OmniSmart™ Reader Family

r

r

Installation Instructions Models OS10/20/30/40/45

7600055 Rev. 4, 5-Dec-03

WHAT IS THE OmniTek OmniSmart™ READER?

The OmniSmart Reader is an RFID Contactless Smart Card

proximity card reader for use with access control systems.

These installation instructions contain the following

information:

• Mounting Instructions

• Connecting the reader to a host using the Wiegand

interface

• Testing and operation of the reader

If a different output protocol is required (Clock & Data or

Serial TTL), or an alternate configuration (different

security keys, tamper operation, LED control, etc.) is

required, consult the OmniSmart Configuration Manual

which can be found at www.omnitek.com/support.shtm

.

Visit www.omnitek.com for the latest information and

technical support.

HOW TO MOUNT THE READER

To surface mount the reader, perform the following:

1. Determine an appropriate mounting position for the

reader. Ideally, for the maximum operating distance,

avoid mounting the reader directly on metal surfaces

and near other OmniSmart readers.

2. Peel off the back of the self-stick mounting label

template included with the unit and position it at the

desired mounting position. (Additional templates can

be downloaded from www.omnitek.com.)

3. Using the template as a guide, drill two holes (hole size

is indicated on mounting template) for mounting the

reader to the surface.

4. Drill a 1/2” (13 mm) hole for the cable. If mounting on

metal, place a grommet or electrical tape around the

edge of the hole to protect the wire from chaffing.

5. Attach the reader to the mounting surface using the

appropriate screws (not supplied). The mounting

template may be left in place if desired since the

reader will cover it completely.

3. Splice the reader pigtail wires to the corresponding

host wires and cover each connection (see Figure 2).

4. If the tamper output is being utilized, connect the

purple wire to the correct input on the host.

