Page 1

T6580

FAN COIL CONTROLLER

PRODUCT SPECIFICATION SHEET

30

20

10

DESCRIPTION

A pleasing and modern appearance makes the T6580 ideal

for living quarter applications, in particular offices and hotels.

In all versions, the control is Proportional + Integral (P+I).

This ensures accurate temperature control in all operating

conditions.

The controller is suitable for mounting on a fan-coil chassis or

for wall mounting.

In 2-pipe plants the summer/winter switching can be activated

by a central contact, controlled automatically through a

connected thermostat or by a sensor installed on the pipe

near the fan coil.

There are two pre-set room regulating levels: Comfort and

Economy, to which two temperature levels are linked; the

selection of which can be made through the room unit or by

digital inputs.

The sensor for the temperature regulation is located inside

the room unit and is overridden if the optional remote sensor

is fitted.

Commands available: set-point configuration knob, fan speed

knob, push button for operating mode setting; push button for

summer/winter switching (Economy mode and summer/winter

switch buttons are not included on the Lite model).

FEATURES

• 2-pipe or 4-pipe fan coil applications

• Installer setup mode allows 11 parameters to be

changed easily on-site

• Proportional + integral digital control regulator

• Heating / cooling sequence and supplementary-

heating with electrical resistance heater

• Electrical resistance / cooling sequence

• Cooling / cooling sequence

• Ventilation only

• Manual or automatic summer / winter switching

• Automatic 3-speed fan control or manual override

• Selectable valve actuators: ON-OFF, PWM

• Actuator voltage: 230 Vac

• Digital inputs: water thermostat, change of season,

economy, window contact

• Analogue inputs: room temperature, inlet water

temperature

• Regulator voltage: 230 Vac, 50/60 Hz

• Destratification cycle

• Filter clean timer

• CE certification

GENERAL INFORMATION

The T6580 microprocessor controls were designed to

regulate heating and/or cooling within a room air-conditioning

systems. The T6580 regulates the water valves, the fan

speed, and the electrical resistance heater (where installed),

in 2-pipe and 4-pipe fan coil systems.

Table 1. Ordering codes for the T6580 FCU Controller:

Model Description

T6580A1008

T6580A1016 LITE FCU Controller 2/4 Pipe

FCU Controller 2/4 Pipe with S/W

switch & Economy function

1 EN0H8560UK07 R0

Page 2

RFC BASIC FAN COIL CONTROLLER

DESCRIPTION

INPUTS AND OUTPUTS

Digital Inputs

PRESENCE or TIMED PROGRAM:

The open contact indicates a presence in the room (room

occupied) and the set point changes from economy to

comfort. This contact can also be linked to an external

timer system.

WINDOW:

The closed contact indicates that the window is open. This

causes the valve(s) to close and the fan to stop (energy

saving function). The anti-freeze protection function is

automatically activated, with 4 °C as default.

SUMMER / WINTER SWITCHING:

A closed contact indicates that warm water is flowing

through the pipes. This automatically changes the control

from summer to winter mode. NB that the water

temperature sensor can also be connected as an

alternative for this feature to operate.

WATER TEMPERATURE THERMOSTAT:

A thermostat can be installed at the water outlet of the heat

exchanger. This thermostat will automatically detect the

presence of warm water in the system during the winter

heating mode. The fan cannot start until warm water is

detected. The temperature of the water must be set on the

thermostat itself.

C) Sensor set to enable both functions: In 2-pipe

systems the sensor detects the supply water temperature

and determines the summer or winter function mode. The

fan function consent during the winter operating mode is

given with a configurable delay time set in Parameter 24.

Analogue and digital outputs

FAN:

Fan speed control, from one to three speeds. A 230 Vac

output, 50 Hz .Max 1.25 (3 peak)A.

HEATING VALVE:

Choice of a 230 Vac, 0.8 A command module for maximum

four on-off or thermal actuators.

COOLING VALVE:

Choice of a 230 Vac, 0.8 A command module for maximum

four on-off or thermal actuators.

