Page 1

62-0197-04

VBN2, VBN3

CAUTION

CAUTION

85 85

M29519A

Control Ball Valve/Actuator

Assemblies

INSTALLATION INSTRUCTIONS

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check ratings given in the product data literature

and on the product to ensure the product is suitable for your application.

3. Installer must be a trained, experienced, licensed

service technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Preparation

Equipment Damage Hazard.

Foreign particles like dirt and metal chips can

damage the ball seals.

Clean upstream lines prior to installation.

Equipment Damage Hazard.

Improper chemicals can damage the valve.

Use neither aerosol products nor petroleumbased lubricants.

1. Clean the lines upstream of particles larger than

1/16 in. diameter. Open valves fully. Flush entire

hydronic system of contaminants (welding slag,

solder, scale, metal chips, etc.) and chemically

treat water according to local conditions prior to

operation.

2. Proceed with installation once the system specifics

(expansion/contraction of the system and its

medium as well as operating pressures) are within

tolerances.

3. Eliminate air from system.

4. Two-way valves are marked to show flow direction.

IMPORTANT

Flow arrows must point in the direction of the

flow for proper operation.

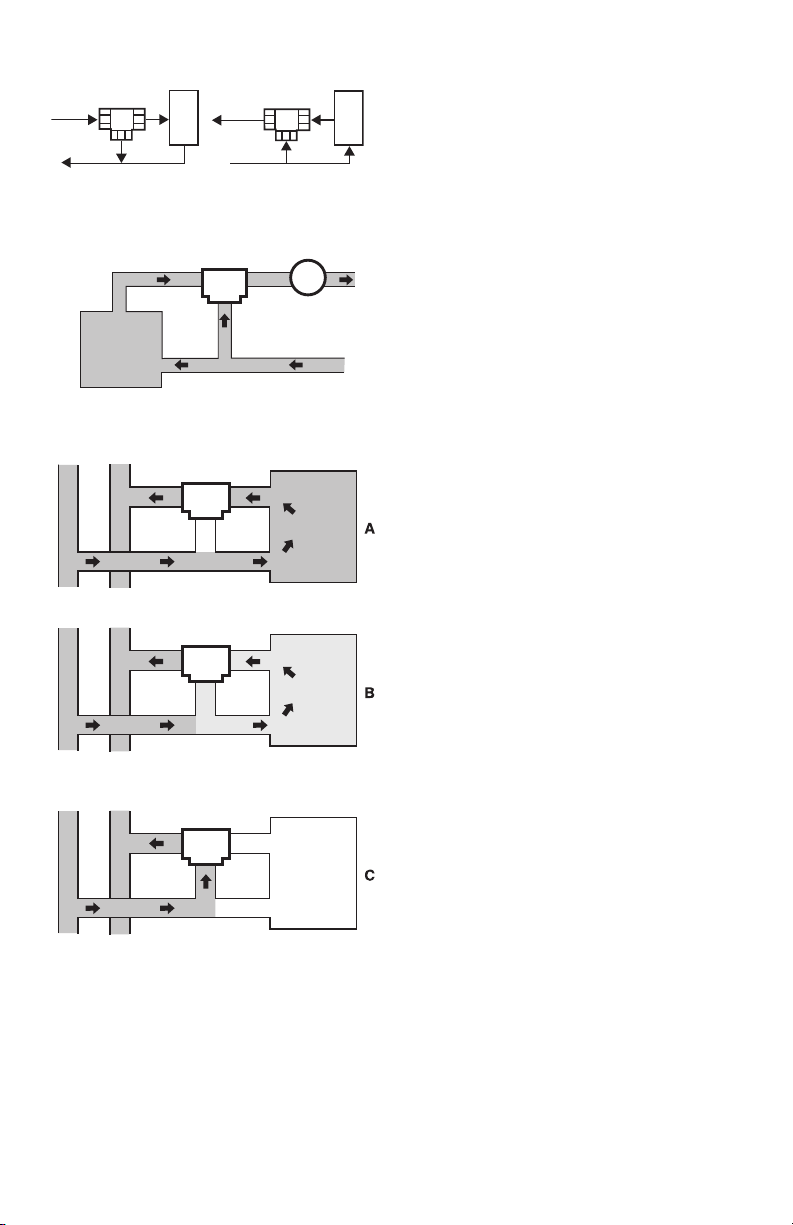

NOTE: For three-way valve mounting, see Fig. 3

through 5.

5. Stem rotation:

a. For two-way valves:

(1) Clockwise to close.

(2) Counterclockwise to open.

b. For three-way valves:

(1) Clockwise to increase B to AB flow.

(2) Counterclockwise to increase A to AB flow.

