Page 1

VB6 SERIES 6-WAY CONTROL BALL

VALVES AND ACTUATORS

INSTALLATION INSTRUCTIONS

® U.S. Registered Trademark. All Rights Reserved

Copyright © 2020 Honeywell Inc. Printed in USA

APPLICATION

The VB6 6-Way Control Ball Valves regulates hot and

chilled water with glycol solutions up to 60% in heating,

ventilating, and air conditioning (HVAC) systems.

These valves ship with a direct coupled actuator factory

installed for modulating control. The valve is designed to

be used exclusively with MN7510A2001 actuator.

Application Notes

IMPORTANT: Valve sizing is important for correct

system operation. Undersized valves do not have

sufficient capacity at maximum load. Oversized

valves do not have sufficient authority over the load

in modulating applications.

Oversized valves can cause excessive cycling and

the seat and ball can be damaged because of the

restricted opening.

Proper Use

These valves are intended for use in chilled water and hot

water closed loop applications only, with a media

temperature range of 0 ºF to +212 ºF (-18 ºC to 100 ºC),

and static pressures up to 600psi. These valves are NOT

suitable for oil, combustible gases, or steam.

These valves are to be operated with the Honeywell

MN7510A2001 actuator only.

Water should be properly filtered, treated and conditioned

for good operating performance, according to local

conditions, and recommendations of the boiler or chiller

manufacturers. The installation of strainers and filters is

recommended.

IMPORTANT: The presence of excessive iron oxide

(red rust) in the system voids the valve warranty.

Required Operating Torque

The VB6 series 6-way control ball valves are to be operated

with the Honeywell MN7510A2001 actuator only

These valves use a patented seat design that reduces the

torque needed. The nominal required operating torque is

88 lb-in.

Table 1: Close off Pressure

Valve Size

Close-off Pressure Rating

1/2 inch

200 psi (1380 kPa)

Flow Characteristic

The VB6 series 6-way Ball Valves have true equal

percentage flow characteristic, thanks to precision

machined metal discs in front of the ball.

Valve Sizing

Typical pressure drop across a control valve is in the range

of 3 to 5 psid, however the best control is achieved when

the valve pressure drop is as close to the coil pressure

drop as possible. A 6-Way valve will have two CV

calculations, one each for Sequence 1 and Sequence 2,

which will feature different flow rates most of the time.

Page 2

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

31-00380M-01 2

INSTALLATION

When installing this product...

1. Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the product to ensure the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

Preparation

CAUTION

Equipment Damage Hazard

Foreign particles like dirt and metal chips can damage the ball seals.

For trouble-free operation of the product, good installation practice must include initial system flushing, and

chemical water treatment. Clean the lines upstream of particles larger than 1/16 inch diameter (welding slag, pipe

scale, sand and other suspended particulate). Use of a 50 micron (or finer) system side stream filter is suggested.

Remove all filters before flushing.

Do not use boiler additives, solder flux and wetted materials which are petroleum based or contain mineral oil,

hydrocarbons, or ethylene glycol acetate. Compounds which can be used, with minimum 40% water dilution, are

diethylene glycol, ethylene glycol, and propylene glycol (antifreeze solutions).

If installing these valves in an addition to, or retrofitting an existing building, do not assume that the fluid in the

existing piping meets these criteria.

CALIFORNIA PROPOSITION 65 WARNING

This product can expose you to chemicals including lead, which is known to the State

of California to cause cancer, birth defects, or other reproductive harm. For more

information, go to www.P65Warnings.ca.gov.

Page 3

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

3 31-00380M-01

Mechanical Installation of the Valve

IMPORTANT: Hold valve with pipe wrench by

hexagonal fitting ONLY. Do NOT handle the Valve

body with the pipe wrench; product damage may

result.

Refer Dimension section on page 9 for more details on

dimensions of Valve body and actuator.

1. Clean the lines upstream of particles larger than 1/16

in. diameter (welding slag, pipe scale and other

contaminants) to properly flush the system.

2. Proceed with installation once the system specifics

(expansion/contraction of the system and its medium

as well as operating pressures) are within tolerances.

