Page 1

62-3117-02

VBF5011, VBF5013 Control Ball

4", 5" and 6"

2-1/2" and 3"

Valves With Flanged Connections

SPECIFICATION DATA

FEATURES

All Models

• Sizes from 2-1/2" to 6" with ANSI Class 125 flanged

connections.

• Flow characteristics.

• Two-way: equal percentage

• Three-way: A-AB equal percentage, B-AB linear

• Can be used with Honeywell electronic actutors.

• Field configurable for normally open or normally

closed fail-safe position.

• For 2-1/2 and 3", removable manual operating

handle to control valve during installation or in an

event of power failure.

• ANSI Class IV leakage specification (0.01% of CV).

• 2-way - ANSI Class IV leakage

• 3-way - A to AB; ANSI Class IV leakage

• 3-way - B to AB; ANSI Class III leakage

• Option of four actuator mounting positions on the

valve for 4", 5" and 6" valves.

APPLICATION

The VBF5011 Two-Way and the VBF5013 Three-Way

Control Ball Valve control hot and chilled water with glycol

solutions up to 50% in heating, ventilating and air

conditioning (HVAC) systems to provide two-position or

modulating functions.

• Wide range of C

• Valve ball and stem 316 stainless steel for all valves

except 3-way 2-1/2" valve.

VBF5013 (Three-way)

• Mixing or diverting control.

• Same flow pattern configuration as Globe valve.

choices from 63 to 360.

V

These valve can be used with Honeywell electronic

actuators.

