Honeywell V4055A, V4055D, V4055B, V4055E User Manual

On-Off Fluid Power

Gas Valve Actuator

The V4055 Gas Valve Actuator in combination

with a V5055 Gas Valve controls the gas supply to

commercial and industrial burners.

V4055A,B,D,E

■ The V4055 Actuator, when used with the V5034 or

V5055 Valve, is rated for final safety shutoff service.

■ The V4055 Actuator may be used with the character-

ized guide model of the V5055 gas valve to enhance

lightoff smoothness.

■ The standard model has an opening time of 26 sec at

60 Hz, or 32 sec at 50 Hz. A fast-opening model, is

available with timings of 13 sec at 60 Hz, or 16 sec at

50 Hz.

■ Maximum closing time is 1 sec, which meets code/

standard/insurer requirements.

■ Models with damper shaft available, with or without

spring return; shaft extends out both sides and rides

in Teflon-like, Delrin bushings; used with standard

7616BR Damper Crank Arm.

■ Red OPEN indicator attached to the actuator stem

shows when valve is even slightly open; yellow

SHUT indicator on valve stem shows only when gas

valve is fully closed.

■ Ambient temperature rating is -40°F to 150°F

[-40°C to 66°C] for 60 Hz models; -10°F to 158°F

[-23°C to 70°C] for 50 Hz and 50/60 Hz models.

■ Valve and actuator combination may be mounted in

any position.

■ Models available with factory installed SPDT field

adjustable auxiliary switch. Field addable auxiliary

switch kits are also available.

■ Standard enclosure meets NEMA 1 general purpose

requirements; models available with NEMA 4

weather proof enclosure.

■ V4055D and high pressure V4055E with proof-ofclosure switch and V5055C or E with valve seal

overtravel interlock (double seal) to meet specific

code/standard/insurer requirements.

CONTENTS

Specifications .................................................2

Ordering Information..................................... 2

Installation .....................................................4

Checkout and Service .....................................8

1 60-2309—8 F.P. • Rev. 10-94 • ©Honeywell Inc. 1994 • Form Number 60-2309—8

V4055A,B,D,E

SPECIFICATIONS • ORDERING INFORMATION

Specifications

MODELS:

NOMINAL OPENING TIME (SECONDS):

V4055A actuator with V5055 gas valves provide on-off

control of fuel. With proper adapter (see Accessories),

it replaces the V4034 actuator on a V5034 gas valve.

V4055B is a high pressure model of the V4055A.

V4055D is identical to the V4055A but incorporates a

proof-of-closure switch. Used with V5055C (double

seal) for valve seal overtravel interlock.

V4055E is identical to V4055B but incorporates a proof-

of-closure switch. Used with V5055E (double seal)

for valve seal overtravel interlock.

NEMA 4 (weatherproof) models available.

Model 50 Hz 60 Hz

Standard 32 26

Fast-opening 16 13

MAXIMUM CLOSING TIME: One second when de-ener-

gized.

AMBIENT OPERATING TEMPERATURE RATING:

60 Hz MODELS: -40°F to 150°F [-40°C to 66°C].

50 Hz, 50/60 HZ MODELS: -10°F to 158°F [-23°C to

70°C].

MOUNTING: V4055 attached directly to V5055 valve with

two set screws positioned with 90 degrees separation.

PRESSURE RATINGS:

Combination is multipoise.

