Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Dryer

ADE7005AK*

ADE7005AY*

ADE9005AG*

ADG7005AW*

CDE6505*

CDE6505AZ*

CDE9505*

CDE9505AZ*

CDG6505*

CDG9505*

CYE3005AG*

CYE3005AK*

CYE3005AY*

CYE3005AZ*

CYG1005AW*

CYG3005AW*

HYE2205AG*

HYE2205AK*

MDE208DAY*

MDE2706AY*

MDE2706AZ*

MDE308DAY*

MDE3706AG*

MDE3706AK*

MDE3706AY*

MDE3706AZ*

MDE3757AY*

MDE3758AY*

MDE3758AZ*

MDE4657AY*

MDE4658AY*

MDE4806AY*

MDE4806AZ*

MDE508DAY*

MDE5806AY*

MDE5806AZ*

MDET236AY*

MDET236AZ*

MDET336AY*

MDET336AZ*

MDET446AY*

MDET446AZ*

MDG208DAW*

MDG2706A*

MDG270SAW*

MDG308DAW*

MDG3706AW*

MDG3757AW*

MDG3758AW*

MDG4657AW*

MDG4658AW*

MDG4806AW*

MDG508DAW*

MDG5806AW*

MDGT236AW*

MDGT336AW*

MDGT446AW*

NDE2335AY*

NDE2335AZ*

NDE5805AY*

NDE5805AZ*

NDE8805AY*

NDE8805AZ*

NDG2335AW*

NDG5805AW*

NDG8805AW*

PDET910AY*

PDET910AZ*

PDET920AY*

PDET920AZ*

PDGT910AW*

PDGT920AW*

©2006 Maytag Services

16026315

January 2006

Page 2

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however , that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts,

testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center Telephone Number

CAIR Center.............................................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Web Site

WWW.MAYTAG.COM

WARNING

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

!

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16026315 ©2006 Maytag Services

Page 3

Important Information .................................................... 2

Important Safety Information ......................................... 4

General Information

Model Identification .................................................... 8

Serial Label Location ................................................. 8

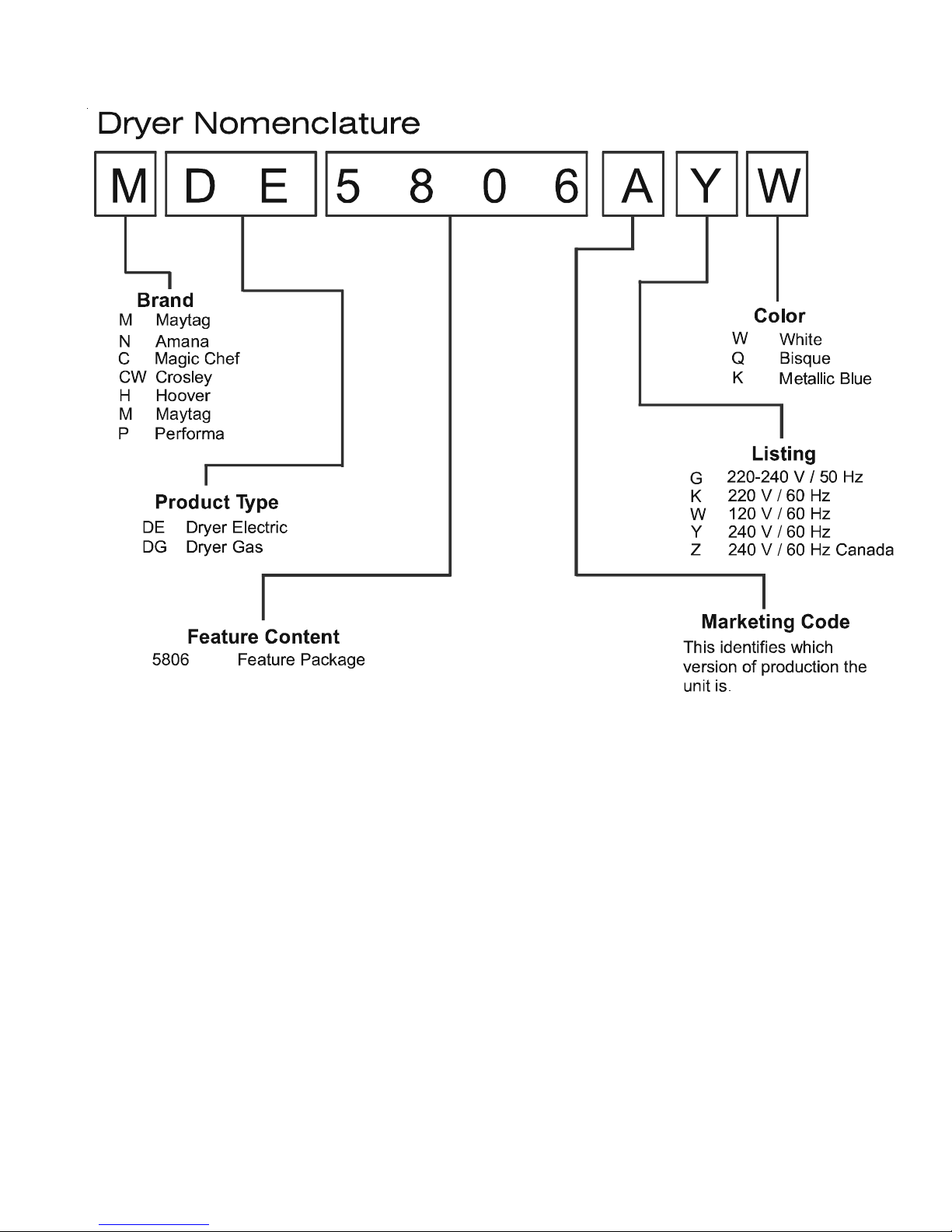

Model Nomenclature.................................................. 9

Troubleshooting

Troubleshooting General Symptoms .........................10

Component T esting Information

Component T esting Information.................................14

Disassembly Procedures

Control Console Access/Facia Removal ...................16

PC Board Removal ...................................................16

Cycle Selector Knob Removal ..................................17

Switch Removal ........................................................17

T op Cover/Door Switch/Front Panel/Gasket Removal 17

Door Reversal/Disassembly Removal........................18

Light Removal ...........................................................19

Motor/Blower/Thermistor/Thermostat Removal..........20

Drum Removal/Roller/Glide Access ..........................22

Heater Removal.........................................................23

Drim Baffle Removal ..................................................23

Gas Model Disassembly Procedures

Igniter Removal .........................................................24

Burner Removal ........................................................24

Appendix A

Installation Instructions........................................... A-1

Appendix B

Use And Care ......................................................... B-1

©2006 Maytag Services 16026315 3

Page 4

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however , that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts,

testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center Telephone Number

CAIR Center.............................................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Web Site

WWW.MAYTAG.COM

WARNING

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

!

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16025315 ©2006 Maytag Services

Page 5

Important Information .................................................... 2

Important Safety Information ......................................... 4

General Information

Model Identification .................................................... 8

Serial Label Location ................................................. 8

Model Nomenclature.................................................. 9

Troubleshooting

Troubleshooting General Symptoms .........................10

Component T esting Information

Component T esting Information.................................14

Disassembly Procedures

Control Console Access/Facia Removal ...................16

PC Board Removal ...................................................16

Cycle Selector Knob Removal ..................................17

Switch Removal ........................................................17

T op Cover/Door Switch/Front Panel/Gasket Removal 17

Door Reversal/Disassembly Removal........................18

Light Removal ...........................................................19

Motor/Blower/Thermistor/Thermostat Removal..........20

Drum Removal/Roller/Glide Access ..........................22

Heater Removal.........................................................23

Drim Baffle Removal ..................................................23

Gas Model Disassembly Procedures

Igniter Removal .........................................................24

Burner Removal ........................................................24

Appendix A

Installation Instructions........................................... A-1

Appendix B

Use And Care ......................................................... B-1

©2006 Maytag Services 16026315 3

Page 6

Important Safety Information

WARNING

!

T o avoid risk of fire, electric shock, serious injury, or death when using your dryer, follow these basic precautions:

1. Read all instructions before

using dryer.

2. Install dryer according to

Installation Instructions. Refer to

the Grounding Instructions in the

Installation Instructions for

proper grounding of the dryer.

3. Do not dry articles that have

been cleaned in, washed in,

soaked in, or spotted with

gasoline, dry-cleaning solvents,

or other flammable or explosive

substances. V apors could ignite

or explode.

4. Do not use dryer to dry clothes

which have traces of any

flammable substance, such as

vegetable oil, cooking oil,

machine oil, flammable

chemicals, thinner, etc., or

anything containing wax or

chemicals, such as mops and

cleaning cloths. Flammable

substances may cause fabric to

catch fire by itself.

5. Do not store or use gasoline or

other flammable vapors and

liquids near this or any other

appliance.

6. Do not allow children to play on

or in dryer. Close supervision of

children is necessary when

dryer is used near children, a

safety rule for all appliances.

7. Before dryer is removed from

service or discarded, remove

doors to drying compartment.

8. Do not reach into dryer if

cylinder is revolving.

9. Do not install or store dryer

where it will be exposed to water

and/or weather.

10.Do not tamper with dryer

controls.

1 1.Do not repair or replace any part

of dryer or attempt any service,

unless specifically recommended

in user-maintenance instructions

or in published user-repair

instructions that you understand

and have skills to carry out, if you

are a consumer.

12.To reduce risk of electric shock or

fire, do not use extension cords or

adapters to connect dryer to

electrical power source.

13.Use the dryer only for its intended

purpose, drying clothes.

14.Always disconnect dryer from

electrical supply before

attempting any service.

Disconnect power cord by

grasping the plug, not the cord.

15.Do not use heat to dry articles

containing foam rubber or

similarly textured rubberlike

materials.

16.Always clean the lint filter after

every load. A layer of lint in the

filter reduces drying efficiency and

prolongs drying time.

17.Use only fabric softeners or

products to eliminate static that

are appropriate for automatic

dryers.

18.Keep your dryer in good condition.

Bumping or dropping dryer can

damage safety features. If

damage occurs, have dryer

checked by qualified service

technician.

19.Replace worn power cords and/or

loose plugs.

20.Do not tumble fiberglass curtains

and draperies unless the label

says it can be done. If they are

dried, wipe out the cylinder with a

damp cloth to remove particles of

fiberglass.

21.Always read and follow

manufacturer’s instructions on

packages of laundry aids. Heed

all warnings or precautions. T o

reduce risk of poisoning or

chemical burns, keep products

away from children at all times,

preferably , in a locked cabinet.

22.Never operate dryer with guards

and/or panels removed.

23.Do not operate dryer with

missing or broken parts.

