WINDTUNNEL TM

UPRIGHT

The WindTunnel TM series of uprights was first introduced

in mid 1997. Four deep wine colored models comprised

the line and all were similar in overall appearance like the

one in Figure 1.

Features included on the various models:

• 13" and 15" nozzles

• Embedded dirt finder (two models)

• Cords 31' and 35'

• Bag check indicator (three models)

• Agitator, replaceable roll sleeve type

• Headlight, one 12 volt 27313101

• Flat belt 38528033

• Hard bag enclosure

• One speed motor

• Stair cleaning handle

• Four position height adjustment

• Tool storage on the cleaner

Micro-filtration throw away bags Type "Y"

• Bag check indicator (three models)

• 4, 5 or 6 stage filtration

• Edge cleaning "Edgers"

• Rotating top cord hook

• 10' and 12' hose reach

7/97

Fig, 1

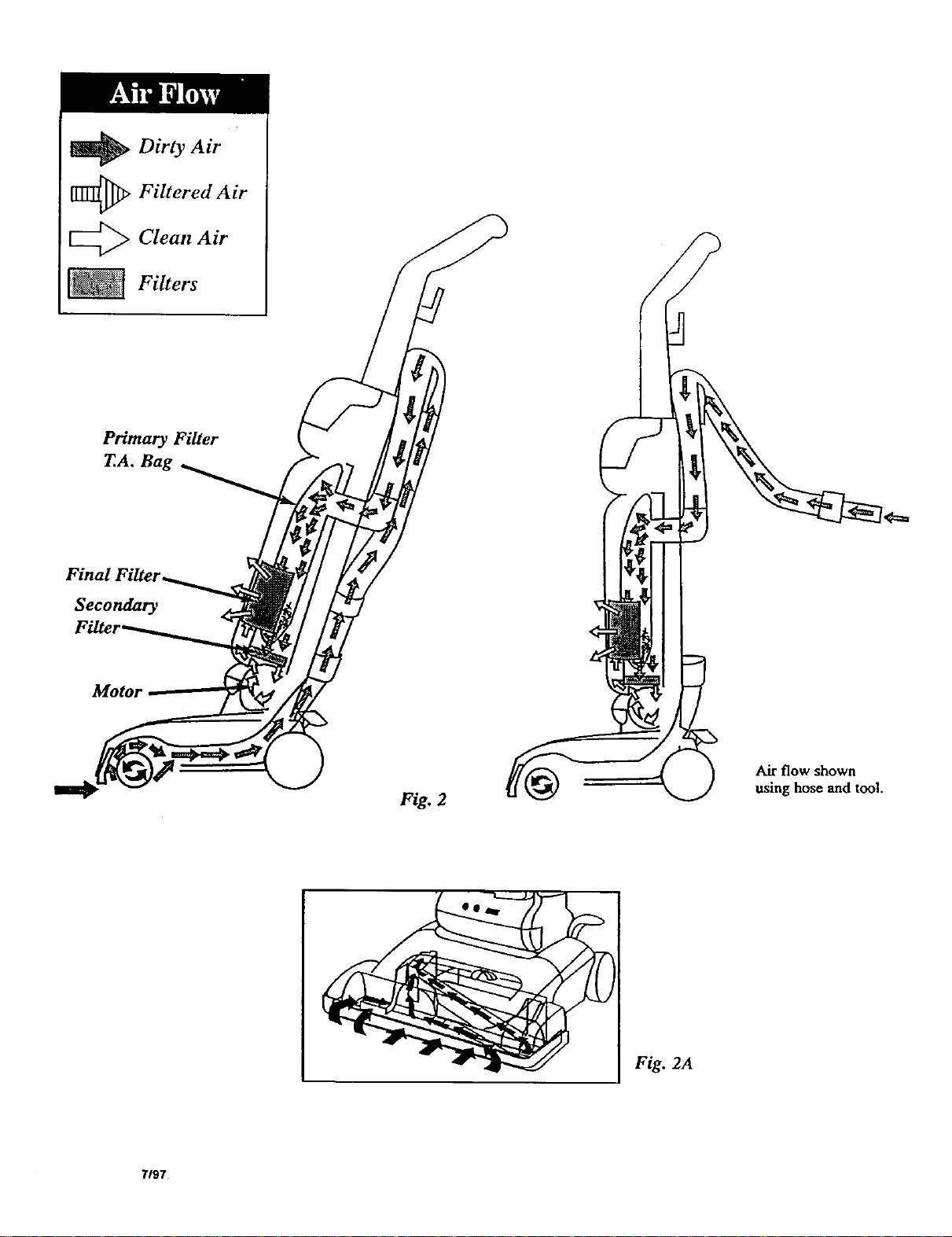

These cleaners operate on a clean air principle, i.e., where

the dirty air enters the bag or dirt receptacle before it goes

past the motor area. Since the same air is used to cool the

motor, it is extremely important that it be filtered ade-

quately to prevent dirt and dust from getting into the motor

and/or back into the room.

Basic operation of the clean air system in these units is

illustrated in Figure 2 on page 2.

Air fl0w in the WindTunnel is shown in Figure 2A on

page 2.

_ Dirty Air

ffff_ Filtered Air

Clean Air

Filters

Primary Filter

T.A. Bag

Secondary

Motor

Air flow shown

using hose and tool.

