Page 1

VC series

BALANCED HYDRONIC VALVES 2--WAY AND 3--WAY

PRODUCT HANDBOOK

APPLICATION

The VC series balanced hydronic valves allow greater control

of hot and/or cold water flow.

The VC series balanced hydronic valves are designed for

both domestic boiler heating and domestic cooling

applications.

Subject to change without notice. Printed in the Netherlands.

Contents

General page

Description 2

Series overview 3

Technical

Construction and operation 4

Specifications 6

Dimensions 8

Valve selection chart 9

Installation and operation

Installation data 10

Adjustment and service data 12

Various

Quality assurance statement 13

Approvals and standards 14

Ordering information 15

Standard product examples 16

Fitting for 1/2” and 15 mm valves

Fitting for 3/4” and 22 mm valves 19

Fitting for 1” and 28 mm valves 20

Accessories 21

EN2R--9011 0108R2--NE

17

Page 2

DESCRIPTION

The VC series 2--position hydronic valves are used in

domestic and small commercial applications to control the

flow of hot and/or cold water. They consist of an actuator,

valve and a cartridge assembly.

2--way valves are designed for ON --OFF ”zone” control of

domestic systems.

3--way valves can be piped for either diverting or mixing valve

applications in domestic central heating and/or cooling

systems. Both versions can be used to control individual fan

coil, baseboard radiator or convector applications.

Depending on the model selected they can be controlled by a

low or line voltage SPST

such as a room thermostat, aquastat or flow switch.

or SPDT controller,

The VC series hydronic valves are designed to take avantage

of sinusoidal valve actuator travel and therefore operate

silently and without water hammer. Through internal logic the

actuator only takes power while driving the valve to the

commanded position.

The actuator head is removable without affecting the integrity

of the water system. All actuator versions are interchangeable

with any valve body, offering the highest flexibility for boiler

production line assembly and maintenance.

The valve piston construction allows for port sealing that is

independent of the differential pressure across the valve.

Flow through the 2--way valve can be in either direction, so

the ports are not designated.

3--way valves are suitable for both diverting water from AB to

A or to B and from A or B to AB.

2

EN2R--9011 0108R2--NE

Page 3

FEATURES

2--way or 3--way body

Wide variety of pipe c onnections including:

ISO 7--1 (BSP. Pl)

BSP.T

NPT

Sweat

Compression

Flare

Control by a low or line voltage SPST or SPDT control

24 Vac, 100 ... 130 Vac or 200 ... 240 Vac actuators

available

SPDT auxiliary switch available

Quick connect electrical connections or 1000 mm leads

Minimal actuator power consumption

Double insulated actuator

Pressure differential up to 4 bar

1 ... 95 _C fluid temperature

0 ... 65 _C ambient temperature

Quick and easy replacement of moving parts

Actuator head installation does not require draining of the

system.

3

EN2R--9011 0108R2--NE

Page 4

CONSTRUCTION AND OPERATION

All moving and sealing parts of the valve are constructed in

the cartridge assembly.

The ports are sealed with ”O”-- rings on the outer surface of

the piston.

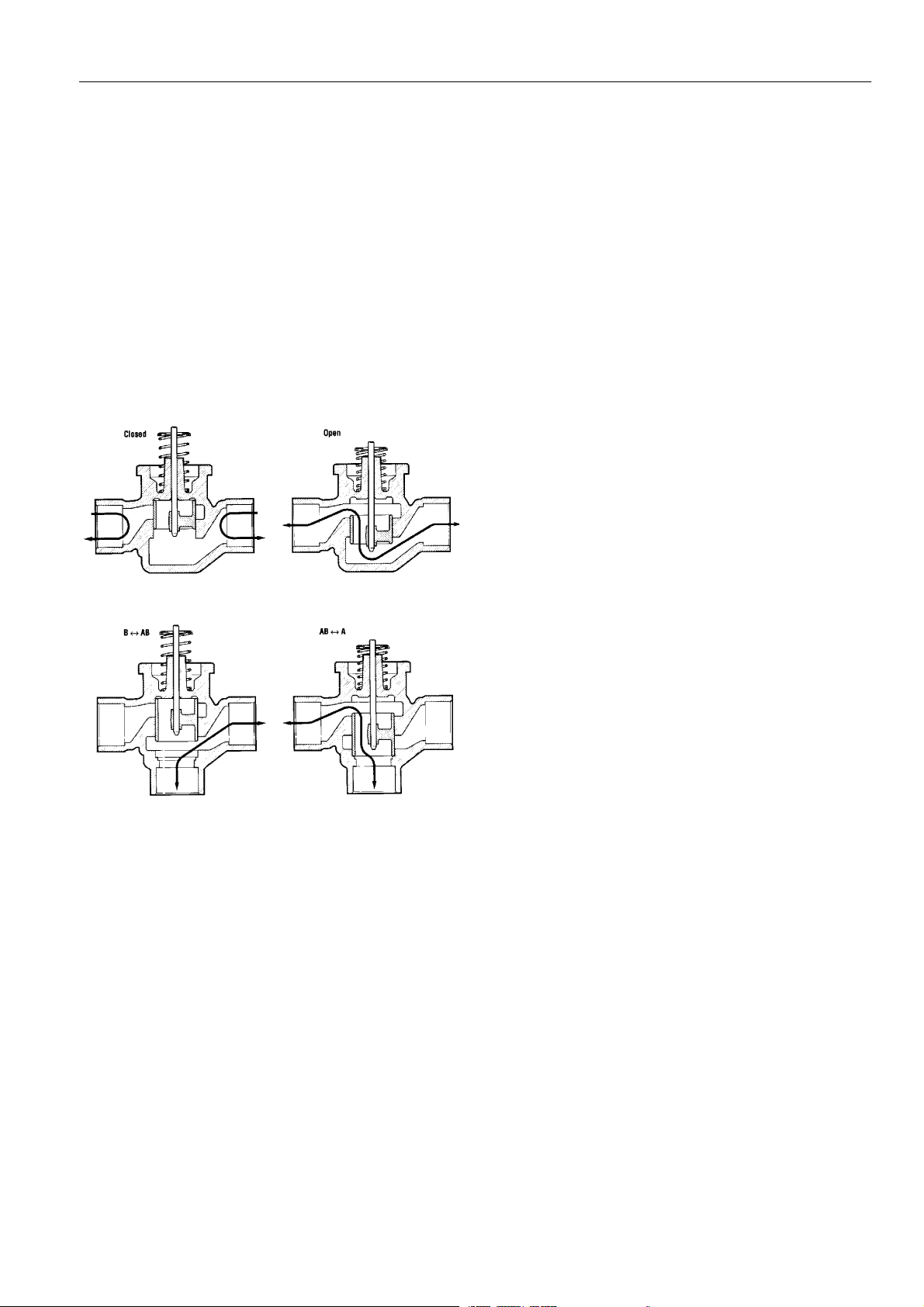

When the valve stem is driven down to open port A the water

will flow through the hollow piston to the other port.