24.Do not bypass safety devices.

25.Keep area around the exhaust

opening and adjacent

surrounding areas free from

accumulation of lint, dust, and

dirt.

26.Interior of dryer and exhaust duct

should be cleaned periodically

by qualified service personnel.

27.Dryer will not operate with

loading door open. DO NOT

bypass door safety switch by

permitting dryer to operate with

door open. Dryer will stop

tumbling when door is opened.

Do not use dryer if it does not

stop tumbling when door is

opened or starts tumbling

without pressing or turning the

ST ART mechanism. Remove the

dryer from use and call

the service person.

28.Remove laundry immediately

after the dryer stops.

29.AL WAYS follow the fabric care

instructions supplied by the

garment manufacturer.

Save These Instructions

4 16026315 ©2006 Maytag Services

Page 7

Important Safety Information

WARNING

Electrical Service Information

Electrical Dryers

• 240 V AC, 60 Hz, 30 Amps,

3–wire or 4–wire installations

Gas Dryers

• 120 VAC, 60 Hz, 15 Amps, 3–wire installations

T o reduce the risk of fire and exposure to combustion

gases, the dryer MUST be exhausted to the outdoors.

DO NOT exhaust dryer air into a window well, gas vent,

chimney or enclosed, unventilated area, such as an

attic, wall, ceiling, crawl space under a building or

concealed space of a building.

Gas Dryer Power Supply

About Ground Wires

In the event of an electrical short circuit, a ground wire

reduces the risk of electric shock by providing an escape

wire for the electric current.

St andard accepted color coding for ground wires is green

or green with a yellow stripe.

Grounding wires and wires colored like grounding wires

are NOT to be used as current carrying conductors.

WARNING

!

To reduce the risk of fire, electric shock, serious injury

or death, all wiring and grounding must conform with

the latest edition of the National Electric Code, or the

Canadian Electrical Code, and such local regulations

as might apply . It is the customer’s responsibility to

have the wiring and fuses checked by a qualified

electrician to make sure your home has adequate

electrical power to operate the dryer.

WARNING

!

T o avoid risk of personal injury or death due to

electrical shock:

• Observe all local codes and ordinances.

• Disconnect electrical power to unit before servicing.

• Ground appliance properly.

• Check with a qualified electrician if you are not sure

this appliance is properly grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water pipe if pipe is

interrupted by plastic, nonmetallic gaskets, or other

insulating (nonconducting) materials.

• DO NOT modify plug on power cord. If plug does not

fit electrical outlet, have proper outlet installed

by qualified electrician.

• DO NOT have a fuse in the neutral or ground circuit.

A fuse in the neutral or ground circuit could result in

an electrical shock.

• DO NOT use an extension cord with this appliance.

• DO NOT use an adapter plug with this appliance.

• DO NOT pinch power cord.

©2006 Maytag Services 16026315 5

This equipment MUST be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the

electrical current. This unit is equipped with a cord

having a grounding wire with a grounding plug. The plug

must be plugged into an outlet that is properly installed

and grounded.

Consult a qualified electrician or servicer if grounding

instructions are not completely understood, or if doubt

exists as to whether the equipment is properly grounded.

Do not use an extension cord. If the product power cord

is too short, have a qualified electrician install a three–

slot receptacle. This unit should be plugged into a

separate 60 hertz circuit with the electrical rating as

shown on the serial plate.

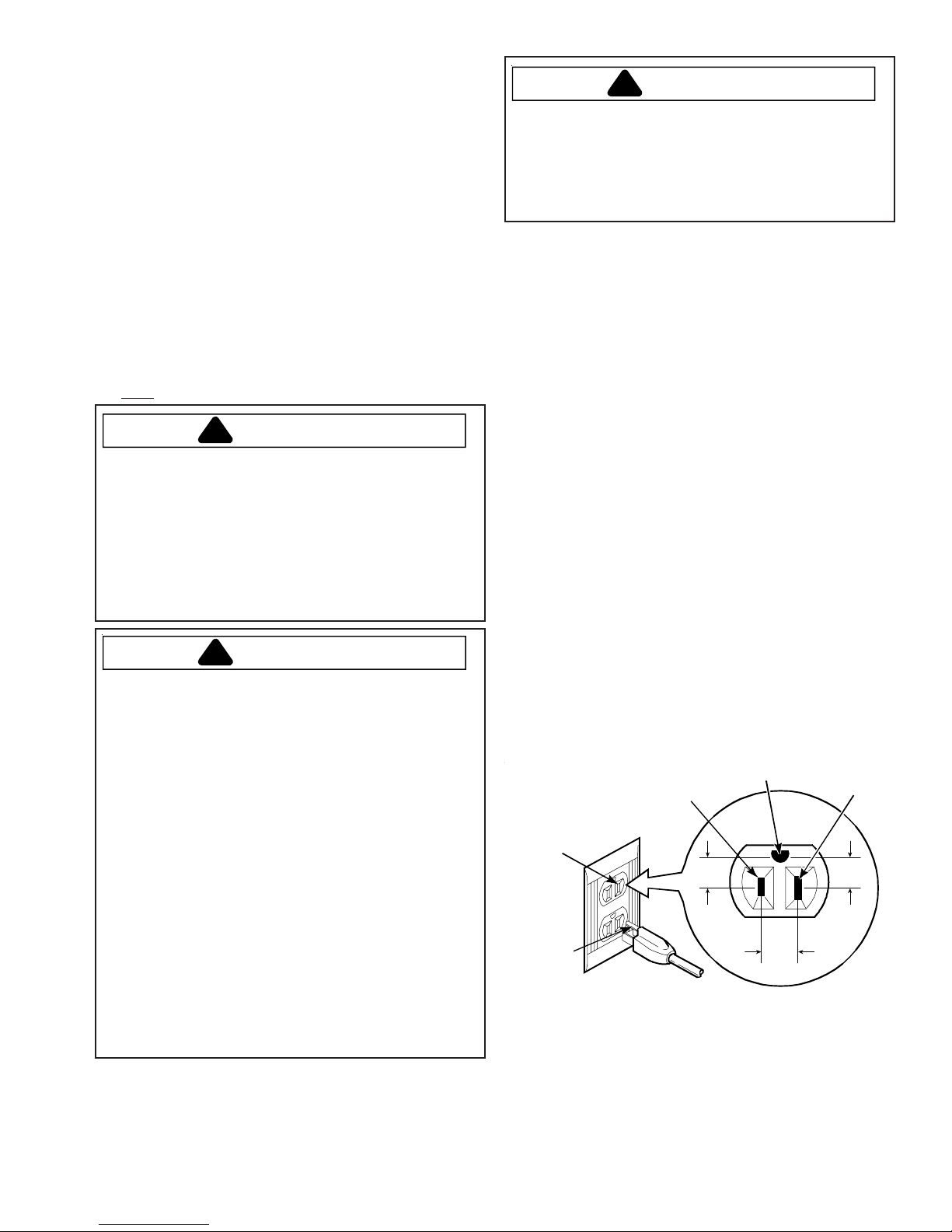

Proper Grounding and Polarization for 120 Volts

Wall Outlets

For the safety of our customers and the service technician ALL gas dryers have a three–prong power cord and

MUST be connected to a properly polarized and grounded

wall outlet. This information was written for those who do

not understand grounding and polarization of a wall

outlet. A 120 VAC wall outlet must always be wired as

shown below.

Neutral

side

Round

grounding

prong

Polarization–This means that the larger slot must be

neutral and the small slot must be hot (live).

Mispolarized–The outlet is miswired so that the larger

slot is hot (live) and the smaller slot is neutral.

Grounded–This means the round hole connection is

connected to ground through a connection to the main

power panel.

Ungrounded–The round hole connection is not

connected to a ground and/or the main power panel.

!

Explanation

L1

115–12

V.A . C .

Ground

115–12

V.A . C.

Neutral

0

V.A . C.

Page 8

Important Safety Information

Gas Connection Information

WARNING

!

To avoid death, personal injury or property damage,

from fire or explosion, information in this manual must

be followed exactly.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

WARNING

!

To reduce the risk of fire and exposure to combustion

gases, the dryer MUST be exhausted to the outdoors.

DO NOT exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated area, such as

an attic, wall, ceiling, crawl space under a building or

concealed space of a building.

6 16026315 ©2006 Maytag Services

Page 9

Important Safety Information

©2006 Maytag Services 16026315 7

Page 10

General Information

Model Identification

Complete registration card and promptly return. If

registration card is missing:

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www.mayt ag.com

• For product in Canada call 1-800-688-2002 or visit the

Web Sites at www .maytag.com or www .jennair.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. T o locate an authorized

servicer:

• For Maytag product call 1-800-462-9824 or visit the

Web Site at www.mayt ag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.mayt ag.com

Warranty service must be performed by an authorized

servicer. W e also recommend contacting an authorized

servicer, if service is required af ter warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. T o order accessories for your product call:

• For Maytag product call 1-800-462-9824 or visit the

Web Site at www.mayt ag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Sites at www.mayt ag.com

Extended Service Plan

We offer long-term service protection for this new dryer .

Serial Label is located in the upper left of the door

opening and back panel.

• Dependability PlusSM Extended Service Plan is

specially designed to supplement Maytag’s strong

warranty . This plan covers parts, labor , and travel

charges.

Call 1-800-925-2020 for information.

8 16026315 ©2006 Maytag Services

Page 11

General Information

Troubleshooting Guide is located inside the

Control Console, see Control Console Access/

Facia Removal Procedure.

©2006 Maytag Services 16026315 9

Page 12

Troubleshooting Procedures

Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

!

WARNING

T o avoid risk of electrical shock, personal injury or death; disconnect power and shut off gas to unit before servicing,

unless testing requires power.

Will not start or run:

• All wires are hooked up to their corresponding terminals.

•

Dryer is plugged in.

• Blown fuse or circuit breaker.

• Door switch functional...door closed. Check for error code 3

(See Table for code definition).

• Start/Pause rotary selector dial functional.

• Control Board operational.

• Drive motor functional.

• Check motor winding resistance.

Motor runs/ tumbler will not turn:

• Belt off or broken/damaged.

Idler tension spring too weak or stretched.

•

• Idler pulley jammed or stuck.

Runs a few minutes and then stops:

• Empty dryer.

• Check motor spins freely.

• Lint buildup around drive motor.

• Low voltage present.

• Blower impeller blocked in blower housing.

• Drive motor - start switch contacts stuck closed.

Improper drying/clothes wrinkled/ rough texture/long dry

time:

• Lint filter is not clean.

Restriction in exhaust.

•

• Outside exhaust hood damper door stuck closed.

• Exhaust too long, too many elbows, flex ductwork installed.