Fig. 2

Fig. 2A

7/97

II o

Fig. 3

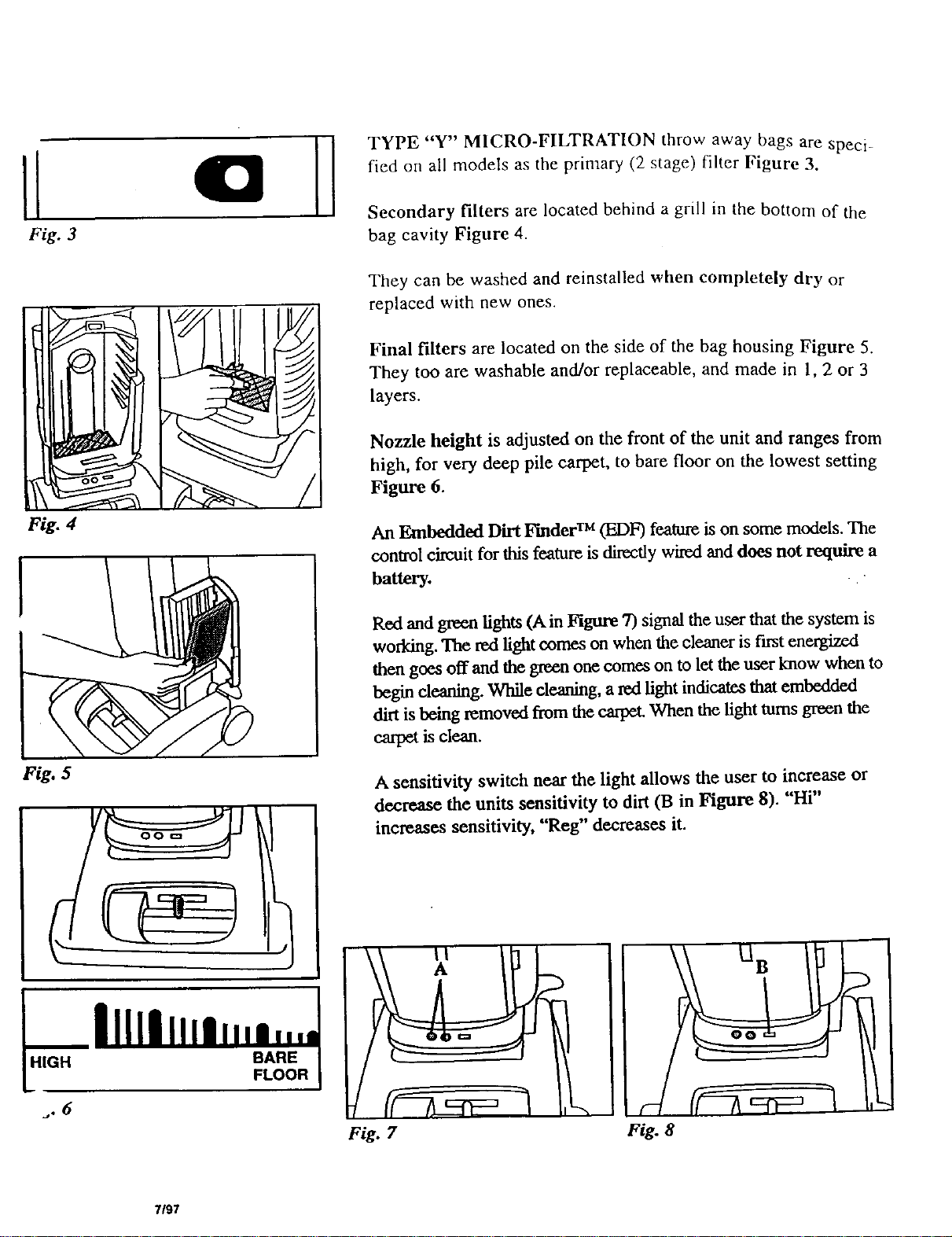

TYPE "Y" MICRO-FILTRATION throw away bags are Speci-

fied on all models as the primary (2 stage) filter Figure 3.

II

Secondary filters are located behind a grill in the bottom of the

bag cavity Figure 4.

They can be washed and reinstalled when completely dry or

replaced with new ones.

Final filters are located on the side of the bag housing Figure 5.

They too are washable and/or replaceable, and made in 1, 2 or 3

layers.

Nozzle height is adjusted on the front of the unit and ranges from

high, for very deep pile carpet, to bare floor on the lowest setting

Figure 6.

Fig. 4

I

Fig. 5

An Embedded Dirt _nder TM (F_DF) feature is on some models. The

conllOl circuit for this feature is directly wired and does not require a

battery.

Red and green lights (A in Figure 7) signal the user that the system is

working. The red light comes on when the cleaner is first energized

then goes off and the green one comes on to let the user know when to

begin cleaning. While cleaning, a red light indicates that embedded

dirt is being removed from the carpet. When the light turns green the

carpet is clean.

A sensitivity switch near the light allows the user to increase or

decrease the units sensitivity to dirt (B in Figure 8). "Hi"

increases sensitivity, "Reg" decreases it.

L.

j. 6

IIII iitlio,,.,,,.

