Page 1

VBF5011, VBF5013 Control Ball

Valves With Flanged Connections

INSTALLATION INSTRUCTIONS

APPLICATION

The VBF5011 Two-Way and the VBF5013 Three-Way

Control Ball Valve control hot and chilled water with glycol

solutions up to 50% in heating, ventilating and air

conditioning (HVAC) systems to provide two-position or

modulating functions.

These valves can be used with Honeywell electronic

actuators.

Application Notes

IMPORTANT

Valve sizing is important for correct system operation. Undersized valves do not have sufficient

capacity at maximum load. Oversized valves do not

have sufficient authority over the load in modulating applications. Oversized valves can cause

excessive cycling and the seat and ball can be

damaged because of the restricted opening.

Proper Use

These valves are only for use in cold, warm, and hot water

systems. Not suitable for oil or combustible gases. For

water application, they are designed for a medium

temperature range from -22 to 250°F, at a maximum

pressure of 360 psi for 2-1/2" & 3" valves and 240 psi for

4", 5", & 6" valves. The valves are to be operated with the

appropriate Honeywell electronic actuators only. Water

should be properly filtered, treated and conditioned

according to local conditions and the recommendations of

the boiler or chiller manufacturers. The installation of

strainers and filters is recommended.

IMPORTANT

The presence of excessive iron oxide (red rust) in

the system voids the valve warranty.

Required Torque

Honeywell electronic actuators can be utilized with the

VBF5011 and VBF5013 valves. See Table 1, which lists the

torque requirement for each valve size. See Table 2, which

lists the close-off pressure rating for the valves with the

different torque actuators. Larger torque actuators may be

used, but there is no increase in close-off pressure rating.

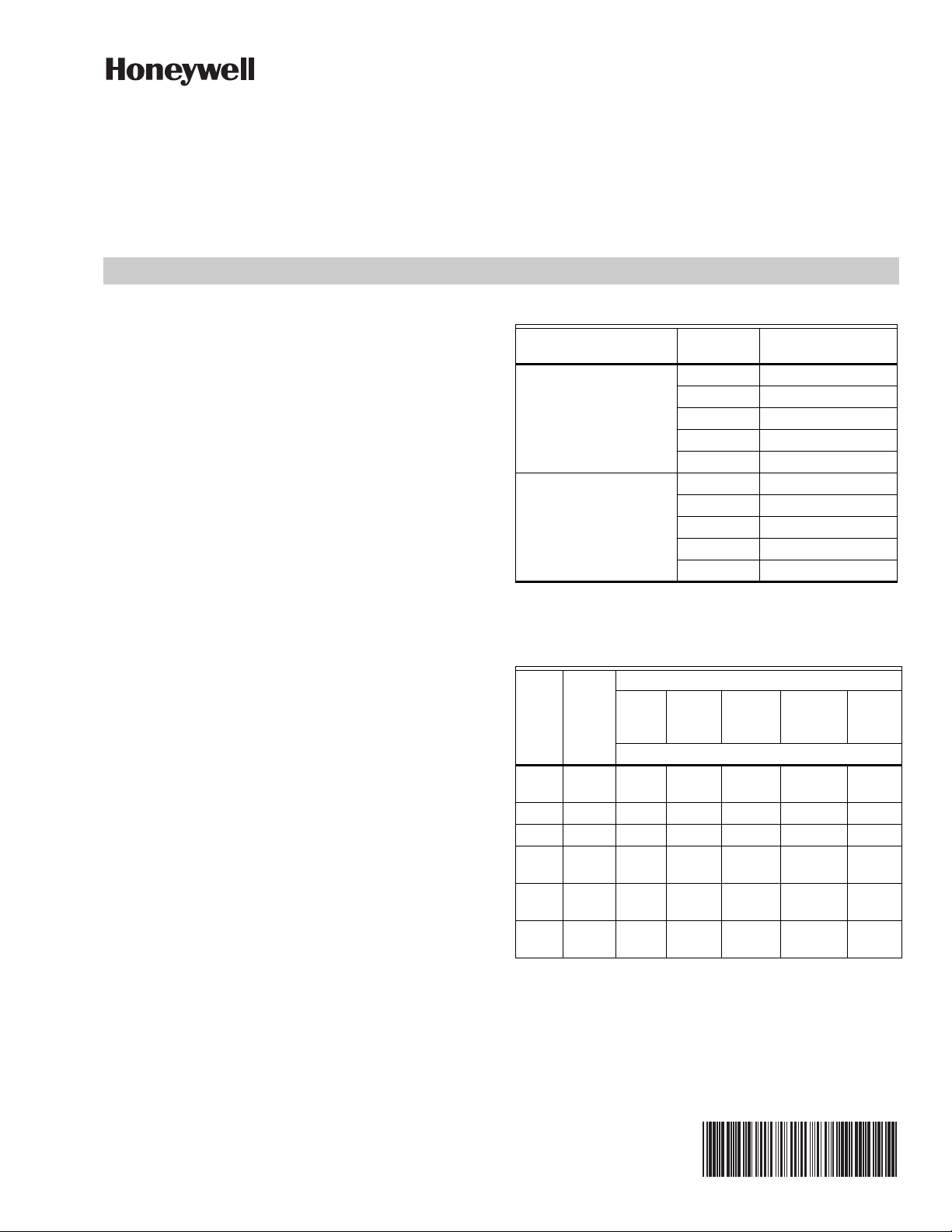

Table 1. Torque Requirement

Torque Requirement

Type Size

2-way 2 1/2” 35

3” 35

4” 85

5” 85

6” * 140

3-way 2 1/2” 35

3” 85

4” 85

5” 85

6” * 140

*6" requires 140 in-lb actuator for flows up to 700 gpm.