In case of a 3--way valve with the piston driven down port B is

sealed, allowing flow between port AB and port A. With the

stem up the flow is between port AB and port B.

The VC series hydronic valves offer a variety of versions of

pipe connections to suit the different applications.

The valve pressure loss characteristic is dependent on the

pipe connection/dimensions

For the actual valve rating please refer to the specification

section.

Fig. 1.

Fig. 2.

2- way valve

When the valve reaches the fully open position the cam

closes switch SW

When the need for heat is satified, the controller contacts

and opens the switch SW2.

1

open, RLY1 is de-- energized and the valve motor driven

through SW

and the NC contacts of SW3.

1

When the valve reaches fully closed position, the cam closes

SW

and opens SW1. The valve is ready for the next call for

2

heat.

For both types of actuator a power failure will leave the valve

at the position it was interrupted.

When power is restored, the valve will respond to controller

demand.

3- way diverter valve

3- way diverter valve with an SPDT (3- wire) actuator

On a call for heat, the NO controller contacts close, the valve

closes port B and opens port A.

When port A is in the fully open position, the cam closes limit

switch SW

When the need for heat is satisfied the NC controller contacts

close, energizing the valve through SW

close.

When port A is fully closed the cam closes SW

SW

1

3- way diverter valve with an SPST (2- wire and common) actuator

On a call for heat, the controller contacts close, RLY

energized making the NO contacts in switch SW

port B to close and port A to open.

When port A reaches the fully open position the cam closes

switch SW

When the need for heat is satified, the controller contacts

open. RLY

and port A is driven closed through SW1 and the NC contacts

of SW

When port A is in the fully closed position, the cam closes

SW

2

heat.

For both types of actuator a power failure will leave the valve

at the position it was when interrupted.

When power is restored, the valve will respond to controller

demand.

and opens limit switch SW2.

1

causing port A to

1

and opens

2

. The valve is ready for the next call for heat.

is

1

causing

3,

and opens the switch SW2.

1

is de--energized making the NC contacts in SW

1

3.

and opens SW1. The valve is ready for the next call for

3

2- way valve with an SPDT (3- w ire) actuator

On a call for heat, the NO controller contacts close and the

valve opens. When the valve is fully open, the cam closes

switch SW

and opens switch SW2.

1

When the need for heat is satisfied the NC controller contacts

close, energizing the valve through SW

and closing the

1

valve.

When the valve is fully closed the cam closes SW

SW

. The valve is ready for the next call for heat.

1

and opens

2

2- way valve with an SPST (2- wire and common) actuator

On a call for heat, the controller contacts close, RLY1is

energized making the NO contacts in switch SW

causing the

3

valve to open.

Wiring

Fig. 3. and 4. show wiring connections for SPDT and SPST

controllers on either 2-- way valves or 3--way valves.

Port A ”open” and ”closed” denotes valve open and closed for

2-- way, and AB-- B open and AB--B open for 3--way valves

respectively.

Ona2--wayvalve:

Port A open denotes valve open

Ona3--wayvalve:

Port A open denotes flow through AB--A

Port A closed denotes flow through AB-- B

For mixed low/line voltage, the cable assembly version

recommended.

4

EN2R--9011 0108R2-- NE

Page 5

Fig. 3. Logic sequence diagram with 3 wire actuator for SPDT controller

Fig. 4. Logic sequence diagram with 2 wire + common actuator for SPST controller

5

EN2R--9011 0108R2-- NE

Page 6

SPECIFICATIONS

ext

ernally

threaded

E--externallythreade

d

Volt a g e Colour-- coded label

24 V, 50/60 Hz Blue

100 ... 130 V, 50/60 Hz Black

200 ... 240 V, 50/60 Hz Red

Power consumption

6 Watt maximum at nominal voltages (during valve position

change only)

6 VA for transformer and wiring

Maximum power time: 15%

Endswitchrating

2.2 A inductive from 5 ... 120 Vac

1.0 A inductive above 120 ... 277 Vac

Minimum dc switching capbility: 0.05A 24 Vdc

Nominal timing

Valve opens in 6 seconds @ 60 Hz (20% longer @ 50 Hz)

Table1.Pipefittingsizes

Pipe fitting sizes

Flare E E -- -- -- -- --

Inverted flare -- I -- -- -- -- --

Sweat -- N N N -- -- --

BSPP -- I E, I E, I -- -- --

BSPT -- I I -- -- -- --

NPT -- -- I I -- -- --

Compression fitting -- -- -- -- I E E

3/8” 1/2” 3/4” 1” 15 mm 22 mm 28 mm Note: N -- not threaded

Electrical termination

Molex

With integral 1000 mm (39”) leadwire cable

Pipe fitting sizes

Seetable1.