7197

BARE

FLOOR

Fig. 7

Fig. 8

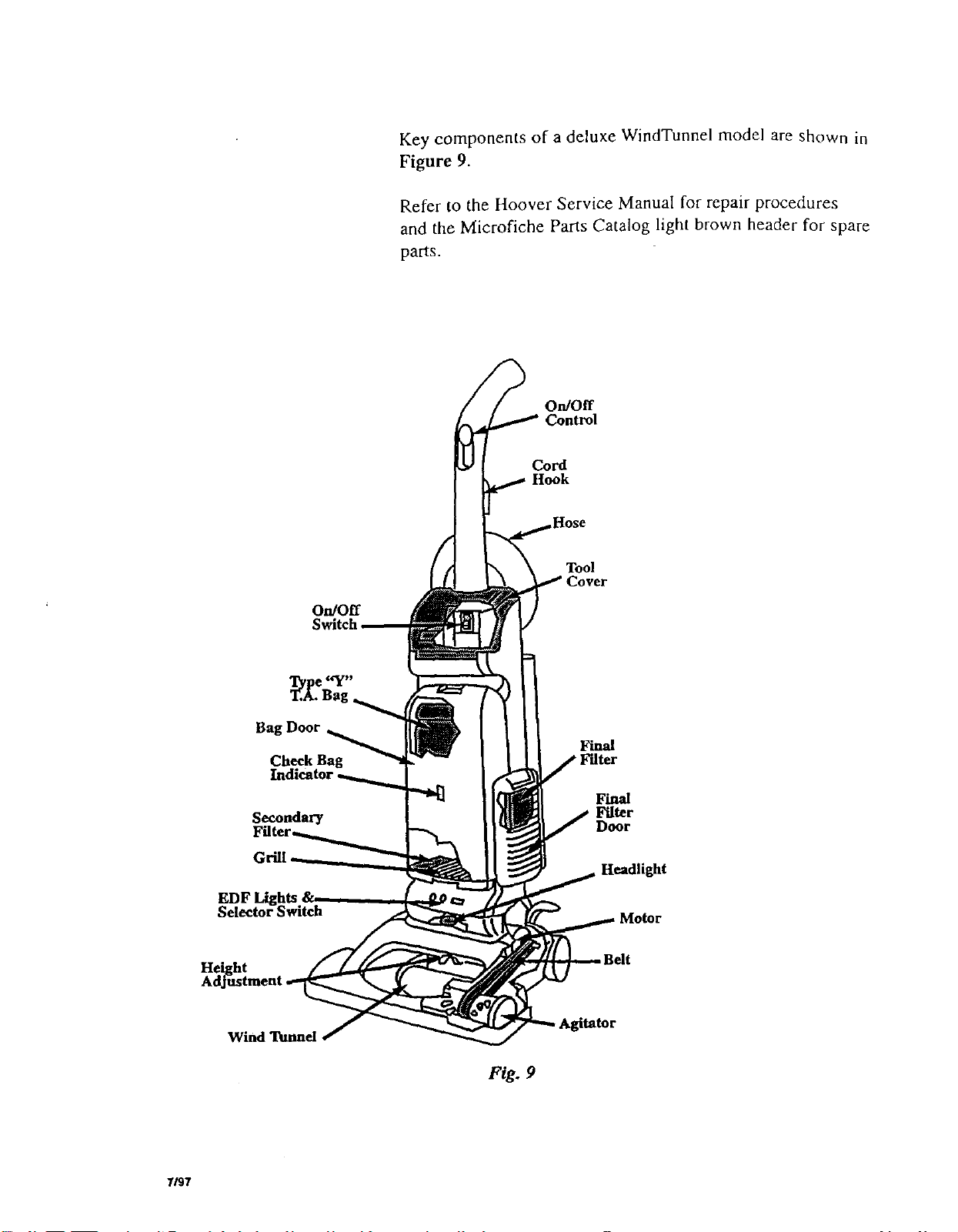

Key components of a deluxe WindTunnel model are shown in

Figure 9.

Refer to the Hoover Service Manual for repair procedures

and the Microfiche Parts Catalog light brown header for spare

parts.