Page 2

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

SPECIFICATIONS

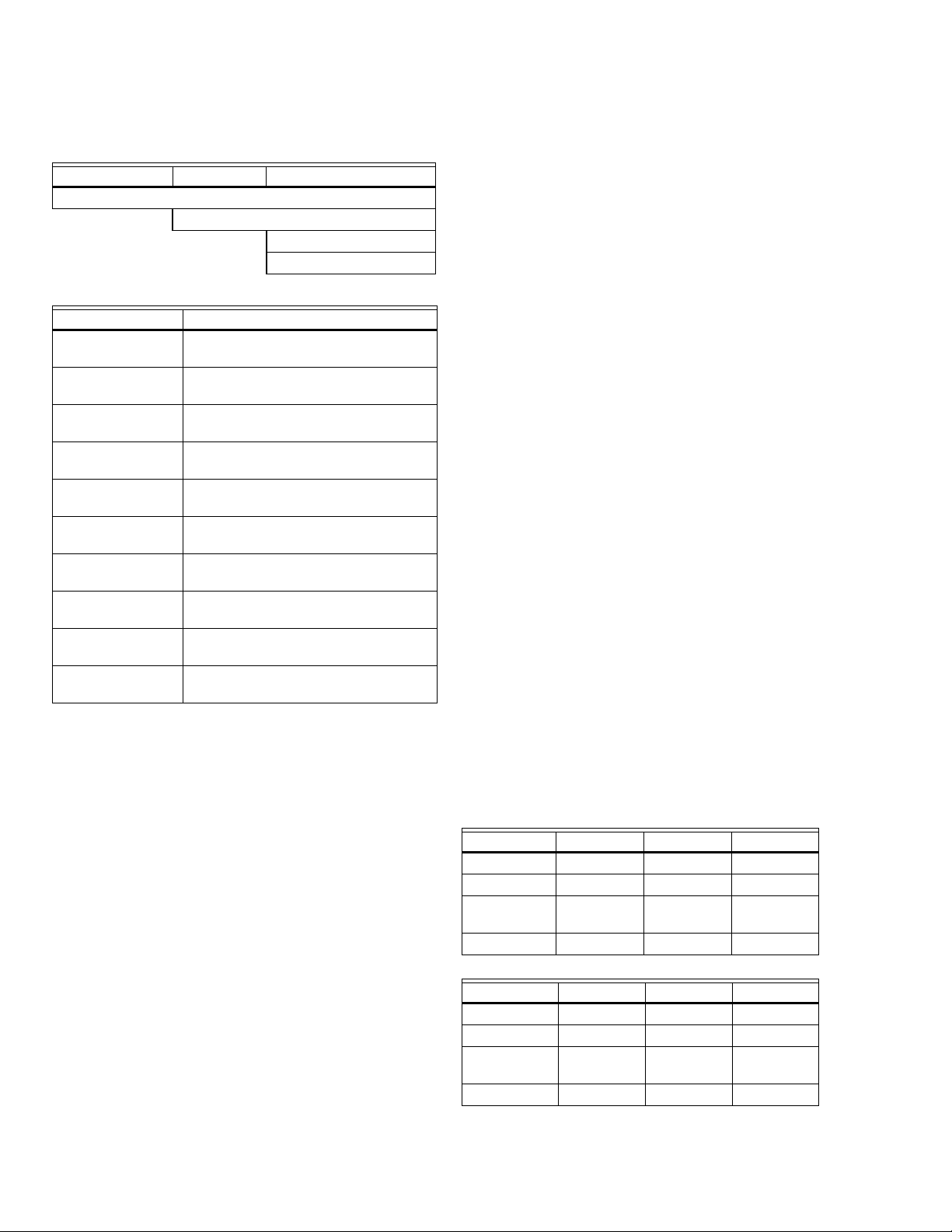

Table 1. Model Selection

Valve Fitting Body / Flow

VB = valve, ball

F = Flanged

5011 = 2-way

5013 = 3 way

Table 2. Control Ball Valve Part Numbers

Part# Description

VBF5011A1734/U 2-1/2", 2-WAY CONTROL BALL

VALVE, 63 CV

VBF5011A1767/U 3", 2-WAY CONTROL BALL VALVE,

100 CV

VBF5011A1858/U 4", 2-WAY CONTROL BALL VALVE,

160 CV

VBF5011A1882/U 5", 2-WAY CONTROL BALL VALVE,

250 CV

VBF5011A1916/U 6", 2-WAY CONTROL BALL VALVE,

360 CV

VBF5013B1003/U 2 1/2", 3-WAY CONTROL BALL

VALVE, 63 CV

VBF5013B1011/U 3", 3-WAY CONTROL BALL VALVE,

100 CV

VBF5013B1029/U 4", 3-WAY CONTROL BALL VALVE,

160 CV

VBF5013B1037/U 5", 3-WAY CONTROL BALL VALVE,

250 CV

VBF5013B1045/U 6", 3-WAY CONTROL BALL VALVE,

360 CV

Dimensions: Refer to Figures 1 through 5 and Tables 6

through 9.

Body Style: Two-way control ball valve, straight-through

flow, full or reduced port using laser-milled stainless

steel control ball.

Three-way control ball valve, A-B-AB characterized flow,

laser-milled stainless steel control ball.

Combination ANSI 125/PN16 flanged connections.

Body Size: 2-1/2" to 6" (DN65, DN80, DN100, DN125,

DN150).

Torque Requirement: See Table 4.

Body Pressure Rating (maximum):

For 2-1/2" & 3":

360 psi (2482 kPa) at 250° F (121° C).

For 4:, 5", & 6":

240 psi (1655 kPa) at 250° F (121° C).

Controlled Medium: Water or Glycol solutions up to 50%.

Not suitable for combustible gases.

Fluid Temperature Range: -22 to +250° F (-30 to +121°

C).

Flow Characteristics:

Two-way: Equal Percentage.

Three-way: Port A to AB: Equal Percentage.

Port B to AB: Linear with 20% reduced flow

capacity.

Rangeability:

Rangeability is a measure of a valve's controllability

(sometimes referred to as its Turndown Ratio). Rangeabil-

ity is

a measured property and is expressed as the ratio of a

valve's

maximum flow rate to its minimum controllable flow rate.

For 2-1/2": 250

For 3": 558

For 4", 5", & 6": 500:1 minimum.

Mounting: Bolt holes conform to ANSI B16.1.