Analogue Inputs

RETURN AIR TEMPERATURE SENSOR:

When installed, this sensor has priority over the room unit

internal sensor. The sensor is positioned at the air intake of

the fan coil and is used as alternative to the room sensor.

WATER TEMPERATUR SENSOR:

This sensor can be set to either switch the summer / winter

mode, or to enable fan operation, or both

A) Summer / winter switching: The sensor measures

water supply temperature. When this drops below the limit

value set in Parameter 14, the summer function mode is

activated. When the water supply temperature is above the

limit set in Parameter 15, the winter function mode is

activated. Supply water between the upper and lower limits

means that the thermostat stays OFF.

B) Enabling fan function: In 2 and 4-pipe fan coils the

sensor is installed on the return pipe after the heating coil.

This enables the fan function. Parameters 14 and 15 set

the temperature that enables the fan to start.

2 EN0H8560UK07 R0

Page 3

RFC BASIC FAN COIL CONTROLLER

TECHNICAL FEATURES

BASIC

Regulation range 10…30 °C

Voltage 230 Vac, 50/60 Hz

Outputs (warm and cold

water)

Selector or Keys

Temperature levels Comfort / Economy Pushbutton

Seasons Summer/Winter Pushbutton

Set point Temperature: 10,…30 °C Dial

Analogue Inputs

Room Temperature Air intake probe (remote) NTC10K

Water Temperature Contact or immersion probe NTC10K

Digital Inputs

Window opening

Presence/timed program

Proportional band Selectable from 1 to 5 °C

Dead Zone From 0 to 4 °C

Applications Fan only

2-pipe system with/without electrical

4-pipe system with/without electrical

Housing Single housing

Automatic valve commands

Local Communication No

Centralized Communication No

Table 2. Technical Features

PWM

On-Off

Fan Auto-0-1-2-3

Consent thermostat/summer-winter

switching/anti-condensation pump

resistance

resistance

5-position selector

dial

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

3 EN0H8560UK07 R0

Page 4

RFC BASIC FAN COIL CONTROLLER

FAN FUNCTION

The fan can function provided the consent thermostat is

satisfied or the water temperature probe detects a

temperature above the fixed value, where these inputs are

present.

The fan is controlled through the 5 position-speed selector

dial.

0 = fan OFF. In this position the valve is also closed.

Only the anti-freeze function is activated.

