Hoover F5835-900, F5808 Owner’s Manual

SERVICE INSTRUCTIONS

CARPET CLEANING MACHINE

STEAM VAC

Maytag Services

16025867

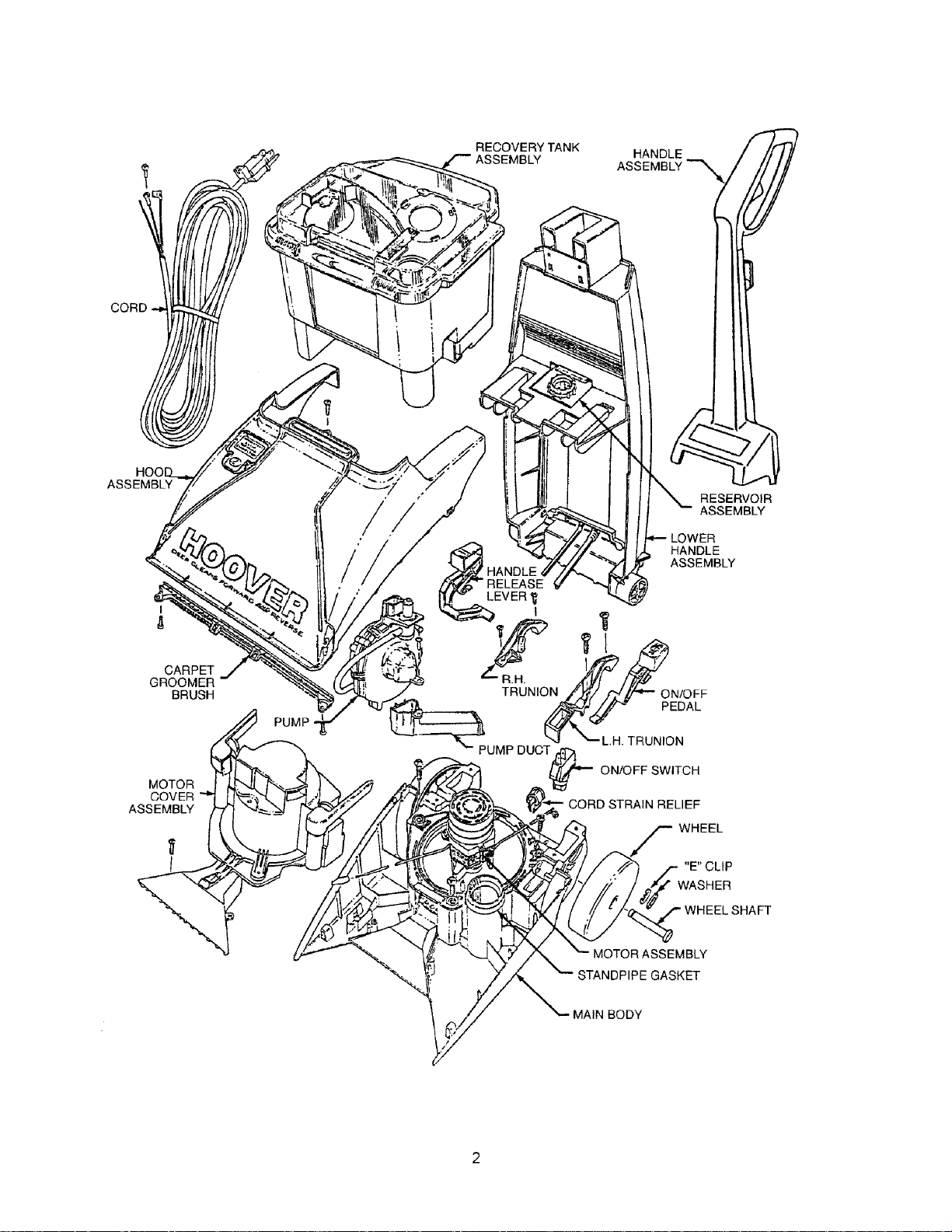

CORD

RECOVERYTANK

HANDLE

ASSEMBLY-'_

ASSEMBLY

GROOMER

MOTOR

COVER

ASSEMBLY

CARPET

BRUSH

!