For flow rates greater than 700 gpm a 200 in-lb actuator is recommended.

Table 2. Close-off Pressure Rating

Actuator Type

35 lb-in

Valve

Type

2-way 2-1/2”, 3”100

3-way 2-1/2” 40

3-way 3” 70 70 70 70

2-way,

3-way

2-way,

3-way

2-way,

3-way

Valve

4” 70 70 70 70

5” 70 70 70 70

6” 70 70

(4 Nm)

Size

88 lb-in

(10 Nm)

Close-off pressure rating (psi)

175 lb-in

(20 Nm)

(in-lbs)

175 lb-in

(20 Nm)

2-position

300 lb-

in (34

Nm)

Flow Characteristics

VBF5011 Two-Way Control Ball Valves have:

• an equal percentage flow characteristic.

VBF5013 Three-Way Control Ball Valves have:

• between ports A and AB: an equal percentage flow

characteristic.

• between ports B and AB: a linear flow characteristic.

62-2035-02

Page 2

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

CAUTION

M34652

D

H

C

B

A

E

G

F

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the prod-

uct to ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Preparation

Safety

The valves are to be installed by skilled personnel and in

strict accordance with the installation instructions and

local regulations. Honeywell assumes no responsibility for

damages or injuries resulting from non-compliance with

installation instructions or standard good practice when

mounting, operating, or maintaining the valves, even if not

explicitly mentioned in the installation instructions.

Observe all safety practices.

Equipment Damage Hazard.

Foreign particles like dirt and metal chips can

damage the ball seals.

For trouble-free operation of the product, good

installation practice must include initial system

flushing and chemical water treatment. Clean the

lines upstream of particles larger than 1/16 inch

diameter (welding slag, pipe scale, sand and other

suspended particulate). Use of a 20 mesh system

side stream filter is suggested. Remove all filters

before flushing.

Do not use boiler additives, solder flux and wetted

materials which are petroleum based or contain

mineral oil, hydrocarbons or ethylene glycol

acetate. Compounds which can be used, with

minimum 50% water dilution, are diethylene

glycol, ethylene glycol, and propylene glycol

(antifreeze solutions).

If installing these valves in an addition to, or

retrofitting an existing building, do not assume

that the fluid in the existing piping meets these

criteria.

IMPORTANT:

1. Hold valve with pipe wrench by hexagonal fitting

ONLY. Do NOT handle the valve body with the pipe

wrench; product damage may result.

2. Clean the lines upstream of particles larger than

1/16 in. diameter (welding slag, pipe scale and

other contaminants).

3. Proceed with installation once the system specifics (expansion/contraction of the system and its

medium as well as operating pressures) are within

tolerances.

4. Eliminate air from system.

5. All the valves are marked to show proper direction.

6. Flow arrows must point in the direction of the flow

for proper operation. If the valves are not installed

in the correct orientation, improper flow or possible system damage could occur.

