Page 1

Thor™ VX8

Vehicle-Mount Computer

Microsoft® Windows® Embedded Standard Operating System

Microsoft® Windows® 7 Professional Operating System

Microsoft® Windows® XP® Professional Operating System

Vehicle Mounting Reference Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult HII to determine whether any such changes have

been made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

© 2009-2013 Honeywell International Inc. All rights reserved.

Web Address: www.honeywellaidc.com

RFTerm is a trademark or registered trademark of EMS Technologies, Inc. in the United States and/or other countries.

Microsoft®Windows, ActiveSync®, MSN, Outlook®, Windows Mobile®, the Windows logo, and Windows Media are

registered trademarks or trademarks of Microsoft Corporation.

Intel®, Atom™, Core™, Celeron®and Pentium®are trademarks or registered trademarks of Intel Corporation or its

subsidiaries in the United States and other countries.

Summit Data Communications, the Laird Technologies Logo, the Summit logo, and "Connected. No Matter What" are

trademarks of Laird Technologies, Inc.

Atheros®and the Atheros logo are registered trademarks of Atheros Communications, Inc.

Broadcom®and the Broadcom logo are registered trademarks of Broadcom Corporation.

The Bluetooth®word mark and logos are owned by the Bluetooth SIG, Inc.

Symbol®is a registered trademark of Symbol Technologies. MOTOROLA, MOTO, MOTOROLA SOLUTIONS and the

Stylized M Logo are trademarks or registered trademarks of Motorola Trademark Holdings, LLC and are used under license.

RAM®and RAM Mount™ are both trademarks of National Products Inc., 1205 S. Orr Street, Seattle, WA 98108.

Freefloat, Freefloat Wlinq and Freefloat Access*One are trademarks of Freefloat, Mölndalsvägen 30B, SE-412 63 Gothenburg,

Sweden.

OneClick Internet is WebToGo’s patented connection manager customized for Honeywell mobile devices. OneClick Internet

documentation is copyright 2010 by WebToGo and modified by Honeywell with WebToGo’s express permission.

Verizon®is a registered trademark of Verizon Trademark Services LLC.

T-MOBILE®is a registered trademark of Deutsche Telekom AG.

AT&T®is a registered trademark of AT&T Intellectual Property.

Option®and GlobeTrotter®are registered trademarks of Option NV.

Acrobat®Reader © 2013with express permission from Adobe Systems Incorporated.

Other product names or marks mentioned in this document may be trademarks or registered trademarks of other companies

and are the property of their respective owners.

Patents

For patent information, please refer to www.honeywellaidc.com/patents.

Limited Warranty

Refer to www.honeywellaidc.com/warranty_information for your product’s warranty information.

Page 3

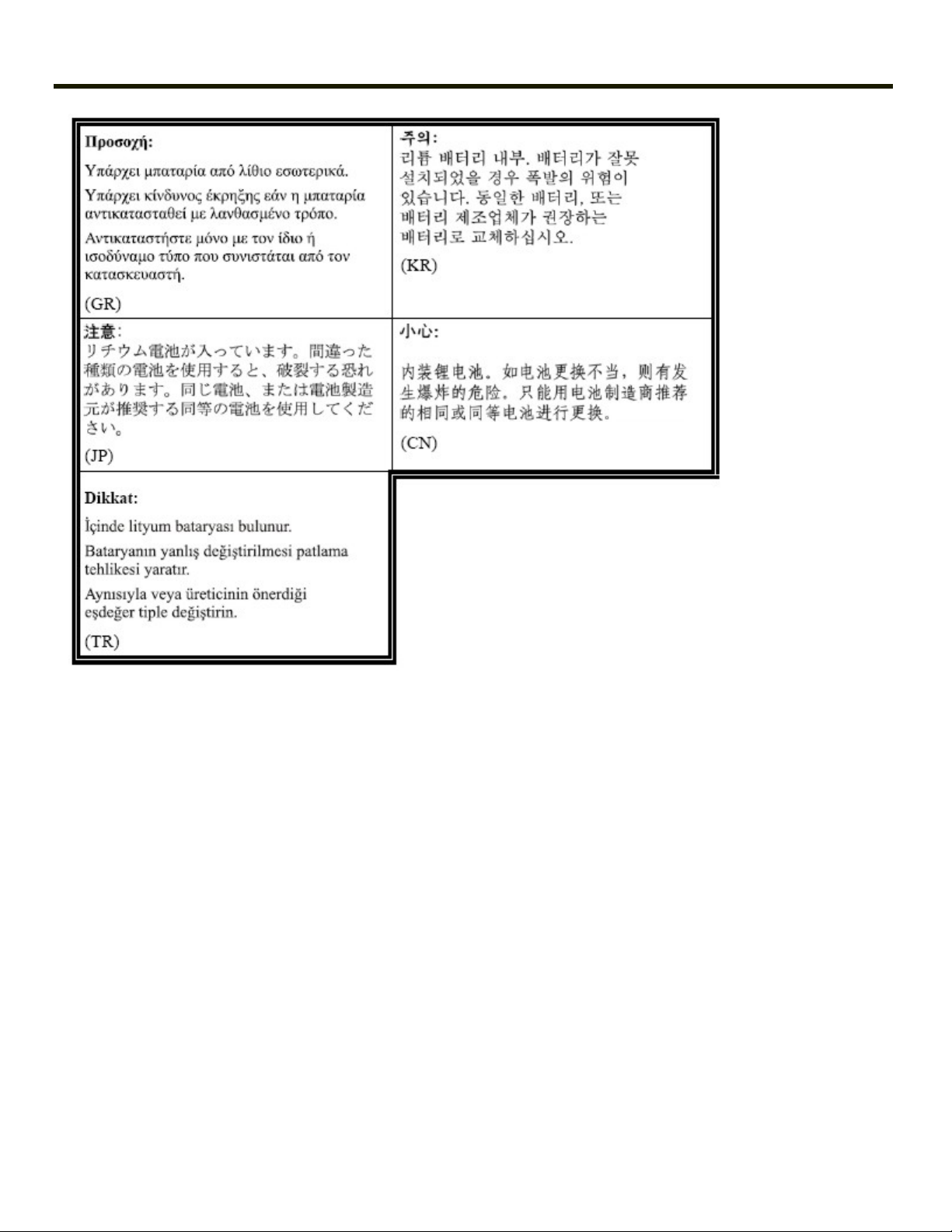

Lithium Battery Safety Statement

Caution: Lithium battery inside. Danger of explosion if battery is incorrectly replaced. Replace only with same or equivalent

type recommended by battery manufacturer. (US)

Attention: Contient une pile de lithium. Risque d’explosion dans le cas où la pile ne serait pas correctement remplacée.

Remplacer uniquement avec une pile semblable ou equivalente au type de pile recommandé par le fabricant. (FR)

Forsigtig: Indeholder lithiumbattterier. Risiko for eksplosion, hvis batteriet udskiftes forkert. Må kun udskiftes med samme eller

tilsvarende type, som anbefalet af fabikanten. (DK)

Varoitus: Tämä tuote käyttää laservaloa. Skannerissa on jokin seuraavista tarroista. Lue Huomio-kohta. (FI)

Vorsicht: Enthält Lithium-Batterie. Bei unsachgemäßem Ersatz besteht Explosionsgefahr. Nur durch gleichen oder vom

Hersteller empfohlenen Typ ersetzen. (DE)

Attenzione: Batteria al litio. Pericolo di esplosione qualora la batteria venga sostituita in maniera scorretta. Sostituire solo con

lo stesso tipo o equivalente consigliato per il fabbricante. (IT)

Atenção: Contém pilha de lítio. Há perigo de explosão no caso de uma substituição incorreta. Substitua somente pelo mesmo

tipo, ou equivalente, recomendado pelo fabricante. (PT)

Varning: Innehåller litiumbatteri. Fara för explosion om batteriet är felaktigt placerat eller av fel typ. Använd endast samma eller

motsvarande typ batterier rekommenderade av tillverkaren. (SE)

Advarsel: Innmontert Lithium batteri. Eksplosjonsfare ved feil montering av batteri. Benytt kun batteri anbefalt av produsent.

(NO)

Cuidado: Pila de litio adentro. Peligro de explosión si la pila se reemplaza incorrectamente. Reemplace solamente con el

mismo tipo o equivalente recomendado por el fabricante. (ES)

Oppassen: Bevat Lithium-batterij. Incorrrecte plaatsing van batterij kan leiden tot explosiegevaar. Alleen vervangen door

hetzelfde of door fabrikant aanbevolen gelijkwaardig type. (NL)

Page 4

Legend: Chinese – CN; Danish – DK; Dutch – NL; English – US; Finnish – FI; French – FR; German – DE; Greek – GR; Italian

– IT; Japanese – JP; Korean – KR; Norwegian – NO; Portuguese – PT; Spanish – ES; Swedish – SE; Turkish – TR.

Page 5

Vehicle Power Supply Connection Safety Statement

Vehicle Power Supply Connection: If the supply connection is made directly to the battery, a ten A slow-blow fuse should be

installed in the positive lead within 5 inches (12.7 cm.) of the battery positive (+) terminal. (US)

Raccordement de l’alimentation du véhicule Si l’alimentation est raccordée directement à la batterie, un fusible à action

retardée de 10 A doit être installé sur le câble positif à moins de 12,7 cm de la borne positive (+) de la batterie. (FR)

EL forsyning af køretøjet. Er forsyningsforbindelsen direkte tilknyttet til batteriet og og tilsluttet til den positive part indenfor

12,7 cm (+ delen). vil der være en langsom tændelse af 10 ampere. (DK)

Kytkentä ajoneuvon virtalähteeseen Jos virtaa otetaan suoraan akusta, 10 ampeerin hidas sulake on asennettava

positiiviseen johtoon enintään 12 cm:n etäisyydelle akun positiivisesta (+) navasta. (FI)

Anschluss an Fahrzeugbatterie Bei direktem Anschluss an die Fahrzeugbatterie sollte eine träge 10A-Sicherung in die

positive Leitung zwischengeschaltet werden, und zwar nicht weiter als ca. 13 cm von der positiven (+) Batterieklemme

entfernt. (DE)

Σύνδεση Τροφοδοτικού Ισχύος Οχήματος Αν η σύνδεση του τροφοδοτικού γίνει κατευθείαν στη μπαταρία, μια ασφάλεια

βραδείας τήξης των 10A θα πρέπει να τοποθετηθεί στο θετικό καλώδιο εντός 5 ιντσών (12,7 εκ.) του θετικού (+) ακροδέκτη

της μπαταρίας. (GR)

Collegamento dell’alimentazione del veicolo Se il collegamento dell’alimentazione viene stabilito direttamente con la batteria, è

necessario installare un fusibile ad azione lenta da 10 A nel conduttore positivo a meno di 5 in. (12,7 cm) dal terminale positivo

(+) della batteria. (IT)

Tilkople strømforsyningen til kjøretøyet Hvis strømforsyningen koples direkte til batteriet, skal det installeres en 10 A treg

sikring i den positive ledningen innen 12,7 cm fra plusspolen (+) på batteriet. (NO)

Ligação do fornecimento de corrente do veículo Se a ligação de fornecimento de corrente for ligada directamente à bateria,

deve instalar-se um fusível de 10A no terminal positivo, a 12,7 cm. do terminal positivo (+) da bateria. (PT)

Conexión de suministro eléctrico para el vehículo Si el suministro eléctrico se proporciona directamente a la batería, se debe

instalar un fusible de retardo de 10 A en el conductor positivo, como máximo a 12,7 cm (5 pulgadas) del terminal positivo (+).