• Poor intake air available for the dryer.

• Incorrect tumbler speed. Tumbler belt slipping.

• Blower impeller bound; check for foreign material in blower

area.

• Customer overloading dryer.

• Check clothing labels for fabric content and cycle selected.

• Clothes too wet due to insufficient spin out by washer.

Troubleshooting the electronic control circuit:

• Check for miswiring of the electrical connector at the electronic

control board.

Will Not Shut Off

• Check dryer heat setting (wet clothes on air fluff will run an

extended period of time).

• Check Membrane Pad.

• Check Electronic Control Board.

• Short in sensor circuit.

• Ensure timer motor is getting 120V with no load or in cool down.

• Check thermostat.

Noisy and/Or Vibration

• Thumping Check for loose tumbler baffle, rear tumbler roller(s)

worn or misaligned, out-of-round tumbler or high weld seam on

tumbler.

• Ticking Check for loose wire harness or object caught in

blower wheel area.

• Scraping Check for front or rear bulkhead felt seal out of

position or worn tumbler front bearings.

• Roaring Check for blower wheel rubbing on blower housing or

bad motor bearings.

• Popping or squealing sound. Check for a sticky or frayed

belt.

Blows fuses or trips circuit breaker —

• The amperage readings are at 240 volts. One line will be 24 amps

and the other line will be 21 amps. The neutral line will be at 3

amps. If the above amperages are not present, then the house

wiring, fuse box or circuit breaker should be suspect.

• Shorted heating element to housing.

• Incorrect wiring or a wire shorting to ground.

• Drive motor winding shorting to ground.

Blows fuses or trips circuit breaker —

• If igniter is not glowing, check for 120 V at igniter.

• Igniter harness may be loose and shorted to base.

• Incorrect wiring or a wire shorted to ground.

• Drive motor winding shorting to ground.

Will Not Dry —

Will not heat (motor runs):

• Check dryer heat setting.

• Open heating element.

• Hi-Limit trips easily or is open.

• Regulating thermostat trips easily or is open.

• Check Thermistor.

Will Not Dry —

Poor Gas Ignition

When the dryer is operated on a heat setting, the igniter should

be energized and burner shall fire within 45 seconds at 120

VAC. The failure of a component in this system will usually be

indicated by one of three symptoms:

1) The igniter does not glow. If the igniter does not heat up,

remove power and using an ohmmeter, check the following:

• Open flame sensor.

• Open igniter.

• Shorted booster coil.

• Open wiring.

• Bad motor switch (Neutral supply).

• No power from control ( L1 supply).

2) Igniter glows - No gas ignition. If the igniter heats up but

the main burner flame is not ignited, remove power and using an

ohmmeter, check the following:

• Open secondary coil.

• Open holding coil.

• Open wire harness.

• Stuck flame sensor (Stuck closed).

• Check:

3) The gas is ignited but the flame goes out. If a normal

ignition takes place and after a short while the flame goes out,

check for the following:

• Radiant sensor contacts opening prematurely.

• Weak gas valve coil may open when stressed by higher

• Weak Hi-Limit.

• Poor venting.

• Bad drum seals.

ELECTRIC Models

GAS Models

Holding coil term 1 and 2, 1365 ohms ±25 ohms.

Booster coil term 1 and 3, 560 ohms ±25 ohms.

Secondary coil term 4 and 5, 1220 ohms ±25 ohms.

temperatures.

ELECTRIC Models:

GAS Models:

10 16026315 ©2006 Maytag Services

Page 13

Troubleshooting Procedures

Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

!

WARNING

T o avoid risk of electrical shock, personal injury or death; disconnect power and shut off gas to unit before servicing,

unless testing requires power.

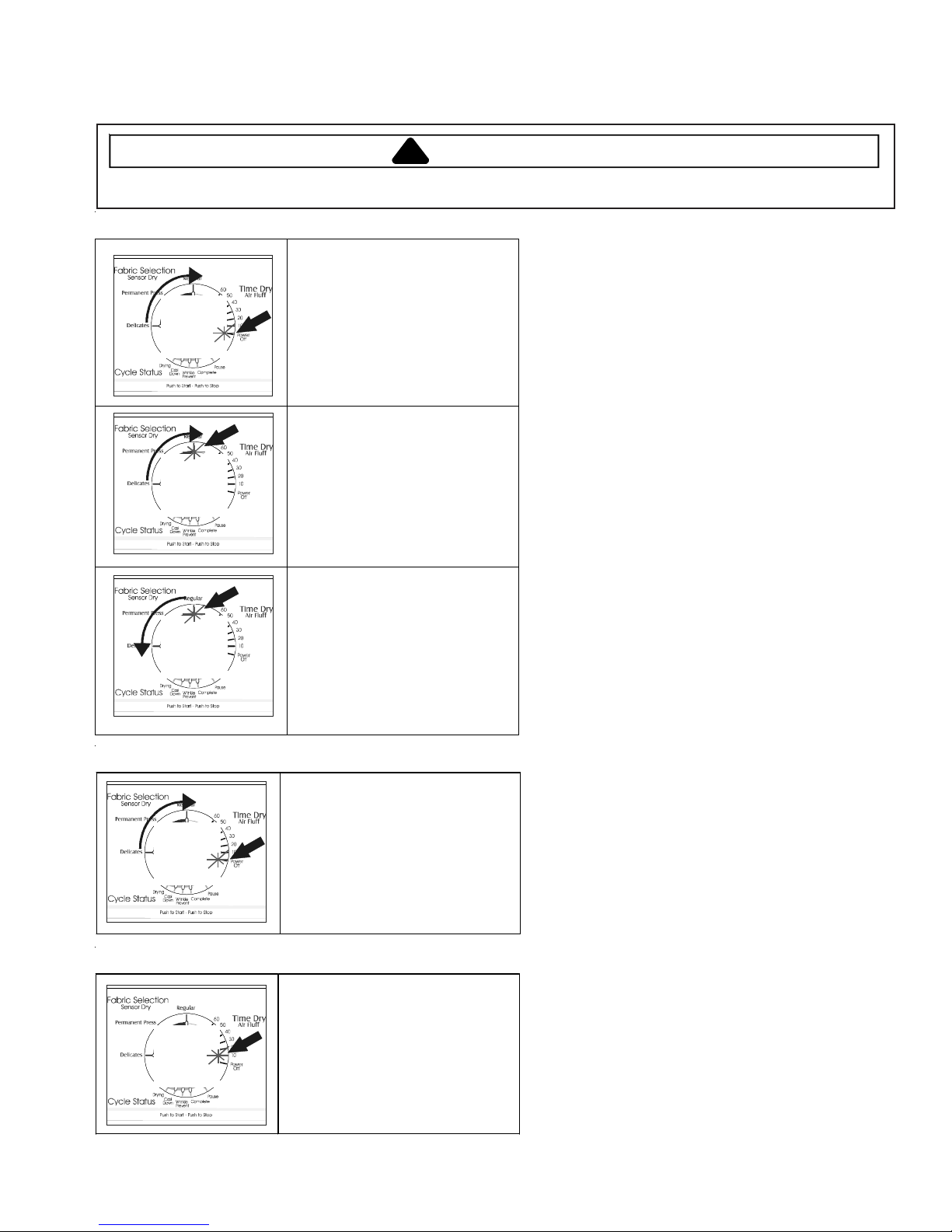

ENTER SERVICE MODE

Rotate the Cycle Selector Knob to the “

position and

press

(All LED’s will be off).

Rotate the Cycle Selector Knob clockwise past

Power Off

“

(LED’s will illuminate as the knob is rotated).

” twice and stop at “

Rotate the Cycle Selector Knob counterclockwise

one revolution back to “Regular” and press knob.

•

Power Off LED will blink. Regular LED will be

illuminated.

•

Model I.D. is displayed by the LED’s around the

bottom of the dial.

•

Model I.D. can be redisplayed while in Service

Mode by setting knob to “

pressing

•

.

Refer to chart for Model I.D.

knob.

Delicate

Power Off

Regular

” and

”

”.

EXIT SERVICE MODE

DISPLAY/CLEAR SERVICE CODES

Rotate Cycle Selection Knob to “

Allow 5 minutes of inactivity.

Disconnect power

Enter Service Mode then set Cycle Selection Knob to

•

•

•

“Time Dry 10”. Press knob.

Time Dry 10 LED will blink if codes other than

power interrupt are pres ent.

Press knob to view codes. Press once for each

code. Codes are displayed newest to oldest.

Machine beeps three times aft er last service code is

displayed.

To clear codes display a code then

Cycle Selection Knob until machine beeps twice.

Time Dry 10 LED stops blink ing.

• Refer to chart for Service Codes.

knob.

or

or

Power Off

press

” and

and

press

hold

©2006 Maytag Services 16026315 11

Page 14

Troubleshooting Procedures

Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

!

WARNING

T o avoid risk of electrical shock, personal injury or death; disconnect power and shut off gas to unit before servicing,

unless testing requires power.