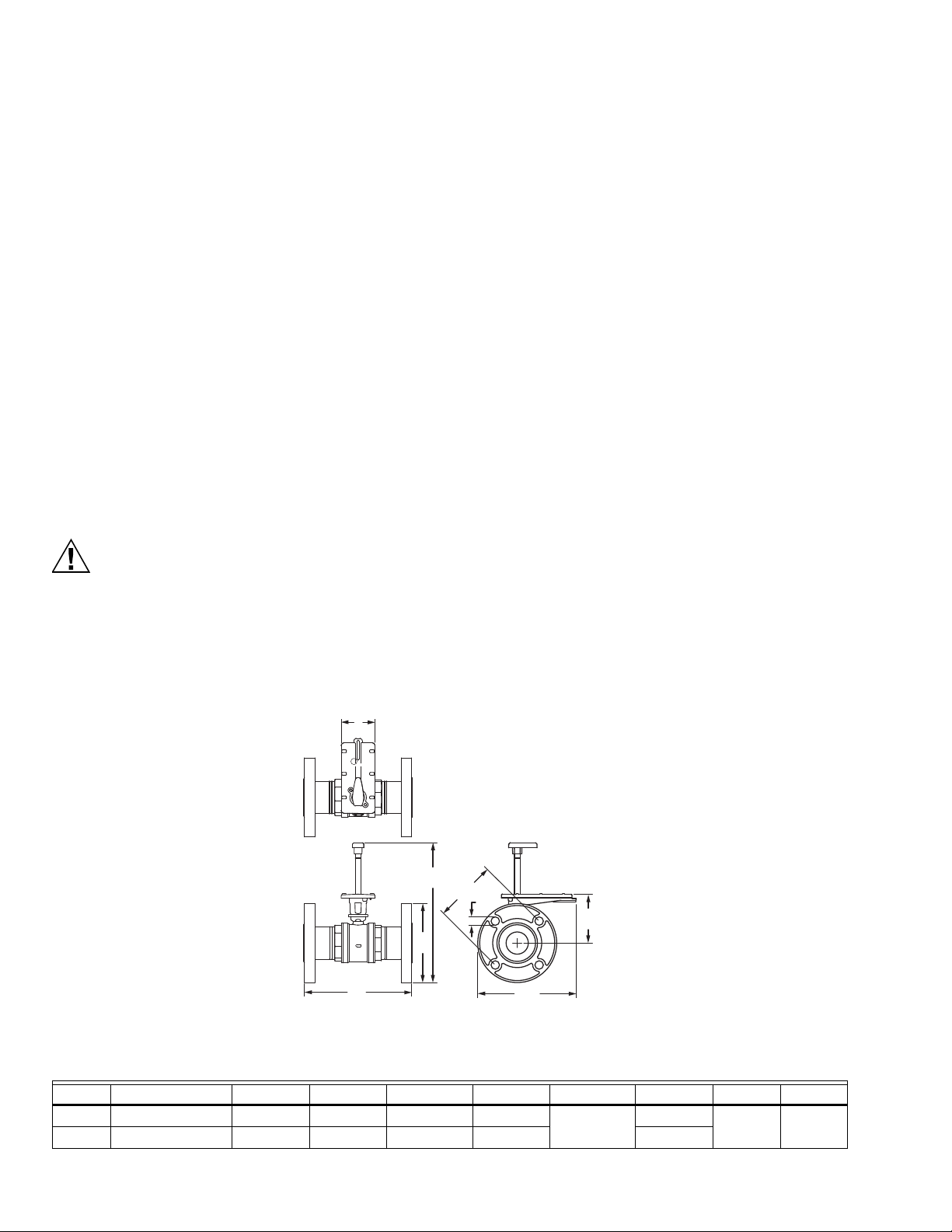

Fig. 1. 2-way 2-1/2" & 3" valve dimensions

Table 3. 2-way 2-1/2" & 3" valve dimensions

Size in. Model Number A in. (mm) B in. (mm) C in. (mm) D in. (mm) E in. (mm) F in. (mm) G in. (mm) H in. (mm)

2-1/2 VBF5011A1734/U 9-1/2 (241) 7 (178) 12-3/8 (314) 8-3/4 (222) 4-5/16 (110) 5-1/2 (140) 3/4 (19) 3 (76)

3 VBF5011A1767/U 11 (279) 7-1/2 (191) 12-5/8 (321) 9 (229) 6 (152)

62-2035—02 2

Page 3

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

M34653

A

C

D

F

I

B

G

E

H

M34656

H

D

C

I

A

B

E

G

F

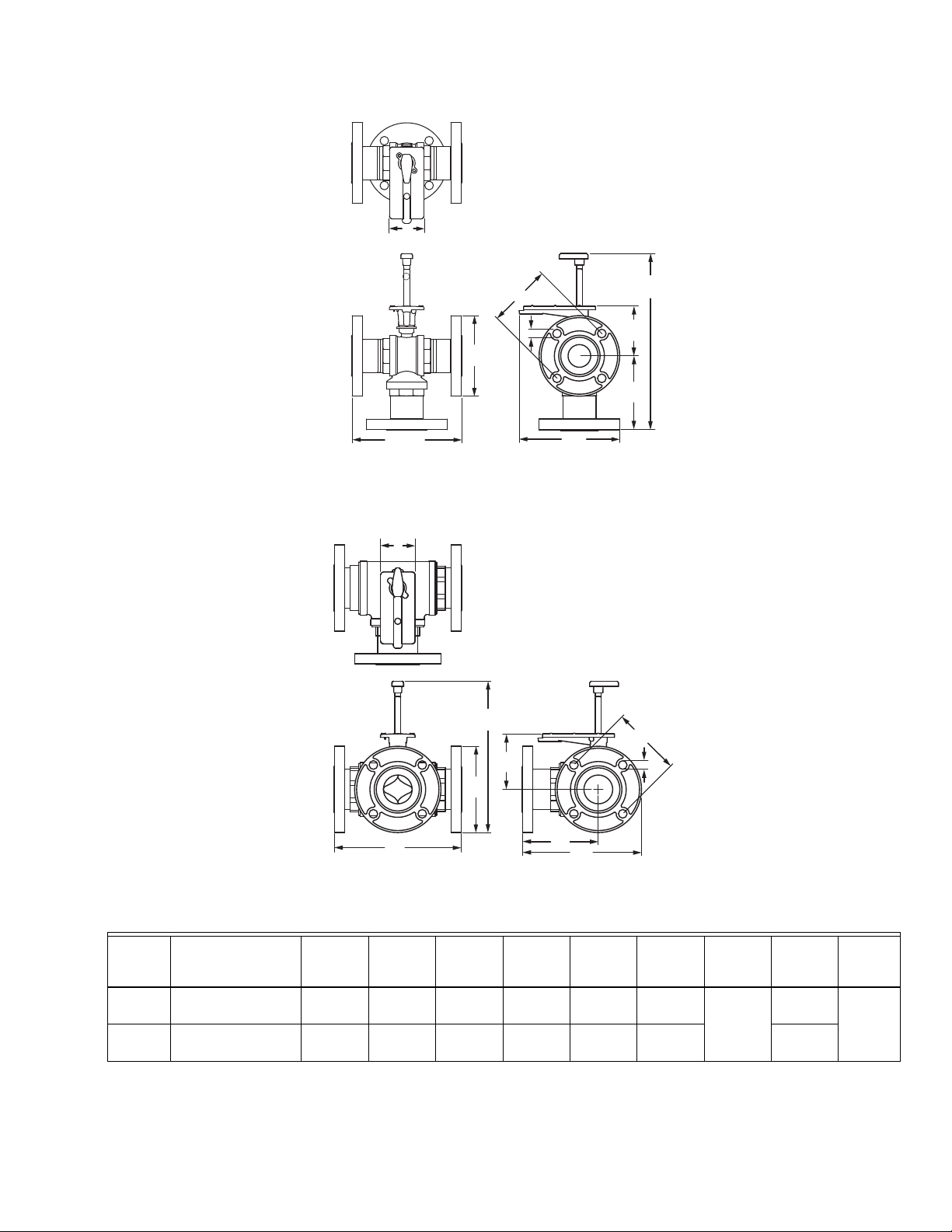

Fig. 2. 3-way 2-1/2" valve dimensions

Fig. 3. 3-way 3" valve dimensions

Size

in. Model Number

2-1/2 VBF5013B1003/U 9-1/2

(241)

3 VBF5013B1011/U 11

(279)

Table 4. 3-way 2-1/2" & 3" valve dimensions

A

in.