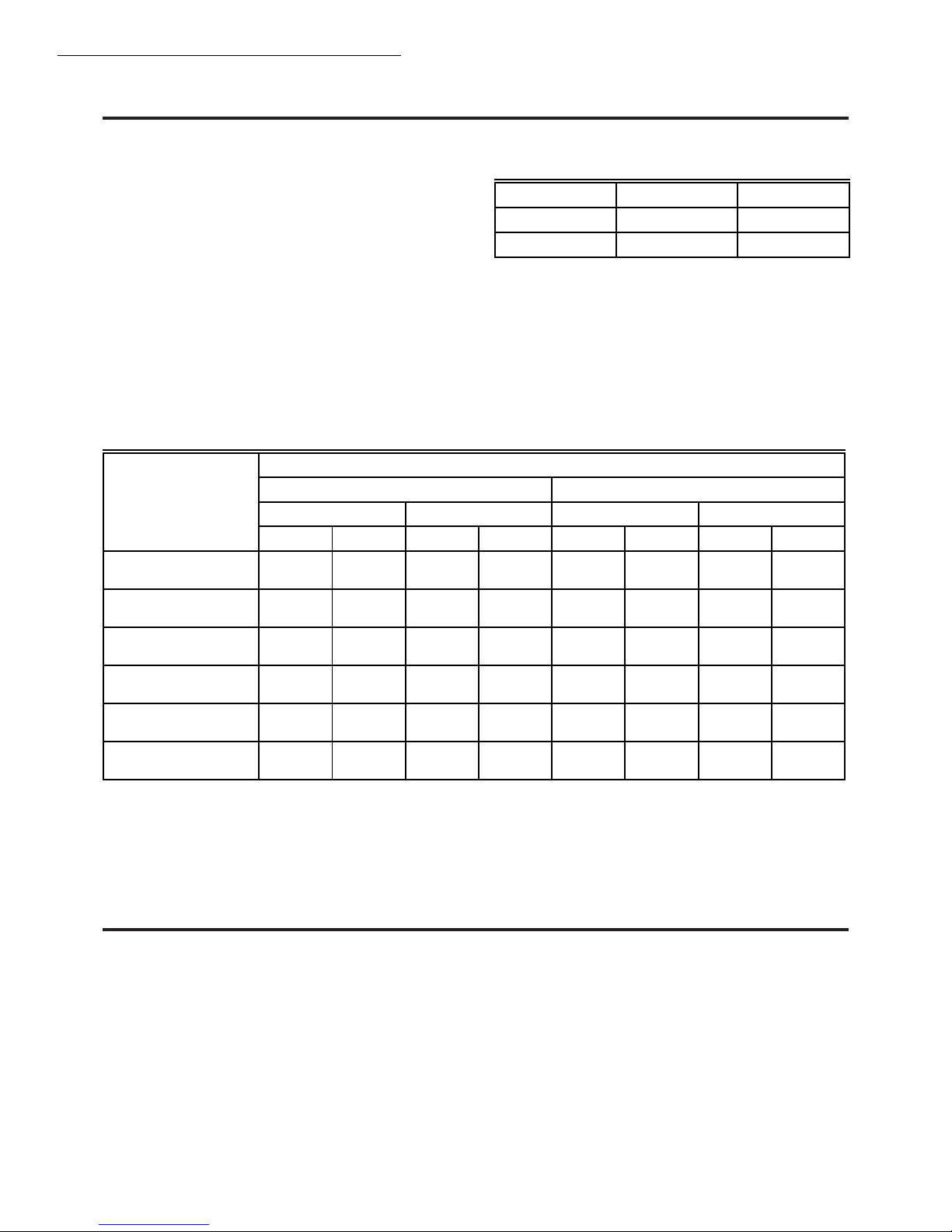

PRESSURE RATINGS OF VALVE-ACTUATOR COMBINATIONS.

Actuator

V4055A,D

b

Diff

Valve psi kPa psi kPa psi kPa psi kPa

V5055A,C

3/4 to 3 in.

V5055A,C

4 in.

V5055B

3/4 to 3 in.

V5055B

4 in.

V5055D,E

3/4, 1-1/4, 1-1/2 in.

V5055D,E

2, 2-1/2, 3 in.

a

Use a V4055D or V4055E (with proof-of-closure switch) with a V5055C or V5055E (with double seal) for valve seal

5 34.5 15 103.4 15 103.4 15 103.4

3 20.7 15 103.4 5 34.5 15 103.4

5 34.5 15 103.4 15 103.4 15 103.4

3 20.7 15 103.4 5 34.5 15 103.4

5 34.5 75 517.1 25 172.4 75 517.1

5 34.5 45 310.3 15 103.4 45 310.3

a

Closeoff

V4055B,E

c

Diff

b

a

Closeoff

c

overtravel interlock.

b

Maximum operating pressure differential.

c

Maximum closeoff pressure without seat leakage. This is the maximum allowable pressure drop to which a valve may be

subjected while fully closed, and is independent of the valve body rating.

