Page 1

Page 2

The HOOVER vacuum cleaner you have just purchased is a combina-

tion cleaner. It has an electronic power nozzle for carpet and floor

cleaning and has cleaning tools for above the floor cleaning.

Your cleaner is a model no.

and has a serial number

For your personal records, please enter the model number and serial

number in the spaces provided above and retain in a safe place.

The model number and serial number appear on the bottom of the

cleaner.

Save!

Index

Assembling Cleaner

Cleaner Description

Energy Saving Tips

How To Use

Check Bag Indicator

Cleaning Tools

Electronic Power Nozzle

Two Speed Switch

If You Have a Problem

Important Safeguards

Lubrication

Maintenance

Cleaning Secondary Filter

Clearing Obstructions

Replacing Agitator Brushes

and Brush Roll

Replacing Bag

Replacing Belt

Replacing Headlight

Storing Cleaner..

...................................

.........................

..........................

...........................

.........................

..........................

.........................

.........................

.........................

..........................

..........................

...........................

...................

.......................

...................

.......................

.....................

.5-7

.3-5

.22

.7

-10-l

.7-10

.7

.21

.2

.

.I5

.I4

.17-19

.13-14

.15-17

.19-20

..I

1

2

@

1975,

1

1978,1980

1992 The Hoover Company

Page 3

Important Safeguards!

l Read all instructions.

l Warning: Electric shock could occur if used outdoors or on wet sur-

faces.

l

Close supervision is necessary when any appliance is used by or

near children. Do not allow vacuum cleaner to be used as a toy or to

run unattended at any time.

l

Keep hands, feet, loose clothing, and hair away from rotating agitator. Do not operate the cleaner in bare feet or when wearing open

toe shoes or sandals.

l

Don’t run power nozzle over cord. It may damage insulation.

l

Do not use cleaner to pick up matches, or live ashes and cigarette

butts.

l Avoid picking up hard, sharp objects with the cleaner. They may

damage the cleaner and the bag.

l

Unplug cleaner when not in use. Turn machine off at switch before

unplugging.

l Always disconnect cord from electrical outlet before servicing the

cleaner.

l

Change bag frequently when picking up very fine materials such as

powder.

l

Grasp the plug to disconnect from wall outlet to avoid damage to

cord, plug, prongs, or receptacle.

l

If cleaner has a cord reel, hold onto the plug while cord is being re-

wound to prevent cord from whipping.

l The use of an extension cord is not recommended.

l

If cleaner is in disrepair, do not attempt to operate.

l

Have repairs made by the qualified personnel at Hoover Factory

Service Centers or Authorized Hoover Warranty Service Dealers.

l

Use vacuum cleaner only for its intended use as described in the in-

structions. The use of attachments not recommended by the appliance manufacturer may cause hazards.

Save these instructions!