Materials:

For 2-way 2-1/2", 3" & 3-way 2-1/2":

Body: Forged Brass (ASTM B283)

Flanges: Cast iron ductile ANSI Class 125

Flow Optimizer: Noryl®

Ball and Stem:

Two-way: Stainless Steel

Three-way: Nickel-chrome Plated Brass.

Stem Seals: EPDM O-rings.

Ball Seals: Reinforced TEFLON™ Seals with EPDM Orings.

For 2-way 4", 5", & 6" & 3-way 3", 4", 5", & 6",

Body: Cast Iron ASTM A395, 60-40-18

Ball and Stem: 316 Stainless Steel.

Stem Seals: EPDM O-Rings.

Ball Seals: Teflon

Leakage Rating:

Valves: ANSI Class IV close-off/leakage (A port only).

2-way - ANSI Class IV leakage

3-way - A to AB; ANSI Class IV leakage

3-way - B to AB; ANSI Class III leakage

Accessories:

For 4", 5", and 6", see Table 3 for replacement parts.

Two-way 4 in. 5 in. 6 in.

Seal 7981-910 7981-915 7981-912

Seal O-ring 7981-914 7981-911 7981-916

Flange Oring

Bottom Stem 7981-701 7981-701 7981-701

Three-way 4 in. 5 in. 6 in.

Seal 7981-911 7981-912 7981-913

Seal O-ring 7981-915 7981-916 7981-917

Flange Oring

Bottom Stem 7981-701 7981-701 7981-701

®

Seals with EPDM O-rings

Table 3. Parts list for Flanged Valves

7978-65 7978-66 7978-68

7978-66 7978-67 7978-69

62-3117—02 2

Page 3

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

Application Notes

IMPORTANT

Valve sizing is important for correct system operation. Undersized valves do not have sufficient

capacity at maximum load. Oversized valves do not

have sufficient authority over the load in modulating applications. Oversized valves can cause

excessive cycling and the seat and ball can be

damaged because of the restricted opening.

Proper Use

These valves are only for use in cold, warm and hot water

systems. Not suitable for oil, or combustible gases. For

water application, they are designed for a medium

temperature range from -22 to 250°F, at a maximum

pressure of 360 psi for 2-1/2" & 3" valves and 240 psi for

4", 5", & 6" valves. The valves are to be operated with the

appropriate Honeywell electronic actuators only. Water

should be properly filtered, treated and conditioned

according to local conditions and the recommendations of

the boiler or chiller manufacturers. The installation of a

strainers and filters is recommended.

IMPORTANT

The presence of excessive iron oxide (red rust) in

the system voids the valve warranty.

Required Torque

Honeywell electronic actuators can be utilized with the

VBF5011 and VBF5013 valves. See Table 4, which lists the

torque requirement for each valve size. See Table 5, which

lists the close-off pressure rating for the valves with the

different torque actuators. Larger torque actuators may be

used, but there is no increase in close-off pressure rating.

