Page 1

BOOKLETMAKER

SPF-200A

/

FC-200A

SPF-200L

/

FC-200L

*UM201102*

BOOKLETMAKER

Important Information

• This manual is designed to help you to install, operate and maintain the

SPF-200A/SPF-200L or FC-200A/FC-200L Bookletmaker. Please read and

understand this manual, and keep it in a safe and convenient place.

• Do not operate the SPF-200A/SPF-200L or FC-200A/FC-200L until you read and

understand the instructions in this manual.

• Horizon International Inc. shall not be liable for incidental consequential

damages resulting from: improper or inadequate maintenance by the customer,

unauthorized modification or misuse, or operation outside of the environmental

specifications for the product.

• Horizon International Inc. pursues a policy of continuing improvement in design

and performance of the product. Therefore, the product design and

specifications are subject to change without prior notice and without our legal

obligation.

• All rights are reserved. No part of this manual may be photocopied, reproduced

or translated to another language without the prior written consent of Horizon

International Inc.

160218/SPF200A/FC200A/SPF200L/FC200L/20E/HN,TM,AT/F7/ICS5/PXI

This manual explains on the basis of the SPF-200A/FC-200A.

The operating instructions for the SPF-200L/FC-200L are added

as necessary.

In case that the sheet length is longer than 500 mm (19.68”),

some functions may not available in the upstream and downstream devices of the SPF-200L.

UM201102-20(000)

i

Page 2

Safety Precautions

Safety precautions are indicated in this manual as follows:

The term WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

The term CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in serious injury, or damage to the machine.

This symbol indicates a note which includes important information. Follow

the note to operate the machine safely.

This symbol indicates a prohibited action. Do not perform any prohibited

action.

This symbol indicates an essential procedure. Follow the procedure to

operate the machine safely.

Important

Attention

Note

Additional

Information

• This lists the range of acceptable values and operating

conditions.

• This information will help you to avoid problems with the

machine or help you learn how to operate the machine.

• Refer to this note when you operate the machine.

• This explains a mechanism in the machine.

ii

Page 3

Operating Safety Precautions

WARNINGS for Operation

This machine must be operated by just one person at a time.

Work alone when you maintain and lubricate the machine. Letting someone else operate the

machine may cause severe personal injury.

Do not remove or bypass any safety features. Moving parts can cause severe personal

injury.

Some adjustments must be made with some of the machine covers opened.

Keep your hands and fingers outside of the safety cover and away from any moving parts

while the machine is running. Otherwise moving parts can cause severe personal injury.

The machine will not stop immediately if the Emergency Stop switch on an upstream device

is pressed. After all in-process booklets are delivered, the machine will stop.

Do not allow anyone else near the machine when you are moving the main section of the

SPF forwards or backwards.

When replacing the knife, wear gloves and do not touch the edge of the knife directly. The

knife is extremely sharp, and may cause severe personal injury.

Press the Emergency Stop button before turning the handwheel. A sudden accidental start

of the machine can cause severe personal injury.

Do not operate the fore-edge trim section separately from the SPF main unit.

CAUTIONS for Operation

After turning off the power switch, wait ten seconds before turning it on again. Otherwise, a

circuit board may be damaged.

The fold knife and roller may strike each other if the fold knife is lifted too far. Turn the fold

knife height adjustment knob in small amounts.

Remove the cable connected to the SPF main unit before moving the fore-edge trim section

away.

iii

Page 4

WARNINGS for Maintenance

Turn off the power switch before beginning any maintenance operation. If the machine accidentally starts suddenly, this can cause severe personal injury.

Turn off the power switch before clearing a jam. If the machine accidentally starts suddenly,

this can cause severe personal injury.

When working inside the machine, be careful to keep your hands away from nearby parts.

Be sure to press the Emergency Stop button before opening the fold section cover. The

machine may start suddenly, causing severe personal injury.

Turn off the power switch before resetting a circuit breaker. Otherwise, the machine may

start suddenly, causing severe personal injury.

Fuse replacement must be done under the supervision of a maintenance administrator.

Turn off the power switch and unplug the power cable before replacing a fuse.

When the booklet thickness detector is installed, evacuate the laser unit.

Otherwise the sensor may be damaged.

CAUTIONS for Maintenance

Use the types of lubrication oil and grease which are recommended by HORIZON. Other oil

or grease may reduce the life of the machine or cause damage.

WARNINGS for Installation

Turn off the main power or circuit breaker in the factory before connecting the power cord to

the machine. High voltage electricity can cause severe personal injury.

CAUTIONS for Installation

Be sure to install the floor mounting plates to keep the machine level. Otherwise, vibration

may cause the machine to move. The binding quality may deteriorate, or the machine may

be damaged.

The SPF-200A +the FC-200A weigh about 720 kg (1590 lb). The SPF-200L +the FC-200L

weigh about 750 kg (1653 lb). Transport and install the machine safely, and keep the weight

of the unit in mind.

Install the machine correctly, referring to the installation manual or installation instructions in

the user’s manual before starting the machine. Otherwise, the binding quality cannot be

guaranteed.

iv

Page 5

CONTENTS

Important Information ............................................................................................................... i

Safety Precautions ...................................................................................................................ii

Operating Safety Precautions .................................................................................................iii

1 Machine Description

1-1 Automatic and Manual Settings ................................................................................. 1

1-2 Machine Descriptions .................................................................................................. 2

1-2-1 Safety Device / Safety Functions ......................................................................... 2

1-2-2 Overall Machine ................................................................................................... 3

1-2-3 Manual Feed / Infeed Conveyor Section ............................................................. 5

1-2-4 Infeed Section ...................................................................................................... 6

1-2-5 Jog Section .......................................................................................................... 7

1-2-6 Stitch Section ....................................................................................................... 8

1-2-7 Fold Section ......................................................................................................... 9

1-2-8 Fore-edge Trim Section ..................................................................................... 10

1-2-9 Delivery Conveyor ............................................................................................. 11

1-2-10 Control Panel ................................................................................................... 12

1-3 Screen Descriptions .................................................................................................. 13

1-3-1 Setting-Binding Pattern Screen ......................................................................... 13

1-3-2 Setting-Sheet Size Screen ................................................................................ 13

1-3-3 Setting-Finishing Size Screen ........................................................................... 14

1-3-4 Setting-Instruction Screen ................................................................................. 15

1-3-5 Setting-Confirmation Screen ............................................................................. 19

1-3-6 Binding-Operation Screen ................................................................................. 20

1-3-7 Binding-Fine Adjust Screen ............................................................................... 22

1-3-8 Binding-Status Setting Screen ........................................................................... 24

1-3-9 Memory Screen ................................................................................................ 28

1-3-10 Information-Main Screen ................................................................................ 29

1-3-11 Information-Monitor/Single Operation Screen ................................................ 30

1-3-12 Information-Administrator Screen .................................................................... 31

1-3-13 Error Screen .................................................................................................... 34

2 Checks before Operating

2-1 Checking the Emergency Stop Function ................................................................. 35

3 Operating Procedures

3-1 Overview of Operating Procedures .......................................................................... 37

3-2 Setting Up a Job Using the Setting Screen ............................................................. 39

3-3 Doing a Changeover .................................................................................................. 44

3-3-1 Removing Parts Before the Changeover ........................................................... 44

3-3-2 Attaching Parts After Changeover ..................................................................... 49

3-3-3 Confirmation After Changeover ......................................................................... 52

3-4 Doing a Test Binding ................................................................................................. 53

3-4-1 Preparing the Upstream Device ........................................................................ 53

3-4-2 Binding a Booklet as a Test ............................................................................... 55

3-4-3 Do a Test Binding and Check the Settings ........................................................ 56

3-4-4 Perform the Test Stitching ................................................................................. 59

3-5 Confirming the Status Settings ............................................................................... 60

v

Page 6

3-6 Start Binding .............................................................................................................. 62

3-7 Manual Feeding .......................................................................................................... 65

3-8 Saving, Loading and Deleting Jobs ......................................................................... 70

3-8-1 Saving a Job ...................................................................................................... 70

3-8-2 Loading a Job .................................................................................................... 71

3-8-3 Deleting a Job .................................................................................................... 73

3-9 Power Saving Mode ................................................................................................... 74

3-10Reversing the Stitcher Heads ................................................................................... 75

4 Adjustments

4-1 Stitch Adjustments ................................................................................................... 77

4-2 Infeed Section Adjustments ...................................................................................... 79

4-3 Jog Section Adjustments .......................................................................................... 81

4-4 Fold Section Adjustments ......................................................................................... 83

4-5 Fore-edge Trim Section Adjustments ...................................................................... 84

5 Troubleshooting

5-1 If an Icon Is Displayed on the Error Screen ............................................................. 87

5-1-1 If An Error Icon Is Displayed .............................................................................. 87

5-1-2 If a System Error Occurs ................................................................................... 90

5-2 Removing Jammed Sheets ....................................................................................... 99

5-3 Stitch-Related Problems ......................................................................................... 101

5-3-1 The Stitches Are Moved Parallel to the Fold Line ........................................... 101

5-3-2 The Distance Is Not Correct ........................................................................... 101

5-3-3 The Stitches Are Angled................................................................................. 101

5-3-4 The Stitch Position Varies............................................................................... 102

5-3-5 The Stitches Are Curved................................................................................. 102

5-3-6 There Are Problems With The Stitch Length.................................................. 102

5-3-7 The Sheets Are Not Stitched.......................................................................... 103

5-3-8 The Wire Jams................................................................................................ 103

5-3-9 The Shape of the Stitch is Incorrect................................................................ 104

5-4 Poor Sheet Arrangement ......................................................................................... 107

5-5 Folding-Related Problems ...................................................................................... 109

5-5-1 Fold Skewing.................................................................................................. 109

5-5-2 The Folding Position Varies............................................................................ 109

5-5-3 Failed to Fold at Correct Position ................................................................... 110

5-5-4 Jog Error Not Detected...................................................................................111

5-5-5 The Sheets Are Bent ...................................................................................... 111

5-6 Fore-edge Trimming-Related Problems ................................................................. 112

5-6-1 The Sheets Are Trimmed Incorrectly.............................................................. 112

5-6-2 Incorrect Trim Position.................................................................................... 112

5-7 Scratched Sheets ..................................................................................................... 113

5-8 Specific Symptom-Related Problems .................................................................... 114

5-8-1 The Buzzer Beeps at an Interval of Two Seconds.......................................... 114

5-8-2 Fine Adjustment from the Touch Panel Does Not Work................................. 114

5-8-3 The Delivery Conveyor Does Not Move ......................................................... 114

5-8-4 The Trim Is Not Collected (The pump does not operate) ................................ 114

5-8-5 The Touch Panel Does Not Light Up.............................................................. 115

5-8-6 A Stitcher Head is Jammed............................................................................115

vi

Page 7

5-9 Other Problems ........................................................................................................ 116

5-9-1

The Booklets Overlap Each Other at the Delivery Conveyor though They are Offset.... 116

6 Maintenance

6-1 Loading Stitch Wire ................................................................................................ 117

6-2 Threading the Wire Through the Stitcher Head .................................................... 118

6-3 Attaching the Transport Pusher ............................................................................. 119

6-4 Lubrication ............................................................................................................... 120

6-4-1 Top and Bottom Guide Slide Shaft .................................................................. 120

6-4-2 Stitcher Vertical Slide Shaft ............................................................................. 120

6-4-3 Fold Knife Section ........................................................................................... 120

6-4-4 Stitcher Head ................................................................................................... 121

6-4-5 Clincher Drive Cam ......................................................................................... 121

6-5 Cleaning ....................................................................................................................122

6-5-1 Around the Stitcher Heads .............................................................................. 122

6-5-2 Transport Belts / Transport Rollers .................................................................. 122

6-5-3 Sensors ........................................................................................................... 123

6-6 Replacing the Fore-edge Trim Knife ...................................................................... 125

6-6-1 Upper Knife Replacement ............................................................................... 125

6-6-2 Lower Knife Replacement ............................................................................... 127

6-7 Clincher Point Replacement ................................................................................... 130

6-8 Guide Sheet Replacement ....................................................................................... 131

6-9 Stitcher Head Removal / Attachment ..................................................................... 132

6-9-1 Stitcher Head Removal .................................................................................... 132

6-9-2 Stitcher Head Attachment ................................................................................ 132

6-10Resetting the Circuit Breakers ............................................................................... 136

6-11Replacing the Fuses ................................................................................................ 137

7 Installation

7-1 Installing the Main Unit ............................................................................................ 139

7-2 Installing the Fore-edge Trim Section .................................................................... 141

7-3 Attaching the Accessories ...................................................................................... 143

7-4 Installing the Delivery Conveyor ............................................................................ 145

7-4-1 SC-200 Short Conveyor .................................................................................. 145

7-4-2 LC-200 Long Conveyor ................................................................................... 146

7-5 Connecting to an Upstream Device ....................................................................... 147

7-6 Checking ROM Versions of Connected Devices ................................................... 150

7-7 Connecting the Main Unit Power Cable ................................................................. 152

7-8 Setting the System Configuration .......................................................................... 153

7-9 Setting Up for Optional Devices ............................................................................. 154

7-10Synchronizing Between the Devices ..................................................................... 155

8 Options

8-1 Preset Kicker PK-30 ................................................................................................. 157

8-1-1 Installation of Preset Kicker ............................................................................. 157

8-1-2 Operation ......................................................................................................... 158

8-2 Paper Insertion Kit PN-200 ...................................................................................... 159

8-2-1 Operation ......................................................................................................... 159

8-2-2 Installation of Paper Insertion Kit ..................................................................... 161

8-3 Four Stitching Kit FST-200 ...................................................................................... 166

vii

Page 8

8-3-1 Accessories for Four Stitching Kit................................................................... 166

8-3-2 Installation of Clincher ..................................................................................... 168

8-3-3 Installation of Stitcher Head ............................................................................. 169

8-3-4 Wire Attachment .............................................................................................. 171

8-3-5 Option Setup .................................................................................................... 173

8-3-6 Limitation for Use ............................................................................................. 174

8-4 Side/Corner Stitch Kit SSK-200/SSK-200L ............................................................ 175

8-4-1 Installation of Side/Corner Stitch Kit............................................................... 175

8-4-2 Option Setup................................................................................................... 178

8-5 Mis-stitch Detector SDS-200 ................................................................................... 179

8-5-1 Installation of Mis-stitch Detector ..................................................................... 179

8-5-2 Operation........................................................................................................182

8-6 Thickness Detector TD-200 ..................................................................................... 183

8-6-1 Installation of Thickness Detector .................................................................... 183

8-6-2 Calibrating the TD-200.................................................................................... 185

8-6-3 Operation ......................................................................................................... 187

8-7 Chip Extractor TB-200 ............................................................................................. 189

8-7-1 Operation ......................................................................................................... 189

8-7-2 Installation of Chip Extractor ............................................................................ 190

8-8 Loop Stitching .......................................................................................................... 192

8-8-1 Loop Stitcher Head Replacement .................................................................... 192

9 Appendix

9-1 Specifications ........................................................................................................... 195

9-1-1 SPF-200A....................................................................................................... 195

9-1-2 FC-200A ......................................................................................................... 198

9-1-3 SPF-200L........................................................................................................ 199

9-1-4 FC-200L.......................................................................................................... 203

9-2 Accessories .............................................................................................................. 204

9-2-1 SPF-200A/SPF-200L ....................................................................................... 204

9-2-2 FC-200A/FC-200L .......................................................................................... 206

9-2-3 IFU-200 ............................................................................................................ 207