On/Off

Control

Cord

Hook

Tool

Check Bag

Secondary

Wind Tunnel

o_off

Final

Filter

Final

Filter

Door

Headlight

_elt

7197

Fig. 9

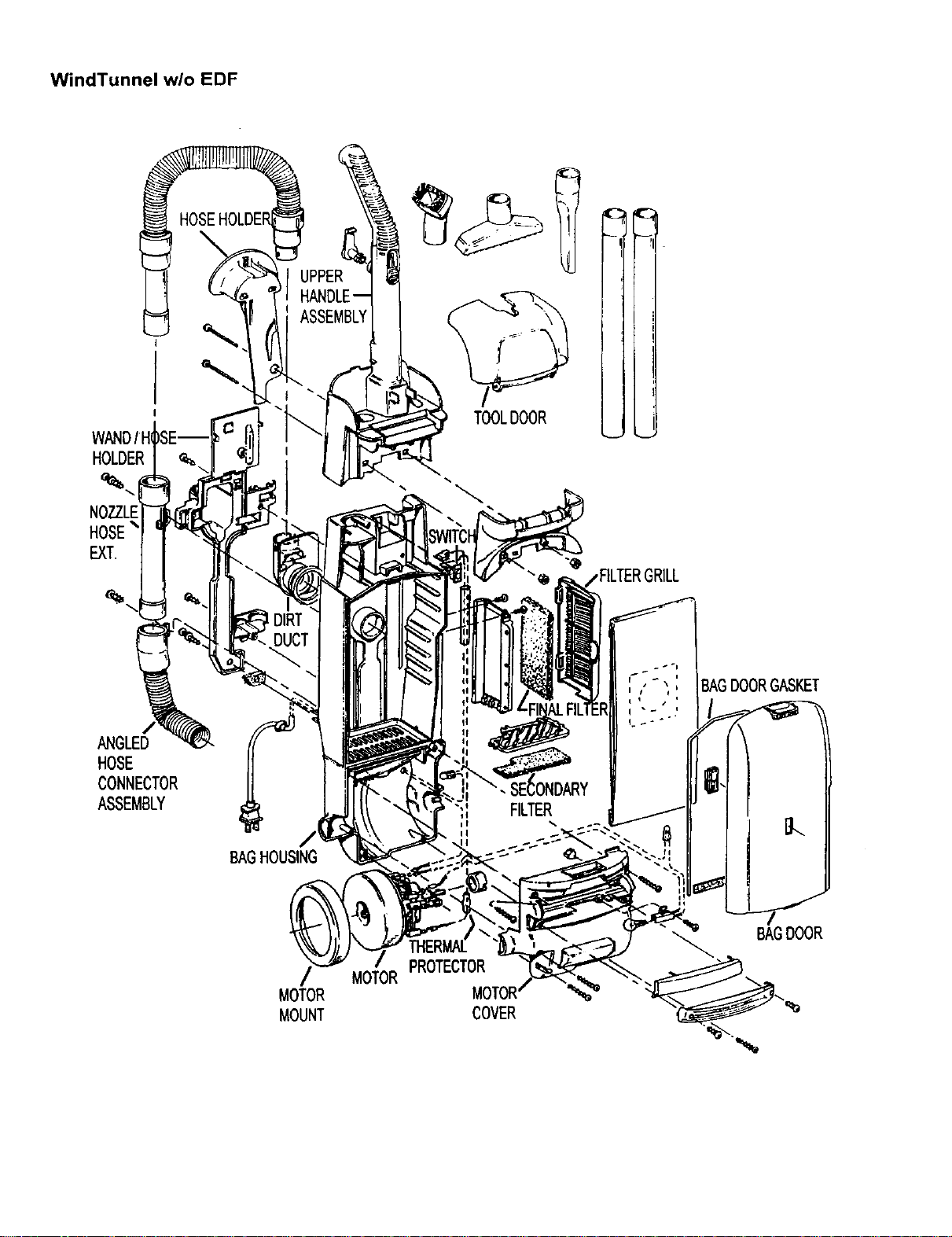

Service Instructions

WindTunnel Uprights

Secvice Su_,'t 7/97

WindTunnel wlo EDF

HOLDER

HOSE_

EXT.

TOOLDOOR

RILL

ANGLED

HOSE

CONNECTOR

ASSEMBLY _ i

BAGHOUSING

/

MOTOR

MOUNT

BAGDOORGASKET

BAGDOOR

MOTOR

COVER

WindTunne| wlEDF

i

Ii

tl

II

If

:i

14. -- --

COMPONENT NAMES ARE THE SAME AS PAGE 149 A-2

EXCEPT THOSE LISTED

=RINTEDCIRCL

)ASSEMBLY

WindTunnel - 13" & 15" Width (Half Hood)

_EA

I t

TRUNNION

SE

I

FRONTWHEELl

SUPPORT_,

t_" DUCTCOVERJ

AE

BODY

ADJ.LEVER

%

PICKER

WindTunnel - 13" & 15" Width (Full Hood)

HOOD--

TRUNNION

COVER_

LEVER

FRONTWHEELI

SUPPORT

DUCTCOVER

BODY

l

LITTER

PICKER

BOTTOMPLATE

I. General

III. Disassembly

The WindTunnel cleaners are upright vacuums

that feature computer designed air vanes to

provide a powerful dual air stream which

dramatically improves dirt pickup capabilities.

These cleaners also come in 13" and 15" widths

and feature on board tool storage and fast easy

above floor cleaning. Some models feature the

Embedded Dirt Finder, Bag Check Indicator,

Edge Cleaning Edgers "Litter Pickers", 10' and

12' hose reach (upper end models include an

extra 20' reach hose).

All models feature type "Y" allergen top fill

disposable bags. Low end units include a 4

stage filtration system and as the line progresses

5 and 6 stage filtration systems are utilized.

II. Basic Operation

These cleaners operate on a clean air principle,

i.e., where the dirty air enters the bag or dirt

receptacle before it goes past the motor area.

Since the same air is used to cool the motor, it is

extremely important that it be filtered adequately

to prevent dirt and dust from getting into the

motor and/or back into the room.

A. Bottom Plate - Agitator - Belt

1. Remove 4 screws and lift off bottom plate

(Fig. 1).

