Hood Seafurl 705, Seafurl 705 LD, Seafurl 810 LD, Seafurl 915 LD, Seafurl 810 Installation Manual And Owner's Manual

...

THIS

UNIT

IS

COMPLETF

WICHT

INSTALLAT'ION

AND

OWNEFI'S

AUGUST 1987

MANUAL

MANUAL

ilLH":5XW

\rs

"s

^V

ry

V7'

8"

A

g

,(n-

rf*

s

\

'ab-

h

t"*

v

_.,*.*

c

I

\t

705/810t9L5

READTHISPAGE

To

trouble-free operation

follow

below.

\'

2. Watch

3.If

4.

insure

the

Rinse

1.

fresh

it

don't

,,'-,!tt.

reat tnls unlt

reat tnls unlt

I

I

equipment

the

water.

jams

force

continued

simple

bearings

for

halyard

find out

it!

-

inspect

satisfaction

is necess

it

guidelines

regularly

wrap.

why

like other

llKe any otner

regularly.

it

listed

Look up!

-

and

ary

with

to

v

If

5.

dealer.

any

problem

persists

,

1

call

your

ffire

ftT

Eh

\,

*"GWO

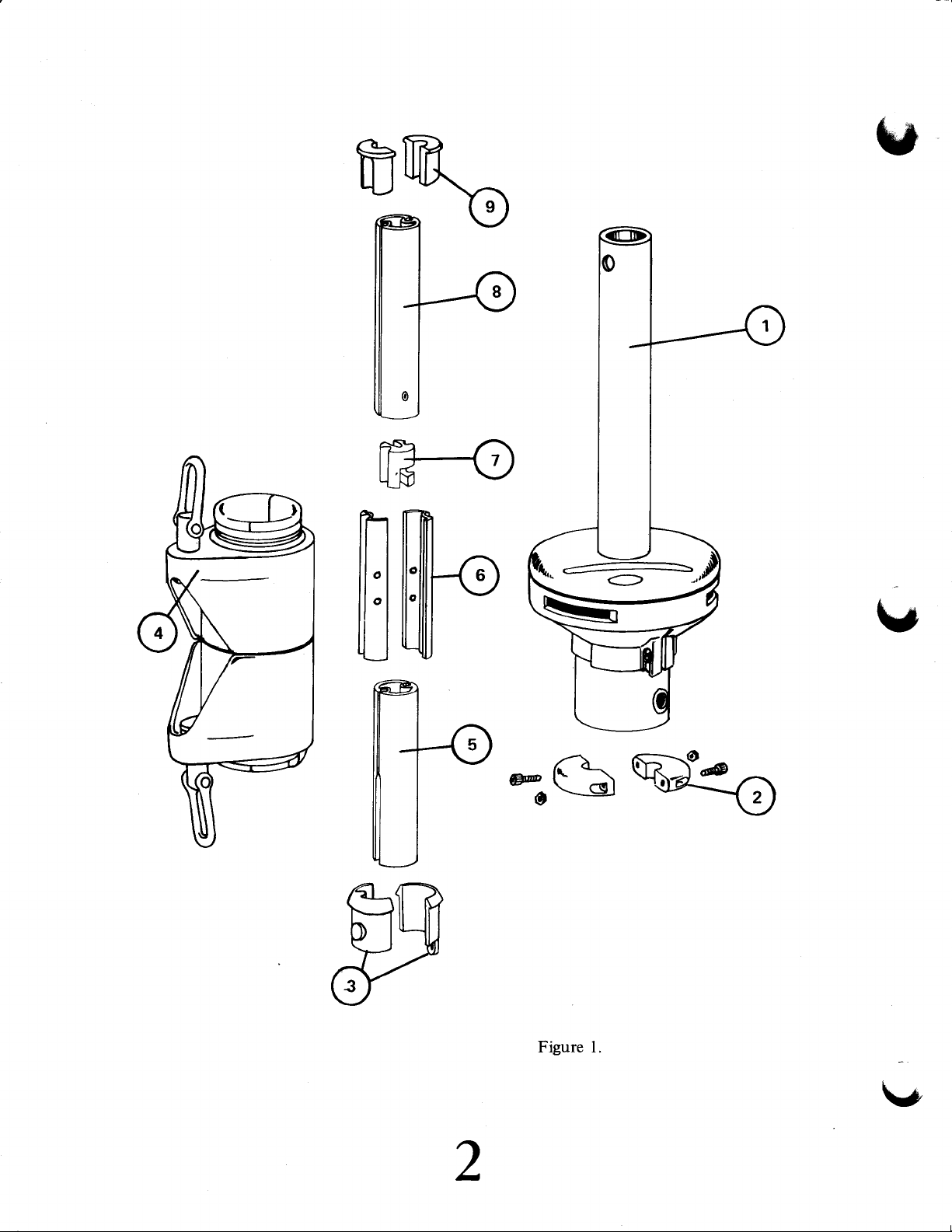

Figure l.