3. Eliminate air or air-bubbles from system.

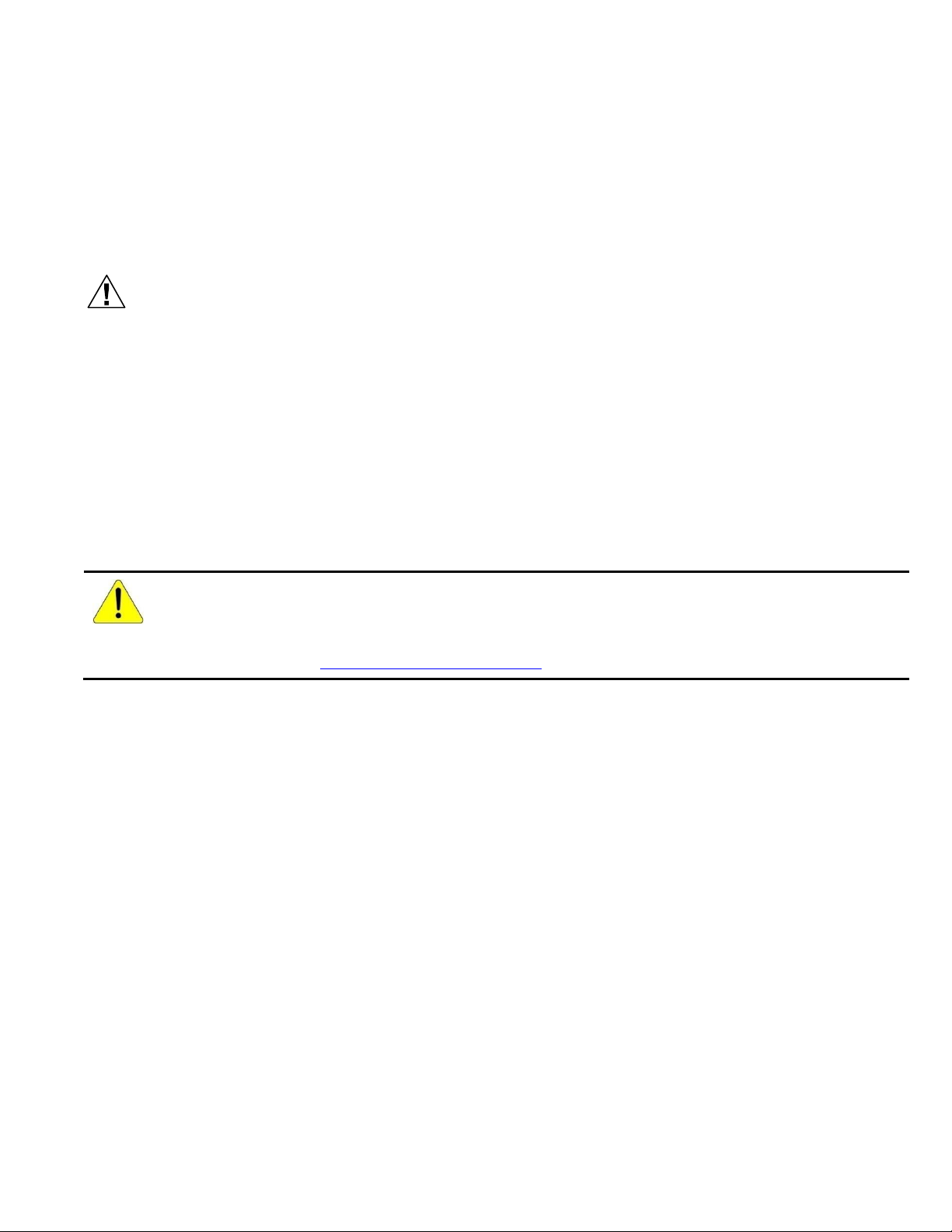

4. Use the markings on the valve bodies to familiarize

yourself with the A, B, and AB piping connections.

5. Connect the AB-ports of the valve to the supply and

return pipes of the coil.

6. Connect the A-ports and B-ports as per the flow

sequences. Refer to below figure.

Figure 1. Typical flow directions for Sequence 1 and 2.

IMPORTANT: Strictly follow flow direction and port

connections as per flow sequences.

7. Clear threads on both valve and piping of any debris.

Honeywell recommends Permabond A1044 or

equivalent thread or pipe sealant. When using Teflon

tape, it is recommended to use 4-6 rounds of tape

applied tightly in clockwise rotation. When using

hemp as pipe sealant, ensure no strands are left in the

valve or piping.

8. Valves must be installed avoiding unnecessary pull or

twist in the valve housing.

9. Use the Bracket as shown below figure if non-flexible

pipes are used in piping to keep pipes firm and

parallel.

Figure 2. Assembly of Bracket for non-flexible piping

Valve Insulation

To avoid water condensation dripping from the 6-way

valve, insulate around the pipe connections and the

structural box, but do not cover the gear box in insulation.

