Page 1

BALANCED 2-WAY AND 3-WAY HYDRONIC VALVES

VC actuator

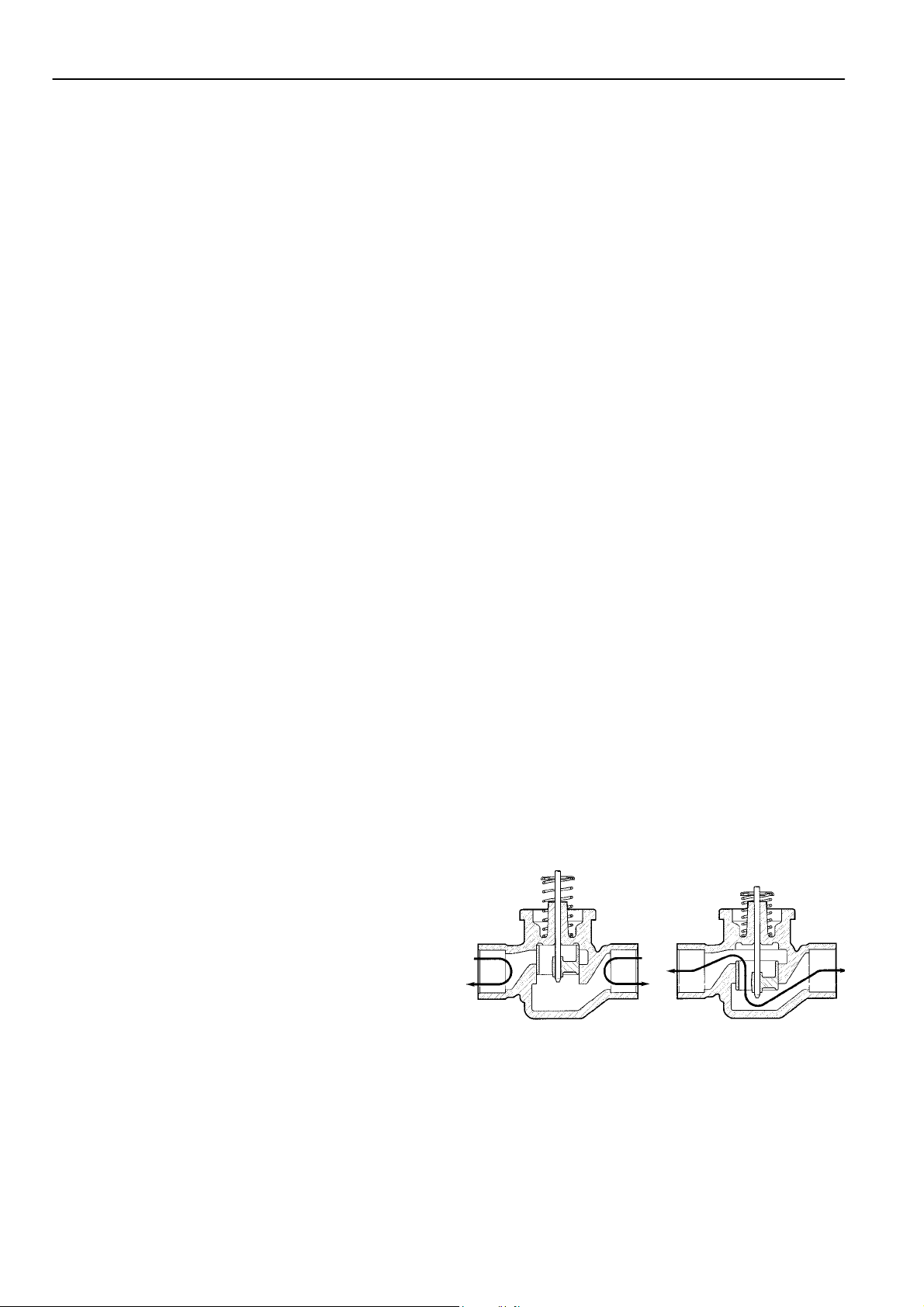

2-way

VC valve body

Design

VC Series zone valves consist of:

• 2-way or 3-way valve housing available with various

connection ends

• Spindle and cartridge assembly

• Actuator with cable or Molex™ socket

• Pipe fittings (most versions)

Materials

• Valve housing made of bronze

• Spindle made of stainless steel

• Cartridge made of Ryton™ (polyphenylene sulphide) and

Noryl™ (polyphenylene oxide)