2

\/

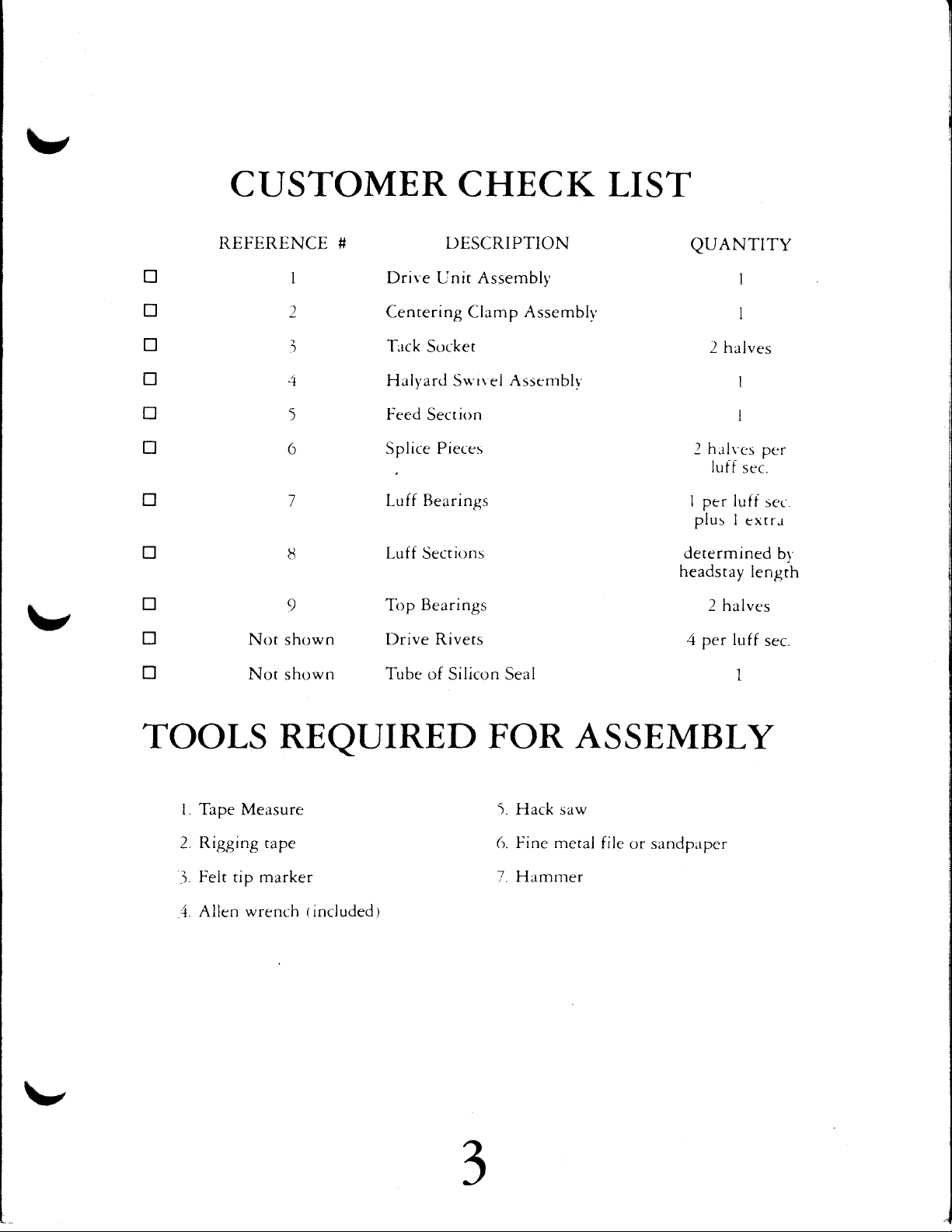

CTJSTOMER CHECK LIST

C

!

!

