T6 Pro

Programmable Thermostat

Installation Instructions

Package Includes:

• T6 Pro Thermostat

• UWP Mounting System

• Honeywell Standard Installation

Adapter (J-box adapter)

• Honeywell Decorative Cover Plate –

Small; size 449/64 in x 449/64 in x

11/32 in (121 mm x 121 mm x 9 mm)

• Screws and anchors

• 2 AA Batteries

• Installation Instructions and User

Guide

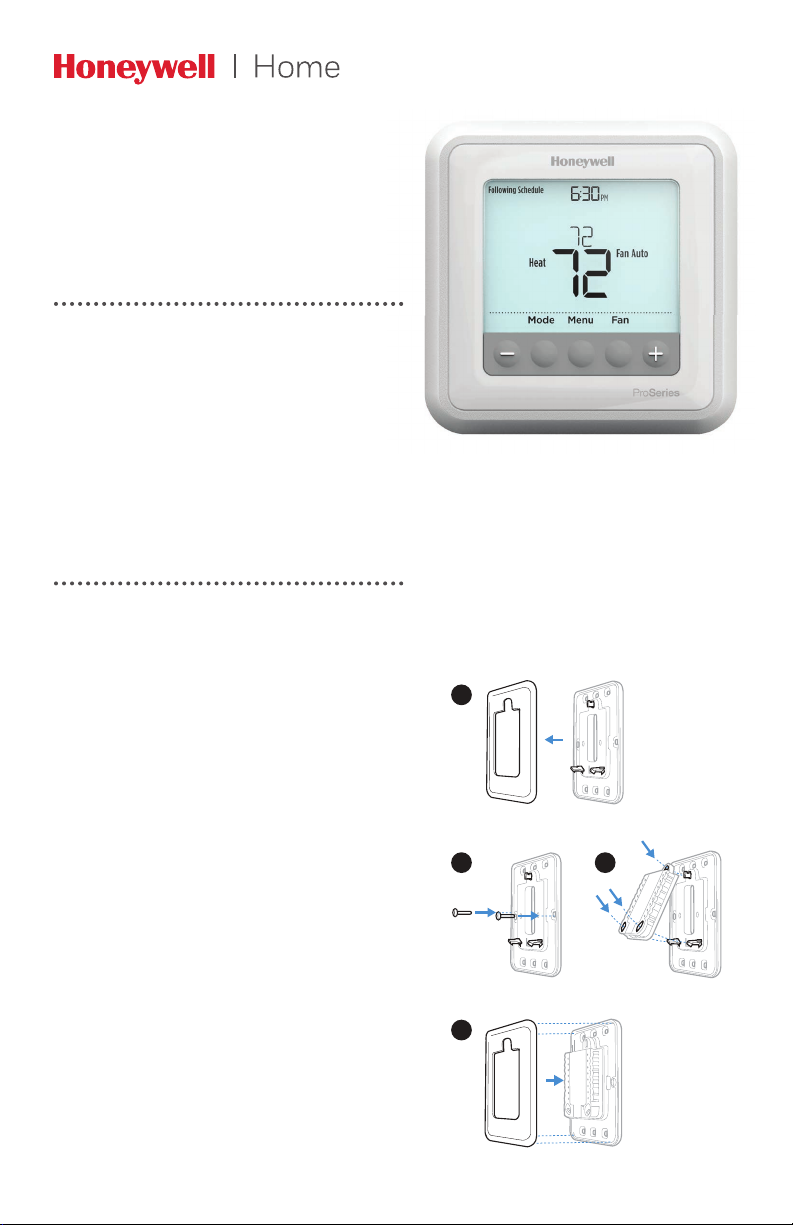

Optional Cover Plate installation

NOTE: If Optional Cover Plate is not

required, see “UWP Mounting System

installation” on next page.

Use the Optional Cover Plate when:

• Mounting the thermostat to an

electrical junction box

• Or when you need to cover paint gap

from old thermostat.

1. Separate the Junction Box Adapter

from the Cover Plate. See Figure 1.

2. Mount the Junction Box Adapter to

the wall or an electrical box using any

of the eight screw holes. Insert and

tighten mounting screws supplied with

Cover Plate Kit. Do not overtighten. See

Figure 2. Make sure the Adapter Plate

is level.

3. Attach the UWP by hanging it on the

top hook of the Junction Box Adapter

and then snapping the bottom of the

UWP in place. See Figure 3.

4. Snap the Cover Plate onto the Junction

Box Adapter. See Figure 4.

1

2

Use 2x

supplied

screws #6

5/8”

4

3

UWP Mounting System installation

6

5. Before starting, turn the power off

at the breaker box or switch. Open

package to find the UWP. See Figure 5.

6. Position the UWP on wall. Level and

mark hole positions. See Figure 6.

Drill holes at marked positions, and

then lightly tap supplied wall anchors

into the wall using a hammer.

‒ Drill 7/32” holes for drywall.

7. Pull the door open and insert the wires

through wiring hole of the UWP. See

Figure 7.

8. Place the UWP over the wall anchors.

Insert and tighten mounting screws

supplied with the UWP. Do not

overtighten. Tighten until the UWP

no longer moves. Close the door. See

Figure 8.