• O-ring seals made of EPDM rubber

• Actuator cover made of Noryl™ (94V-0)

• Actuator base made of Ryton™ (94V-0)

3-way

VC valve body

VC Series

Zone Valves

PRODUCT DATA

Application

Honeywell VC Series balanced 2-position hydronic valves are

used in domestic and small commercial heating and cooling

applications to control the flow of hot and/or cold water. They

consist of an actuator, valve and a cartridge assembly

2-way valves are designed for on-off zone control of domestic

systems. 3-way valves can be piped for either diverting or

mixing valve applications in domestic central heating and/or

cooling systems. Both versions can be used to control individual fan coil, radiator, space heater or convector applications. Depending on the model selected they can be controlled by a low or line voltage SPST or SPDT controller such

as a room thermostat, aquastat or flow switch.

VC Series hydronic valves are designed to take advantage of

sinusoidal valve actuator travel, and therefore operate silently

and reduce water hammer. Through internal logic the actuator only takes power while driving the valve to the commanded position.

The actuator head is removable without affecting the integrity

of the water system. All actuator versions are interchangeable

with any valve body, offering the highest flexibility for boiler

production line assembly, and maintenance. The valve piston

construction allows for port sealing that is independent of the

differential pressure across the valve. Flow through the 2-way

valve can be in either direction, so the ports are not designated. 3-way valves are suitable for both diverting water from

AB to A or B, and from A or B to AB.

Features

• Rugged design

• Control by a low or line voltage SPST or SPDT

controller

• Minimal actuator power consumption

• Pressure differential up to 4 bar

• Double insulated actuator

• Quick connect electrical connections

• Quick and easy replacement of moving parts

• Actuator head installation does not require draining of

the system

• High flow rate capacity

Honeywell • All rights reserved EN0H-0327GE25 R0206

Page 2

VC SERIES

Specifications

Medium Water or water-glycol mixture

pH-value 8...9.5

Operating temperature 1...95°C (34...203°F)

Ambient temperature max. 65°C (149°F)

Operating pressure max. 20 bar (290 psi) static

Differential pressure max. 4 bar (58 psi)

k

vs (cv)-values see chapter “Dimensions” below

Flow 2-way: flow can be in either

(max. 50% glycol content),

quality to VDI 2035

120°C (248°F) short duration

peak

max. 100 bar (1,450 psi) burst

direction. When actuator is not

mounted valve is in closed

position

3-way: bottom port is marked

AB. End ports are marked A and

B. When actuator is not

mounted port A is closed.

Function

VC Series 2-position hydronic valves are used in domestic

and small commercial applications to control the flow of hot

and/or cold water. They consist of an actuator, valve and a

cartridge assembly.All moving and sealing parts of the valve

are constructed in the cartridge assembly. The ports are

sealed with O-rings on the outer surface of the piston.

When the valve stem is driven down to open port A the water

will flow through the hollow piston to the other port. In case of

2-way valve

With an SPDT (3-wire) actuator

On a call for heat, the NO controller contacts close and the

valve opens. When the valve is fully open, the cam closes

switch SW1 and opens switch SW2. When the need for heat

is satisfied the NC controller contacts close, energising the

valve through SW1 and closing the valve. When the valve is

fully closed, the cam closes SW2 and opens SW1. The valve

is ready for the next call for heat.

With an SPST (2-wire and common) actuator

On a call for heat, the controller contacts close, RLY1 is energized making the NO contacts in switch SW3 causing the

valve to open. When the valve reaches the fully open position

the cam closes switch SW1 and opens switch SW2. When

the need for heat is satisfied, the controller contacts open,

RLY1 is de-energized and the valve motor is driven through

SW1 and the NC contacts of SW3. When the valve reaches

the fully closed position, the cam closes SW2 and opens

SW1. The valve is ready for the next call for heat.

Voltage 24 V, 50-60 Hz (blue label)

200-240 V, 50-60 Hz (red label)

Power consumption 4 VA

(when valve position changes)

Auxiliary switch rating 1.0 A @ 250 V, 50-60 Hz

(minimum 0.05 A @ 24 Vdc)

Nominal timing Valve opens in 7 seconds

(20% faster for 60 Hz)

Electrical termination 1. Molex™ socket: requires

mating connector,

alternatively

2. With integral 1 m leadwire

Shipping temperature -40…65°C (-40…149°F)

Humidity rating 5…95% RH (non-condensing)

Atmosphere non-corrosive, non-explosive

a 3-way valve with the piston driven down port B is sealed,

allowing flow between port AB and port A. With the stem up

the flow is between port AB and port B.