!

n

n

tr

!

n

!

n

REFERENCE

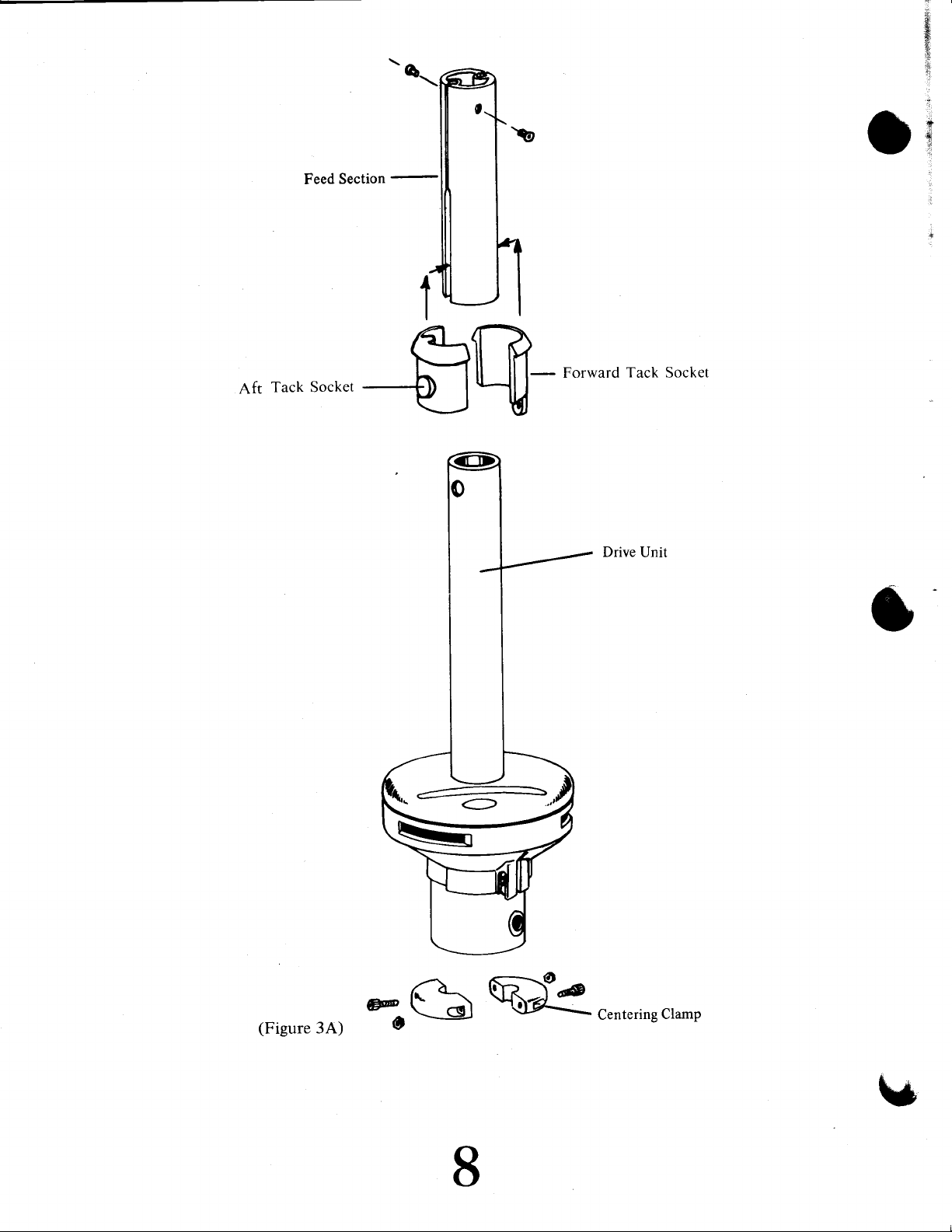

I Drive

2 Centering

I

1i

5

6

7

8

9

Not

shown

Not shown

# DESCRIPTION

Assembll'

Unit

Clamp

Trrck

Socket

Hali'ard Sg'rrei Assemblr'

Feed

Splice

Luff

Luf f

TopBearings

Drive Rivets

'Iube

ion

Sect

Pieces

Bearings

rns

Secri,

of Silicon Seal

Assemblr

QUANTITY

I

I

2 halves

I

I

h.rlvcs

2

luif

I pcr lufi

plus

determined

headstay

2 halves

1+

per luff

sec.