Ql.Blity

p?i%i

c3

UL

0

Employee

Particioation

Page 4

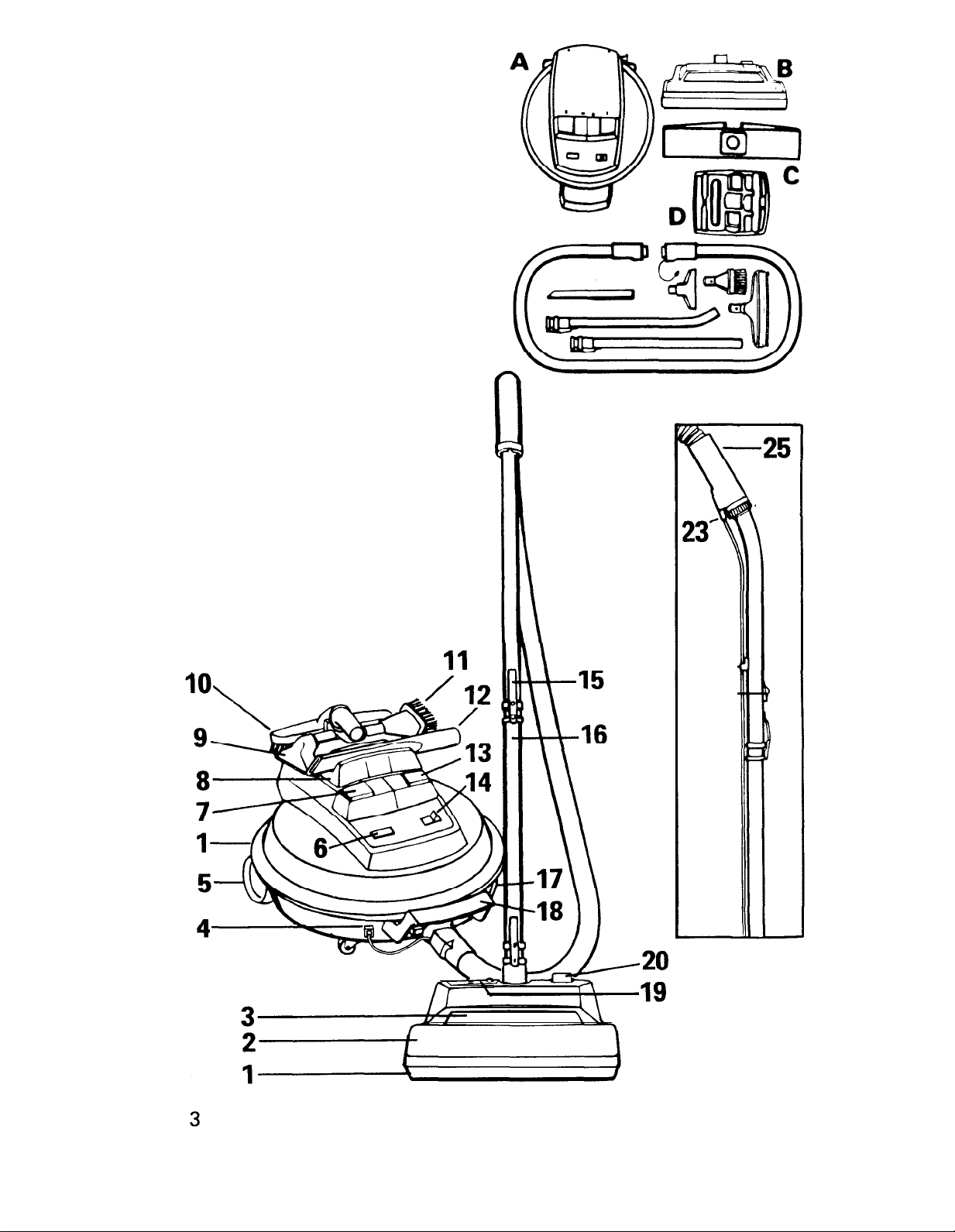

Unpacking

Unpack the cleaner from the

carton and identify the parts

shown. Remove and dispose of

the cardboard packing.

A. Canister cleaner

B. Electronic power nozzle

C. Throw away bag

D. Tools with tool storage rack,

extension wands (Model S3237

has two sets of wands), and

hose.

The cleaner assembled will look

like the drawing below.

-24

23.

F

22-

21-

Page 5

1.

Furniture Guard is located around cleaner and electronic power noz-

zle.

2. Combination Carpet and Floor Electronic Power Nozzle contains

agitator (brush mechanism) and automatically adjusts to different

carpet heights. The nozzle has both a “NORMAL” and a “DEEP

CLEAN” agitator speed and a panel of four LED indicator lights.

3. Headlight

4.

Hose Cord Connection to Cleaner is made by plugging hose cord

into cleaner base at receptacle.

5. Large Wheels provide easier towing; pull cleaner using hose to

guide the cleaner easily over carpet, area rugs, and door sills.

6. Check Bag Indicator lights up when throw away bag should be

checked to determine if changing is required.

7. Cord Rewind Control is foot operated. To unwind cord, pull to

desired length. Step on Cord Rewind Control to automatically re-

wind for storage. Hold plug until cord is rewound.

8. Tool Storage Rack provides tool storage for crevice tool, furniture

nozzle, wall/floor brush and dusting brush. (Removable)

9. Furniture Nozzle

10. Wall/Floor Brush

Il.

Dusting Brush

12. Crevice Tool

13. ON-OFF Control is a convenient foot-operated control on top of

cleaner.

14. Two Speed Switch allows for “HI” or “LO” speed selction.

15. Spring Latch locks extension wands.

16. Extension Wands connect to hose and electronic power nozzle or

cleaning tools. Model S3237 - use curved wand and straight wand

with cord clips when using electronic power nozzle; use extra set of

wands with cleaning tools.

17. Cover Latch

18. Carrying Handle

19. LED (Light Emitting Diode) Indicator Lights show settings for

“FLOOR” and “CARPET” cleaning, and warnings for “CHECK

BELT” and “POWER GUARD”.

20. Agitator Control Pedal is a foot-operated control to set nozzle for

“CARPET” or hard surface “FLOOR”.

Page 6

21. Suction Regulator should be opened for easy cleaning of some

types of carpet, lightweight flexible rugs and lightweight draperies,

22. Cord Clips clip nozzle cord to extension wands.

23. Nozzle Cord Connection to Handle is made by plugging nozzle cord

into receptacle underneath the handle.

24. Plastic Latch Ring rotates to connect handle to extension wand or

to cleaning tools.