9-3 Consumables ........................................................................................................... 208

viii

Page 9

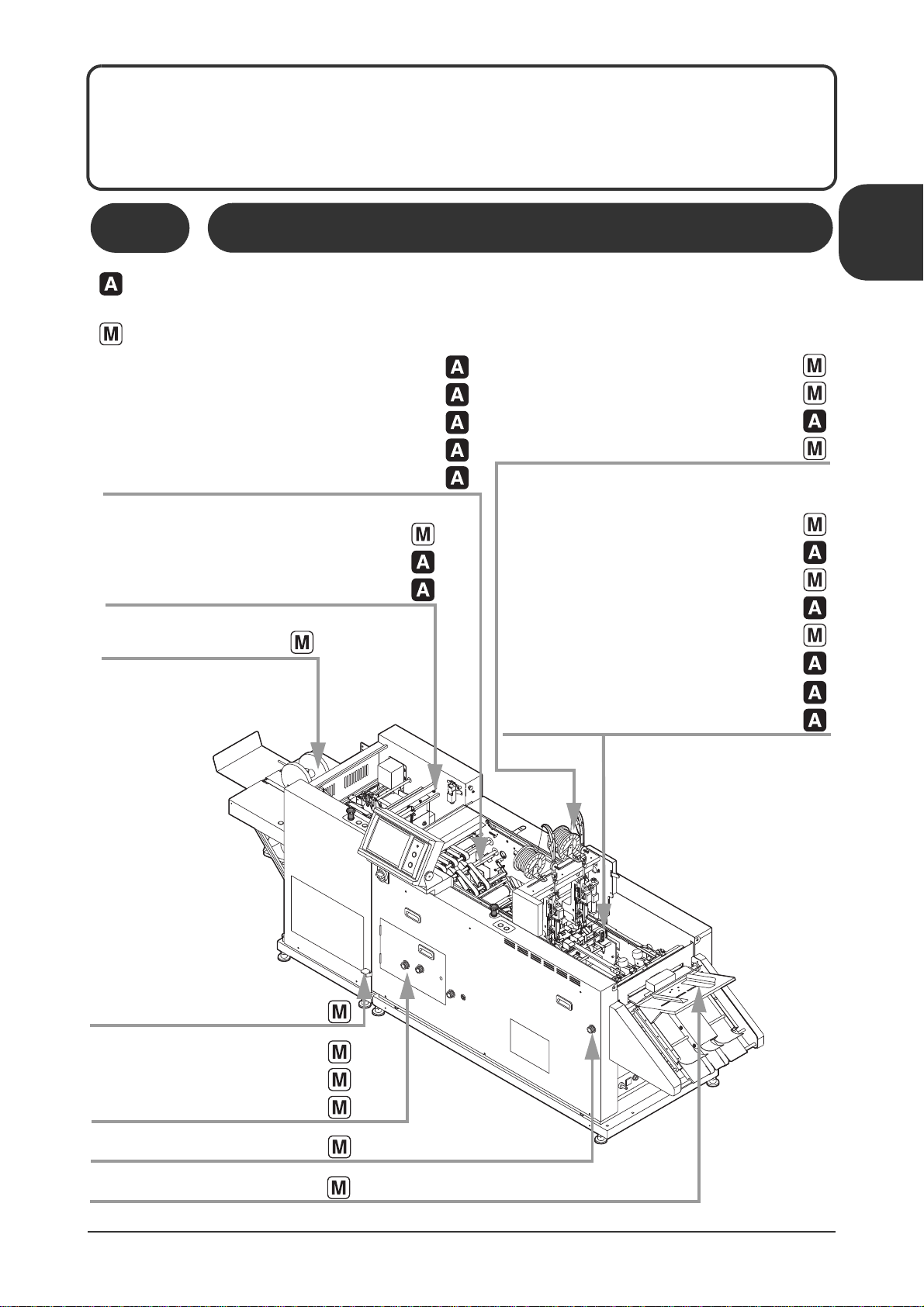

s

11119

10101A1

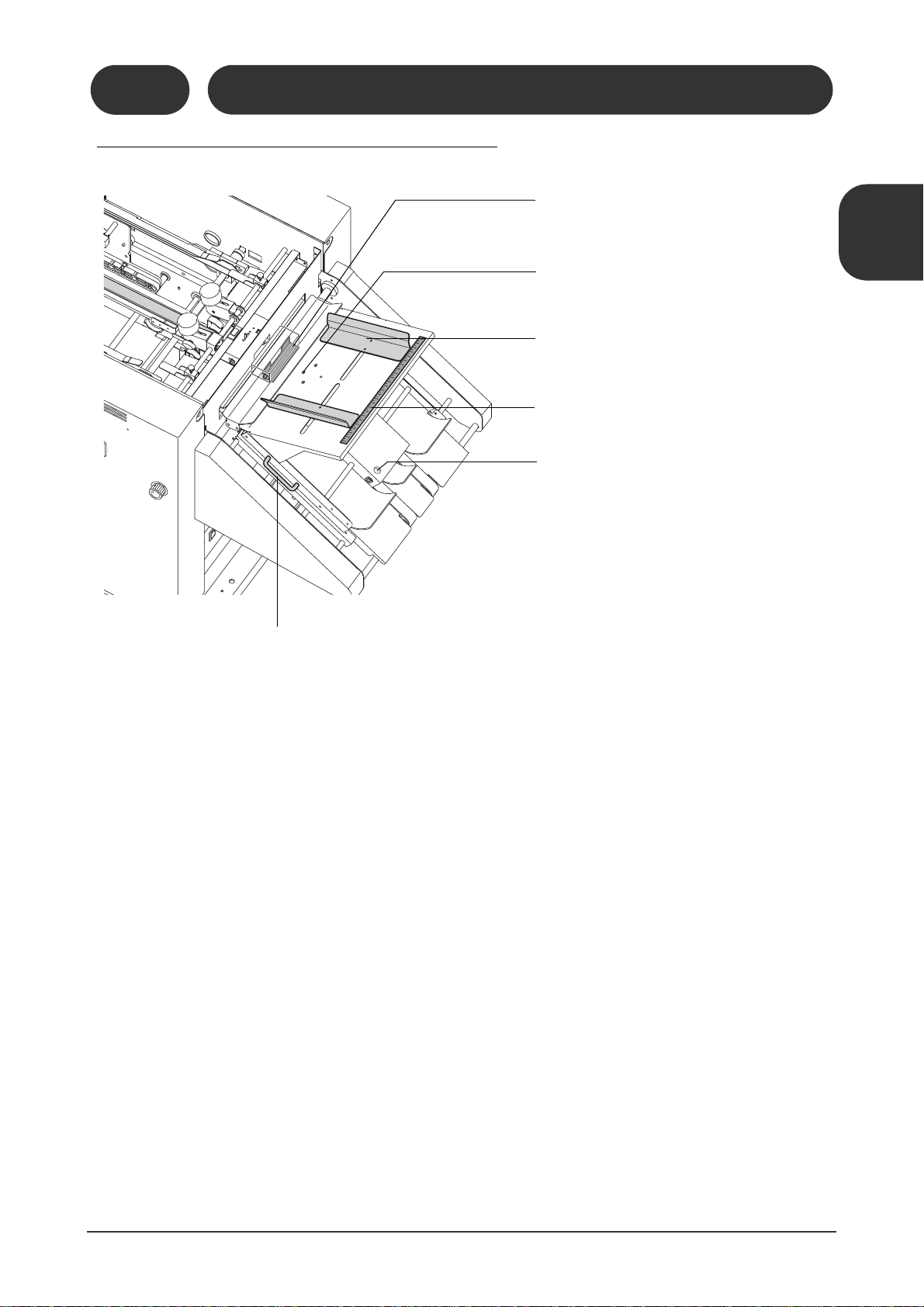

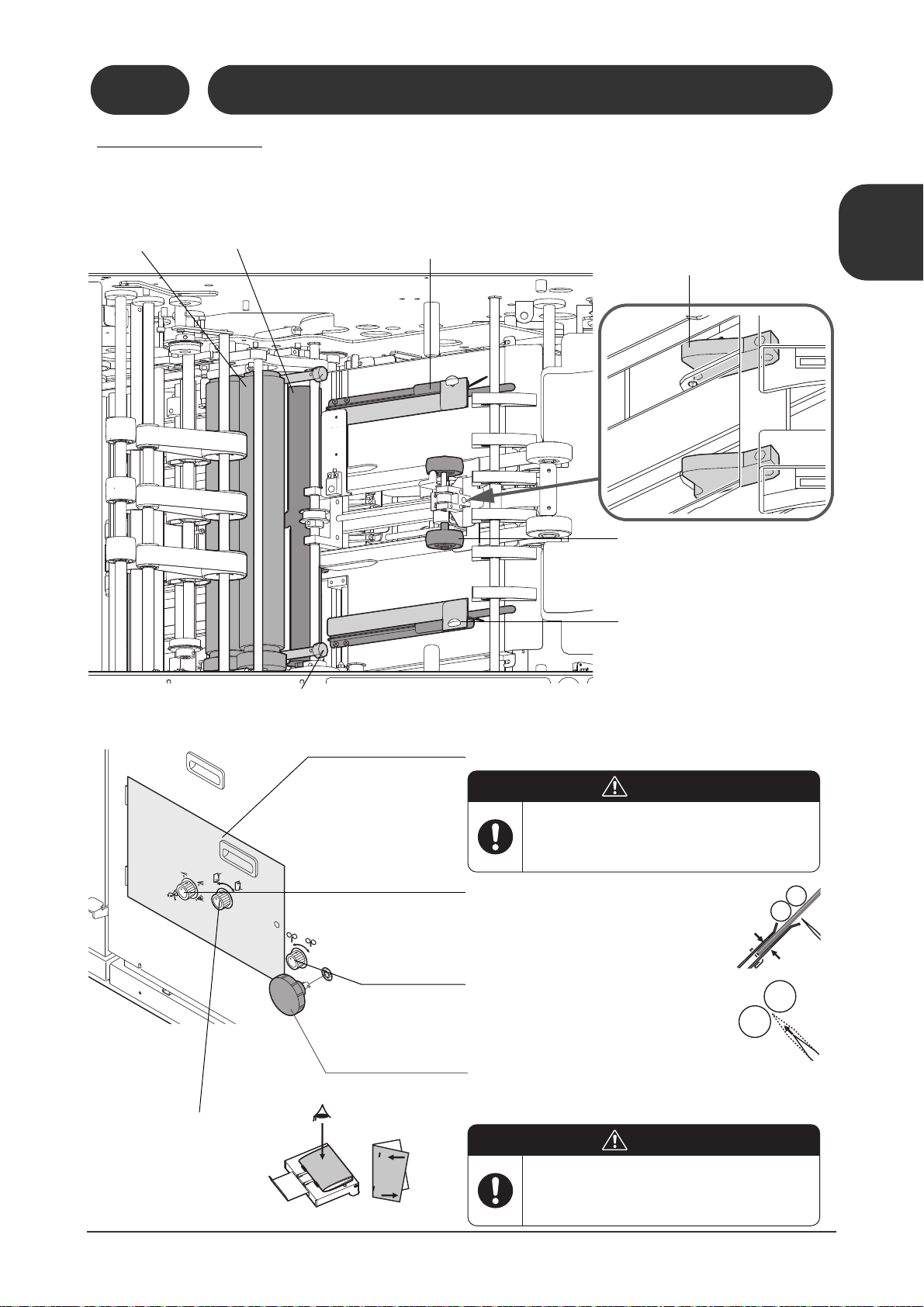

Front Transport Belt Gap Adjustment

Transport Belt Height Adjustment

Stopper Position

Fold Roller Gap

Jog Pusher

Fold Section Top and Bottom Guide Width

Fold Section Top and Bottom Guide Stroke

Forward Roller Position

Delivery Roller Position

Saddle Stitch Stopper Replacement

(Large / Small)

Saddle Stitch Stopper Position

Guide Bar Attachment

Transport Pusher Speed

Corner Stitch Guide Replacement

Top and Bottom Guide Width

Top and Bottom Guide Stroke

Jogging Frequency

Manual Feed Guide Width

Fore-edge Trim Section

Alignment for a Small Booklet

Buckle Gap Adjustment

Fold Skew Correction

Fold Knife Height Adjustment

Infeed Section Direction

Stitcher Head Drive Block Attachment

Stitch Angle

Stitch Distance

Stitch Length

1 Machine Description

This chapter explains how to use the automatic and manual settings, and describes the

parts of the machine and their functions.

1-1 Automatic and Manual Settings

Automatic: This indicates a setting which is performed automatically to match the sheet size and

binding pattern. The setting can be changed using the touch panel.

Manual: This indicates a setting which is performed manually using a knob or lever.

1

Machine Description

Automatic and Manual Settings /

1

Page 10

11119

10201A1

Jog Section

Cover

Fore-edge Trim Section

Cover

Infeed Section

Cover

Emergency Stop Button

Press

Release

Fold Section

Cover

1-2-1

1-2 Machine Descriptions

Safety Device / Safety Functions

1-2-1 Safety Device / Safety Functions

The whole system stops when a safety cover is opened or the Emergency Stop bottom is pressed during operation.

2

Page 11

21102

10202A1

11119

10202D1

11119

10202B1

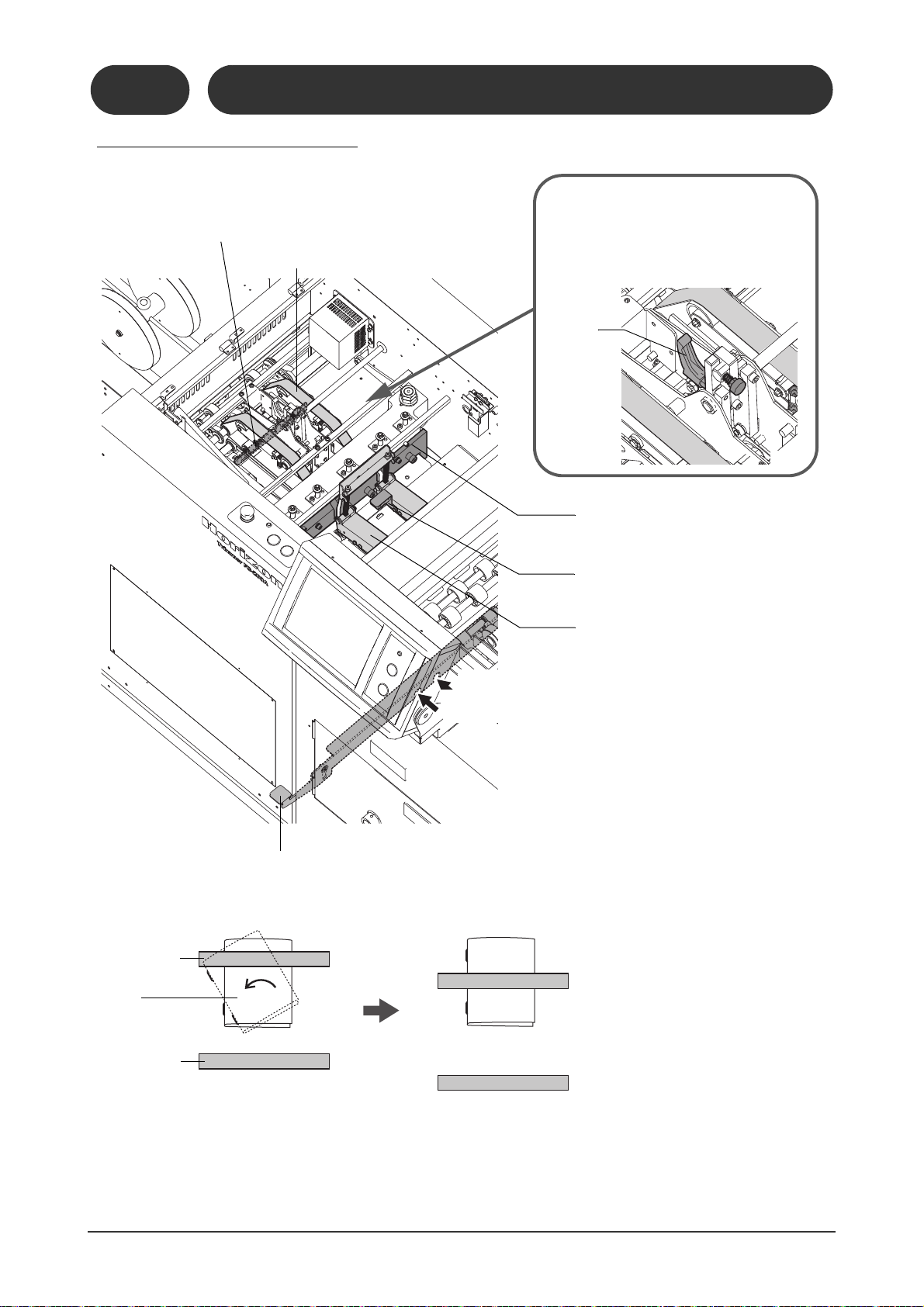

Fold Section

Connectors for Upstream Devices

2. The sheet is pushed up by the fold knife, then is

caught in the fold roller and folded. Next the press

rollers crease the folded sheet.

Power Switch

Control Panel

Refer to 1-2-10.

Horizontal Transport

Section

The unfolded sheets are

transported through this section.

Stitch Section

Control Panel

1. The sheet is squared-up in the top-bottom and

fore-edge directions before folding. (This happens if the top and bottom guide jog function is

turned on.)

Infeed Section

The sheets are transported from this section to

the jog section.

Manual Feed Section

The sheets can be manually fed when the stopper

opens in this section.

Press

Rollers

Fold Rollers

Fold Knife

Air Line from the Collator

Not Used

Signal Connectors for Collator

Signal Connector for

IFU-200 Infeed Conveyor

Stitch Section

The sheets are stapled here.

11119

10202C1

Jog Section

The sheet is squared-up in

the top-bottom and fore-edge

direction before stitching.

Connectors for

Downstream Device

Power Connector

for Fore-edge Trim

Connector for Delivery Conveyor

Signal Connector

for Fore-edge Trim

Section

Arcnet Communication Connector

Optional IFU-200

Infeed Conveyor

The collated sheets are transported

from the collator to the infeed section

of the SPF-200A/200L.