(ES)

Fordonets strömförsörjningskoppling Om strömkopplingen görs direkt till batteriet, måste en 10A-säkring installeras i den

positivt laddade ledningen inom 12.7 cm från batteriets pluspol (+). (SE)

Taşıt Güç Kaynağı Bağlantısı Kaynak bağlantısı doğrudan aküye yapılırsa, pozitif bağlantı kablosu üzerinde akünün pozitif (+)

kutbuna 12.7 cm mesafede 10A’lık yavaş atan bir sigorta monte edilmelidir. (TR)

Legend: Danish – DK; English – US; Finnish – FI; French- - FR; German – DE; Greek – GR; Italian – IT; Norwegian – NO;

Portuguese – PT; Spanish – ES; Swedish – SE; Turkish – TR.

Page 6

Page 7

Table of Contents

Chapter 1 - Introduction 1-1

About This Guide 1-1

Powered Vehicle Mounting 1-1

Preparing the Powered Vehicle Mounted Cradle for Use 1-2

Quick Start 1-2

Maintenance - Vehicle Mounted Devices 1-3

Cleaning 1-3

Chapter 2 - RAM Mount Options 2-1

Thor VX8 with single RAM ball option 2-1

Thor VX8 with dual RAM ball option 2-1

Keyboard mounting options 2-1

Individual brackets 2-1

Install Mounting Brackets 2-2

Mounting Procedure 2-2

Step 1 – Mount Vehicle RAM Ball(s) 2-2

RAM Ball Mount 2-2

Mounting Dimensions 2-3

RAM Clamp Mount 2-4

Mounting Dimensions 2-6

RAM Plate Mount 2-6

Mounting Dimensions 2-7

Step 2 – Prepare Thor VX8 2-7

Step 3 – Attach Keyboard to Bracket 2-9

Honeywell Keyboards 2-9

Other Keyboards 2-10

Step 4 – Attach Thor VX8 and Keyboard Assembly to RAM Base 2-10

Single RAM ball 2-10

Dual RAM balls 2-10

Completed Assembly 2-11

Chapter 3 - Connect Cables 3-1

Removing the Port Lid 3-1

Connect Keyboard 3-1

95 key Rugged Keyboard 3-2

60 key Rugged Keyboard 3-2

Connect Antenna 3-4

External Antenna 3-4

Remote Antenna Installation Kit 3-5

i

Page 8

802.11 Remote Mount Antenna 3-5

Components and Mounting Diagram 3-6

Typical Installation 3-6

Mounting Instruction 3-7

WAN Remote Mount Antenna 3-7

Connect Power Cable 3-8

Connecting Vehicle Power 3-9

Specifications for electrical supply 3-9

How To: Connect Vehicle Electrical Connection 3-10

Connection without Screen Blanking 3-12

Connection with Screen Blanking Box 3-13

Connection with Relay/Mechanical Switch for Screen Blanking 3-14

External AC Power Supply, Optional 3-15

How To: Connect External Power Supply 3-15

Securing Port Lid 3-16

Chapter 4 - Technical Assistance 4-1

ii

Page 9

Chapter 1 - Introduction

The Thor VX8Family is a rugged vehicle-mounted computer with a Windows XP, Windows 7 or Windows Embedded Standard

operating system. The Thor VX8 includes a power cable but requires a DC/DC power supply. Several RAM mount options are

available to mount the Thor VX8 in a vehicle.

About This Guide

This Thor VX8Vehicle Mounting Reference Guide provides instruction for the installer to follow when mounting a Thor VX8in a

vehicle.

Powered Vehicle Mounting

Vehicle mounting brackets are specifically designed for vehicle mount applications. The vehicle mounted assembly restrains

the Thor VX8 and isolates it from shock and vibration.

Overhead, dash and roof support pillar mounting is via a RAM Mount accessory which includes all the hardware required for

vehicle mounting.

Never put the Thor VX8 into the vehicle mounted assembly until the assembly is securely fastened to the vehicle.

1-1

Page 10

Preparing the Powered Vehicle Mounted Cradle for Use

The powered vehicle mounted assembly should be secured to an area in the vehicle where it:

l Does not obstruct the driver's vision or safe vehicle operation .

l Will be protected from rain or inclement weather.

l Will be protected from extremely high concentrations of dust or wind-blown debris.

l Can be easily accessed by a user seated in the driver's seat while the vehicle is not in operation.

Quick Start

The following list outlines, in a general way, the process to follow when preparing the Thor VX8 powered vehicle mounted

cradle for use. Refer to the following sections in this document for more details.

1. Attach the RAM base vehicle mounting assembly to the vehicle.

2. Attach the RAM arm assembly to the vehicle mounting assembly.

3. Attach the Thor VX8 assembly to the RAM arm.

4. Adjust the Thor VX8 to the best viewing angle.

5. Connect antenna. Note: The vehicle remote mount antenna cannot be used by devices with an internal antenna.

6. Connect peripheral cables.

7. Secure the DC/DC or 12 VDC power connector from the vehicle mounted power supply to the Power port.

8. Secure all cables in strain relief cable clamps.

The Thor VX8 in the powered vehicle mounted assembly is ready for use.

1-2

Page 11

Maintenance - Vehicle Mounted Devices

Check the vehicle mounting hardware frequently and re-tighten if necessary.

If the vehicle mounting hardware and connections become broken, loose or cracked, the assembly must be taken out of

service and replaced. Contact Technical Assistance for help.

Cleaning

Do not use paper towels or harsh-chemical-based cleaning fluids since they may result in damage to the Thor VX8 surfaces,

cables, connectors and mounting hardware.

Use a clean soft cloth to wipe any dirt, moisture or grease from the Thor VX8, connectors, cables or the vehicle mounting

hardware. Do not use any liquid to clean the Thor VX8, or connectors. Spray or dampen the cleaning cloth with the cleaning

liquid. If possible, clean only those areas which are soiled. Lint/particulates can be removed with clean, filtered canned air.

1-3

Page 12

1-4

Page 13

Chapter 2 - RAM Mount Options

Several types of mounts are provided for the Thor VX8. For a complete listing of mounting kits and the contents of each kit,

please refer to the VX8 and VX9 accessory list. Contact Technical Assistance for more information.

Thor VX8 with single RAM ball option

If the Thor VX8 is ordered with a single RAM ball, available mounting options include:

l Truck bracket with a single RAM ball (no keyboard mount provision)

l Truck bracket with a RAM ball for Thor VX8 mount plus a RAM ball for keyboard mount

l RAM ball base with integrated keyboard bracket for back of Thor VX8.

Thor VX8 with dual RAM ball option

If the Thor VX8 is ordered with dual RAM balls, available mounting options include:

l Truck bracket with dual RAM balls (no keyboard mount provision)

l Truck bracket with dual RAM balls for Thor VX8 mount plus a third RAM ball for keyboard mount

Keyboard mounting options

They keyboard may be mounted using:

l Integrated keyboard bracket included in some single RAM ball mounting kits

l A RAM mount using the keyboard ball on some truck brackets

l A stand alone keyboard mount using a RAM ball attached to the vehicle

Individual brackets

l Many individual mounting brackets are also available.

2-1

Page 14

Install Mounting Brackets

Caution:

This device is intended to transmit RF energy. For protection against RF exposure to humans and in accordance

with FCC rules and Industry Canada rules, this transmitter should be installed such that a minimum separation distance of at least 20 cm (7.8 in.) is maintained between the antenna and the general population. This device is not

to be co-located with other transmitters.

The following RAM balls are used to mount the Thor VX8:

D-sized (2.25”) balls and arms

l Used to mount the Thor VX8 when a single RAM ball is ordered on the back of the Thor VX8. A D-sized ball is also used

on the truck.

C-sized (1.5”) balls and arms

l Used to mount the Thor VX8 when dual RAM balls are ordered on the back of the Thor VX8. A pair of C-sized balls is

also used on the truck.

l Keyboard brackets also use C-sized ball. A corresponding C-sized ball is either included as part of the Thor VX8

mounting bracket or mounted independently on the truck for the keyboard assembly.

Mounting Procedure

Step 1 – Mount Vehicle RAM Ball(s)

Determine the position for mounting the RAM ball(s). Be sure to position the RAM ball(s) to allow access to the switches and

ports on the bottom of the Thor VX8.

Depending on the options ordered with the Thor VX8, the RAM ball may be:

l A single or dual RAM ball mounted directly to the truck

l A single or dual RAM ball mounted to a plate. The plate then mounts to the truck.

l A single RAM ball integrated with a mounting plate

l A single or dual RAM squeeze clamp style ball

l A single or dual RAM pipe clamp style ball

Additionally, some mounting plates contain a provision for another RAM ball which is used to mount the keyboard.

