

this tray.

Stopper Adjust Knob

This knob is used to adjust stopper according to the sheet size.

This knob can be locked with top

knob on this knob.

Stop Button

Side Guide Adjust Knob

This knob is used to adjust side

guide according to the sheet size.

This knob can be locked with top

knob on this knob.

Side Guide

This guide moves up and down

every single cycle for off-set

receiving.

Stopper

Delivered collated-sets stops by

hitting this stopper.

(Operation Panel)

Tray UP Button

This button is used to raise Tray.

Tray DOWN Button

This button is used to lower Tray.

Tray can be lowered only while

this button is being pressed.

Tray Lower Time Knob

This knob is used to adjust the

lowering length of tray every

single cycle.

Single Motion Button

Movable side guide can be

actuated with this button.

Off-set Timing Knob

This knob is used to adjust the side

guide delay after sheets are delivered to ST-20.

Off-set ON/OFF Switch

This switch is used to switch on/off

off-set.

16

Page 23

1-2 Machine Descriptions

1-2-8 Stacker (ST-20R)

1. Before You Begin

Emergency Stop Button

Side Guide Adjust Knob

This knob is used to adjust side

guide according to the sheet

size. This knob can be locked

with top knob on this knob.

Stopper

Delivered collated-sets stops

by hitting this stopper.

Side Guide

This guide moves up and down

every single cycle for off-set

receiving.

Tray

Collated sets are loaded on this tray.

Stopper Adjust Knob

This knob is used to adjust

stopper according to the sheet

size. This knob can be locked

with top knob on this knob.

Delivery Rollers

These rollers transport collated

sets to receiving tray. Weights

correct sheet skew.

Operation Panel

Off-set Guide

This guide is for off-set receiving.

(Operation Panel)

Tray UP Button

This button is used to raise tray.

Tray DOWN Button

This button is used to lower tray.

Tray can be lowered only while

this button is being pressed.

Tray Lower Time Knob

This knob is used to adjust the lowering

length of tray every single cycle.

Single Motion Button

Movable side guide can be

actuated with this button.

Off-set Timing Knob

This knob is used to adjust the side

guide delay after sheets are delivered to ST-20R.

Off-set ON/OFF Switch

This switch is used to switch on/off

off-set.

17

Page 24

1. Before You Begin

1-2 Machine Descriptions

1-2-9 Stacker (ST-40)

Feed Error Tray

All errored sets are

delivered to this tray.

Delivery Section

Removing the feed error

tray and to bring

the transport

section to a level,

collated sets are

delivered to the

stitcher.

Delivery Section

Collated sets are

delivered to the

stitcher through this

section.

Connector Section

Connect to the stitcher

Stopper

Stopper A Adjust Knob

This knob is used to adjust stopper

A according to the sheet size. The

knob can be turn-locked into

position by the lock knob.

Feed Error Lamp A

When the feed error occurs at the

collator, then the last set is delivered to the stack tray A, this lamp

will blink to alart the operator.

Stop Button

Side Guide A Adjust Knob

This knob is used to adjust side

guide According to the sheet size.

The knob can be turn-locked into

position by the rock knob.

Delivered collated sets stop

by hitting this stopper.

Folk

The stack tray is placed on this

folk. Collated sets are accumulated on the tray.

(Operation Panel)

Stack Tray UP Button

Depressing this button is

raises the stack tray.

Stack Tray Down Button

Depressing this button

lowers the stack tray.

Off-set ON/OFF Switch

This switch turns the off-set

function ON/OFF. This

button is used to raise the

stack tray.

Stack/ Stitch Select Button

Lamp ON : Stitch the collated sets at

stitcher .

Lamp OFF : Stack the collated sets at

ST-40.

Side Guide

This guide moves up and down with

every cycle for off-set receiving.

Off-set Guide

This guide is for off-set receiving.

Single Motion Button

The movable side guide can

be actuated with this button.

1 2 3

1 2 3

Off-set Delay Button

This button is used to select a delayed time for

the off-set function.

Lamp ON : Delayed time for off-set is 0.3

second

Lamp OFF : Delayed time for off-set is zero.

Feed Error Reject Function ON/OFF Button

This button is used to turn ON/OFF the function of

delivering errored sets, to the feed-error tray.