(mm)

B

in.

(mm)

7

(178)

7-1/2

(191)

C

in.

(mm)

15-5/16

(389)

13-1/8

(333)

D

in.

(mm)

8-3/4

(222)

10-5/16

(262)

3 62-2035—02

E

in.

(mm)

4-5/16

(110)

4-13/16

(122)

F

in.

(mm)

5-1/2

(140)

6

(152)

(mm)

3/4

(19)

G

in.

H

in.

(mm)

6-7/16

(164)

6-5/8

(168)

I

in.

(mm)

3

(76)

Page 4

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

F

G

H

M34655

B

A

D

C

E

F

E

B

A

D

C

M34654

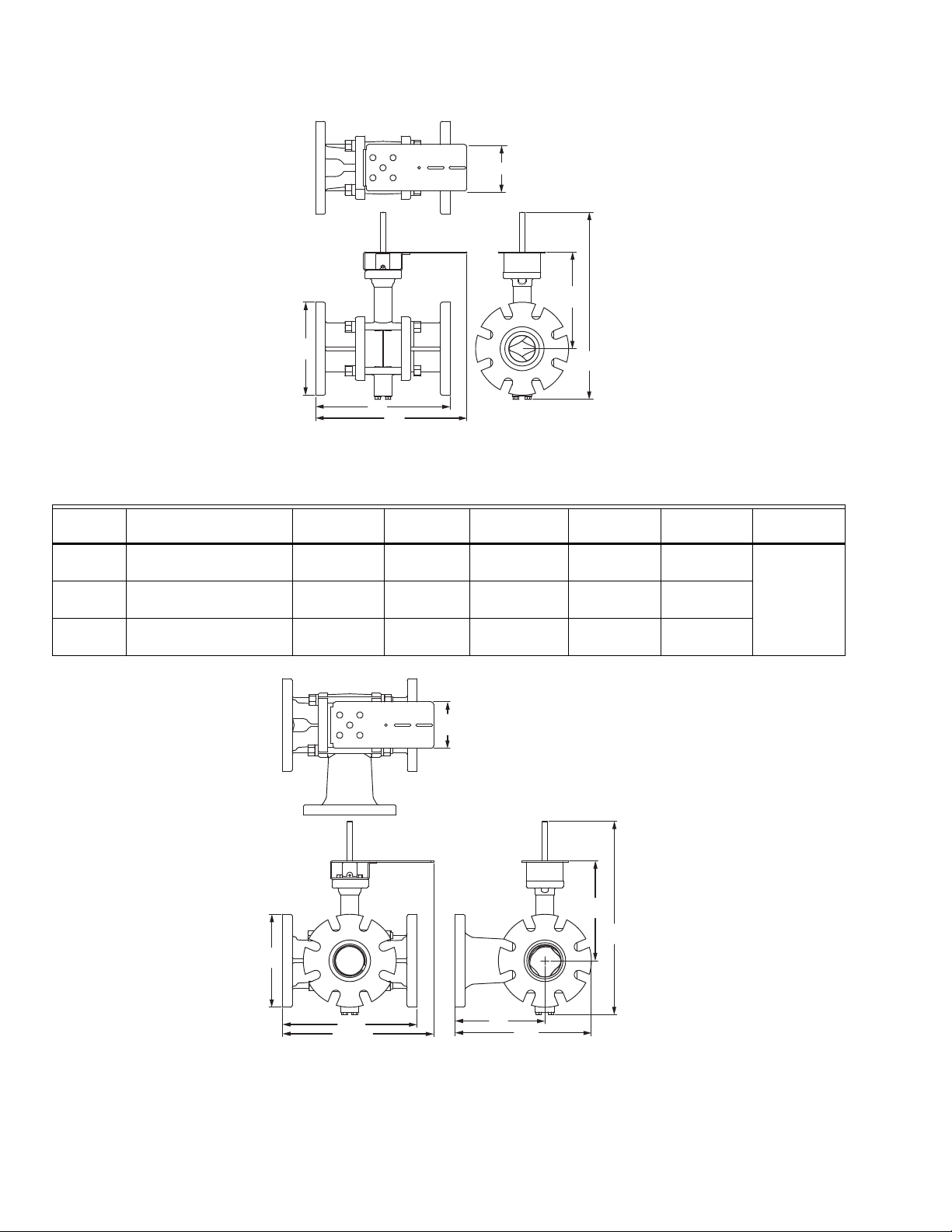

Fig. 4. 2-way 4", 5" & 6" valve dimensions

Table 5. 2-way 4", 5" & 6" valve dimensions

Size

in. Model Number

A

in. (mm)Bin. (mm)

C

in. (mm)

D

in. (mm)

4 VBF5011A1858/U 13 (330) 9 (229) 18-1/8 (460) 14-5/8

(371)

5 VBF5011A1882/U 15 (381) 10 (254) 18-13/16

(478)

6 VBF5011A1916/U 16-1/2

(419)

11 (279) 19-11/16

(500)

15-5/8

(397)

16 3/8 (416) 10-1/8

E

in. (mm)

F

in. (mm)

9-3/8 (238) 4-1/2 (114)

9-11/16

(246)

(257)

Fig. 5. 3-way 4", 5" & 6" valve dimensions

62-2035—02 4

Page 5

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

WARNING

CAUTION

Table 6. 3-way 4", 5" & 6" valve dimensions

B

Size

in. Model NumberAin. (mm)

4 VBF5013B1029/U 13 (330) 9 (229) 1- 13/16

5 VBF5013B1037/U 15 (381) 10

6 VBF5013B1045/U 16-1/2

(419)

in.