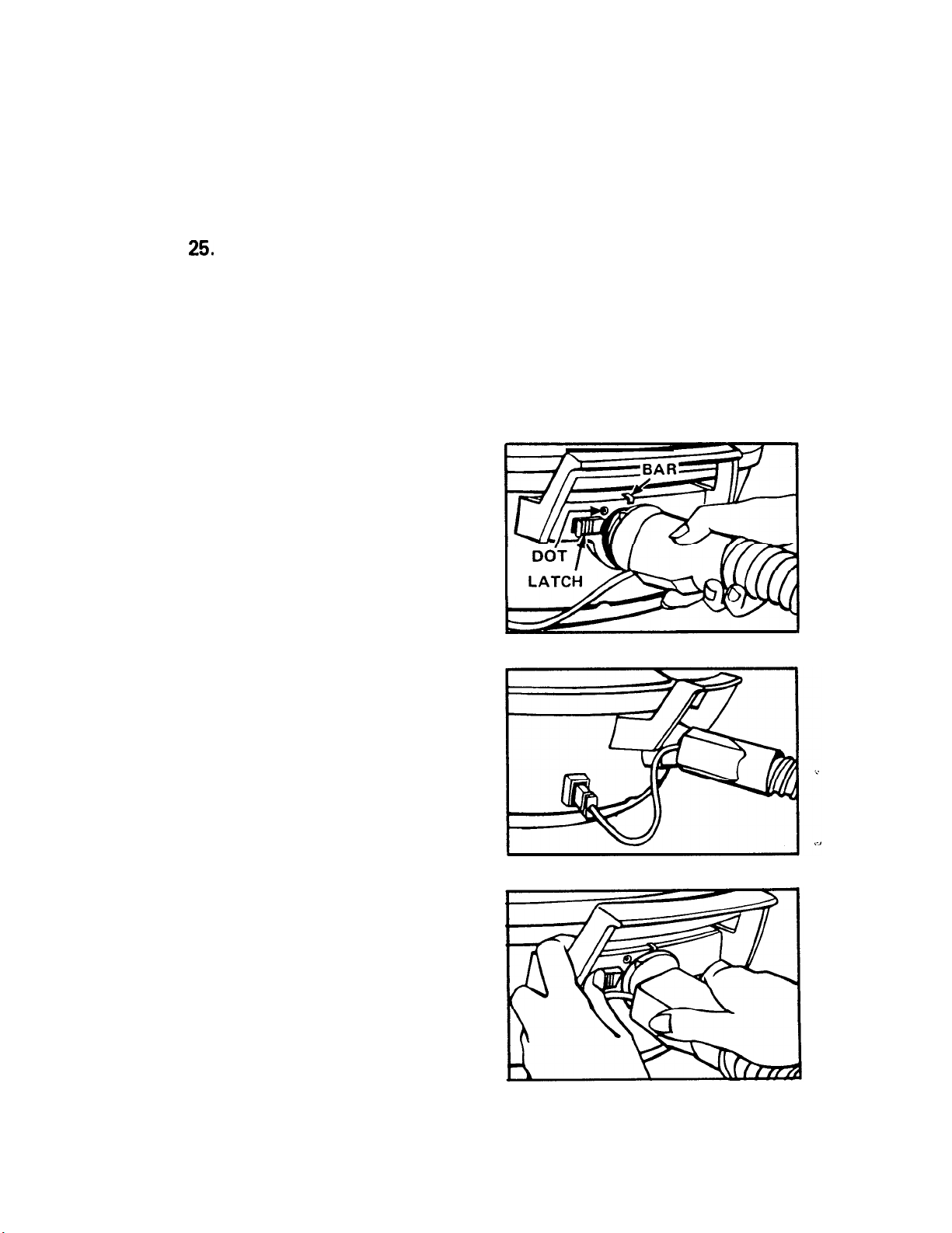

25.

Handle is on end of hose for use with extension wands or cleaning

tools.

Operate cleaner only at voltage specified on data plate on bottom of

cleaner.

How to assemble

1. Connect hose

To connect hose, insert hose into

opening of cleaner lining up the

arrow on the hose with the dot on

the cleaner. Turn the hose clockwise until the arrow lines up with

the bar on the cleaner and latch

locks into place.

DO’T fy

LATCH&

When the hose is attached prop-

erly, the hose cord plug will reach

to the receptacle on the cleaner.

Insert the plug firmly and as deep

into the receptacle as possible.

To disconnect hose, first remove

hose cord plug from receptacle.

Then, depress latch away from

hose connection opening in cleaner. While holding latch, turn the

hose counterclockwise until the

arrow lines up with dot on the

cleaner, Remove hose.