18

Page 25

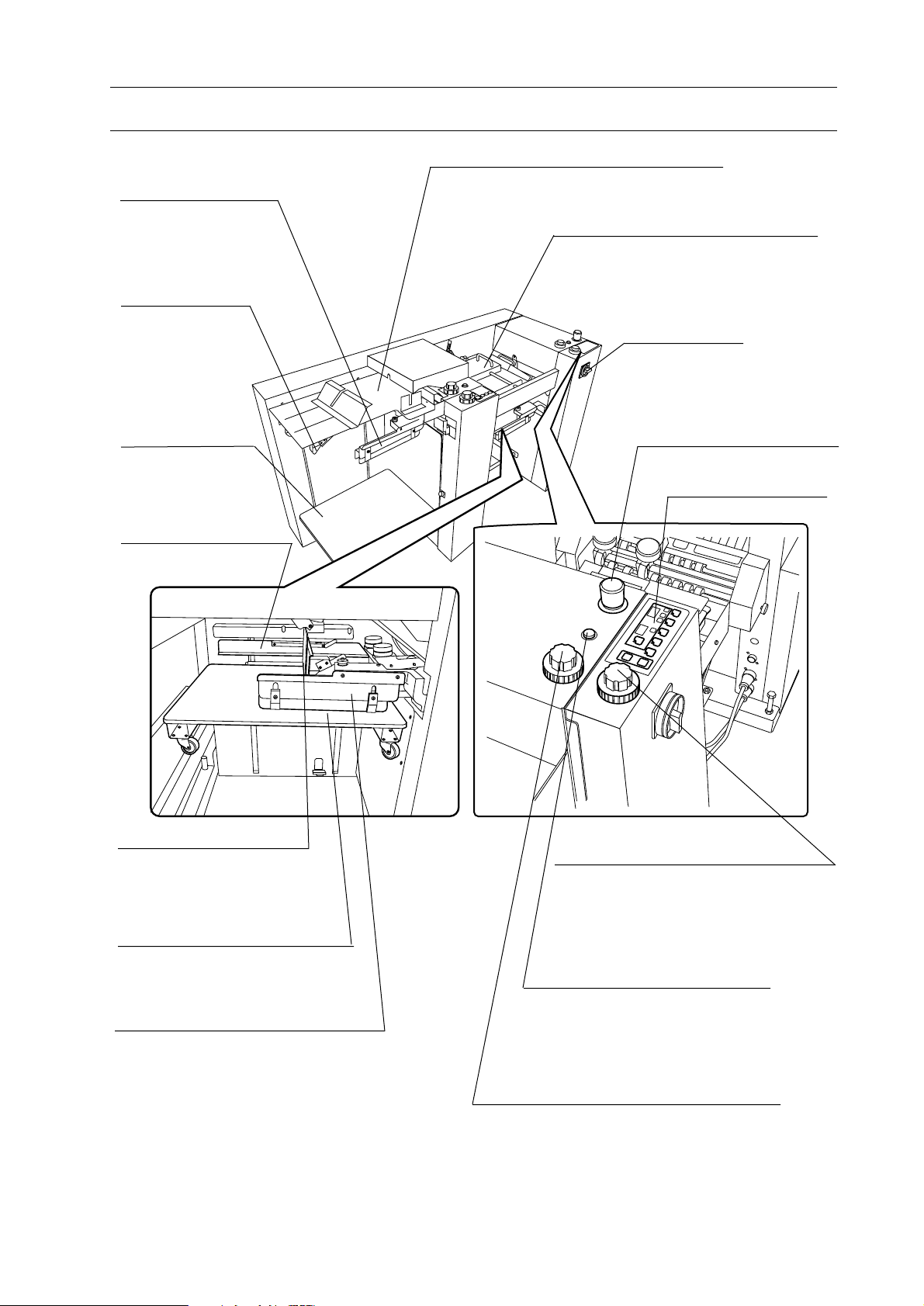

1-2 Machine Descriptions

1. Before You Begin

1-2-10 Stacker (ST-60)

Side Guide B

This guide moves up

and down every cycle

for off-set receiving.

Stopper B

Delivered collated

sets stop by hitting

this stopper.

Stack Tray B

Collated sets are

accumulated on this

tray.

Off-set Guide A

This guide is for off-set

receiving.

Feed Error Tray

All errored sets are delivered to this tray.

Transport Unit

Collated sets are transported to side B

through this unit.

Power Switch

Stop Button

Operation Panel A

Stopper A

Collated sets are stopped

by hitting this stopper.

Stack Tray A

Collated sets are loaded on this

tray.

Side Guide A

This guide moves up and down with

every cycle for off-set receiving.

Side Guide A Adjust Knob

This knob is used to adjust side guide A

according to the sheet size. The knob

can be turn-locked into position by the

rock knob.

Feed Error Lamp A

When the feed error occurs at the

collator, then the last set is delivered to the stack tray A, this lamp

will blink to alart the operator.

Stopper A Adjust Knob

This Knob is used to adjust stopper A

according to the sheet size. The knob can

be turn-locked into position by the rock

knob.

19

Page 26

1. Before You Begin

1-2 Machine Descriptions

(Operation Panel A)

Counter Button

This button is used to select

the mode of the counter. For

further information, refer to 2-3.

Stack Tray UP Button

Depressing this button is

raises the stack tray.

Stack Tray Down Button

Depressing this button lowers

the stack tray.

Off-set ON/OFF Switch

This switch turns the off-set function

ON/OFF. This button is used to raise the

stack tray.

Counter Input Button

Single Motion Button

The movable side guide

can be actuated with

this button.

1 2 3

1 2 3

Off-set Delay Button

This button is used to select a delayed

time for the off-set function.

Lamp ON : Delayed time for off-set is

0.3 second

Lamp OFF : Delayed time for off-set

is zero.

Stack Mode Select Button

Lamp ON :

The collated sets are alternately routed to the

stack trays A/B one after the other.

Lamp OFF :

The collated sets are alternately routed to one of

the stack trays only. When one stack tray is full,

the collated sets are routed to the other stack tray.

(Operation Panel B)

Stack Tray Up Button

This button is used to raise the

tray.

Stack Tray Down Button

This button is used to lower the

stack tray. Stack tray can be

lowered only while this button

is being pressed.

Feed Error Reject Function ON/OFF Button

This button is used to turn ON/OFF the function of

delivering errored sets, to the feed-error tray.

ON :

When a feed error occurs at the collator, the

errored set is delivered to the feed error tray without stopping the collator. The collator will stop

after 4 consecutive errored sets are delivered to the

feed error tray.

OFF:

When a feed error occurs at the collator, collating

will stop. Errored sets will be delivered to the stack

tray.

Single Motion Button

The movable side guide

can be actuated with

this button.

Stack Tray B Height Select Button

Lamp ON : 580 mm Maximum

( 55 kg. about 700 sheets)

Lamp OFF : 580 mm Maximum

( 55 kg. about 430 sheets)

Delivery Air ON/OFF Button

This button is used to turn ON/OFF the delivery

air on the side B( left side).