HANDLE

RELEASE

LEVER '_

PUMP

DUC ./_j,_T,_'_ ON/OFF SWITCH

L.H. TRUNION

RESERVOIR

ASSEMBLY

LOWER

HANDLE

ASSEMBLY

WHEEL

"E" CLIP

WASHER

WHEEL SHAFT

STANDPIPE GASKET

MAIN BODY

1. General

The steam vac is a self contained domestic extractor

designed for deep cleaning of carpet and rugs.

Suction is directed to the floor through the clear

nozzle and up into the recovery tank where the air

and water are separated. A float prevents the

recovery tank from being overfitled.

Initial models incorporate six and seven amp motors.

Top of the line models include a tool kit which allows

the unit to be used for stair or upholstery cleaning.

This instruction deals with the top of the line models.

Instructions that pertain only to low end models will be

noted,

II. Operation

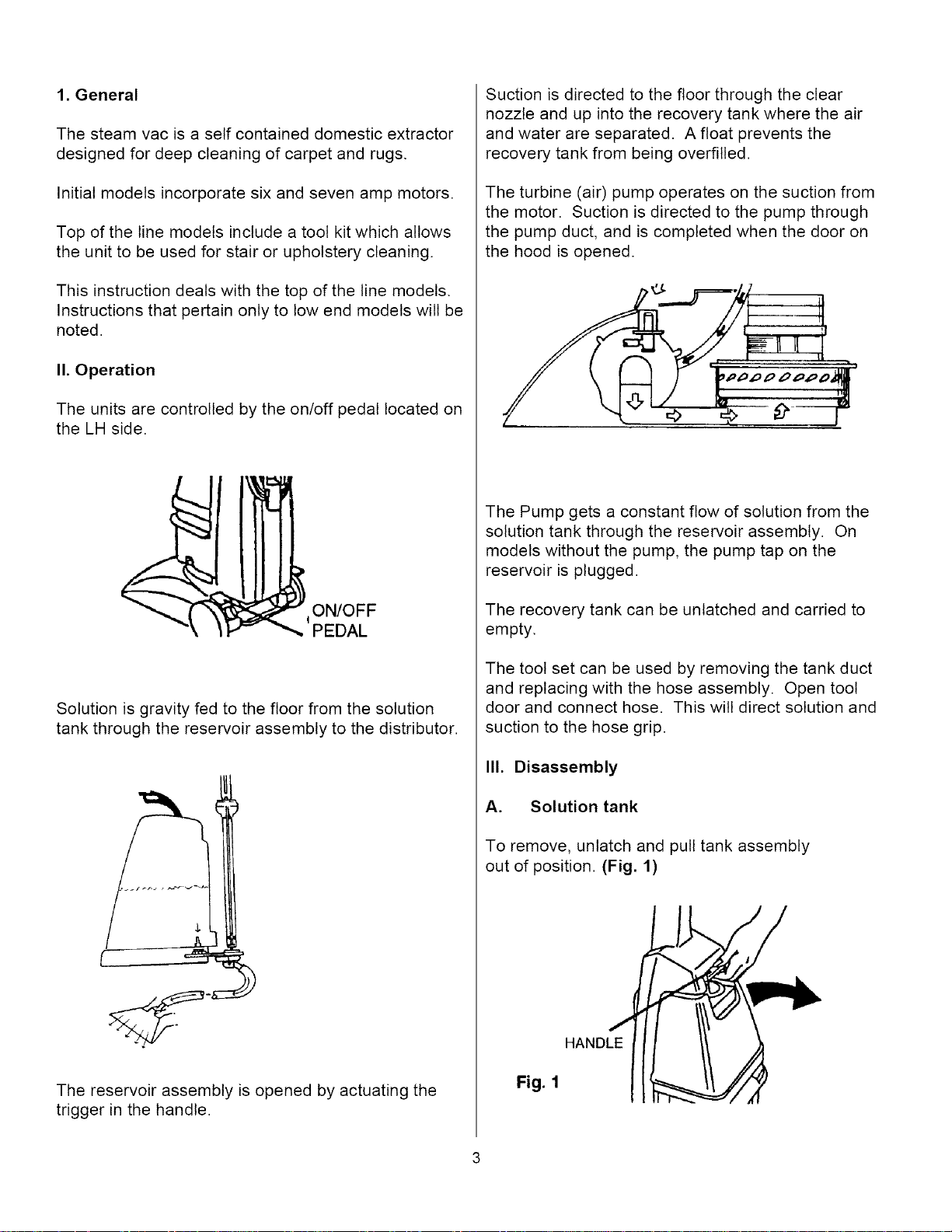

The units are controlled by the on/off pedal located on

the LH side,

ON/OFF

PEDAL

The turbine (air) pump operates on the suction from

the motor. Suction is directed to the pump through

the pump duct, and is completed when the door on

the hood is opened.

The Pump gets a constant flow of solution from the

solution tank through the reservoir assembly. On

models without the pump, the pump tap on the

reservoir is plugged.

The recovery tank can be unlatched and carried to

empty.

Solution is gravity fed to the floor from the solution

tank through the reservoir assembly to the distributor,

The reservoir assembly is opened by actuating the

trigger in the handle.

The toot set can be used by removing the tank duct

and replacing with the hose assembly. Open tool

door and connect hose. This will direct solution and

suction to the hose grip.