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the Tradeline

Catalog or price sheets for complete ordering number, or specify—

1. Order number. 4. Damper shaft, with or without return spring, if required.

2. Voltage and frequency. 5. NEMA 4 enclosure, if required.

3. Standard or fast opening time. 6. Accessories, if desired.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Home and Building Control Sales Office (please check the white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell, Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 740 Ellesmere Road, Scarborough, Ontario M1P2V9. International Sales and

Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico,

Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2309—8 2

Ordering Information

V4055A,B,D,E

SPECIFICATIONS

ELECTRICAL RATINGS: V4055A,D:

Voltage and Opening (Standard) Opening (Fast) Holding

Frequency Inrush W A VA Inrush W A VA W A VA

100/50-60

100/50-60

a

b

– 43.0 0.91 91 – 58.0 1.30 130 10.4 0.16 16

– 33.0 0.67 67 – 43.0 0.91 91 8.4 0.14 14

120/60 3.9 50.0 0.94 115 5.4 71.0 1.33 160 9.5 0.12 14

200/50-60

200/50-60

a

b

– 68.0 0.79 158 – 88.0 1.10 220 10.6 0.09 18

– 48.0 0.52 104 – 63.0 0.72 144 9.0 0.07 14

220/50 1.6 55.5 0.55 121 3.0 76.0 0.80 176 9.0 0.06 14

240/50 – 81.5 0.79 190 – 95.0 1.00 240 9.1 0.06 14

240/60 2.6 51.0 0.45 115 4.0 71.5 0.68 160 9.2 0.06 14

a

50 Hz power supply.

b

60 Hz power supply.

V4055B,E–120V, 60 Hz.

Opening—60W 0.94A (5.4A inrush), 115 VA.

Holding—9.5W, 0.16A, 19 VA.

AUXILIARY SWITCH AND PROOF-OF-CLOSURE

SWITCH RATINGS: 1/2 hp [0.37 kW]a:

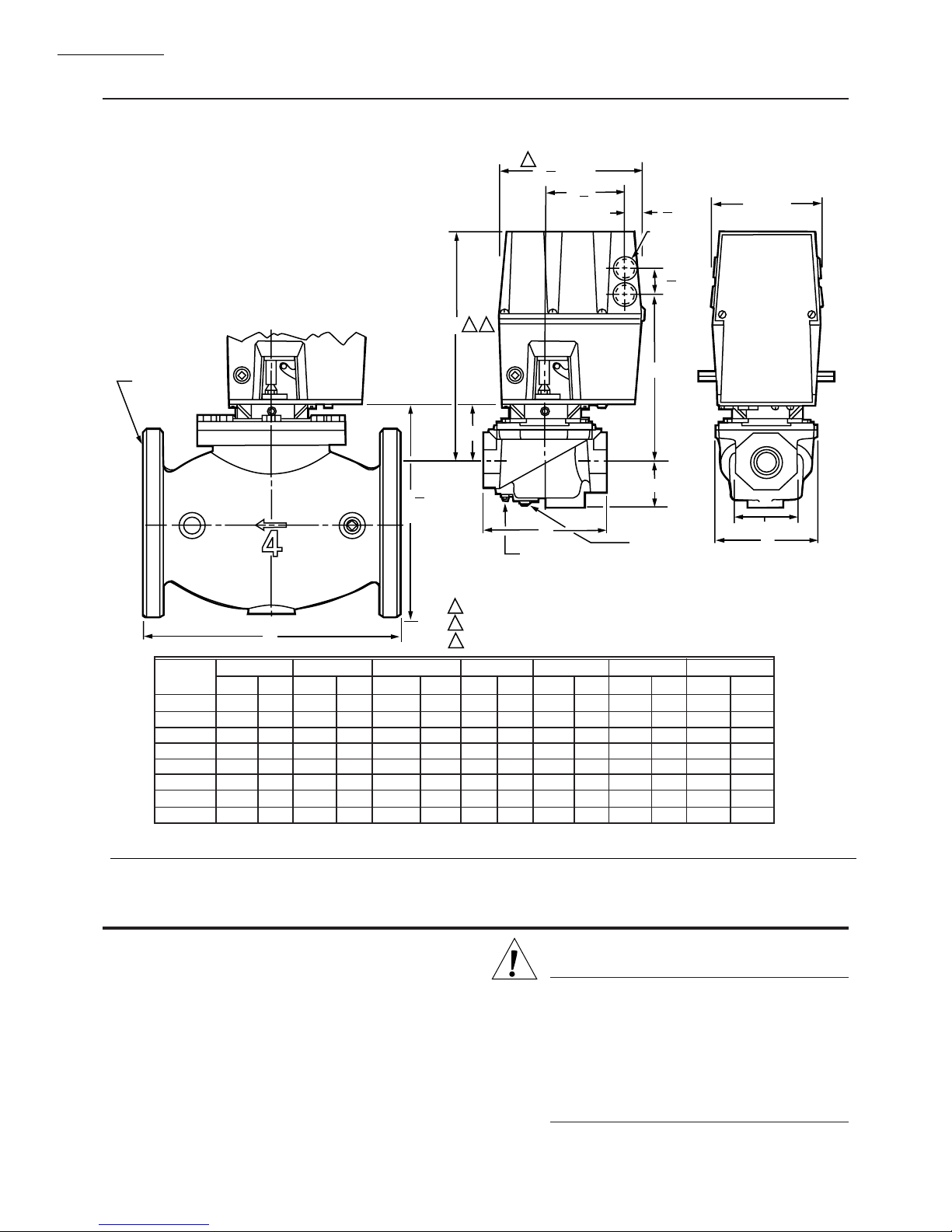

MOUNTING DIMENSIONS: See Fig. 1.

DAMPER SHAFT: Models available with or without inte-

gral damper shaft. Shaft is 3/8 in. [9.5 mm] square, for use

with 7616 BR Damper Crank Arm (not included). Models available with or without damper shaft return spring.

MAXIMUM DAMPER SHAFT ROTATION: 52 angular

Load 120V 240V

Full Load 9.8A 4.9A

Locked Rotor 58.8A 29.4A

a

Maximum total connected power to both switches (if used)

is 1800 VA.

degrees.

DAMPER SHAFT MAXIMUM FORCE A 2-11/16 in.

[68.3 mm] RADIUS FOR 7616 BR DAMPER CRANK

ARM (ordered separately):

NOTE: Damper shaft drives damper crank arm in one direc-

tion only; optional return spring is available on damper

shaft to turn damper crank arm in opposite direction.

-40°F to 20°F [-40°C to -7°C] 20°F to 150°F [-7°C to 66°C]

V4055 Model lb N lb N

Without return spring 5 22.2 20 89.0

With return spring 5 22.2 10 44.5

APPROVALS:

Underwriters Laboratories Inc. Listed: File No. MH1639,

Guide No. YIOZ.

Factory Mutual Approved.

International Approval Services (IAS, a joint venture of

AGA and CGA): 60 Hz only.

British Gas Corporation and Dutch Gas Institute Ap-

proved:

V4055 with several V5055A and V5055B models.

V4055D with V5055C models with an internal screen.

ACCESSORIES:

133533A Short Stem Adapter for mounting actuator on

133534A Long Stem Adapter for mounting actuator on

V5034 valve.

133568 Auxiliary Switch Bag Assembly.

133569 Valve-Closed Indication Switch Bag Assembly

(do not use with V5034 valve body).

7616BR Damper Crank Arm (damper arm and clip).

Q5055A1001 Adapter Assembly: Adapts ITT General

V710 Gas Valve to accept Honeywell gas valve

actuators. Replaces ITT General AH2 gas valve

actuators.

AVAILABLE MODELS:

V4055 with NEMA 4 enclosure (weatherproof).

V5034 valve.