TM

Requires mating connector receptacle/housing

# 39-- 01 --2060

Contacts: Mini--Fit 5556 series

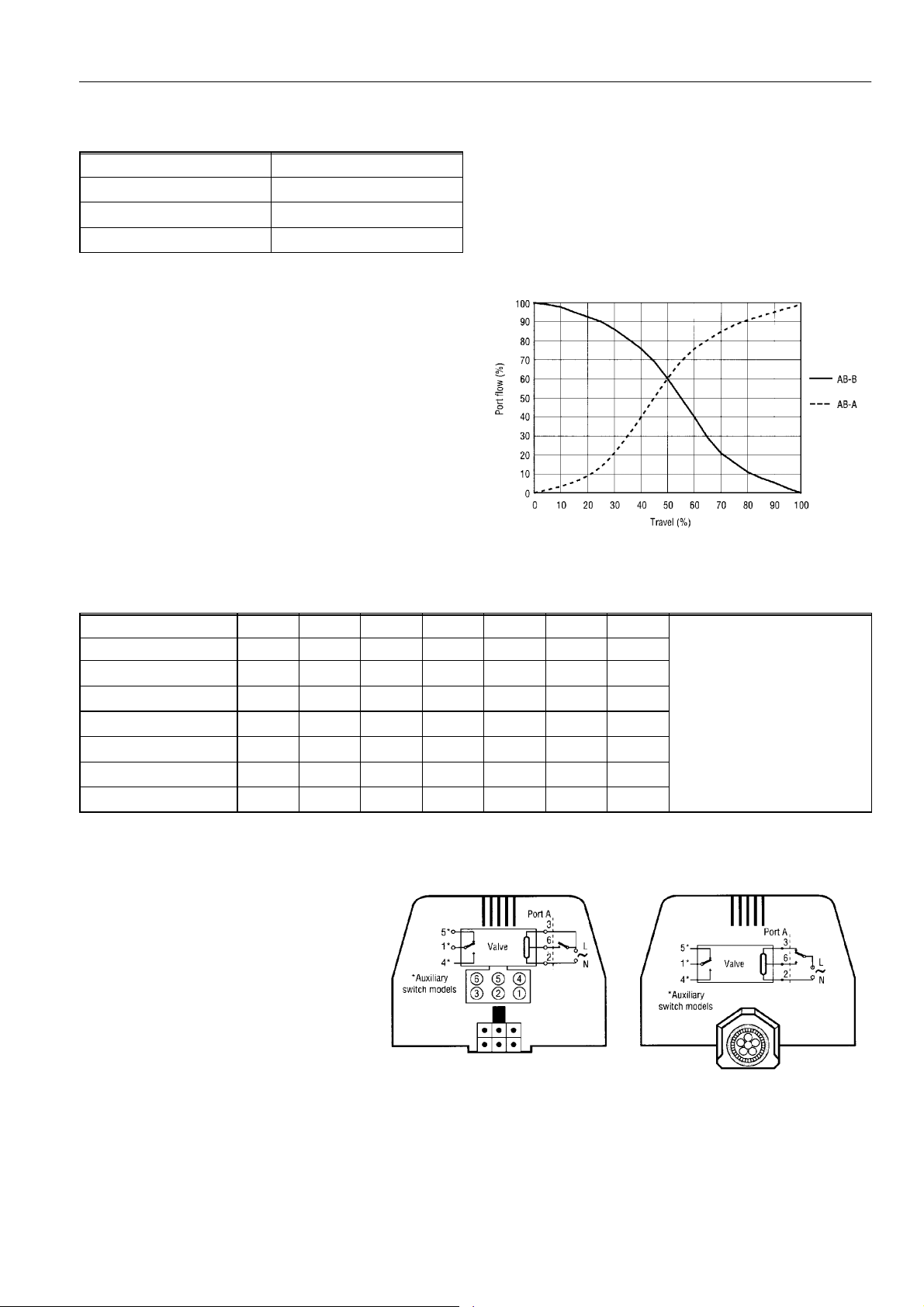

Fig. 5. 3--way valve diverting flow characteristic at

(header# 39--30--1060)

constant pressure on port AB

I -- internally threaded

E--

Terminal Action Wire colour

1Com* Orange

2 Neutral Blue

3Closed** Brown

4NO* Grey

5NC* White

6 Open** Black

* Terminals 1, 4 and 5 are only

connected if an auxiliary switch is used.

NO, NC refers to port A closed position

** Refers to port A (closed or open)

NOTE: For mixed voltages (low/line voltage)

thecableassemblyversionis

recommended

Fig. 6. Wiring terminal colour coding

MolexTMversion

6

Lead wire cable

EN2R--9011 0108R2-- NE

Page 7

Actuator type

3

/

3-- wire

(for SPDT controller)

2--wire + common

(for SPST controller)

Table 2. Wiring connections and valve movements

Connections 2-- way valve

Cable model MolexTMmodel

Blue & brown energized

Black de--energized

Blue & black energized

Brown de--energized

Blue & brown energized

Brown and black open

Blue & brown energized

Brown and black closed

Pin #2 & 3 energized

Pin #6 de --energized

Pin #2 & 6 energized

Pin #3 de --energized

Pin #2 & 3 energized

Pin #3 and 6 open

Pin #2 & 3 energized

Pin#3and6closed

movement movement

Closes A port closes

Opens B port closes

Closes A port closes

Opens B port closes

3-- way valve

Ambient temperature

0 ... 65 _C

Fluid temperature

1 ... 95 _C (120 _C short duration peak)

Shipping storage temperature

--40 ... 65 _C

Pressure rating

Static: 20 bar

Burst: 100 bar

Maximum operating pressure differential

4 bar

Flow rating

Dependent upon body configuration (see fig. 5., 7. and 8.)

Q

Kv

3

/h to be calculated as:

p(bar)

2

Flow rate Q m

Q = Kv × ∆

Pressure loss αp(bar)tobecalculatedas:

∆p =

Flow

2-way

Flow can be in either direction

Valve is closed without the actuator mounted

3-way

Flow can be diverting (AB to A or B) or mixing (A or B to AB).

Port A is closed without the actuator mounted

10

Kv 6,0

h)