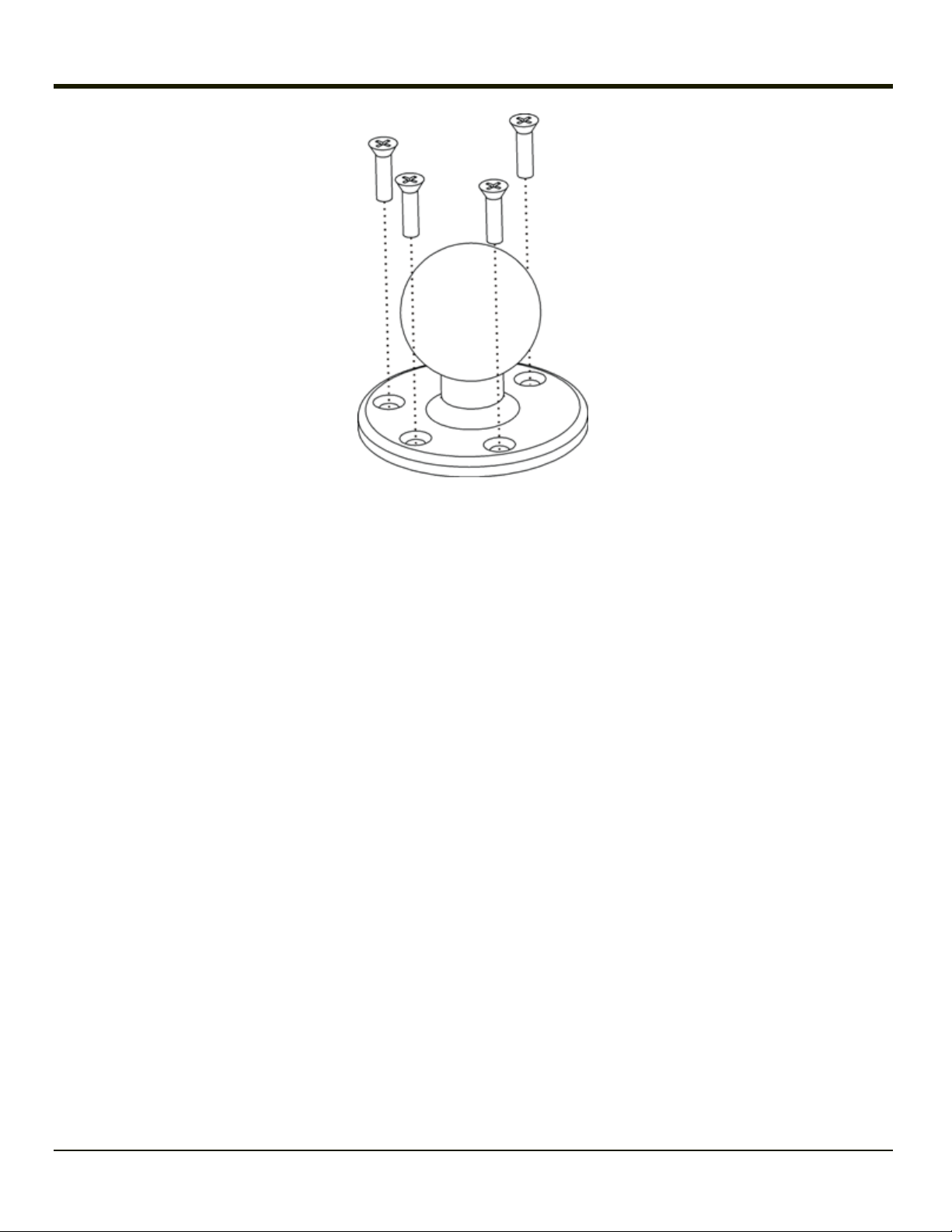

RAM Ball Mount

Depending on the option ordered, there may be a single RAM ball or dual RAM balls to mount the Thor VX8.

1. Determine the position for mounting the RAM ball base. Be sure to position the RAM bracket to allow access to the

switches and ports on the bottom of the Thor VX8.

2. Attach the RAM ball base to the vehicle mounting surface using four 1/4 bolts (or equivalent) fasteners.

Note: 1/4 bolts not included.

IMPORTANT: Mount to the most rigid surface available.

2-2

Page 15

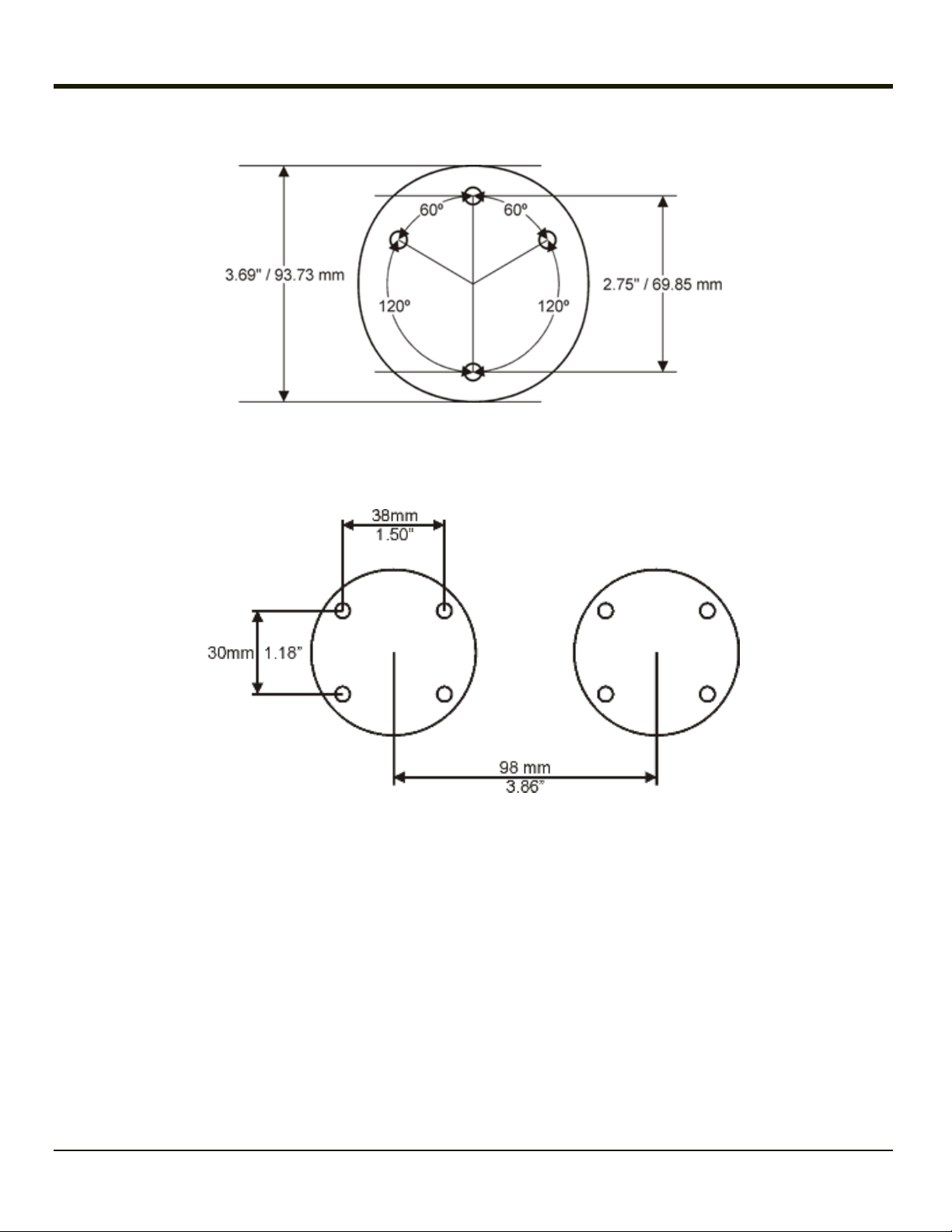

Mounting Dimensions

Note: Drill and tap holes for 1/4 bolts.

2-3

Page 16

Single RAM Ball

Dual RAM Balls

(Not To Scale)

(Not To Scale)

RAM Clamp Mount

1. Determine the position for mounting the RAM clamp mount. The clamp mount can be used on a beam (such as on a fork

lift truck) up to 2.5” (63.5 mm) wide and approximately 2” (50.8 mm) thick. The clamp may be attached to a thicker beam

by substituting longer bolts (not included). Be sure to position the RAM clamp mount to allow access to the switches

and ports on the bottom of the Thor VX8.

2-4

Page 17

2. Position the upper clamp piece with ball (A) on the beam. Place the bolts (B) through the holes in the upper clamp piece.