Lamp ON : Delivery air is ON

Lamp OFF : Delivery air is OFF

20

Page 27

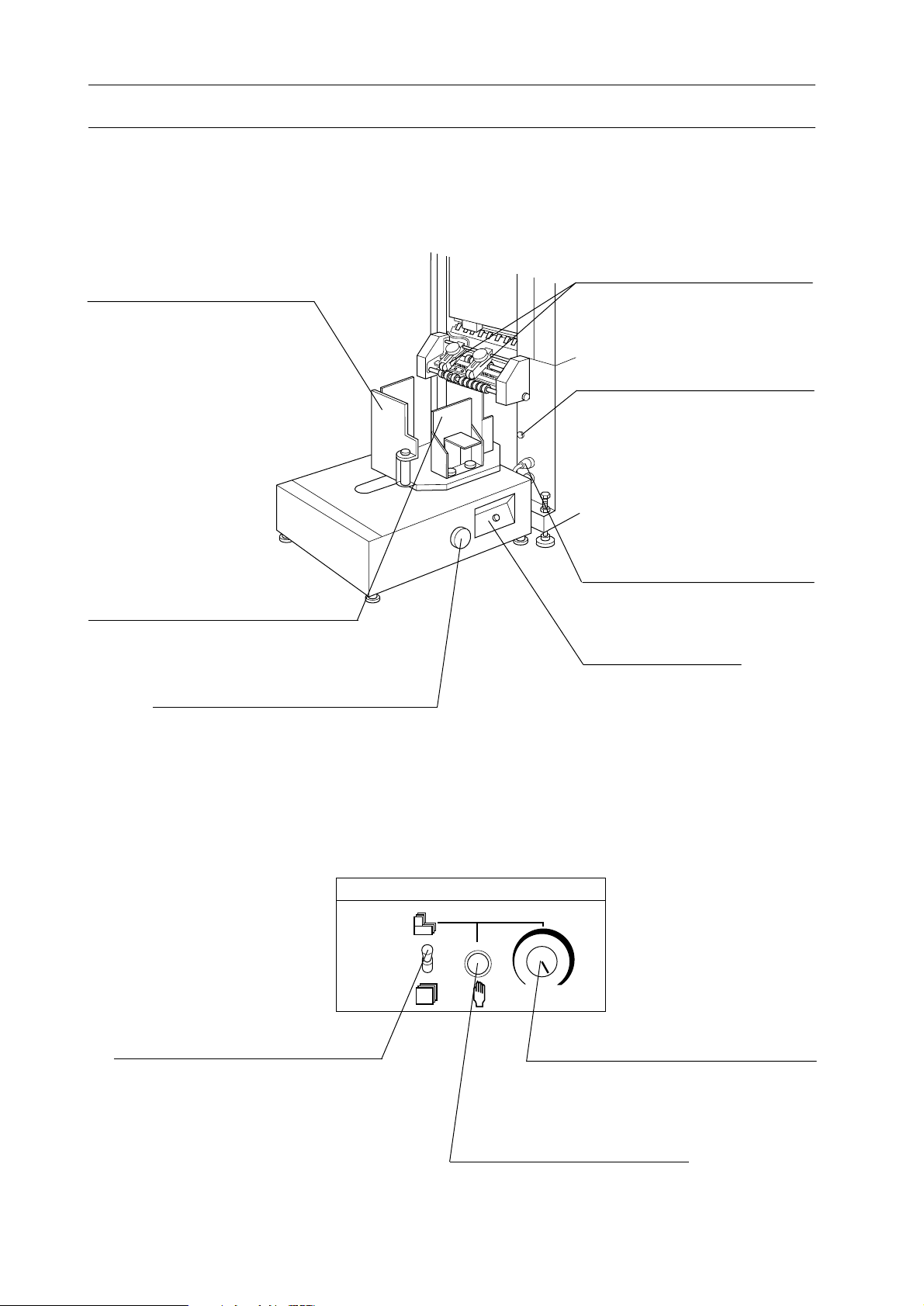

1-2 Machine Descriptions

1-2-11 Hand Marry Unit (HMU-100)

Sheet Detection Sensor

When this sensor detects a sheet, collating

operation starts.

1. Before You Begin

Sheet Registration Guide

Sheets to marry are registered with this

guide.

Sub-table

Hand Marry Table

Sheets to marry are placed on the table.

Sheet Guide

This guide is set according to sheet width.

Insert Mode Selecting Switch

This switch is used to select the mode to insert a

sheet on or under collated sheets from VAC-100

or to be off.