5

7

8

Use 3x supplied

screws #8 11/2”

Power options

L/A

S

S

Y

Y

G

C

U

U

Insert R and C wires into

designated terminals for primary

AC power (C terminal is optional

if batteries are installed, but it is

recommended). Remove wires by

depressing the terminal tabs.

A

O/B

AUX

W2

E

W

K

R

Rc

Insert AA batteries for primary or backup

power.

2

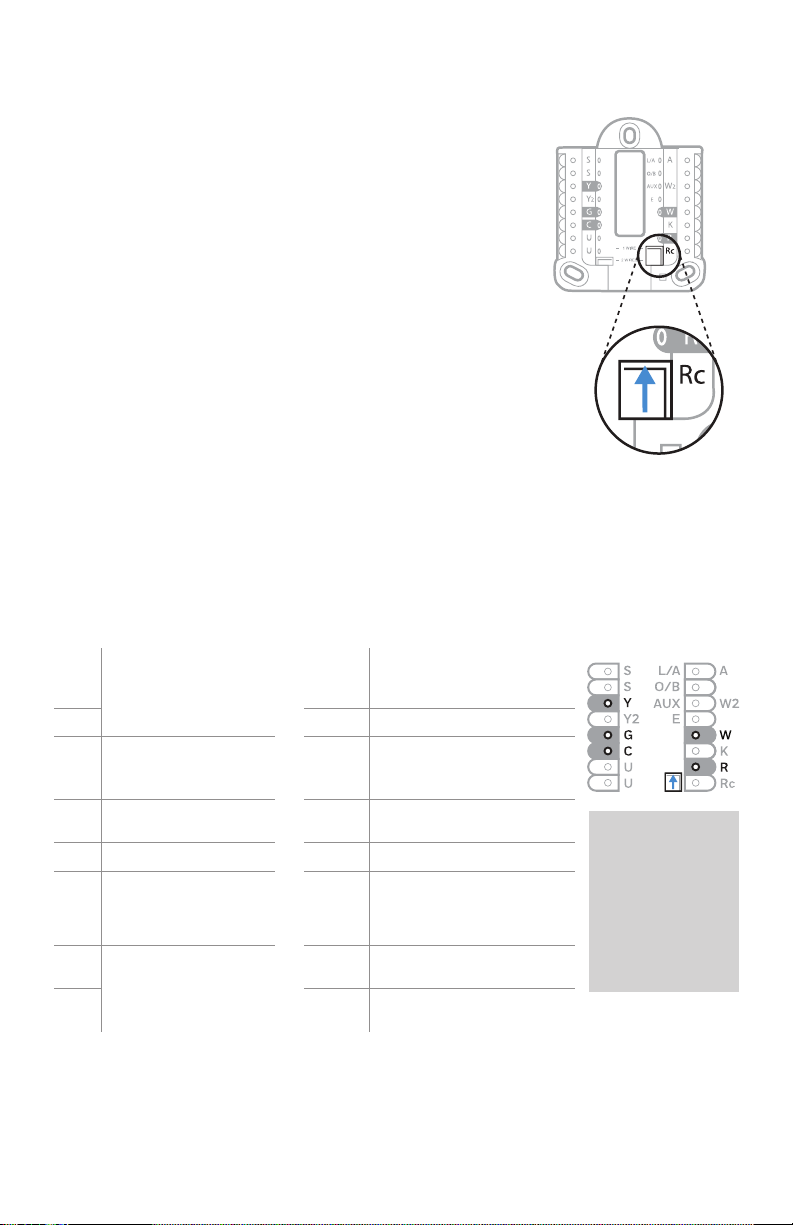

Setting Slider Tabs

Set R Slider Tab.

• Use built-in jumper (R Slider Tab)

to differentiate between one or two

transformer systems.

• If there is only one R wire, and it is

connected to the R, Rc, or RH terminal, set

the slider to the up position (1 wire).

• If there is one wire connected to the R

terminal and one wire connected to the Rc

terminal, set the slider to the down position

(2 wires).

NOTE: Slider Tabs for U terminals should be

left in place for T6 Pro models.

Wiring terminal designations

UWP Mounting System

R/Rc slider tab

Universal input for

S

wired indoor or outdoor

sensors

S

Compressor contactor

Y

(stage 1)

Compressor contactor

Y2

(stage 2)

Fan Relay W Heat relay (stage 1)

G

24VAC common. For 2

transformer systems,

C

use common wire from

cooling transformer.

U

Unused

U

L/A

- A

O/B Changeover valve

AUX W2

E Emergency Heat relay

K

R

Rc

Heat Pump fault input (most

common case)

Auxiliary heat relay

Heat relay (stage 2)

Connect to K on Wire Saver

Module**

24VAC power from heating

transformer*

24VAC power from cooling

transformer*

Note: Not all

terminals may be

used, depending

on the system

type that is being

wired. The most

commonly used

terminals are

shaded.

* Terminal can be jumped using Slider Tab. See “Setting Slider Tabs” above.

** The THP9045A1023 Wire Saver Module is used on heat/cool systems when you

only have four wires at the thermostat, and you need a fifth wire for a common wire.

Use the K terminal in place of the Y and G terminals on conventional or heat pump

systems to provide control of the fan and the compressor through a single wire—the

unused wire then becomes your common wire. See THP9045 instructions for more

information.