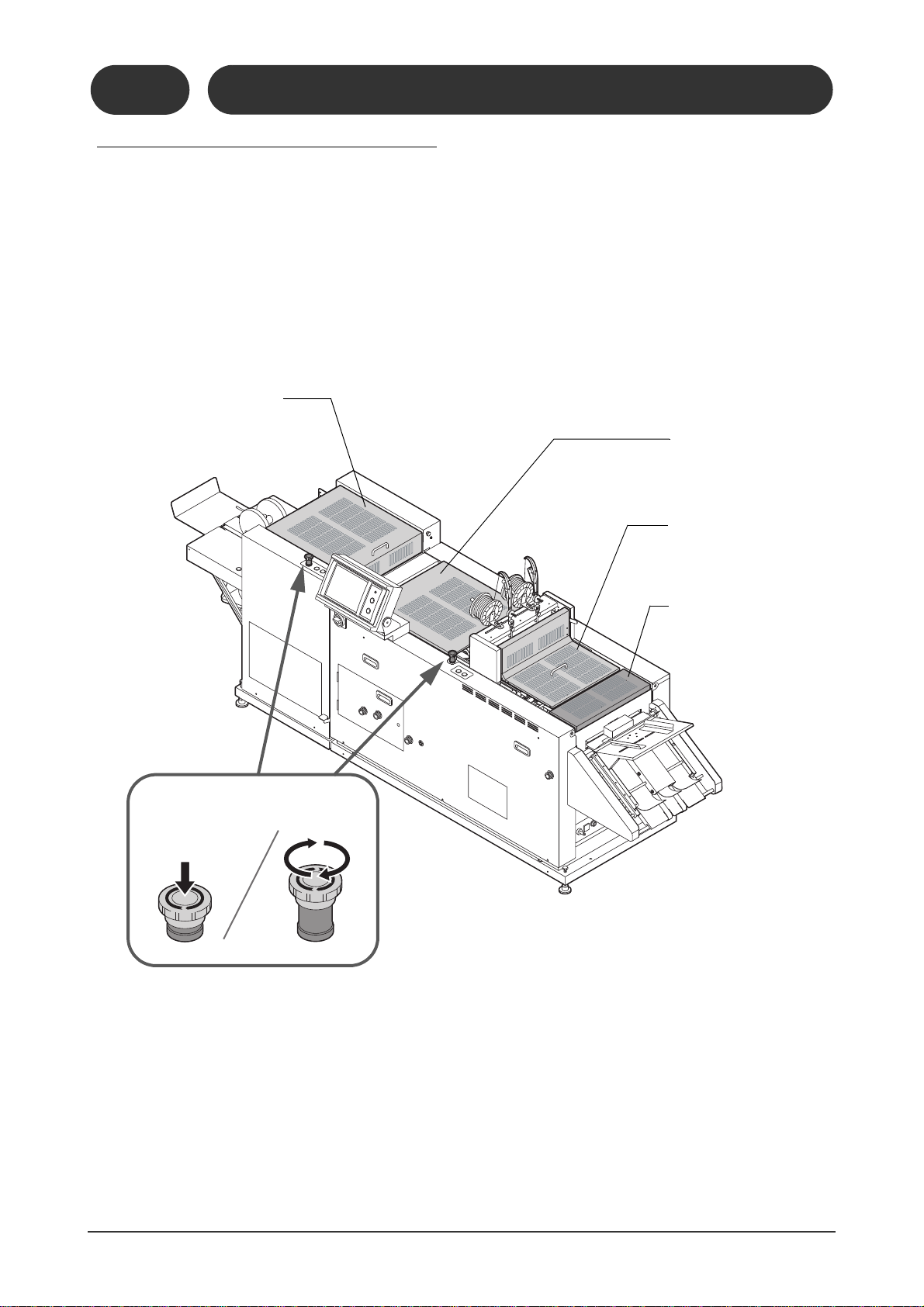

1-2-2

1-2 Machine Descriptions

Overall Machine

1-2-2 Overall Machine

This explains how to use the system configuration including the optional IFU-200 infeed conveyor, FC200A/200L fore-edge trim section, and the SC-200 delivery conveyor.

1

11119

10202J1

Machine Description

Machine Descriptions /

11119

10202E1

3

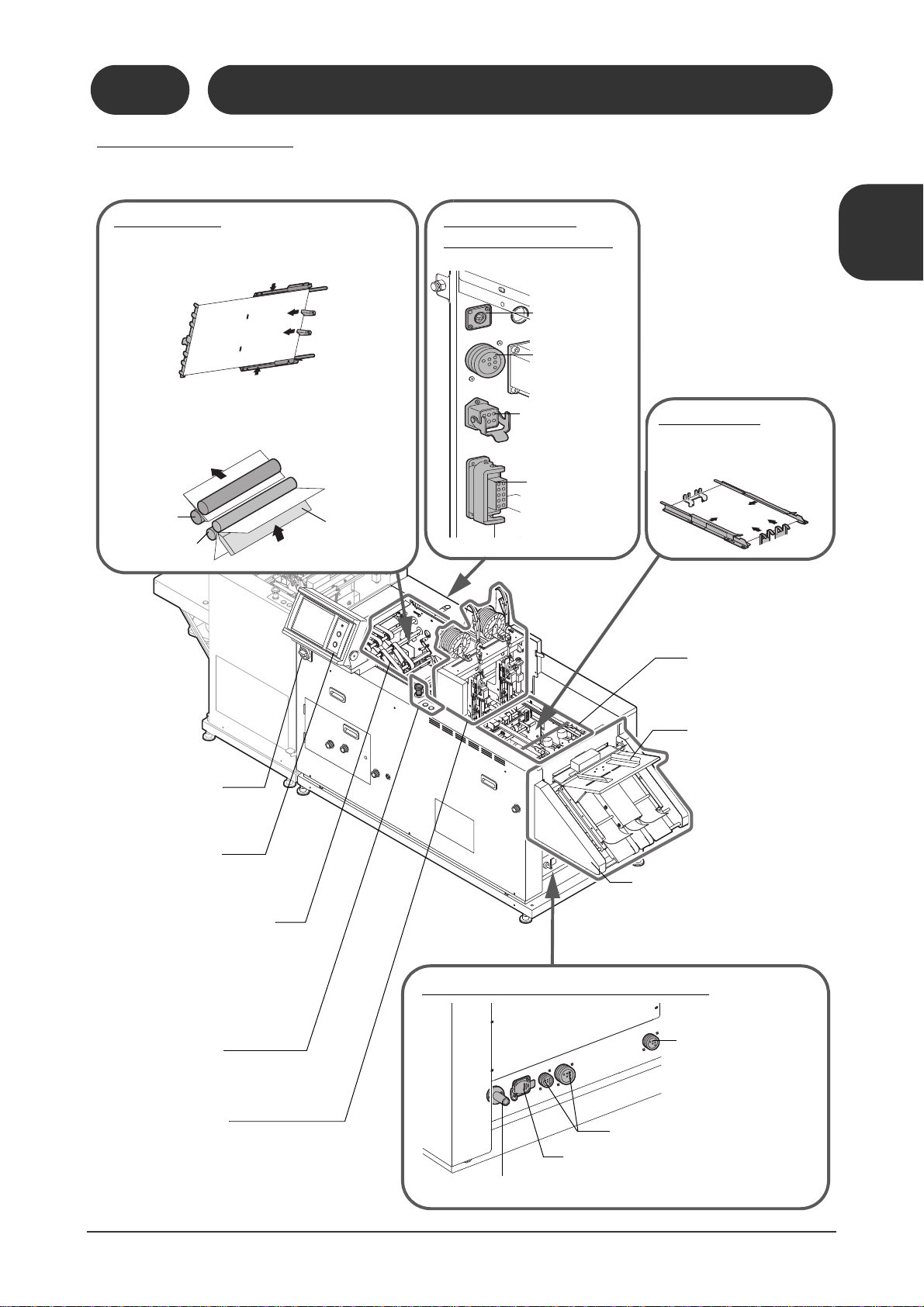

Page 12

1-2 Machine Descriptions

Fore-edge Trim

Section

The transport belts compress the booklets, and

then the fore-edge of

each booklet is trimmed.

Connectors for Downstream

Devices

Connector

for TB-200

Chip

Extractor

Fore-edge Trim Section

Control Panel

Transport

Belt

Not Used

Hole for MKU54, MKU-54T or

PST-40 Communication

Cable

Delivery Conveyor

(Option)

This illustration shows a short conveyor.

Connector

for PK-30

Preset

Kicker

Power Connector for

Delivery Conveyor

Faulty Set Ejecting Section

A faulty set is ejected to the faulty set

ejecting tray.

Good

Set

Bad

Set

Gate

Faulty Set Ejecting Tray

Trim Chute

The trim is ejected from this chute.

Not Used (for

Short Circuit

Connector)

1-2-2

Overall Machine

11119

10202H1

11119

10202G1

4

11119

10202I1

11119

10202F1

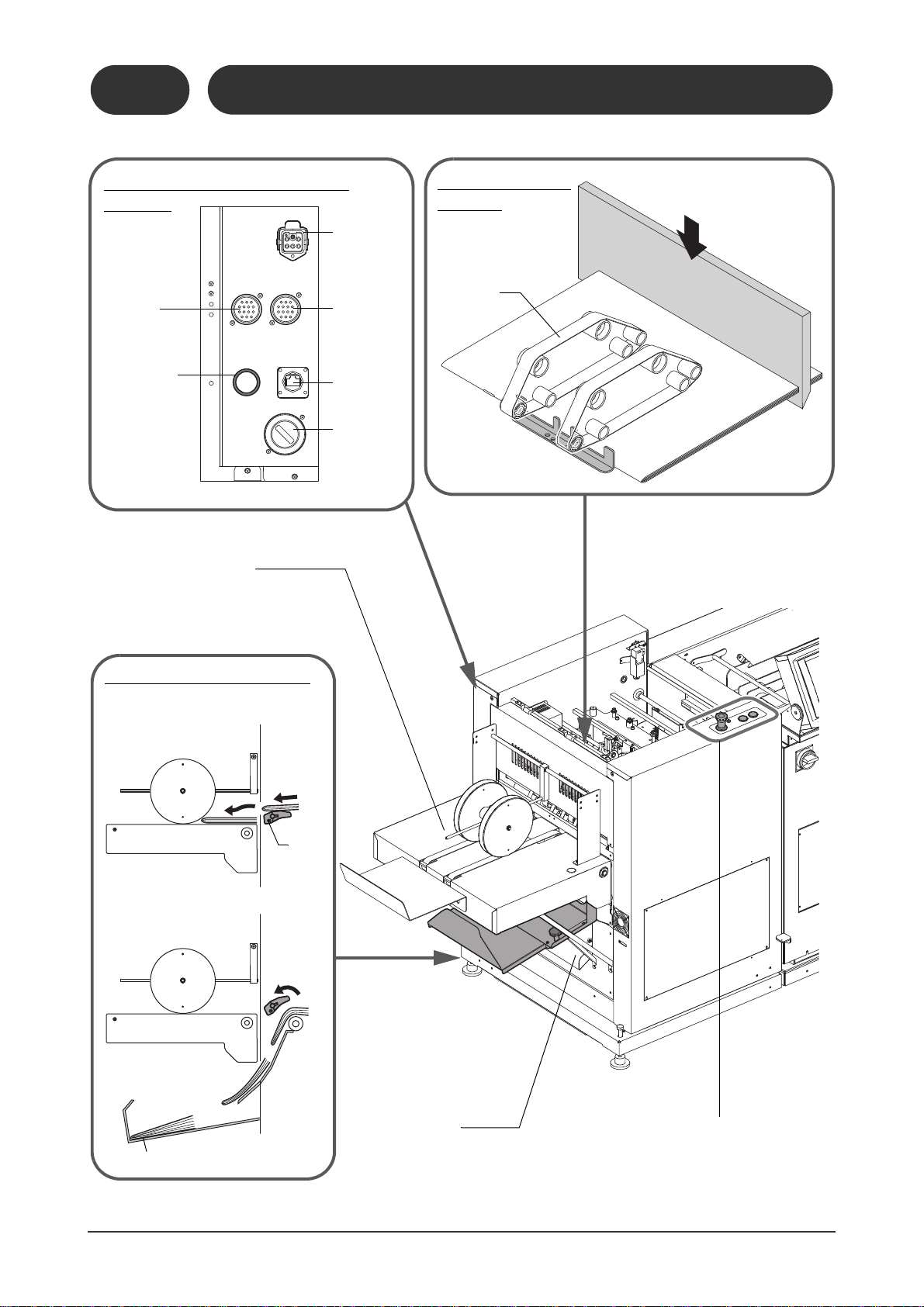

Page 13

1-2 Machine Descriptions

Manual Feed Stopper

Sheets can be fed manually if the stopper is lowered.

Manual Feed Sheet Sensor

This sensor detects any sheets placed on the manual

feed table.

Manual Feed Guide

This guide can be set to match the width of the sheet

being fed.

Guide Position Scale

Sheet Sensor

This sensor detects a sheet as it feeds from the collator and triggers the manual feed.

Upper Transport Section Lifting

Handle

1-2-3 Manual Feed / Infeed Conveyor Section

1-2-3

Manual Feed / Infeed Conveyor Section

1

Machine Description

11119

10203A1

Machine Descriptions /

5

Page 14

1-2 Machine Descriptions

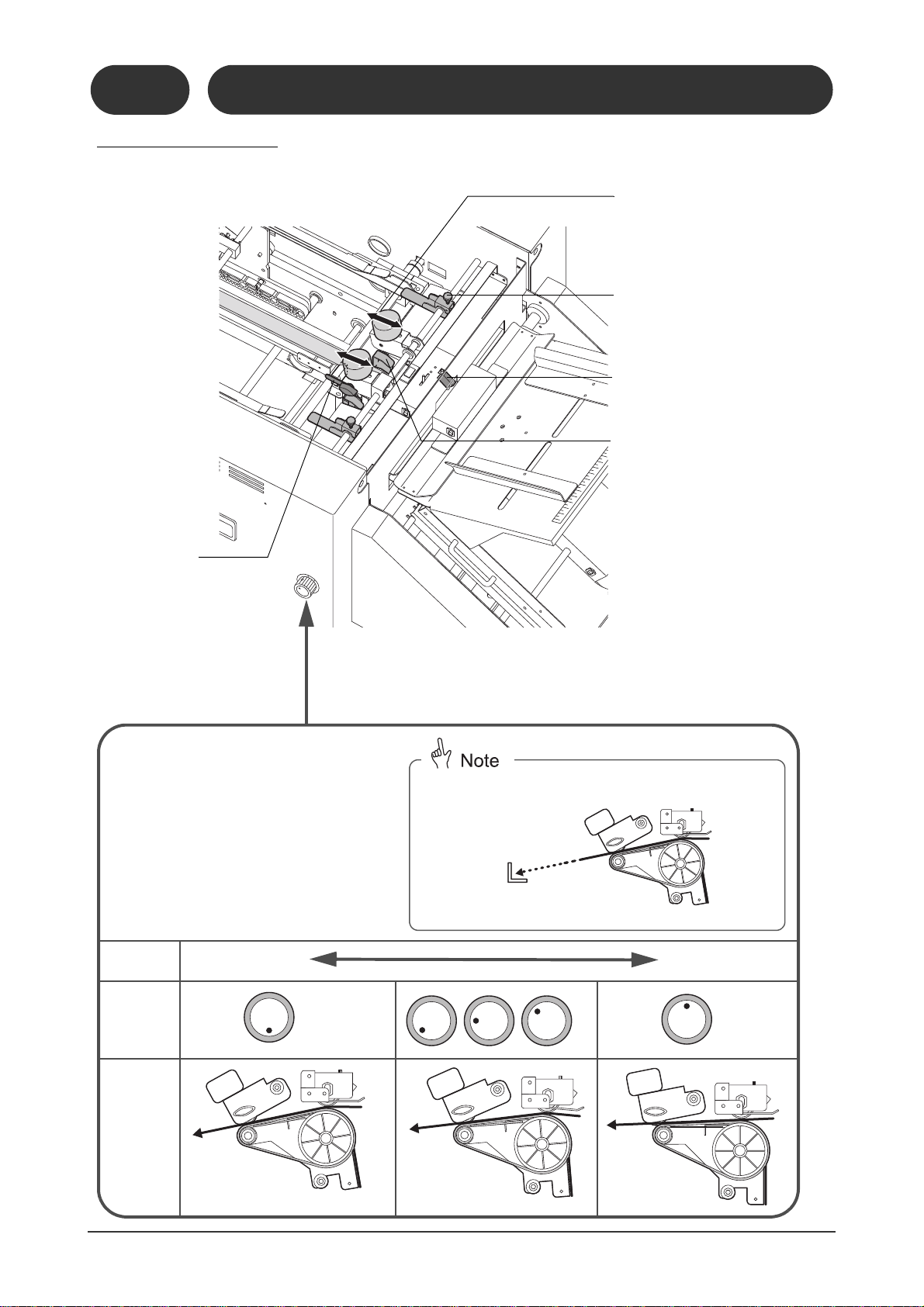

Infeed Section Direction

Adjusting Knob

There are five possible settings. To make an adjustment, pull the knob and turn it.