5

Page 7

-

. ..--

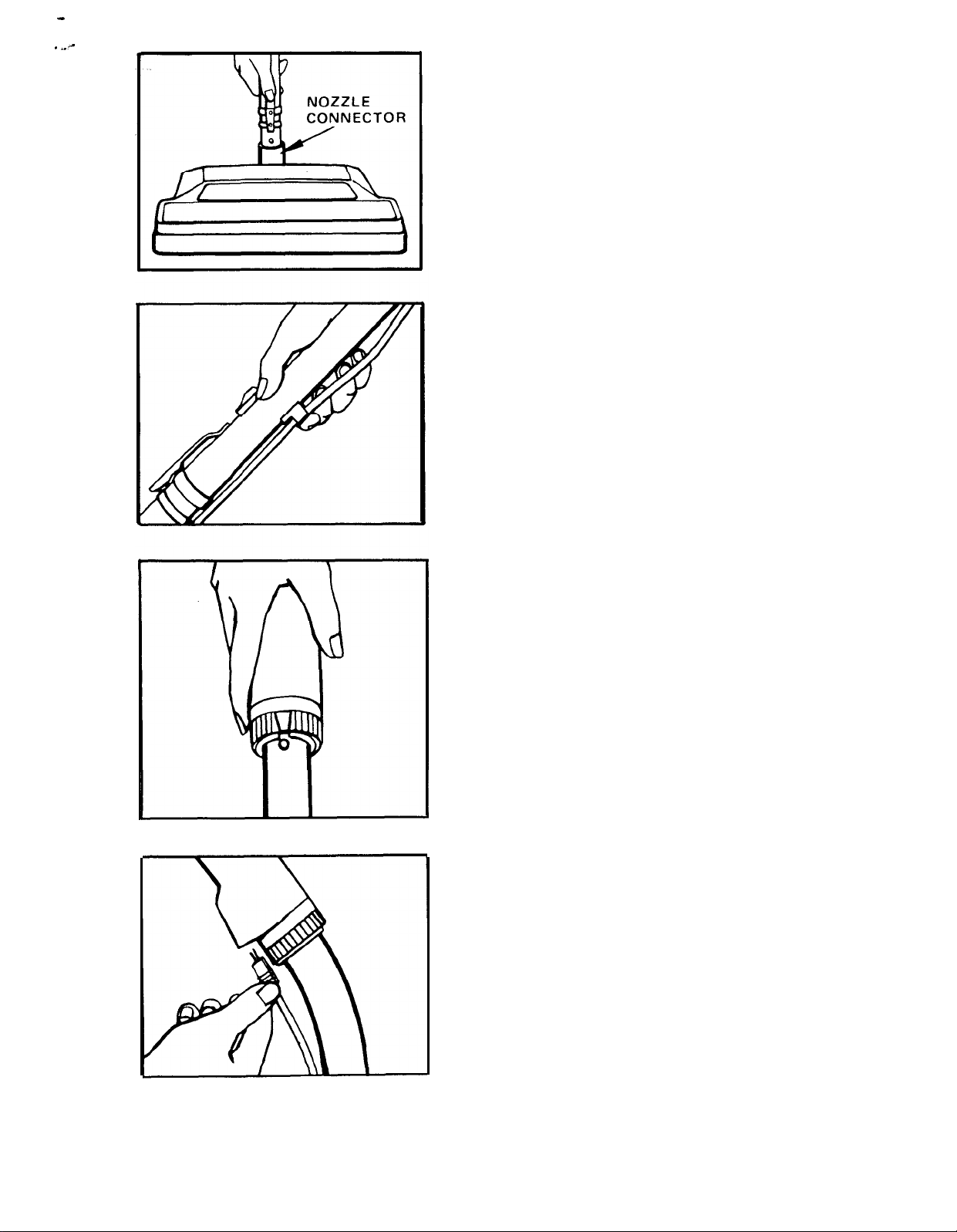

2. Attach electronic

power nozzle

Note: For most convenient use

with electronic power nozzle,

connect curved and straight

wand with cord clips to nozzle.

Attach the electronic power nozzle at the end of the straight wand

by fitting the button projection

on the nozzle connector into the

opening at the end of the wand.

Be sure the nozzle is locked in

place.

To release, press down on the

center of the spring latch.

Attach the curved wand to the

straight wand. Position cord into

cord clips on extension wands,

placing excess cord between

nozzle and bottom cord clip.

To attach the hose to the extension wands, rotate the plastic

latch ring on the handle to accept

the button projection on the curv-

ed wand.

Push the handle over the wand so

that the button projection fits into

the slot. Turn the latch ring to lock

wand in place.

Connect nozzle power cord to

receptacle underneath handle.