3

Wiring conventional systems: forced air and hydronics

Shaded areas below apply only to TH6320U/TH6220U or as otherwise noted.

1H/1C System (1 transformer)

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor

C 24VAC common [3]

W Heat relay

G Fan relay

Heat-only System

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

C 24VAC common [3]

W Heat relay

Heat-only System (Series 20) [5]

R Series 20 valve terminal “R” [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Series 20 valve terminal “W”

C 24VAC common [3]

W Series 20 valve terminal “B”

Heat-only System

(power open zone valve) [5]

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

W Valve

C 24VAC common [3]

1H/1C System (2 transformers)

R Power (heating transformer) [1]

Rc Power (cooling transformer) [1]

Y Compressor contactor

C 24VAC common [3, 4]

W Heat relay

G Fan relay

Heat-only System with Fan

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

C 24VAC common [3]

W Heat relay

G Fan relay

Cool-only System

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor

C 24VAC common [3]

G Fan relay

2H/2C System (1 transformer) [6]

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor (stage 1)

C 24VAC common [3]

W Heat relay (stage 1)

G Fan relay

W2 Heat relay (stage 2)

Y2 Compressor contactor (stage 2)

NOTES

Wire specifications: Use 18 to 22-gauge thermostat wire. Shielded cable is not required.

[1]

Power supply. Provide disconnect means and overload

protection as required.

Move RSlider Tab on UWP to the R setting. For more

[2]

information, see “Setting Slider Tabs” on page 3

Optional 24VAC common connection.

[3]

[4] Common connection must come from cooling transformer.

[5] In ISU set Heat system type to Radiant Heat. Set number of

cool stages to 0.

In Installer Setup, set system type to 2Heat/2Cool

[6]

Conventional.

4

Wiring heat pump systems

Shaded areas below apply only to TH6320U/TH6220U or as otherwise noted.

1H/1C Heat Pump System

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor

C 24VAC common [3]

O/B Changeover valve [7]

G Fan relay

2H/1C Heat Pump System [8]

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor

C 24VAC common [3]

O/B Changeover valve [7]

G Fan relay

Aux Auxiliary heat

E Emergency heat relay

L Heat pump fault input

2H/2C Heat Pump System [9]

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor (stage 1)

C 24VAC common [3]

O/B Changeover valve [7]

G Fan relay

Y2 Compressor contactor (stage 2)

L Heat pump fault input

3H/2C Heat Pump System

(TH6320U only) [10]

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor (stage 1)

C 24VAC common [3]

O/B Changeover valve [7]

G Fan relay

Aux Auxiliary heat

E Emergency heat relay

Y2 Compressor contactor (stage 2)

L Heat pump fault input

Dual Fuel System

R Power [1]

Rc [R+Rc joined by Slider Tab] [2]

Y Compressor contactor (stage 1)

C 24VAC common [3]

O/B Changeover valve [7]

G Fan relay

Aux Auxiliary heat

E Emergency heat relay

Y2 Compressor contactor (stage 2 - if needed)

L Heat pump fault input

S Outdoor sensor

S Outdoor sensor

NOTES

Wire specifications: Use 18 to 22-gauge thermostat wire. Shielded cable is not required.

[1]

Power supply. Provide disconnect means and overload

protection as required.

Move RSlider Tab on UWP to the R setting. For more

[2]

information, see “Setting Slider Tabs” on page 3

Optional 24VAC common connection.

[3]

[6] In Installer Setup, set system type to 2Heat/2Cool

Conventional.

[7]

In Installer Setup, set changeover valve to O (for cool

changeover) or B (for heat changeover).

In ISU set Heat system type to Heat pump. 1 compressor

[8]

and 1 stage of backup heat.

In ISU set Heat system type to Heat pump. 2 compressors

[9]

and 0 stage of backup heat.

In ISU set Heat system type to Heat pump. 2 compressors

[10]

and 1 stage of backup heat.