21

Page 28

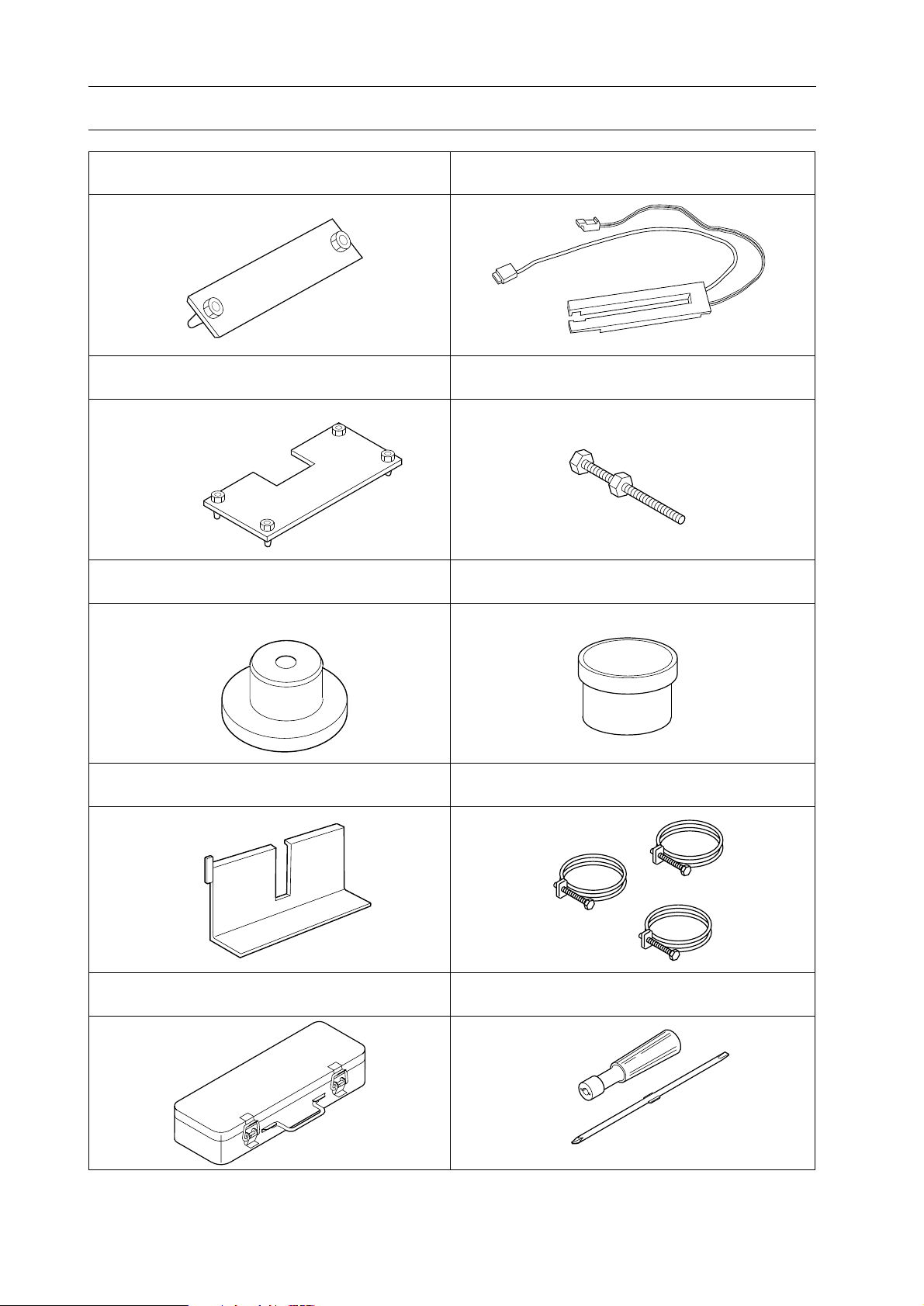

1. Before You Begin

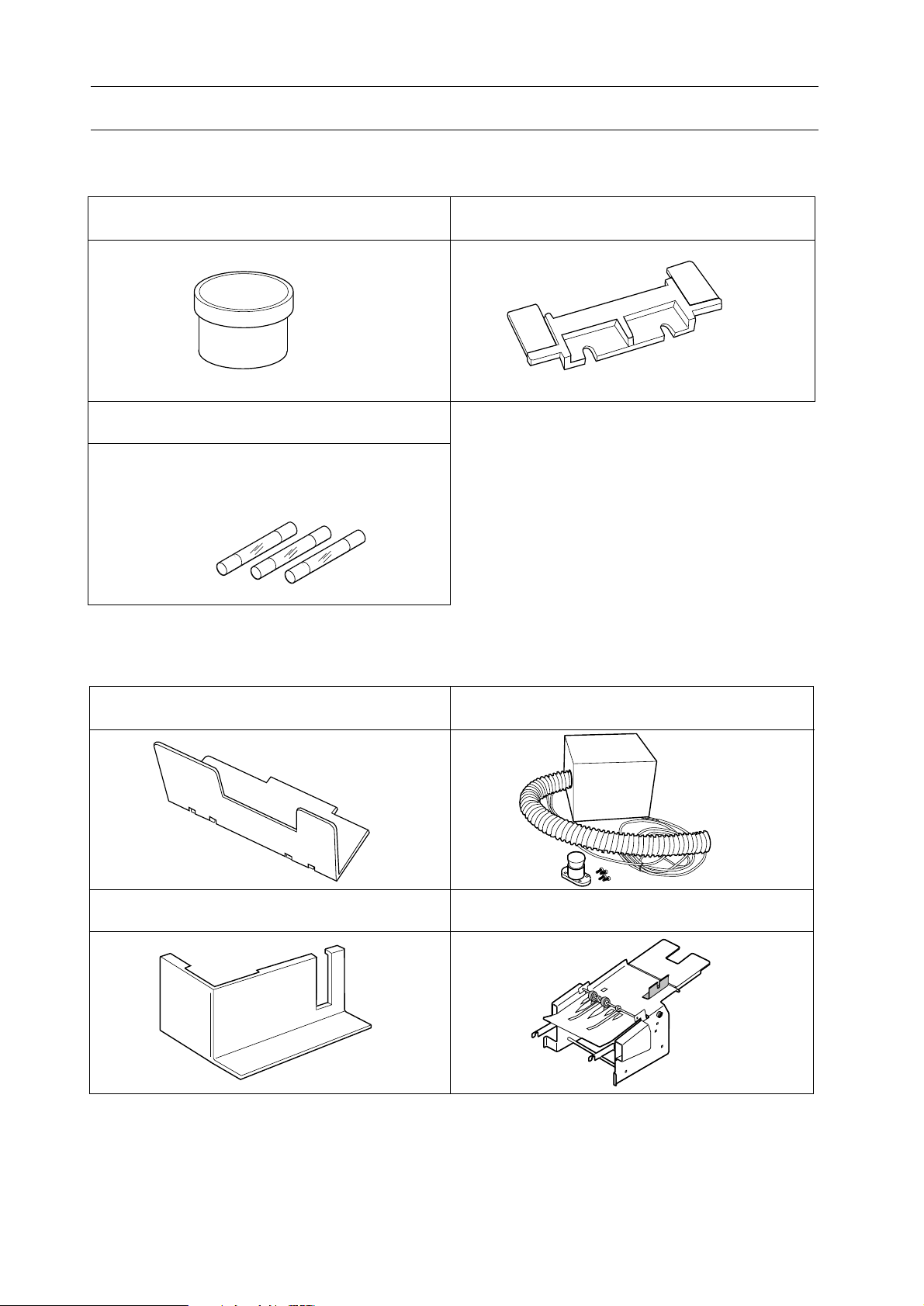

1-3 Accessories

Connecting Plate (A920112-00)

m:1pc c:1 pc

Connecting Plate (A920111-00)

m:1 pc c:1 pc

Setting Plate (M000025-01)

a: 3 pcs m: 3 pcs c: 3 pcs

Detector (A924699-00) a:1 pc

Leveling Bolt (M12-120), Nut (M12)

a: 3 pcs m:3 pcs c:3 pcs

Grease (4-001272-00)

a:1 pc c:1 pc

Sheet Guide (A924698-01)

a: 20 pcs m: 20 pcs

c: 20 pcs

Tool Box (4-003344-00)

a: 1 set c: 1 set

Hose Band

a: 3 pcs m: 3 pcs

c: 3 pcs

Reversible Screwdriver (4-005382-00)

a:1 pc c:1 pc

22

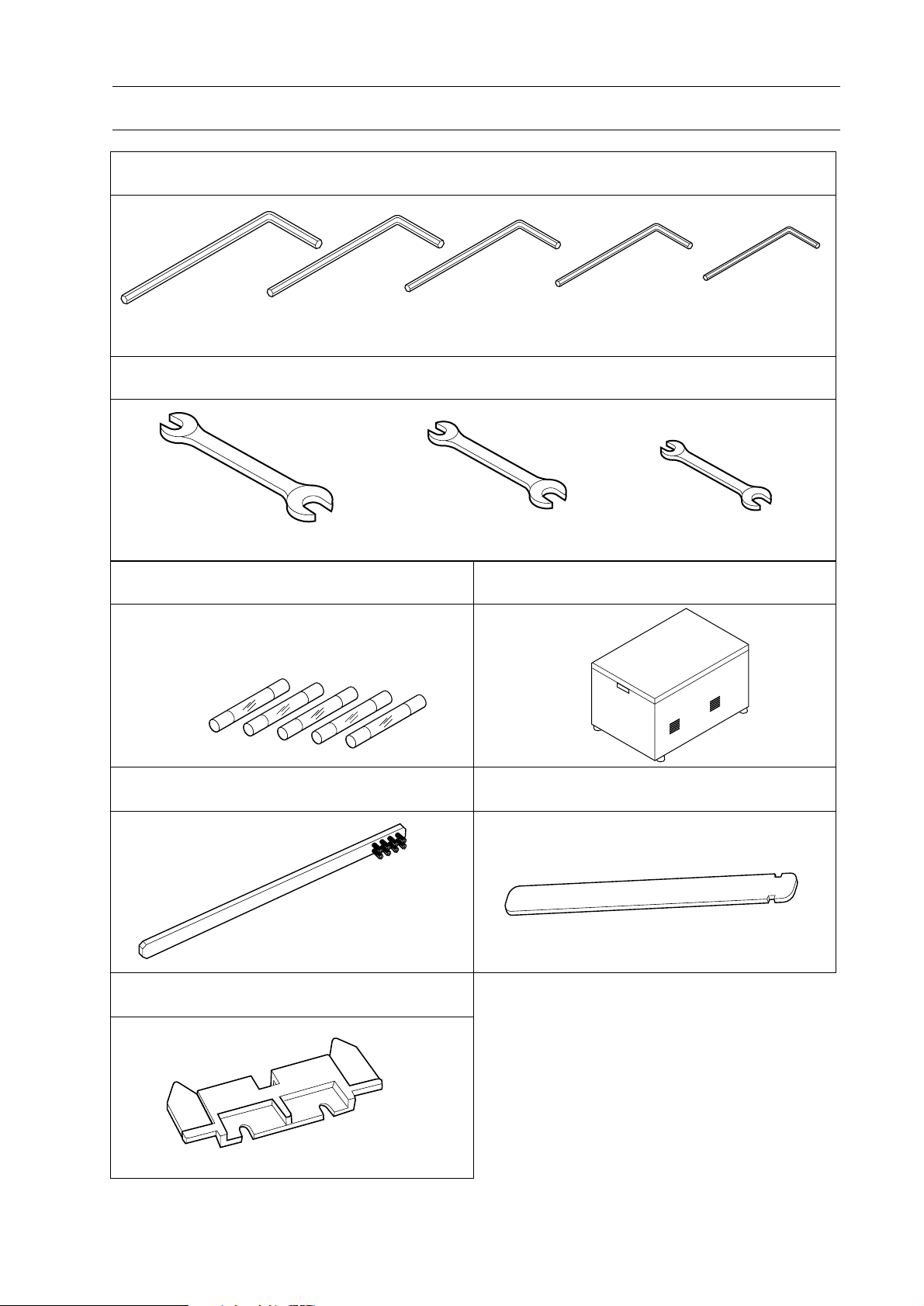

Page 29

1. Before You Begin

1-3 Accessories

Allen Wrench a: 1 pc each c: 1 pc each

5 mm (4-000968-00)