III. Disassembly

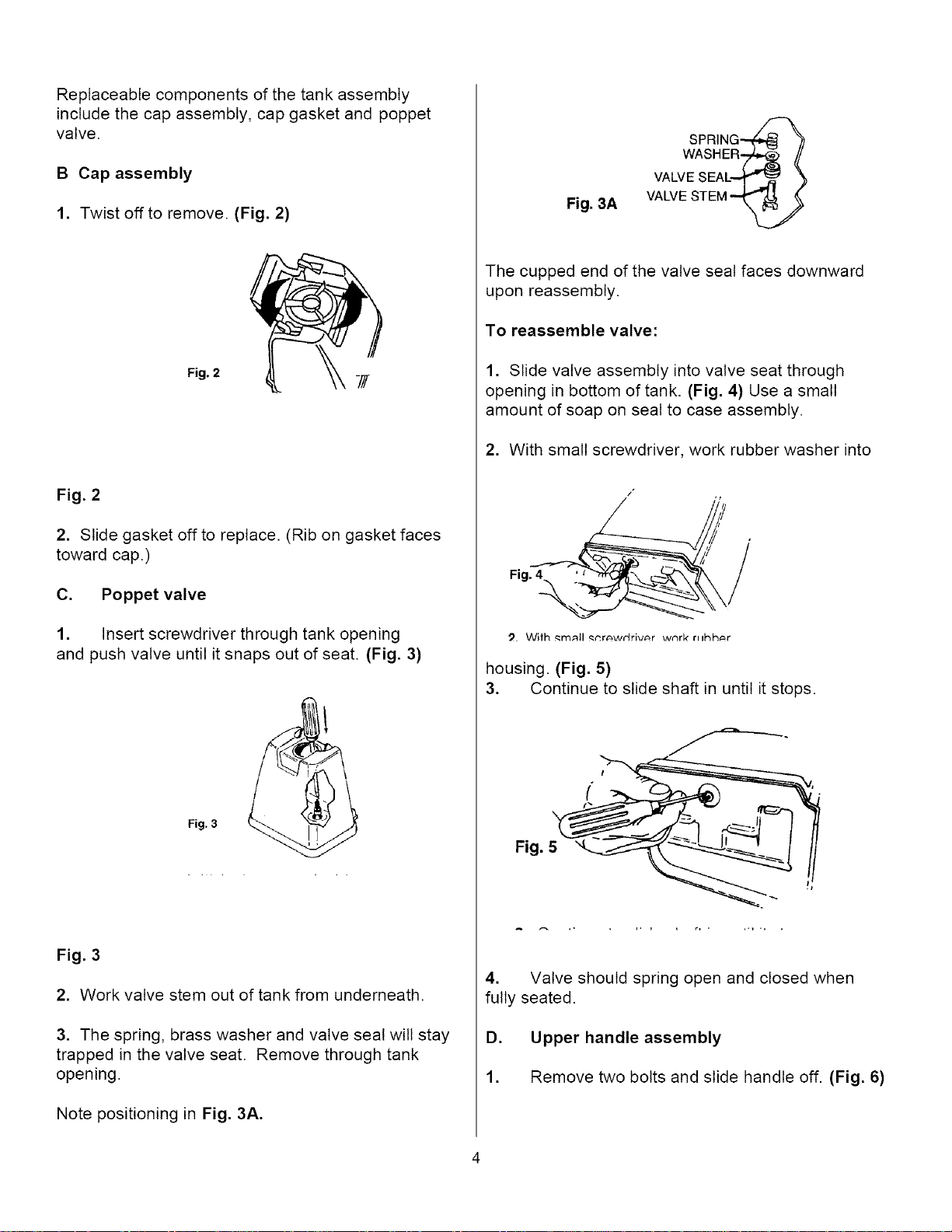

A. Solution tank

To remove, unlatch and pull tank assembly

out of position. (Fig. 1)

HANDLE

Fig. 1

Replaceable components of the tank assembly

include the cap assembly, cap gasket and poppet

valve.

B Cap assembly

1. Twist off to remove. (Fig. 2)

SPRING-._/_

WASHERT_ _'

VALVE SEAL'_t_

Fig. 3A VALVE STEM "'_ ._

The cupped end of the valve seal faces downward

upon reassembly.

To reassemble valve:

Fig. 2

Fig. 2

2. Slide gasket off to replace. (Rib on gasket faces

toward cap.)

C. Poppet valve

1. Insert screwdriver through tank opening

and push valve until it snaps out of seat. (Fig. 3)

Fig. 3

1. Slide valve assembly into valve seat through

opening in bottom of tank. (Fig. 4) Use a small

amount of soap on seal to case assembly.

2. With small screwdriver, work rubber washer into

With £mnll £nr#wttrivnr wnrk rllhh#r

housing. (Fig. 5)

3. Continue to slide shaft in until it stops.

Fig. 5

Fig. 3

2. Work valve stem out of tank from underneath.

3. The spring, brass washer and valve seat will stay

trapped in the valve seat. Remove through tank

opening.

Note positioning in Fig. 3A.

4. Valve should spring open and closed when

fully seated.