3. Position the lower clamp piece (C) below the beam. Align the bolts with the holes in the lower clamp piece.

4. Place the nylon locking nuts (D) on the bolts and tighten the bolts.

2-5

Page 18

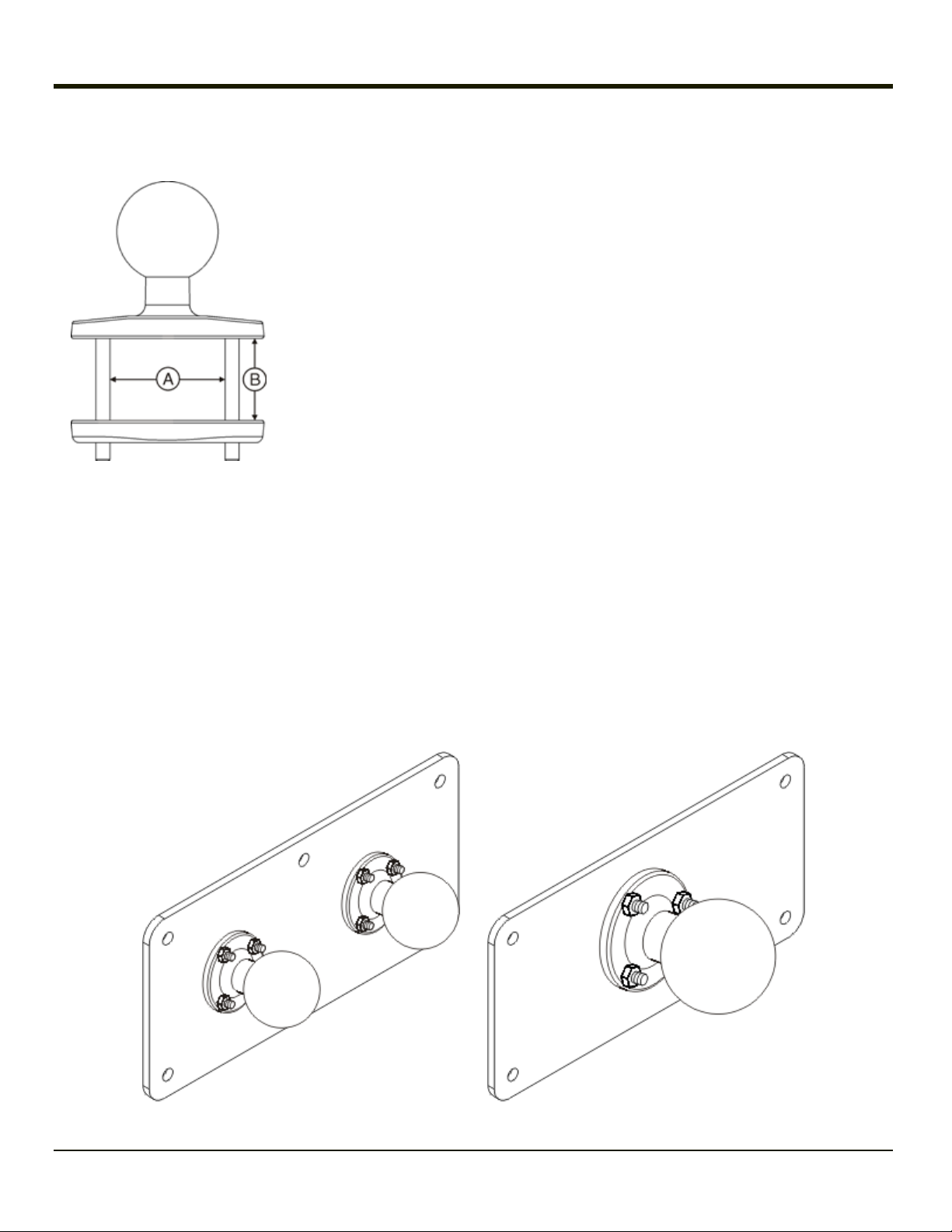

Mounting Dimensions

A. 2.56” (65.02 mm)

B. 1.84” (46.74 mm) Varies depending on bolt length

(Not To Scale)

RAM Plate Mount

1. Determine the position for mounting the RAM ball plate. Be sure to position the RAM plate to allow access to the

switches and ports on the bottom of the Thor VX8.

2. Attach the RAM ball plate to the vehicle mounting surface using four or six (depending on plate type) 1/4 bolts (or

equivalent) fasteners.

3. If not already attached, attach the RAM ball(s) to the RAM ball plate.

Note: 1/4 bolts not included.

IMPORTANT: Mount to the most rigid surface available.

2-6

Page 19

Mounting Dimensions

Depending on the option ordered, there are four or six mounting holes in the plate. Use the proper number of 1/4 bolts to secure

the plate to the vehicle. Additionally, some mounting plates contain a provision for a separate RAM ball mount for a keyboard,

illustrated by the dashed lines in the illustration below.

(Not to Scale)

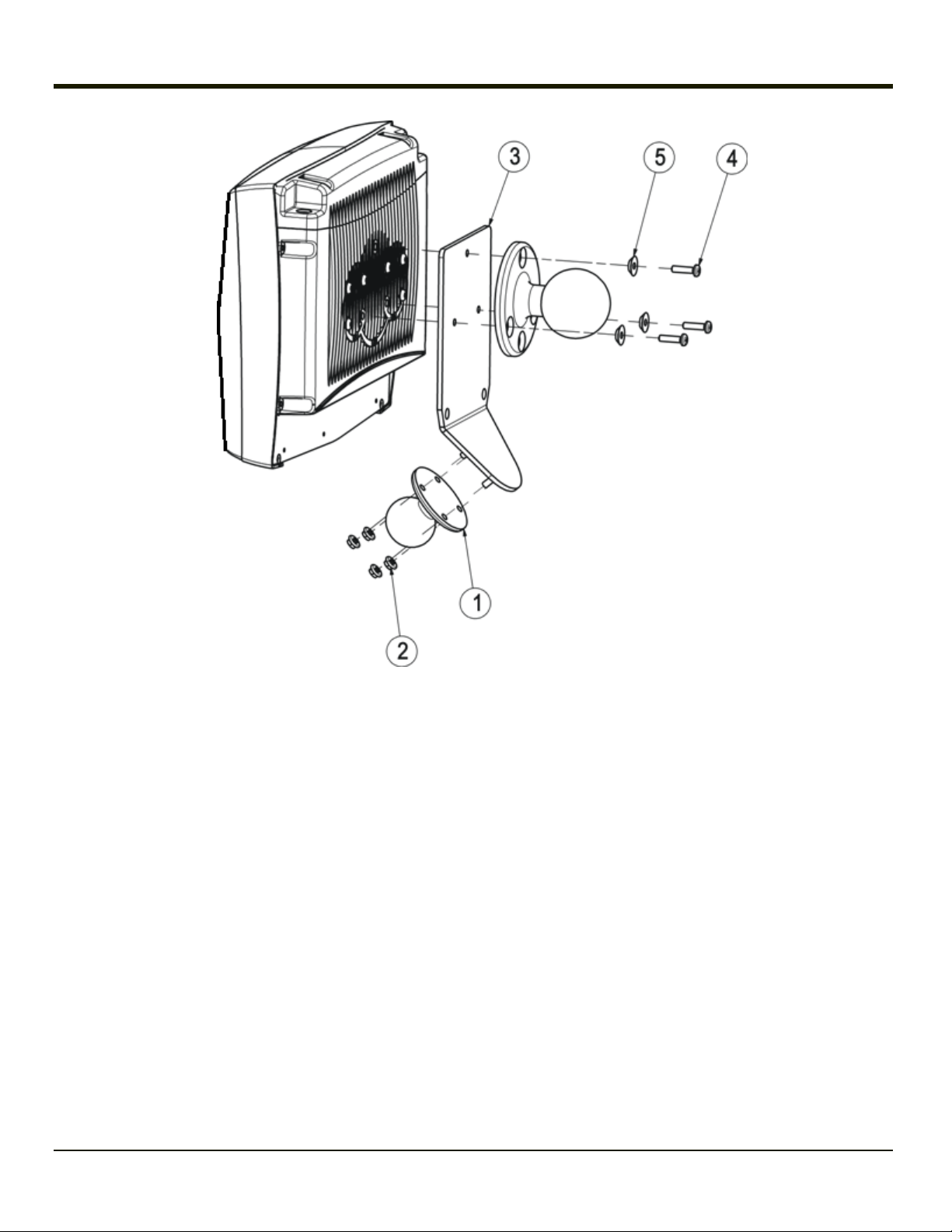

Step 2 – Prepare Thor VX8

The Thor VX8 is delivered with one or two RAM balls installed depending on the configuration ordered.

If an integrated keyboard bracket is to be mounted to the rear of the Thor VX8, follow the procedure below. Otherwise, skip to

the next step.

1. The Thor VX8 must be off and the power cord should not be attached during this procedure.

2. Place the Thor VX8 face down on a stable surface.

3. Remove the RAM ball from the back of the Thor VX8. The hardware attaching the RAM ball is not reused.

4. Install the 2 M5x6 screws in the holes shown below.

2-7

Page 20

5. Install the 1.5” (C-size) RAM ball on the keyboard bracket using four M5 locking nuts.

6. Install the keyboard bracket and the 2.25” (D-Size) RAM ball (removed previously) onto the back of the Thor VX8. Use

three M5x20 screws with three tapered washers.

2-8

Page 21

1. 1.5” RAM ball

2. Locking nut, M5

3. Integrated keyboard bracket

4. Screw, M5x20 (DO NOT reuse original screws)

5. Washer for RAM ball (DO NOT reuse original washers)

Step 3 – Attach Keyboard to Bracket

Honeywell Keyboards

If using the optional integrated keyboard mount, attach the keyboard to keyboard mounting plate, using the appropriate screws:

l For the 95 key keyboard, use four 8-32x5/8 screws and #8 washers

l For the 60 key keyboard, use four 10-32x5/8 screws and #8 washers

Note: 95-key Honeywell keyboard shown.

2-9

Page 22

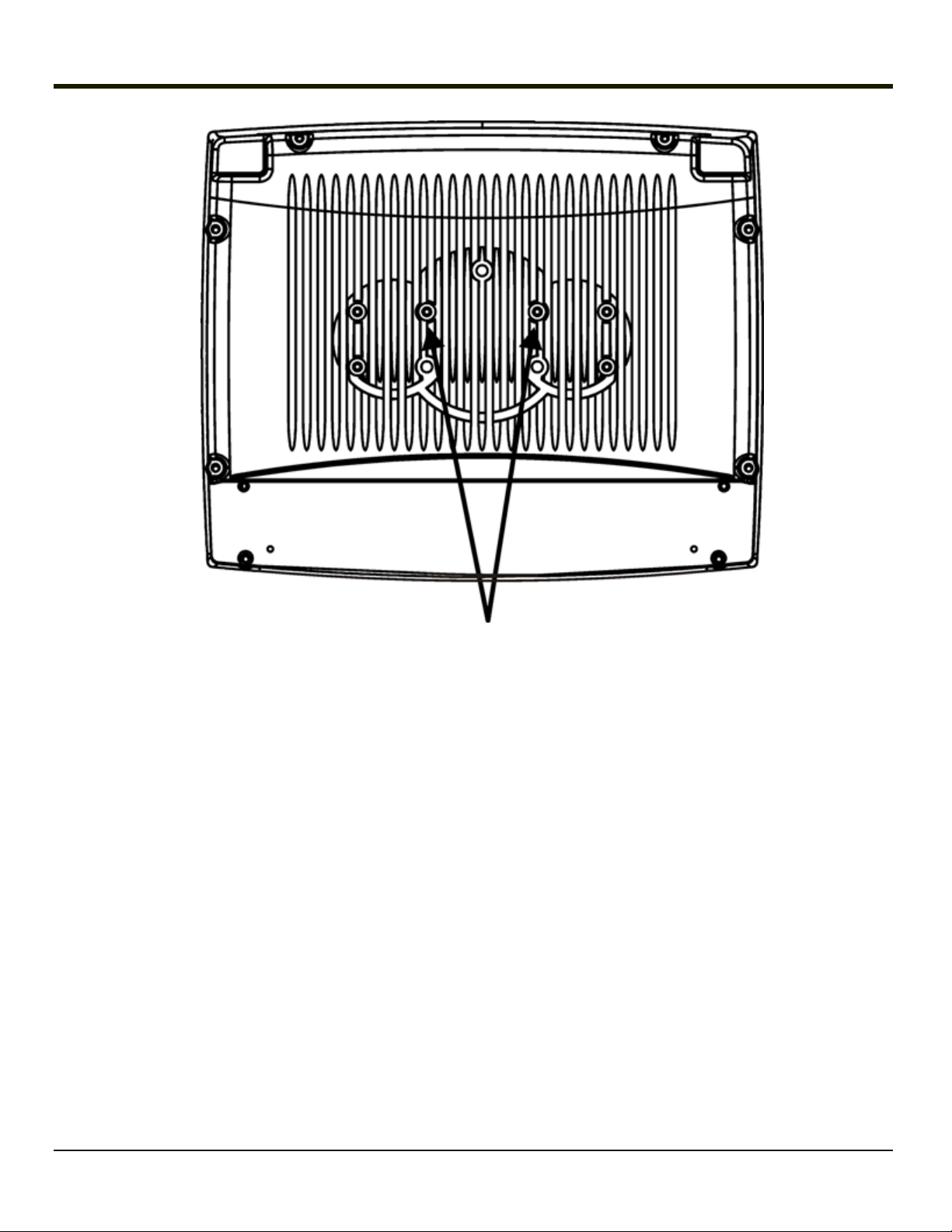

Note: Excess keyboard cable length can be looped around the hooks on the bottom of the keyboard mounting plate.