4 mm (4-001439-00) 3 mm (4-001438-00)

2.5 mm (4-001437-00)

2 mm (4-001320-00)

Spanner a: 1 pc each c: 1 pc each

19 x 24 mm (4-005401-00)

Fuse

1 A (4-008911-00) : 2 pcs

2 A (4-008912-00) : 1 pcs

5 A (4-008915-00) : 3 pcs

13 x 17 mm (4-005400-00)

Blower Box

a: 3 pcs

m: 1 pcs

c: 1 pcs

8 x 10 mm (4-005397-00)

Cleaning Brush (M072641-00) a: 1 pc

Double Feed Stop Plate P (A924701-00)

10 pcs

Sheet Hold Plate (M072585-00) a: 5 pcs

23

Page 30

1. Before You Begin

1-4 Consumables and Options

Consumables

Grease (4-001272-00)

Fuse

1 A (4-008911-00)

2 A (4-008912-00)

5 A (4-008915-00)

Options

Double Feed Stop Plate (A924697-01)

Support Guide(A924629-01)

Sheet Guide (A924700-00) Hand Marry Unit (HMU-100)

Extra Air Blower (EAB-100)

24

Page 31

2. Operation Procedures

2. Operation Procedures

2-1 Power ON ................................................................................................. 26

2-2 Preparation for Operation...................................................................... 27

2-3 Collating Operation ................................................................................. 43

2-4 Feed Error Indication and Remedy ....................................................... 45

2-5 Program Collation ................................................................................... 47

2-6 Job Memory ............................................................................................. 53

2-7 Right Side Delivery.................................................................................. 54

2-8 Hand Marry ............................................................................................. 55

25

Page 32

2. Operation Procedures

123

2-1 Power ON

NOTE

- When two towers or more are used, turn on

power from the right tower.

1. Turn on power switch.

NOTE

- When turning off main power, turn off atower. Other towers can be turned off by

turning off only a-tower.

- The initial page as shown in the drawing

at right appears and 20 to 30 seconds later

the main page appears.

Power Switch

VAC-100

Now Loading....

123

123

123

123

NOTE

- When start button is pressed with inching

button pressed, the collator starts warming

up with " " indicated on the screen. Five

minutes later, warming up is stopped automatically. Press stop button when stopping

warming up.

Inching Button

60 min.

C

60 min.

?

Start Button

26

Stop Button

Page 33

2-2 Preparation for Operation

2-2-1 Tower ON/OFF and Delivery Direction Setup

1. Select Set 1 page.

2. Operation Procedures

2. Turn on tower switch of collator which is

used, turn off tower switch of collator

which is not used.

: ON

: OFF

3. When the c-tower is combined, select the

delivery direction.

NOTE

- When the c-tower is not combined, the

delivery direction is only left side.

- When the right side delivery is required,

refer to "2-7 Right Side Delivery."

1 2 3 4 5 6

Tower SwitchDelivery Direction

27

Page 34

2. Operation Procedures

2-2 Preparation for Operation

2-2-2 Collating Sheet Preparation

This section shows how to load sheets to be

collated.

123

123

123

60 min.

C

60 min.

?

1. Select the main page.

2. When bins are raised, press stop button on

the main page or remote controller to lower

bins.

3. Place sheets against side guide and front

guide.

123

Stop Button

123

Stop Button

NOTE

- When collated sheets are delivered to the

left, load sheets from the top bin in page

order. When collate sheets are delivered to

the right, load sheets from the bottom bin in

page order.

- When the number of collate pages are few,

it is efficient to load sheets from the bottom

bin.

- When two towers or more are used, it is

efficient to load sheets equally into each

tower. For example, it is more efficient to

load seven pages of sheets on both first and

second towers than to load ten pages of

sheets into the fist tower and four pages of

sheets into the second tower.

Front Plate

Collate Sheets

Side Guide

The Page Number of Collate Sheets

P1

P2

P3

P9

P10

P10

P9

P8

P2

P1

[Left Side Delivery] [Right Side Delivery]

28

Page 35

2-2 Preparation for Operation

NOTE

- Fan sheets well before loading them into

bins. Otherwise double feeding may occur. If

the sheets are bend, straighten then before

loading them into bins.

- Press firmly folded sheet edges when 4-page

signatures are collated to prevent misfeeding

or double feeding and to keep the sheet pile

height low level. Load sheets so the folded

edges touch front plate.

- The optional support guide allows collator

to collate 120 to 148 mm (4.7" to 5.8") width

sheets. (Refer to the next page.)

2. Operation Procedures

3. Set sheet guides so that they touch the

operation and right sides of sheet edges

respectively.

NOTE

- When handling acccordion-folded sheets or

NCR papers, set sheet hold plate on the right

sheet guide.

Support Guide

Sheet Guides

Sheet Hold Plate

Sheet Hold Plate

Right Sheet

Guide

Setting Direction of Accordion-folded Sheets

29

Page 36

2. Operation Procedures

2-2 Preparation for Operation

2-2-3 Small Size Sheet Setup

When small size sheets whose width is 120 to

148 mm (4.8" to 5.9") are handled, use

optional support guide.

1. Set support guide on bin where small size

sheets are loaded.

Support Guide

Sheet

Bin

2. Raise feed height sensor and move it to the

operation side.

Support Guide

Feed Height Sensor

30

Page 37

2-2 Preparation for Operation

3. Place sheets against support guide and

front guide.

2. Operation Procedures

Front Guide

Sheets

Support Guide

4. Set sheet guides so that they touch the front

and right sides of sheet edges respectively.

Sheet Guides

31

Page 38

2. Operation Procedures

2-2 Preparation for Operation

2-2-4 Feed Height Adjustment

This section shows how to adjust the feed

height.

1. Adjust feed height adjust lever (White).

UP : High

DOWN : Low

NOTE

- The standard position of feed height adjust

lever is where lever is level.

3

Feed Height Adjust Lever (White)

- When feed height adjust lever is raised, the

feeding position is raised.

- When feed height adjust lever is lowered,

the feeding position is lowered.

- After test collating, raise feed height adjust

lever when thick sheets are handled and

misfeeding occurs. Lower feed height adjust

lever when thin sheets are handled and

double feeding occurs.

- When double feeding occurs on all bins,

weaken suction air on the main page.

2-2-5 Blower Adjustment

This section shows how to adjust blower air

on each bin.

1. Adjust separation air adjust lever (Blue).

UP : Strong

DOWN : Weak

Feeding Side

3

NOTE

- Air is stronger where separation air adjust

lever is raised; weaker lowered.

- Normally, use blower with separation air

adjust lever on the top position.

- When sheets are blown up or pushed by air,

weaken air by lowering separation air adjust

lever.