(mm)Cin. (mm)Din. (mm)Ein. (mm)

(478)

19-11/16

(254)

11

(279)

(500)

20-3/4

(527)

14-5/8

(371)

15-5/8

(397)

16-3/8

(416)

9-11/16

(246)

10-1/16

(256)

10-11/16

(271)

F

in. (mm)Gin. (mm)Hin. (mm)

8-11/16

(221)

9-5/8 (244) 14-5/8

10-11/16

(271)

1- 3/16

(335)

(371)

16-3/16

(411)

4-1/2

(114)

Valve Installation Location

Select a location where the valve and actuator will be

accessible once installed. Allow sufficient space for

servicing the valve and actuator. Clearance for valve

installation is dependent on actuator size and the valve

pipe size. See Figures 1 and 5 for valve body dimensions.

Refer to actuator literature for actuator dimensions.

1. Clean the lines upstream of the valve to remove par-

ticles larger than 1/16 inch diameter (welding slag,

pipe scale and other contaminants). Upstream

installation of a 20 mesh strainer is recommended.

2. Air should be eliminated from the system so the

valves remain full of fluid during operation.

3. Straight sections of piping upstream and down-

stream of the valves are not necessary for proper

operation. Reducing bushings or flanges may be

attached directly to valves. Standard adapters are

adequate for installation of flow control valves.

4. Proceed with installation once the system specifics

(expansion/contraction of the system and its

medium as well as operating pressures) are within

tolerances.

5. Do not lift the valve by holding the stem.

Severe Burn Hazard.

Contact with hot liquid can lead to severe injury

or cause death. Release system pressure and

isolate or drain the valve pipe section so the

medium (water or glycol solution) does not leak

out of the valve body during installation (see

Fig. 7).

Mounting Valve

1. Before installing the valve, rotate the valve stem to

make sure that the valve stem operates freely.

Impaired stem operation can indicate that the stem

was bent by rough handling. This condition can

require replacing the valve.

2. Protect the stem from damage due to bending or

scratching.

3. For horizontal piping, install the valve so the actua-

tor is above the valve body. Install the valve in any

position between vertical and horizontal. Do not

install the valve with the stem below horizontal or

upside down. For vertical piping, the actuator can be

mounted in any orientation.