3 60-2309—8

V4055A,B,D,E

INSTALLATION

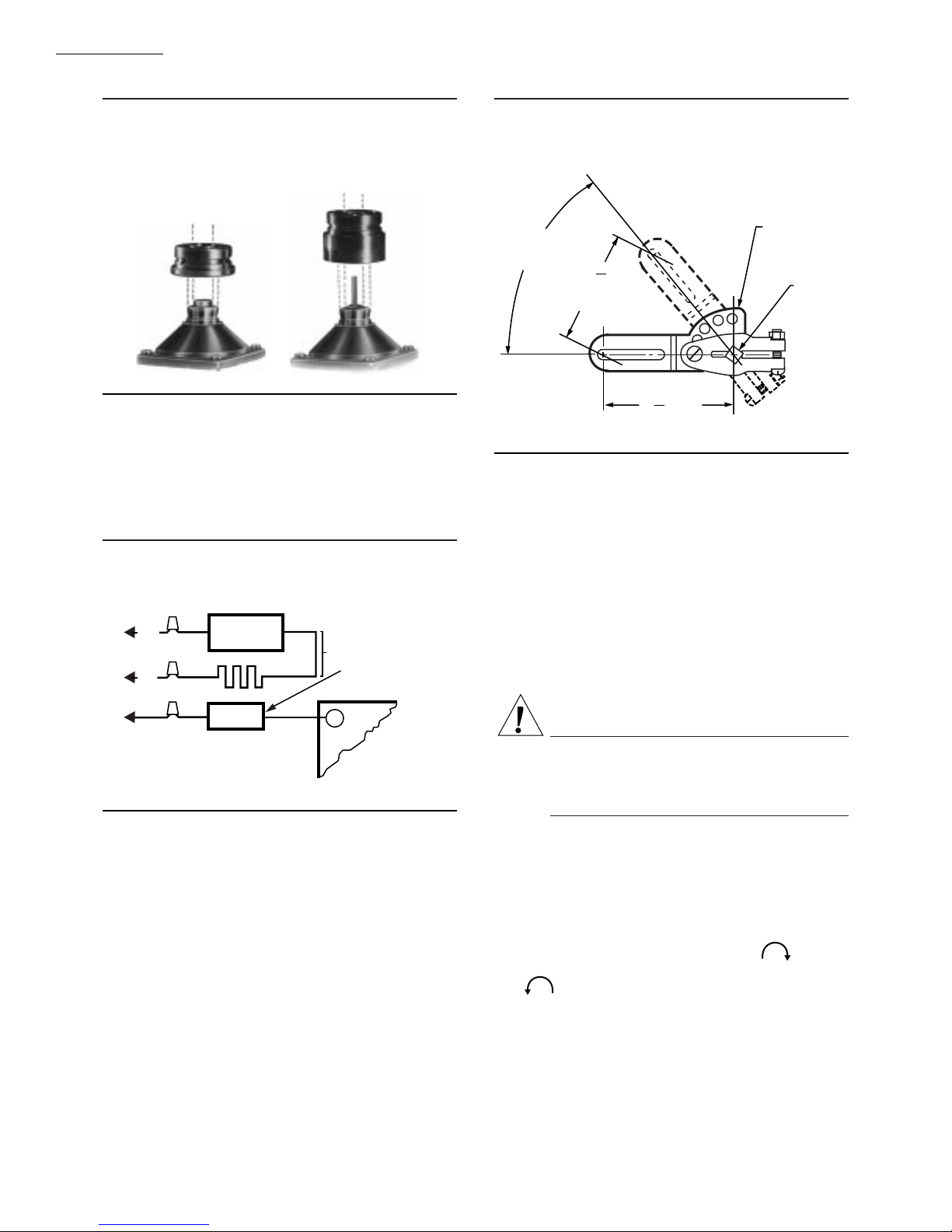

Fig. 1—Approximate Mounting Dimensions of V4055 Actuators and V5055 Valves, in in. [mm].

2

3

[171.5]

6

4

23

3

32

[94.5]

1

A

3

27

[21.4]

32

KNOCKOUT

FOR1/2 INCH

CONDUIT (4)

9

1

32

[32.5]

5 [127.0]

3/4 (19.1) BOLT

HOLES (8)

ON 3-3/4 [95.3]

RADIUS

VALVE SIZE

INCH

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

DIM A

IN. MM

11-1/8

11-1/8

11-1/8

11-1/8

11-1/4

11-3/4

11-3/4

14-1/8

D

282.6

282.6

282.6

282.6

285.8

298.5

298.5

358.8

DIM B

IN. MM

2-3/4

2-3/4

2-3/4

2-3/4

2-7/8

3-3/8

3-3/8

5-13/16

69.9

69.9

69.9

69.9

73.0

85.7

85.7

147.6

9

[233.4]

DIM C

IN. MM

8-3/16

8-3/16

8-3/16

8-3/16

8-5/16

8-13/16

8-13/16

11-7/32

C

B

3

16

D

1/4 INCH NPT

DOWNSTREAM TAP

AND PLUG

1

ALLOW 4 IN. [101.6 MM] CLEARANCE FOR ACTUATOR REMOVAL.