5

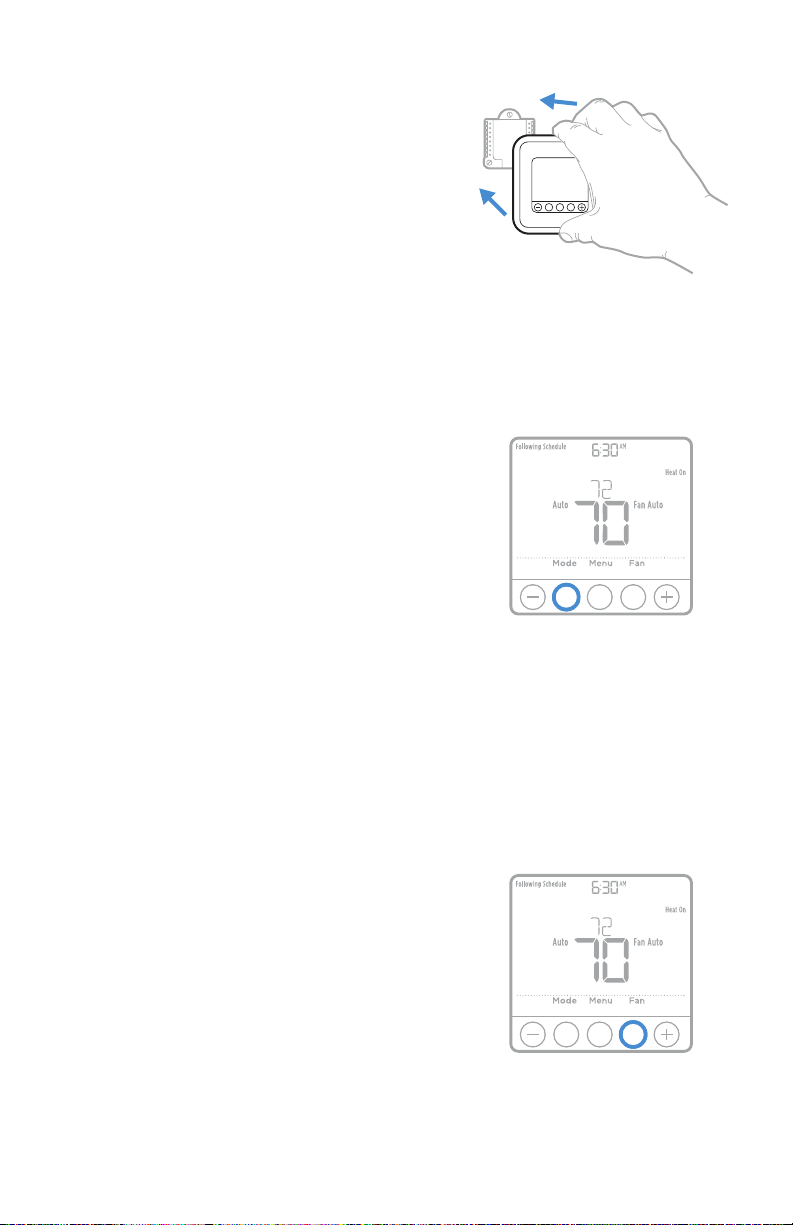

Thermostat mounting

1. Push excess wire back into the wall

opening.

2. Close the UWP door. It should remain

closed without bulging.

3. Align the UWP with the thermostat, and

push gently until the thermostat snaps in

place.

4. Turn the power on at the breaker box or

switch.

System operation settings

1 Press the Mode button to cycle to the next

available System mode.

2 Cycle through the modes until the required

System mode is displayed and leave it to

activate.

NOTE: Available System modes vary by model

and system settings.

System modes:

‒ Auto

‒ Heat

‒ Cool

‒ Em Heat

‒ Off

Fan operation settings

1 Press the Fan button to cycle to the next

available Fan mode.

2 Cycle through the modes until the required

Fan mode is displayed and leave it to

activate.

NOTE: Available Fan modes vary with system

settings.

Fan modes:

‒ Auto: Fan runs only when the heating or

cooling system is on.

‒ On: Fan is always on.

‒ Circ: Fan runs randomly about 33% of

the time.

6

Installer setup (ISU)