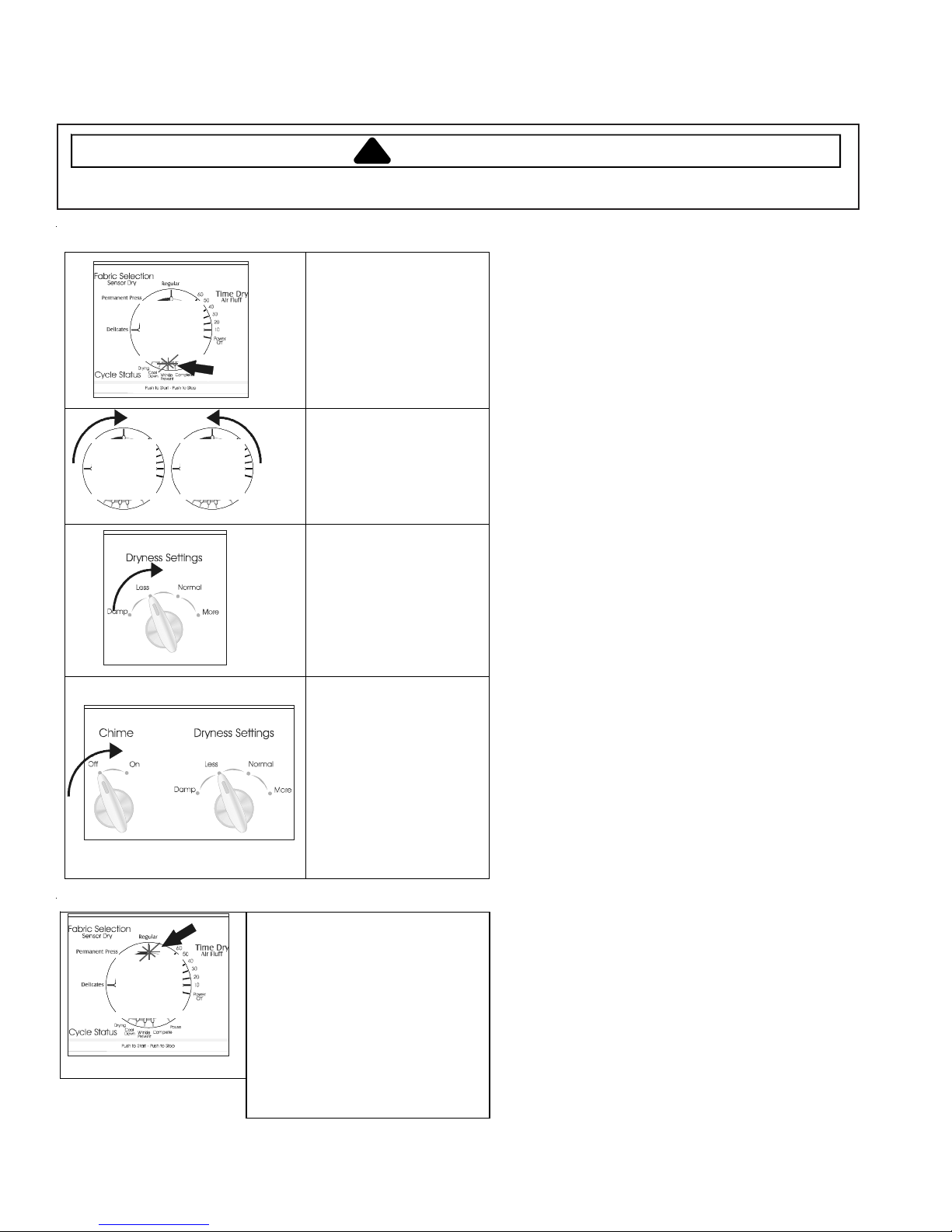

CONSOLE SWITCH TEST

Enter Service Mode then set Cycle

SERVICE CYCLE

X

Selection Knob to “Wrinkle Prevent” and

•

Power Off LED blinks.

•

Pause and Wrinkle Prevent LED’s are

illuminated.

Rotate th e Cycle Selec tion Knob clockwise

for ascending, and counterclockwise for

decending test mode. Rotate 32 clicks in

the same direction to complete the test.

Press

the test for the rotary switches. The test

begins with the rotary switch imediately to

the left of the Cycle Se lection Knob .

Rotate the switch in either direction. The

LED’s illuminate around the bottom of the

Cycle Selection Knob for each switch

NOTE:

Press the Cycle Se lection Kno b. T he test

continues with the switch immediately to

the left of the previous switch tested.

Repeat rotating the switch and monitoring

the LED’s around the bottom of the Cycle

Selection Knob. Continue

Cycle Selection Knob for each switch

tested right to left untill all rotary switches

•

press

knob.

the Cycle Selection Knob to activate

position.

Any attempt to move a knob or

After the last rotary s witch is tested the

next time the Cycle Se lection Knob is

pressed

rocker switches. Continue

the Cycle Selection Knob and testing

switches until the last switch is tested.

When all switches have been tested

Complete

the “

switch other than the one being

tested results in a chirp sound.

pressing

the

are tested.

the test will continue with the

” LED will illuminate.

pressing

Enter Service Mode then set Cycle Selection Knob to

•

•

• Press

•

•

NOTE:

“Regular” and press knob.

Cool Down LED illuminates. Motor on.

Press

knob Cool Down and Wrinkle Prevent LED’s

illuminate. Motor/Heater on.

knob Cool Down LED illuminates. Motor on.

Press knob Complete LED illuminates. Cycle

Complete.

Press

knob Exit back to Service Mode.

Press knob until Pause LED begins blinking to

pause cycle.

12 16026315 ©2006 Maytag Services

Page 15

Troubleshooting Procedures

Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

!

T o avoid risk of electrical shock, personal injury or death; disconnect power and shut off gas to unit before servicing,

unless testing requires power.