Other Keyboards

A generic keyboard plate is provided for non-Honeywell keyboards.

1. Attach the RAM ball to the keyboard mounting plate.

2. Attach the keyboard to the keyboard mounting plate. The mounting kit DOES NOT include hardware to attach the

keyboard to the plate.

Step 4 – Attach Thor VX8 and Keyboard Assembly to RAM Base

Single RAM ball

1. Use a single D-sized RAM arm to attach the Thor VX8 assembly to the RAM ball on the vehicle.

2. Use a single C-sized RAM arm to attach the keyboard assembly to the C-sized ball on either the Thor VX8 keyboard

bracket or a C-sized ball on the vehicle.

Dual RAM balls

1. Use a pair of C-sized arms to attach the Thor VX8 assembly to the RAM balls on the vehicle.

2. Use a C-sized arm to attach the keyboard assembly to a C-sized ball on the vehicle.

2-10

Page 23

Completed Assembly

Samples of completed Thor VX8 bracket assemblies are shown below

VX89A021KIT21 including RAM ball base and Honeywell key-

board bracket

VX89A025KIT25 including RAM ball base and generic key-

board bracket

2-11

Page 24

2-12

Page 25

Chapter 3 - Connect Cables

There are many cables available for the Thor VX8. This section deals with those cables that are a part of the installation

process, such as:

Various data and communication cables are available for the Thor VX8.

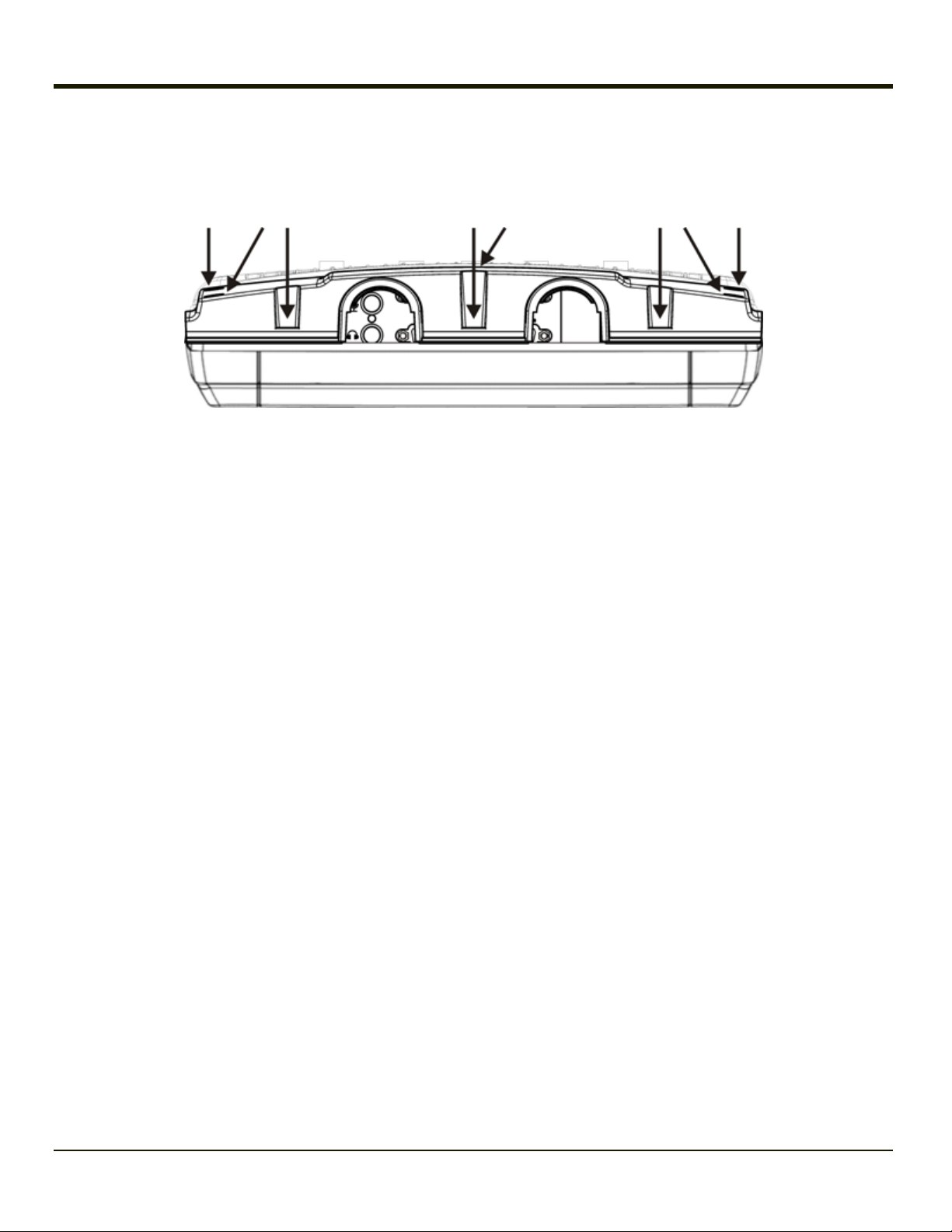

Removing the Port Lid

Before any cables can be attached to the Thor VX8, the port lid must be removed. The port lid is held in place with eight (8) Torx

20 screws. Remove the screws and the port lid and set aside for reinstallation once all accessories are attached.

Reinstall the port lid after all cables are attached.

Connect Keyboard

The Thor VX8 has PS/2 connectors for the keyboard and mouse.

Connect the adapter cable to the PS/2 connectors on the Thor VX8.

Connect the Honeywell keyboard to the adapter cable.

3-1

Page 26

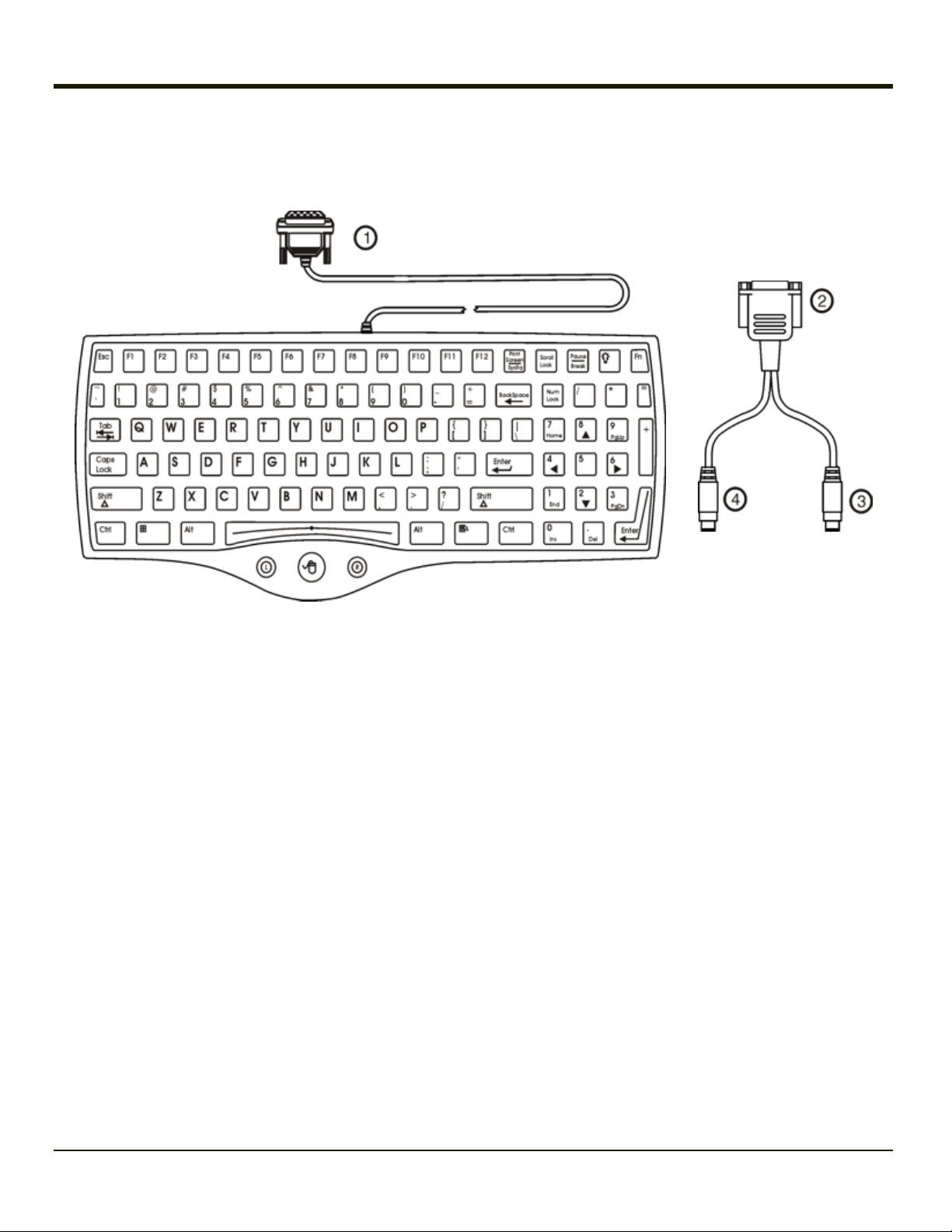

95 key Rugged Keyboard

The 95 key keyboard contains an integrated 2 button mouse, shown with adapter cable.