Flow rate (m

1

Kv 5,0

Kv 5,3

Kv 2,1

Kv 3,0

0,1

0,001 0,01 0,1

bar

0,1 1 10kPa

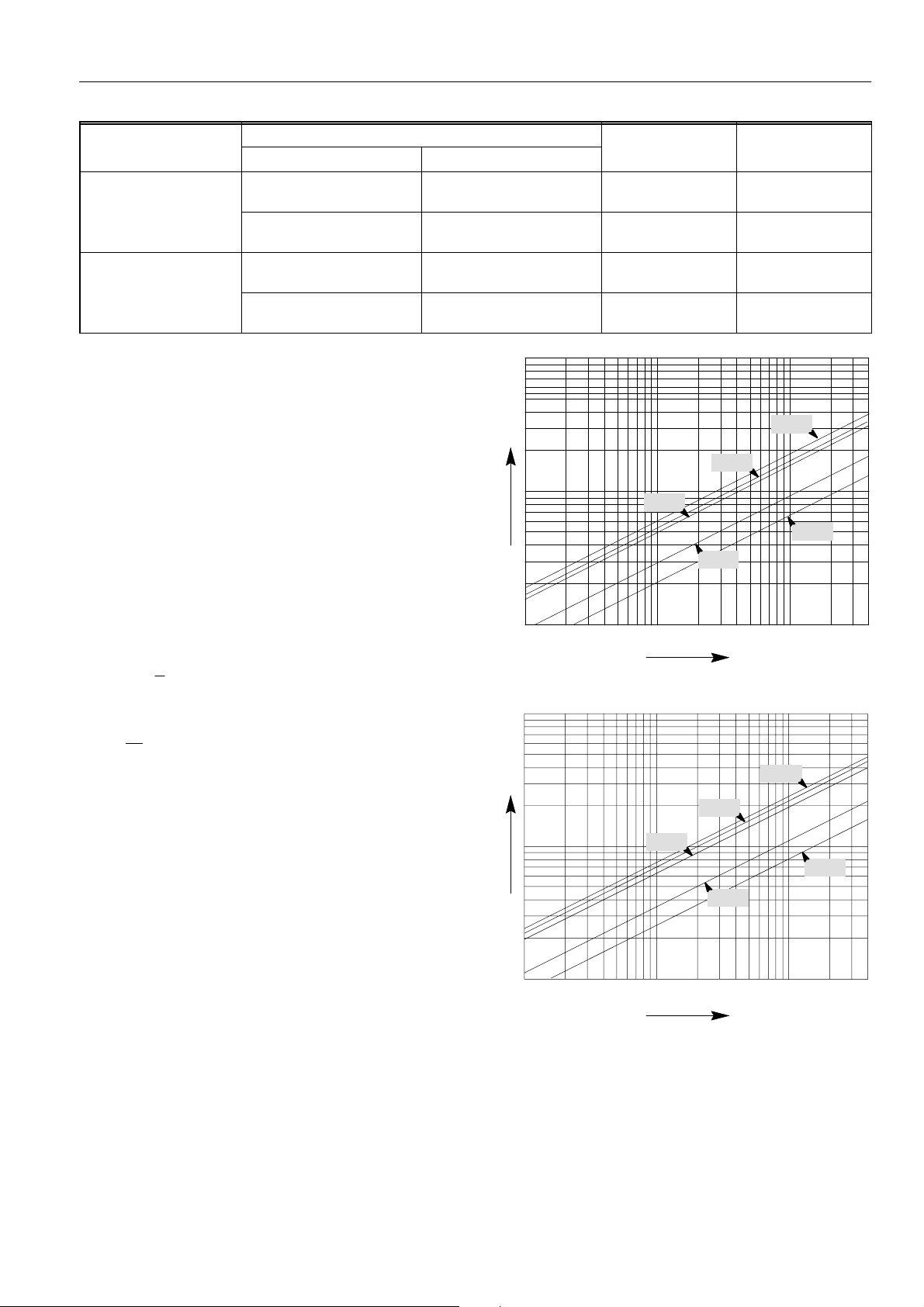

Pressure loss

Fig. 7. Valve pressure loss characteristic for 2-- way valves

10

Kv 7,7

/h)

3

1

Kv 6,4

Kv 7,0

Kv 2,6

Flow rate (m

Kv 3,4

Valve material

Body: bronze

Cartridge: Ryton

”O”-- ring seals: EPDM rubber

Stem: stainless steel

Actuator cover: Noryl

Actuator base: Ryton

Noryl

TM

(polyphenylene sulphide)

TM

(polyphenylene oxide)

TM

(94V--0)

TM

(94V--0)

0,1

bar

0,001 0,01 0,1

kPa

0,1 1 10

Pressure loss

Fig. 8. Valve pressure loss characteristic for 3-- way valves

7

EN2R--9011 0108R2-- NE

Page 8

DIMENSIONS (NOMINAL)

Pipe fitting 2-- way valve 3-- way valve

Dim. C

mm

1

/2” Sweat 98 111 3.0 98 136 3.6

1

/2” BSPT (internal thread) 98 111 3.0 98 136 3.4

3

/8” flare (no adapter) 98 111 2.1 98 136 2,6

1

/2” flare (no adapter) 98 111 2.9 98 136 3.4

1

/2” inverted flare (no adapter) 98 111 3.1 98 136 3.6

1

/2” BSPP/15 mm (internal thread) 98 111 3.0 98 136 3.4

22 mm compression fitting* 112 113 5.3 112 140 7.1

3

/4” BSPP (external thread) 94 113 5.3 94 130 6.9

3

/4” BSPP (internal thread) 94 113 5.3 94 130 7.0

3

/4” BSPT (internal thread) 94 113 5.3 94 130 7.0

3

/4” NPT (internal thread) 94 11 3 5.4 94 130 7.4

3

/4” Sweat 94 113 5.0 94 132 6.4

28 mm compression fitting* 11 6 11 3 6.0 11 6 147 7.7

1” BSPP (internal thread) 94 113 6.0 94 136 7.7

1” BSPP (external thread) 94 11 3 6.0 94 136 7.7

1” NPT (internal thread) 94 11 3 6.0 94 136 7.7

1” Sweat 94 11 3 6.0 94 136 7.7

* Includes compression nuts and olives

Dim. D

mm

Nom. flow

rating -- Kv

Dim. C

mm

Dim. E

mm

Nom. flow

rating -- Kv

2--way valve 3--way valve

94 68 94 68

90 90

C

D

Fig. 9. Valve dimensions

8

E

AB

AB

C

EN2R--9011 0108R2-- NE

Page 9

VALVE SELECTION CHART

PACKAGING

Description Designation

Unit pack --

(10 per overpack)

SPECIAL

CUSTOMER

”C” CARTRIDGE

Kv Designation

00

Standard

Designation

3.0 10

3.2 10

2--way valves

Egg crate (20) E

(20 actuators per pack)

(10 body/cartidge(s)

01 ... 99

2.1 10

2.3 10

per pack)

Customer

special

3.1 10

3.0 10

assigned by

5.3 10

Note:

Order in multiples of 20

actuators & 20 valves

for egg crate pack.

Example:

A ”VC 4612 MM 6000” valve has a

200/240 V, 50/60 Hz, 6 second nominal

timing actuator (with a SPDT auxiliary

switch) for operation by a SPST

thermostat suitable for MolexTMconnection.

The valve has a 3--way body with 28 mm

compression fittings rated at 7.7 Kv & 60

psi differential.

Honeywell

5.3 10

5.3 10

5.3 10

5.4 10

5.0 10

6.0 10

6.0 10

6.0 10

6.0 10

6.0 10

6.0 10

3.6 60

2,6 60

3,4 60

3.6 60

3.4 60

7.1 60

6.9 60

7.0 60

7.0 60

7,4 60

6.4 60

7.7 60

3.4 60

7.7 60

7.7 60

7.7 60

7.7 60

7.7 60

Shipped in unit pack.

3--way valves

”B” BODY

”A” ACTUATORS

Description Designation

Description Designation

2--way valves

Nominal timing @ 50 Hz: 7 seconds

machined to accept 15 mm

* The valve end fittings are internally

connector 4612

TM

-- w i t h M o l e x

compression fittings.

** Compression fittings included

-- with 1000 mm cable 4613

” Flare (no adapter) AC

” Sweat AA

” BSPT (internal thread) AB

” Flare (no adapter) AD

” Inverted Flare (no adapter) AE

” BSPP (internal thread)* AF

” BSPP (external thread) AH

” BSPP (internal thread) AJ

” BSPT (internal thread) AK

” NPT (internal thread) AL

8

2

2

/

2

2

2

/

/

/

/

3

1

1

1

1

connector 2010

TM

-- with 1000 mm cable 2011

-- w i t h M o l e x

24 V (50 ... 60 Hz)

3wireforSPDTstat.

3 wire for SPDT stat.(w/SPDT aux. sw.)

/

1

connector 2610

TM

-- w i t h M o l e x

-- with 1000 mm cable 2611

22 mm Compression fitting** AG

3

2 wire + com. for SPST stat.