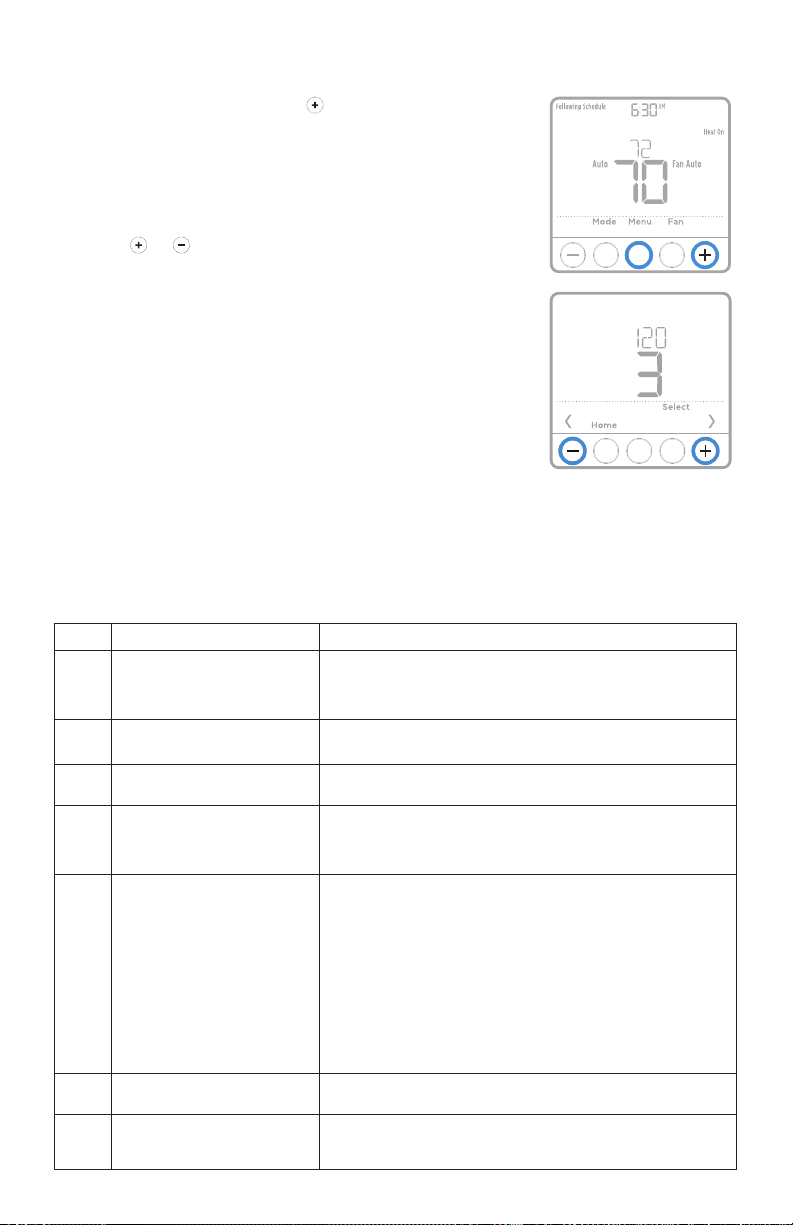

1 Press and hold CENTER and buttons for

approximately 3 seconds to enter advanced

menu.

2 Press Select to enter ISU.

3 Press Select to cycle through menu setup

options.

4 Press or to change values or select

from available options.

5 Press Select and confirm your settings or

press Back to ignore changes and return

to ISU menu screen to continue editing

another setup option.

6 To finish setup process and save your

setting, press Home and return to Home

screen.

NOTE: A complete list of all setup (ISU)

parameters and options starts below and

continues through page 10.

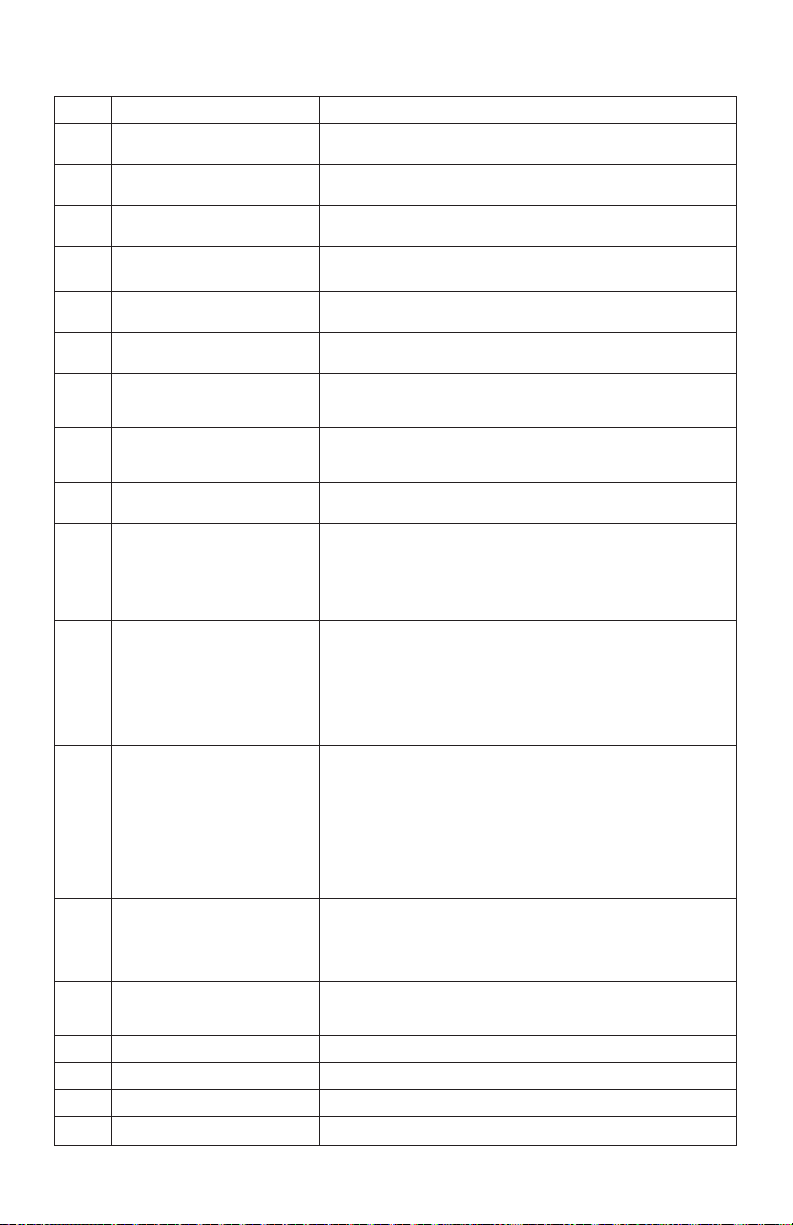

Advanced setup options (ISU)

NOTE: Depending on system settings, not all options may be available.