I

cxtr.i

lengrh

pe r

sec

br

sec.

TOOLS

i. Tape Measure

Rigging tape

2.

Felt tip marker

l.

Allen wrench rincluded

4.

REQUIRED

t

FOR ASSEMBLY

i. Hack

6. Fine metal

7.

saw

Hamrner

file

or sandpaper

-GD

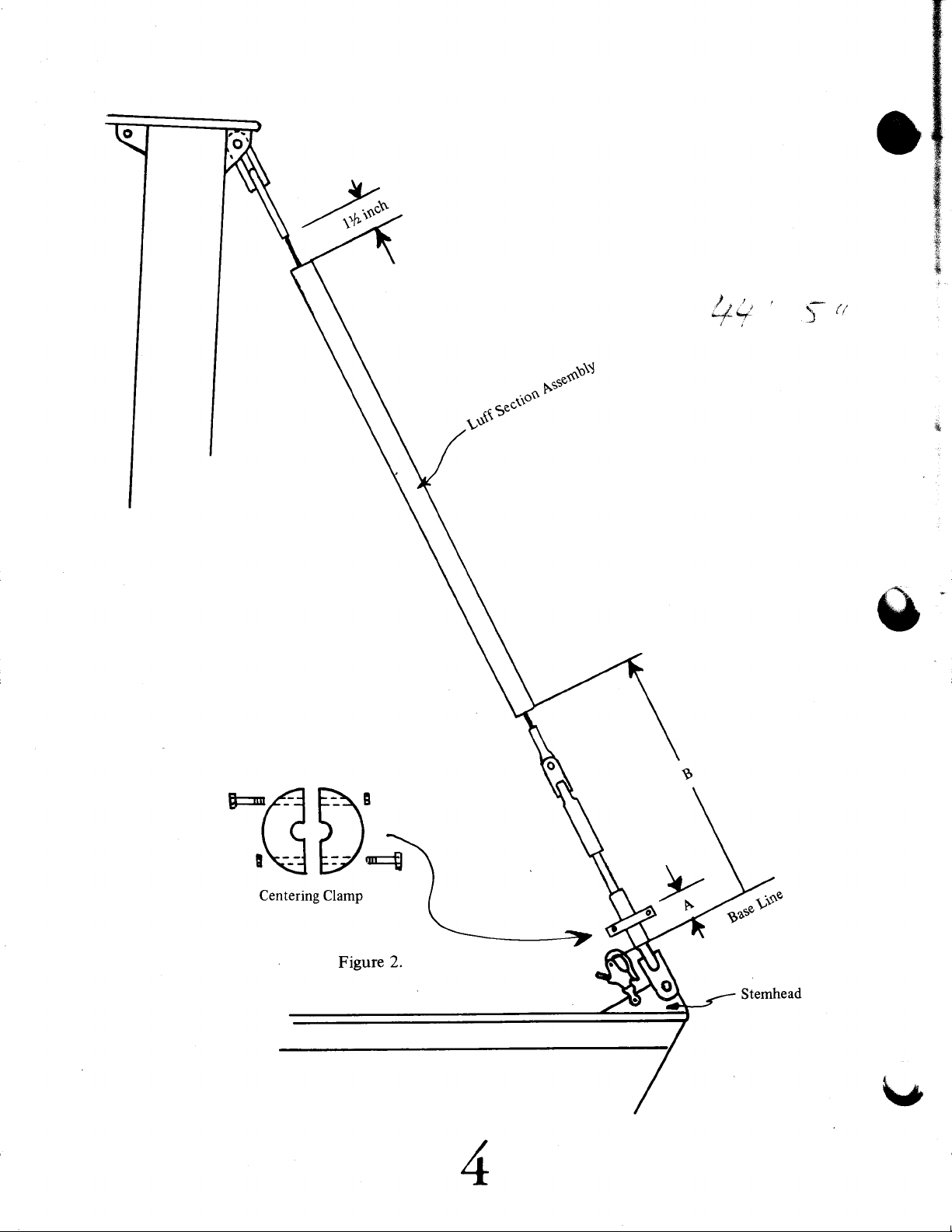

Figure

2,

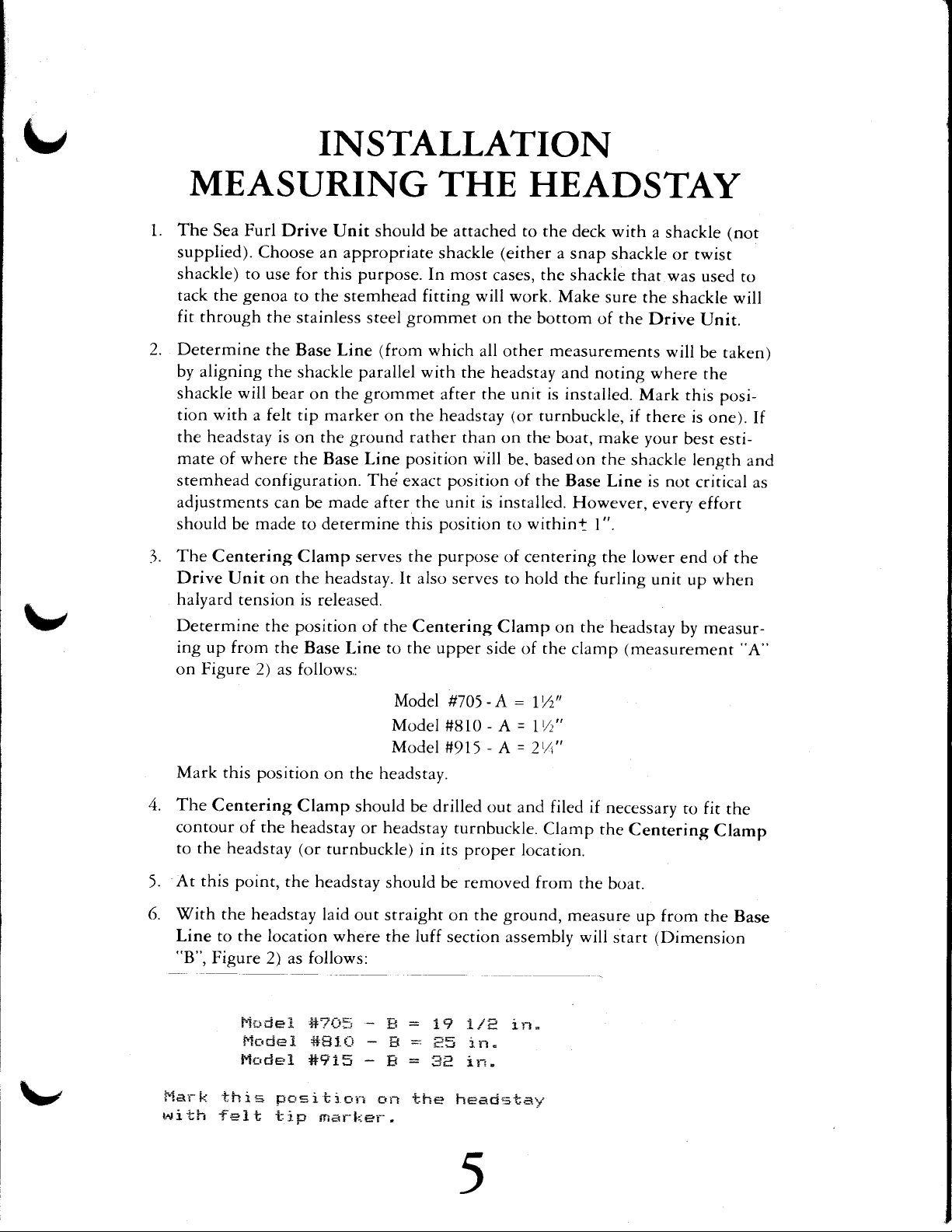

INSTALLATION

MEASURING

l.

The Sea Furl

supplied). Choose

shackle) to

tack the genoa

fit through

Determine

by aligning the

shackle

tion with

the headstay is

mate

of where the Base

stemhead

adjustments

should be

The

t.

Centering

Drive

Unit on

halyard tension is

Determine

ing up from

Figure

on

Drive

Unit should be attached to the

an appropriate

use for this purpose.

to the

the

stainless

the

Base Line

stemhead fitting will

shackle

will

bear

on the grommet

a felt tip

marker on the headstay

on the ground rather than

configuration.

can be

made

made to determine this posirion to withint

Clamp

the

serves the

headstay. It also

released.

position

the

the Base

Line to

2) as follows:

grommer

steel

(from

parallel

position

Line

The

exact

after

the

of

Centering

the

THE HEADSTAY

deck

with

a

shackle

shackle

In most

which

with the headstay

after

position

the

unit is

purpose

serves

upper

(either

cases,

work. Make

on the bottom

a snap

the

shackle that

shackle

sure the

the

of

Drive

all other measurements

and noting

rhe

unir is installed.