4

/

/

3

connector 8010

TM

-- w i t h M o l e x

” Sweat AM

4

4

4

4

/

/

/

3

3

3

28 mm Compression fitting** AN

1” BSPP (internal thread) AP

1” BSPP (external thread) AQ

1” NPT (internal AR

1” Sweat AS

connector 8610

TM

-- with 1000 mm cable 8011

-- w i t h M o l e x

-- with 1000 mm cable 8611

2 wire + com. for SPST stat. (w/SPDT aux. sw)

connector 6010

TM

-- with 1000 mm cable 6011

-- w i t h M o l e x

100 ... 130 V (50 ... 60 Hz)

3wireforSPDTstat.

1” BSPT (internal thread) AT

3 wire for SPDT stat. (w/SPDT aux. sw.)

” Sweat MA

” Flare (no adapter) MB

2

8

/

/

3--way valves

1

3

connector 6610

TM

-- w i t h M o l e x

-- with 1000 mm cable 6611

2 wire + com. for SPST stat.

9

” Flare (no adapter) MC

2

/

1

connector 4010

TM

-- w i t h M o l e x

” Inverted Flare (no adapter) MD

/

1

-- with 1000 mm cable 4011

” BSPP (internal thread)* ME

” BSPP (external thread) MG

” BSPP (internal thread) MH

” BSPT (internal thread) MJ

” NPT (internal thread) MK

” Sweat ML

2

2

4

4

/

1

22 mm Compression fitting** MF

4

/

/

/

3

/

3

3

3

connector 4610

TM

-- w i t h M o l e x

-- with 1000 mm cable 4611

2 wire + com. for SPST stat. (w/SPDT aux. sw.)

200 ... 240 V (50 ... 60 Hz)

3wireforSPDTstat.

4

4

/

3

connector 6012

TM

-- w i t h M o l e x

” BSPT (internal thread) MN

2

/

1

28 mm Compression fitting** MM

-- with 1000 mm cable 6013

3 wire for SPDT stat.(w/SPDT aux. sw.)

1” BSPP (internal thread) MP

1” BSPP (external thread) MQ

1” NPT (internal MR

1” Sweat MS

1” BSPT (internal thread) MT

connector 6612

TM

-- w i t h M o l e x

-- with 1000 mm cable 6613

connector 4012

TM

-- w i t h M o l e x

-- with 1000 mm cable 4013

2 wire + com. for SPST stat.

EN2R--9011 0101R1-- NE

2 wire + com. for SPST stat. (w/SPDT aux. sw.)

Page 10

INSTALLATION

IMPORTANT

Take care that installer is a trained experienced

service person.

When installing this product read these instructions

carefully.

Failure to follow them could damage the product or

cause a hazardous condition.

Check the ratings given in the instructions and on the

product to make sure it is suitable for your

application.

Always conduct a thorough checkout after

installation.

CAUTION

Switch off power supply before making electrical connections to prevent electrical shock and equipment

damage.

It is advisable to remove the actuator head from the

valve body for ease of installation.

Fit the actuator head in the most convenient position

for wiring.

On sweat fitted valves, the cartridge is shipped loose

or is removed to avoid being damaged during the

solder operation.

On 24 Volt systems, never short circuit the valve coil

terminals as this may burn out the heat anticipator in

the thermostat.

To remove the actuator head 25 mm clearance is

needed above the actuator.

Plumbing (see fig. 10.)

The valve may be plumbed in any angle but preferably not

with the actuator head below the horizontal level of the valve

body. Make sure there is enough room around the actuator

head for servicing or replacement.

When used to form a part of a central heating system, do not

locate it where it will block the system vent, cold feed or any

bypass when the valve is closed

Mount the valve directly in the tube or pipe. Do not grip

actuator head while making and thightening plumbing

connections. Either hold valve body in your hand or attach

adjustable spanner across the hexagonal or flat faces on the

valve body.

Compression models

For compression fitted models, tighten the compression nuts

enough to make a watertight seal.

Take care not to overtighten.

Maximum torque limit is 33 ft--lb for the 22 mm compression

fitting and 48 ft--lb for the 28 mm compression fitting.

Fig. 10. Plumbing

Sweat models

On sweat fitted valves, the cartridge is shipped loose to avoid

being damaged during the solder operation.

Remove valve actuator from body and solder the

connecting pipes in accordance with normal soldering

practices.

After soldering and valve has cooled, remove cartridge

assembly from plastic bag, insert into the valve body and

tighten down with enclosed wrench until it bottoms out. Do

not overtighten (maximum torque is 40 ft--lb).

The top surface of the cartridge will be flush with the top

edge of the body casting.

Replace valve actuator.

10

EN2R--9011 0108R2-- NE

Page 11

To install a replacement actuator head

IMPORTANT

Installation of a new actuator head does not require

draining the system providing the valve body and

cartridge assembly remain in the pipe line.

Disconnect power supply before servicing to avoid

electrical shock or equipment damage.

Disconnect leadwires to actuator head, or depress

tabonMolex

TM

connector and remove.

Where appropriate, label wires for rewiring.

The actuator head is automatically latched to the valve

(see fig. 11.) To remove lift up on the latch mechanism

located directly below the red manual open lever.

Press the actuator head down towards the valve body with

moderate hand force and turn counter--clockwise by

turn (45 degrees) simultaneously.

1

/

8

Lift the actuator head off the valve body.

NOTE: The actuator can also be installed at right angles

to the valve body but in this position the latch

mechanism is not engaged.

Install the new actuator head by reversing the process.

Reconnect leadwires or Molex

TM

connector.

Restore power.

Fig. 11. Latch mechanism

11

EN2R--9011 0108R2-- NE

Page 12

ADJUSTMENT, CHECKOUT AND SERVICE

Manual opener

The manual opener can be manipulated when in the up

position.

The motorized valve can be opened by firmly pushing the red

manual lever down to midway and in (only possible if the

actuator is in the upper position).

This holds all ports in the open position and with auxiliary

switch models the NO switch is closed.

Ports A and B of 3--way valves are opened.

This ”manual open” position may be used for filling, venting or

draining the system or for opening the valve in case of power

failure. The valve can be restored manually to the closed

position by depressing the red manual lever ligthly and then

pulling it out.

The valve actuator returns to the automatic position when

power is restored.

Checkout

Raise the setpoint of the thermostat above room

temperature to initiate a call for heat.

Valve position indicator should move downward to the

open position.

For all auxiliary switch models, monitor the control devices.

2--way valve:

check that the valve opens, the auxiliary switch (if

present) closes and at the end of the opening

stroke the circuit to the circulator or another valve

is made.

3--way valve:

check that port A opens, port B closes, the

auxiliary switch (if present) operates and at the

end of the opening stroke the circuit to the

circulaotr or another valve is made.

Lower the set point of the thermostat below room

temperature.

Observe the control devices.

2--way valve:

check that the valve closes and all auxiliary

equipment stops.

3--way valve:

check that port A closes and all auxiliary

equipment stops.