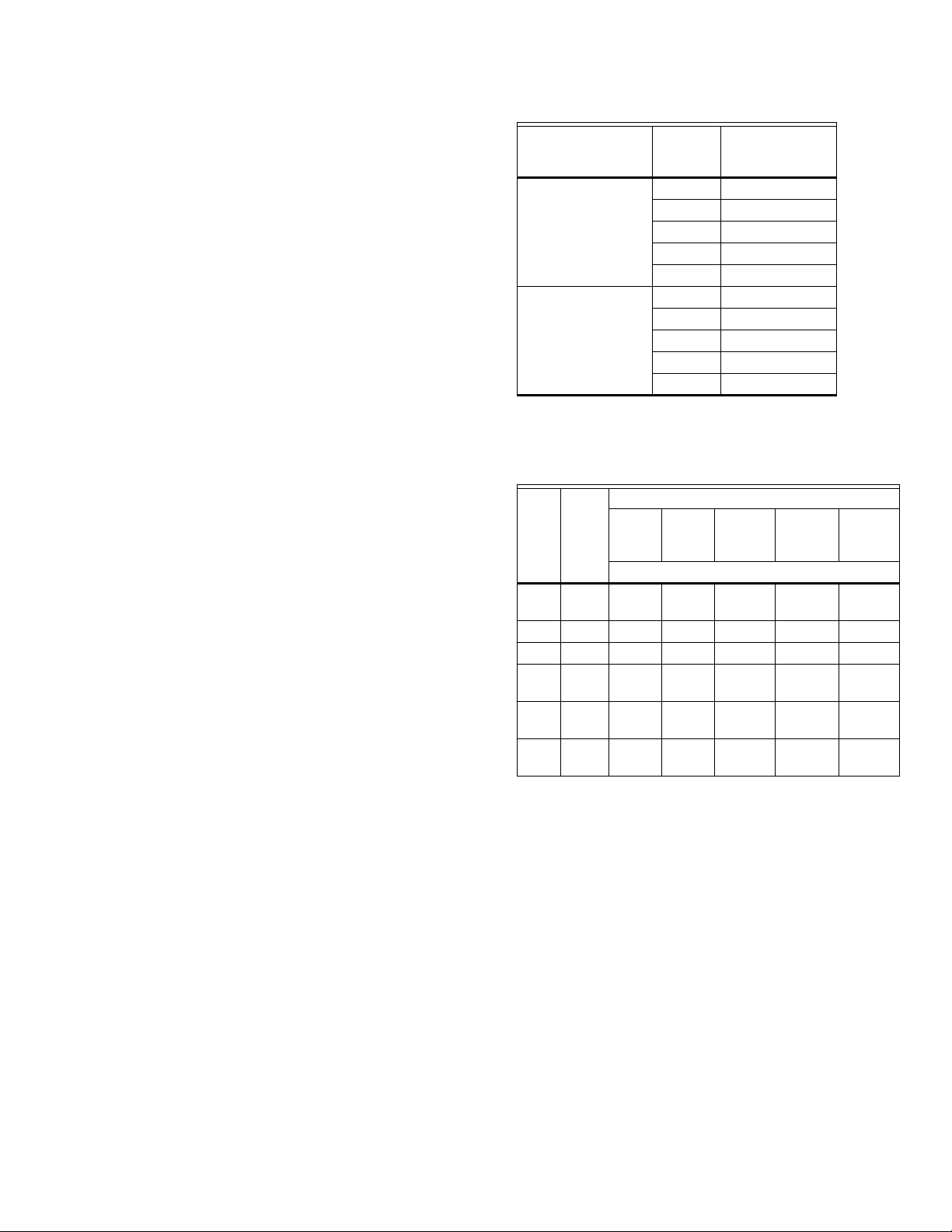

Table 4. Torque Requirement

Tor que

Requirement

Type Size

2-way 2 1/2” 35

3” 35

4” 85

5” 85

6” * 140

3-way 2 1/2” 35

3” 85

4” 85

5” 85

6” * 140

* 6” requires 140 in-lb actuator for flows up to

700 gpm. For flow rates greater than 700 gpm

a 200 in-lb actuator is recommended.

Table 5. Close-off Pressure Rating

35 lb-in

Valve

Valve

Type

2-way 2-1/2”, 3”100

3-way 2-1/2” 40

3-way 3” 70 70 70 70

2-way,

4” 70 70 70 70

3-way

2-way,

5” 70 70 70 70

3-way

2-way,

6” 70 70

3-way

(4 Nm)

Size

88 lb-in

(10 Nm)

Close-off pressure rating (psi)

(in-lbs)

Actuator Type

175 lb-in

(20 Nm)

2-position

175 lb-in

(20 Nm)

300 lb-in

(34 Nm)

Flow Characteristics

VBF5011 Two-Way Control Ball Valves have:

• an equal percentage flow characteristic.

VBF5013 Three-Way Control Ball Valves have:

• between ports A and AB: an equal percentage flow

characteristic.

• between ports B and AB: a linear flow characteristic

with 20% reduced flow capacity.