WARNING

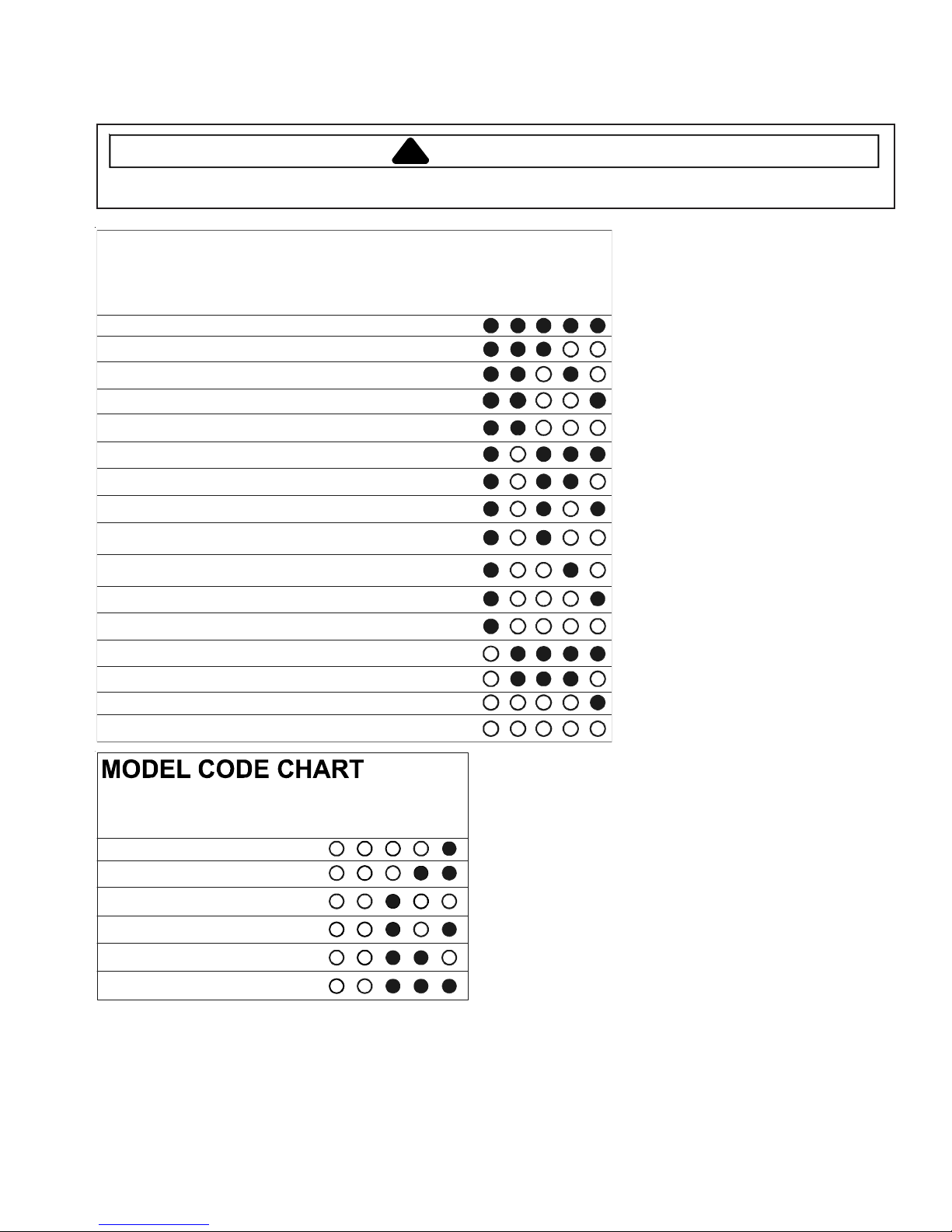

DIAGNOSTIC CODE CHART

Service Code Description

Model ID Unknown, Default used 31

Rotary Switch 3 left of encoder failed

Rotary Switch 2 left of encoder failed at startup

Rotary Switch 1 left of encoder failed at startup 25

Incorrect rotary switch position seen

Dryness sensor bar possibly shorted

Dryness sensor bar possibly open

Selected dryer temperature not reached

Dryer over temp without shutdown 20

Motor thermal protector opened more than 5

times during cycle

Thermistor pos si ble short

Thermistor pos si ble ope n

Thermistor out of range

Heater on and drum temp no t inc reas ing

Power failure

No code

at startup

Service

Code

28

26

24

23

22

21

18

17

16

15

14

0

Wrinkle

Drying

Prevent

Cool Down

Complete

Pause

Model Numbers

MDE/GT446

MDE/G4657

MDE/G4658, MDE/G4806

MDE/G508D

MDE/G5806

NDE/G8805

©2006 Maytag Services 16026315 13

Drying

Wrinkle

Cool Down

Prevent

ete

Pause

Compl

Page 16

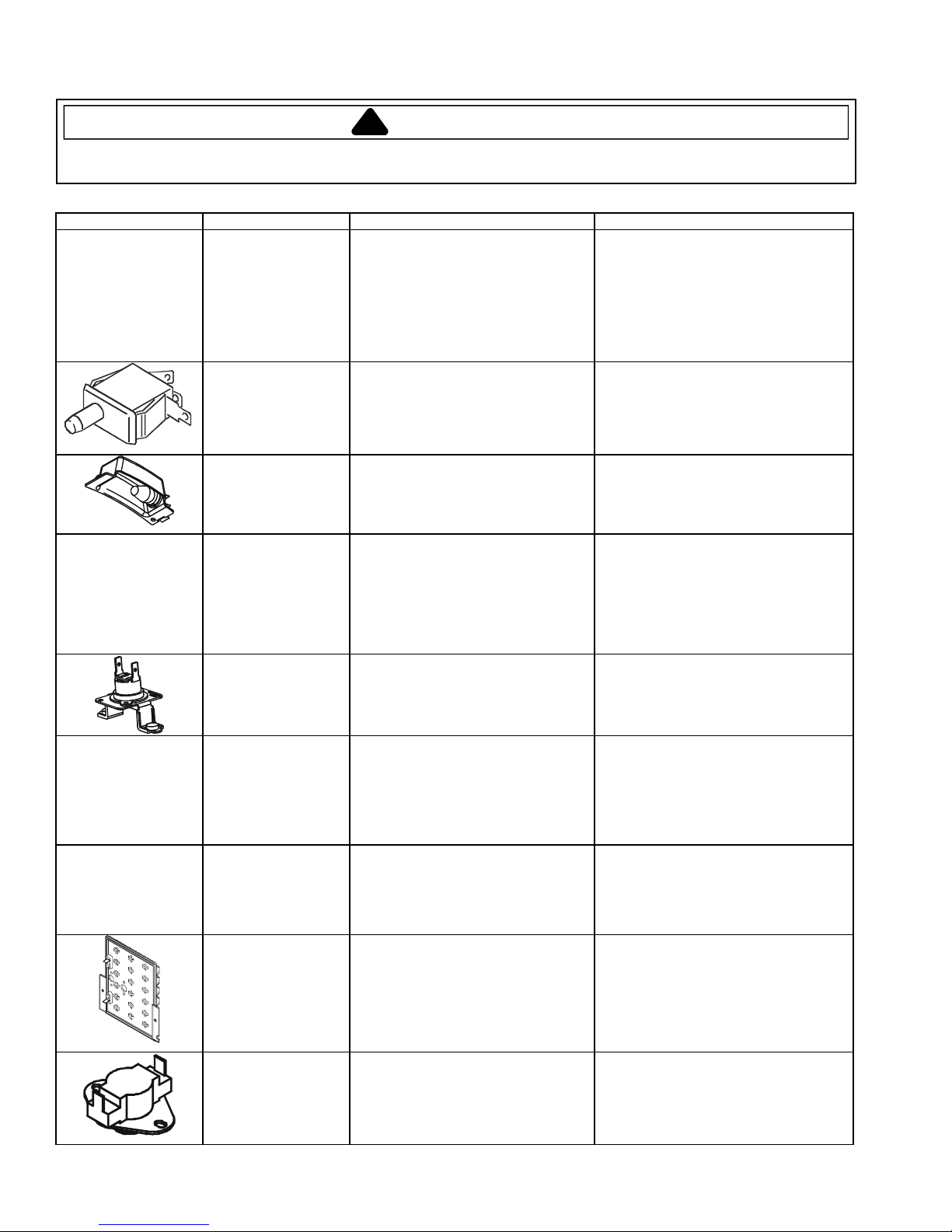

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and shut off gas to unit before servicing,

unless testing requires power.

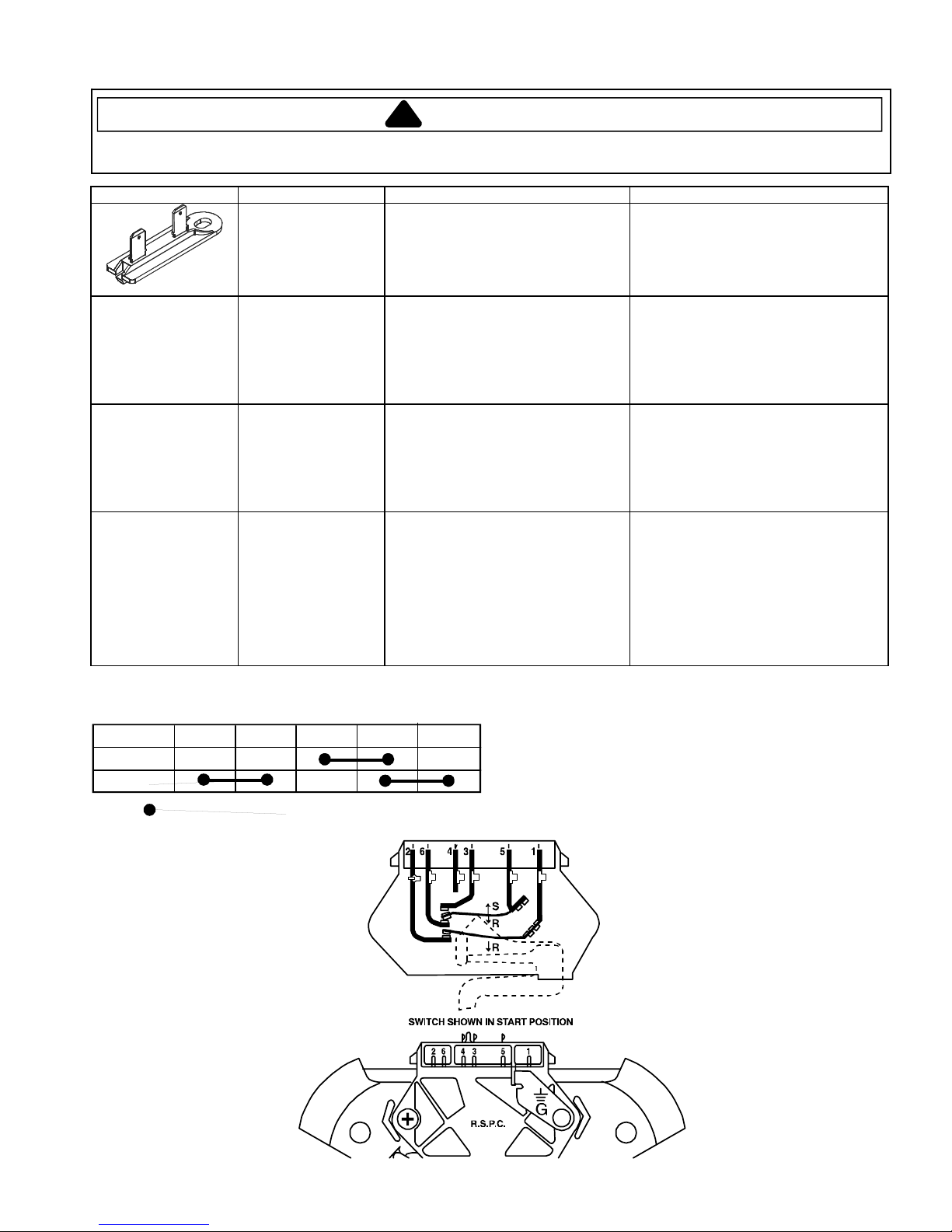

Illustration Component Test Procedure Results

Thermistor

Unplug harness connector and test

from wire insert ion side.

Pin #1 PK and Pin #11 PK of PS5.......

10000 ohms @ 77° F (25° C)

Door Switch Unplug connectors and t est switch

Light Unplug connectors and test switch

Motor

Thermal Fuse

Hi Limit Thermostat

terminals.

Door open terminals............................

Door closed terminals..........................

terminals.

Check across terminals.......................

Unplug harness connector and test

motor circuits.

Pin #9 GY and Pin #9 Red (W indings).

Unplug connectors and test

Thermostat terminals.

Check across terminals.......................

Unplug connectors and test

Thermostat terminals.

Check across terminals.......................

Infinity

Less than 1 ohm

80 to 100 ohms

2 ohms

Less than 1 ohm

Less than 1 ohms

Thermal Cut Off Unplug connectors and test

Thermostat terminals.

Check across terminals.......................

Heater Element Unplug connectors and t est Heater

terminals.............................................. 10 ohms

Less than 1 ohm

Cycling Thermostat

146 °F

14 16026315 ©2006 Maytag Services

Unplug connectors and test

Thermostat terminals...........................

Less than 1 ohm

Page 17

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and shut off gas to unit before servicing,

unless testing requires power.

Illustration Component Test Procedure Results

Sensor Bars Unplug harness connector and test

Radiant Sensor Unplug connectors and test sensor

TH2 Safety

Thermostat

from wire insert ion side. Short sensor

bar.

Pin #3 BU to Pin # 7 BU of PS5...........

terminals..............................................

Unplug connectors and test

Thermostat terminals........................... Less than 1 ohm

Less than 1 ohm

Closed

Gas Valve Unplug connectors and test valve

terminals.

Check across terminals #1 and #3

(Booster Coil)......................................

Check across terminals #1 and #2

(Holding Coil).......................................

Check across terminals #2 and #3

(Both coils in series)............................

Check across terminals #4 and #5

(Secondary Coil)..................................

550 ohms

1350 ohms

1900 ohms

1300 ohms

Motor Contacts

Function 1M 2M 3M 5M 6 M

Start

Run

= Contact closed

Gas Valve

Centrifugal Switch (Motor)

123

45

©2006 Maytag Services 16026315 15

Page 18

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

Control Console Access / Facia Removal

1. Disconnect power supply to unit.

2. Remove Control Knobs and Cycle Selector Knob.

3. Remove three screws from Console top.

NOTE: W ear an Anti-St atic Wrist S trap and ground

yourself before working with Electronic Control

Boards. Always handle boards by the edge and don’t

touch discreet components.

3. Remove wiring harness connectors from PC Board.

4. Depress the locking tab on the PCB.

NOTE: Be sure to protect the shafts on the front of the

Console when tipping.

4. Tip the Console forward to access the wiring harness

and PC Board.

NOTE: W ear an Anti-St atic Wrist S trap and ground

yourself before working with Electronic Control

Boards. Always handle boards by the edge and don’t

touch discreet components.

5. Depress locking tabs on Facia to remove and replace.

PC Board Removal

1. Disconnect power supply to unit.

2. Access Control Console, see “Control Console

Access / Facia Removal” procedure.

16 16026315 ©2006 Maytag Services

5. Remove the PCB.

Page 19

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

Cycle Selector Knob (CSK) Removal

1. Disconnect power supply to unit.

2. Access Control Console, see “Control Console

Access / Facia Removal” procedure.

3. Remove PC Board.

4. Lift locking tab on CSK and rotate switch to remove.

Switch Removal

1. Disconnect power supply to unit.

2. Access Control Console, see “Control Console

Access / Facia Removal” procedure.

3. Remove ribbon connectors to switch.

4. Lift locking tab on switch and rotate to remove.

T op Cover / Door Switch / Front Panel /

Gasket Removal

1. Disconnect power supply to unit.

2. Use a plastic putty knife to depress the locking clip

between the T op Cover and Front Panel.

3. Disconnect wiring from the Door Switch.

©2006 Maytag Services 16026315 17

4. Depress the locking tabs on switch side and remove

through the front.

Page 20

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

5. Remove two screws, 1 each side, from the back flange

of the Front Panel.

6. Tip Front Panel back and remove. Rotate Front Panel

to the back side and remove gasket.

Door Reversal / Disassembly

1. Disconnect power supply to unit.

2. Remove four screws on Door Hinge.

18 16026315 ©2006 Maytag Services

3. Remove hole covers opposite hinge side and install

them in the new location.

Page 21

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

4. T o switch Door Hinge side, remove screws around the

perimeter of the Door Panel. Rotate Door Panel 180

degrees and move Door Strike to opposite side of

Door. Reinst all screws. Reinstall Door . Continue to

next step for complete Door disassembly .

5. After Door Panel screws are removed the Door Gasket

can be removed from the Inner Door Panel.

Light Removal

1. Disconnect power supply to unit.

2. Remove T op Cover , see “Top Cover / Door Switch /

Front Panel / Gasket Removal” procedure steps 1 - 2.