5. Trim and cover all conductors that are not used.

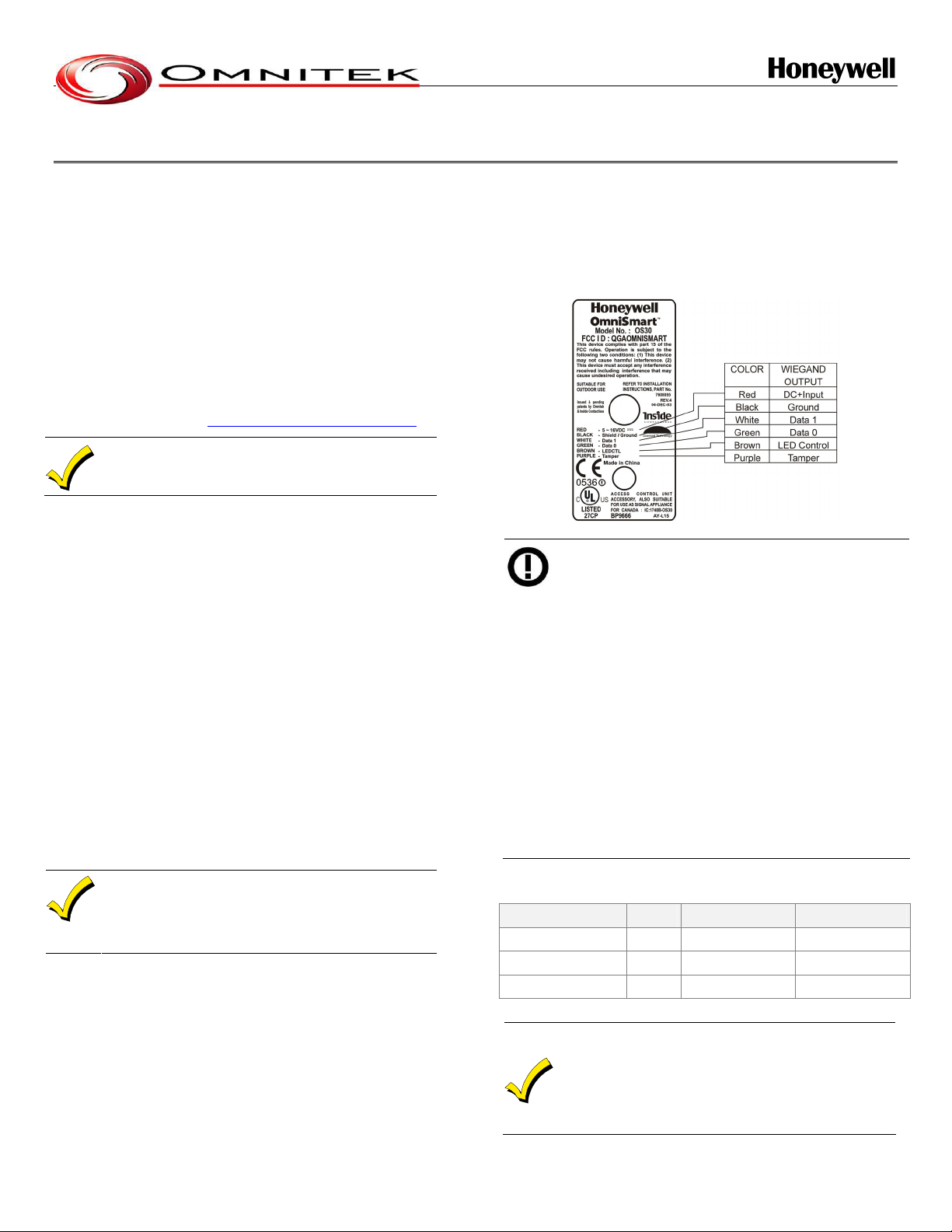

Figure 1 below shows how to wire the reader to the host.

Wiring Notes:

1. The individual wires coming out of the reader are colo

coded according to the recommended Wiegand standard.

2. If either 5 or 12 volts are available, use 12 volts for bette

performance.

3. When using a separate power supply for the reader, the

reader, power supply and host must have a common ground.

4. The recommended cable depends on the distance from

the reader to the host. See Table 1 below for the correct

wire gauge based upon distance. Larger wire gauges

(lower numbers) are desirable. The wire must be stranded

with an overall shield, either foil or braided. If the tamper is

not being used, 5 conductor cable is required; otherwise 6

conductor cable is required.

5. The cable shield wire on the reader should be attached to

an Earth ground (best) or signal ground connection at the

panel or power supply end of the cable. This configuration

is best for shielding the reader cable from external

interference.

Check all electrical codes for proper installation.

Card Reader Models OS10/30/40/45 are to be used

with control panels whose power supply is UL

listed Class 2 or equivalent.

HOW TO CONNECT THE READER TO THE HOST

The OmniSmart Reader is supplied with an 18-inch pigtail,

having a 6-conductor cable. To connect the reader to the

host, perform the following steps:

1. If the reader has a connector attached to it, cut it off

and discard it. This connector is used during testing.

2. Prepare both the reader cable and host cables by

cutting the cable jacket back 1¼ inches and strip the

½ inch.

wires

TABLE 1: WIRE GAUGE SPECIFICATIONS

Distance Gauge 5 Conductor 6 Conductor

≤ 200 ft. (61m) 22 Alpha 1295C Alpha 1296C

≤300 ft. (91m) 20 Alpha 58126 Alpha 58126

≤ 500 ft. (153 m) 18 Alpha 58136 Alpha 58136

Cable recommendations are only a guideline; use

any manufacturer that meets the gauge and shield

specifications. Lower gauges (smaller numbers)

have less resistance and are preferrable. The use of

plenium cable may be required by the local building

codes.

-1-

HOW TO TEST AND OPERATE THE READER

The reader should be tested after wiring it to the host. Do

this by performing the following steps:

1. Power up the reader. The LED and beeper will

activate three times. This indicates that the

reader is working properly.

2. Present an OmniSmart Contactless Smart Card

to the reader. The LED will momentarily flash

green and a short beep will be emitted (if the

reader is the factory default configuration). This

indicates that the card was read properly by

OmniSmart.