1 = always 1st fan speed

2 = always 2nd fan speed

3 = always 3rd fan speed

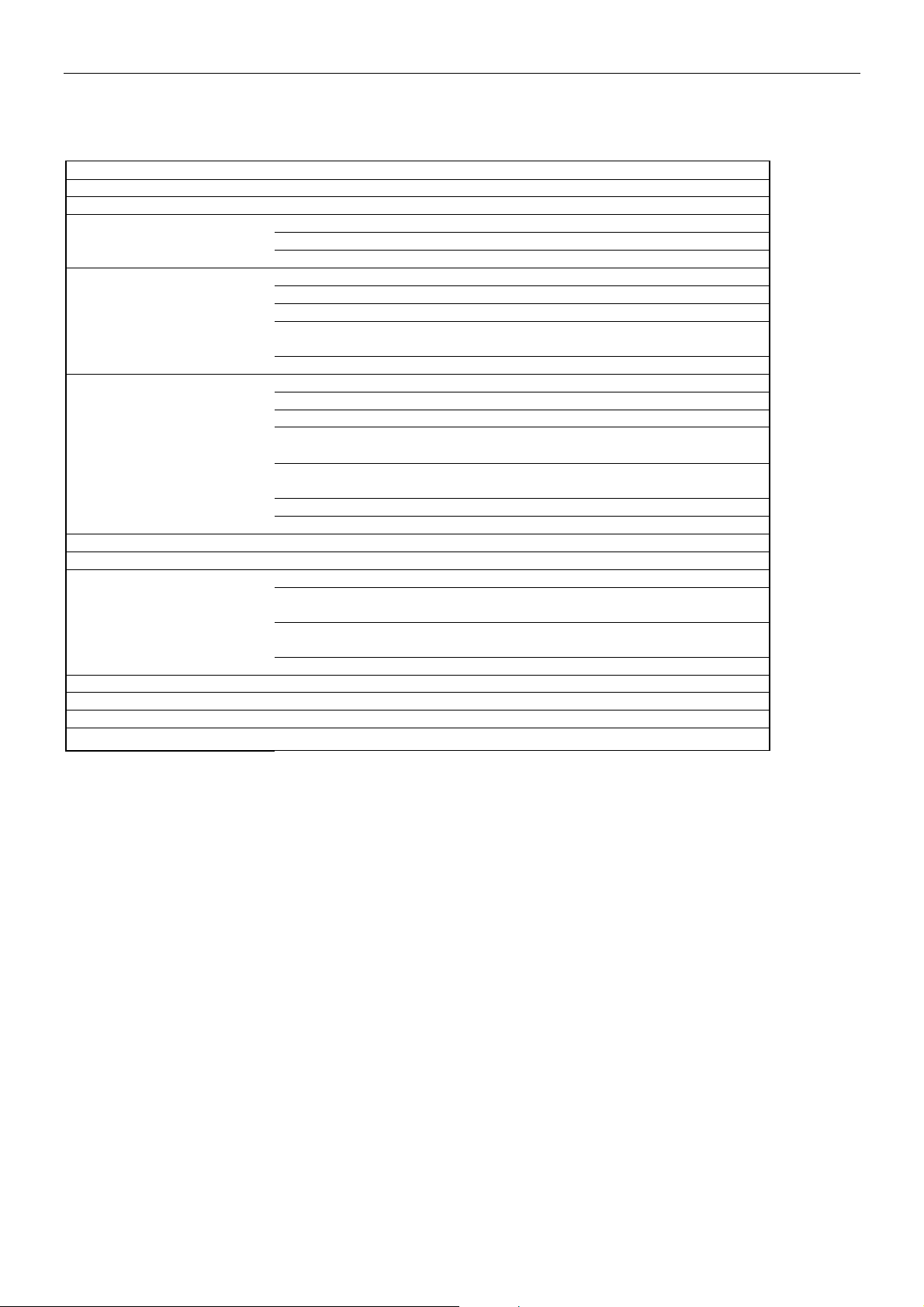

FAN SPEED

3

DEAD BAND

2

1

COOLING PROP. BANDHEATING PROP. BAND

DESTRATIFICATION CYCLE

When the room probe is positioned at the air intake, and

the setpoint is reached, the fan cycles according to the time

settings made in Parameters 20 and 21 to enable correct

reading of the room temperature.

FAN START DELAY DURING THE WINTER

SEASON

During the heating action, the fan switches from OFF to the

first speed, after the delay programmed in Parameter 22.

ELECTRICAL RESISTANCE

When using electrical resistance heater, (i.e., instead of the

water heating system), the fan is started after the delay set in

Parameter 23, starting as soon as the resistance heater was

turned on. When the resistance heater turns off the fan

continues to operate for the time set in Parameter 24.

0

WINTER SETPOINT SUMMER SETPOINT

TEMPERATURE

Fig. 1 Fan speed sequence

In the AUTO function, the fan and the valves are

automatically activated. The fan output varies as a function

of the difference between the room temperature and the set

point.

Auto Position: the fan operates with the speed determined

by the regulator.

In the heating mode, the fan will have speed 0 when Tamb

> (set point ).

1st speed when (set point -30% of the BP) <Tamb < (set

point).The minimum time at this speed is 2 minutes in

normal conditions.

2nd speed when (set point -90% of the BP) <Tamb < (set

point –30% of the BP).The minimum time at this speed is 2

minutes in normal conditions.

3rd speed when Tamb < (set point –90%).The minimum

time at this speed is 2 minutes in normal conditions.

If a variation of more than the BP value occurs between the

set point and the actual temperature, the minimum length

of time in any one state is reduced to 5 seconds.