D. Upper handle assembly

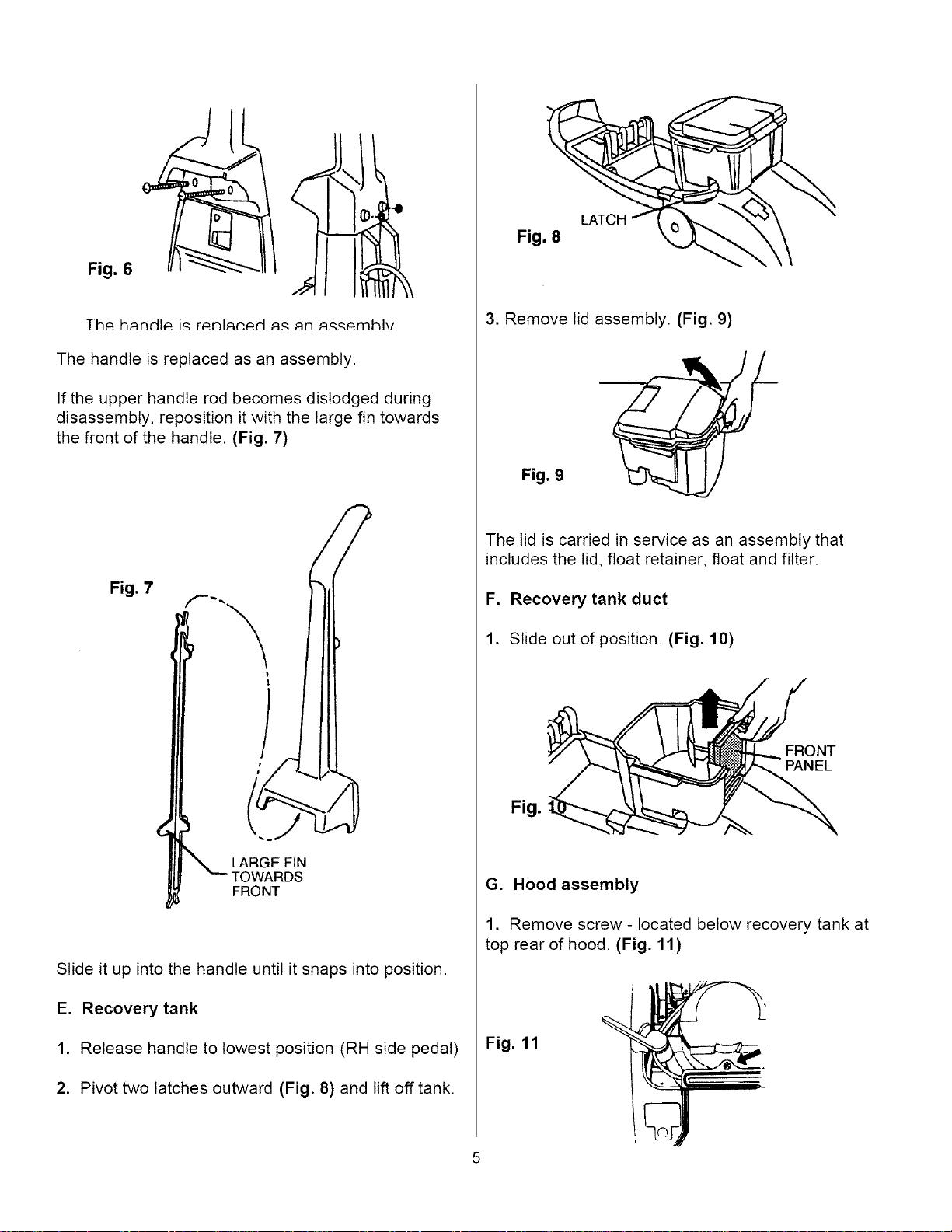

1. Remove two bolts and slide handle off. (Fig. 6)

Fig. 6

LATCH

Fig. 8

The. handle i.qr_.nlaep.d a._ an a._._.mhlv

The handle is replaced as an assembly.

If the upper handle rod becomes dislodged during

disassembly, reposition it with the large fin towards

the front of the handle. (Fig. 7)

Fig. 7

3. Remove lid assembly. (Fig. 9)

The lid is carried in service as an assembly that

includes the lid, float retainer, float and filter.

F. Recovery tank duct

1. Slide out of position. (Fig. 10)

FRONT

PANEL

_ LARGE FIN

TOWARDS

FRONT

Slide it up into the handle until it snaps into position.

E. Recovery tank

1. Release handle to lowest position (RH side pedal)

2. Pivot two latches outward (Fig. 8) and lift off tank.

Fig.

G. Hood assembly

1. Remove screw - located below recovery tank at

top rear of hood. (Fig. 11)

Fig. 11

Loading...

Loading...