# ISU IS U Name ISU Op tions (fac tory defau lt in bold)

120 Scheduling Options 0 = NonProgrammable

125 Temperature Indication Scale

130 Outdoor Sensor

(TH 6320 / TH6220 only)

200 Heati ng System Type

205 Heating Equipment Type Conventional Forced Air Heat:

218 Reversing Valve O/B

220 Cool Stages / Compressor Stages

200= Conv / 200 =HP

(TH 6320 / TH6220 only*)

2 = 52 Progra mmable

3 = 511 Programmable

4 = 7Day Progr ammable

0 = Fahrenheit

1 = Cel sius

0 = None

1 = Wired O utdoor Sen sor

1 = Conventional Forced Air Heat

2 = Heat Pu mp

3 = Radian t Heat

5 = None (Co ol Only)

1 = Standa rd Efficie ncy Gas For ced Air

2 = High Efficiency Gas Forced Air

3 = Oil For ced Air

4 = Elec tric Force d Air

5 = Hot Wate r Fan Coil

Heat Pum p:

7 = Air to Air Heat Pump

8 = Geot hermal Heat P ump

Radiant Heat:

9 = Hot Water Radiant Heat

12 = Steam

0 = O (O/B in Cool)

1 = B (O/B in He at)

0, 1, 2*

7

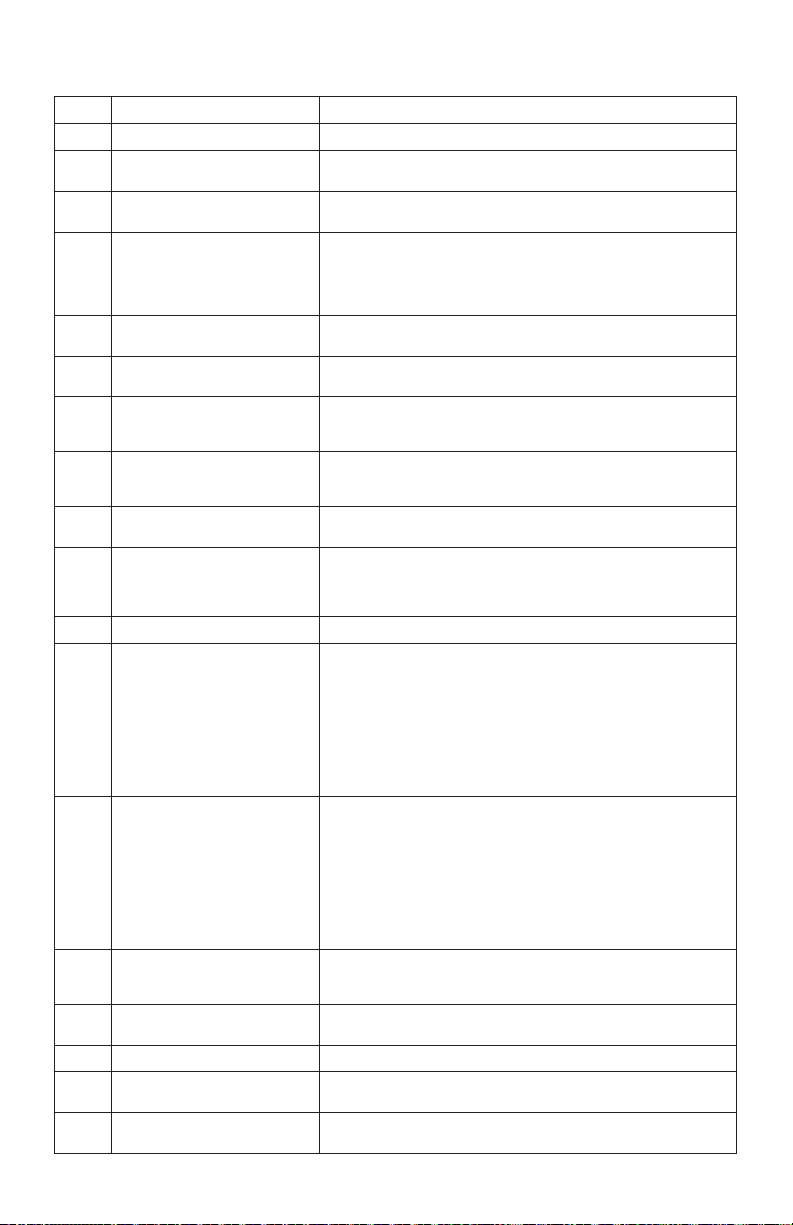

Advanced setup options (ISU)

# ISU IS U Name ISU Op tions (fac tory defau lt in bold)

221 Heat Sta ges / Backu p Heat Stage s Heat Stag es: 1, 2

230 Fan Co ntrol in Heat 1 = Equipment Controls Fan

253 Aux /E terminal c ontrol (T H6320

only)

255 Back up Heat Sourc e

(Heat P ump Only)

256 Emerg ency Heat S ource (TH 6320

only)

260 Ex ternal Fos sil Fuel Kit

(TH 6320 / TH6220 only)

270 Ba ckup Heat Fan 1 = Equipment Controls Fan

271 Emergency Heat Fan 1 = Equipment Controls Fan

300 System Changeover

303 Auto Changeover Differential 0 °F to 5 °F

340 Backup Heat Droop

350 Upsta ge Timer for B ackup Heat

355 Compre ssor Lock out / Balanc e Point

356 Outdoo r Lockout Ba ckup Heat

365 Compre ssor Cyc le Rate (Stage 1 ) 1 - 6

366 Compre ssor Cyc le Rate (Stage 1 ) 1 - 6

370 He ating Cycl e Rate (Stage 1) 1 - 12

371 He ating Cycle R ate (Stage 2) 1 - 12

Backu p Heat Stage s: 0, 1

2 = Thermostat Controls Fan

0 = Drive both Aux & E together

1 = Aux and E in dependent

1 = Electric Forced Air

2 = Gas/ Oil Forced A ir (or Fossil Fo rced Air)

1 = Electric Forced Air

2 = Gas/ Oil Forced A ir (or Fossil Fo rced Air)

0 = Thermostat Controls Backup Heat

1 = Ex ternal Fos sil Fuel Kit C ontrols B ackup Heat

2 = Thermostat Controls Fan

Note: S etting onl y active wi th TH6320 in Heat P ump mode.