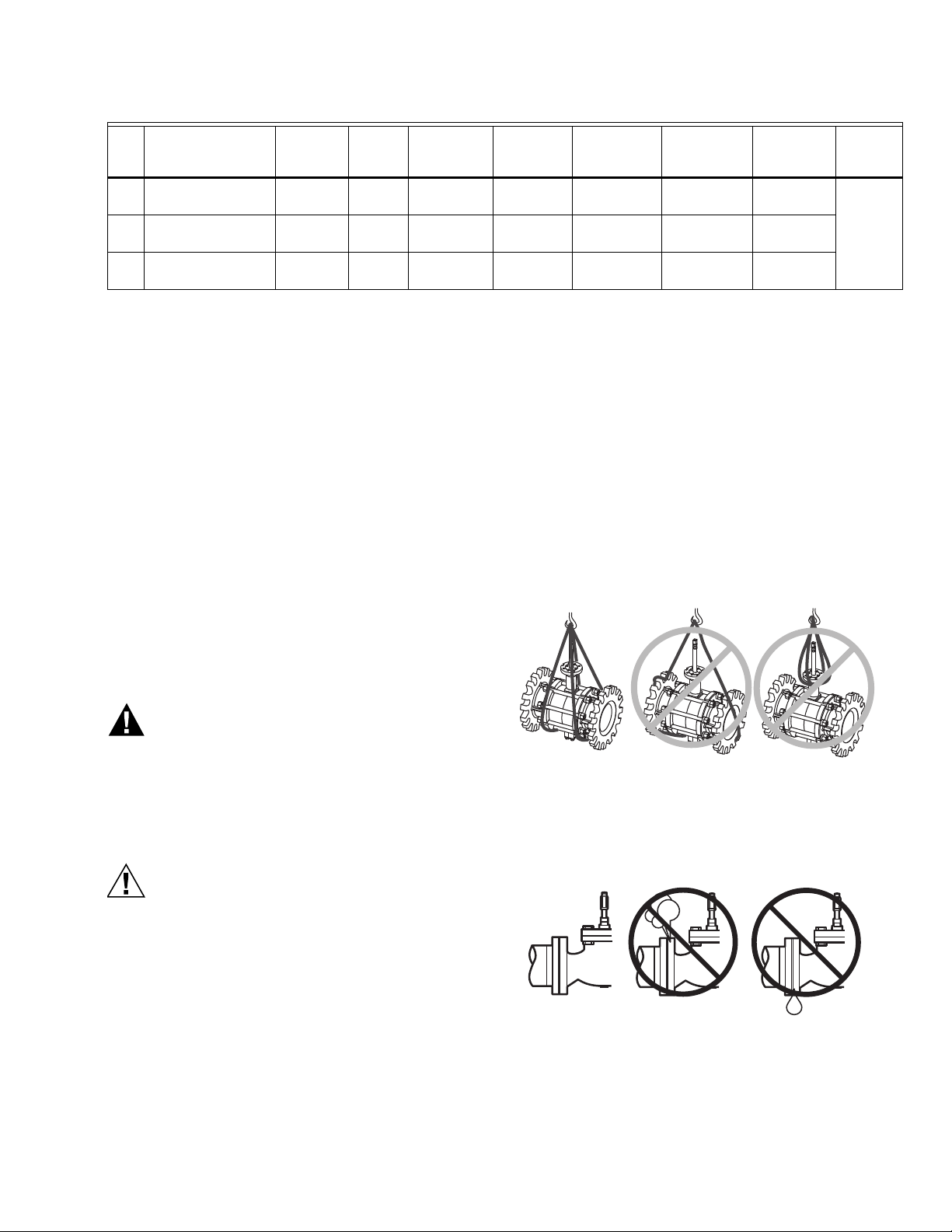

4. Hoist valve by its body only. Do not lift by stem, bon-

net, flanges, or flange holes. (See Fig. 6 for proper

hoisting method.)

M13752

Fig. 6. Proper hoisting of VBF Valves

5. Mount the valve between aligned pipes. Mounting

the valve on pipes that are not aligned causes leakage at the valve-to-pipe connection.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply to the actuator to prevent

electrical shock and equipment damage, or remove

and cap the air line to the actuator.

M22591

Fig. 7. Piping must prevent leakage

5 62-2035—02

Page 6

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

M22592

133 IN-LB

(15 NM)

M13753

PORT

CLOSED

PORT

CLOSED

STEM ROTATION

COIL FLOW

STEM ROTATION

BYPASS FLOW

AB

B

A

M23853

Fig. 8. Basic pipe orientation

6. Iron valves are mechanically compatible with stan-

dard ANSI 150 lb flat-faced or raised-face steel

flanges, or with 125 lb cast iron flanges.

7. Release system pressure and drain the valve pipe

section so the medium (water or glycol solution)

does not leak out of the valve body during installation.

8. Mount three-way valves as shown in Fig. 13, accord-

ing to whether they are to be used for mixing or

diverting control.

9. Use a gasket material recommended for the medium

to be handled.

10. Use mounting bolts long enough so the nuts can use

the full length of the nut threads. Use four bolts to

connect 2-1/2" & 3" valves and use eight bolts to

connect 4", 5", & 6" valves. Use bolts 1/8" smaller

than the diameter of the bolt hole to allow clearance

for installing.

MIXED

DISCHARGE

WATER TO

HEAT LOAD

Fig. 9. Basic proper bolt length

VBF5013

B

AB

A

BYPASS

BOILER

PUMP

M34677

Fig. 10. Boiler bypass for reset control

Fig. 11. Stem Rotation

62-2035—02 6

Page 7

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

AB A

B

M34668

HEATING COIL

FULL

H EAT

5 GPM

5 GPM

2.5 GPM

5 GPM

AB A

B

P ROPORTIONED

H EAT

2.5 GPM

S UPPLY

M AIN

RETURN

MAIN

5 GPM

5 GPM

AB

VBF5013

VBF5013

VBF5013

A

B

N O

H EAT

NO FLOW

THROUGH COIL

Stem rotation:

1. For two-way valves:

a. Rotate stem clockwise to open.

b. Rotate stem counter clockwise to close.

2. For three-way valves:

a. Rotate stem clockwise to increase A to AB flow.

b. Rotate stem counter clockwise to increase B to

AB flow.

M13741

Fig. 12. Three-way mixing valve operation with

coil bypass

B PORT

COIL

RETURN

AB PORT A PORT

B PORT

SUPPLY

MIXINGDIVERTING

COIL

M13737

AB PORT A PORT

SUPPLY

RETURN

Fig. 13. Three-way control ball valve flow orientation

(not to scale)

Fig. 14. Vertical Valve Installation

45°

45°

M13740

Fig. 15. Acceptable valve angle from vertical

(when installed in horizontal piping)

7 62-2035—02

Page 8

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

Mounting Actuator

For information on mounting, refer to the Product Data

Sheet for the specific Honeywell actuator coupled to the

valve. It is important to have the correct actuator available

for the installation.

Checkout

For instructions for operating the valve actuator, see the

specific actuator's Product Data Sheet. Operate the

control system and check valve operation to determine

that the valve stem positions the ball smoothly through its

full stroke without binding.Check valve body and

connections for leaks. After installing linkage and

actuator, check the operation according to installation

information provided with these controls. Operate the

system through one complete cycle to be sure the valve

controls properly.

Ensure that the actuator selected provides the force to

position the valve ball. For actuators, the actuator provides

normally closed or normally open operation on electric

power or pressure failure, depending on the

valve/actuator combination selected.

General

Spring return actuators return the valve to its normal

position (open or closed, depending on the actuator and

valve selected) in the event of a power failure. Non-spring

return actuators hold the last commanded position.

HANDLE (REMOVABLE) FOR

MANUALLY ROTATING SHAFT

SCREWS (2)

STEM ASSEMBLY COVER

STEM ASSEMBLY

SCREWS (2)

BOLT

ANTI-ROTATION

BRACKET

MOUNTING

PLATE

WING NUT

Service Parts

For 2-1/2" & 3", see Fig. 16 for exploded view.

For 4", 5”, & 6", see Table 7 and Fig. 17 for diagram of

replacement parts.

VALVE STEM COUPLER

VALVE BODY

M13738B

Fig. 16. Valve assembly, exploded view

Table 7. Parts list for Flanged Valves

Two-way 4 in. 5 in. 6 in.