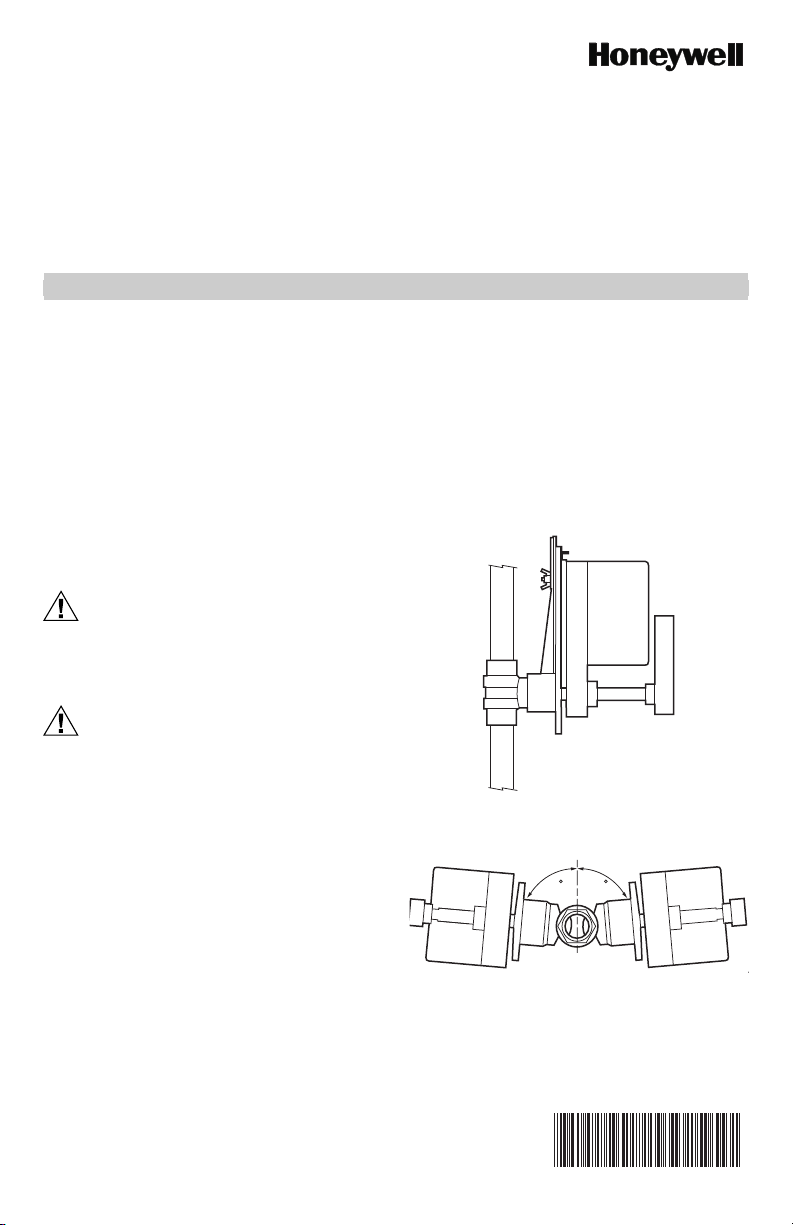

6. Valve must be mounted with the actuator/bracket

above the valve body. Do not install the valve with

the stem below horizontal or upside down. (See

Fig. 1 and 2.)

M29518

Fig. 1. Vertical valve installation.

Fig. 2. Acceptable valve angle from vertical.

Page 2

VBN2, VBN3 CONTROL BALL VALVE/ACTUATOR ASSEMBLIES

See Fig. 8 and 9 for valve dimensions. Refer to actuator

AB PORT A PORT

SUPPLY

RETURN

Fig. 3. Three-way ball valve flow orientation

BOILER

COIL

B PORT

(not to scale).

RETURN

VBN3

A AB

B

AB PORT A PORT

SUPPLY

MIXINGDIVERTING

B PORT

COIL

M13737

PUMP

M29517

literature for actuator dimensions.

Mounting Plate Adjustment

The Actuator Mounting Plate can be rotated to a different

position for installation in confined spaces. This is

accomplished as follows:

1. Remove the handle from the shaft and set it aside.

2. Remove the two screws that hold the stem

3. Remove and set aside the stem assembly.

4. Remove and set aside the two screws that attach

5. ENSURE VALVE IS ISOLATED AND DEPRES-

Fig. 4. Reset mixing control for discharge hot water.

FULL

HEAT

AB A

VB3

B

5 GPM

PROPORTIONED

HEAT

AB A

VB3

B

2.5 GPM

RETURN

MAIN

5 GPM

AB

VB3

B

5 GPM

5 GPM

with coil bypass.