Sheet

Length

Short Long

Knob

Position

Infeed

Direction

In the ideal setting, the sheet is directed toward the corner of the stopper.

11119

11119

10204B1

Low

Middle

High

(Horizontal)

Weights

The transport roller pressure can be

adjusted by changing the positions of

these weights. To move a weight, turn

the top to loosen it.

Hold-down Guides

These guides help to control sheets

which are bent or rolled.

Fore-edge Jog Plate

This squares up the sheet in the foreedge direction.

Jam Sensor

Sheet Holder

If the tail of the sheet remains at

the exit of the infeed section and

is not transported completely, the

sheet can be pushed to the belt

using this holder. (If the holder

pushes too strongly, the sheet

may be scratched.)

1-2-4 Infeed Section

1-2-4

Infeed Section

11119

10204F1

11119

10204G1

11119

10204A1

11119

10204E1

6

11119

10204C1

11119

10204D1

Page 15

1-2 Machine Descriptions

21102

10205A1

Transport Pusher for

Paper Insertion (Option)

Transport Pusher

This pusher transports the flat

sheet when it is inserted into the

center page of a stitched booklet.

The sheet is pushed and transported by this pusher. The

pusher may be removed if there

are paper jams. (Remember to

re-install the pusher for normal

setups.)

The waiting position for the transport pusher can be adjusted using

the touch panel screen. Refer to page 25 for details.

11119

10205C1

Saddle Stitch Stopper

Install large or small stoppers to match the sheet

width. (The instruction screen is displayed on the

touch panel.)

Side Stitch Stopper

This stopper is used for side stitching and corner

stitching.

Top and Bottom Guides

- These guides jog the sheets from the top and bottom sides before stitching.

- The settings listed below can be done using the

touch panel.

- Jogging frequency before stitching

- Stroke (Guide opening when the sheet comes in)

- Delivery Stroke (Guide opening when the sheet

goes out)

- When you are doing corner stitching, these guides

are replaced by the corner stitch guide.

- This guide assembly consists of three parts. When

you are running small booklets, you may have to

remove these guides. (The instruction screen is

displayed on the touch panel.)

Side Stitch Sheet Hold-Down Plate

This plate prevents the sheets from floating.

Long type and short plates are available.

Guide Bar

This bar prevents the sheets from being bent

down. You must remove this bar before doing a

changeover. (The instruction screen is displayed

on the touch panel.)

Parallel Adjusting Bolt

This bolt is used as a gauge to adjust the

top-bottom guide so that it is parallel.

1-2-5 Jog Section

11119

10205B1

1-2-5

Jog Section

1

Machine Description

Machine Descriptions /

11119

10205D1

11119

10205E1

7

Page 16

1-2 Machine Descriptions

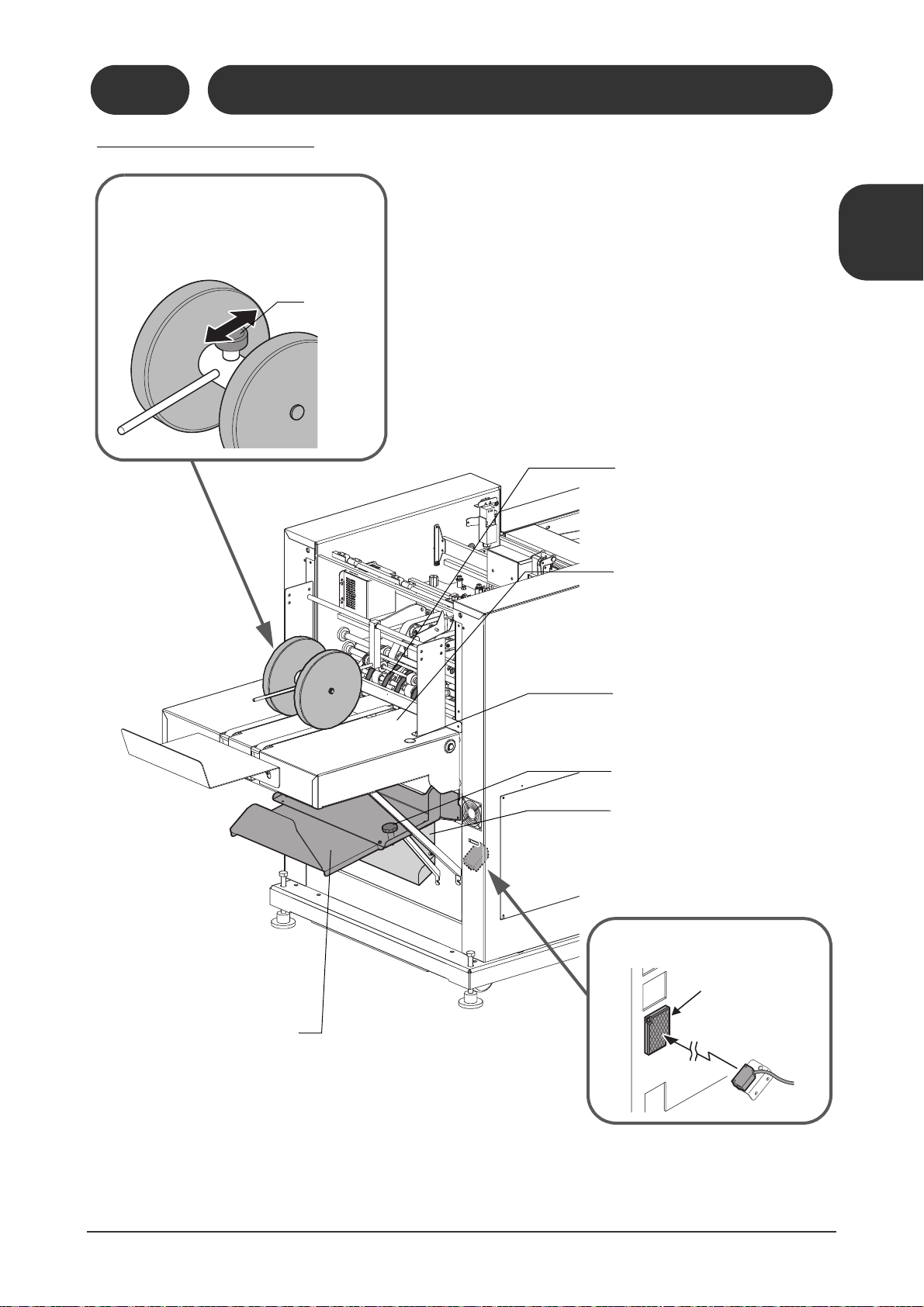

11119

10206D1

Wire Feeding

Detection Sensor

As the wire is feeding, the

wire guide bends down and

immediately returns to its

original position. This sensor

watches the movement of the

wire guide to see that the

wire is feeding properly. The

sensor is turned on (red LED

lights) when the wire guide is

bent down.

Clincher Lever

This allows you to remove a stitch which remains in

the clincher section.

Stitcher Head Drive Block

When one of these blocks is removed, the machine

does not make stitches on that side. The block on

the non-stitched side should be removed when you

are doing corner stitching. (The instruction screen

is displayed on the touch panel.)

Coil Brake

This brake prevents the coil from turning too easily and tangling

the wire. If the brake is pressed harder against the coil, it becomes

harder to turn the coil.

Stitch Angle Adjusting Knob

The stitch angle can be adjusted using this knob if one

stitch is not lined up.

Wire Coil

Standard wire is No.25 (0.5 mm in diameter)

Optional wire No.26 (0.45 mm in diameter) is

available.

Wire

Guide

Red LED

This lamp lights

when the sensor

detects the wire

guide.

There are circuit breakers inside this cover. See Section 6-10.

These holes allow for

installation of two

optional stitcher heads.

The positions of these

two stitchers are fixed.

Sheet Holder

This holder prevents the sheet from

floating. Long, short, and side stitching holders are available. Select the

holder to match the binding pattern

and sheet size. To change the holder,

loosen the locking knob. Set the

position of the holder to match

the thickness of the booklet.

Locking Knob

1-2-6 Stitch Section

The operation of the stitcher head is explained in Section 4-1.

Stitch Section

11119

10206C1

1-2-6

11119

10206A1

11119

10206B1

8

11119

10206E1

Page 17

1-2 Machine Descriptions

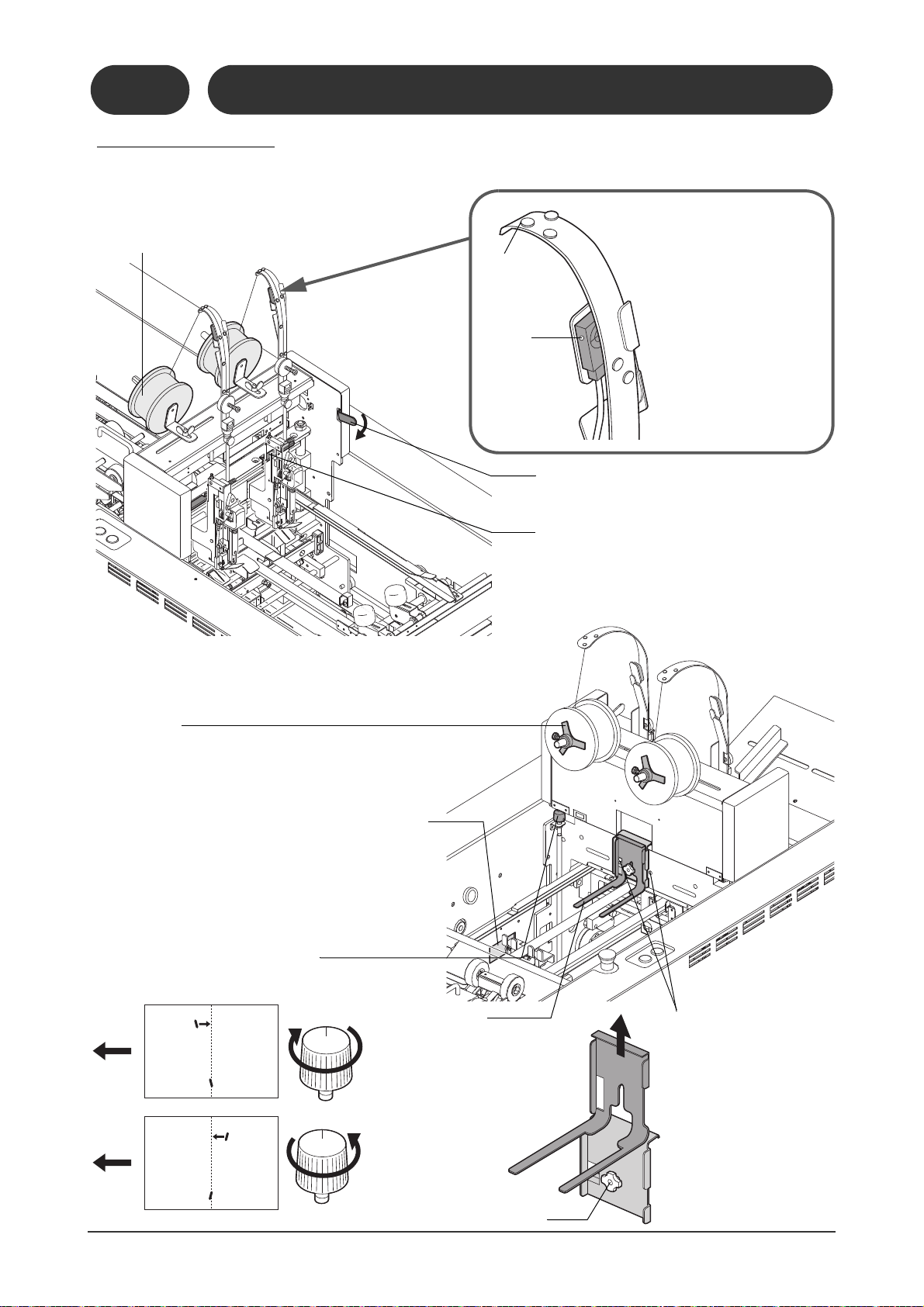

Fold Knife Height Adjusting Knob

The fold knife lifts when you turn this knob clockwise. (If you lift the fold knife too far, it may hit the

fold roller.)

Press

Rollers

These rollers

compress the

booklets.

Fold Rollers

The gap between the rollers

is automatically set to match

the booklet thickness

entered on the touch panel.

Fold Section Top and Bottom Guides

-These guides jog the sheets before folding.

-The settings listed below can be done using the touch panel.

- Distance between guides when jogging sheets

- Stroke (Guide opening when the sheet comes in)

- Delivery stroke (Guide opening when the sheet

goes out)

Fold Section Jog Pushers

-These pushers jog the sheets

before folding.

-The positions of these pushers

when jogging the sheets can be

adjusted on the touch panel.

(Refer to 1-3-7.)

Sheet Hold-Down Plate

These plates prevent the sheets from

floating.

Sheet Guide Locking Knobs

If sheets jam between the fold rollers and press rollers, remove the sheet guide by loosening these knobs.

Fold Skew Correction

Knob

As shown in the illustration, any

fold skewing can be corrected

by turning this knob clockwise.

Buckle Gap Adjusting Knob

The buckle gap can be adjusted in three levels

to match the sheet thickness.

The fold section stopper can be reached by opening this cover.

Press the Emergency Stop button before

turning the handwheel. A sudden accidental start of the machine can cause severe

personal injury.

WARNING

Do not open this cover while the machine

is running. Otherwise, moving parts can

cause severe personal injury.

WARNING

Forward Rollers

These rollers transport the sheets to

the fold section and prevent the sheets

from bouncing.

Handwheel

The fold roller and press rollers can be turned by hand for cleaning.