3. Remove Lens screw.

4. Depress locking tab on Light Socket and remove

through light cavity .

©2006 Maytag Services 16026315 19

Page 22

Disassembly Procedures

!

WARNING

Motor/Blower/Thermistor/Thermostat

Removal

1. Disconnect power supply to unit.

2. Remove T op Cover.

3. Remove Front Panel.

4. Disconnect wiring from Moisture Sensor.

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

6. T o remove Thermistor or Thermostat, disconnect wiring

from component(s) and remove retaining screws.

5. Remove three screws inside drum retaining Blower

Duct.

7. Remove nine screws retaining Blower Cover panel.

20 16026315 ©2006 Maytag Services

Page 23

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

8. Remove Blower Cover Panel.

9. Disconnect Motor Harness connector from Motor.

10.Rotate Blower Assembly as shown to remove from

dryer.

1 1.Remove Blower Wheel by placing a wrench on the rear

of the Motor shaft and the nut on the Blower Wheel.

Rotate counterclockwise to loosen.

12.Remove three screws from Blower Scroll.

©2006 Maytag Services 16026315 21

13.Remove Motor locking collar front and back to remove

Motor.

Page 24

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

Drum Removal / Roller / Glide Access

1. Disconnect power supply to unit.

2. Remove T op Cover and Front Panel, see “Top Cover /

Door Switch / Front Panel / Gasket Removal”

procedure.

3. Remove wires from light, see “Light Removal”

procedure steps 3 - 4.

4. Remove four screws on Front Bulkhead.

5. Remove belt from Idler Pulley.

6. Grasp the Drum with one hand and the belt with the

other. Lif t the Drum and slide out the front. Carefully

spread the cabinet as needed to gain additional

clearance.

7. Rear Rollers and Glides can be serviced as needed.

22 16026315 ©2006 Maytag Services

Page 25

Disassembly Procedures

!

WARNING

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

Heater Removal

1. Disconnect power supply to unit.

2. Remove T op Cover and Front Panel, see “Top Cover /

Door Switch / Front Panel / Gasket Removal”

procedure.

3. Remove Belt from Idler Pulley .

4. Remove Drum.

5. Remove two screws securing Heater Assembly to rear

bulkhead.

Drum Baffle Removal

1. Disconnect power supply to unit.

2. Remove T op Cover , see “Top Cover / Door Switch /

Front Panel / Gasket Removal” procedure.

3. Remove two screws retaining Drum Baffle.

6. Disconnect wiring, drop Heater Assembly down and

rotate out to remove.

©2006 Maytag Services 16026315 23

Page 26

Disassembly Procedures

!

WARNING

!

WARNING

To avoid risk of personal injury or death; shut off gas

supply to unit before servicing Burner Assembly .

Gas Model Disassembly

Igniter Removal

1. Disconnect power supply to unit.

2. Remove T op Cover.

3. Remove Console.

4. Remove Front Panel.

5. Loosen the single screw attaching the igniter to the

Burner Assembly . Slide the Igniter back and remove.

T o avoid risk of electrical shock, personal injury or death;

disconnect power to unit and shut off gas supply before

performing any disassembly procedure.

NOTE: The Igniter Bar is fragile. Be careful not to

damage Igniter when removing Burner Assembly.

Burner Removal

1. Disconnect power supply to unit.

2. Shut off gas supply .

3. Disconnect incoming gas line to unit.

4. Remove two screws securing burner to bracket.

NOTE: The Igniter Bar is fragile. Be careful not to

damage Igniter when removing Burner Assembly.

5. Remove the two screws attaching the housing to the

burner bracket. The screws are recessed from view .

6. Slide Burner Assembly from dryer .

24 16026315 ©2006 Maytag Services

Page 27

Appendix A

©2006 Maytag Services 16026315 A–1

Page 28

NOTES

A-2 16026315 ©2006 Maytag Services

Page 29

Power Cord

(3-wire or 4-wire)

and Strain Relief

Installation

®

Screws

(supplied)

Duct Tape

Wrench

Screw

Drivers

Level

Instructions

Electric Dryer

Keep instructions for future reference.

Be sure manual stays with dryer.

Questions?

See the User’s Guide or

call Maytag Appliances

Sales Company

1-800-688-9900 USA

1-800-688-2002

Canada

1-800-688-2080

TTY USA Only

REMOVE PARTS

AND CLEAN

1

Part No. 40136301

Printed in U.S.A. 11/01

©2006 Maytag Services 16026315 A-3

DRYER DRUM

Wipe drum with clean rag and soap

diluted in warm water to remove

any oil used in manufacturing. Make

a paste of laundry detergent and

clean drum if necessary.

To reverse the direction that door

opens, see the User’s Guide.

You'll Need a Few Things Before You Begin

Optional Kits

Kits are available at extra cost

through your Maytag dealer or

Maytag Customer Assistance at

1-800-688-9900 USA

1-800-688-2002 Canada

1-800-688-2080 TTY USA Only

Directional Exhaust Kit

DK1 Sales Accessory (Directional

Exhaust Kit #528P3).

Flexible Metal Vent Kit

Exhausting the dryer in hard-toreach locations can be accomplished by installing Kit # 521P3.

Page 30

CONNECT DRYER

Flexible Foil

4" (10,16 cm)

4" (10,16 cm)

2-1/2" (6,35 cm)

TO EXHAUST

2

SYSTEM

Secure all joints with clamps or duct

tape. DO NOT use sheet metal

screws or other fastening means

which extend into the duct to attach

exhaust pipe joints. They could

catch lint and reduce the efficiency

of the exhaust system.

IMPORTANT: Keep exhaust duct

as short as possible.

Be sure old ducts are clean before

installing your new dryer.

To prevent backdraft when dryer is

not in operation, outer end of

exhaust pipe must have a weather

hood with hinged dampers (obtain

locally).

Weather hood should be installed at

least 12" (30.5 cm) above the

ground. Higher clearances may be

necessary in areas where heavy

snowfall can occur.

No extra system length consideration is necessary when exhausting

through the roof. Use MAXIMUM

EXHAUST LENGTH table to

calculate system length. Use a roof

cap that provides air flow equal to

weather hood.

Exhaust Directions

Dryer can be exhausted to the outdoors through the back, left, right or

bottom of the dryer.

Dryer is shipped from factory ready

for rear exhaust. No kits required.

To exhaust dryer through sides or

bottom, install a DK1 Sales

Accessory (Directional Exhaust Kit

528P3). Available as optional equipment at extra cost.

Exhaust System Materials

Exhaust duct must be four inches

(10.2 cm) in diameter without

obstructions. Rigid metal duct is

recommended. Non-combustible

semi-rigid flexible metal duct is

acceptable.

DO NOT use plastic pipe, foil pipe,

or flexible plastic pipe, because it

contributes to poor drying performance and collects lint, which can

lead to a fire hazard. To identify

flexible foil or plastic duct, pinch the

coils of the duct between your fingers. If the coils can be brought

together, do not use the duct.

Rigid Metal Semirigid Metal

Use

Do Not Use

Maximum Exhaust Length

Rigid Metal Duct

Number of Weather Hood Weather Hood

90° Elbows 4-inch Opening 2

0 44 feet (13.4 m) 34 feet (10.4 m)

1 34 feet (10.4 m) 26 feet (7.9 m)

2 26 feet (7.9 m) 20 feet (6.1 m)

3 20 feet (6.1 m) 14 feet (4.3 m)

Flexible Metal Duct

Number of Weather Hood Weather Hood

90° Elbows 4-inch Opening 2

0 24 feet (7.3 m) 20 feet (6.1 m)

1 20 feet (6.1 m) 16 feet (4.9 m)

2 16 feet (4.9 m) 12 feet (3.7 m)

3 12 feet (3.7 m) 8 feet (2.4 m)

Recommended Weather Hood

1

-inch Opening

⁄

2

1

⁄

2

-inch Opening

Recommended for

Short Runs Only

Plastic

A-4 16025315 ©2006 Maytag Services

2

Page 31

3

Access

cover

Strain relief

(not supplied with dryer)

Dryer

Base

Level

Leveling

Leg

"L1"

"L2"

Black

White

Neutral

Ground

screw

Red

"L2"

Ground

Wire

Black

White

"L1"

Neutral

Ground

screw

Green

Red

CONNECT

ELECTRICAL

CORD

3-wire Cord Installed 4-wire Cord Installed

3-wire or 4-wire Plug Connection

Four-wire cord is required for mobile

homes or where codes do not permit grounding through neutral.

1. Remove access cover from rear

of dryer.

2. Use a strain relief and insert end

of power cord through power

supply hole.

3. Use the three screws from envelope located in the drum to

attach the remaining power cord

wires to the terminal block as

follows:

• Red wire to “L1” terminal.

• Black wire to “L2” terminal.

• White wire to Neutral terminal.

• 4-wire Plug Only—Remove

ground screw and detach

ground wire from bulkhead.

Attach power cord ground

(green) wire to rear bulkhead

using ground screw. Attach

free ground wire, previously

attached with ground screw,

with white wire to the neutral

(center) terminal on the terminal block.

4. Tighten all screws and reinstall

access cover removed in step 1.

POSITION AND

LEVEL DRYER

4

Place dryer in position, adjust all

legs (4) until dryer is level side to

side and front to back.

©2006 Maytag Services 16026315 A-5

3

Page 32

Important Safety Information

About Ground Wires

In the event of an electrical short

circuit, a ground wire reduces the

risk of electric shock by providing

an escape wire for the electric

current.

Standard accepted color coding for

ground wires is green or green

with a yellow stripe.

Grounding wires and wires colored

like grounding wires are NOT

used as current carrying conductors.

to be

WARNING

To reduce the risk of fire, the

dryer MUST be exhausted to

the outdoors. DO NOT exhaust

dryer air into a window well,

gas vent, chimney or enclosed,

unventilated area, such as an

attic, wall, ceiling, crawl space

under a building or concealed

space of a building.

WARNING

To reduce the risk of fire, DO

NOT use plastic pipe, foil pipe,

or flexible plastic pipe to exhaust

the dryer. Never install flexible

duct in concealed spaces, such

as a wall or ceiling.

Grounding Instructions

This dryer must be connected to a grounded metal, permanent wiring system,

or an equipment-grounding conductor must be run with the circuit conductors

and connected to the equipment-grounding terminal or lead on the dryer.

• Power cord (pigtail) is not supplied with electric dryer. Type of pigtail and

gauge of wire must conform to local codes and instructions.

Method of wiring dryer is optional and subject to local code requirements.

• Connect dryer to power supply with MAXIMUM RATED VOLTAGE listed on

the nameplate.

• Use copper wire only. Shorter than 15' (4.5 m) use 10 A.W.G. Longer than

15' (4.5 m) use 8 A.W.G.