Mechanical Installation for Actuator

CAUTION

To avoid personal injury (electrical shock) and to

prevent equipment damage, before installation,

you must remove power.

Mounting Position

1. Choose a mounting position permitting easy access

to cables and controls.

2. Make sure that the actuator stem is in horizontal to

upright vertical position, but never in below horizontal

position. Condensate from Valve body may flow into

the Gear box or actuator, causing damage.

Page 4

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

31-00380M-01 4

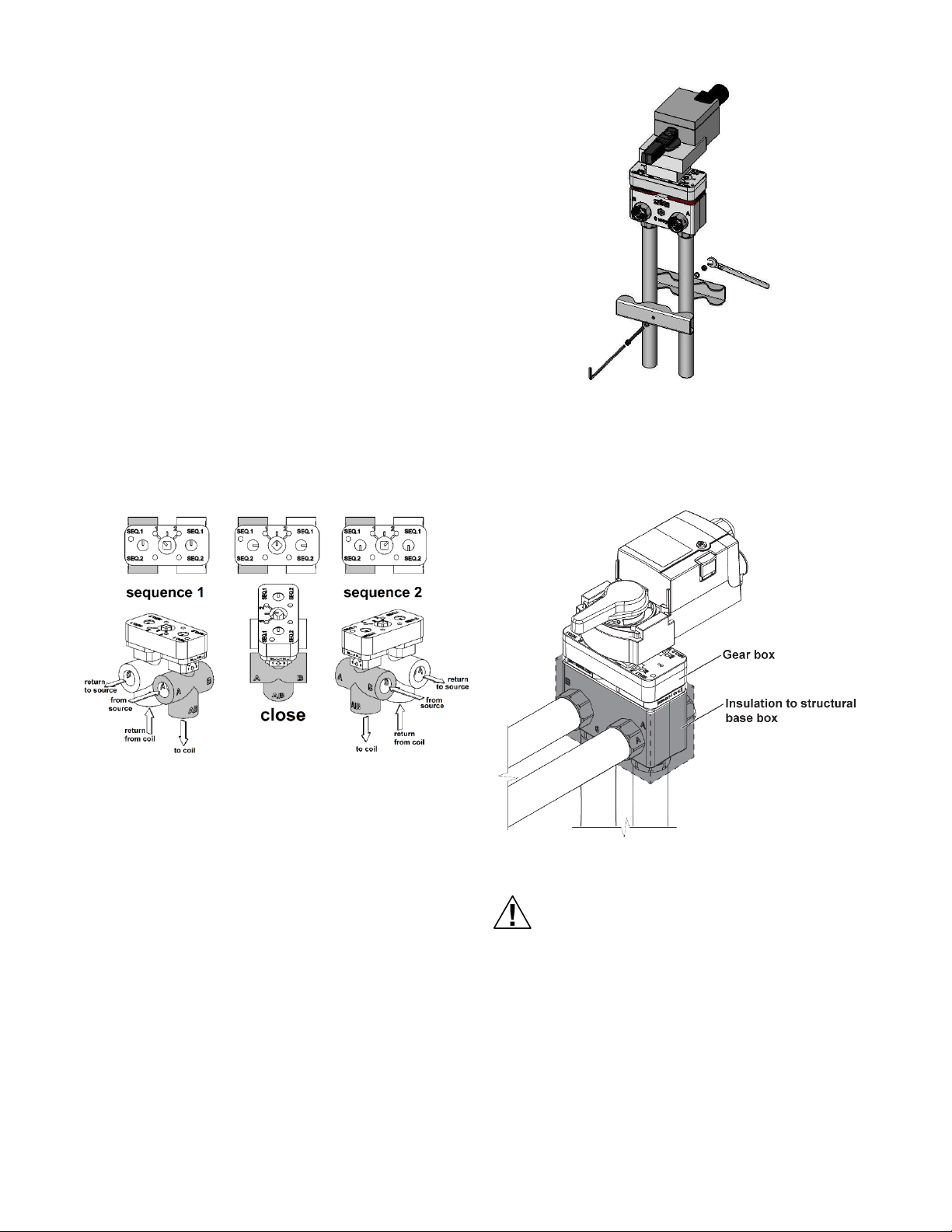

Figure 3. Actuator mounting

NOTE: Further, in order to guarantee IP54, only

original Honeywell grommets may be used.

Preparing Actuator for mounting

1. Use a suitable plier to hold the clip of the Universal

shaft adapter.