1-2-7 Fold Section

1-2-7

Fold Section

11119

10207B1

11119

10207A1

1

Machine Description

Machine Descriptions /

11119

10207F1

11119

10207E1

11119

10207D1

9

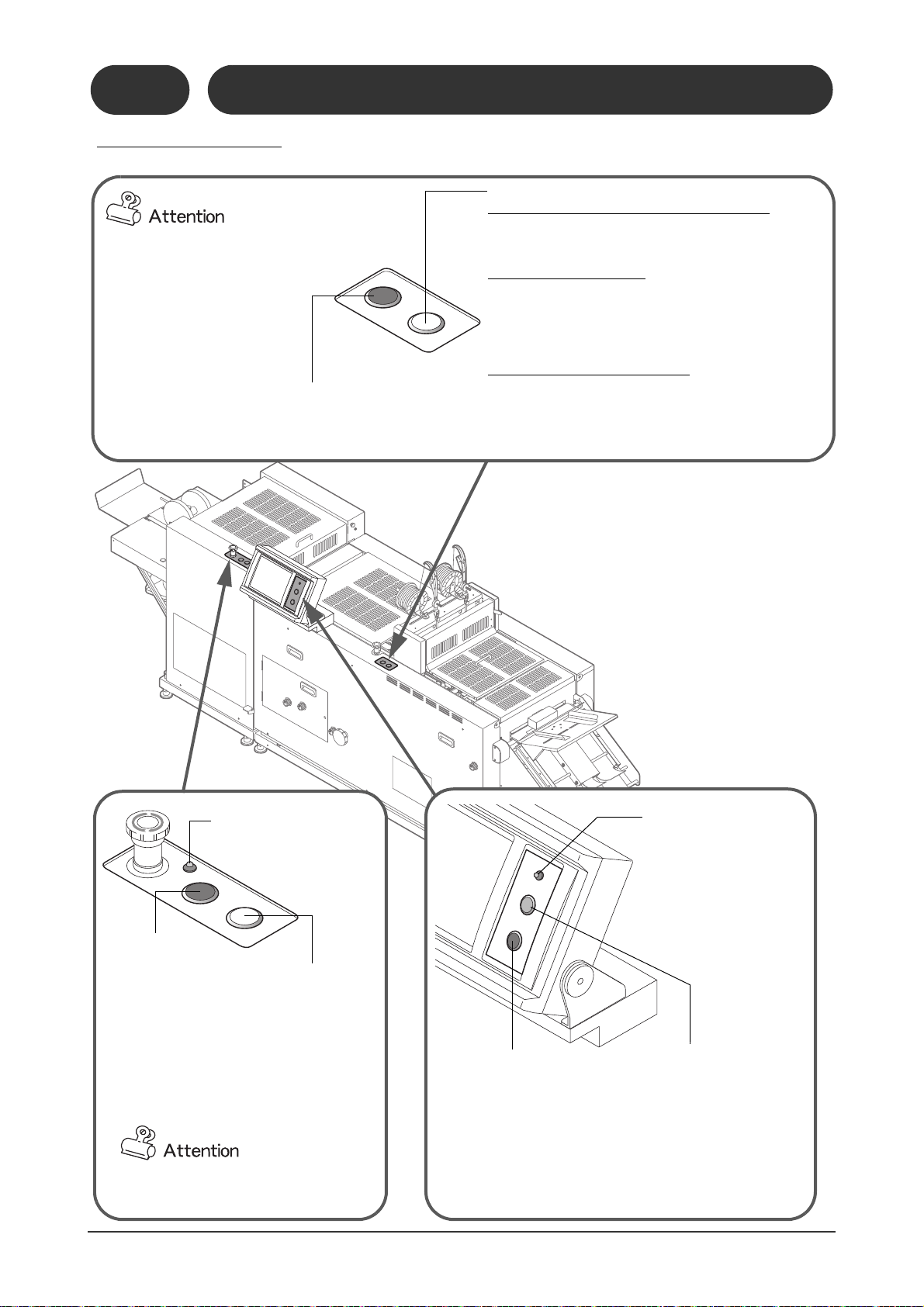

Page 18

1-2 Machine Descriptions

11119

10208A1

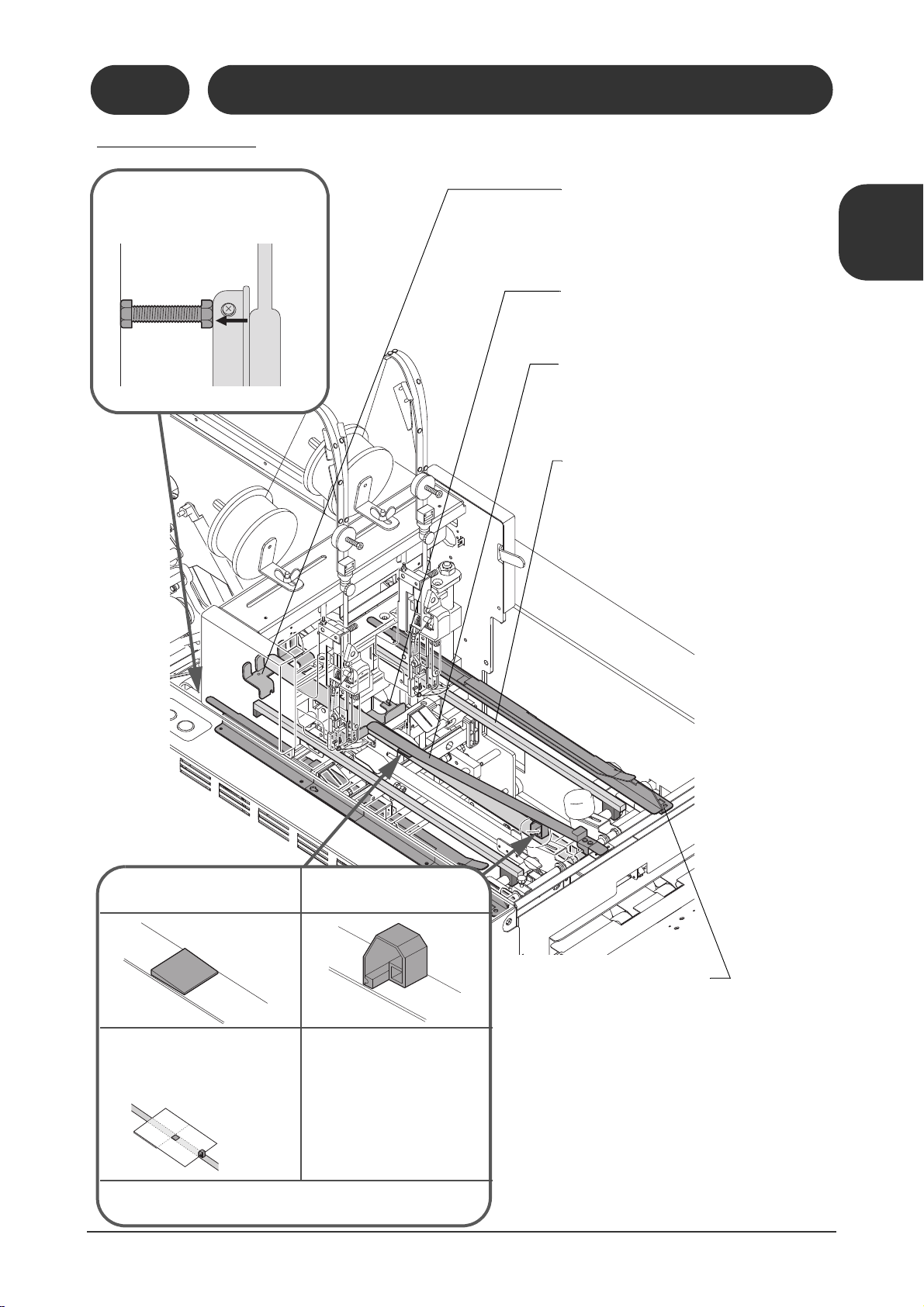

Booklet Stopper

This stopper is automatically

set to match the finishing size

of the booklet.

Transport Belts

The sheet is transported by these belts.

The gap between the upper and lower

belts is automatically set up to match the

book thickness entered on the touch panel.

Locking

Lever

Front Transport Belt Height

Adjusting Knob

If the booklets do not move correctly, adjust

this knob. To reduce the gap at the front of the

transport belts, loosen the locking lever and

turn the knob clockwise.

Jam Sensor

Trim Knife (Upper Knife)

Infeed Belts

These belts move the sheet into the foreedge trim section.

Fore-edge Trim Section Locking Lever

If you are trimming small booklets (smaller than B5), the booklet may not move correctly if the pressure is

different at the front and rear transport belts.

Transport Belt

Transport Belt

Lift the locking lever up and

move the fore-edge trim mechanism to the front.

When the fore-edge trim mechanism is moved to the front, the stopper holds the far side of the booklet,

and the booklet should stop straight against the stopper.

(The instruction screen for this is displayed on the touch panel when binding sheets smaller than B5.)

Position for Small Booklet

Normal Position

Stopper

1-2-8 Fore-edge Trim Section

1-2-8

Fore-edge Trim Section

11119

10208B1

10

11119

10208C1

Page 19

1-2 Machine Descriptions

11119

10209A1

Faulty Set Ejecting Gate

If the machine detects a faulty set, this

gate moves and the faulty set is delivered to the faulty set ejecting tray.

Delivery Conveyor

When a booklet is delivered, the belts

move for a moment. The running time

for the belts can be set on the touch

panel.

Delivery Rollers

These rollers hold the delivered booklet. These

rollers should be placed about 30 mm (1.2")

from the end of the booklet.

Locking Knob

Locking Knob

Jog Button

The conveyor belts move when this

button is pressed.

Faulty Set Ejecting Tray

When the faulty set eject function is activated on the touch

panel, faulty sets are delivered to this tray.

The possible causes of faulty sets are:

- Mis-feed / double feed / Jam in upstream device

- Fold section jog error

- Missed stitch detection (option)

- Fore-edge trim section thickness detection (option)

If the operation starts with a sheet remaining in the machine,

the sheet is delivered to this tray.

Trim Chute

The trim is ejected through this chute.

Trim Full Sensor

This sensor detects the trim full error.

Mirror

1-2-9 Delivery Conveyor

1-2-9

Delivery Conveyor

1

Machine Description

Machine Descriptions /

11

Page 20

1-2 Machine Descriptions

11119

10210C1

Fore-edge Trim

Section Power LED

Trim Knife

Reverse Jog

Button

When this button is

pressed and held, the trim

knife operates once and

then stops at the top position. If the knife is locked,

the trim knife can be

returned to the top position using this button.

When some screens are displayed on

the touch screen, these buttons will not

work.

Stop Button

This button stops the binding

operation. Feeding from the

upstream device stops when

this button is pressed. All booklets in-process are delivered,

and the transport rollers keep

moving. When this button is

pressed again, the machine

stops completely.

Main Machine Power

LED

This LED lights when the

power switch is turned On.

The LED blinks if the machine

is using the power saving

mode.

Transport Belt

Inching Button

The transport belt at

the fore-edge trim section drives only while

this button is pressed.

Start Button

This button starts the binding operation. If there are sheets remaining

inside the machine, they will be

ejected. While this is happening,

the button blinks. When the

machine is ready, the button lights

and feeding from the upstream

device (collator) starts.

Machine Jog Button

This jogs the jog section and the fold section. Jogging is stopped when this button is pressed again.

This button will work even if a cover is opened.

Stitch Jog Button

Operating the stitcher heads in the normal direction

Press and hold this button to make one stitch in the normal

direction while the cover is closed and the Emergency Stop

button is not pressed.

Reversing the stitcher heads

The stitcher heads will return to the original position by

reverse movement if you press this button while pressing

the Machine Jog button when the cover is closed and the

Emergency Stop button is not pressed. See page 75 for

details.

Releasing the top and bottom guides

The top and bottom guides move outward if this button is

pressed while the cover is opened or the Emergency Stop

button is pressed. Any sheets remaining at the jog section

can be removed easily. (The top and bottom guide returns to

its setting position when the jog button is pressed.)

When the power is first turned on,

these buttons will not work until the

first changeover has been done.

1-2-10 Control Panel

11119

10210B1

1-2-10

Control Panel

12

11119

10210A1

11119

10210D1

Page 21

1-3 Screen Descriptions

21102

10301A1

- After the power is turned on, the Initial Screen and Binding

Pattern Screen are displayed.

- The binding pattern can be selected on this screen. Press

one of the icons, and the Sheet Size screen shown below

is displayed.

If the SSK-200A or the SSK-200L has been selected on the

Administrator Mode-Option Screen, these icons are active.

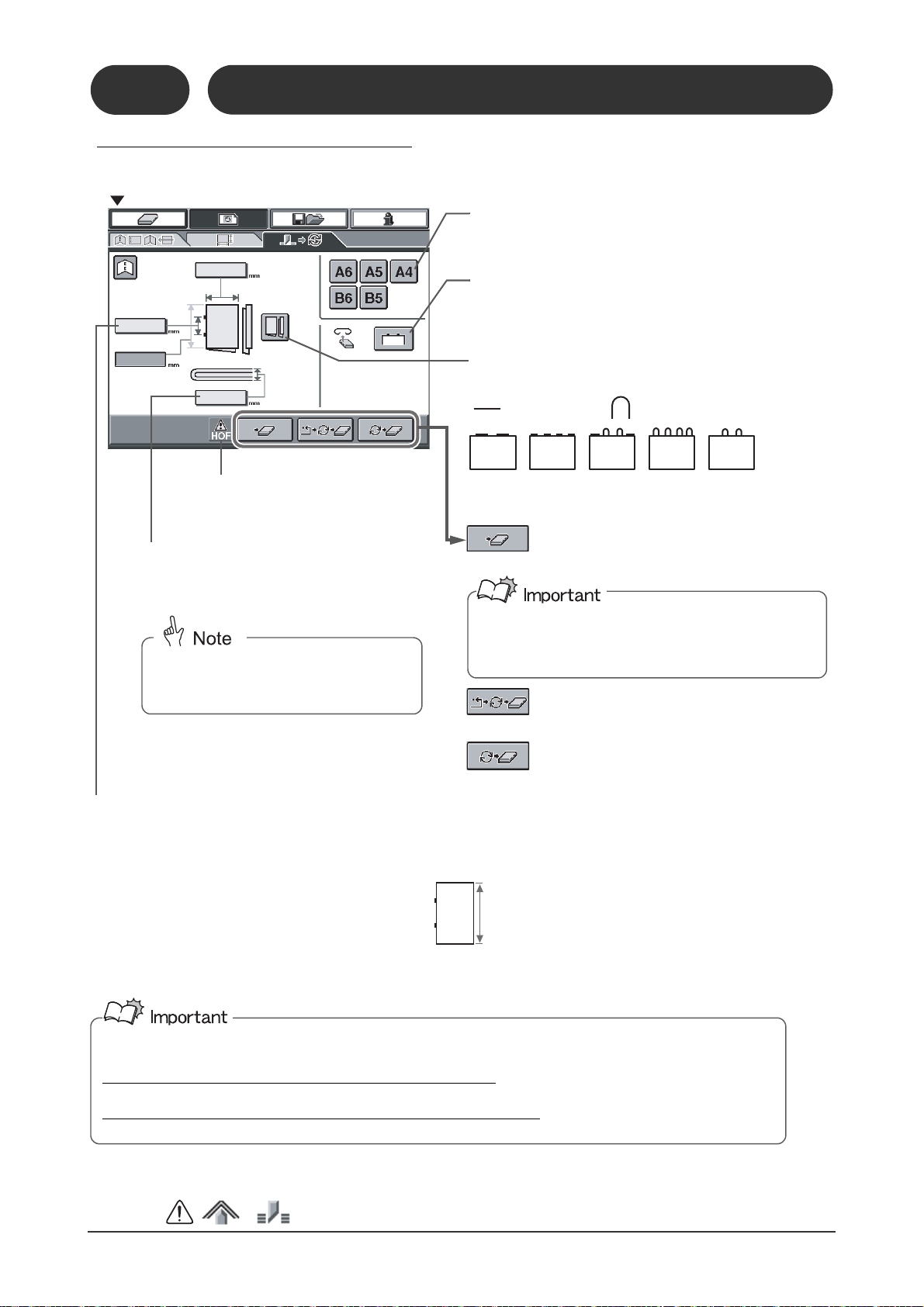

Binding Pattern Screen

OK

21102

10302A1

21102

10302B1

Sheet Size-Saddle Stitch Screen

Sheet Size-Side Stitch Screen

The dimensions are entered in steps of 0.1 mm (0.005").

Sheet Size

Press one of these buttons for standard size sheets, and the

dimensions are entered automatically.

Press this button after entering the sheet size.

The Finishing Size screen (next page) is displayed.

Booklet Thickness

Measure the thickness using a caliper (accessory), and enter the

value. The allowable range is 0.1mm (0.005") to 4.0mm (0.155”).

This icon blinks if the HOF-20/30 connected upstream of the

SPF-200A/200L has a problem.

= No changeover is performed and the

Binding screen is displayed.

= Each section returns to its home

position and then starts the changeover.

= The machine starts the changeover with

going to the home positions.

The actual positions of the guides and stoppers may be

different from the set positions. If there is a problem with

the binding quality, send all of the parts to the home positions before doing the changeover.

1-3-1 Setting-Binding Pattern Screen

1-3-1

Setting-Binding Pattern Screen

1

Machine Description

1-3-2 Setting-Sheet Size Screen

Screen Descriptions /

13

Page 22

1-3 Screen Descriptions

Stitch Distance

For Saddle Stitching

The “stitch distance” is the distance between the centers of the stitches. Set the stitch distance as listed below:

When top and bottom distance is 185mm (7.285") or more

- 79.1 to 92.0 (mm)

- 138.0 to 150.9 (mm)

- 234.0 to 246.0 (mm)

- 3.860” to 5.905”

If the top-to-bottom distance is less than 185mm (7.285")

- 79.1 to 80.9 (mm)

If the stitch distance is adjusted outside this range, skewing may occur because the stitch hits the fold knife, or the crooked trimming

may occur because the stitch hits the booklet stopper. If a value outside the normal range is entered, the value is shown in red and the

caution icons( ) are displayed.

On a machine set to measure in inches, you must set the stitch distance carefully so that the stitches do not hit

the fold knife or booklet stopper.

Stitch distance so that the stitch does not hit the fold knife

- 3.860” to 5.905”

Stitch distance so that the stitch does not hit the booklet stopper

- 3.115” to 3.185”

21102

10303A1

Finishing Size-Saddle Stitch Screen

Finishing Size

Press one of these buttons for standard size sheets, and

the dimensions are entered automatically.

Stitch Type

Select a stitch type from one of the five styles.

Depending on the sheet size, some stitch types may not be

available.

Press this button to do fore-edge trimming.

This icon blinks if the HOF-20/30

connected upstream of the SPF200A/200L has a problem.

Booklet Thickness

Measure the thickness using a caliper (accessory),

and enter the value. The allowable range is 0.1mm

(0.005") to 4.0mm (0.155”).

The fold roller gap and the height of the

fore-edge transport belts are adjusted

automatically to match this value.

Top-to-Bottom Distance

= Flat Stitch = Loop Stitch

= No changeover is performed and the

Binding screen is displayed.

= Each mechanism returns to the home

position and then starts the changeover.

= The machine starts the changeover without

sending the parts to the home positions.

The actual positions of the guides and stoppers may be

different from the set positions. If there is a problem with

the binding quality, send all of the parts to the home positions before doing the changeover.