WARNING

To avoid risk of personal injury or death due to electrical shock:

• Observe all local codes and

ordinances.

• Disconnect electrical power to

unit before servicing.

• Ground appliance properly.

• Check with a qualified electrician

if you are not sure this appliance

is properly grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water

pipe if pipe is interrupted by

plastic, non-metallic gaskets or

other insulating (non-conducting)

materials.

• DO NOT modify plug on power

cord. If plug does not fit electrical outlet, have proper outlet

installed by qualified electrician.

• DO NOT have a fuse in the neutral or ground circuit. A fuse in

the neutral or ground circuit

could result in an electrical

shock.

• DO NOT use an extension cord

with this appliance.

• DO NOT use an adapter plug

with this appliance.

• DO NOT pinch power cord.

WARNING

WARNING

To avoid risk of personal injury

or death:

• Do not allow children to play

on or in the appliance. Close

supervision of children is

necessary when the appliance is used near children.

WARNING

To avoid injury or death due to

suffocation, remove door to

dryer compartment before

appliance is removed from

service or discarded.

A-6 16025315 ©2006 Maytag Services

To reduce the risk of fire, electric shock, serious injury or death, all wiring

and grounding must conform with the latest edition of the National Electric

Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is the customer’s responsibility to

have the wiring and fuses checked by a qualified electrician to make sure

your home has adequate electrical power to operate the dryer.

Save These Instructions

4

Page 33

Installation Requirements

Before You Install…

Consider

Location

Electrical Requirements

Exhaust

Description

Use dimensions shown in manual to determine space needed for installation.

Place dryer on a solid floor in an area with an adequate air supply. A closet door

must have a supply air vent of 80 sq. in. (517 sq. cm) minimum.

1

⁄

4

Leveling legs can be adjusted from inside the dryer with a

must rest firmly on the floor so the weight of the dryer is evenly distributed. The

dryer must not rock.

Dryer must not be installed or stored in an area where it will be exposed to water

and/or weather.

Dryer needs a 3- or 4-wire 120/240 volt, 30 amp, 60 hertz, 1 phase electrical supply.

Refer to serial plate for specific requirements. Wiring diagram is located in control

hood.

Use rigid or semi-rigid duct and exhaust the dryer to the outside by the shortest

route possible. Failure to exhaust dryer properly will void warranty.

• Dryer exhaust duct must be secured to the mobile home structure. Dryer exhaust

MUST NOT terminate under the mobile home.

• Exhaust duct must not be connected to any other duct, vent or chimney.

• Venting materials are not supplied with the dryer (obtain locally). Do not use plastic or thin foil flexible ducting.

• Static pressure in the dryer’s exhaust duct should be no greater than .6 inches

(1.5 cm). Check with dryer running and no load. This can be measured with a

manometer placed on the exhaust duct approximately two feet (61 cm) from the

dryer.

For the best exhaust system:

• Locate dryer so exhaust duct is as short as possible.

• Verify old ducts are cleaned before installing new dryer.

• Use 4 inch (10.2 cm) diameter rigid or flexible metal duct.

• Use duct tape on all joints.

• Use as few elbows as possible.

" driver. All four legs

©2006 Maytag Services 16026315 A-7

5

Page 34

Dryer Dimensions and Minimum Clearances

*With leveling legs turned fully into base

23.5"

(59,7 cm)

7.7"

(19,6 cm)

4.0"

(10,2 cm)

4.0"

(10,2 cm)

28"

(71,1 cm)

.4"

(1,1 cm)

15.4"

(39,1 cm)

26.9"

(68,3 cm)

*36" (91,4 cm)

*43" (109,2 cm)

FRONT VIEW

(w/o Closet Door)

12"

(30,5 cm)

0" (0 cm)0" (0 cm)

SIDE VIEW FRONT VIEW

Closet

Door

2" (5,1 cm)

12"

(30,5 cm)

Min.

Outer wall of

enclosure

2" (5,1 cm)

0"

(0 cm)

(Closet Door)

3" (7,6 cm)

Centered air

openings minimum

40 sq. in.

(260 sq. cm) each

3" (7,6 cm)

A-8 16025315 ©2006 Maytag Services

6

Page 35

Stainless Steel

or Hard Pipe

Gas Connector

Teflon Tape or

Joint Compound

Duct Tape

Wrench

Screw

Drivers

Level

Installation

®

Instructions

Gas Dryer

Keep instructions for future reference.

Be sure manual stays with dryer.

Questions?

See the User’s Guide or

call Maytag Appliances

Sales Company

1-800-688-9900 USA

You'll Need a Few Things Before You Begin

REMOVE PARTS

AND CLEAN

1

Part No. 40136401 Printed in U.S.A. 11/01

©2006 Maytag Services 16026315 A-9

DRYER DRUM

Wipe drum with clean rag and soap

diluted in warm water to remove

any oil used in manufacturing. Make

a paste of laundry detergent and

clean drum if necessary.

To reverse the direction that the

door opens, see the User’s Guide.

1-800-688-2002

Canada

1-800-688-2080

TTY USA Only

Optional Kits

Kits are available at extra cost

through your Maytag dealer or

Maytag Customer Assistance at

1-800-688-9900 USA

1-800-688-2002 Canada

1-800-688-2080 TTY USA Only

Directional Exhaust Kit

DK1 Sales Accessory (Directional

Exhaust Kit #528P3).

Flexible Metal Vent Kit

Exhausting the dryer in hard-toreach locations can be accomplished by installing Kit # 521P3.

Manufactured (Mobile) Home

Installation Kit

Manufactured home anchor Kit

#526P3.

Propane Gas Conversion Kit

LPK1 Sales Accessory

(L.P./ Propane Kit # 649P3).

Page 36

CONNECT DRYER

Flexible Foil

4" (10,16 cm)

4" (10,16 cm)

2-1/2" (6,35 cm)

TO EXHAUST

2

SYSTEM

Secure all joints with clamps or duct

tape. DO NOT use sheet metal

screws or other fastening means

which extend into the duct to attach

exhaust pipe joints. They could

catch lint and reduce the efficiency

of the exhaust system.

IMPORTANT: Keep exhaust duct

as short as possible.

Be sure old ducts are clean before

installing your new dryer.

To prevent backdraft when dryer is

not in operation, outer end of

exhaust pipe must have a weather

hood with hinged dampers (obtain

locally).

Weather hood should be installed at

least 12" (30.5 cm) above the

ground. Higher clearances may be

necessary in areas where heavy

snowfall can occur.

No extra system length consideration is necessary when exhausting

through the roof. Use MAXIMUM

EXHAUST LENGTH table to calculate system length. Use a roof cap

that provides air flow equal to

weather hood.

Exhaust Directions

Dryer can be exhausted to the outdoors through the back, right, or

bottom of the dryer. Gas dryers

cannot be vented out the left side

because of the burner housing.

Dryer is shipped from factory ready

for rear exhaust. No kits required.

To exhaust dryer through sides or

bottom, install a DK1 Sales

Accessory (Directional Exhaust Kit

528P3). Available as optional equipment at extra cost.

Exhaust System Materials

Exhaust duct must be four inches

(10.2 cm) in diameter without

obstructions. Rigid metal duct is

recommended. Non-combustible

semirigid flexible metal duct is

acceptable.

DO NOT use plastic pipe, foil pipe,

or flexible plastic pipe, because it

contributes to poor drying performance and collects lint, which can

lead to a fire hazard. To identify

flexible foil or plastic duct, pinch the

coils of the duct between your fingers. If the coils can be brought

together, do not use the duct.

Rigid Metal Semirigid Metal

Use

Do Not Use

Maximum Exhaust Length

Rigid Metal Duct

Number of Weather Hood Weather Hood

90° Elbows 4-inch Opening 2

0 44 feet (13.4 m) 34 feet (10.4 m)

1 34 feet (10.4 m) 26 feet (7.9 m)

2 26 feet (7.9 m) 20 feet (6.1 m)

3 20 feet (6.1 m) 14 feet (4.3 m)

Flexible Metal Duct

Number of Weather Hood Weather Hood

90° Elbows 4-inch Opening 2

0 24 feet (7.3 m) 20 feet (6.1 m)

1 20 feet (6.1 m) 16 feet (4.9 m)

2 16 feet (4.9 m) 12 feet (3.7 m)

3 12 feet (3.7 m) 8 feet (2.4 m)

Recommended Weather Hood

1

⁄

2

-inch Opening

1

⁄

2

-inch Opening

Recommended for

Short Runs Only

Plastic

A-10 16025315 ©2006 Maytag Services

2

Page 37

CONNECT GAS

Dryer

Base

Level

Leveling

Leg

Use new stainless steel flexible connector

only if allowed by local codes (use Design A.G.A. certified connector)

3/8" NPT gas

connection

1/8" NPT pipe plug

(for checking inlet

gas pressure)

Install equipment

shut-off valve

within 6' (1,8 m)

of dryer

.

Black iron pipe

Shorter than 20' (6,1 m) - use 3/8" pipe

Longer than 20' (6,1 m) - use 1/2" pipe

SUPPLY

3

L.P./Propane

DO NOT connect dryer to

L.P./Propane gas service without

converting the gas valve. An LPK1

Sales Accessory L.P./Propane Gas

Conversion Kit 649P3 must be

installed.

Test for Gas Leaks

After final gas connection is made,

turn on manual gas

valve and test all

connections in gas supply piping for

gas leaks. Leak testing of the appliance shall be conducted according

to the manufacturer’s instructions.

1. Place soap suds on connections.

2. If bubbles appear, a leak is present. Shut off gas supply valve.

3. Tighten joint if leak is at factory

fitting.

• If leak is not at factory fitting,

unscrew, apply more joint

compound, and tighten to correct leak.

4. Retest connection for leak after

tightening or adding joint

compound.

• Retest any connections that

were disturbed.

Connect gas supply to dryer using a

new stainless steel flexible connector or hard pipe (check local codes)

according to illustration. Test for

leaks and check burner flame after

gas supply is connected. See

Checking Burner Flame section on

back page.

• Dryer must be connected to type

of gas as shown on nameplate

located in the door recess.

For proper operation at altitudes

above 2,500 feet

The natural gas valve spud orifice

size must be reduced to ensure

complete combustion. See table.

• Use pipe joint compound insoluble on LP (propane) Gas, or

Teflon tape, on all pipe threads.

• Purge air and sediment from gas

supply line before connecting it to

the dryer. Before tightening the

connection, purge remaining air

from gas line to dryer until odor of

gas is detected. This step is

required to prevent gas valve

contamination.