6

Page 8

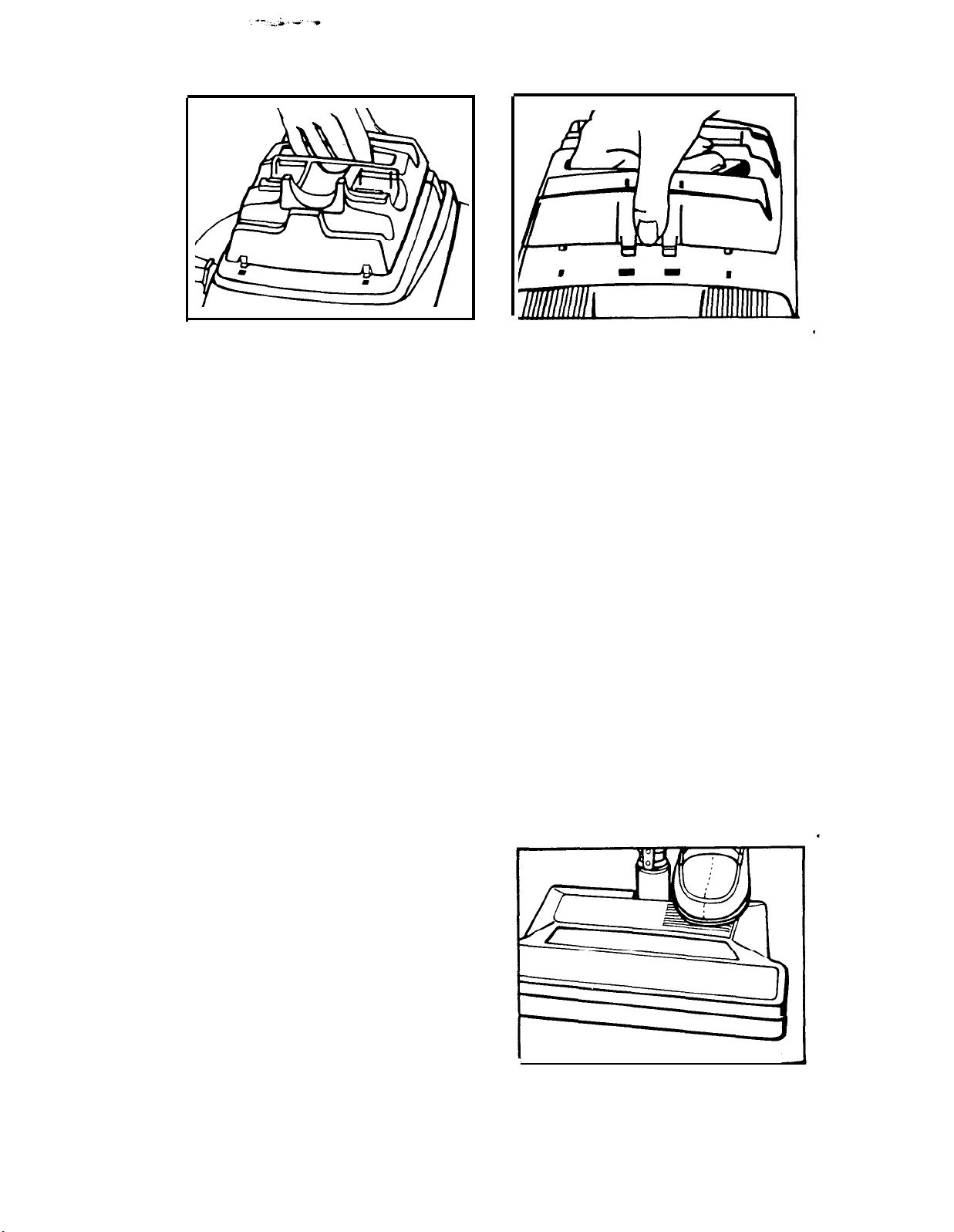

3. Attach tool storage rack

To attach tool storage rack, insert rear projections of rack into

the two rear slots on top of the

cleaner. Snap front middle sec-

tion into place.

How

to use

To remove, press front middle

section and lift rack up.

Position tools in appropriate sections on rack as indicated by

symbols.

Two speed switch

Your cleaner is equipped with a switch for “Hi” and “Lo” speed.

Use “Lo” speed when reduced suction is desired such as when cleaning

throw rugs or when using the tools on delicate fabrics.

Use “Hi” speed for all cleaning tasks when maximum suction is desired.

Check bag indicator

With the cleaner on “Hi” speed, the Check Bag Indicator will light up

when the bag needs replaced. If powdery substances have been picked

up, the bag may need replaced even if it is not full.

Note: The bag may not need replaced if the light comes on during tool

use or if there is an obstruction in the hose, wands, or power nozzle.

(See Maintenance Section.)

’

,

Electronic power nozzle

Handle adjustment

The handle has two positions

when used with the electronic

power nozzle: Upright and

Operating.

To lower handle to the Operating

position, place your foot on the

grooved area (located above the

Agitator Control Pedal on the

nozzle) and push the handle

down,

7

I

Page 9

Swiveling handle and wands

The handle and wands conveniently swivel to the right for ease in clean-

ing under low furniture.

To swivel handle and wands, twist handle to the right. The handle and

wands should “click” out of the original position.

To swivel handle and wands back to the original position, twist handle to

the left.

Carpet and rug cleaning

When using the electronic power

nozzle for carpet and rug cleaning, a green LED light on the control panel should indicate the

“CARPET” position. This setting

provides the suction and agitator

action necessary to deep clean

carpets. Step on the Agitator

Control Pedal to change the setting.

Hard surface floor

cleaning

t

ti

DEEP

CLEAN

FLOOR

CARPET

I

4

POWER

GUARD

The electronic power nozzle can

be used for cleaning hard surface

floors such as wood, linoleum,

vinyl, asphalt and rubber tile,

sealed cork, concrete and terrazzo as well as carpet.

To adjust the electronic power

nozzle for hard surface floor

cleaning, step on the Agitator

Control Pedal.

A green light will indicate the

“FLOOR” position. This setting

provides suction but no agitator

action. The Wall/Floor Brush may

also be used for cleaning bare

floors.

Agitator speed selection

The electronic power nozzle offers

two agitator speed settings. The

“NORMAL” speed is used for

most carpet cleaning and the

“DEEP CLEAN” setting is available for increased agitator action.

8

Page 10

“CHECK BELT” light

The electronic power nozzle automatically monitors its belt condition. When the belt needs replaced, the red “CHECK BELT” light

will come “ON” and remain

“ON” until the belt is replaced.

To replace belt, refer to “The

belt” section under Maintenance.

“POWER GUARD”

feature

The electronic power nozzle has

a unique feature which warns of

motor overload conditions. The

red “POWER GUARD” light will

come “ON” and the nozzle will

shut “OFF” if the motor is stalled

or if an agitator obstruction causes

a motor overload. Before removing any agitator obstructions or

opening the Suction Regulator

(see “Automatic nozzle adjustment”), the CAUTION statement

below must be followed.

0

I

FLOOR

\

CARPET

\

CAUTION: If the “POWER

GUARD” light is “ON”, the agitator may suddenly start while you

are removing obstructions from

the agitator area. Therefore, turn

cleaner “OFF” and unplug before

cleaning or servicing. The elec-

tronic circuitry will be automati-

cally reset when the cleaner is

turned “OFF”.

Brushed edge cleaning

Brushed edge cleaning is provided

on both sides of the nozzle to remove imbedded dirt in carpet near

baseboards and furniture. Guide

either side of the nozzle parallel to

the edge of the carpet or furniture

as shown.

Page 11

9

I

OPEN

t

Automatic nozzle

adjustment

The electronic power nozzle ad-

.justs automatically to the correct

cleaning height for all carpets from

low pile to shag. If the power

nozzle is difficult to push, or if the

“POWER GUARD” activates due

to heavy carpet load, open the

Suction Regulator.

Cleaning tools

Removing and

replacing tools

To remove tools from tool storage

rack, grasp the top of the tool, as

shown in the illustration, and lift

UP.

To replace tools, position tool in

appropriate section on the tool

storage rack and snap into place.

Select the proper cleaning tool

The cleaning tools have many uses. Select the tool best suited for the

cleaning task from the descriptions below. Adjust the Suction Regulator

to select the amount of suction appropriate to the cleaning task.

1. Crevice tool

dresser drawers, spaces between

kitchen appliances.