1-3-3 Setting-Finishing Size Screen

Setting-Finishing Size Screen

11119

10303B1

1-3-3

11119

10303C1

14

Page 23

1-3 Screen Descriptions

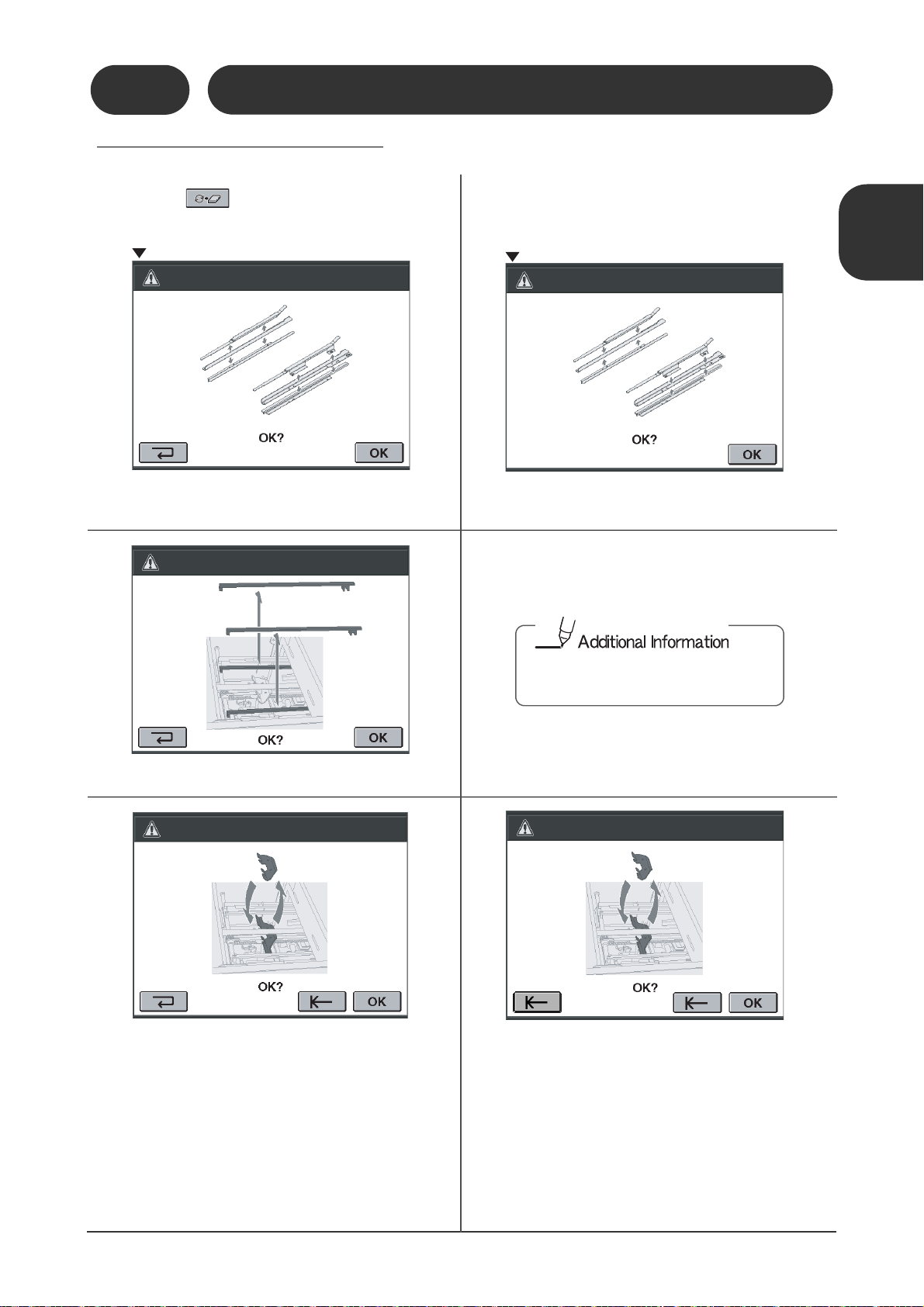

Instruction-Remove Screen

11119

10304E1

Instruction-Attachment Screen

11119

10304B1

There is no instruction screen for the

guide bar attachment. Attach the guide

bars if necessary.

11119

10304C1

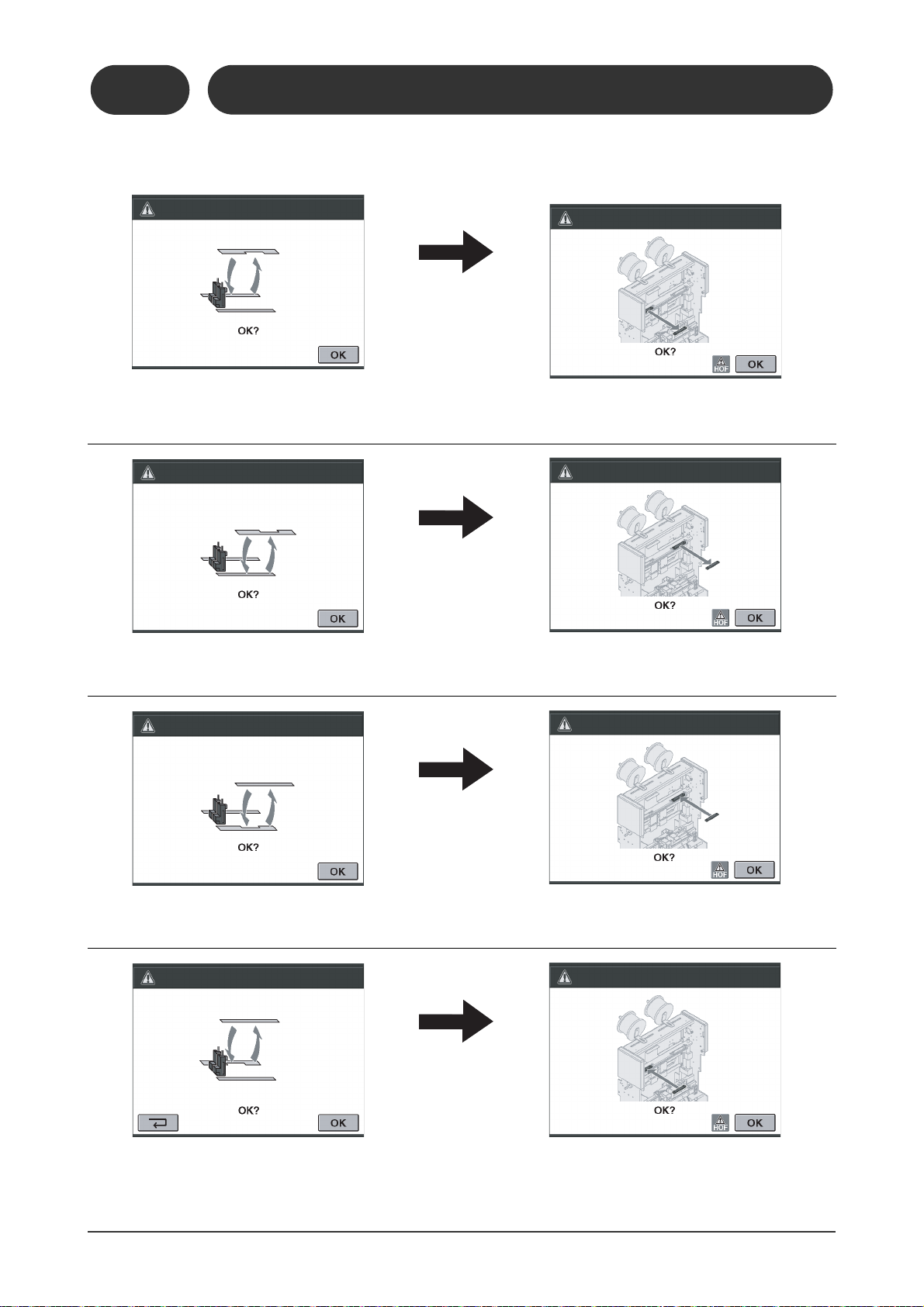

1-3-4 Setting-Instruction Screen

1-3-4

Setting-Instruction Screen

If you press , the following instruction

screens appear:

11119

10304A1

Remove the upper and lower parts for the top and

bottom guides.

The following screens are displayed after the

changeover.

1

Machine Description

Attach the upper and lower parts for the top and

bottom guides.

Screen Descriptions /

Remove the guide bars.

Replace the large saddle stitch stopper with the

small one.

11119

10304F1

Replace the small saddle stitch stopper with the

large one.

15

Page 24

1-3 Screen Descriptions

11119

10304J1

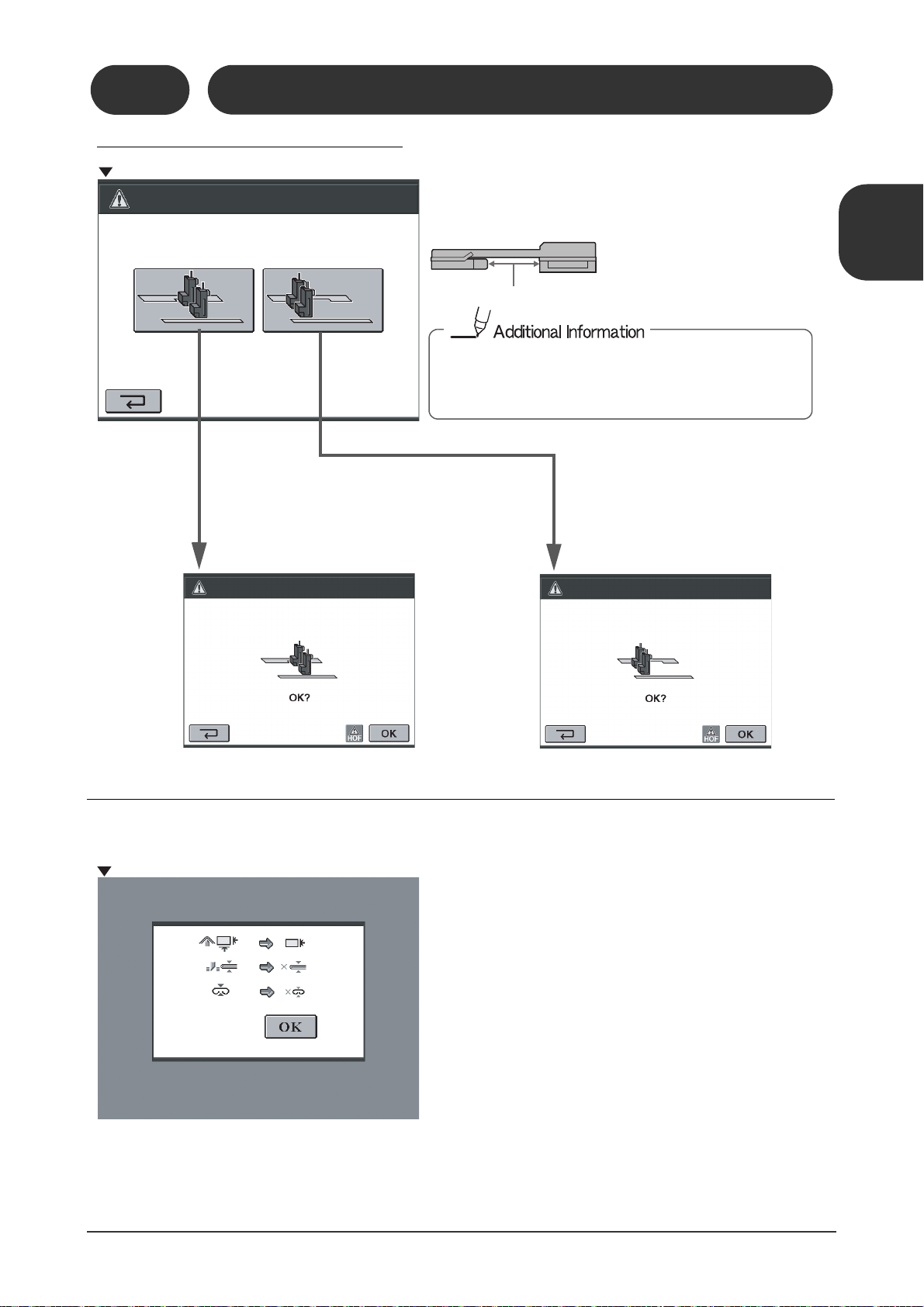

1-3-4

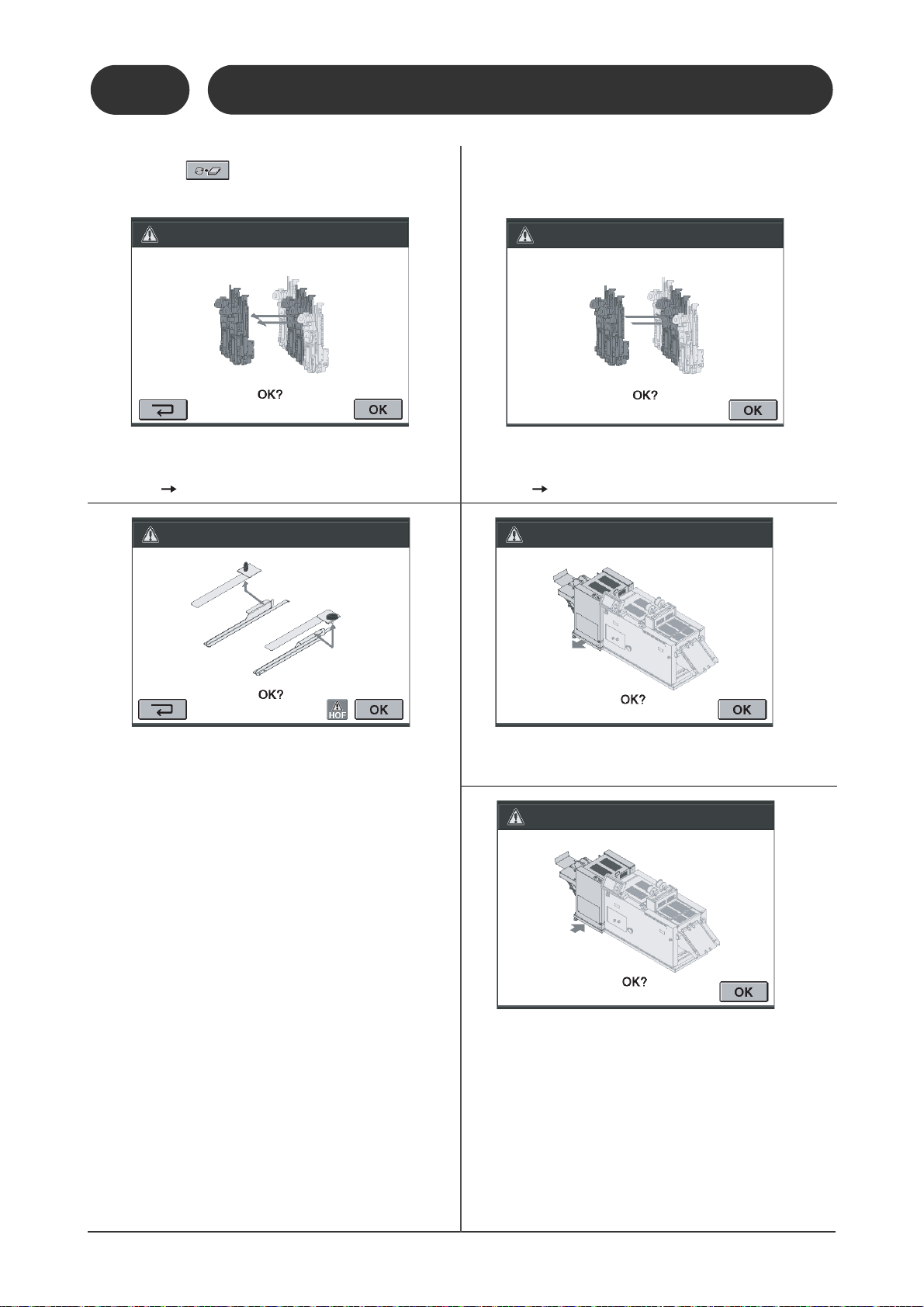

Setting-Instruction Screen

If you press , the following instruction

screens appear:

11119

10304D1

Remove two stitcher head assemblies, including

the mounting block and the clincher inside.

(Four stitch Two stitch)

The following screens below are displayed after

the changeover.

11119

10304G1

Attach two stitcher head assemblies, including the

mounting block and the clincher inside.

(Two stitch Four stitch)

Remove the sheet hold-down plates in the fold

section.

11119

10304H1

Move the fore-edge trim section to the front (for

small sheets).

11119

10304I1

Move the fore-edge trim section back (for normal

or large sheets).