Service

WARNING

The VC series hydronic valves should be serviced by

trained, experienced service personnel.

If the valve is leaking, drain system or isolate valve from

the system.

Check to see if the cartridge needs to be replaced.

If the gear train of the motor is damaged, replace the

actuator assembly.

NOTE: The VC series hydronic valves are designed and

tested for silent operation in properly designed and

installed systems.

However, water noises may occur as a result of

excessive water velocity.

Piping noises may occur in high temperature

(over 100 _C) systems with insufficient water

pressure.

12

EN2R--9011 0108R2-- NE

Page 13

QUALITY ASSURANCE STATEMENT

The quality system is described in Honeywell Limited’s Quality

Manual and supporting operational procedures and

instructions.

The quality system is approved by Quality Management

Institute (accredited by the Standards Council of Canada and

RvC) against certificate 001082 and is reviewed annually.

The quality organisation is responsible for defining,

maintaining, improving and verification of the quality systems

in the field of design, production process and field quality

service.

Each production operation has manufacturing instructions

containing work procedures, set--up information, quality

standards and quality checks.

All products are tested prior to shipping.

Assembly inspection is conducted by the assembly workers.

All inspections (incoming and assembly) are performed by

trained personel and according inspection procedures.

13

EN2R--9011 0108R2-- NE

Page 14

STANDARDS AND APPROVALS

Approvals

The VC series balanced hydronic valves 200 ... 240 V and

24 V versions meet the Low Voltage Directive 73/23/EEC

(EN 60730 --1 and -- 2 -- 8) and EMC Directive 89/336/EEC for

incorporation in household electrical applications according to

EN 60335 series.

14

EN2R--9011 0108R2-- NE

Page 15

ORDERING INFORMAT ION

Before ordering p lease determine the following:

The body type:

2-- way or 3-- way. See Valve selection chart page 9

The actuator voltage:

24, 100 ... 130 or 200 ... 240 Vac. See Valve selection

chart page 9

Thepipefittingsize:

to do this first determine the flow rating (Kv) required.

Refer to Dimensions page 6 to select the pipe fitting

that is applicable.

Then, contact your Honeywell account manager who will

assist you in determing the order specification number.

VC

4013

Product family specifier

Actuator specifier

-- the first digit denotes a standard

Honeywell control circuit series.

-- the second, third and fourth digits

denote actuator and termination

variations

Order from:

Your nearest Honeywell branch office.

Your local Honeywell agent or wholesaler.

NOTE: Most models of valves and replacement components

MG 60

will be available under ”TRADELINE” label.

Ask your wholesaler for details.

E00

Accessories and packing specifier

-- this letter denotes the packaging and

accessory configurations for complete

devices and merchandised items

Customizing specifier

-- expresses variations in a valve

configuration which consists of a

product family, actuator, body and

cartridge

-- 00 is standard configuration

Body specifier

-- a first letter from A to L denotes 2--way

operation, whereas M to Z denotes

3-- way operation

-- the second letter accommodates

first letter variations

Cartridge specifier

-- a number from 10 to 59 denotes

2-- way operation, whereas 60 to 99 de

notes 3--way operation.