SUP PL Y

MAIN

NO

HEAT

Fig. 5. Three-way mixing valve operation

A

HEATING COIL

5 GPM

2.5 GPM

NO FLOW

THROUGH COIL

M19523

Mechanical Installation

The valveshave female NPT pipe fittings and should be

sealed with an approved pipe sealant or tape. Take care

not to use excess pipe dope to avoid interfering with

operation of ball. Torque should not exceed 75 ft-lb.

6. Rotate mounting plate around valve top to the

IMPORTANT

7. Lower ring down to valve body and engage it in the

8. Tighten screws to valve body securing the mounting

9. Reattach the stem assembly to the mounting plate.

10. If desired, replace the handle on the shaft.

NOTE: See Fig. 6 for valve exploded view.

IMPORTANT

Electrical Installation

1. If necessary, remove actuator wiring cover.

2. Wire the actuator according to the appropriate

3. If applicable, position reverse/direct acting switch

4. Replace cover.

assembly to the mounting plate and set them aside.

the mounting plate to the valve.

SURIZED BEFORE PROCEEDING. Remove yellow pressure plate marked “HIGH PRESSURE”

from valve bonnet, rotate 90° or 180°, and re-install

screws using same holes in pressure plate and the

appropriate pair of tapped holes in the valve bonnet.

NOTE: Take note of the screw hole positions on

the valve. They limit the mounting plate

positions.

desired position.

Do not rotate the valve stem while the hold-down

ring is removed. This can change the common

port from AB to A.

new position relative to the mounting plate.

plate.

After adjusting a three-way valve mounting plate,

take note whether the AB port or the A port is the

common port.

diagram provided with actuator or job specifications. For detailed actuator information, see Honeywell literature:

— 62-0274—MS7505/MS8105 Spring Return

Actuator Installation Instructions

— 63-2632—MN6105 Floating Actuator

Product Data

— 63-2633—MN7505 Modulating Actuator

Product Data

— 63-2209—ML6161/ML6164/ML7161/ML7164

Non-spring return direct Coupled Actuators

Product Data

for desired operation.

62-0197—04 2

Page 3

VBN2, VBN3 CONTROL BALL VALVE/ACTUATOR ASSEMBLIES

HANDLE (REMOVABLE) FOR

MANUALLY ROTATING SHAFT

SCREWS (2)

STEM ASSEMBLY COVER

STEM ASSEMBLY

SCREWS (2)

VALVE STEM

COUPLER

STEM RETAINER PLATE

VALVE BODY

1

1

ANTI-ROTATION

BRACKET

1

WING NUT

MOUNTING

PLATE

1

1

BOLT

1

1

BOLT

1

ANTI-ROTATION

BRACKET

2

1

1

OPERATION AND CHECKOUT

Once both the mechanical and electrical installations are

complete:

1. Cycle the actuator to verify that the direction of rotation suits the control sequence.

2. If the rotation direction is incorrect:

a. For 2-position control actuators: Remount actu-

ator on the bracket.

b. For floating control actuators: Reverse two con-

trol signal wires (CW/CCW).

c. For analog control actuators either:

(1) Reposition reverse/direct acting switch, or

(2) Remount actuator on the bracket.

3. If the control scheme requires fail-safe operation,

ensure that, upon removal of power, the valve

rotates to the desired position.

4. Spring return actuators are factory-configured for

A-port normally-closed fail-safe operation. To

change this to normally-open, remove and reinstall

the actuator in the opposite orientation as follows:

(a) Loosen the shaft coupling bolt using a 10

mm wrench.

(b) Loosen all other mounting bolts connect-

ing the actuator to the mounting bracket,

and set aside.

(c) Remove the actuator from the valve

shaft.

(d) Move the actuator shaft coupling to the

opposite side of the actuator, as displayed

in Figure 7.

1

INCLUDED IN REPLACEMENT KIT (PART NO. 5112-11).

2

THIS PART USED WITH NON-SPRING RETURN ACTUATORS.

Fig. 6. Valve assembly exploded view.

M29526

M27714

Fig. 7. SCSA Mounting

For detailed actuator information, see Honeywell forms:

— 63-2209 ML6161,ML7161 Product Data Sheet.

— 63-2607 S05,S10,S20 Series Actuator Product Data

Sheet.

3 62-0197—04

Page 4

VBN2, VBN3 CONTROL BALL VALVE/ACTUATOR ASSEMBLIES

F

B

E

A

C

D

PIPE SIZE Cv DIMENSIONS IN INCHES (mm) WEIGHT REPLACEMENT

CODE DESIGNATORS

(DN)

VBN2A...

15

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

B,D,E,F,G,H,K

J 2-5/8 (67)

VBN2B...