3. After the card data is processed by the host, the

host can then turn the LED green or yellow.

Refer to the host description of the LED

operation if the reader LED is controlled by the

host.

HOW TO USE THE COVERS

OmniSmart readers include three different color covers.

After installation and test, the cover should be installed to

hide the mounting screws and deter vandalisim. Choose

the desired color and place on the reader from the top first

to engage the mounting tabs and then swing it down onto

the reader. Secure the cover to the reader using the

supplied Philips head screw or the supplied security screw.

(A security tool is included in the package with the screws.)

ERROR CONDITIONS

Whenever an error condition is signaled by the reader, the

red LED is flashed accompanied by a beep several times. The

following table explains what error message is being conveyed

by the number of flashes/beeps:

# of Beeps Meaning

4 The first byte of the data in the OmniTek

format is invalid, i.e., it is not of type

Wiegand, Clock & data, or Serial Text.

5 The Application Issuer data in the reader

does not match what is on the card.

6 No matching cryptographics keys were

found; authentication failed.

Continually A tamper condition exists

SPECIFICATIONS

Electrical Characteristics:

Frequency:

13.56 MHz

Power Supply Type:

Linear or switching; ripple < 30 MHZ @ 50 mVss

Operating Voltage Range:

5.0 – 16 VDC (Operational down to 4.25 VDC)

Maximum input current:

OS10

Standby: 60 mA

Read: 75 mA

OS20, OS30, OS40, OS45

Standby: 60 mA

Read: 100 mA

Tamper Output

Open collector, active low, max.sink current is 30 mA

Maximum Cable Distance to Host:

500 ft. (150 meters)

Output Interfaces

Wiegand1, Clock & Data, TTL serial asychronus2

ISO Standards Supported

IEC/ISO 14443A, 14443B, and 15693

Card Read Distance: (Ideal conditions3)

OmniSmart

Model

OS10 1.8 – 2.0 4.5 – 5.0

OS20 2.56 – 2.76 6.5 – 7.0

OS30 2.76 – 2.95 7.0 – 7.5

OS40 2.95 – 3.15 7.5 – 8.0

OS45 3.0 – 3.35 7.6 – 8.5

Regulatory Approvals:

USA: FCC Part 15 B, UL294 (only model OS30)

Canada: Industry Canada, C22.2 No. 205-M1983

Europe: CE Listed

Note: The term "IC:" before the radio certification number

only signifies that Industry of Canada technical

specifications were met.

Operating Temperature Range:

-31° F to 150° F (-35°C to 66°C)

Operating Humidity:

0 to 85% (non condensing)

Suitable for outdoor use

Dimensions:

OS10:

OS20:

OS30:

OS40:

OP45:

3.15” (80mm) L x 1.58” (40mm) W x 0.50” (12.8mm) D

4.73” (120mm) L x 1.65” (42mm) W x 0.55” (14mm) D

5.71” (145mm) L x 1.69” (43mm) W x 0.79” (20mm) D

4.33” (110mm) L x 2.96” (75mm) W x 0.59” (15mm) D

3.5” (89mm) L x 3.5” (89mm) W x 0.59” (15mm) D

Read Ranges

(inches)

Read Range

(cm)

1

For additional information on the Wiegand™ Protocol, see

“Access Control Standard – Wiegand Card Reader Interface SIA

AC-01 (1996.10)” which can be purchased from SIA (see

www.siaonline.org).

2

A converter module to true RS232 is optionally available.

3

Using 2k bit PVC PicoPass card, part # OCP0. Mounting

on metal can reduce read range up to 25%.

-2-

FEDERAL COMMUNICATIONS COMMISSION (FCC) Part 15 STATEMENT

This equipment has been tested to FCC requirements and has been found acceptable for use. The FCC requires the following statement

for your information:

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the

manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with

the limits for a Class B computing device in accordance with the specifications in Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference in a residential installation. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• If using an indoor antenna, have a quality outdoor antenna installed.