2 = Thermostat Controls Fan

Note: S etting onl y active wi th TH6320 in Heat P ump mode.

0 = Manual

1 = Automatic

0.0 °C to 2.5 ° C

Note: Differential is NOT deadband. Differential means how far past the setpoint

before switching to the mode selected. Deadband setup is not an option.

Honeywell uses an advanced algorithm that fixes deadband at 0 °F. This is more

advanced than previous thermostats.

0 = Comfort

2 = 2 °F

3 = 3 °F

4 = 4 °F

5 = 5 °F

6 = 6 °F

7 = 7 °F

8 = 8 °F

0 = Off

1 = 30 minute s

2 = 45 minute s

3 = 60 minut es

4 = 75 minute s

5 = 90 minut es

6 = 2 hours

7 = 3 hours

8 = 4 hours

10 = 5 hours

-- = Of f

5 °F to 60 ° F (in 5 °F increme nts)

15.0 °C to 15.5 ° C (in 2.5 °C or 3.0 ° C increment s)

Note: Us e a wired senso r to set compres sor lockout / b alance point o n TH6320

/ TH6220 .

-- = Of f

5 °F to 65 °F ( in 5 °F increme nts)

15.0 °C to 18.5 ° C (in 2.5 °C or 3.0 ° C increment s)

9 = 9 °F

10 = 10 °F

11 = 11 °F

12 = 12 °F

13 = 13 °F

14 = 14 °F

15 = 15 °F

8

Advanced setup options (ISU)

# ISU IS U Name ISU Op tions (fac tory defau lt in bold)

375 He ating Cycle R ate Auxili ary Heat 1 - 12

378 H eating Cycl e Rate Emerge ncy Heat

(TH 6320 only)

387 Compre ssor Protection 0 = Off

425 Adaptive Intelligent Recovery 0 = No

430 Minimum Cool Setpoin t 50 °F to 99 ° F (50 °F)

431 Maxim um Heat Setp oint 40 °F to 90 ° F (90 °F)

435 Keypad Lockout

500 Is Indoor Temperature Sensor WIRED

to your s ystem? (T H6320 / TH6220

only)

515 Indoor Sensor type

(TH 6320 / TH6220 only)

520 Whi ch Sensor s will be used f or

TEMPERATURE Control ? (Multiple

Sens ors are Aver aged) (TH 6320 /

TH6220 only)

702 Numb er of Air Filt ers 0 - 2

711 Air Filter 1 Replacement Reminder

712 Air Filter 2 Replacement Reminder

140 0 Backlighting

1401 Backlight brightness 1 - 5

1410 Clock Format 12 / 24

1415 Daylight Saving T ime 0 = O ff

1420 Temperature Display Offset 3 to 3F (0)

1 - 12

1 - 5 minutes

1 = Yes

Note: Adaptive Intelligent Recovery (AIR) is a comfort setting. Heating or cooling

equipment will turn on earlier, ensuring the indoor temperature will match the

setpoint at the scheduled time.

10.0 °C to 37.0 °C (10.0 °C)

4.5 °C to 32 .0 °C (32.2 °C)

0 = None

1 = Part ial

2 = Full

0 = No

1 = Yes

0 = 10k

1 = 20k

1 = Ther mostat Onl y

2 = Wired O nly

3 = Average

0 = Off

1 = 10 Run Time D ays

2 = 20 Run Tim e Days

3 = 30 Run Ti me Days

4 = 45 Run Tim e Days

5 = 60 Run Ti me Days

6 = 90 Run Ti me Days

7 = 120 Run Tim e Days

8 = 150 Run Tim e Days

9 = 30 Cale ndar Days

0 = Off

1 = 10 Run Time D ays

2 = 20 Run Tim e Days

3 = 30 Run Ti me Days

4 = 45 Run Tim e Days

5 = 60 Run Ti me Days

6= 90 Run T ime Days

7 = 120 Run Tim e Days

8 = 150 Run Tim e Days

9 = 30 Cale ndar Days

0 = On Demand

1 = Continuous

Note: Common wire needed for continuous.

Note: Only displayed if continuous backlight selected.

1 = On

1.5 to 1.5C (0)