Seal 7981-910 7981-915 7981-912

Seal O-ring 7981-914 7981-911 7981-916

Flange O-

7978-65 7978-66 7978-68

ring

Bottom Stem 7981-701 7981-701 7981-701

Three-way 4 in. 5 in. 6 in.

Seal 7981-911 7981-912 7981-913

Seal O-ring 7981-915 7981-916 7981-917

Flange O-

7978-66 7978-67 7978-69

ring

Bottom Stem 7981-701 7981-701 7981-701

62-2035—02 8

Page 9

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

SEAL O-RING

SEAL

STEM

FLANGE O-RING

M13742

.

Fig. 17. Exploded View of Flanged Ball Valve

Mounting Plate Adjustment

The Actuator Mounting Plate can be rotated to a different

position for installation in confined spaces. This is

accomplished as follows:

For 2-1/2" and 3":

1. Remove the handle from the shaft and set it aside.

2. Remove the two screws that hold the stem assembly

to the mounting plate and set them aside.

3. Remove and set aside the stem assembly.

4. Remove and set aside the two screws that attach the

mounting plate to the valve.

5. Remove and set aside hold-down ring from mount-

ing plate.

6. Rotate mounting plate around valve top to the

desired position.

NOTE: Take note of the screw hole positions on the valve.

They limit the mounting plate positions.

7. Lower ring down to valve body and engage it in the

new position relative to the mounting plate.

8. Tighten screws to valve body securing the mounting

plate.

9. Reattach the stem assembly to the mounting plate.

10. If desired, replace the handle on the shaft.

NOTE: See Fig. 16 for valve exploded view.

For 4", 5", and 6":

1. Remove the four bolts and lock washers that hold

the mounting plate to the valve stem housing and

set them aside.

2. Rotate mounting plate around valve top to the

desired position.

NOTE: There are four positions possible (incre-

ments of 90 degrees from each other) for

the mounting plate position

3. Once the mounting plate is in the desired position,

re-insert the bolts through the lock washers and into

the four bolt holes in the valve stem housing.

4. Tighten bolts to the valve body securing the mount-

ing plate.

See Fig. 18 for location of mounting bolts.

9 62-2035—02

Page 10

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

M13745

VALVE STEM

HOUSING

BOLTS WITH

LOCK WASHERS (4)

MOUNTING

PLATE

DRIVE SHAFT

The following wiring instructions are provided as a

convenience to the installing contractor. For more detailed

information about these actuators, refer to the Product

Data sheets for the corresponding Honeywell actuator as

follows:

Literature #Actuator Model and Literature Type

63-2632 MN6105, MN6110, MN7505, MN7510 Floating Actuator (Product Data)

63-2588 MN6120, MN6134 (Product Data)

63-2587 MN7220, MN7234 (Product Data)

63-2607 MS7510, MS7520, MS8110, MS8120 (Product Data)

63-2633 MN6105, MN7505 Modulating Actuator

(Product Data)

The 2-1/2" and 3" valves will be shipped with 2 antirotation clips. Please use narrow clip for MN6105 and

MN7505 actuators and use wide clip for MS8105 and

MS7505.

The 4" and 5" valves will be shipped with 2 sets of antirotation components. Please use short bolt for MN6110

and MN7510 actuators and use long bolt for MS8110 and

MS7510.

The 6" valves will be shipped with 2 sets of anti-rotation

components. Please use short bolt for MN6134 and

MN7234 actuators and use long bolt for MS8120 and

MS7520.

Fig. 18. Mounting Plate Adjustment Bolts

Electrical Installation

Pipe Size

2-1/2” & 3” 4” & 5” 6”

MN6105A1011 MN6110A1003 MN6134A1003

MN7505A2001 MN7510A2001 MN7234A2008

MS8105A1030 MS8110A1008 MS8120A1007

MS7505A2030 MS7510A2008 MS7520A2007*

* 2-position only

1. If necessary, remove actuator wiring cover.

2. Wire actuator using Figures 28 through 37 for the

application required.

3. Replace cover.

Wiring

VALVES WITH NON-SPRING RETURN ACTUATORS

(MN6105, MN7505)

FLOATING ACTUATOR

Direct

Service/Off

Reverse

432

1

24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

CONNECTION REQUIRED FOR SPST CONTROL.

2

Fig. 19. Wiring for On/Off Control

CONTROLLER

2

M18945A

62-2035—02 10

Page 11

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

ACTUATOR

SPST

24 VAC

1

1

2

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

V

1

2

M19718B

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

M19573A

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

FLOATING ACTUATOR

Direct

Service/Off

Reverse

2

1

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

4

3

Fig. 20. Wiring for Floating Control

2 -10 Vdc

PROPORTIONAL ACTUATOR

0 -10 Vdc

0 -10 Vdc

2 -10 Vdc

FLOATING

CONTROLLER

M18946A

VALVES WITH SPRING RETURN ACTUATORS (MS7505,

MS8105)

1

1 LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SPST

1

2

ACTUATOR

V

M22289

Fig. 22. Wiring for On/Off Control

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

0(2)-10 VDC OF 0(4)-20 mA CONTROL SIGNAL ACCEPTABLE.

SET CONTROL SIGNAL DIP SWITCH TO "OFF" FOR VOLTAGE.

SET TO "ON" FOR CURRENT.