2

ADD 1/8 IN. [13.2 MM] TO DIMENSION FOR MODELS WITH NEMA 4 ENCLOSURE.

3

ADD 1/4 IN. [6.4MM] TO DIMENSION A FOR MODELS WITH NEMA 4 ENCLOSURE.

208.0

208.0

208.0

208.0

211.1

223.8

223.8

285.0

DIM D

IN. MM

5-3/4

5-3/4

5-3/4

5-3/4

8-3/8

9-1/4

9-1/4

12-1/2

146.1

146.1

146.1

146.1

212.7

235.0

235.0

317.5

DIM E

IN. MM

2-1/4

2-1/4

2-1/4

2-1/4

2-3/4

2-3/4

2-3/4

4-5/8

57.2

57.2

57.2

57.2

69.9

69.9

69.9

117.5

E

1/4 INCH NPT

UPSTREAM TAP

AND PLUG (1/4 BSP

ON INTERNATIONAL

MODELS)

DIM F

IN. MM

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

4-13/16

122.2

7-19/32

192.9

7-19/32

192.9

7-19/32

192.9

—

—

OCTAGON

IN. MM

2-13/16

2-13/16

2-13/16

2-13/16

3-1/2

4-1/2

4-1/2

—

OCTAGON

F

71.4

71.4

71.4

71.4

88.9

114.3

114.3

—

M7332

WHEN INSTALLING THIS PRODUCT . . .

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame safeguard control technician.

4. After installation is complete, check out product operation as provided in these instructions.

60-2309—8 4

Installation

CAUTION

1. Disconnect power supply before making wiring

connections to prevent electrical shock and

equipment damage.

2. Voltage and frequency of the power supply

connected to this control must agree with those

marked on the device.

3. Maximum total connected load to both switches

(if used) must not exceed 1800 VA.

V4055A,B,D,E

INSTALLATION

INSTALL VALVE

The actuator is mounted directly on the valve bonnet

after the valve is installed in the gas supply line. Refer to the

instructions packed with the gas valve for installation details. When installing the valve, assure that:

1. Sufficient clearance is left for installation and service

of the actuator.

2. Ambient temperatures at the valve location will re-

main within -40° to 150°F [-40°C to 66°C] or -10°F to 158°F

[-23°C to 70°C] (see Specifications section).

3. Position of the valve permits hookup to the damper if

one is controlled.

INSTALL ACCESSORY SWITCHES (IF NEEDED)

A spdt auxiliary switch may be installed to operate a

load up to 1/2 hp [0.37 kW]. The switch may be adjusted to

operate at any point in the valve stroke.

A proof-of-closure switch may also be installed on any

V4055 actuator to provide a valve seal overtravel interlock

when used with a V5055C or E valve (with double seal).

The spdt proof-of-closure switch is installed to make or

break a circuit when the valve is in the closed position. The

switch is not adjustable.

NOTE: Mark the actuator or valve to indicate any changes

made.