2. Wall/floor brush for walls

and very irregular hard surface

floors such as brick and slate.

3. Furniture nozzle

stered furniture, draperies, tapes-

tries, mattresses, clothing, automobile interiors and carpeted

stairs.

4. Dusting brush

niture, table tops, books, lamps,

lighting fixtures, Venetian blinds,

baseboards, shutters and regis-

ters.

for radiators,

for uphol-

for carved fur-

10

Page 12

IMPORTANT USER INFORMATION

This Electronic Power Nozzle features a reliable electronic circuit to control and protect the nozzle. The

headlight functions as part of this electronic protection

system.

The headlight bulb should provide years of normal use;

however, the motor will not operate if the bulb burns

out. For bulb replacement use a 15 watt lamp only.

Hoover part number 16113 or Sylvania 15T7DC bulb.

11-82

Litho

USA

Use

54823-026

Page 13

To connect and

remove tools

To use the cleaner with tools disconnect the nozzle from the extension wands. (For Model

S3237, leave the nozzle assembl-

ed to the wands and only discon-

nect nozzle cord and curved

wand from handle, since two additional wands are provided for

use with tools.

To connect the tools, insert end

of tool into the extension wand

and snap into position. To dis-

connect, press down on the cen-

ter of the white plastic spring

latch and remove tool.

Tools may also be attached to the

handle grip by rotating the plastic

latch ring to accept the button

projection on the tool. Then, turn

the latch ring as shown to lock

the tool in place.

1

m

-’

I

To remove the tool, reverse the

above procedure.

Power cord

To avoid damage to the power

cord, leave it connected to the

receptacle on the cleaner at all

times.

To clean stairs

Clean stairs by standing the

cleaner on its side as pictured in

the illustration. Clean stairs from

bottom to top.

11

Page 14

To clean hard to

reach areas

The tools attached to the curved

wand, as shown will enable you to

clean many hard to reach areas;

especially crown moldings, tops

of drapery rods, shelves, and picture frames.

Storing cleaner

Your cleaner can be stored on

end as shown in the illustration.

Store the electronic power nozzle

with the handle in the upright

position.

The hose, extension wands, elec-

tronic power nozzle and tool storage rack can be stored separately

from the cleaner if desired.

Maintenance

The following sections are concerned with proper maintenance of the

cleaner. Familiarize yourself with these home maintenance tasks and

keep this owner’s manual in a convenient place where you can refer to it

when needed. Proper use and care of your cleaner will assure continued

cleaning effectiveness.

The bag

When to replace

When the Check Bag Indicator light is on, the bag should be checked for

fullness and replaced if necessary.

CAUTION: Very fine materials, such as face powder, cornstarch, fire-

place ashes or fireplace soot, may seal the throw away bag and may

cause it to burst even though it is only partially full of dirt. When the

cleaner is used to remove material of this nature, the bag should be

changed frequently.

12

Page 15

Where to buy bags

Bags may be purchased from your local Authorized Hoover Dealer or

from a Hoover Factory Service Center. When ordering bags, be sure to

give the model number of your cleaner.

What bags to buy

Use HOOVER bag type H with this cleaner.

To assure that your HOOVER cleaner operates at

peak performance, it is imperative that you use

only genuine HOOVER throw away bags made

by The Hoover Company. HOOVER bags can be

identified by the trademarks -

-

Replacing the throw

away bag

Disconnect cleaner from electri-

cal outlet.

Open the cleaner by lifting up on

the latch to release the cover.

I

I

Push used bag away from holder

and lift out.

Grasp edges of collar section and

push opening of collar section of

new bag onto holder. Make sure

collar is pushed completely up to

the ridge on the holder.

Page 16

Adjust bag around the motor

housing and open the folds of the

bag to allow the bag to properly

fill. Make sure all four folds are

open.

Note: A bag that does not ex-

pand properly may restrict air

flow. In this event, check the

bag, making sure all the folds are

open. High suction on some

carpet surfaces can cause the

nozzle to hug the carpet and also

restrict air flow. When this occurs, reducing the suction with

the Suction Regulator or swit-

ching to “LO” speed may be

helpful.

Clearing obstructions

Removing larger items from carpet and floor surfaces before vacuuming will help prevent obstructions in the hose wands or nozzle

connector, and maintain the

cleaning effectiveness of your

cleaner.

/-’

CoNNECTOR

To check for obstructions, first

disconnect power nozzle cord

and wands from cleaner base.

Turn cleaner “ON” and check

hose end for suction. Remove any

obstructions. Remove power

nozzle from wands and attach

wands to hose. Check for suction

and remove any obstructions.

Before attaching power nozzle to

wands, check nozzle connector.

While holding nozzle, push noz-

zle connector down to lowest po-

sition,

Look into nozzle connector and

remove any obstructions.

14

Page 17

Secondary filter

To clean secondary filter

Disconnect cleaner from electri-

cal outlet.

The secondary filter protects the

motor from dirt particles. If the

filter becomes dirty, either clean

or replace it.

To remove secondary filter, open

cover of cleaner and lift filter off

of motor housing. Clean filter by

rinsing it in water. When dry,

position filter around motor housing with notched edge at the bottom and to the back of the motor

housing.

The belt

The belt in your electronic power nozzle drives the agitator. It has been

designed specifically for use in this cleaner and is important for effective

operation. There are other belts manufactured that are similar in shape

and size but are not designed for the HOOVER electronic power nozzle.