The valve family offers a variety of versions of pipe connections to suit the different applications. The valve pressure loss

characteristic is dependent on the pipe connections/ dimensions. For the actual valve rating please refer to the specification section.

For both types of actuator a power failure will leave the valve

at the position it was when interrupted. When power is restored, the valve will respond to controller demand.

Fig. 1. Fluid flow through 2-way VC valve

EN0H-0327GE25 R0206 2 Honeywell • All rights reserved

Page 3

3-way diverter valve

With an SPDT (3-wire) actuator

On a call for heat, the NO controller contacts close, the valve

closes port B and opens port A. When port A is in the fully

open position the cam closes limit switch SW1 and opens

limit switch SW2. When the need for heat is satisfied the NC

controller contacts close, energising the valve through SW1,

causing port A to close. When port A is fully closed the cam

closes SW2 and opens SW1. The valve is ready for the next

call for heat.

With an SPST (2-wire and common) actuator

On a call for heat the controller contacts close, RLY1 is energized making the NO contacts in switch SW3, causing port B

to close and port A to open. When port A reaches the fully

open position the cam closes switch SW1 and opens switch

SW2. When the need for heat is satisfied, the controller contacts open. RLY1 is de-energized making the NC contacts in

SW3 and port A is driven closed through SW1 and the NC

contacts of SW3. When port A is in the fully closed position

the cam closes SW2 and opens SW1. The valve is ready for

the next call for heat.