\

Fig. 1

Rubber edge groomers on bottom plate are

replaceable to remove slide off of plate (Fig. 2).

Fig. 2

2. Remove agitator and belt.

To service agitator, consult the agitator section of

the service manual.

B. Duct Cover

1. Slide out of main body (Held into place by

bottom plate screws). (Fig. 3).

Fig. 3

C. Front Wheels and Wheel Support

Pull short leg of spring backward and hook into

track on wheel support.

Wheels and wheel shaft can be replaced by

removing plastic wheel retainers. Note: Once

wheel retainers are removed they should be

replaced.

1. Pry spring leg up and out of track in wheel

support (Fig. 4)

[]

Fig. 4

2. Pivot wheel support up and out of main body.

To reassemble:

D. Hood

Remove 2 screws (Fig. 6) and remove hood.

Fig. 6

E. Height Adjustment Lever

1. Release two lockingtabs and separate cam

and lever (Fig. 7).

Position spring on wheel support with the long

leg inward.

Position spring so that longest leg slides into slot

on main body (Fig. 5).

Fig. 5

Fig. 7

Note the position of cam for proper reassembly

Improper assembly will cause the lever to lock

into position.

F. Main Body

1. Remove two R.H. and two L.H. trunnion

screws - marked "A" (Fig. 9)

, j'.

A A

A

Fig. 9

2. Remove hose clamp - two screws ("B") (Fig.

9)

Lift entire upper assembly up and off of main

body.

Fig. 10

I. Hose

Hose is replaced as an assembly.

1. Twist hose connector to unlock from duct

assembly and remove (Fig. 11).

\

Fig. 11

G. Handle Release Lever

Snap fit into base. Pivot lever inward and work a

screwdriver in behind to release tabs. Slide lever

out of main body.

H. Rear Wheels

Remove "E" clips and slide shaft out of main

body (Fig. 10).

J. Nozzle Hose Extension (Where Applicable)

1. Remove screw.

2. Pivot clockwise and remove.

K. Angled Hose Conn. Assembly.

1. Remove screw (Fig. 12).

i

'1 I

Fig. 12

M. Filter Holder

Deluxe, Plus and Supreme models:

1. Remove two screws which secures holder to

bag housing and lift off.

Standard Models:

1. Trapped into position by motor cover.

N. Wand/Hose Holder

Models with "up front" tool storage.

1. Remove three screws (Fig. 14).

L. Upper Handle

Replaces as an assembly.

1. Remove two bolts and lift off of bag housing.

(Fig. 13).

Fig. 14

1. Release two clips (Fig. 15)

Fig. 13 Fig. 15

2. Lift wand / hose holder out of position. Dirt

Duct is trapped into position by wand / hose

holder. On EDF models it is supplied with the

microphone. Gasket is replaceable.

Note the routing of the wiring to the switch and

microphone (where applicable) (Fig. 16).

P. Headlight Lens

1. Remove two screws and lift off lens (Fig. 17).

Fig. 17

Q. EDF Printed Circuit Board Assembly

(where applicable)

Fig. 16

O. Switch

/IICROP_"3NE

\

\

1. Remove headlight bracket screw.

2. Raise panel and board out of position

3. Unsnap four tabs to separate the board and

cover.

4. Disconnect leads and replace board.

To ease reassembly of the board into the cover

remove the red and green lens, snap board into

position then reassemble both the lens.

Note: The discharge of static electricity to a

circuit board can damage the components.

When removing the circuit board from the

following precautions should be taken.

1. Avoid being statically charged when handling

board.

1. Switch is exposed once upper handle and

wand / hose holder are removed. Disconnect

leads and remove switch.

2. Circuit board should be handled by outside

edge only.

3. DON'T touch the metal traces (circuits) on

bottom of circuit board.

R, Wire Opening Plug

T. Cord

This plug is in the bottom of the EDF cavity. It is

important to keep this plug in position to eliminate

air leakage (Fig. 18)

Fig. 18

S. Motor Cover

1. Remove strain relief.

2. Disconnect leads and replace cord.

U. Motor

1. Remove bottomplate and agitator (Section A)

2. Remove hood (Section C)

3. Remove trunnion covers and hose clamp

screws. (Section F)

4. Remove motor cover. (Section S)

5. Remove motor sound foam. (late models only)

6. Lift motor out of position and disconnect leads.

The motor is replaced as an assembly. Motor

brushes are available.