• Reorient the receiving antenna until interference is reduced or eliminated.

• Move the radio or television receiver away from the receiver/control.

• Move the antenna leads away from any wire runs to the receiver/control.

• Plug the receiver/control into a different outlet so that it and the radio or television receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user or

master may find the following booklet prepared by the Federal Communications Commission helpful: "Interference Handbook"

This booklet is available from the U.S. Government Printing Office, Washington, DC 20402.

The user shall not make any changes or modifications to the equipment unless authorized by the Installation Instructions or User's

Manual. Unauthorized changes or modifications could void the user's authority to operate the equipment.

CE CERTIFICATION

DECLARATION OF CONFORMITY TO COUNCIL DIRECTIVE R&TTE 1999/5/CE

Issued by: EMITECH, 3 rue des Coudriers, ZA de l’Observatoire - CAP 78, 78180 Montigny le Bretonneux, France

Date of issue: 25-March-2003

Equipment type: Access Control Contactless Smart Card Reader

Model numbers OS30

File No.

BP9666

0536

UL Notes:

1. The Model OS-30 is compatible with Control Units as indicated in the Control Unit’s Installation

Instructions.

2. OS30 reader was tested by UL for compliance using Control Unit, Model NSTAR/NS2,

manufactured by Northern Computers Inc.

3. Only the OS30 is UL Listed. The models OS10, OS20, OS40, and OS45 have not been investigated

by UL.

Acknowledgements:

OmniSmart is a registered trademark of Honeywell Corp.

PicoPass is a registered trademark of Inside Contactless.

-3-

OmniTek Limited Warranty

OmniTek and its divisions, subsidiaries and affiliates ("Seller"), 135 West Forest Hill Avenue, Oak Creek, WI 53154, warrants

OmniSmart products to be in conformance with its own plans and specifications and to be free from defects in materials and

workmanship under normal use and service for the life of the product. Seller's obligation shall be limited to repairing or replacing, at its

option, free of charge for materials or labor, any product which is proved not in compliance with Seller's specifications or proves

defective in materials or workmanship under normal use and service. Seller shall have no obligation under this Limited Warranty or

otherwise if the product is altered or improperly repaired or serviced by anyone other than Ademco factory service. For warranty

service, return product transportation prepaid, to OmniTek Factory Service, 135 West Forest Hill Avenue, Oak Creek, WI 53154.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE

OR OTHERWISE, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO CASE SHALL SELLER BE

LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH OF THIS OR ANY OTHER

WARRANTY, EXPRESS OR IMPLIED, OR UPON ANY OTHER BASIS OF LIABILITY WHATSOEVER, EVEN IF THE LOSS OR

DAMAGE IS CAUSED BY THE SELLER'S OWN NEGLIGENCE OR FAULT.

Seller does not represent that the products it sells may not be compromised or circumvented; that the products will prevent any

personal injury or property loss by burglary, robbery, fire or otherwise; or that the products will in all cases provide adequate warning

or protection. Customer understands that a properly installed and maintained alarm may only reduce the risk of a burglary, robbery,

fire or other events occurring without providing an alarm, but it is not insurance or a guarantee that such will not occur or that there

will be no personal injury or property loss as a result. CONSEQUENTLY, SELLER SHALL HAVE NO LIABILITY FOR ANY

PERSONAL INJURY, PROPERTY DAMAGE OR OTHER LOSS BASED ON A CLAIM THE PRODUCT FAILED TO GIVE WARNING.

However, if Seller is held liable, whether directly or indirectly, for any loss or damage arising under this Limited Warranty or

otherwise, regardless of cause or origin, Seller's maximum liability shall not in any case exceed the purchase price of the product, which

shall be the complete and exclusive remedy against Seller. This warranty replaces any previous warranties and is the only warranty

made by Seller on this product. No increase or alteration, written or verbal, of the obligations of this Limited Warranty is authorized.

135 W. Forest Hill Avenue, Oak Creek, WI 53154

Copyright 2003 Honeywell Corporation

Loading...

Loading...