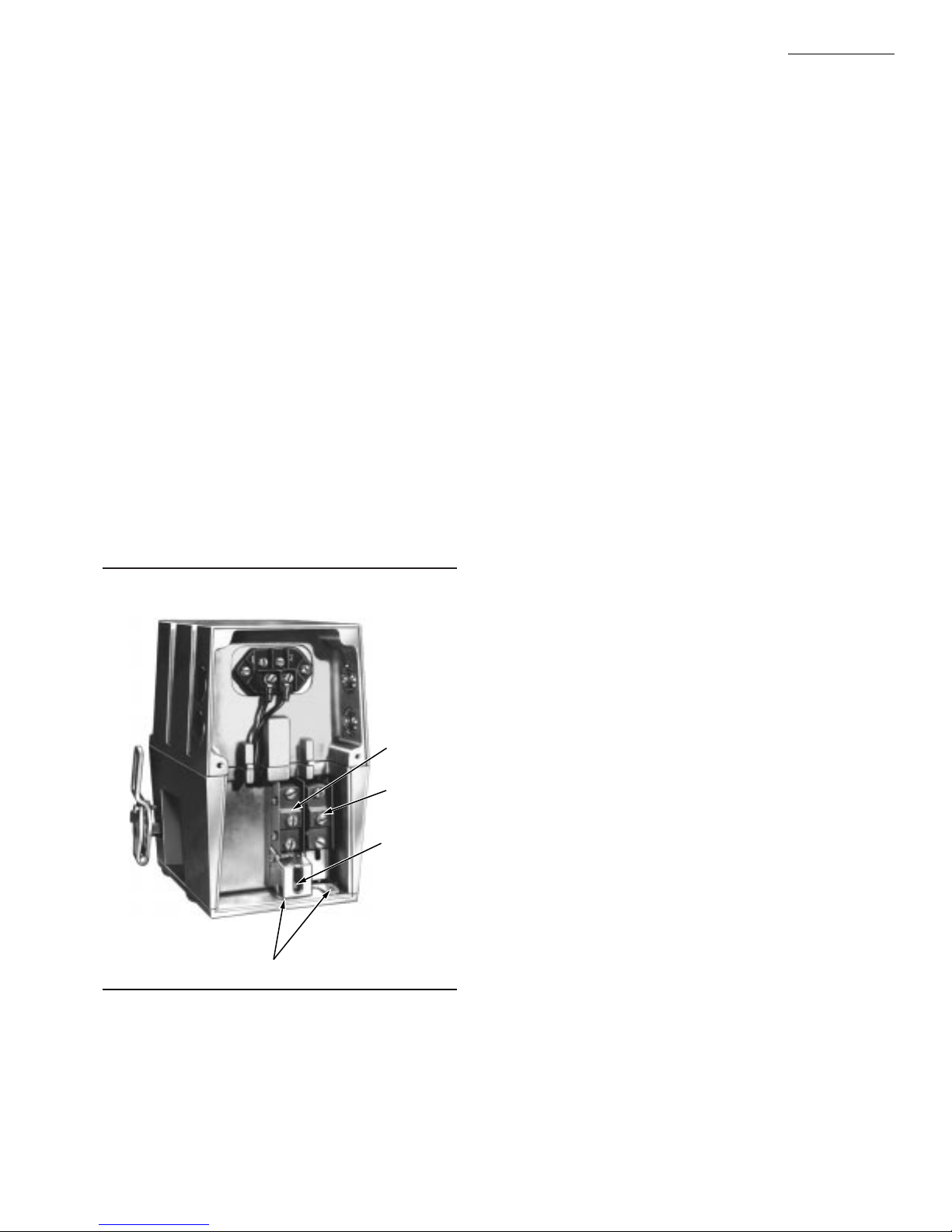

4. Insert the proof-of-closure switch in the position shown

in Fig. 2. The switch mounts against the side of the actuator

housing. The mounting holes are spaced to mount the switch

only in the correct position. Fasten with two screws through

the actuator base. The proof-of-closure switch is not adjustable.

5. If only one switch is used, install the narrow barrier

included with the switch in the unused space.

6. Mount the actuator before making wiring connections

and adjustments to the auxiliary switch.

MOUNT ACTUATOR ON VALVE

Check the final position of the valve body to be sure that

the actuator will be in the proper position when mounted on

the valve. This is especially important if the actuator is used

to drive a damper.

If two smaller sized valves are mounted very closely

together, as in an Industrial Risk Insurers type valve train, it

may be necessary to mount the actuator off center to

provide adequate clearance.

Slip the bottom collar of the actuator over the valve

bonnet assembly. Rotate the actuator to the desired position and use a 5/32 inch Allen wrench to securely tighten

the two set screws. (50 to 60 lb/in [5.7 to 6.8 Nm]).

Connect the damper linkage, if used. Refer to the instructions packed with the damper arm.

Fig. 2—V4055 Actuator with cover removed.

133568

AUXILIARY

SWITCH

133569

PROOF-OFCLOSURE

SWITCH

ADJUSTING

SCREW FOR

AUXILIARY

SWITCH

EACH SWITCH

SECURED BY TWO

SCREWS FROM

BOTTOM OF BASE.

IF ONLY ONE SWITCH IS

USED, INSTALL BARRIER

IN OPEN POSITION.

M7326

To install the switches, proceed as follows:

1. Remove the actuator faceplate (two screws).

2. Remove the sliver-colored barrier to expose the actua-

tor stem.

3. Insert the auxiliary switch in the position indicated in

Fig. 2. Fasten with two screws through the actuator base.