2. Pull out the Clip as shown in below figure to remove

Universal shaft adapter. Now, the actuator is ready to

assemble on 6-way control ball valve.

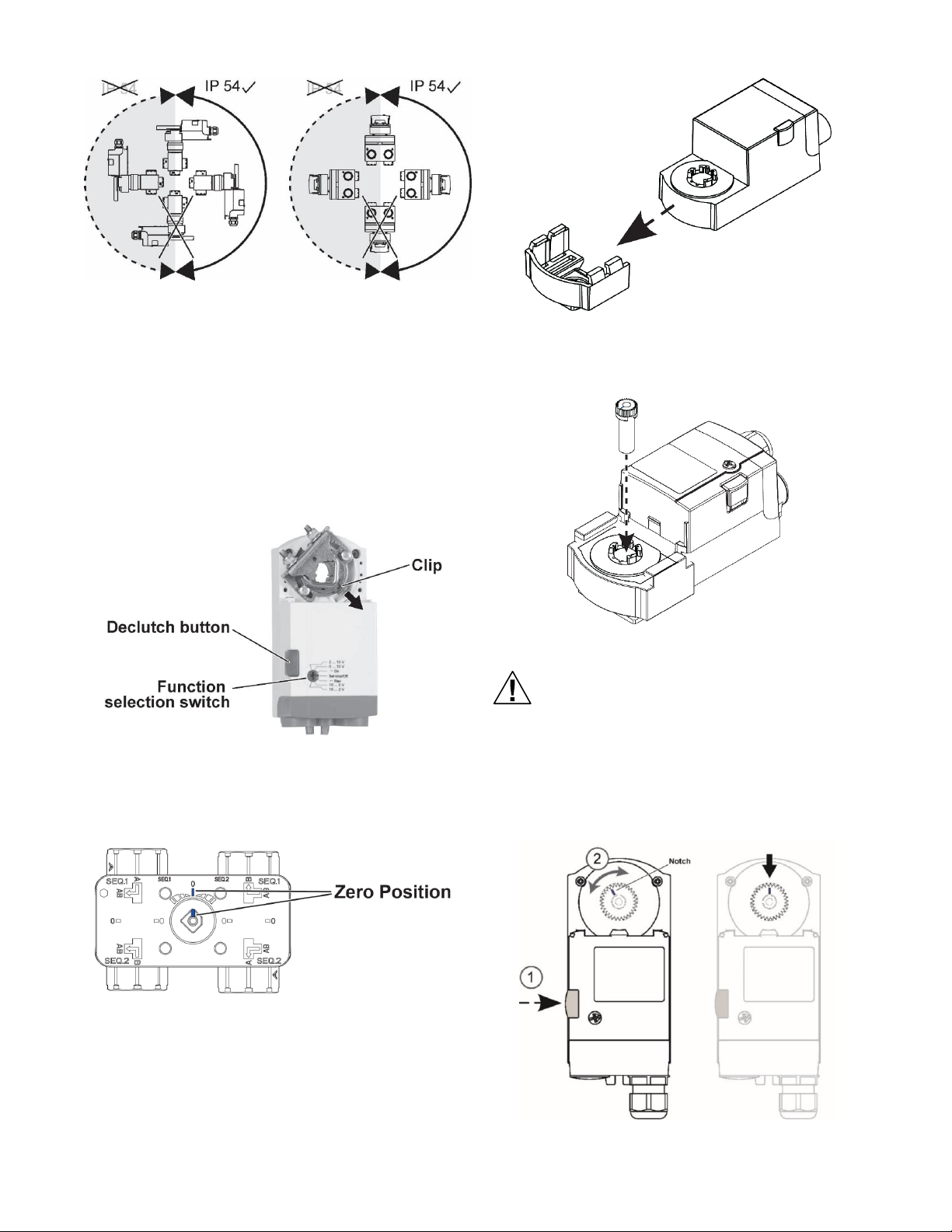

Assembling the actuator on Valve body

1. Make sure that the Gear box is in zero position as

shown in below figure. Use the appropriate wrench to

adjust (if necessary).

Figure 4. Zero position of Gear box on Valve body

2. Slide the actuator into Actuator pedestal as shown in

below figure. Do not use additional tools or pressure

as the Actuator pedestal is designed to press fit with

the MN7510A2001 actuator.

Figure 5. Assembly of Actuator pedestal

3. Insert the Stem adapter into the Actuator output hub

(Stem adapter and Output hub are keyed so they can

be assembled in one way only).