Fig. 12. Model number chart

15

EN2R--9011 0108R2-- NE

Page 16

STANDARD PRODUCT EXAMPLES

NOTE: The letter ”Z” denotes the absence of a component

VC2010MG 6000

VC2010 actuator packed with a MG6000 body

VC2010ZZ 00E

Egg crate with 20 actuators type 2010

VC Z MG6000E

Egg crate with 10 bodies type MG6000

VC2010ZZ00

Actuator only

VC ZZ 6000

Cartridge for 3-- way valve

Minimum quantity 10 pcs

VC ZZ 1000

Cartridge for 2-- way valve

Minimum quantity 10 pcs

16

EN2R--9011 0108R2-- NE

Page 17

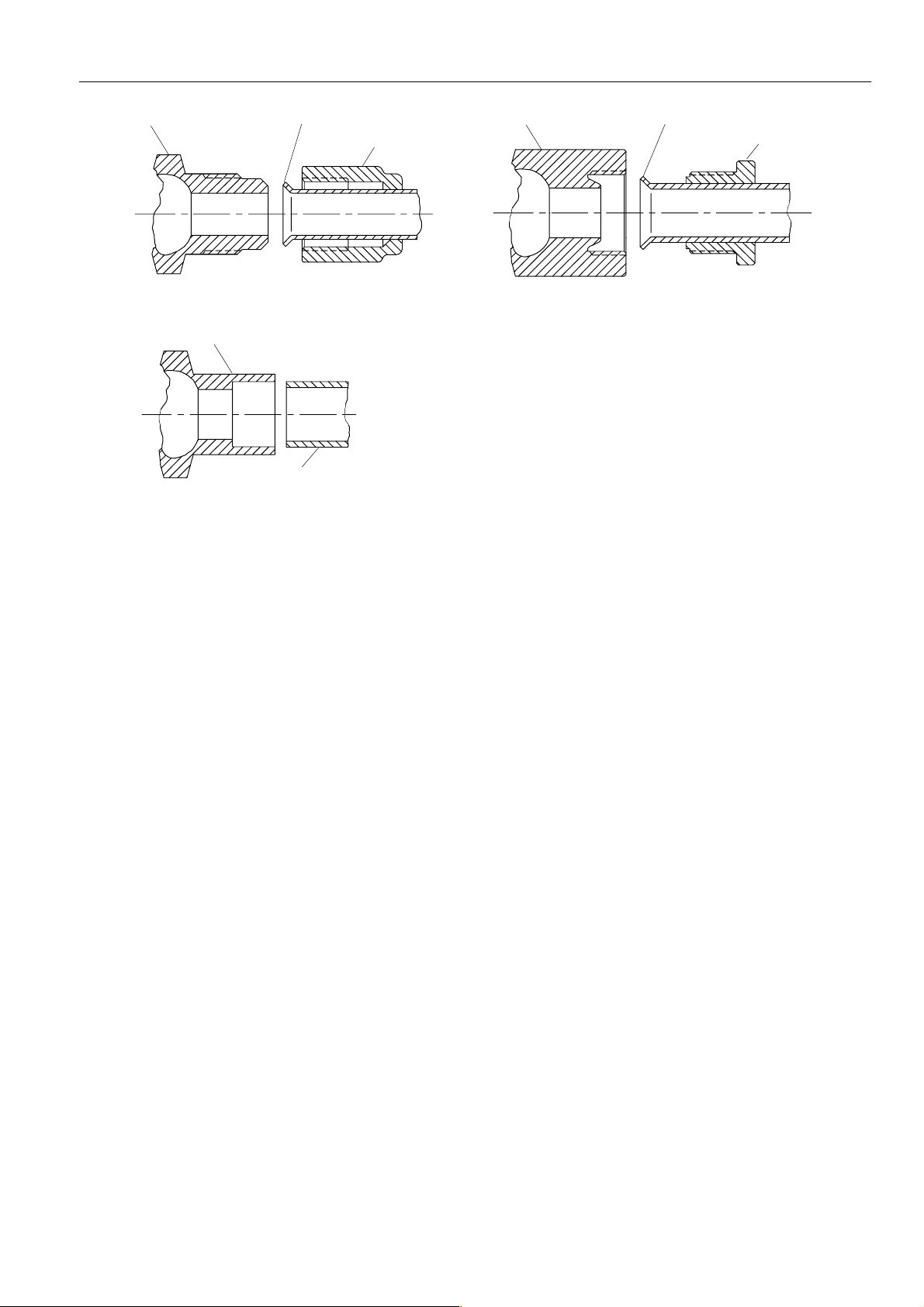

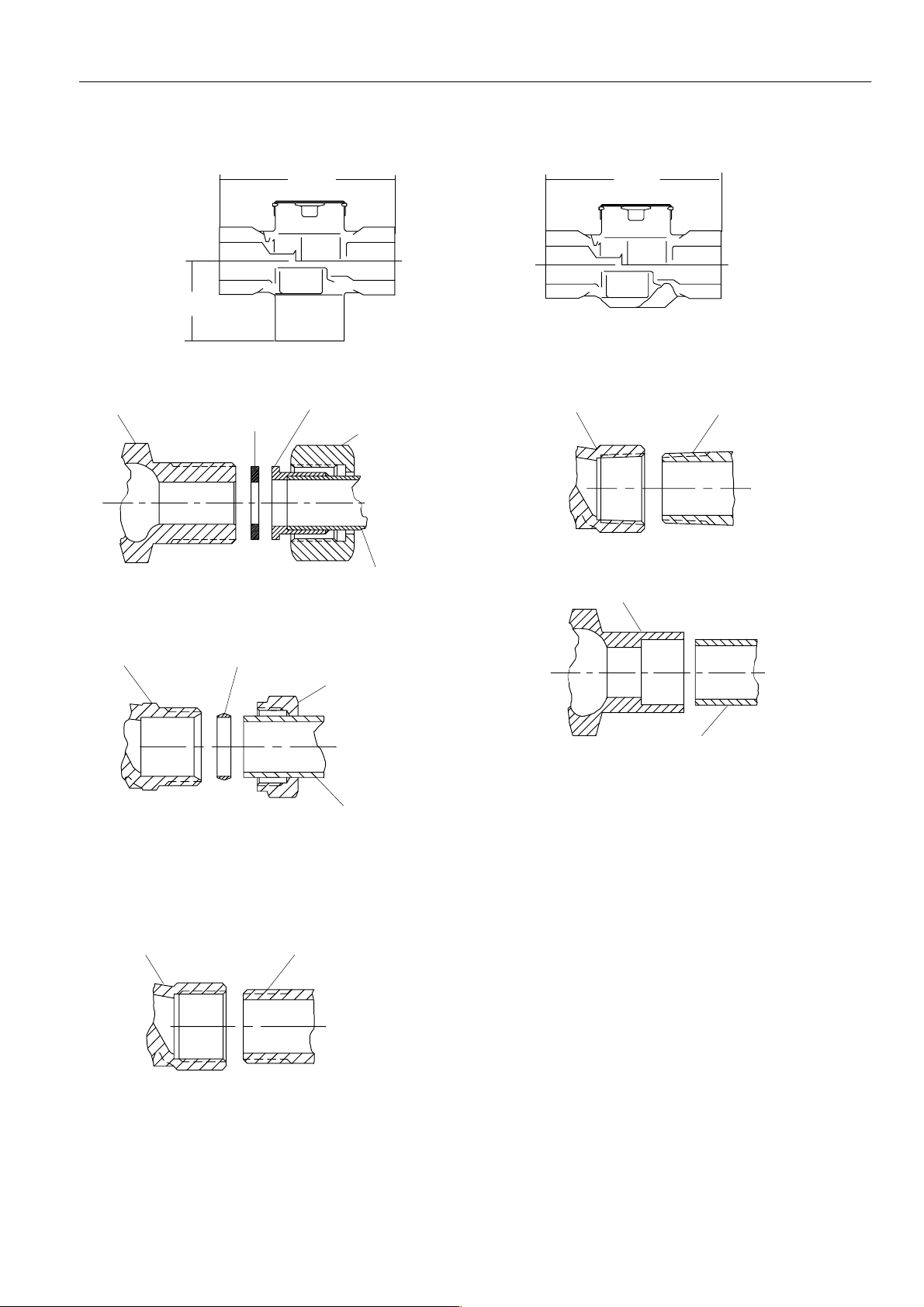

FITTINGS FOR 1/2” AND 15 MM VALVE FAMILY (COMMONLY USED WITH VC VALVES)

46.0

Valve body

98.0

A

B

AB

Fig. 13. Finished dimensions of 1/2” or 15 mm bronze bodies (VC valves)

Metal flange

Gasket

Pipe is soldered or threaded into metal

flange (solder joint shown)

Fig. 14. 1/2” BSPP external (G 1/2 B)

Loose brass nut

98.0

A

B

Valve body Pipe has paralel threads

Fig. 16. 1/2” BSPP internal (Rp 1/2”)

Valve body Loose brass nut

Valve body

North America 1/2”pipe (5/8” outer diameter)

Pipe has 45_ flare

Loose nut

Fig. 15. 1/2” flare

Loose ferrule (compression ring)

Fig. 17. 1/2” BSPP internal (Rp 1/2”) using ferrule & nut

for sealing 15 mm outer diameter pipe

17

EN2R--9011 0108R2-- NE

Page 18

Valve body

V

Pipe has 45_ flare

Loose nut

Valve body

Pipe has 45_ flare

Loose nut

For North America 3/8”pipe (1/2” outer diameter)

Fig. 18. 3/8” flare

alve body

Pipe is sweat soldered into valve body

North America 1/2” pipe sweat fitting

Fig. 19. 1/2” Sweat

For North America 1/2” pipe (5/8” outer diameter)