Separation Air Adjust Lever

(Blue)

32

Blowers

Page 39

2-2 Preparation for Operation

2-2-6 Double Feed Stop Plate Height Adjustment

2. Operation Procedures

This section shows how to adjust the double

feed stop plate height on each bin.

1. Adjust double feed stop plate adjust lever

by moving up and down.

Lever UP : Lower plate

Lever DOWN : Raise plate

NOTE

- Double feed stop adjust lever is usually used

in the lowest position.

- After test collating, raise double feed stop

plate adjust lever to lower double feed stop

plates when misfeeding occurs.

Double Feed Stop Plates

Double Feed Stop Plate Adjust Lever

2-2-7 Separate Nose Adjustments

When double feeding occurs because of thin

sheets, use separate nose.

1. Move separate nose to the left and push out

separate nose.

NOTE

- Use separate nose only when double feeding

occurs because of thin sheets.

Separate Nose Knob

Separate Nose

33

Page 40

2. Operation Procedures

2-2 Preparation for Operation

2-2-8 Delivery Section Setup

WARNING

- Press stop button before setting up the

delivery section. Otherwise the delivery

section may hurt your hands.

[1] Bulging Nose and Delivery Roller Setup

Attach bulging nose and adjust delivery

rollers so that sheets are delivered smoothly

and jogged well.

1. Attach bulging nose so that it positioned in

the middle of the sheet.

Delivery Roller

NOTE

- Sheets are delivered with 2 cm (0.8") distance from the rear side.

2. Set delivery rollers by sliding so that

bulging nose is positioned in the middle of

delivery rollers according to the sheet size

and weight.

- Delivery rollers can be slid by raising the

end of rollers.

Bulging Nose

Delivery Rollers

Bulging Nose

Push here to lock.

Push here to remove.

2 cm

(0.8")

Thick Sheet

4-page Signature

NOTE

- When thick sheets or 4-page signature are

handled, lower bulging nose. When thin

sheets or soft sheets are handled, raise bulging nose. When large and thin sheets are

handled, use two bulging noses.

Thin Sheet

Soft Sheet

Large and Thin Sheet

34

Page 41

2-2 Preparation for Operation

[2] Weight Setup

1. Adjust the weight positions according to

the sheet thickness.

2. Operation Procedures

- Weights can be moved by turning counterclockwise.

- The standard position of weight is the

middle.

NOTE

- When sheets are delivered on the skew, the

skew can be corrected by moving weight.

- When sheets are skew in the (1) direction

shown in the drawing at right, move weights

in the A direction.

- When sheets are skew in the (2) direction

shown in the drawing at right, move weights

in the opposite direction of A.

- Weight pressure is reduced in the UP direction. When thin sheets are handled, set

weights in the UP direction. When thick

sheets are handled, you do not have to set

weight in the DOWN direction if sheets are

delivered smoothly.

Weight

A

(1)

(2)

Weight Position

UP : For thin sheets

MIDDLE : For normal sheets

DOWN : For thick sheets

A

UP

MIDDLE

DOWN

35

Page 42

2. Operation Procedures

2-2 Preparation for Operation

[3] Delivery Air Adjustment

1. Release stop button.

2. Turn on delivery air ON/OFF button.

Stop Button

123

123

123

60 min.

C

60 min.

?

3. Adjust delivery air with delivery air knob.

123

Delivery Air ON/OFF Button

Air Nozzles

NOTE

- When thin collated sets or sheets which are

difficult to be transported are handled, use

delivery air.

- Turn delivery air knob within the range of

the arrow mark shown in the drawing at

right.

Delivery Air Knob

Max.

OFF

36

Page 43

2-2 Preparation for Operation

2-2-9 Tray Unit Setup

[1] When CCR or CCR-DX Is Used

1. Insert small or large tray into shaft.

Small Tray : A5 to A4

Large Tray : B4 to A3

NOTE

- Two shafts project into tray. Insert these

shaft properly.

2. Operation Procedures

Shaft

- The sheet set direction is different depending on the tray to be used.

2. When using ST-20, insert full tray sensor

cable into main connector.

Insert Position

Small Tray Large Tray

(The arrow direction is the feed direction.)

Full Tray Sensor Cable

37

Page 44

2. Operation Procedures

2-2 Preparation for Operation

3. Place two sheets as shown with dotted lines

in the drawing at right and adjust stoppers

and off-set bar to the sheet size in number

order.

(Small Tray)

Sheet Registers

(Large Tray)

Sheet Register

Off-set Bar

3

Stopper

2

Stopper

1

Off-set Bar

- Stoppers and off-set bar can be moved by

loosening lock knobs.

NOTE

- Provide 5 to 10 mm (0.2" to 0.4") between

the sheet edge and stoppers, and between the

sheet edge and off-set bar.

Stopper

Stopper

Lock Knob

38

Page 45

2-2 Preparation for Operation

CAUTION

2. Operation Procedures

- Set receiving tray so that it does not

hit the collator delivery section when

turning receiving tray by 90˚.

4. Adjust the tray position.

- Move tray close to the collator where it

does not touch collator delivery section

and the lock tray with tray lock knob.

NOTE

- Press single motion button to turn tray and

check the distance between tray and collator.

5. Set the operation mode.

- When off-set receiving is required, turn

on off-set ON/OFF switch.

(CCR)

Stopper

Collator

Tray Lock Knob

Off-set Timing Knob

- Set off-set timing knob to the required

position.

- When using small tray of CCR-DX, turn

on full tray detection switch.

Off-set ON/OFF Switch

Single Motion Button

(CCR-DX)

Full Tray Detection Switch

L

S

L

S

Off-set Timing Knob

39

Page 46

2. Operation Procedures

2-2 Preparation for Operation

[2] When ST-20/ST-20R Is Used

WARNING

- Press stop button before setting stoppers and guides on tray. Otherwise

personal injury may result.

(Off-set Receiving)

1. Press tray UP button to raise tray.

2. Press stop button.

3. Place a sheet as shown with dotted lines in

the drawing at right and then adjust side

guide and stopper in number order.

NOTE

- Provide 5 mm (0.2") gap between the sheet

edge and stopper, and between the sheet edge

and side guide.

- When the sheet size is B4 or more, attach

guide strip.

4. Attach support stopper on the same posi-

tion as stopper's.

Off-set Guide

Support Stopper

Stopper

Side Guide

5 mm

(0.2")

Side Guide Adjust Knob

Off-set Timing KnobTray UP Button

Guide Strip

Sheet Registers

5 mm

(0.2")

Sheet

1 2

Stopper Adjust Knob

5. Set the operation mode.

- Turn on off-set ON/OFF switch. (" "

position)

-Set off-set timing with off-set timing knob.

Turning knob clockwise makes off-set

time longer.

- Set tray lower time with tray lower time

knob according to the collated set thickness. Tray lowers by turning knob clockwise.

(Straight Receiving)

CAUTION

- Turn off off-set ON/OFF switch

" position) when straight receiving

("

is required.

1. Attach straight receiving guides and lock

them with lock knob.

Tray Lower Time Knob

Lock Knob

Off-set Timing Knob

Off-set ON/OFF Switch

Straight Receiving Guides

2. Adjust stoppers and side guide in the same

procedure as the step 3 above.