If the action is cooling, fan control will be opposite to that

used during the heating action.

During the cooling cycle function, and if the set point is

satisfied, the fan will continue to operate at speed 1 for 3

minutes, and will then stop.

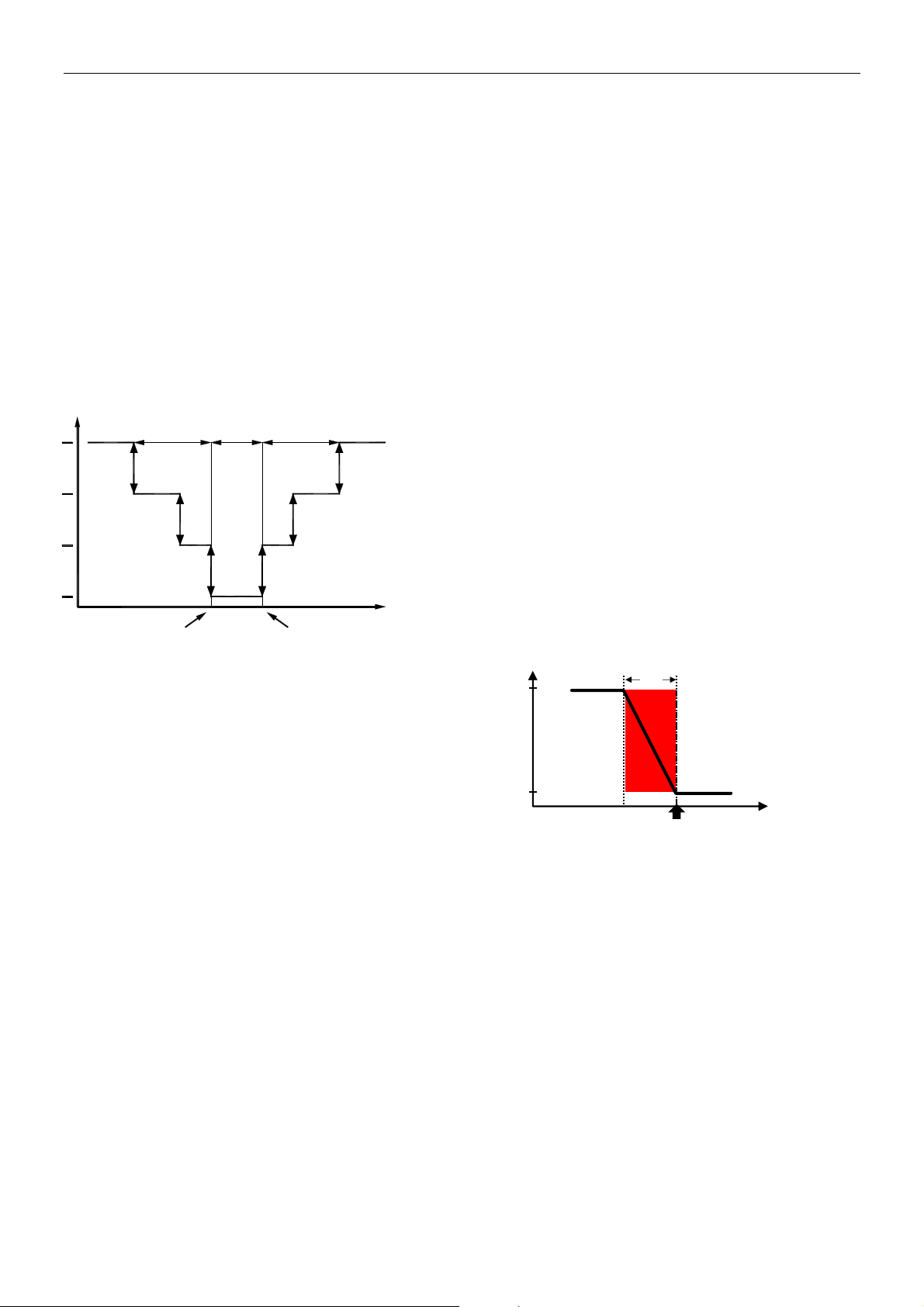

HEATING & COOLING

OUTPUT FUNCTION

Valve Opens

100%

0%

2-PIPE FAN COIL WITH AN ON-OFF and PWM

ACTUATOR:

Fig. 2 :

2-PIPE FAN COIL WITH AN ON-OFF & PWM ACTUATOR

The set point is set to the upper point (to the lower point for

cooling) of the proportional band, so the valve is closed

when the temperature exceeds the set point.