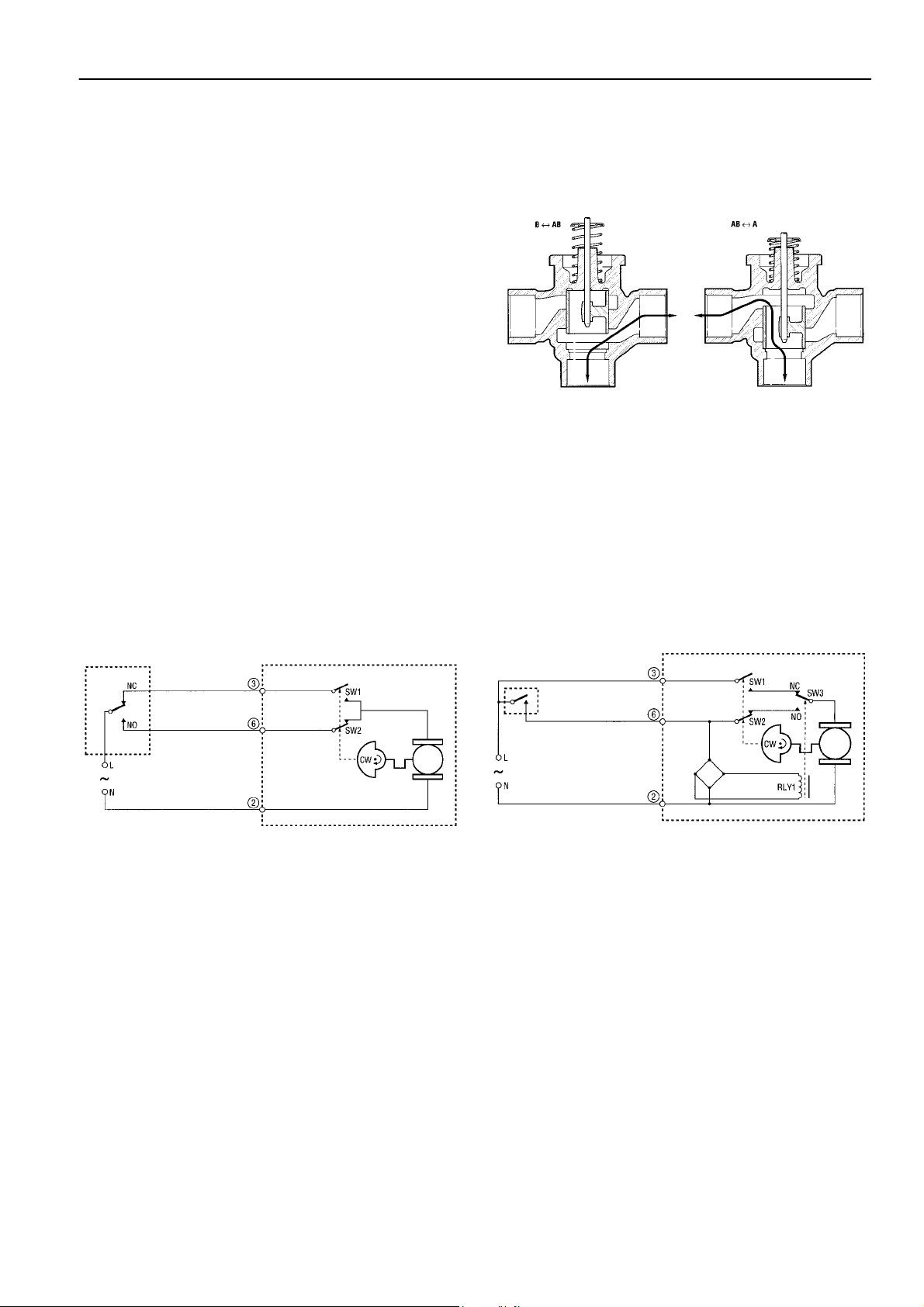

Wiring

Figures 3 and 4 show wiring connections for 2-way and 3-way

valves. Port A open and closed denotes valve open and closed for 2-way, and AB-A open and AB-B open for 3-way

valves respectively. A means for disconnection from the

supply having a contact separation of at least 3 mm in all

VC SERIES

For both types of actuator a power failure will leave the valve

at the position it was in when interrupted. When power is

restored, the valve will respond to controller demand.

Fig. 2. Fluid flow through 3-way VC valve

poles must be incorporated in the fixed wiring. On Molex™

connector models, actuator and auxiliary switch voltages

must be the same to meet the approval requirement. For

mixed voltages, the cable assembly version is recommended.

Fig. 3. Logic sequence diagram with 3-wire actuator for

SPDT contoller

Honeywell • All rights reserved EN0H-0327GE25 R0206

Fig. 4. Logic sequence diagram with 2-wire + common

actuator for SPST contoller

Page 4

VC SERIES

Dimensions

Fig. 5. 2-way VC valve

Table 1. Dimensions and k

Body 2-way VC valve 3-way VC valve

C kvs-value C D kvs-value

15mm compression 98 3.4 98 136 4.3

22mm compression* 112 6.8 112 140 8.6

28mm compression* 112 7.7 112 140 8.6

1/2” BSPP (external) 98 3.4 98 136 4.3

3/4” BSPP 94 6.8 94 130 7.7

1” BSPP 94 7.7 94 136 8.6

1/2” sweat 98 3.4 98 136 4.3

3/4” sweat 94 6.8 94 132 8.6

1” sweat 94 8.6 94 136 8.6

NOTE: All dimensions in mm

* Includes compression nuts and olives

vs-value

Fig. 6. 3-way VC valve

Ordering Information

Use the Valve Selection Chart to find the right version. The Valve Selection Chart provides the necessary information to put

together the OS-No. (OS=Ordering System). Example with OS-No. VC6012MP6000E:

VC6012MP6000E

Product family. Always “VC”

Actuator specifier –

see Valve Selection Chart column A

Body specifier –

see Valve Selection Chart column B

Accessories and packing specifier –

see Valve Selection Chart column E

Customisation specifier –

see Valve Selection Chart column D

Cartridge specifier –

see Valve Selection Chart column C

EN0H-0327GE25 R0206 4 Honeywell • All rights reserved

Page 5

Valve Selection Chart

VC SERIES

Honeywell • All rights reserved EN0H-0327GE25 R0206

Page 6

VC SERIES

Installation

WARNING

Installer must be a trained, experienced service

person.

When installing this product:

• Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

• Check the ratings given in the instructions and on the

product to make sure it is suitable for your

application.

• Always conduct a thorough checkout after installation.

Plumbing

Fig. 7. Plumbing

To install a replacement actuator head

Fig. 8. Latch mechanism

CAUTION

• Disconnect power supply before wire connection to

prevent electrical shock and equipment damage.

• It is advisable to remove the actuator head from the

valve body for ease of installation. Fit the actuator

head in the most convenient position for wiring.

• On sweat fitted valves, the cartridge is shipped loose

or is removed to avoid being damaged during the solder operation.