3 62-3117—02

Page 4

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

H

C

F

G

B

E

Size

in. Model Number

(mm)

2 1/2 VBF5011A1734/U 9 1/2

(241)

3 VBF5011A1767/U 11

(279)

A

D

M34652

Fig. 1. 2-way 2-1/2" & 3" valve dimensions

Table 6. 2-way 2-1/2" & 3" valve dimensions

A

in.

(mm)

7

(178)

7 1/2

(191)

B

in.

C

in.

(mm)

12 3/8

(314)

12 5/8

(321)

D

in.

(mm)

8 3/4

(222)

9

(229)

E

in.

(mm)

4 5/16

(110)

(mm)

5 1/2

(140)

6

(152)

F

in.

3/4

(19)

G

in.

(mm)

H

in.

(mm)

3

(76)

62-3117—02 4

Page 5

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

M34653

A

C

D

F

I

B

G

E

H

M34656

H

D

C

I

A

B

E

G

F

Fig. 2. 3-way 2-1/2" valve dimensions

Fig. 3. 3-way 3" valve dimensions

Size

in. Model Number

2 1/2 VBF5013B1003/U 9 1/2

(241)

3 VBF5013B1011/U 11

(279)

Table 7. 3-way 2-1/2" & 3" valve dimensions

A

in.

(mm)

in.

(mm)

7

(178)

7 1/2

(191)

B

C

in.

(mm)

15 5/16

(389)

13 1/8

(333)

D

in.

(mm)

8 3/4

(222)

10 5/16

(262)

5 62-3117—02

4 5/16

(110)

4 13/16

(122)6(152)

E

in.

(mm)

in.

(mm)

5 1/2

(140)

F

(mm)

3/4

(19)

G

in.

H

in.

(mm)

6 7/16

(164)

I

in.

(mm)

3

(76)

6 5/8

(168)