1. To adapter cable

2. To 95-key keyboard cable

3. To VX8 PS/2 keyboard connector (color coded)

4. To VX8 PS/2 mouse connector (color coded)

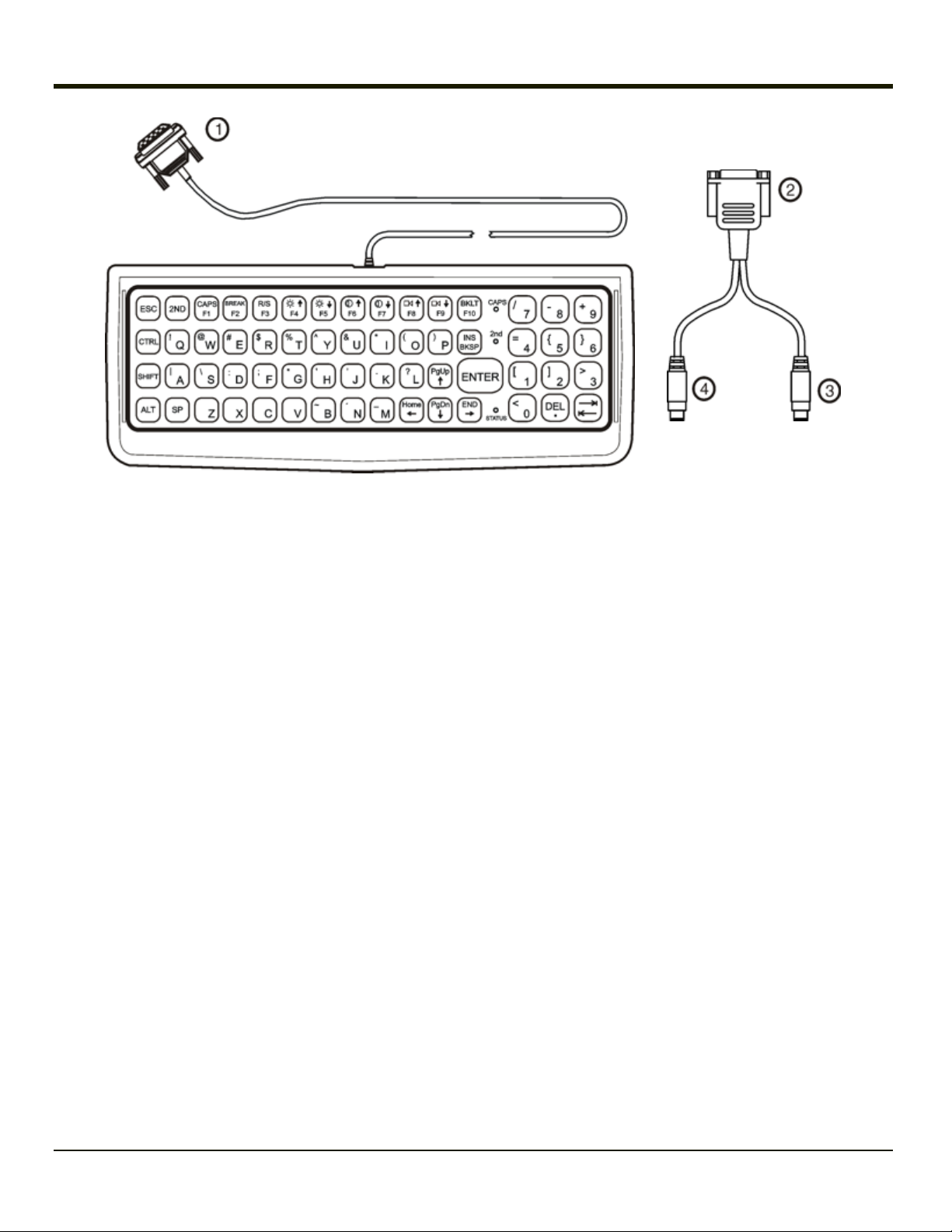

60 key Rugged Keyboard

Shown with adapter cable.

3-2

Page 27

1. To adapter cable

2. To 60-key keyboard cable

3. To VX8 PS/2 keyboard connector (color coded)

4. To VX8 PS/2 mouse connector (color coded)

3-3

Page 28

Connect Antenna

Several antenna configurations are available for the Thor VX8. Options include:

l single 802.11 external antenna

l dual 802.11 external antennas

l remote vehicle mount 802.11 antennas

l remote mount WAN antenna

l external Bluetooth antenna

The VX8 has up to four antenna connectors.

l Generally, the two top antenna connectors are used for the 802.11 antennas.

l The two bottom connectors are used for the Bluetooth antenna and the remote WAN antenna.

Note: Thor VX8’s are equipped with a radio and require an antenna. Some Thor VX8’s may be equipped with a dual antenna

option. For these Thor VX8’s, an external antenna must be connected to each antenna connector.

External Antenna

The external 802.11 and Bluetooth antennas are pre-installed.

To use a remote mount 802.11 antenna, unscrew the pre-installed antenna to remove and follow these instructions.

Repeat for second 802.11 antenna connector, if present.

Note: Substitution of antennas is not permitted unless authorized by Honeywell. Use of unauthorized antennas will void the

FCC emissions certification of the Thor VX8.

3-4

Page 29

Remote Antenna Installation Kit

802.11 Remote Mount Antenna

The Remote Antenna Installation Kit consists of the whip antenna, cable, a flat mounting plate and a right angle mounting

bracket. Choose the mounting plate or mounting bracket depending on vehicle configuration. Tools are not included. For radio

antenna diversity, two remote mount antennas are required. Many components in the kits are also available individually.

The remote antenna bracket is mounted on the top of a forklift, truck or other vehicle and cabled to the Thor VX8 inside the

vehicle.

3-5

Page 30

Components and Mounting Diagram

1. Nut

2. Washer

3. Washer

4. Base Plate Bracket

5. To Antenna

6. To Thor VX8 Antenna

Connector

7. Antenna

8. Right Angle Bracket (not

shown)

Typical Installation

3-6

1. Antenna

2. Mounting Bracket

3. Vehicle Safety

Cage

4. Cable

5. Vehicle Mounted

Thor VX8

Page 31

Mounting Instruction

1. Attach and secure the mounting plate or bracket to the highest point on the safety cage, following these precautions:

l The mounting plate or bracket must be mounted so the antenna is not damaged while the vehicle or any of

its parts are moving.

l The antenna mounting portion of the plate or bracket must be parallel to the floor.

l If the Thor VX8 requires two antennas, they must be mounted at least 12 inches (304.8mm) apart.

2. Attach the female connector of the coaxial cable to the antenna connector on the vehicle mounted Thor VX8.

3. Secure the antenna to the mounting bracket or plate.

4. Connect the antenna cable to the whip antenna.

5. Use cable ties to secure the coaxial cable to the vehicle as necessary. Make sure the cable is routed so it is not

damaged by any moving parts of the vehicle.

6. If the Thor VX8 is using dual 802.11 antennas (diversity option), repeat these steps for the second antenna.

WAN Remote Mount Antenna

The Remote Antenna Installation Kit consists of the WAN antenna and integrated cable. Tools are not included.

The remote antenna is mounted on the top of a forklift, truck or other vehicle and cabled to the Thor VX8 inside the vehicle.

1. Locate a mounting position on highest point on the vehicle, following these precautions:

l The antenna must be mounted so the antenna is not damaged while the vehicle or any of its parts are

moving.

2. Clean the area where the antenna is to be mounted.

3. Remove the protective backing paper from the adhesive on the antenna and position the antenna on the vehicle.

4. Attach the connector on the coaxial cable to the antenna connector on the vehicle mounted Thor VX8.

5. Use cable ties to secure the coaxial cable to the vehicle as necessary. Make sure the cable is routed so it is not

damaged by any moving parts of the vehicle.

3-7

Page 32

Connect Power Cable

The power supply connector is located on the bottom of the Thor VX8.

3-8

Page 33

Connecting Vehicle Power

Complete vehicle cradle mounting and power instruction is contained in the Thor VX8 Cradle Guide.

The DC to DC converter is used to power the Thor VX8. The converter must be used with the Thor VX8 regardless of vehicle

voltage.

Specifications for electrical supply

Input Voltage

Output Voltage

Power

Fuse

Please refer to the appropriate wiring schematic below for wiring colors and connections:

Always observe input voltage range specified on the DC to DC power supply and the optional screen blanking box.

12 VDC ± 10%: models VX89301PWRSPLY, VX89A302PSDC48V, VX89303PWPSPLY

13.2 VDC ± 10%: models VX89305PWRSPLY, VX89306PWRSPLY

50 W: models VX89301PWRSPLY, VX89A302PSDC48V, VX89303PWPSPLY

75 W: models VX89305PWRSPLY, VX89306PWRSPLY

10 A (slow blow fuse)

3 A (for optional screen blanking box)

Fuses are USER SUPPLIED

For proper and safe installation, the input power cable must be connected to a fused circuit on the vehicle. This

fused circuit requires a user supplied 10 Amp maximum time delay (slow blow) high interrupting rating fuse. If the

supply connection is made directly to the battery, the fuse should be installed in the positive lead within 5 inches of

the battery positive (+) terminal.

The VX power supplies listed above are sealed per IPXX. Usage in areas where moisture can affect the power

supply connections should be avoided. The power supply should be mounted in a dry location within the vehicle or

placed in a suitable protective enclosure.

For installation by trained service personnel only.

Risk of ignition or explosion. Explosive gas mixture may be vented from battery. Work only in well ventilated area.

Avoid creating arcs and sparks at battery terminals.