(or

rurnbuckle,

the

on

will

be. basedon

of

boat,

the

installed.

Base

However,

Mark this

if

there

make your

the

shackle length

Line is

1".

of centering rhe lower

to hold the

Clamp

side of

the

the

on

clamp

furling

headstay

(measurement

or rwist

was

shackle

will

where

best

not

every

end of the

unit up when

by measur-

(not

used

to

will

Unit.

be taken)

the

posi-

is

one).

esti-

critical

effort

"A"

If

and

as

Mark

The

4.

contour

position

this

Centering

of

to the headstay

At this point,

5.

With the headstay

6.

to the location

Line

"B",

Figure

I'i+dei

i*ic,del

H.:,$s1

i'!a'i-il

r+iih

thi=

fsit

Clamp

the

headstay

(or

the

2) as

F-;=i

i3.p

Model #705-A:

Model

Model

on the headstay.

should be drilled

headstay

or

turnbuckle)

headstay

laid

should be

out straight

where the luff

follows:

S?rJ=

+*1t:i

#Fi=

i!.ni-:

nrark=i-,

- *

-

F

- E

c.1 th+

=L+

-

:3E

#810- A=lt/2"

#9It-A=2t/t"

out and filed if

turnbuckle.

proper

in its

removed

rhe ground,

on

section

1t/

i:r

q:J

tl-?.

h*e.rirt;1V

IYz"

Clamp the

location.

from

the

measure

assembly will

ara

necessary

Centering

boat.

up from the

(Dimension

start

to

fit the

Clamp

Base

-?

l v

-

[!

,,:

$-f-

r

.,

n

I

;,

.,

t,#

-.

;

-.)

Bearings

Top

T

I

Bearings

Luff

+

r

m[fi

[1[][]

-

.3

Splice

Pieces

.{-

An

G'I.