Such belts do not operate the agitator correctly and may create stress

which could damage your electronic power nozzle. Use only a genuine

HOOVER Belt No. 38528-011 when a belt replacement is necessary.

When to replace the belt on electronic power nozzle

The belt, located under the nozzle cover, should be replaced if the

“CHECK BELT” light remains “ON”. To service, remove the nozzle

cover (see following section).

How to replace the belt

Disconnect cleaner from electrical outlet and disconnect electronic power nozzle from extension wands.

Turn nozzle over and unscrew

the 2 Phillips head screws from

the nozzle base.

15

Page 18

MOTOR

PULLEY

AGITATOR

PULLEY

Return nozzle to original position

and lift up back of nozzle cover.

Then remove cover, rotating it

forward and lifting it off.

To remove the agitator, position

your hand underneath the nozzle

base at the agitator opening and

push up the belt end of the agitator. Remove agitator and old belt.

Place one end of new belt around

the plastic agitator pulley, with

lettering on outside of belt.

Then slip other end of belt around

motor pulley.

PR‘OJECTION

SiOT

Position round projection on end

of agitator (opposite the belt) into

the opening in the wall of the

nozzle base.

Slide belt end of agitator into

place by pulling agitator forward

and lining up metal projection on

end of agitator with slot in wall of

nozzle base. Then push agitator

down into position.

Roll agitator to make sure belt is

positioned properly.

I

16

Page 19

The cover attaches at the front of

the nozzle. Place the notched

edge at the front of the cover into

the groove in the nozzle base.

While maintaining front connection, rotate cover over nozzle

base and pull nozzle cord through

opening in cover.

Turn nozzle over and replace

screws.

Agitator brushes

and brush roll

When to replace brushes

Disconnect cleaner from electrical outlet before checking

brushes.

To check condition of brushes,

place edge of a card on the bottom of nozzle base, across agitator opening. Rotate agitator by

hand. If brushes do not touch

edge of card, all four brushes and

brush roll should be replaced to

maintain cleaning effectiveness.

When replacing agitator brushes

and brush roll, ask for HOOVER

part No. 48445017 and part No.

48418401.

17

Page 20

ION

How to replace agitator

brushes and brush roll

Disconnect cleaner from electrical outlet and disconnect electronic power nozzle from extension wands.

Remove nozzle cover, agitator

and belt following directions in

“How to replace belt” section.

1. Hold agitator as shown. Turn

end plates in opposite directions

until one end plate comes off.

2. Pull or pry out end sections as

shown in illustration.

Note: Remove brush roll and then

pulley end section by pulling

straight out.

3. Note position of bar-brush assemblies to assure correct re-

placement.

Remove bar-brush assemblies by

pulling them from agitator slots.

Use pliers if necessary.

The word “BAR” is stamped

near the slots on the agitator.

Match the bar side of the bar-

brush assembly with the label on

the agitator shell. Slide the new

assemblies into the slots, while

twisting the assemblies in a counterclockwise motion. Push in as

far as possible, tapping the other

end lightly if necessary. Be sure

brushes and bars are aligned for

full length of agitator.

18

Page 21

4. Line up locator on end sections

with slot on agitator. Push end

sections into position.

Note: The pulley end section has

a U-shaped locator that fits into

the U-shaped slot on the appro-

priate agitator end.

5. Slide new brush roll onto

pulley end section, fitting indented areas on brush roll over

projections on end section. Ar-

row in brush roll must point toward agitator.

6. Screw on end plates and

tighten.

7. Should you accidentally displace any part of the agitator during assembly, reassemble as

shown.

SHAFT

,goer

PLASTIC

DUST

END

PLATE SHIELD

I

SPACER

’ I

FL*7

SIDED

PROJECTION COVER

METAL

BEARING

WASHER BRUSH u--

END PULLEY

SECTION

through cen,er of ag,tatorl

I

Replace belt, agitator and nozzle cover.

The headlight

The headlight located on top of the electronic power nozzle operates

when the cleaner is turned on.

Note: The headlight bulb is part of the electronic circuit and the electronic power nozzle motor will not operate if the bulb is burned out.

The bulb must be replaced with a 15 watt bulb. Use Hoover part

number 16113 or Sylvania

How to replace the headlight

15l7DC

bulb.

METAL

BEARING

COVER

PROJECTION

Disconnect cleaner from electrical outlet and disconnect electronic

power nozzle from extension wands.

19

Page 22

Turn nozzle over and unscrew

the 2 Phillips head screws from

the nozzle base.

Return nozzle to original position

and lift up back of nozzle cover.

Then remove cover, rotating it

forward and lifting it off.

Push bulb into socket and twist

to remove. Push new bulb into

socket and twist into place.

The cover attaches at the front of

the nozzle. Place the notched

edge at the front of the cover into

the groove in the nozzle base.

Maintaining front connection, rotate cover over nozzle base and

pull nozzle cord through opening

in cover.

Turn nozzle over and replace

screws.

20

Page 23

If you have a problem

This appliance was inspected thoroughly and was in good operating condition

when it was shipped from the factory. If a minor problem develops, it usually

can be remedied quite easily when the cause is identified. Accordingly, this

check list is provided for your convenience.

Problem

A. Cleaner

won’t run 2. No voltagein wall plug. 2. Check fuse or breaker.