The valve opening percentage is regulated by the P+I algorithm.

X

pH

Set

Temperature (

o

EN0H8560UK07 R0

4

Page 5

RFC BASIC FAN COIL CONTROLLER

4-PIPE FAN COIL WITH ON-OFF & PWM OUTPUT:

Fig. 3

4-PIPE FAN COIL WITH ON-OFF & PWM

Valve Opens

0%

X

pH

ZEB

Set

X

pC

Temperature o C

OUTPUT

The heating set point is set to the upper point, while the

cooling setpoint is set to the heating setpoint plus the dead

band.

The valve opening percentage is regulated by the P+I algorithm.

SIGNALS AND COMMANDS

A

20

30

SEL

2

SEL

3

SEL

1

10

Honeywell

SEL

LED MOD

LED SUMMER/WINTER

LED FILTE

LED MODE

0

E

Fig. 4 Room Unit

The room unit has two signal LEDs that give different

indications during the various operating and configuration

phases.

SUMMER/WINTER LED (BASIC MODEL ONLY):

RED ON when the RFC is in the WINTER function mode.

GREEN ON when the RFC is in the SUMMER function

mode.

RED or GREEN LED BLINKING (1 second ON, 1 second

OFF) when the set point is satisfied, but the fan is still

running, or when the valve is opening and the fan hasn’t

been started yet.

ORANGE LED BLINKING (1 second ON, 5 seconds OFF)

when the room temperature is in the dead band or the set

point is satisfied, since the controller is in the COMFORT

mode.

ORANGE LED BLINKING (1 second ON and 1 second

OFF) in the ECONOMY mode, when the set point is

satisfied.

A

30

20

Honeywell

R

10

ORANGE LED BLINKING (1 second ON and 15 seconds

OFF) in the OFF state.

MODE LED:

Function mode display

The flashing of the Mode LED shows the current state of

the regulator (COMFORT or ECONOMY).

When pressing the SEL 3 key, the changes to the flashing

of the Mode LED indicates the state of the device. In

particular:

With the controller in COMFORT mode: when pressing the

SEL 3 key the Mode LED turns on.

With the controller in the ECONOMY mode: when pressing

the SEL 3 key the Mode LED flashes regularly 3 times a

second.

Dirty Filter Signal and Alarm

With the controller in normal operating mode the

Mode LED turns on

have been reached.

This signal indicates that the filter must be cleaned.

After cleaning the filter, proceed as described below to

reset the operating hours count down:

1. Press the SEL3 knob until the Mode LED briefly

blinks 8 times. The filter operating hours are then

reset to zero.

when the filter maintenance hours

Daily valve drive

SEL

SEL

To prevent a possible valve blockage due to a prolonged

0

standstill period, the valve is driven automatically at least

2

once every 24 hours for 150 seconds. This function is

enabled by parameter 19.

CHANGE OF THE ROOM UNIT

FUNCTION MODES

FOR ROOM UNITS WITHOUT A DISPLAY

CHANGE OF SEASON – SUMMER / WINTER

(BASIC MODEL ONLY)

If Parameter #9 (summer / winter switching) is in the

MANUAL mode, changing the season is possible by using

the SEL1 KEY on the front panel. Press this key for 5

seconds until the colour of the selected season appears on

the S/W LED for 5 seconds. After this, the LED will assume

the appropriate operating mode. The default value of

Parameter #9 is Manual.