-

6

\}

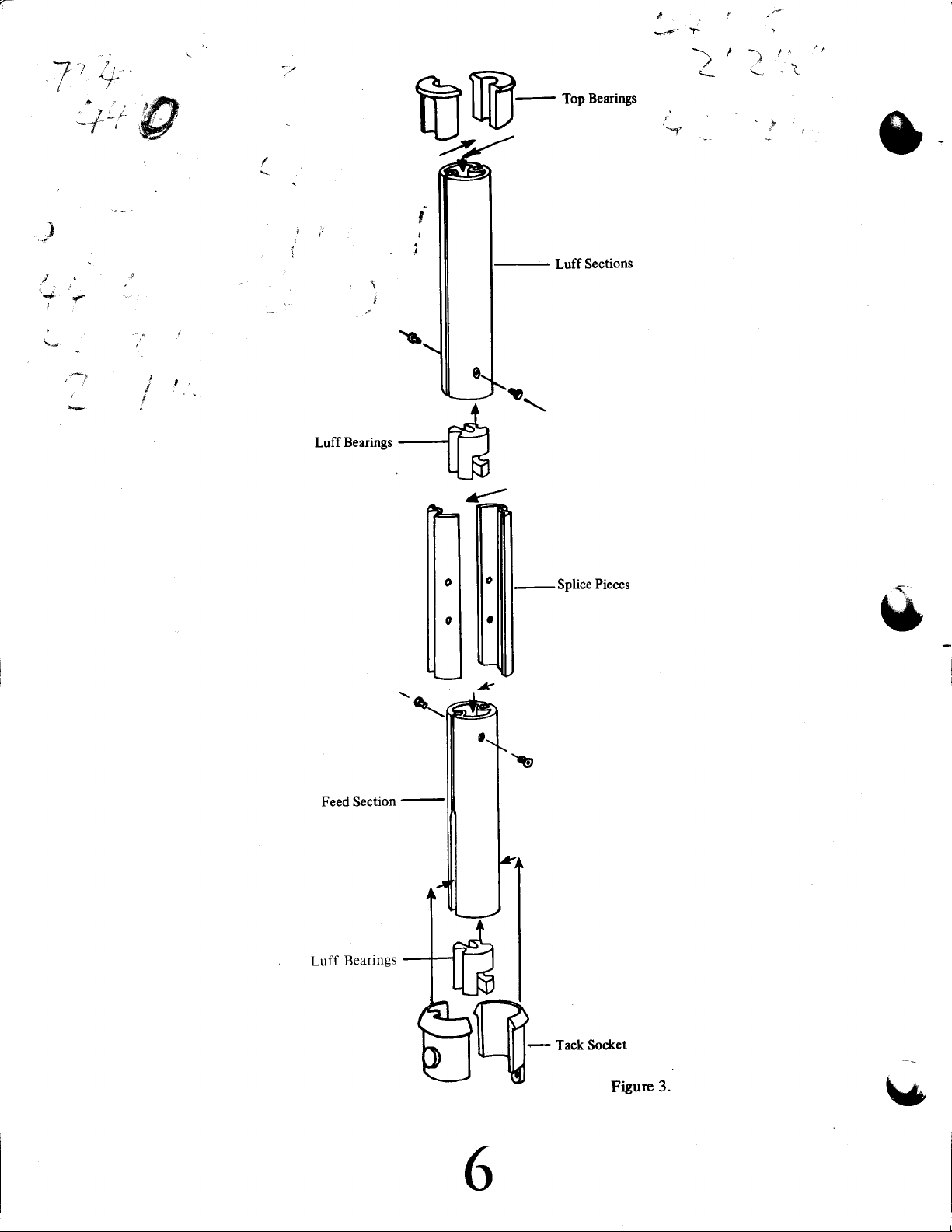

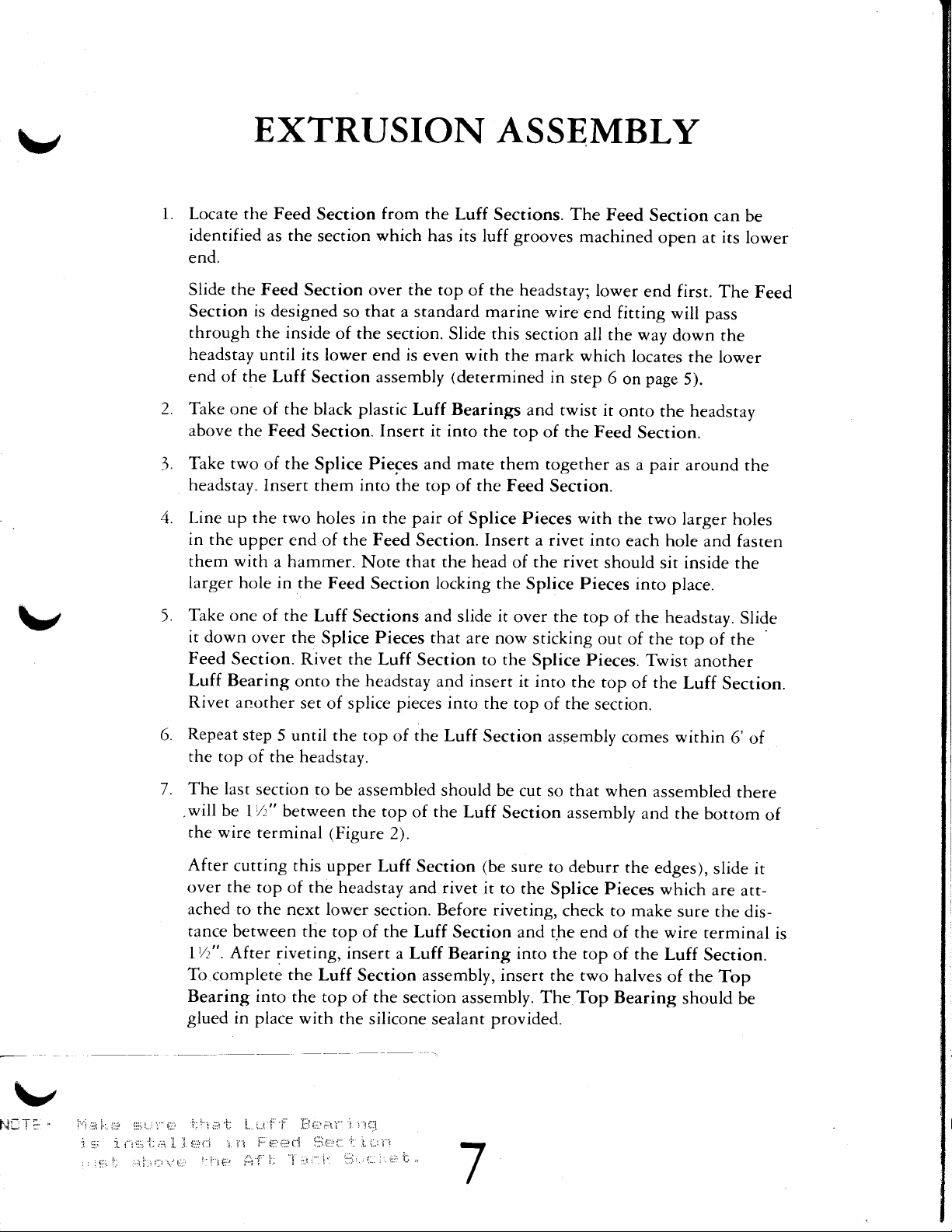

1.

NOTE: Make sure that Luff Bearing

is Installed in Feed Section

just above the Aft Tack Socket.

Locate the Feed

identified

end.

EXTRUSION

from

which

the Luff

has its

Sections. The

luff

as

the

Section

section

ASSEMBLY

Feed

Section

grooves

machined

open

ar

can be

its

lower

Slide the Feed

Section

through the

headstay

of the

end

Take

2.

one of the

above the Feed

Take two

3.

headstay.

Line up the

4.

in the

upper

them with

larger hole in

Take

one

it down

Feed

Section.

Luff Bearing

Repeat

6.

Rivet

another

step

the top

Section over rhe top

is

designed

inside

its

until

Luff

Section assembly

Section.

the

of

black

Splice Pieces and mate them rogether

so

of the

lower

plastic

thar

a standard

secion. Slide this

is

end

Luff Bearings

Insert it into

Insert them into the top

two holes in the

end of

hammer.

a

the Feed

the

of

over the

Luff

Splice Pieces that

Rivet the

the headstay

onto

set

of splice

5 until the top

the Feed

Note

Sections and slide

pair

that the head

Section locking the

Luff Section to rhe

pieces

of

of the headstay.

the

of

with

even

(determined

of the Feed

headstay;

marine wire

section

the

mark

in

and twist

the rop

of

the

Section.

lower

end fitting

all the

which

step

6

it

Feed

of Splice Pieces with

Section. Insert a rivet into

the rivet

of

it

over

are now

Splice

the

sticking

should

Pieces

top

our

Splice Pieces.

insert

the

and

into

Luff

it into

the top

Section

the top

the

of

section.