B. Cleaner

suction

low

C. Agitator

won’t run power nozzle cord not firmly

D. Nozzle

won’t pick

up

Possible cause

1. Not firmly plugged in. 1. Plug unit in firmly.

3. Blown fuse/tripped breaker. 3. Replace fuse/reset breaker.

1. Bag full.

2. Obstruction in hose, wands

or nozzle connector.

3. Secondary filter dirty.

4. Bag not opening.

5. Suction regulator control

open.

6. Hose not properly connected

to cleaner.

7. Switch on “LO” speed.

1. Hose power cord and/or

plugged in.

2. Broken belt. “CHECK BELT”

light “ON”.

3. Motor overload. “POWER

GUARD” light “ON”.

4. Headlight bulb burned out.

1. Low cleaner suction.

2. Obstruction in nozzle

connector.

3. Agitator not running.

4. Agitator brushes and

brush roll worn.

Possible solution

1. Change throw away bag.

2. Remove foreign object.

3. Clean filter.

4. Open bag by pulling folds.

5. Close suction regulator.

6. Insure hose properly

connected.

7. Turn switch to “HI”.

1. Plug firmly into receptacle

on cleaner base and underneath hose handle.

2. Replace belt and replace agitator brushes if severly worn.

3. Remove obstruction from agitator or motor pulley.

4. Replace bulb.

1. See Item B.

2. Remove foreign object.

3. See Item C.

4. Replace brushes and

brush roll

If the problem persists, check the Yellow Pages of your telephone book

under “Vacuum Cleaners - Household” for your nearest Hoover Factory

Service Center or Authorized Warranty Service Dealer where approved

HOOVER service and genuine HOOVER replacement parts may be ob-

tained. The warranty provided with this product has a listing of the

Hoover Factory Service Centers. If you are unable to obtain the informa-

tion you need from the Yellow Pages, contact a Hoover Factory Service

Center to find your nearest Authorized Warranty Service Dealer. For

service under warranty, follow the instructions in the Warranty provided

with this product. Do not send your cleaner to The Hoover Company in

North Canton for service, as this will result in delay.

Always identify your cleaner by model number when requesting informa-

tion or ordering replacement parts. (The model number appears on the

bottom of the cleaner.)

If further assistance is needed, contact The Hoover Company Con-

sumer Affairs Department, North Canton, Ohio 44720.216-499-9200.

21

Page 24

.

Lubrication

The motor is equipped with one ball bearing and one roller bearing.

These bearings contain sufficient lubrication for the life of the motor.

The addition of lubricant could cause damage. Therefore, do not add

lubricant to either motor bearing.

The agitator is equipped with two ball bearings that should be lubricated

periodically. This should be done by a Hoover Factory Service Center or

an Authorized Hoover Warranty Service Dealer.

Energy saving tips

1. Replace throw away cleaner bag promptly, before overfilled. Use a

genuine HOOVER bag made for your model cleaner.

2. To maintain effective cleaning, replace agitator brushes, brush roll

and belt when necessary.

3. Turn off cleaner when not in use, such as when moving furniture.

4. Keep your cleaner operating at peak performance level - have in-

spection and service performed by a Hoover Factory Service Center or

Authorized Hoover Warranty Service Dealer.

22

Page 25

VCMA

VACUUM CLEANER MANUFACTURERS ASSOCIATION

(HOOVER -AN ASSOCIATION MEMBER)

Servce

This

mformatron has been compiled by the Vacuum Cleaner

at/on from Government and Private Sources concerned

baste gurdelmes

are for your protection and convenrence

To

The Consumer

Srnce

19

13

Matwfacturers

w/l/i

product safety

Associ-

Thosc~

TO AVOID ELECTRIC SHOCK

Never vacuum damp or wet surfaces or

Do not store machtne outdoors.

Replace worn or frayed power cord immedrately.

ltqulds

TO AVOID ACCIDENTS

Never vacuum

Never run machine over or place sharp objects on the power cord.

Never let children use machine as a toy.

Use extra caution when cleaning on stairs.

Keep machine on floor - not on chairs, tables, etc.

When machine is turned on, never allow frngers, eyes,

near intake suction ports or revolving brushes.

Never leave machine running or cord plugged in when unattended.

Turn machlne off at switch before unpluggmg from wall outlet

When unplugging machine, grasp plug -- not cord; guide cord and plug during

wrapping or cord reel rewinding.

The use of an extension cord is not recommended.

Never vacuum in the presence of flammable or combustible

Always unplug power cord from wall outlet before

accessories.

Store machine promptly after each use to prevent accidents from tripping over power

cord or machine.

Use machine and accessones only In manner Intended by manufacturers.

live ashes or cigarette

butts.

hair,

garments,

llqulds

or fumes.

servlclng machrne

etc

to come

or attaching

FOR BEST PERFORMANCE

Keep your machine and all accessories clean and in good operating condition.

Change or clean bags and/or filters as recommended by manufacturer to maintain

optimum cleaning efficiency, after unplugging the power cord.

Periodically check revolving brush for build-up of lint, hair or other foreign material

and remove as necessary, after unplugging the power cord.

Adjust or replace cleaning brushes when worn, after unplugging the power cord.

Have machine checked periodically by manufacturer’s authorized

Use only manufacturer’s authorized service center for parts or service

Store machine carefully in a dry area.

For optimum cleaning performance and safety, study and follow your Owner’s

Manual - keep it in a handy and safe place for future reference.

service

center

THE HOOVER COMPANY, NORTH CANTON, OHIO 44720

R3 9-83

S3237/39

Litho

USA

56513-194

Loading...

Loading...