1. Remove five screws and lift off (Fig. 19)

Fig. 19

V. Motor Brushes

Brushes are supplied as an assembly which

include the brush and brush holder.

To Replace:

1, Pry open tab on brush holder and work out of

holder.

2. Grasp brush holder with needle nose pliers

and pull out of position.

To install:

Position brush holder and slide into position

insuring the terminal connection.

Note: Do not grasp outside of brush holder with

pliers as it could damage the holder and cause

the brush to stick.

III. Troubleshooting check list - WindTunnel

The following is a guide to aid in determining the origin of a problem for which this model could conceivably be brought in

for service

Problem Possible Cause

A. Motor won't 1 Open in attachment cord.

run 2. Open in wiring.

3, Thermal protector open.

4. Switch failed.

5. Switch rod failed.

6. Motor brushes failed.

7. Motor failed.

B. No pickup

at nozzle

1. Agitator belt broken.

2. Agitator brushes worn.

3. Paper bag full.

4. Secondary filter clogged.

5. Gasket on bag door damaged.

6. Gasket at base of bag door damaged,

7. Seal on dirt duct damaged.

8. Hose disconnected at rear of unit.

9. Hole in hose or hose clogged.

10. Hose from nozzle damaged or mispositioned.

11. Seals in agitator cavity or bottomplate worn or

missing,

12. Motor mount mispositioned or damaged.

Possible Solution

1. Replace cord.

2. Check connections at motor and insulated

terminals. Check wiring to switch.

3. Replace TOC (eady models). Unplug unit

and plug it back in and check operation

(late models). Continual tripping of TOC

requires further attention.

4. Replace switch.

5. Replace upper handle assembly.

6. Replace motor brushes.

7. Replace motor assembly.

1. Replace belt.

2. Replace agitator.

3. Replace bag.

4. Clean or replace filter.

5. Replace gasket.

6. Replace gasket,

7. Replace seal.

8. Check to insure hose is locked into dirt duct

and nozzle hose extension or angled hose

connection.

9. Replace hose or clear obstruction,

10. Replace if damaged. Check to insure hose

is properly held in position by hose clamp at

main body,

11. Replace. This condition will not result in

significantsuction loss.

12. Replace or reposition. Positioniscritical.

C. No pickup

using tools

1. Hose damaged or clogged.

2. Hose not locked into dirt duct.

3. Bag full.

4. Secondary filter clogged.

5. Gasket on bag door damaged,

6. Gasket at base of bag door damaged.

7. Seal on dirt duct damaged.

8. Motor mount mispositioned or damaged.

1. Clear obstructionor replace hose.

2. Check connection.

3. Replace bag,

4, Clean or replace filter.

5. Replace gasket.

6. Replace gasket.

7. Replace seal.

8. Replace or reposition. Position iscritical.

Problem

Possible Cause

Possible Solution

D EDF circuitry

not working

Green light

won't come

on

E. Light doesn't

change from

green to red

during normal

operation 1.

F. Red light

stays on. 1.

Won't go to

green

G. Thermal 1.

protector 2.

trips 3.

Note: When the unit is energized there is a slight delay then the green light illuminates If the green

light does not come on check the following:

1. No power to board

1. Check 120 volt leads on the LH side of the

board. Also check connection at wire nut

and motor connector.

2 Circuit board failed.

2. Replace board

Note: The red light may seldom come on during cleaning. This means your cleaner is picking up

primarily fine surface dust and lint which the system may not detect or the carpet is clean. Switch the

unit to Hi sensitivity and re-check. Also check the following:

Microphone out of position.

1. Check to insure the microphone is firmly

pressed into the seat in the dirt duct.

2. Dirt duct opening "caked" with dirt.

3. Microphone leads disconnected from board. (Small

2. Clean and check operation.

3. Check connection.

leads on RH side)

4. Microphone failed.

4. Replace- check the above first.

Note: Run cleaner while holding it off the floor. If green light does not come on check the following:

Circuit board failed. 1. Replace board.