TO REPLACE A V4034 ACTUATOR ON A V5034

VALVE

IMPORTANT: When replacing a standard (26 sec) V4034

actuator on a V5034 Valve, check the main burner

flame-establishing period (MFEP) of the burner primary safety control. If the MFEP is 10 sec, you must

use a fast-opening (13 sec) V4055 Actuator on the

older V5034 Valve.

The initial action of the V4055 Actuator does not

immediately open the V5034 Valve because of a difference in stroke length. The pilot may be shut off before

the main burner flame is established. The fast-opening

V4055 Actuator will open the V5034 Valve fast enough

to establish the main burner flame within the ten

second flame-establishing period.

If it is desirable to maintain the slower opening

characteristic of the standard V4034 Actuator, both

the V4034 Actuator and V5034 Valve should be replaced. Use a standard V4055 Actuator on a V5055

Valve.

Select the correct adapter, depending on whether the

V5034 has a long or short stem (Fig. 3). Fasten the adapter

to the V5034 Valve bonnet, and then mount the actuator on

the adapter. Follow the instructions for mounting the actuator on the valve.

If the V4034 being replaced is equipped with a heater,

there will be a low limit control connected in series with the

V4034 power supply to prevent actuator operation below

25°F [-4°C]. There will also be a constant source of the line

voltage power to the heater and its control thermostat.

5 60-2309—8

V4055A,B,D,E

INSTALLATION

Fig. 3—Adapters permit use of V4055 Actuator

with V5034 Valve.

USE NO. 133534A

ADAPTER WITH

USE NO. 133533A

ADAPTER WITH

SHORT STEM V5034

LONG STEM V5034

M7325

The V4055 is rated for ambient temperature down to -

40°F [-40°C] for 60 Hz models, or -10°F [-23°] for 50 Hz

and 50/60 Hz models, and does not require a heater. Remove all the wiring associated with the heater. Disconnect

the power supply for the heater at its source and remove the

wires. See Fig. 4.

Fig. 4—Remove heater circuits, if installed,

when replacing V4034 Actuator.

BLACK

WHITE

HEATER

THERMOSTAT

HEATER

LOW

LIMIT

HEATER

CIRCUIT

REMOVE HEATER CIRCUIT

COMPLETELY AND

REMOVE LOW LIMIT

V4034

1

M7333

L1

(HOT)

L2

TO MAIN

VALVE TERMINAL

ON BURNER CONTROL

Fig. 5—7616BR Damper Crank Arm may be

attached to actuator shaft to drive a damper

when valve is opened.

7616BR

52 DEGREE

ANGULAR

ROTATION

5

2

16

MAXIMUM

TRAVEL

[59]

11

1

16

RADIUS

[68]

DAMPER

ARM

M7322

SHAFT

WIRING

Disconnect power supply before making electrical con-

nections to prevent electrical shock or equipment damage.

Wiring must comply with all applicable electrical codes,

ordinances, and regulations. Wiring to the actuator must be

NEC Class 1.

Connect the power supply to terminals 1 and 2 on the

V4055 terminal strip. Refer to Fig. 6 for auxiliary switch

connections. For typical system hookups, refer to Fig. 7

and to instructions packed with device used to control

valve.

When all wiring connections are complete, replace the

actuator faceplate.

CAUTION

Label all wires prior to disconnection when servicing values.Wiring errors can cause improper and

dangerous operation.

Verify proper operation after servicing.

MOUNT AND ADJUST 7616BR DAMPER CRANK

ARM (IF USED)

IMPORTANT: When a damper crank arm is used with a

NEMA 4 actuator that is exposed to ice or sleet, a

suitable shield must be installed to prevent ice or sleet

buildup.

Follow installation and adjustment directions included

with damper crank arm. Maximum pushrod travel is 2-5/16

in. [58.7 mm] through a stroke of 52 degrees. See Fig. 5.

60-2309—8 6

NOTE: Pipe sealant is required on the conduit threads of

actuators with NEMA 4 enclosures.

ADJUST THE AUXILIARY SWITCH (IF USED)

The auxiliary switch is adjustable throughout the stroke

of the actuator. With the switch installed in the actuator,

turn the adjusting screw (Fig. 2) clockwise to cause

the switch to operate earlier in the stroke or counterclockwise to cause the switch to operate later in the stroke.

NOTE: The proof-of-closure switch is not adjustable.

Loading...

Loading...