3-9

Page 34

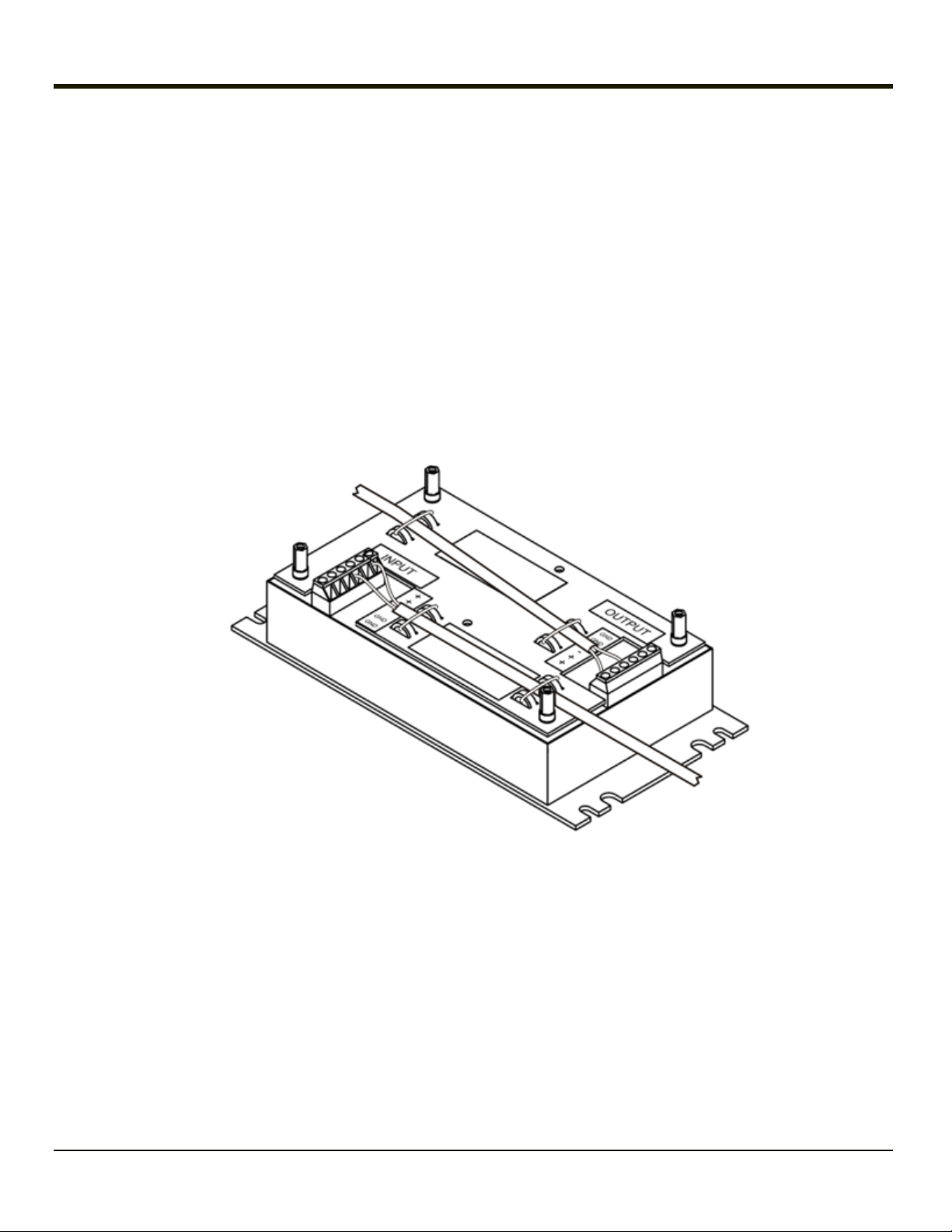

How To: Connect Vehicle Electrical Connection

1. Please review the proper wiring schematic illustration, later in this section, before beginning power cable install.

2. The computer must be powered off.

3. Begin by connecting the power cable to the Thor VX8. Work from this connection with the last connection being to the

vehicle’s power source.

4. Route the cable from the Thor VX8 to the DC to DC converter and, optionally, the screen blanking box. Cut the cable to

length and strip the wire ends. If the screen blanking box is not used, do not strip the green and yellow wires.

Route the power cable the shortest way possible. The cable is rated for a maximum temperature of 105°C (221°F). When

routing this cable it should be protected from physical damage and from surfaces that might exceed this temperature.

Do not expose the cable to chemicals or oil that may cause the wiring insulation to deteriorate.

Always route the cable so that it does not interfere with safe operation and maintenance of the vehicle.

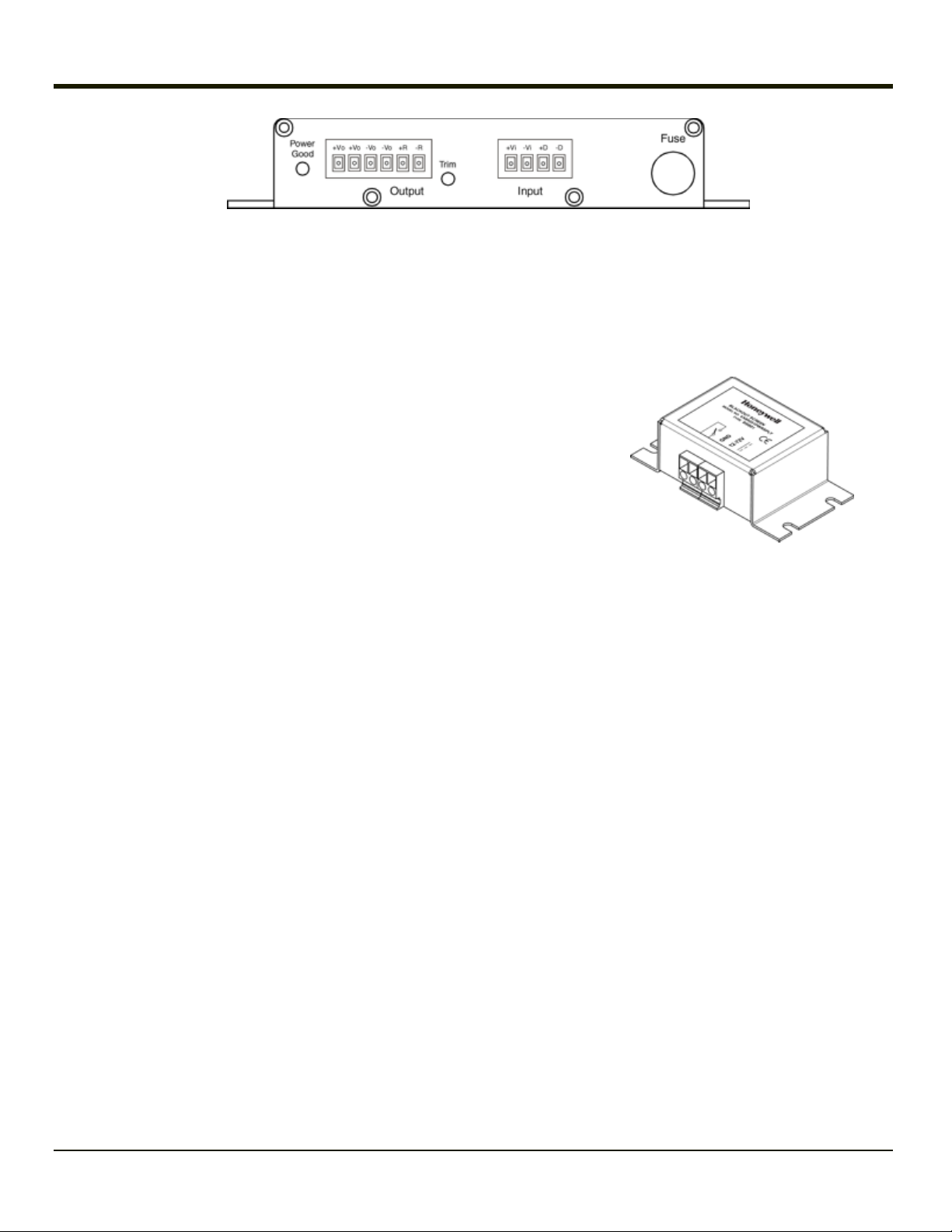

5a. For models VX89301PWRSPLY, VX89A302PSDC48V, VX89303PWPSPLY only:

Remove the lid from the DC to DC converter. Attach the stripped wire ends to the output side of the DC to DC converter.

Attach stripped wire ends to the input side of the DC to DC converter.

The input and output blocks each have two + and two – minus connectors. Either connector in the block can be used to

connect the matching polarity wire.

Use the looms and wire ties to secure all wiring then reattach the cover with the screws.

5b. For models VX89305PWRSPLY, VX89306PWRSPLY only:

3-10

Page 35

Attach the stripped wire ends to the output side of the DC to DC converter. Attach stripped wire ends to the input side of

the DC to DC converter.

The input block has one +Vi and one –Vi connection to connect the matching polarity wire.

The output block has two +Vo and two –Vo connectors. Either connector in the block can be used to connect the matching polarity wire.

Use wire ties to secure all wiring, providing strain relief for the power supply connections.

6. If the screen blanking box is used for the Thor VX8 installation, attach the

stripped wire ends to the box. Refer to the applicable following diagram and

the label on the screen blanking box for proper wiring connection.

7. Connect the DC to DC converter to the vehicle’s electrical system.

8. While observing the fuse requirements specified above, connect the power cable as close as possible to the actual battery terminals of the vehicle. When available, always connect to unswitched terminals in vehicle fuse panel, after providing proper fusing.

ATTENTION: For uninterrupted power, electrical supply connections should not be made at any point after the ignition

switch of the vehicle.

9. If used, connect the wiring for the screen blanking box.

10. Use proper electrical and mechanical fastening means for terminating the cable. Properly sized “crimp” type electrical terminals are an accepted method of termination. Please select electrical connectors sized for use with 18AWG (1mm2)

conductors.

11. Provide mechanical support for the cable by securing it to the vehicle structure at approximately one foot intervals, taking

care not to over tighten and pinch conductors or penetrate outer cable jacket.

3-11

Page 36

Connection without Screen Blanking

1. Existing circuitry on vehicle

2. Forklift Battery

3. Main Switch

4. 10A slow fuse close to power source

5. Power input

6. Isolated DC power output

7. White

8. Brown

9. Yellow

10. Green

11. Vehicle mounted computer

12. Circular power connector

13. Supplied power cable (shielding to be trimmed)

3-12

Page 37

Connection with Screen Blanking Box

It is assumed that the motion sensing circuitry in the illustration below is powered by internal vehicle circuitry.