assembly

end first.

The

will pass

way

locates

page

on

down

the

5).

the

lower

onto the headstay

Section.

pair

as a

rhe two

each hole

around the

larger

holes

and fasten

sit inside the

into place.

of the headstay.

the

of

of

comes within

top

Twist

the

of the

anorher

Luff

Section.

6'

Feed

Slide

of

The last

7.

will

the

After

over

section

be

1%" berween

wire terminal (Figure

cutting this

the

top

ached to the

tance

between

It/2". After riveting,

To

complete

Bearing into

glued in place

irit

.i.

.i.

.'..r

'i

*:i::i i ii

i

iii1,,

i"i

:: ::. i::i !:!

i :,,, :'i i:'.:l'1.:.*

:::$1

l..j

,.;i:i.r...'1i,,

1;

:"'

'i.:

i;

j'

!'

i... l..i

i-:iL".,'.lr:i llii+.':i::

j'i:

;"i;

to

be assembled

the top

upper

the

of

headstay

next lower

the

top

of

insert

the

Luff

Section assembly, inserr the two

the top

with

ii'ii

'!'.,',".i

of

the silicone

:

i

i':

i-

','r

::

.:. i:.,

::::l

should

the

of

2).

Luff Section

and rivet it

secion.

the

Before

Luff

a Luff

the

section

sealanr

i::i

r

i i

i;

i:-.

'

''

be cut so thar

Luff

Section assembly

(be

sure to

to the

riveting,

Section and

Bearing

into the rop

Splice Pieces

the

when

deburr

check to

end

of

of the

rhe

make

the

halves

assembly. The Top Bearing

provided.

assembled

and the

bottom

edges),

which

sure the

wire

terminal

Luff

Section.

the

of

should

there

slide it

are

att-

dis-

Top

be

of

is

Feed

Section

,vr /r-,

rack Socket

Art

+J

Crlt fi?

tlu-

Forward rack Socket

Drive

Unit

(Figure3A)

*(\w

O

s

8

-centeringclamP

\*

Loading...

Loading...