Fig. 20. 1/2” inverted flare

18

EN2R--9011 0108R2-- NE

Page 19

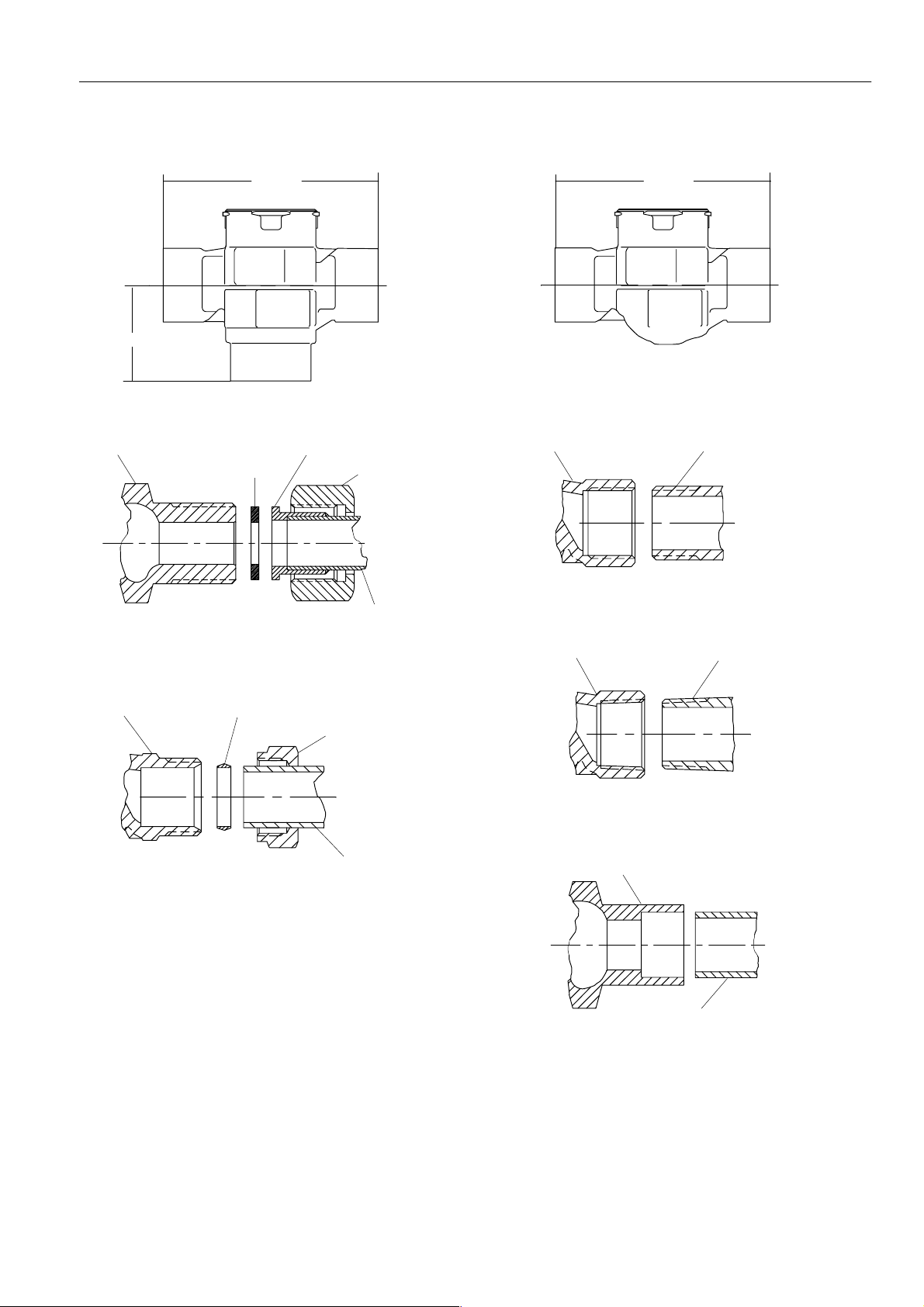

FITTINGS FOR 3/4” AND 22 MM VALVE FAMILY (COMMONLY USED WITH VC VALVES)

93.2 93.2

’B’

Valve body

1)

’B’ = 39.9

Valve body

A

B

AB

1)

Fig. 21. Finished dimensions of 3/4” or 22 mm bronze bodies (VC valves)

Metal flange

Gasket

Pipe is soldered or threaded into metal

flange (solder joint shown)

Fig. 22. 3/4” BSPP external (G 3/4 B)

Loose ferrule (olive) *

Loose brass nut *

Loose brass nut

1)

’B’ = 39.9

A

Valve body

Fig. 24. 3/4” BSPP internal (Rp 3/4)

Valve body

Pipe has tapered threads

B

Pipe has parallel threads

Pipe is slip fit into valve body

Using ferrule and nut for sealing 22 mm outerdiameter pipe.

1)

’B’ = 39.9

* Compression nut and olive are supplied with the valve

body.

Fig. 23. 22 mm compression (external thread)

1)

’B’= 39.9

Fig. 25. 3/4” BSPT internal (Rc 3/4) or NPT internal

Valve body

Pipe is sweat soldered into

1)

’B’ = 42

North America 3/4” pipe sweat fitting

19

valve body

Fig. 26. 3/4” Sweat

EN2R--9011 0108R2-- NE

Page 20

FITTINGS FOR 1” AND 28 MM VALVE FAMILY (COMMONLY USED WITH VC VALVES)

Valve body

93.2

A

B

AB

45.5

Fig. 27. Finished dimensions of 1” or 28 mm bronze bodies (VC valves)

Metal flange

Gasket

Pipe is soldered or threaded into metal

flange (solder joint shown)

Fig. 28. 1” BSPP external (G 1 B)

Loose brass nut

93.2

A

Valve body

Fig. 31. 1” BSPT internal (Rc 1) or 1” NPT internal

Valve body

B

Pipe has tapered threads

Valve body

Using ferrule and nut for sealing 28 mm outerdiameter pipe.

* Compression nut and olive are supplied with the valve

body.

Fig. 29. 28 mm compression (external thread)

Valve body

Fig. 30. 1” BSPP internal (Rp 1)

Loose ferrule (olive) *

Loose brass nut *

Pipe is slip fit into valve body

Pipe has parallel threads

Pipe is sweat soldered into valve body

Fig. 32. 1” Sweat

20

EN2R--9011 0108R2-- NE

Page 21

ACCESSORIES

Replacement cartridge (includes change tool)

Cartridge for 2- way valve

-- order number: VCZZ1000

-- supplied in overpacks of 10 units

Cartridge for 3- way valve

-- ordernumber: VCZZ6000

-- supplied in overpacks of 10 units

MolexTMconnector with wires

CAUTION

Not to be used for line voltage or mixed low/line

voltage applications.

TM

3-wire Molex

-- ordernumber: 40.007.035-- 001

6-wire MolexTMconnector, length 5”

-- ordernumber: 40.007.035-- 002

3-wire MolexTMconnector, length 1000 mm

-- ordernumber: 40.007.035-- 005

connector, length 5”

Home and Building Control

Combustion Controls Center Europe

Honeywell BV

Phileas Foggstraat 7

7821 AJ Emmen

The Netherlands

Tel: +31 (--)591 695911

Fax: +31 (--)591 695200

http://europe.hbc.honeywell.com

21

EN2R--9011 0108R2-- NE

Loading...

Loading...