20

B,D,E,G,H,J,L

K,M

VBN2C...

25

J

HLP 3-1/16 (78)

M,N 4-5/16 (109)

VBN2D...

30

H,J,K,L,N

M,S 3-5/8 (92)

VBN2E...

40

L,M,R

N,1 4-1/16 (103)

VBN2F...

50

N,T

P,R,S,1,2 4-15/16 (125)

VBN2G...

65

N,P,R,S,U,1

VBN2H...

80

N,P,R,T,U

INDICATES FULL PORT VALVE: NO FLOW CHARACTERIZING INSERT.

1

WILL BE SHORTER WITH NON-SPRING-RETURN ACTUATORS.

2

A

2-3/8 (60)

1

1

2-3/4 (70) 7-1/16 (179)

1

1

1

3 (76) 3-1/8 (79)

1

1

3-7/16 (87)

1

4 (102)

1

1

5-5/16 (135)

1

5-3/4 (146)

1

B

C D E F LB (KG)

2-3/4 (70)

6-5/8 (168)

2-7/8 (73)

6-1/2 (165)

2-3/4 (70)

6-7/16 (163)

2-7/8 (73)

6-1/2 (165)

3-1/16 (78)

6-3/4 (171)

3-1/4 (82)

7-3/8 (187)

6-11/16 (170) 3

3-1/4 (82)

7 (178)

6-15/16 (176)

3-3/4 (95)

7-1/16 (180)

7-3/16 (183)

4-1/16

7-7/16 (189)

(103)

7-9/16 (192)

7-11/16 (195)

(76)4(102)

2

8-1/8 (206)

8-5/16 (211)

8-1/8 (206) 1.0 (0.5)

8-5/16 (211)

8-11/16 (221) 1.4 (0.6)

8-7/8 (225)

8-11/16 (221)

9-1/16 (230)

8-7/8 (225)

10-1/2 (267)

10-11/16 (271)

Fig. 8. VB2 dimensions in inches (mm).

B

G

A

C

PIPE SIZE Cv WEIGHT REPLACEMENT

IN.

(DN)

CODE DESIGNATORS

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

B,D,E,F,H,J

15

VBN2A...

20

VBN2B...

25

VBN2C...

30

VBN2D...

40

VBN2E...

50

VBN2F...

65

VBN2G...

INDICATES FULL PORT VALVE: NO FLOW CHARACTERIZING INSERT.

1

3-1/2 (89)

C,D,E,F,G,K

2-13/16 (71)

1

3-13/16 (97)

C,D,E,F,G

3 (76)

J,L

4-5/16 (110)

H,K,M

1

H,J,L

3 (76) 3-13/16 (97)

K,M,N 3-5/8 (92)

1

1

H,J,K,M

4-5/16 (110) 7-13/16 (198) 10-13/16 (275)

4 (102)

L,P

L,N,P

R,T 5 (127)

P,R , S ,

1

E D

DIMENSIONS IN INCHES (mm)

B

A

CDEF GLB(KG)

7 (178)

6-1/2 (165)

3-5/16 (84)

7-5/16 (186) 9-1/2 (241)

3-13/16 (97)

6-13/16 (173)

4 (102)

7-13/16 (198)

6-13/16 (173) 3

4 (102)

7-5/16 (186)

4-1/2 (114)

7-5/16 (186)

5-13/16 (148)

7-13/16 (198)

(76)4(102)

9-3/8 (238)

8-13/16 (224)

9-13/16 (249)

10-13/16 (275)

9-13/16 (249)

10-5/16 (262)

11 (279)

12-5/16 (313)

2 (51) 2.4 (1.1)

2-1/16 (52)

2-7/16 (62)

3-1/8 (79)

2-13/16 (71)

2-7/16 (62)

2-3/4 (70)

3-3/16 (81)

3-1/8 (79)

3-7/8 (98)

4-1/8 (105)

Fig. 9. VB3 dimensions in inches (mm).

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

http://customer.honeywell.com http://customer.honeywell.ca

® U.S. Registered Trademark

© 2010 Honeywell International Inc.

62-0197—04 E.K. Rev. 04-10 Printed in U.S.A.

2.4 (1.1)

1.4 (0.6)

2.4 (1.1)

3.2 (1.5)

2.0 (0.9)

2.8 (1.3)

2.6 (1.2)

3.3 (1.5)

2.4 (1.1)

2.8 (1.3)

3.3 (1.5)

3.8 (1.7)

ASSEMBLYIN.

5112-19

5112-22 (SS)

5112-20

5112-23 (SS)

5112-21

5112-24 (SS)

F

STEM ASSEMBLY

5112-19

5112-20

5112-21

STEM

M31359

M31360

Loading...

Loading...