16

Page 25

1-3 Screen Descriptions

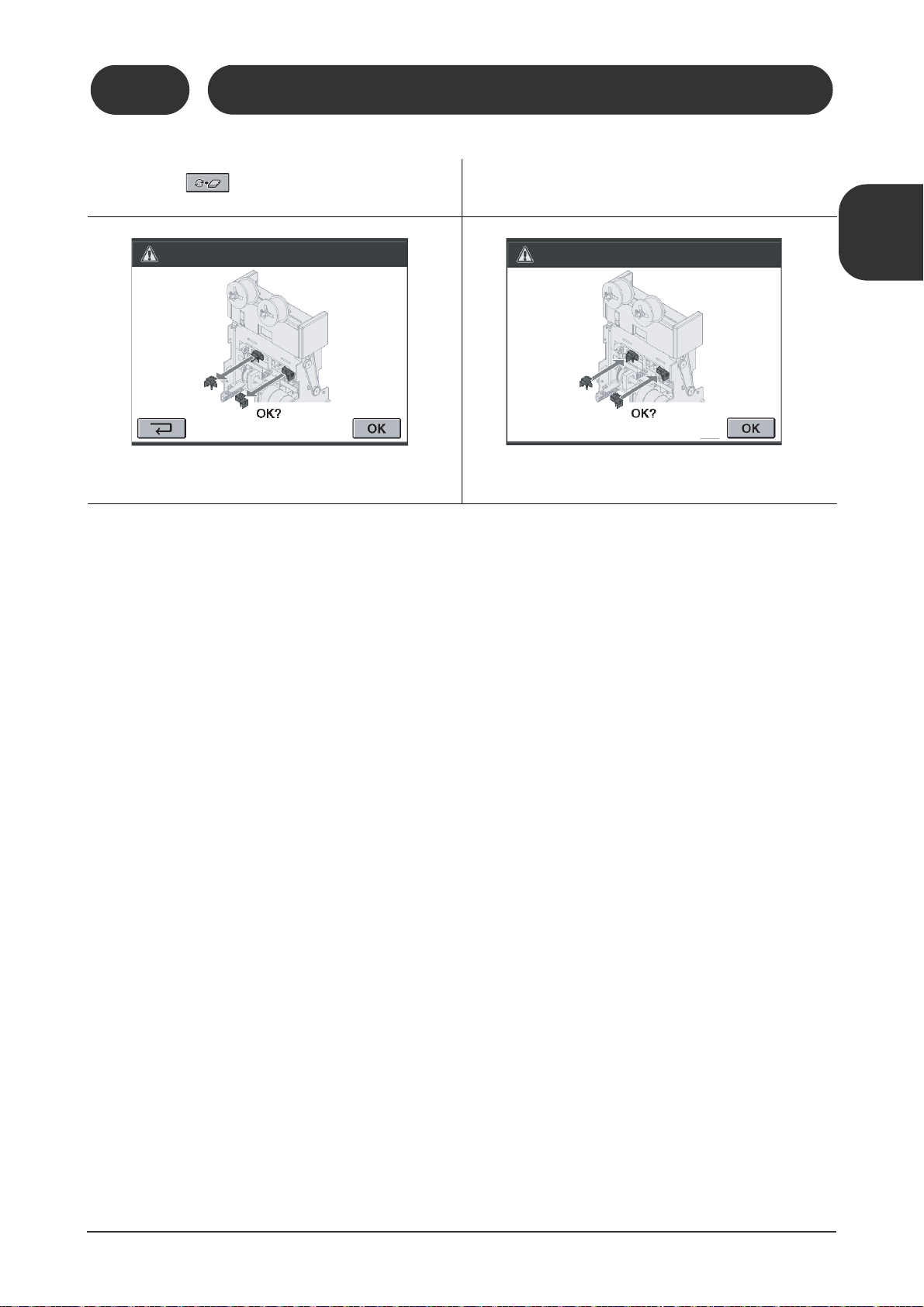

1-3-4

Setting-Instruction Screen

If you press , the following instruction

screens appear:

11119

10304K1

The following screens below are displayed after

the changeover.

Remove the stitch detection sensor. Install the stitch detection sensor.

11119

10304L1

1

Machine Description

Screen Descriptions /

17

Page 26

11119

10305F1

11119

10305L1

11119

10305M1

1-3-4

1-3 Screen Descriptions

Setting-Instruction Screen

If corner stitching has just been selected, or if you are stopping corner stitching and using another

binding pattern, the following instruction screens are displayed. (Corner stitching is an option.)

11119

10305G1

Replace the rear top and bottom guides

with the corner stitch guides.

11119

10305H1

Replace the front top and bottom guide with

the corner stitch guides.

Remove the front stitcher head drive block.

11119

10305I1

Remove the rear stitcher head drive block.

11119

10305J1

Replace the front corner stitch guide with

the top and bottom guides.

Replace the rear corner stitch guide to the

top and bottom guide.

18

11119

10305K1

Attach the rear stitcher head drive block.

Attach the front stitcher head drive block.

Page 27

1-3 Screen Descriptions

11119

10305N1

21102

10305Q1

Stitcher Head Position Confirmation Screen

If the stitch heads are positioned in

the hollow area of the corner stitch

guide:

Setting Confirmation Screen

Automatically deactivated functions due to the selected sheet

size are displayed here.

Hollow Area Under Corner Stitch Guide

If the stitch heads are positioned

outside the hollow area of the corner stitch guide:

This screen confirms the stitcher head position. Check the position of

the stitcher head in relation to the corner stitch guide.

If the stitcher head is positioned in the hollow area of the

corner stitch guide, the stitcher head can interfere with the

guide during changeover. This screen appears to prevent

the stitcher head from hitting with corner stitch guide.

1-3-5 Setting-Confirmation Screen

1-3-5

Setting-Confirmation Screen

11119

10305R1

1

Machine Description

Screen Descriptions /

11119

10305O1

11119

10305P1

19

Page 28

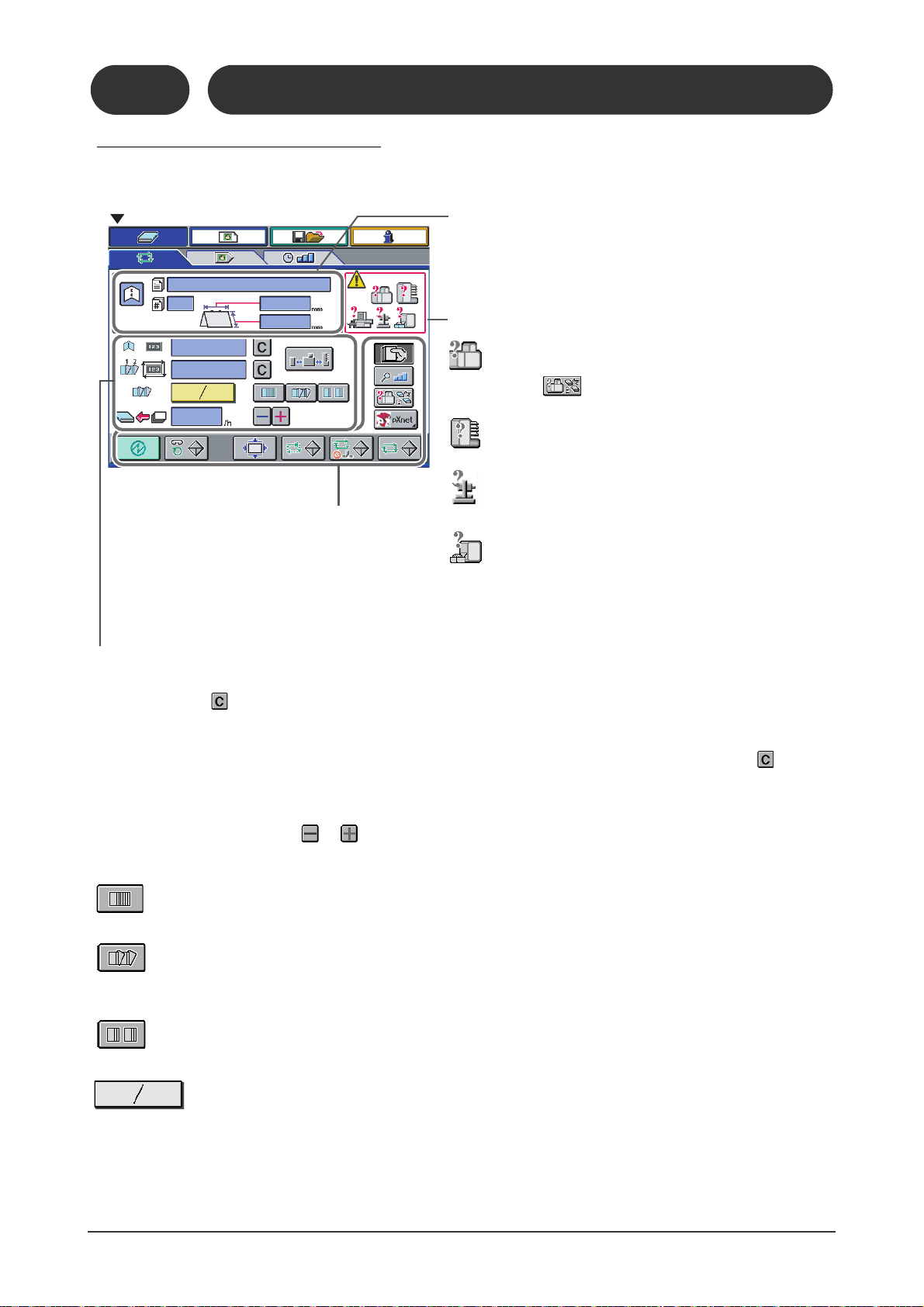

1-3 Screen Descriptions

Operation Screen

Job Information

The job name and the job number are displayed after the job

is saved.

Upstream/Downstream Device Information

= The SPF-200A/200L or FC-200A/200L has a problem.

Press to learn about the problem.

= The collator has a problem.

= A downstream device has a problem.

= Trim Full

If the binding operation continues for one more minute,

feeding stops.

Total Count

- The total binding count is displayed here. The total count does not clear even when the power is turned Off. To clear the

total count, press .

Batch Count

- When delivered booklets are offset, the number of batch is displayed here. To clear the batch count, press .

Production Speed (book per hour.)

- Maximum production speed differs depending on the binding type, sheet size, and the status settings. When the production speed is changed using the or , the feeding speed from the upstream device will adjust automatically.

Delivery Conveyor Offset settings

= The booklets are delivered straight without offsetting.

= The last booklet is offset when the count reaches a preset number.

(This icon is available only if the optional PK-30 Kicker is connected.)

= The booklets are offset by changing the speed of the delivery conveyor.

=The current number of booklets / The preset number of booklets per batch (Available range: 1 to 99)

See Next Page

1-3-6 Binding-Operation Screen

1-3-6

Binding-Operation Screen

21102

10306A1

20

Page 29

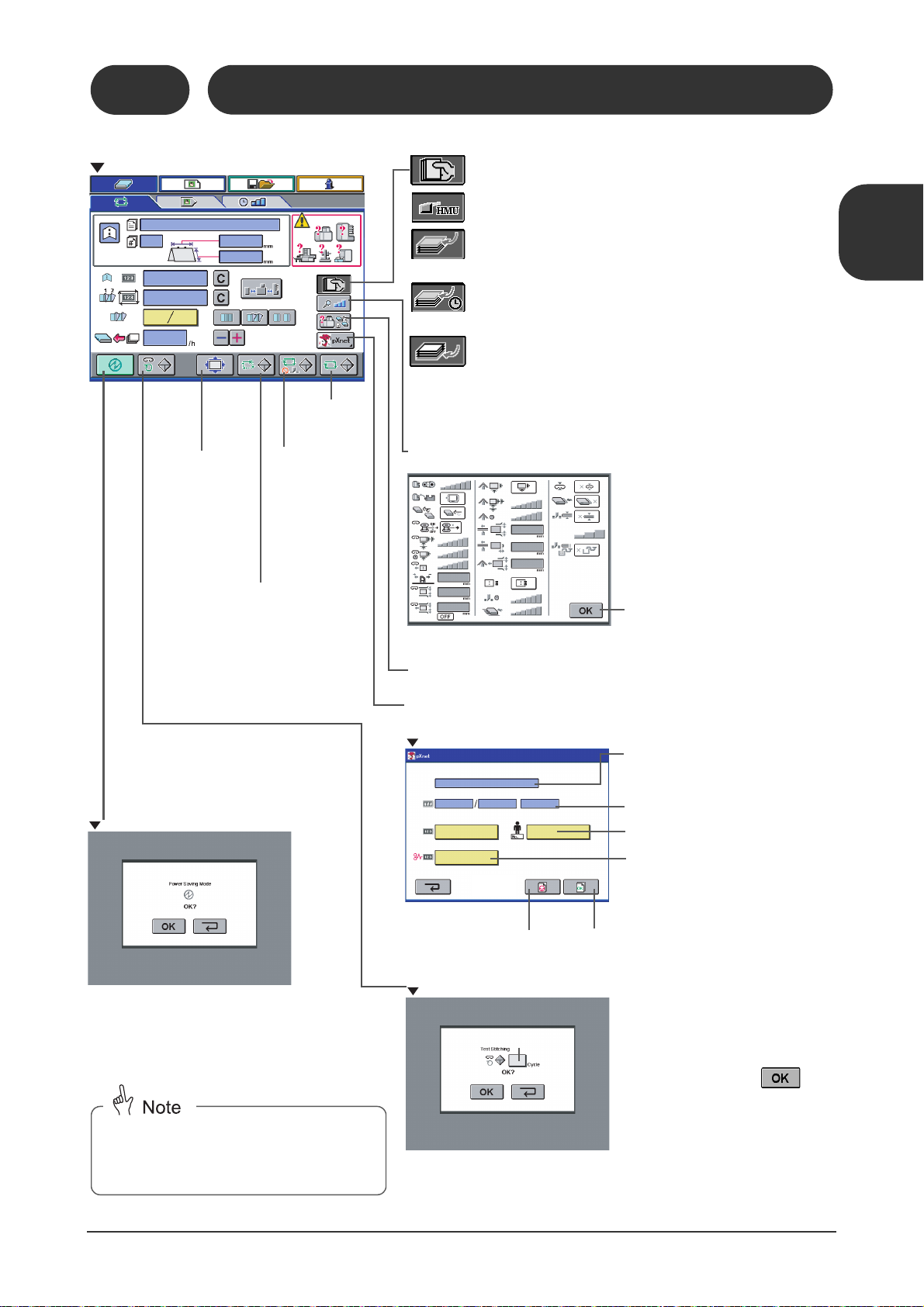

1-3 Screen Descriptions

21102

10305D1

Operation Screen

= Only manual feeding

= Using the HMU (Hand Marry Unit on the collator)

= Feeding starts from the collator after sheets are loaded

into the manual feed section.

= Feeding the sheets manually to match the feed

from the collator.

= When feeding the sheet manually under the sheets fed

from the collator.

This button is available only if the SPF-200A/200L

is operated using the pXnet system.

Jog Button

Press once to jog

the sheets using

the guides. Press

again to deactivate

jogging.

This mode is used to reduce power consumption when the machine will not be

operated for a long time.

This button is used to do the

test binding step by step.

When this button is pressed,

the Binding-Fine Adjust screen

is displayed and one sheet is

transported to the jog section.

Status Indication Screen

After you press the button for the

setting to be changed, the BindingStatus Setting screen is displayed.

Return to the Operation screen.

pXnet Screen

The total binding count and the numbers of the remaining sets at starting

or restarting are displayed.

Enter the number if you are changing

the operator.

Press this button to pause the

current job and start another job.

Press this button when the job is

complete.

Place a sheet which is the same size

as the current setting under the

stitcher head, and press

.

The sheet will be stitched the preset

number of times.

Available Range:3 to 30

Power Saving Mode

Confirmation Screen

The touch panel turns off and the machine enters

the power saving mode. When you touch the

screen, the Setting screen is displayed, and the

machine returns from the power saving mode. Do

a changeover.

When the machine returns from the power

saving mode, changeover is required. Save

the job before entering the power saving

mode.

Error screen is displayed.

One booklet

is produced

as a test.

Stitching Test Screen

One booklet is

produced without trimming as

a test.

Enter the number of faulty sets.

The job name is displayed.