40

Page 47

2-2 Preparation for Operation

2-2-10 Setup in Main Page

This section shows how to set the feeding

condition in main page.

1. Set the belt speed. (3 scales)

2. Operation Procedures

[Main Picture]

NOTE

-The belt speed can be adjusted on three

scales. Normally, set the middle speed. After

test collating, set the fast speed if sheets are

fed smoothly. On the contrary, if misfeeding

occurs, set the slow speed.

2. Set the feed speed.

NOTE

- The feed speed changes depending on the

belt speed and overlap used.

- The feed speed can be adjusted during the

operation.

- When SPF-20A is combined, the feed speed

is automatically adjusted by pressing automatic set up button.

3. Set air strength. (2 scales)

NOTE

- Air strength can be adjusted on two scales.

Normally, select strong. When double feeding

occurs because of thin sheets, select weak to

decrease the sucking force of the rotor.

123

123

123

123

60 min.

C

60 min.

?

4. Set overlap. (4 scales)

NOTE

- Overlap can be adjusted on four scales.

- After the actual collation, adjust the overlap

for good delivery to the receiving tray or

stitcher & folder.

5. When using total counter, press clear key

to reset the counter.

6. When using preset counter, press the

required number with 10-number keys, and

then press enter key to input the number.

To clear the input number, press clear key.

After pressing enter key, the main page

appears.

[Preset Input Picture]

Clear Key

41

17181

14151

11121

1C101

9

6

3

E

Enter Key

Page 48

2. Operation Procedures

2-2 Preparation for Operation

2-2-11 Hand Marry Unit Setup (HMU-100: Option)

When using hand marry unit, set the sheet

guide and select the mode to insert a sheet on

or under collated sheets.

1. Select the mode with the insert mode

selecting switch.

: A sheet from hand marry unit is inserted on

collated sheets.

: Hand marry function is not used.

: A sheet from hand marry unit is inserted

under collated sheets.

- The selected mode on HMU-100 is indicated

by the icon on main page of VAC operation

panel.

2. Place sheets on hand marry table register-

ing with the sheet registration guide and set

the sheet guide according to sheet width.

Insert Mode Selecting Switch

123

123

123

123

60 min.

C

60 min.

?

(Main Page Of VAC Operation Panel)

Place the sheets registering with this guide

42

Sheet Guide

Page 49

2-3 Collating Operation

2-3-1 Sheet Thickness Calibration

Before actual collating operation, sheets

thickness must be calibrated and memorized.

Adjust sensor and/or lamp on each bin on the

Set 2 page with sheet calibration.

1. Select Set 2 page.

NOTE

- When each bin power is off, sheets are not

fed even if sheets are loaded on the bin.

2. Set senor to middle sensitivity and lamp to

normal.

NOTE

- The initial setting of sensor is middle sensitivity and lamp, normal.

- When sensor detects double feeding without

double feeding during the actual operating,

set sensor to low sensitivity. After that, sensor

still detects double feeding occurs, turn off

sensor. When sensor detects misfeeding

without misfeeding, set sensor to low sensitivity.

- When sensor is turn off, sensor detects only

misfeeding, not double feeding.

- Normally, set lamp to normal. When sensor

senses thick image on sheets or detects misfeeding without misfeeding, set lamp to

bright.

2. Operation Procedures

All Tower Calibration Button

Individual Calibration Buttons

123

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Sensor

: High Sensitivity

: Middle Sensitivity

: Low Sensitivity

: Double Sheet Detection OFF

Lamp

: Normal

: Bright

1

2

3. Press all tower calibration button.

- Each bin on all used towers feeds one

sheet.

NOTE

- When individual calibration button is

pressed, sheets only on the tower whose

button is pressed are fed once.

4. Check the number of collated sheets is

correct.

NOTE

- When the number of collated sheets is not

correct, press individual calibration button of

the tower which has a problem.

- When double feeding is monitored during a

sheet calibration, set lamp to bright and

check again.

- When double feeding of a collated set is

missed on receiving tray, misfeeding will be

detected during the actual operation.

Bin

: ON

: OFF

43

Page 50

2. Operation Procedures

2-3 Collating Operation

2-3-2 Collating Operation

This section shows how to operate the collator.

1. Select the main page.

2. Press start button either on the main page

or on remote controller.

NOTE

- The operation will not start before sheet

thickness calibration is completed. (Refer to

"2-3-1 Sheet Thickness Calibration.")

- When using the hand marry unit, refer to

"2-8 Hand Marry"

3. Press stop button either on the main page

or on remote controller.

NOTE

- When stop button is pressed during operation, only feeding is stopped, not motor and

blower. When stop button is pressed again,

motor and blower are stopped, but bins are

not lowered. When stop button is pressed

again, bins are lowered.

123

123

123

123

60 min.

C

Start Button

123

60 min.

?

Stop Button

Start Button

Stop Button Pressing Times

0

1

2

3

Feeding

ON

OFF

OFF

OFF

Motor and Blower

ON

ON

OFF

OFF

Stop Button

Bin

Up

UP

UP

DOWN

44

Page 51

2-4 Feed Error Indication and Remedy

: Double Feed

: Jam

: Misfeed

Feed Error Mark

123

When jam, misfeeding and double feeding

occur, the collator delivers the collated sets

and then stops with errors indicated on the

screen and remote controller.

2. Operation Procedures

1. When the operation is stopped because of

feeding errors, the numbers 1 and 3 on

the right side on the screen mean that top

collated sets and 3rd collated sets from the

top on receiving tray have feed error. The

feed error icons indicate all errors when the

collator is stopped.

NOTE

- The feed error can be indicated on up to the

eighth collated set.

2. Press the number 1 button on the right

side. Check the top collated set delivered

on receiving tray.

- Jam occurred on the second bin of the

second tower.

- Double feeding occurred on the first bin

of the fourth tower.

112 3

2

3

4

5

6

7

8

9

10

1

1

2

3

4

5

6

7

8

9

10

2 3

5 6

4

1

2

3

4

5

6

7

8

9

10

4

1

2

3

4

5

6

7

8

9

10

5 6

OK

1

2

1

3

4

3

5

6

7

8

9

10

OK

1

2

1

3

4

3

5

6

7

8

9

10

NOTE

- Jam may be monitored though sheets are

ejected. This is because feed timing is delayed. Check that sheets are not jammed.

Inching Button

When jammed, press inching button to transport the sheet, open transport door and then

remove the sheet.

Transport Door

45

Page 52

2. Operation Procedures

2-4 Feed Error Indication and Remedy

3. Press the number 3 button on the right

side. Check the third collated set from the

top on receiving tray.

- Double feeding occurred on the first bin

of the sixth tower.

- Misfeeding occurred on the third bin of

the sixth tower.

NOTE

- When sheet feed timing is delayed, the

operation stops immediately with all tower

numbers and jam marks indicated on screen

as shown in the drawing at right. When this

occurs, eject the jammed sheet by pressing

inching button and check from the top to the

fifth collated sets on receiving tray.