Page 6

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

F

E

B

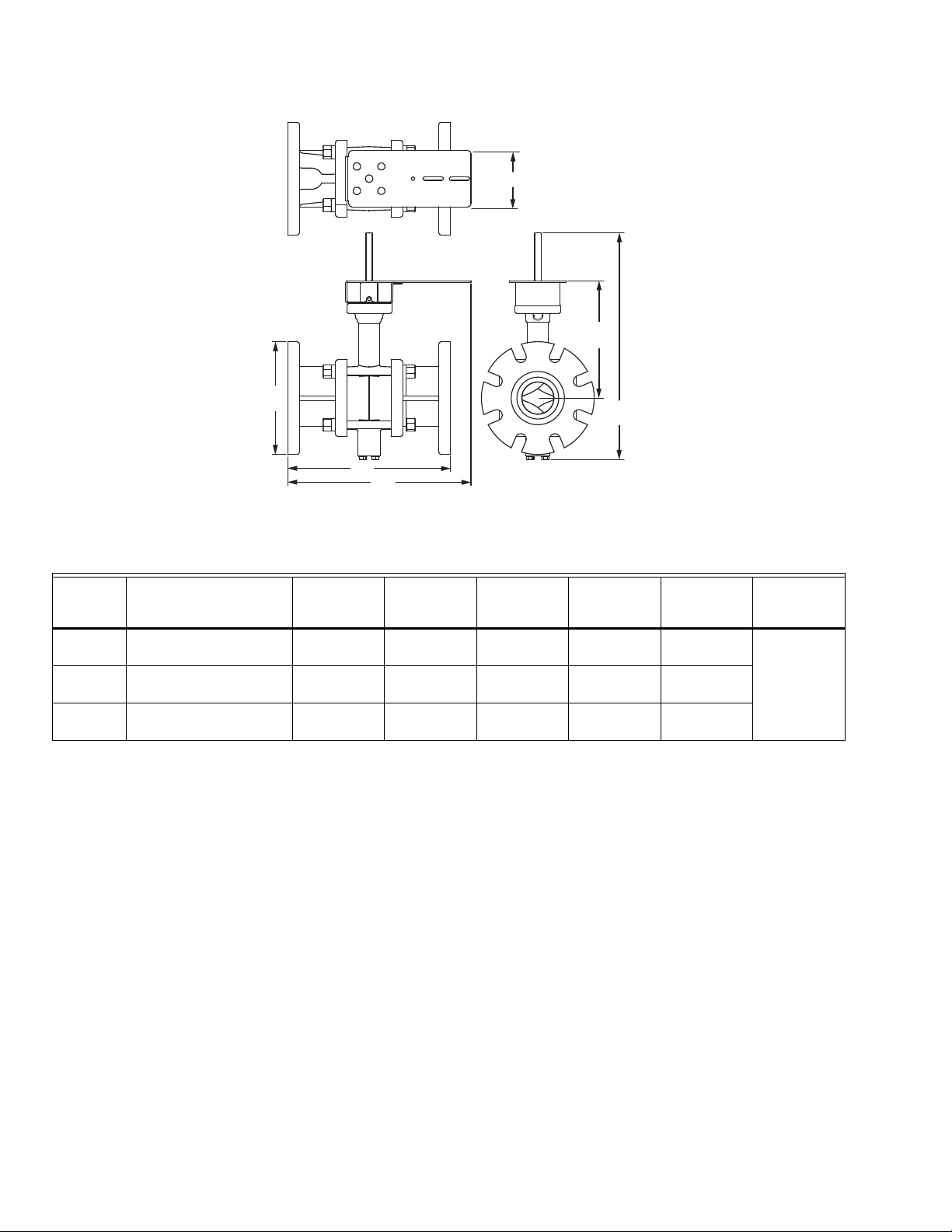

Fig. 4. 2-way 4", 5" & 6" valve dimensions

Table 8. 2-way 4", 5" & 6" valve dimensions

Size

in. Model Number

(mm)

4 VBF5011A1858/U 13

(330)

5 VBF5011A1882/U 15

(381)

6 VBF5011A1916/U 16 1/2

(419)

A

in.

C

A

D

M34654

B

in.

(mm)

9

(229)

10

(254)

11

(279)

C

in.

(mm)

18 1/8

(460)

18 13/16

(478)

19 11/16

(500)

(mm)

14 5/8

(371)

15 5/8

(397)

16 3/8

(416)

D

in.

E

in.

(mm)

9 3/8

(238)

9 11/16

(246)

10 1/8

(257)

F

in.

(mm)

4 1/2

(114)

62-3117—02 6

Page 7

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

F

G

H

M34655

B

A

D

C

E

Size

in. Model Number

in.

(mm)

4 VBF5013B1029/U 13

(330)

5 VBF5013B1037/U 15

(381)

6 VBF5013B1045/U 16 1/2

(419)

A

Fig. 5. 3-way 4", 5" & 6" valve dimensions

Table 9. 3-way 4", 5" & 6" valve dimensions

B

in.

(mm)

9

(229)

10

(254)

11

(279)

C

in.

(mm)

18 13/16

(478)

19 11/16

(500)

20 3/4

(527)

D

in.

(mm)

14 5/8

(371)

15 5/8

(397)

16 3/8

(416)

E

in.

(mm)

9 11/16

(246)

10 1/16

(256)

10 11/16

(271)

F

in.

(mm)

8 11/16

(221)

9 5/8

(244)

10 11/16

(271)

G

in.

(mm)

13 3/16

(335)

14-5/8

(371)

16 3/16

(411)

H

in.

(mm)

4 1/2

(114)

7 62-3117—02

Page 8

VBF5011, VBF5013 CONTROL BALL VALVES WITH FLANGED CONNECTIONS

TYPICAL SPECIFICATIONS

ACCESSORIES

Identification tags shall be available for all valves; tags

shall be indelibly marked with C

location.

, model number and

V

Honeywell

®

is a registered trademark of Honeywell International.

Tef lon® is a registered trademark of E I DuPont de Nemours.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any

liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Honeywell Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

buildingcontrols.honeywell.com

® U.S. Registered Trademark

©2020 Honeywell International Inc.

62-3117—02 M.S. Rev. 10-20

Printed in United States

Loading...

Loading...