1. Existing Circuitry on Vehicle

2. Forklift Battery

3. Main Switch

4. 10A slow fuse close to power source

5. Power Input

6. Isolated DC power output

7. White

8. Brown

9. Yellow

10. Green

11. Vehicle mounted computer

12. Circular power connector

13. Screen blanking box

14. 3A fuse

15. Motion circuitry - any 12-60/72VDC signal triggered by vehicle motion (see blanking box label for

allowable range)

16. Supplied power cable (shielding to be trimmed)

3-13

Page 38

Connection with Relay/Mechanical Switch for Screen Blanking

1. Existing Circuitry on Vehicle

2. Forklift Battery

3. Main Switch

4. 10A slow fuse close to power source

5. Power Input

6. Isolated DC power output

7. White

8. Brown

9. Yellow

10. Green

11. Vehicle mounted computer

12. Circular power connector

13. Supplied power cable (shielding to be trimmed)

14. Relay/switch that supplies a mechanical electrically conductive connection on vehicle motion.

3-14

Page 39

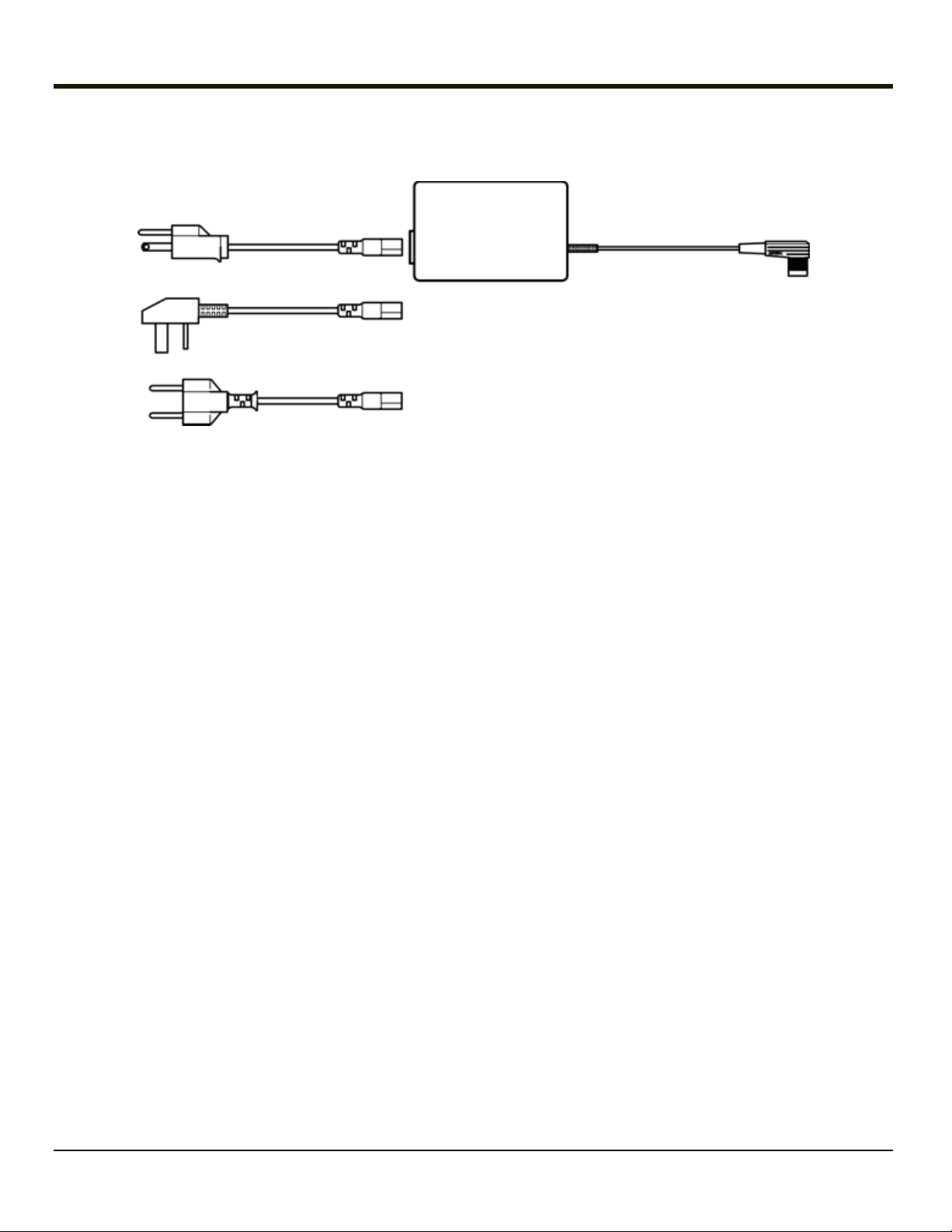

External AC Power Supply, Optional

How To: Connect External Power Supply

1. Turn the Thor VX8 off.

2. Connect the appropriate detachable cordset to the external power supply.

3. Plug cordset into appropriate, grounded, electrical supply receptacle (AC mains).

4. Connect the watertight connector end to the Thor VX8’s Power Connector by aligning the connector pins to the power

connector; push down on the watertight connector and twist it to fasten securely.

5. Turn the Thor VX8 on.

3-15

Page 40

Securing Port Lid

The screws used for the port lid should be alternately tightened to provide proper dust and moist protection (IP65 requirement).

There are eight (8) Torx 20 screws securing the port lid.

Fasten the cable tube in the vehicle, without putting strain on the tube. Now the Thor VX8 is ready to be mounted in the vehicle.

3-16

Page 41

Chapter 4 - Technical Assistance

If you need assistance installing or troubleshooting your device, please contact us by using one of the methods below:

Knowledge Base: www.hsmknowledgebase.com

Our Knowledge Base provides thousands of immediate solutions. If the Knowledge Base cannot help, our Technical Support

Portal (see below) provides an easy way to report your problem or ask your question.

Technical Support Portal: www.hsmsupportportal.com

The Technical Support Portal not only allows you to report your problem, but it also provides immediate solutions to your

technical issues by searching our Knowledge Base. With the Portal, you can submit and track your questions online and send

and receive attachments.

Web form: www.hsmcontactsupport.com

You can contact our technical support team directly by filling out our online support form. Enter your contact details and the

description of the question/problem.

Telephone: www.honeywellaidc.com/locations

For our latest contact information, please check our website at the link above.

Product Service and Repair

Honeywell International Inc. provides service for all of its products through service centers throughout the world. To obtain

warranty or non-warranty service, please visit www.honeywellaidc.comand select Support > Contact Service and Repair

to see your region’s instructions on how to obtain a Return Material Authorization number (RMA #). You should do this prior to

returning the product.

Limited Warranty

Honeywell International Inc. ("HII") warrants its products to be free from defects in materials and workmanship and to conform

to HII’s published specifications applicable to the products purchased at the time of shipment. This warranty does not cover

any HII product which is (i) improperly installed or used; (ii) damaged by accident or negligence, including failure to follow the

proper maintenance, service, and cleaning schedule; or (iii) damaged as a result of (A) modification or alteration by the

purchaser or other party, (B) excessive voltage or current supplied to or drawn from the interface connections, (C) static

electricity or electro-static discharge, (D) operation under conditions beyond the specified operating parameters, or (E) repair or

service of the product by anyone other than HII or its authorized representatives.

This warranty shall extend from the time of shipment for the duration published by HII for the product at the time of purchase

("Warranty Period"). Any defective product must be returned (at purchaser’s expense) during the Warranty Period to HII factory

or authorized service center for inspection. No product will be accepted by HII without a Return Materials Authorization, which

may be obtained by contacting HII. In the event that the product is returned to HII or its authorized service center within the

Warranty Period and HII determines to its satisfaction that the product is defective due to defects in materials or workmanship,

HII, at its sole option, will either repair or replace the product without charge, except for return shipping to HII.

EXCEPT AS MAY BE OTHERWISE PROVIDED BY APPLICABLE LAW, THE FOREGOING WARRANTY IS IN LIEU OF

ALL OTHER COVENANTS OR WARRANTIES, EITHER EXPRESSED OR IMPLIED, ORAL OR WRITTEN, INCLUDING,

WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT.

HII’S RESPONSIBILITY AND PURCHASER’S EXCLUSIVE REMEDY UNDER THIS WARRANTY IS LIMITED TO THE

REPAIR OR REPLACEMENT OF THE DEFECTIVE PRODUCT WITH NEW OR REFURBISHED PARTS. IN NO EVENT

4-1

Page 42

SHALL HII BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, AND, IN NO EVENT, SHALL

ANY LIABILITY OF HII ARISING IN CONNECTION WITH ANY PRODUCT SOLD HEREUNDER (WHETHER SUCH

LIABILITY ARISES FROM A CLAIM BASED ON CONTRACT, WARRANTY, TORT, OR OTHERWISE) EXCEED THE

ACTUAL AMOUNT PAID TO HII FOR THE PRODUCT. THESE LIMITATIONS ON LIABILITY SHALL REMAIN IN FULL

FORCE AND EFFECT EVEN WHEN HII MAY HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH INJURIES,

LOSSES, OR DAMAGES. SOME STATES, PROVINCES, OR COUNTRIES DO NOT ALLOW THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU.

All provisions of this Limited Warranty are separate and severable, which means that if any provision is held invalid and

unenforceable, such determination shall not affect the validity of enforceability of the other provisions hereof. Use of any

peripherals not provided by the manufacturer may result in damage not covered by this warranty. This includes but is not

limited to: cables, power supplies, cradles, and docking stations. HII extends these warranties only to the first end-users of the

products. These warranties are non-transferable.

The duration of the limited warranty for the Thor VX8is 1 year.

The duration of the limited warranty for the Thor VX8 Vehicle Mount Assembly is 1 year.

The duration of the limited warranty for the Thor VX8 internal UPS battery is 1 year.

The duration of the limited warranty for the Thor VX8AC power supply and cables is 1 year.

The duration of the limited warranty for the Thor VX8DC-DC Converter is 1 year.

The duration of the limited warranty for the Thor VX8cables (USB, Serial, Communication, Power) is 1 year.

4-2

Page 43

4-3

Page 44

Honeywell Scanning & Mobility

9680 Old Bailes Road

Fort Mill, SC 29707

www.honeywellaidc.com

E-EQ-VX8DKRG

Rev G

2/13

Loading...

Loading...