CHANGE OF FUNCTION MODE (COMFORT /

ECONOMY)

During normal functioning, while the unit is turned ON, it is

possible to change the operating mode mode, from

COMFORT to ECONOMY, in succession by using SEL3.

Proceed as follows:

In the COMFORT mode: when pressing the SEL3 key, the

Mode LED turns on and stays on (comfort). By continuing

5 EN0H8560UK07 R0

Page 6

RFC BASIC FAN COIL CONTROLLER

to press the key, the controller switches to the ECONOMY

mode after 5 seconds and the Mode LED blinks for 0,3

seconds ON - 0,3 seconds OFF until the key is released.

From the ECONOMY mode: if the SEL3 key is pressed

again, the Mode LED blinks for 0,3 seconds ON - 0,3

seconds OFF. By continuing to press the key for another 5

seconds the controller switches to the COMFORT mode,

and the Mode LED will turn to on and stay on.

INSTALLATION

POSITION

The RFC series room unit is the room temperature control

element in a fan coil plant, or small split system units. The

room probe of the unit must be positioned 1.5 m from the

floor (according to local legislation, this may be 1.2m), in a

position exposed to good room air circulation. It should not

be affected by:

Fig. 5 Positioning the room unit

INSTALLATION

IMPORTANT: this product must be installed according to

the local safety norms in force and only by qualified

personnel. Isolate the electrical power supply before

starting to install or dismantle the device.

INSTALLING THE ROOM UNIT

a. Air currents or dead zones behind doors or in

corners

b. Warm or cold air coming from air ducts

c. Solar radiation or radiation from household

appliances

d. Non heated or cooled areas such as external walls

behind the room unit

e. Pipes or chimneys embedded in the wall

1. Using a screwdriver, loosen the retaining screw in

the bottom side of the housing, until the cover can

be removed.

2. Pass the wires to rear holes of housing and then

fix to the wall with screws.

3. Fix the wires to the connector, taking care to

follow the electrical diagram.

4. Replace the cover and secure it by tightening the

screw in the bottom part of the housing.

TO

THE

WALL

C

WALL

FIXING

HOLES

A

B

A

30

20

10

Honeywell

Fig. 6

Installing the wall-mount room unit

INSTALLING THE SENSORS:

1. Water Temperature sensor for automatic

Summer/Winter switching: position the sensor

upstream from the valve as shown in Fig. 7.

2. Water Temperature sensor for automatic

Summer/Winter switching and fan start

consent thermostat: position the sensor as

shown in Fig. 7.

3. Temperature sensor with fan start consent

thermostat function: position the sensor on the

exchanger fins as shown in Fig. 8.

Fan Coil System

Fig. 7 Locating the Summer / Winter water sensor

EN0H8560UK07 R0

6

Page 7

RFC BASIC FAN COIL CONTROLLER

Exchanger Fins

Fig. 8 Locating the Fan Coil consent water sensor

WIRING THE REGULATOR

2

The terminals are suitable for 1.5 mm

cables.

WIRING THE ACTUATORS FOR 4-PIPE SYSTEMS

The actuators must be wired to terminals 4-3 (heating

water valve) and 4-2 (cooling water valve).

WIRING THE ACTUATORS FOR 2-PIPE SYSTEMS

In 2-pipe fan coil systems, the actuator must be connected

to the heating water outlet, terminals 4, 3.

STARTUP

MANUAL PARAMETER SETUP PROCEDURE

The RFC regulator allows manual access to the

parameters without the need of a PC.

SEL

2

SEL

3

SEL

1

Fig. 9

Setting the parameters

The SEL0 selector knob allows parameters (from 1 to 10)

to be selected, (see parameter table below).

The fan speed selector SEL2 allows the value of the

chosen parameter to be set.

The SEL1 and SEL3 keys, if pressed simultaneously for 5

seconds, allow access to the “parameter settings mode”.

A

30

20

10

Honeywell

SEL

0

LED MOD

LED SUMMER/WINTER

LED FILTE

LED MODE

E

R

SEL1 is used as the “Enter” button when pressed during

the programming phase and confirms the newly set value.