Final filter clogged.

Motor bearing tight- motor dragging.

Thermal Protector defective.

1. Clean or replace filter.

2. Replace motor.

3. Replace TOC and check operation. Check

items 1 and 2 first.

WIRING DIAGRAM

MODELS WITH EDF

"=\

WIRING DIAGRAM

" -"1

f_rE

ATTACHMENT

V_ItE CO_IE_r _

Troubleshooting Guide

WindTunnel Cleaners

The following is a guide to aid in determining the origin of a problem for which this model could conceivably be brought in

for service.

Problem Possible Cause

A. Motor won't 1. Open in attachment cord.

run 2. Open in wiring.

3. Thermal protector open.

4. Switch failed.

5. Switch rod failed.

6. Motor brushes failed.

7. Motor failed.

B No pickup

at nozzle

t. Agitator belt broken.

2. Agitator brushes worn.

3. Paper bag full.

4. Secondary filter clogged.

5. Gasket on bag door damaged.

6. Gasket at base of bag door damaged.

7. Seal on dirt duct damaged.

8. Hose disconnected at rear of unit.

9. Hole in hose or hose clogged.

10. Hose from nozzle damaged or mispositioned.

11. Seals in agitator cavity or bottomplate wom or

missing.

12. Motor mount mispositioned or damaged.

Possible Solution

1 Replece cord.

2. Check connections at motor and insulated

terminals. Check wiring to switch

3. Replace TOC (early models). Unplug unit

and plug it back in and check operation

(late models). Continual tripping of TOC

requires further attention.

4. Replace switch.

5. Replace upper handle assembly.

6. Replace motor brushes,

7, Replace motor assembly,

1. Replace belt.

2. Replace agitator.

3. Replace bag.

4. Clean or replace filter.

5. Replace gasket,

6. Replace gasket.

7. Replace seal.

8. Check to insure hose is locked into dirt duct

and nozzle hose extension or angled hose

connection.

9. Replace hose or clear obstruction.

10. Replace if damaged. Check to insure hose

is properly held in position by hose clamp at

main body.

11. Replace. ]'his condition will not result in

significant suction loss.

12. Replace or reposition. Position is critical.

C. No pickup

using tools

1. Hose damaged or clogged.

2. Hose not locked into dirt duct,

3. Bag full.

4. Secondary filter clogged.

5. Gasket on bag door damaged.

6. Gasket at base of bag door damaged.

7. Seal on dirt duct damaged.

8. Motor mount mispositioned or damaged,

1. Clear obstruction or replace hose.

2. Check connection,

3. Replace bag.

4. Clean or replace filter.

5. Replace gasket.

6. Replace gasket.

7. Replace seal.

8. Replace or reposition. Position is critical.

Problem Possible Cause

Possible Solution

D EDF circuitry

not working

Green light

won't come

on

E Light doesn't

change from

green to red

during normal

operation 1.

F. Red light

stays on.

Won't go to

green

G. Thermal

protector

trips

Note When the unit is energized there is a slight delay then the green light illuminates If the green

light does not come on check the following:

1 No power to board

1 Check 120 volt leads on the LH side of the

board Also check connection at wire nut

and motor connector.

2 Circuit board failed•

2. Replace board

Note: The red light may seldom come on during cleaning• This means your cleaner is picking up

primarily fine surface dust and lint which the system may not detect or the carpet is clean• Switch the

unit to Hi sensitivity and re-check. Also check the following:

Microphone out of position.

1. Check to insurethe microphone is firmly

pressed into the seat in the dirt duct.

2. Dirt duct opening "caked" with dirt.

3. Microphone leads disconnected from board. (Small

2. Clean and check operation.

3. Check connection.

leads on RH side)

4. Microphone failed.

4. Replace- check the above first.

Note: Run cleaner while holding it off the floor. If green light does not come on check the following:

1. Circuit board failed. 1. Replace board.

1. Final filter clogged.

2. Motor bearing tight- motor dragging.

3. Thermal Protector defective.

1. Clean or replace filter.

2. Replace motor.

3. Replace TOC and check operation. Check

items 1and 2 first.

Loading...

Loading...