Altitude Orfice Part

Ft. (M) Size # Number

3000 (915) 43 503778

6000 (1830) 44 58719

8000 (2440) 45 503779

9000 (2740) 46 503780

10000 (3050) 47 503781

CONNECT

POWER CORD

4

TO ELECTRICITY

See Installation Requirements

section. Plug dryer into 3-prong

grounded outlet only.

©2006 Maytag Services 16026315 A-11

POSITION AND

LEVEL DRYER

5

Place dryer in position,

adjust all legs (4)

until dryer is level

side to side and

front to back.

3

Page 38

Important Safety Information

About Ground Wires

In the event of an electrical short

circuit, a ground wire reduces the

risk of electric shock by providing

an escape wire for the electric

current.

Standard accepted color coding for

ground wires is green or green

with a yellow stripe.

Grounding wires and wires colored

like grounding wires are NOT

used as current carrying conductors.

to be

WARNING

To reduce the risk of fire, the

dryer MUST be exhausted to

the outdoors. DO NOT exhaust

dryer air into a window well,

gas vent, chimney or enclosed,

unventilated area, such as an

attic, wall, ceiling, crawl space

under a building or concealed

space of a building.

Grounding Instructions

Dryer must be grounded. Dryer is equipped with a cord having a grounding

conductor and a 3-prong grounding plug. The three-prong grounding plug on

the power cord should be plugged directly into a polarized three-slot grounded

receptacle rated 110/120V AC (alternating current) 15 Amps.

WARNING

To avoid risk of personal injury or death due to electrical shock:

• Observe all local codes and

ordinances.

• Disconnect electrical power to

unit before servicing.

• Ground appliance properly.

• Check with a qualified electrician

if you are not sure this appliance

is properly grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water

pipe if pipe is interrupted by

plastic, non-metallic gaskets or

other insulating (non-conducting)

materials.

• DO NOT modify plug on power

cord. If plug does not fit electrical outlet, have proper outlet

installed by qualified electrician.

• DO NOT have a fuse in the neutral or ground circuit. A fuse in

the neutral or ground circuit

could result in an electrical

shock.

• DO NOT use an extension cord

with this appliance.

• DO NOT use an adapter plug

with this appliance.

• DO NOT pinch power cord.

WARNING

To reduce the risk of fire, DO

NOT use plastic pipe, foil pipe,

or flexible plastic pipe to exhaust

the dryer. Never install flexible

duct in concealed spaces, such

as a wall or ceiling.

WARNING

To reduce the risk of fire, electric shock, serious injury or

death, all wiring and grounding

must conform with the latest

edition of the National Electric

Code, ANSI/NFPA 70, or the

Canadian Electrical Code,

CSA C22.1, and such local

regulations as might apply. It is

the customer’s responsibility to

have the wiring and fuses

checked by a qualified electrician to make sure your home

has adequate electrical power

to operate the dryer.

WARNING

To avoid death, personal injury or property damage, from fire or explosion, information in this manual must be followed exactly:

• Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your

building.

– Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Save These Instructions

A-12 16025315 ©2006 Maytag Services

4

Page 39

Installation Requirements

Before You Install…

Consider

Location

Electrical Requirements

Gas

Description

Use dimensions shown in manual to determine space needed for installation.

Place dryer on a solid floor in an area with an adequate air supply. A closet door

must have a supply air vent of 80 sq. in. (517 sq. cm) minimum.

No other fuel burning appliance should be installed in the same closet with the dryer.

Dryer must not be installed or stored in an area where it will be exposed to water

and/or weather.

Manufactured (mobile) home installation must conform to the Manufactured

Home Construction and Safety Standards, Title 24 CFR, Part 32-80 or Standard

CAN/CSA-Z240 MH.

Gas dryers must be permanently attached to the floor at the time of installation.

Order No. 526P3 Dryer Installation Kit for a manufactured (mobile) home installation.

Dryer requires 120 volt, 15 amp, 60 Hz power supply and 3-prong grounding plug.

Power cord is approximately 69" long. Do not operate other appliances on the same

circuit when this appliance is operating. Refer to serial plate for specific requirements. Wiring diagram is located in control hood.

Natural Gas Pressure, 1000 Btu/ ft3(37.3 MJ/m3), service must be supplied at 6.5 +

1.5 inch water column pressure. L.P. (propane) Gas Pressure, 2,500 Btu/ ft

3

MJ/m

), service must be supplied at 10 + 1.5 inch water column pressure.

NOTE: The dryer and its appliance main gas valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 psi (3.45 kPa). Dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less than 1/2 psi (3,45 kPa).

When connecting to a gas line, an equipment shutoff valve must be installed within

6' (1.8 m) of the dryer. An 1/8" N.P.T. pipe plug must be installed.

The gas service to a gas dryer must conform with the local codes and ordances or in

the absence of local codes and ordinances, with the latest edition of the National

Fuel Gas Code ANSIZ223.1/NFPA 54 or the CAN/CGA-B149, National Gas

Installation Code. LPK1 Sales Accessory (L.P./Propane Gas Conversion Kit 649P3)

must be installed. DO NOT connect dryer to L.P./Propane Gas Service without

converting the gas valve.

3

(93.1

Exhaust

©2006 Maytag Services 16026315 A-13

Use rigid or semi-rigid duct and exhaust the dryer to the outside by the shortest

route possible. Failure to exhaust dryer properly will void warranty.

• Dryer exhaust duct must be secured to the mobile home structure. Dryer exhaust

MUST NOT terminate under the mobile home.

• Exhaust duct must not be connected to any other duct, vent or chimney.

• Venting materials are not supplied with the dryer (obtain locally). Do not use plastic or thin foil flexible ducting.

• Static pressure in the dryer’s exhaust duct should be no greater than .6 inches (1.5

cm). Check with dryer running and no load. This can be measured with a manometer placed on the exhaust duct approximately two feet (61 cm) from the dryer.

For the best exhaust system:

• Locate dryer so exhaust duct is as short as possible.

• Verify old ducts are cleaned before installing new dryer.

• Use 4 inch (10.2 cm) diameter rigid or flexible metal duct.

• Use duct tape on all joints.

• Use as few elbows as possible.

5

Page 40

Installation Checks and Adjustments

*With leveling legs turned fully into base

23.5"

(59,7 cm)

7.7"

(19,6 cm)

4.0"

(10,2 cm)

4.0"

(10,2 cm)

28"

(71,1 cm)

.4"

(1,1 cm)

15.4"

(39,1 cm)

26.9"

(68,3 cm)

*36" (91,4 cm)

*43" (109,2 cm)

2.8"

(7 cm)

2.3"

(6 cm)

Appliance main

gas valve

Air shutter

lockscrew

Air

shutter

View of burner

with front access

panel removed

FRONT VIEW

(w/o Closet Door)

SIDE VIEW FRONT VIEW

(Closet Door)

Centered air

openings minimum

40 sq. in.

(260 sq. cm) each

Closet

Door

Outer wall of

enclosure

3" (7,6 cm)

3" (7,6 cm)

2" (5,1 cm)

2" (5,1 cm)

0"

(0 cm)

0" (0 cm)0" (0 cm)

12"

(30,5 cm)

Min.

12"

(30,5 cm)

Checking Burner Flame

To view the burner flame, remove the

lower front panel of the dryer.

WARNING

To p revent personal injury or

property damage, front panel

must be in place during normal

operation.

Close the loading door, start the

dryer in a heat setting (refer to User’s

Guide) The dryer will start, ignitor will

glow red, and main burner will ignite.

IMPORTANT: If all air is not purged

out of gas line, gas ignitor may go

off before gas is ignited. If this

happens, after approximately two

minutes ignitor will again attempt

gas ignition.

After the dryer has operated for

approximately 5 minutes, observe

burner flame through lower front

panel. Adjust air shutter to obtain a

soft, uniform blue flame. (A

yellow tipped flame indicates lack of

air. Aharsh, roaring, very blue flame

indicates too much air

lazy,

.)

Adjusting Air Flow to Burner

1. Loosen air shutter lock screw.

2. Turn air shutter to left to get a

luminous yellow-tipped flame,

turn it back slowly to the right to

obtain a steady, soft blue flame.

3. After air shutter is adjusted for

proper flame, tighten air shutter

lock screw securely.

After the dryer has operated for

approximately three minutes,

exhaust air or exhaust pipe should

be warm.

A-14 16025315 ©2006 Maytag Services

6

Page 41

Appendix B

The Use and Care information provided in this service manual is representative of a limited

number of models. Reference the customer’s Use and Care literature included with the

product, order a copy , or consult the manufacturer’s website for the specific model

(www.maytag.com).

©2006 Maytag Services 16026315 B–1

Page 42

B-2 16026315 ©2006 Maytag Services

Page 43

MD-1

Use & Care Guide

Table of Contents

Important Safety

Instructions . . . . . . . . . . . . . . . .1-2

Using the Controls

Auto Dry Models . . . . . . . . . . . . . .3-4

Sensor Models . . . . . . . . . . . . . . . .5-6

Electronic Controls . . . . . . . . . . . .7-9

Operating Tips . . . . . . . . . . . . . . 10

Accessories . . . . . . . . . . . . . . . . 10

Care & Cleaning . . . . . . . . . . . . 11

Form No. A/06/05 Part No. 2202687 www.maytag.com Litho U.S.A. ©2005 Maytag Appliances Sales Co.

Reversing the Door . . . . . . . . . . 12

Dryer Exhaust Tips . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . 14

©2006 Maytag Services 16026315 B-3

Page 44

1

B-4 16026315 ©2006 Maytag Services

Page 45

©2006 Maytag Services 16026315 B-5

2

Page 46

3

B-6 16026315 ©2006 Maytag Services

Page 47

©2006 Maytag Services 16026315 B-7

4

Page 48

5

B-8 16026315 ©2006 Maytag Services

Page 49

©2006 Maytag Services 16026315 B-9

6

Page 50

7

B-10 16026315 ©2006 Maytag Services

Page 51

©2006 Maytag Services 16026315 B-11

8

Page 52

9

B-12 16026315 ©2006 Maytag Services

Page 53

©2006 Maytag Services 16026315 B-13

10

Page 54

11

B-14 16026315 ©2006 Maytag Services

Page 55

©2006 Maytag Services 16026315 B-15

12

Page 56

13

B-16 16026315 ©2006 Maytag Services

Page 57

©2006 Maytag Services 16026315 B-17

14

Page 58

B-18 16026315 ©2006 Maytag Services

Page 59

Dryer

Use & Care Guide

Important Safety Instructions . . . . . . . . 1-2

Using the Controls

Auto Dry Models . . . . . . . . . . . . . . . . . . . . .3-4

Electronic Controls . . . . . . . . . . . . . . . . . . . .5-7