10 = 45 Calen dar Days

11 = 60 Cal endar Days

12 = 75 Calen dar Days

13 = 3 Calen dar Months

14 = 4 Calenda r Months

15 = 5 Calen dar Months

16 = 6 Calen dar Months

17 = 9 Calenda r Months

18 = 12 Calen dar Months

19 = 15 Calen dar Months

10 = 45 Calen dar Days

11 = 60 Cal endar Days

12 = 75 Calen dar Days

13 = 3 Calen dar Months

14 = 4 Calenda r Months

15 = 5 Calen dar Months

16 = 6 Calen dar Months

17 = 9 Calenda r Months

18 = 12 Calen dar Months

19 = 15 Calen dar Months

9

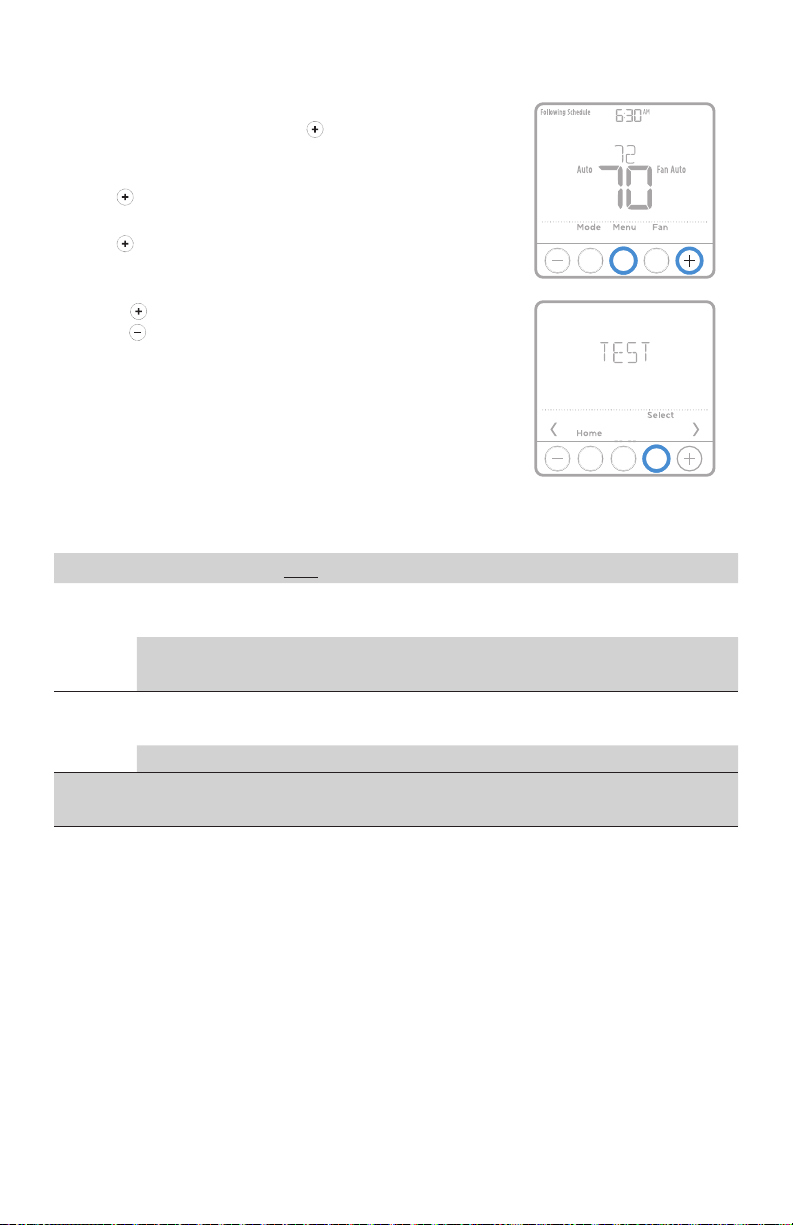

Installer system test

To perform a System Test:

1 Press and hold CENTER and buttons for

approximately 3 seconds to enter advanced

menu.

2 Use to go to TEST. Press Select to enter

System Test.

3 Use to change between Heat, Cool, Fan, Em

Heat, or Ver (thermostat version information).

Press Select.

4 Press to turn stages on one at a time, and

press to turn them off.

5 Use the Home button to exit the System Test.

System test System status

Shaded areas below apply only to TH6320U/TH6220U or as otherwise noted.

All Off

0

Heat Stage 1 on

Heat

Cool

Em Heat

Fan

1

Heat Stage 2 also on

2

Heat Stage 3 also on

3

All Off

0

Cool Stage 1 on

1

Cool Stage 2 also on

2

All Off

0

Em Heat on

1

Fan Off

0

Fan On

1

10

Specifications

Temperature Ranges

Heat: 40 °F to 90 °F (4.5 °C to 32.0 °C)

Cool: 50 °F to 99 °F (10.0 °C to 37.0 °C)

Working Ambient Temperature

32 °F to 120 °F (0 C° to 48.9 °C)

Operating Ambient Temperature

37 °F to 102 °F (2.8 °C to 38.9 °C)

Shipping Temperature

20 °F to 120 °F (28.9 °C to 48.9 °C)

Operating Relative Humidity

5% to 90% (non-condensing)

Physical Dimensions in inches (mm) (H x W x D)

41/16” H x 41/16” W x 15/32” D

103.5 mm H x 103.5 mm W x 29 mm D

Electrical Ratings

Terminal Voltage

(50/60Hz)

W Heating 2030 Vac 0.021.0 A

(Powerpile) 750 mV DC 100 mA DC

W2 (Aux) Heating 2030 Vac 0.021.0 A

E Emergency Heat 2030 Vac 0.020.5 A

Y Compressor Stage 1 2030 Vac 0.021.0 A

Y2 Compressor Stage 2 2030 Vac 0.021.0 A

G Fan 2030 Vac 0.020.5 A

O/B Changeover 2030 Vac 0.020.5 A

L/A Input 2030 Vac 0.020.5 A

Running

Current

11

Loading...

Loading...