+

FEEDBACK

1 32 5

PROPORTIONAL

24 VAC

Fig. 21. Wiring for Modulating Control

CONTROLLER

FEEDBACK

+

-

M18947A

2

Fig. 23. Wiring for Floating Control

(Floating mode setting)

11 62-2035—02

Page 12

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19576A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPDT

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19577A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPST

1

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

–

+

FEEDBACK

LINE VOLTAGE POWER SUPPLY.

1

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

24 VDC SUPPLY ACCEPTABLE.

3

SET SWITCH TO MODULATING.

Fig. 24. Override to full open

1

(Modulating mode setting)

4 TO 20 mA

PROPORTIONING

CONTROLLER

–

+

FEEDBACK

LINE VOLTAGE POWER SUPPLY.

1

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

24 VDC SUPPLY ACCEPTABLE.

3

SET SWITCH TO MODULATING.

24 VAC

24 VAC

2

2

490 TO 510

OHMS,

1/2 W

MINIMUM

1

2

3

4

5

3

1

2

3

4

5

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M19574A

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M22282A

Fig. 25. Override to full closed

(Modulating mode setting)

62-2035—02 12

Fig. 26. Wiring for Proportioning Controllers

(Modulating mode setting)

Page 13

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M22288

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

24 VAC

1

24 VAC

1

2

24 VAC

1

HOT

COM

–

+

432

FLOATING ACTUATOR

24 VAC

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CONNECTION REQUIRED FOR SPST CONTROL.

2

CONTROLLER

2

Direct

Reverse

Service/Off

M18945A

4

3

2

FLOATING ACTUATOR

24 VAC

Direct

Reverse

Service/Off

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

FLOATING

CONTROLLER

M18946A

.

Fig. 29. Wiring for Floating Control

Fig. 27. Wiring for Proportioning controllers operating

multiple actuators (Modulating mode setting)

VALVES WITH NON-SPRING RETURN ACTUATORS

(MN6110A, MN6134A, MN7234A, MN7510A)

Fig. 28. Wiring for On/Off Control

2 -10 Vdc

PROPORTIONAL ACTUATOR

0 -10 Vdc

0 -10 Vdc

2 -10 Vdc

+

FEEDBACK

1 32 5

1

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

0(2)-10 VDC OF 0(4)-20 mA CONTROL SIGNAL ACCEPTABLE.

SET CONTROL SIGNAL DIP SWITCH TO "OFF" FOR VOLTAGE.

SET TO "ON" FOR CURRENT.

Fig. 30. Wiring for Modulating Control

13 62-2035—02

PROPORTIONAL

CONTROLLER

FEEDBACK

+

2

-

M18947A

Page 14

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

M19573A

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19576A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPDT

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19574A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

VALVES WITH SPRING RETURN ACTUATORS

(MS7510A, MS7520A, MS8110A, MS8120A)

1

1

2

24 VAC

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SPST

Fig. 31. Wiring for On/Off Control

Fig. 32. Wiring for Floating Control

(Floating mode setting)

1

2

ACTUATOR

V

M19718B

Fig. 34. Wiring for Proportioning Controllers

(Modulating mode setting)

ACTUATOR

1

4 TO 20 mA

PROPORTIONING

CONTROLLER

FEEDBACK

1

2

3

24 VAC

2

500

OHMS

–

+

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

1

2

3

4

5

3

FEEDBACK

V

OR +

OR N/A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M22282

Fig. 33. Override to full open

(Modulating mode setting)

62-2035—02 14

Fig. 35. Wiring for Proportioning Controllers

(Modulating mode setting)

Page 15

Fig. 36. Override to full closed

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19577A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPST

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M22288

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

24 VAC

1

24 VAC

1

2

24 VAC

1

HOT

COM

–

+

(Modulating mode setting)

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

Fig. 37. Wiring for Proportioning controllers operating

multiple actuators (Modulating mode setting)

15 62-2035—02

Page 16

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

OPERATION AND CHECKOUT

Once both the mechanical and electrical installations are

complete:

1. Cycle the actuator to verify that the direction of rota-

tion suits the control sequence.

2. If the rotation direction is incorrect:

a. For 2-position control actuators: Remount

actuator on the bracket.

b. For floating control actuators: Reverse two

control signal wires (CW/CCW).

c. For analog control actuators either:

(1) Reposition reverse/direct acting switch, or

3. If the control scheme requires fail-safe operation,

4. If the fail safe position is incorrect, remove and rein-

(2) Remount actuator on the bracket.

ensure that, upon removal of power, the fail position

coincides with the control sequence.

stall the actuator in the opposite orientation as follows:

a. Loosen the shaft coupling bolt using a 10 mm

wrench.

b. Loosen all other mounting bolts connecting the

actuator to the mounting bracket and set aside.

c. Remove the actuator from the valve shaft.

d. Move the actuator coupling to the opposite side

of the actuator, as displayed in Figure 38.

Fig. 38. Mounting shaft coupling to actuator

(1) Remove the retainer clip from the shaft cou-

pling and set it aside for later use.

(2) Remove shaft coupling from one side of the

actuator.

(3) Replace the shaft coupling on the opposite

side of the actuator, aligning it based on the

stroke labeling.

(4) Replace the retainer clip on the shaft cou-

pling using the groove of the coupling.

e. Reconnect the actuator to the valve mounting

bracket by replacing the screws previously

removed (step b)

f. Tighten the shaft coupling bolt using a 10 mm

wrench.

M19579A

opposite side

Honeywell Building Technologies

In the U.S.:

Honeywell

buildingcontrols.honeywell.com

® U.S. Registered Trademark

©2020 Honeywell International Inc.

62-2035—02 M.S. Rev. 10-20

Printed in United States

Loading...

Loading...