If pressed for 5 seconds during programming, SEL1 saves

the parameter settings (the green S/W LED blinks 3 times

to indicate that the data has been saved).

The green or red LED indicates which value was set in the

parameter selected by the “selector SEL 0” knob.

SETTING OR CHANGING THE PARAMETER

VALUES

To access the “parameter setting” mode, proceed as

follows:

1) Rotate and set the SEL0 knob to position 10 degrees.

2) Set the SEL2 knob to the AUTO position.

3) Press keys SEL1 and SEL3 for >= 5 sec.

After pressing the keys for 5 seconds, the S/W LED will

start to blink alternating red-green-red-green for 3 seconds

to indicate that the “parameter setting” mode Has been

accessed.

Three seconds after accessing the ‘parameter selection

menu’, the LED turns to green if the current parameter

corresponds to the value selected with the SEL0 knob.

The LED turns red if the current parameter is not the

selected one.

To change a parameter value, position the SEL2 knob to

the selected value (the LED will turn red), then press the

SEL1 programming key and wait until the LED turns to

green.

To save a new setting in the permanent memory of the

controller, press the SEL1 key for >= 5 seconds; the green

LED will blink 3 times to confirm the new parameter

settings.

After saving the value, the controller immediately exits the

parameter configuration mode.

The above sequence is valid for the configuration of all

parameters that are selectable with the SEL0 knob,

therefore:

Select a parameter by rotating the SEL0 knob, and set its

value with the selector knob SEL2.

CHECKING THE PARAMETER SETTINGS

By simply moving selector knob SEL2 one can also check

which value was set in any specific parameter (green LED

= the same chosen parameter, red LED = a different

parameter). If no controls are touched for two minutes, the

controller will revert to normal operating mode.

RESETTING TO THE DEFAULT VALUES

1. Set the SEL0 knob to + 10 °C.

2. Set the SEL2 knob to position 2.

3. The red LED blinks quickly to indicate that the

default parameter table has been chosen.

4. Press the programming key SEL1.

5. The GREEN LED on the device blinks 3 times to

indicate that the device is saving the DEFAULT

parameter table.

7 EN0H8560UK07 R0

Page 8

RFC BASIC FAN COIL CONTROLLER

st

1

LEVEL PARAMETER TABLE

The parameters below are the ones that can be directly modified from the controller key pad.

SEL0

KNOB

POSITIO

N

10 1

11 2 DEAD BAND

12 3

13 4

14 5

15 6

16 7

17 8

18 9

19 10

20 11

PARAMETER

No.

TO BE SET

PARAMETER

COMFORT

SET POINT

RANGE

TYPE OF

PLANT

TYPE OF

OUTPUT

WINDOW

CONTACT

DESTRATIFIC

ATION

WATER

TEMPERATUR

E SENSOR

FUNCTION

SUMMER /

WINTER

SWITCHING

SENSOR

READING

OFFSET

RESET

FAN

Selector Position

PARAMETER

DESCRIPTION

DEFAULT VALUE

Configuring the

COMFORT

set point range

Defines the Dead

Band

by 4-pipe plants

Type of plant 2-PIPE 4-PIPE FAN ONLY

Defines the fan

operating

mode in the dead

band

Defines the type of

regulation at output 1

Defines if the window

contact is n. o. or n. c.