21102

10305A1

Binding-Operation Screen

21102

10305B1

1-3-6

1

Machine Description

Screen Descriptions /

21102

10305C1

21102

10305E1

21

Page 30

1-3 Screen Descriptions

11119

10307E1

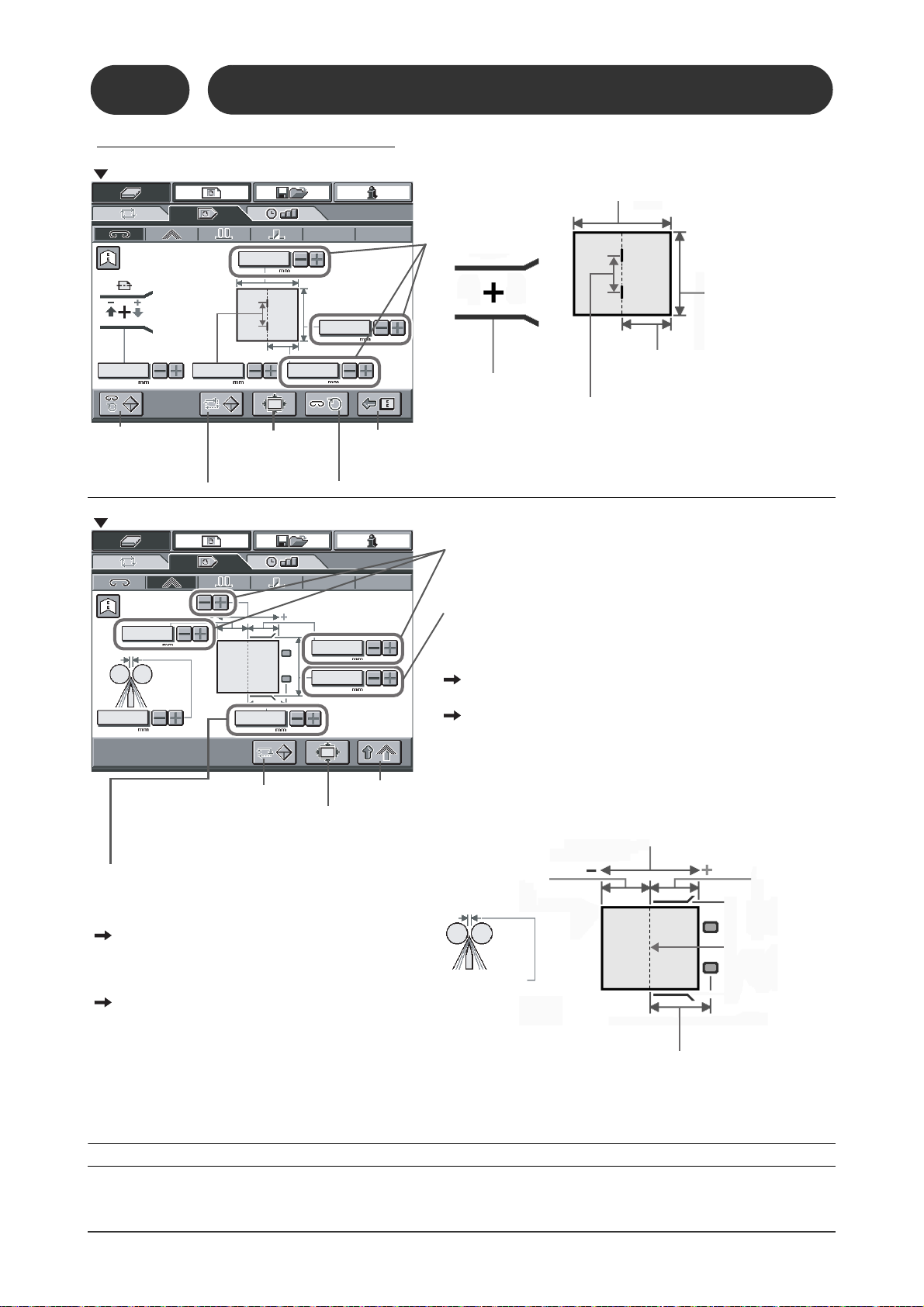

Fine Adjust-Stitch Section Screen

The sheets are

stitched the set

number of times.

The sheets are fed to the jog section.

Press once to jog the

sheets.

The sheets are transported

to the fold section.

These areas can be

changed when sheets

are being jogged.

Body fore/back position:

(-10.0 to +10.0mm)

(-0.400 to 0.400")

Press to stitch once.

Distance between jog plate and the stopper:

(-10.0 to +10.0mm)(-0.400 to 0.400")

Top and bottom guide

width:

(-10.0 to +10.0mm)

(-0.400” to 0.400")

Stitch position:

(-10.0 to +10.0mm)(-0.400 to 0.400"

Stitch distance:

(-10.0 to +10.0mm)(-0.400 to 0.400")

Distance between fold

knife and the stopper:

(-10.0 to +10.0mm)

(-0.400 to 0.400")

The parts move together so

that the distance between the

stopper and the jog pusher

does not change.

Distance

between fold

roller and the

jog pusher:

(-10.0 to

+10.0mm)

(-0.400 to

0.400")

Distance between fold knife and the forward

roller: (-10.0 to +10.0mm)(-0.400 to 0.400")

Maximum Fine Adjust Value =

4.0mm (0.15")-(booklet thickness)

Booklet Thickness

Fold Position

(Knife)

Fine Adjust-Fold Section Screen

These areas can be

changed when sheets

are being jogged.

The sheets are fed to

the fold section.

Press once to jog

the sheets.

Transport the sheets to

the next process.

The Fine Adjust- Punch Section Screen is described in the user's manual of the HP-200A hole punch unit.

The status setting of "fold section jog direction" has influence on

this area.

If the sheets are jogged by the jog pusher and the top and bottom

guides:

This area can be changed only when sheets are being jogged.

If the sheets are jogged only by the jog pusher:

This area always cannot be changed.

The status setting of "forward roller movement" has

influence on this area.

If the sheets are jogged while being pushed by the

forward rollers:

This area can be changed whether the sheets

are being jogged or not.

If the forward rollers move away from the sheets

when the sheets are being jogged:

This area can be changed only when the sheets

are not being jogged.

1-3-7 Binding-Fine Adjust Screen

21102

10307A1

11119

10307D1

1-3-7

Binding-Fine Adjust Screen

22

21102

10307B1

11119

10307F1

11119

10307G1

Page 31

1-3 Screen Descriptions

21102

10307C1

11119

10307I1

Transport Belt Height

Maximum fine adjust value: 7.0mm (0.275")(booklet thickness)

Finishing fore-edge dimension: (-10.0 to +10.0)

(-0.400” to 0.400”)

The default setting for the trim width is 3mm

(0.125").

Feed the sheets to the

fore-edge trim section.

Lower the

transport belts.

Trim once.

Press this button to

deliver the sheets.

Fine Adjust-Fore-edge Trim Section Screen

This area can be

changed when the

transport belts are

raised.

1-3-7

Binding-Fine Adjust Screen

11119

10307H1

1

Machine Description

Screen Descriptions /

23

Page 32

1-3 Screen Descriptions

This button is used to match (decrease)

the speed of the trim section with the

stitch section and prevent a booklet from

being pulled while delivery when using

single sheet or performing the job with

folding only.

21102

10308A1

Collator/Faulty Set Detect/Manual

Feed/Stitch Screen

- Normally use .

- If there is just a small amount of wire left, the sensor may keep deactivating

even though the wire is being fed correctly. If this happens, select .

1-3-8 Binding-Status Setting Screen

Items marked like this are default settings.

Transport Speed

This indicates the operating speed of the belt or roller. It

can be adjusted in six steps.

VAC Support Guide

(Used for sheets with a width smaller than 148 mm (5.83”).)

= Guide is not used.

= Guide is used. This can be selected when sheet

width is 230 mm (9.05”) or smaller.

Faulty Set Ejection

= Faulty Set Ejection Off

1-3-8

Binding-Status Setting Screen

= Faulty Set Ejection On (When an error

occurs in the upstream device, booklets are

delivered to the mis-feed tray without trim.)

Wire Feeding Detection

This function is used to watch that the wire is fed correctly.

= Off

= An error is detected if the sensor is activated for a set time.

= An error is detected if the sensor is active or not active for

longer than the specified time.

Manual Feed Setting

= No manual feeding

= Only manual feeding

= Using the HMU (Hand Marry Unit on the collator). This function cannot be selected from the screen.It must

be selected by using the switch on the HMU.

= Feeding starts from the collator after sheets are loaded in the manual feed section. (Production speed:

Slow)

= Use when feeding the sheet manually to match the feeding from the collator. (Production speed: Fast)

= Use when feeding the sheet manually under the sheets fed from the collator.

24

Page 33

1-3 Screen Descriptions

21102

10308H1

Collator/Faulty Set Detect/Manual

Feed/Stitch Screen

Items marked like this are default settings.

1-3-8

Binding-Status Setting Screen

Stitch Section Jogging Frequency

This indicates the number of jogs done before

stitching. Press if the sheets are not squared up.

(This will slow down the production speed.)

Stitch Delay Time

This indicates the delay from the moment the

sheets are transported from the jog section until the

sheets are stitched.

1

Transport Pusher Speed

Slow the speed of the transport pusher if the booklets

bend between the jog section and the fold section.

Transport Pusher Waiting Position

- The adjustable range is from -50 to +40mm (-1.97"

to +1.58".)

- If the transport pusher for paper inserter does not

catch the sheet, adjust the waiting position using

.

Stitch Section Top and Bottom Guide

Stroke

- This sets the opening between the top and bottom

guides when the sheets enter.

- The default setting is 3.0 mm (0.120").

- This is adjustable within 1.0 to 6.0 mm (0.050" to

0.200").

Machine Description

Screen Descriptions /

Stitch Section Top and Bottom Guide Delivery Stroke

- This indicates the opening between the top and bottom guides while the sheets are being delivered from the jog section.

- The default setting is 0.5 mm (0.025").

- This is adjustable within 0.5 to 2.0 mm (0.025" to 0.080").

=The guides open for the guide delivery stroke when the sheets are delivered. This ensures stable delivery

although the highest production speed is not available.

=The guides open for the normal guide stroke when the sheets are delivered.The delivered sheets may not

move correctly.

25

Page 34

1-3 Screen Descriptions

Fold/Fore-edge Trim/Conveyor

Screen

Fold Section Top and Bottom Guide

Delivery Stroke

- This indicates the opening between the top and

bottom guides while the sheets are being delivered.

- The default setting is 1 mm (0.040").

- This is adjustable within 0.5 to 3.0mm (0.025" to

0.100").

Fold/Fore-edge Trim/Conveyor Screen

Items marked this way are default settings.

Fold Section Jog Direction

= The

sheets are jogged

top and bottom guides.

= The

sheets are jogged only by the jog pusher.

Using the default setting, the sheets are jogged only by the jog

pusher. If you are doing folding only, or using the paper insertion

function, you must jog using the top and bottom guides.

Fold Section Jogging Frequency

If you are only doing folding and the sheets are

not arranged correctly, press .

Fold Delay Time

delay from the moment the sheets are transported to the fold

section until the sheets are jogged and folded.

by the jog pusher and the

1-3-8

Binding-Status Setting Screen

Fold Section Top and Bottom Guide Stroke

- This indicates the opening between the top and bottom guides while

the sheets are being fed.

- The default setting is 3.0mm (0.120").

- This is adjustable within 1.0 to 6.0mm (0.050" to 0.200").

When Stitch Section Top and Bottom Guide Delivery Stroke is On

If you set this value smaller than the stitch section top and bottom guide

delivery stroke, its value is also reduced.

When Stitch Section Top and Bottom Guide Delivery Stroke is Off

If you set this value smaller than the stitch section top and bottom guide

stroke, its value is also reduced.

Fold Section Jog Pusher Stroke

- This indicates the opening width of the jog pusher while

the sheets are being fed.

- The default setting is 5.0 mm (0.260").

- This is adjustable within 2.0 to 10.0mm (0.075" to 0.400").

21102

10308C1

Forward Roller Movement

The movement of the forward rollers while the sheets are

being jogged can be selected.

= The sheets are jogged while being pushed

by the forward rollers.

= The forward rollers move away from the sheets

when the sheets are being jogged. When using

thin sheets, they may be bent by the forward

roller and the jog error may not be detected correctly. If this happens, use this button.

Delivery Conveyor Run Distance for Offset Function

- When you use the offset function, this indicates how long

the conveyor runs between the last booklet in one batch

and the first one in the next batch.

- If the first booklet in the one batch slips inside the last one in

the previous batch, press to increase the run distance.

26

21102

10308G1

11119

10308F1

Fore-edge Trim Delay Time

- This indicates the delay from the moment the sheets reach

the fore edge trim stopper until the sheets are trimmed.

- Press to increase the pause time.

Delivery Conveyor Run Distance

- This indicates how long the conveyor runs after a booklet

is delivered.

- Press to increase the run time.

Page 35

1-3 Screen Descriptions

21102

10308D1

Option Screen

Option Screen

Return to the initial setting.

Items marked this way are default settings.

Stitch Detection

This function detects if the stitching has been done correctly.

It can be selected only if the optional SDS-200 is connected.

1-3-8

Binding-Status Setting Screen

Paper Insertion

This selects whether the paper insertion function is used. It

can be selected only if the optional PN-200 Paper Inserter

is installed.

= Off

= On

= Function not used

= Function used

1

Machine Description

Screen Descriptions /

21102

10308i1

21102

10308E1

FC Booklet Thickness Detection

Faulty set is detected by measuring the booklet thickness

in the fore-edge trim section. These buttons are active only

if the optional TD-200 is connected.

= Off

= On

Sensitivity Low High

Chip Extractor

This sets whether the optional TB-200 Chip Extractor is

used. These buttons are active only if the TB-200 is connected.

= Not Used

= Used

27

Page 36

1-3 Screen Descriptions

Job No. Input

Enter the number of the job to be

displayed using the numeric keypad screen which appears when

this is pressed. (Job no.01 to

200)

Save Confirmation Screen

Keyboard Screen

Save

This saves the current machine

settings under the selected job number.

= This uses the stan-

dard typewriter

keyboard layout.

= The keys are laid

out in alphabetical

order.

Display Window Up to 19 letters can

be entered.

= The job is saved and the Memory-

Main screen is displayed.

= The Memory-Main screen is displayed

without saving the settings.

Detailed Information Screen

Delete Confirmation Screen

Load Confirmation Screen

1-3-9 Memory Screen

21102

10309A1

1-3-9

Memory Screen

The detailed information for the selected job is displayed.

21102

10309B1

Scroll Buttons

= Screen Scrolling (5 previous jobs)

= Scrolling (up)

= Scrolling (down)

BOOK

1

Book

21102

10309C1

=

Screen Scrolling (5 following jobs)

Delete

The selected job is deleted.

(* Once deleted, the job cannot be recalled.)

21102

10309F1

= The job is deleted and the Memory-

Main screen is displayed.

= The Memory-Main screen is displayed

without deleting the job.

Load

The selected job is loaded.

28

21102

10309D1

21102

10309E1

= The Setting-Finishing Size screen is

displayed. Do the changeover.

= The Memory-Main screen is displayed

without loading the job.

Page 37

1-3 Screen Descriptions

21102

10310A1

Information-Main Screen

Password Input Screen

Administrator Mode Screen

A Password is required to display this screen.

Enter the password

and then press

.

See [1-3-12]

This button is used by

the service person

only.

See next page.

This is the total binding count

since the machine was shipped.

This counter can be cleared

in the Administrator Mode.

Use the counter as a guide

for trim knife replacement.

This is the total trim count since

the machine was shipped.

21102

10310D1

System Error Code

The last eight errors are shown on the

page, and a total of 24 errors are

recorded.

This shows the system configuration and any optional

devices which are installed with the SPF-200A/200L.

These settings can be changed in the Administrator Mode.

1-3-10 Information-Main Screen

1-3-10

Information-Main Screen

11119

10310F1

1

Machine Description

= Counter

= Error History = System Configuration /Option

21102

10310B1

= Software Version/Serial Number

21102

10310C1

Screen Descriptions /

21102

10310E1

29

Page 38

1-3 Screen Descriptions

Each section of the machine

can be operated separately

using these screens.

2110110311H1

Stepper Motor Lock Release

If the is displayed you can

move each guide and stopper by hand.

The input condition of each sensor signal can be monitored using

these screens.

= Sensor is inactive (Off).

= Sensor is active (on).

2110210311E1

2110210311D1

Stepper Motor Lock Release

If the is displayed you can move each guide and stopper

by hand.

Information-Monitor/Single Operation Screen

1-3-11 Information-Monitor/Single Operation Screen

= Single Operation

21102

10311A1

1-3-11

= Monitor

2110210311F1

2110210311G1

30

2110210311B1

2110210311C1

Page 39

1-3 Screen Descriptions

21102

10312A1

21102

10312D1

21102

10312E1

21102

10312F1

Administrator Mode Screen

= Page 32

= Page 32

= Next page

= Next page

Power Saving Mode

When is selected, enter

the time until the machine goes

over to a power saving mode.

(The possible delay range is 1

to 120 min.) If the machine is

not operated within the delay

period, it automatically switches

to the power saving mode.

Press to clear the counter.

Administrator-Password Screen

Press after the password is entered.

Trim Count

The same trim count as on the Information-Counter screen is displayed here.

Information-Counter

Screen

Wire Feeding

Detection

= An error is triggered

if the sensor has

been activated even

though the stitching

has been done for the

correct number of

times.

= An error is triggered if

the sensor is not activated even though

the stitching has been

done for the correct

number of times.

ON

OFF

The top and bottom guides open and release.

The guides return to the set positions.

Stitch Section Top and Bottom

Guide Adjustment

This screen is used to ensure that the top

and bottom guides are parallel.

1-3-12 Information-Administrator Screen

1-3-12

Information-Administrator Screen

11119

10312B1

21102

10312C1

1

Machine Description

Screen Descriptions /

31

Page 40

1-3 Screen Descriptions

21102

10312G1

21102

10312I1

Enter the correction or offset value here. To

increase the correction, use a larger number

The values entered on the current fine

adjustment screen are displayed here.

This corrects the home position value so

that the fine adjustment value becomes

zero.

This corrects the home position values so

that the all fine adjustment values

become zero.

= Home Position Calibration

= Input Signal ON/Off

If one of the motors or sensors stops working, the binding operation can

be continued by turning off the broken motor or sensor.

If you want to turn off one of these motors, contact a service technician

for detailed instructions.

= The selected motor or

sensor is included in

the control circuit.

= The selected motor or