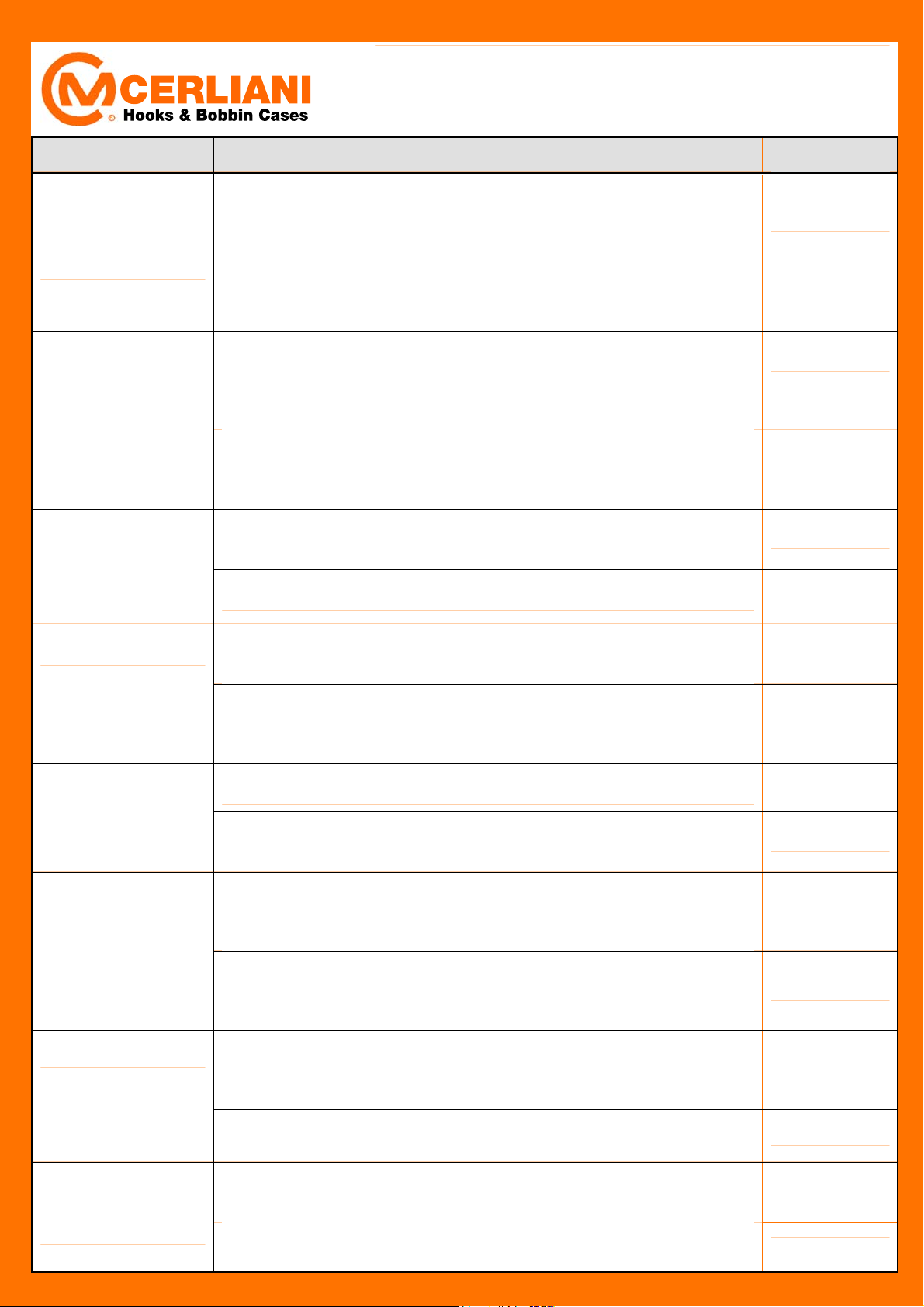

Common sewing problems, their

PROBLEMS CAUSES

- incorrect balance between upper and lower tension - uneven pu lloff of the upper thread - worn upper tension unit - broken or

weakened check spring - bobbin unevenly wound - worn

Uneven stitches

Upper thread

breaking

Lower thread

breaking

bobbincase tension spring - too coarse or unvene thread - incorrect

needle for the thread

- incorrect timing of hook and needle - too little clearance between

base and retaining finger - incorrect timing of base and looper base does not move freely in hook - poor hook lubrication

- incorrect threading of upper thread - upper thread tension too

tight - damaged thread guide - bent or blunt needle - incorrect

needle for the thread - needle hole of needleplate too small - poor

quality thread, too dry or badly stored - needle overheating defective bobbincase latch

- incorrect timing of hook and needle - too little clearance between

base and retaining finger - incorrect timing of base and looper damaged hook point - scratched needle guard on the hook - sharp

edges on feed dog or needle hole

- lower thread tension too tight - bobbincase threaded incorrectly bobbin unevenly wound - damaged or poor quality bobbin damaged bobbincase

- sharp edges or needleplate needle hole - feed dog too sharp

behind the needle

causes and repairs

PERSON

INVOLVED

Operator

Technician

Operator

Technician

Operator

Technician

Skipped stitches

Needle unthreading

at start

Looping underneath

material

Needle breaking

- needle not inserted correctly - damaged or blunt needle - needle

too thin compared to fabric - incorrect needle point for fabric - t oo

elastic or badly wound thread - upper thread incorrectly threaded

- needle bar height wrong - incorrect clearance between needle and

hook point - needle and hook not correctly timed - damaged hook

point - needle hole in needleplate too large - needle hole in feed

dog too large

- too little upper thread coming through the needle - too little

bobbin thread coming out of the bobbincase

- thread trimmer leaving bobbin thread to short - tension

tightening during trimming operation

- lower thread tension too tight - upper thread tension too lose bobbin not running smoothly - upper thread too stiff or too variable

- needle eye too small for thread - pressure or presser foot too

heavy

- hook is not passing the thread easily - incorrect timing of needle

and hook - incorrect timing of base and looper - feed dog timing

too advanced - needleplate or presser foot do not have the correct

thread groove

- incorrect needle for the material - material too thick for the

sewing machine - sewing over buttons, pins, zips etc. - bobbincase

incorrectly inserted - using up the lower thread on machin es with

roller presser foot - needle stop not correctly timed

- feed dog timing retarded - needle striking hook point - needle

guard fitted too far back - needle and hook not correctly timed

Operator

Technician

Operator

Technician

Operator

Technician

Operator

Technician

- starting sewing with too long or uncontrolled upper thread upper thread tension too loose - sewing at the start or end without

Hook jams

material

too little clearance between base and retaining finger - base not

running smoothly in hook - insufficient lubrication

Operator

Technician

Loading...

Loading...