Activate or deactivate

the destratification

function

Selecting the NTC

probe function for the

water temperature

Selecting summer

to winter switching

Modifies the room

temperature sensor

reading

Resetting the

DEFAULT

values or the Filter

hours

10-30 12-28 13-27 14-26 15-25

CONTINUOUSLY

FAN FUNCTION

SEL 1

AUTO

4 3 2 1 0

CYCLED CONTINUOUS

PWM ON-OFF

ACTIVE =

CLOSED

ENABLED DISABLED

CONSENT

Manual

0 + 1°C - 1°C + 2°C - 2°C

Selector

Position

SEL 1

OFF

ACTIVE =

CONTINUOUSL

YOPEN

SUMMER /

WINTER

SWITCHING

Centralized

or by

NTC probe

Setting the filter

hours to zero

Selector

Position

SEL 1

1

CYCLED IN

WINTER /

CONTINUOUS

IN SUMMER

WITHOUT

PROBE

From the room

unit

Selector

Position

SEL 1

CYCLED

SUMMER /

CONTINUO

US IN

WINTER

SUMMER /

WINTER

SWITCHIN

+ FAN

FUNCTION

CONSENT

Resetting

the default

parameters

Other parameters that are listed in the following table can be modified with factory software, though the TTL port.

Selector

Position

2

IN

G

SEL 1

3

EN0H8560UK07 R0

8

Page 9

RFC BASIC FAN COIL CONTROLLER

nd

2

LEVEL PARAMETER TABLE

PARAMETER

No

12

13

14

15

16

17 Dirty filter signal Parameter K value 0 0 (disabled) 1 – 20 K x300 HH

18 NOT AVAILABLE

19 Valve exercise

20

21

22

23

24

PARAMETER TO

BE

CONFIGURED

Proportional band

°C

Economy set point

variation

Winter

temperature

function consent

Summer

temperature

function consent

Anti-freeze

protection °C

De-stratification,

maximum

fan OFF time

(minutes)

De-stratification,

minimum

fan ON time

(minutes)

Fan start delay

(seconds)

Fan start through

electrical

resistance

(seconds)

Fan stop through

electrical

resistance

(seconds)

PARAMETER DESCRIPTION DEFAULT VALUE RANGE NOTES

Defines the temperature range in which

the P+I regulation is carried out

Defines the value to be added to the summer

set point and subtracted from the winter set

point

when the room is not occupied

This parameter defines the water

temperature

above which the system switches to the

winter mode or enables the fan

This parameter defines the water

temperature

below which the system switches to the

summer mode or enables the fan

Room temperature value, below which

the anti-freeze function is activated

Enables or disables a periodic valve

activation to avoid valve blockage

Defines the fan disabling time

during the de-stratification process

Defines the fan enabling time

during the de-stratification process

The fan start delay with respect to

the heating output activation time

Defines the time delay between the electrical

heater switching on and the fan starting

Defines the time that the fan overruns after

the electrical heater is switched off

2 1-5

2 5-10

38 20-60

14 5 - 25

4 0 - 10 °C

Disabled

15 1 – 60

1 1-10

120 0 – 250

30 0-250

60 0-250

• Disabled

• Enabled

9 EN0H8560UK07 R0

Page 10

RFC BASIC FAN COIL CONTROLLER

ELECTRICAL CONNECTIONS

L

1

2

3

EN0H8560UK07 R0

10

Page 11

RFC BASIC FAN COIL CONTROLLER

,

DIMENSIONS

A

20

30

10

Honeywell

The T6580 product family and its associated documentation and packaging are protected by various intellectual property rights belonging to

Honeywell Inc and its subsidiaries and existing under the laws of the UK and other countries. These intellectual and property rights may include

patent applications, registered designs, unregistered designs, registered trade marks, unregistered trade marks and copyrights.

Honeywell reserves the right to modify this document, product and functionality without notice. This document replaces any previously issued

instructions and is only applicable to the product(s) described.

This product has been designed for applications as described within this document. For use outside of the scope as described herein, refer to

Honeywell for guidance. Honeywell cannot be held responsible for misapplication of the product(s) described within this document.

Manufactured in the UK, for, and on behalf of the Environment and Combustion Controls Division of Honeywell Technologies Sàrl, ACS-ECC

EMEA

Z.A. La Pièce 16, 1180 Rolle, Switzerland by its Authorised Representative Honeywell Inc.

Honeywell Control Systems Ltd.

Newhouse Industrial Estate,

Motherwell ML1 5SB,

United Kingdom

http://europe.hbc.honeywell.com EN0H8560UK07 R0

Loading...

Loading...