112 3

2

3

4

5

6

7

8

9

10

112 3

2

3

4

5

6

7

8

9

10

5 6

4

1

2

3

4

5

6

7

8

9

10

4

1

2

3

4

5

6

7

8

9

10

5 6

OK

1

2

1

3

4

3

5

6

7

8

9

10

OK

1

2

1

3

2

4

3

5

4

6

5

7

6

8

7

9

8

10

4. Press

button or stop button on

OK

remote controller to go back to the main

page.

NOTE

- When feed error monitor is required to see

again, press error monitor button on the

main page.

123

123

123

123

60 min.

C

60 min.

?

46

Page 53

2-5 Program Collation

A

B

AB

AB

BBAA

A

B

1

5

6

10

1

10

1

10

1

10

1

5

6

10

1

10

AB

A

B

1

10

A

1

10

1

5

6

10

1

10

B

1

10

1

10

1

10

1

10

1

10

BBAA

1

10

A

1

10

1

10

1

10

1

10

B

1

10

2-5-1 Double Cycle

The VAC-100 system is divided into two

sections. When any bin empties, the VAC-100

immediately switches over to the second

section and continues collating.

2. Operation Procedures

1 Tower

2 Towers

3 Towers

4 Towers

1. Load sheets on bins so that the first section

A and the second section B in the drawing

above have the same contents.

NOTE

- When using only 1 tower and 1 collated sets

use four bins, load sheets from the bins 1 to

4, and then load the same content sheets from

the bins 6 to 9, from the bins 7 to 10, or the

bins 6, 8 to 10.

- On the tower divided half of 1 tower, 3 or 5

towers, load sheets by 40 mm (1.5") height or

less because separation air may curl loaded

sheets.

5 Towers

6 Towers

2. Prepare for collating referring to the "2-2

Preparation for Collation."

3. Select program page.

4. Turn on double cycle button.

5. Select which section is started first with

double cycle select button.

NOTE

- When sheets are delivered to the right, the A

and B sections are reversed.

Double Cycle Select Button

Double Cycle Button

1

47

123

123

123

Page 54

2. Operation Procedures

2-5 Program Collation

6. Press all tower calibration button on the Set

2 page referring to the "2-3-1 Sheet Thickness Calibration."

Individual Calibration Buttons

All Tower Calibration Button

- All sheets on bins of all towers are collated once.

7. Select the main page and press start button.

- When any bin empties in the first section,

the collator switches over to the second

section automatically and continues

collating.

NOTE

- Add sheets on bins which are paused.

- Double cycle and dual cover feed programs

can be operated together. Refer to "2-5-2

Dual Cover Feed" and "2-5-3 Tab Insert."

123

1

2

3

4

5

6

7

8

9

10

123

123

123

123

1

2

3

4

5

6

7

8

9

10

60 min.

C

60 min.

Start Button

1

2

3

4

5

6

7

8

9

10

Stop Button

1

2

?

- When the collating speed is too fast or some

bin empties in one section, misfeeding may be

indicated on screen. In this case, remove the

top collated set on receiving tray and press

start button. The collator switches over to the

other section automatically to start collating

operation.

123

Start Button

Stop Button

48

Page 55

2-5 Program Collation

2-5-2 Dual Cover Feed

Normally, cover sheets are thicker than

inside sheets, so the bin loading cover sheets

empties earlier than other bins. This dual

cover feed program enables operation to

continue without interrupting by switching

over to the other bin loading cover sheets

when one bin loading cover sheets empties.

1. Load cover sheets into the top two bins,

and inside sheets into the rest bins. (Refer

to "2-2 Preparation for Collation.")

NOTE

- For example, when using the third to ninth

bins, load cover sheets into the third and

fourth bins.

2. Operation Procedures

Cover Sheets

Inside Sheets

2. Select the program page.

3. Turn on dual cover feed button.

4. Select which bin loading cover sheets is

used first with bin select button.

5. Press all tower calibration button on the Set

2 page referring to "2-3-1 Sheet Thickness

Calibration" and check the collating condition.

- All sheets of all towers are collated once.

Cover sheets on both bins are also collated.

123

1

Dual Cover Feed Button

Bin Select Button

All Tower Calibration Button

Individual Calibration Buttons

123

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

123

123

1

2

49

Page 56

2. Operation Procedures

2-5 Program Collation

6. Select the main page and press start button.

- When one bin loading cover sheets empties, the collator switches over to the other

bin automatically.

123

123

123

123

60 min.

C

60 min.

?

NOTE

- Dual cover feed and double cycle programs

can be operated together. The position of

cover sheet loading in the second section is

the top two bins in the second section.

- Dual cover feed and tab insert programs can

not be operated together.

- When the collating speed is too fast or some

bin empties in one section, misfeeding may be

indicated on screen. In this case, remove the

top collated set on receiving tray and press

start button. The collator switches over to the

other section automatically to start collating

operation.

10

Start Button

123

Stop Button

Start Button

Stop Button

1

Cover Sheets

(The first and second bins)

5

6

Cover Sheets

(The sixth and seventh bins)

50

Page 57

2-5 Program Collation

2-5-3 Tab Insert

2. Operation Procedures

Up to two tab sheets can be inserted between

collated sets preset.

1. When one tab sheet is inserted, load the tab

sheets into the top bin. When two tab

sheets are inserted, load the tab sheets into

the top two bins. And then load inside

sheets into the rest bins. (Refer to "2-2

Preparation for Collation.")

2. Select the program page.

3. Turn on tab insert button.

4. Select one or two with tab sheet button.

Tab Insert Button

Tab Sheet Button

1

Tab Sheets

Collated Sets

Collated Sets

Collated Sets

Collated Sets

Tab Sheets

Preset Button

123

Preset Stop Button

123

123

5. Input the required number of collated sets

between tab sheets with preset button.

6. When the operation is required to stop after

any tab inserting times, input the required

number of inserting times with preset stop

button.

7. Press all tower calibration button on the Set

2 page referring to "2-3-1 Sheet Thickness

Calibration" and check the collating condition.

- All sheets of all towers are collated once.

Cover sheets on both bins are also collated.

17181

14151

11121

1C101

9

6

3

E

All Tower Calibration Button

Individual Calibration Buttons

123

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

51

Page 58

2. Operation Procedures

2-5 Program Collation

8. Select the main page and press start button.

- Tab sheets are inserted between the preset

number of collated sets and operation is

stopped with preset number of tab inserting times.

NOTE

- When preset stop is used, the set number is

indicated in tab counter on the main page.

123

123

123

123

Tab Counter

C

123

60 min.

60 min.

Start Button

?

Stop Button

NOTE

- Tab insert and double cycle programs can

be operated together. The position of tab

sheet loading in the second section is the top

bin or two in the second section.

- Tab insert and dual cover feed programs

can not be operated together.

10

Start Button

Stop Button

1

Tab Sheets

(The first and second bins)

5

6

Tab Sheets

(The sixth and seventh bins)

52

Page 59

2-6 Job Memory