Figure 6. Assembly of Stem adapter

IMPORTANT: To prevent equipment damage, you

must remove power or set the function selection

switch to the “Service/Off” position before manual

adjustment.

4. Press and hold the Declutch button to permit rotation

of the Stem adapter to any position.

Rotate the Stem adapter, so that the notch on the

Stem adapter points as shown in figure below.

Figure 7. Adjusting the Stem adapter to zero position

Page 5

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

5 31-00380M-01

5. Slide the Brass sleeve over the end of the Stem

adapter as shown in figure below.

Figure 8. Assembly of Brass sleeve

6. Place the actuator assembly on the Valve body as

shown in below figure.

IMPORTANT! The only possible way that the valve

stem and actuator Stem adapter can be assembled

together is with both in the Zero position.

Figure 9. Assembly on the Valve body.

7. Insert the Screw (M4) and Washer (supplied with

package) into the linkage shaft and tighten the screw

(1.8 -2.5 Nm) to firmly assemble the actuator with

Valve body. See figure below.

Figure 10. Mounting of Screw in actuator assembly

8. Hold the handle in the vertical position (as shown

below) and insert the handle on the linkage Stem

adapter knob by pressing it downwards (press fit) to

assemble it firmly.

Figure 11. Mounting of Handle on the actuator

Manual Adjustment

IMPORTANT: To prevent equipment damage, you

must remove power or set the function selection

switch to the “Service/Off” position before manual

adjustment.

After removing power or setting the function selection

switch to the “Service/Off” position, the Gear box can be

disengaged using the Declutch button, permitting the

handle to be manually rotated to any position.

Page 6

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

31-00380M-01 6

Electrical Installation

The most important part of the electrical installation is the

power supply for the actuator.

CAUTION

To avoid personal injury (electrical shock) and

to prevent equipment damage, before

installation, you must remove power.

1. Unscrew the actuator wiring cover in order to access

to the terminal block(s) as shown below.

Figure 12. Removable Access Cover

2. Perform the wiring of actuator using Figure 13 to

Figure 15 as per the required application.

Figure 13. MN7510 (Modulating Mode).

Figure 14. MN7510 (Floating Mode).

Figure 15. MN7510 (2-Position Mode).

3. If necessary, use the appropriate electrical cable

conduits and cable gland to properly secure the

actuator wiring.

4. Replace the wiring cover once done.

Page 7

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

7 31-00380M-01

Actuator Run modes

The function selection switch (see Figure 16) can be used to place the actuator into any one of two different modes:

• Modulating run mode

• Floating/2-position run mode

• Service/Off mode.

Figure 16. Function Selection Switch

Modulating Run Mode

The Modulating Run mode can be used in four different types of control settings:

• 2…10 Vdc

• 0…10 Vdc

• 10…0 Vdc

• 10…2 Vdc

If the function selection switch has been set to one of the four modulating control settings - and if the actuator is wired

correspondingly (see Figure 13) - then as soon as operating power is applied, the shaft adapter will run first completely

counterclockwise and then completely clockwise, after which it will run according to the control signals applied.

Figure 17. Flow curve with control signal settings

Page 8

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

31-00380M-01 8

Use the above flow curve with given actuator control signal settings to configure 6-way valve for Sequence 1 (cooling),

Sequence (2), and Off-position. Note that in Figure 13 it is shown how to override the actuator with a switch on wiring

terminal 4 to go to the 50% position. This may also be used to rotate the valve to the zero (closed) position.

IMPORTANT: The zero (closed) position of the valve can be achieved with control signal shown in the below table.

Valve closed command

(45-degree actuator rotation)

Actuator Control Signal Setting

Controller Output

0-10 Vdc

5 Vdc

2-10 Vdc

6 Vdc

10-0 Vdc

5 Vdc

10-2 Vdc

6 Vdc

Floating/2-Position Run Mode (Not recommended)

Using the MN7510A2001 actuator in floating / 2-position mode is not recommended with 6-way valves. Because both

Sequence 1 and Sequence 2 are closed at the actuator mid-stroke, 45 degree actuator rotation, it must be possible to

command the actuator to position itself in the mid-stroke position, which is difficult to do with precision in floating mode,

and impossible when floating mode is used for 2-position control.