• On 24 V systems, never short circuit the valve coil

terminals. This may burn out the heat anticipator in

the thermostat.

• To remove the actuator head 25 mm clearance is

needed above the actuator.

The valve may be plumbed in any angle but preferably not

with the actuator head below the horizontal level of the valve

body. Make sure there is enough room around the actuator

head for servicing or replacement.

When used to form part of a central heating system, do not

locate it where it will block the system vent, cold feed or any

bypass when the valve is closed.

Mount the valve directly in the tube or pipe. Do not grip

actuator head while making and tightening plumbing

connections. Either hold valve body in your hand or attach

adjustable spanner across the hexagonal or flat faces on the

valve body.

Compression models

For compression fitted models, tighten the compression nuts

enough to make a watertight seal. Take care not to

overtighten.

Important

Installation of a new actuator head does not require draining

the system providing the valve body and cartridge assembly

remain in the pipeline.

1. Disconnect power supply before servicing to avoid electrical shock or equipment damage.

2. Disconnect leadwires to actuator head, or depress tab on

Molex™

wires for rewiring.

3. The actuator head is automatically latched to valve (see

figure 8). To remove, lift up on the latch mechanism located directly below the red manual open lever. Press the

actuator head down towards the body with moderate hand

force and turn counter-clockwise by 1/8 turn (45 degrees)

simultaneously. Lift the actuator head off the valve body.

NOTE: Actuator can also be installed at right angles to valve

body but in this position latch mechanism is not engaged.

4. Install the new actuator head by reversing process in (3).

5. Reconnect leadwires or Molex™

6. Restore power.

connector and remove. Where appropriate, label

connector.

EN0H-0327GE25 R0206 6 Honeywell • All rights reserved

Page 7

VC SERIES

Adjustment and Testing

Manual Opener

The manual opener can be manipulated when in the up

position. The motorized valve can be opened by firmly

pushing the red manual lever down to midway and in (only

possible if the actuator is in the upper position). This holds all

ports in the open position, and with auxiliary switch models

the NO switch is closed. Ports A and B of 3-way valves are

opened. This 'manual open' position may be used for filling,

venting or draining the system, or for opening the valve in

case of power failure. The valve can be restored manually to

the closed position by depressing the red manual lever lightly

and then pulling it out. The valve actuator returns to the

automatic position when power is restored.

Checkout

1. Raise the set point of the thermostat above room temperature to initiate a call for heat. Valve position indicator

should move downward to the open position.

2. For all auxiliary switch models, monitor the control devices. 2-way valve: check that the valve opens, the auxiliary switch (if present) closes, and at the end of the opening stroke the circuit to the circulator or another valve is

made. 3-way valve: check that port A opens, port B

closes, the auxiliary switch (if present) operates, and at

the end of the opening stroke the circuit to the circulator or

another valve is made.

3. Lower the set point of the thermostat below room temperature.

4. Observe the control devices.

2-way valve: check that the valve closes and all auxiliary

equipment stops.

3-way valve: check that port A closes and all auxiliary

equipment stops.

Service

WARNING

This valve should be serviced by a trained,

experienced service person.

1. If the valve is leaking, drain system or isolate valve from

the system.

2. Check to see if the cartridge needs to be replaced.

3. If the gear train or the motor is damaged, replace the

actuator assembly.

NOTE: Honeywell hydronic valves are designed and tested

for silent operation in properly designed and installed systems. However, water noises may occur

as a result of excessive water velocity. Piping noises

may occur in high temperature (over 100

with insufficient water pressure.

°

C) systems

Honeywell • All rights reserved EN0H-0327GE25 R0206

Page 8

VC SERIES

Flow Diagrams

Fig. 9. Valve pressure loss characteristic

Port flow (%)

Travel (%)

Fig. 10. Typical 3-way valve diverting characteristic at constant pressure on port AB

ACS Control Products

Honeywell GmbH

Möhnestraße 55

59755 Arnsberg, Germany

Phone: +49 (2932) 9880

Fax: +49 (2932) 988324

www.honeywell.com

EN0H-0327GE25 R0206

February 2006

© 2005 Honeywell International Inc.

Subject to change • All rights reserved

Manufactured for and on behalf of the Environmental and Combustion

Controls Division of Honeywell Technologies Sàrl, Ecublens,

Route du Bois 37, Switzerland or by its Authorized Representative.

Loading...

Loading...