If it is desired to use the 6-way valve for simple seasonal changeover service, it is best if three distinct positions can be

achieved:

1. Fully clockwise actuator rotation for Sequence 2 to be fully open.

2. Fully counterclockwise actuator rotation for Sequence 1 to be fully open.

3. Exactly mid-stroke, 45-degree actuator rotation, for Sequence 1 and 2 both being closed.

This scheme can only be achieved with the actuator selector switch set to one of the four modulating modes, using 0-10

Vdc, 2-10 Vdc, 10-0 Vdc, or 10-2 Vdc to achieve full clockwise, full counterclockwise, and precisely mid-stroke actuator

positions. If desired, the actuator analog feedback can be used to verify actual position.

If only step 1 and 2 above are desired, and there is no need for step 3 to rotate the actuator to exactly 45 degrees to turn

both Sequence 1 and 2 completely off, the floating mode may be used for 3-wire 2-position control.

Power-Off Behavior

If power is removed, the shaft adapter remains in position.

Service/Off Mode

If the function selection switch is set to the “Service/Off” position, then all rotary movement is cancelled, and all control

signals are ignored, thus allowing the actuator to be manually operated safely. Press and hold the Declutch button and

use the handle to operate the actuator from Sequence 1, 2, or, Off positions.

Overriding

An override is a condition in which a 24 V signal is applied to terminal 4 of an actuator in the modulating mode, thus

causing the actuator to ignore the control signal at terminal 3, whereupon it will instead move to a position of 50% of its

maximum stroke.

Feedback

If correspondingly wired, the actuator provides, via terminal 5 (see Figure 13 to Figure 15), a feedback signal proportional

to the actual position of the shaft adapter.

Page 9

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

9 31-00380M-01

Flow Rate as per Valve Pressure Difference (ΔP)

Table 2. Flow rate as per Valve Pressure difference

Valve Size

(inch)

CV value

for sequence

1 or 2*

Flow Rate (in gpm) for below Valve ΔP (in psid)

0.50

0.75

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

9.00

10.00

1/2 inch

CV 0.30

0.21

0.26

0.30

0.42

0.52

0.60

0.67

0.73

0.79

0.85

0.90

0.95

CV 0.46

0.33

0.40

0.46

0.65

0.80

0.92

1.03

1.13

1.22

1.30

1.38

1.45

CV 0.80

0.57

0.69

0.80

1.13

1.39

1.60

1.79

1.96

2.12

2.26

2.40

2.53

CV 1.20

0.85

1.04

1.20

1.70

2.08

2.40

2.68

2.94

3.17

3.39

3.60

3.79

CV 1.90

1.34

1.65

1.90

2.69

3.29

3.80

4.25

4.65

5.03

5.37

5.70

6.01

CV 3.00

2.12

2.60

3.00

4.24

5.20

6.00

6.71

7.35

7.94

8.49

9.00

9.49

CV 4.70

3.32

4.07

4.70

6.65

8.14

9.40

10.51

11.51

12.44

13.29

14.10

14.86

CV 7.40

5.23

6.41

7.40

10.47

12.82

14.80

16.55

18.13

19.58

20.93

22.20

23.40

*For fully open valve position.

For example:

The VB6A003+012+AL valve is with CV 0.30 (for sequence 1) and CV is 1.20 (for sequence 2). If we consider the valve

pressure difference (ΔP) 0.5 psid then as per above table, the Flow rate for sequence 1 will be 0.21 gpm and for sequence

2 will be 0.85 gpm.

Page 10

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

31-00380M-01 10

DIMENSIONS

Dimension of Valve body

Figure 18. Dimension drawing of VB6 series 6-way control valve

Table 3. Dimensions

Valve nominal size

A B C D E

F

Valve body

Inch

in (mm)

in (mm)

in (mm)

in (mm)

in (mm)

in (mm)

VB6A

1/2"

6.85 (174)

2.76 (70)

6.63 (168)

5.33 (135)

4.14 (105)

3.77(95)

Page 11

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

11 31-00380M-01

Dimension of Actuators

Figure 19. Dimension drawing of the MN7510A2001 actuator

Page 12

VB6 series 6-Way Control Ball Valves and Actuators - Installation Instructions

31-00380M-01

January 2021

© 2020 Honeywell International Inc.

http://buildingcontrols.honeywell.com

Printed in USA

VB6 SERIES 6-WAY CONTROL

VALVES AND ACTUATORS

ORDERING INFORMATION

https://www.cpq.honeywell.com/eCommerce#/

Honeywell Building Technologies

715 Peachtree Street NE

Atlanta, GA 30308

United States of America.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use

or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against

any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature

by you.

Loading...

Loading...