Page 1

T6570, T8570 Series

Digital Fan-Coil Thermostats

FEATURES

• Simple user interface.

• Attractive modern styling ideal for offices or hotels.

• Digital display of ambient temperature, with user

activated temperature display.

• Digital display shows mode icons when cooling or

heating relays operate, or when energy savings mode

is active.

• Push button setpoint adjustment.

• Switches allow manual control of system operation

and fan speed.

• Energy savings mode - external energy savings input

from time switch, occupancy sensors or hotel cardkey

overrides comfort setpoint with setback heating or

cooling setpoint.

• Energy savings input configurable, normally open or

normally closed.

• Proportional plus integral (P+I) control algorithm for

precision temperature regulation.

• Mounts directly onto wall or standard junction box or

vertical junction box with optional adapter plate.

• Installer setup mode allows changes of operating

APPLICATION

T6570 Series Digital Fan-Coil thermostats provide line voltage

on/off control for fans, valves, compressors or auxiliary

electric heaters in fan-coil and small air-conditioner

applications.

T8570 Series provides low voltage control of these functions.

Models are available for control of single stage air-conditioner

and various fan-coil units

–2-pipe.

– 2-pipe with manual heat/cool changeover.

– 4-pipe with manual heat/cool changeover.

– 4-pipe with automatic heat/cool changeover.

All models are suitable for multiple applications. Changes in

output wiring and external links between wiring terminals can

configure the thermostat for the appropriate application.

The fan can also be controlled from the thermostat. In some

cases it is wired to run continuously and can be switched off

with the On/Off switch. Other models can be installed with fan

running continuously or cycling with the thermostat.

Compressors and auxiliary electric heaters can be controlled

using a relay or contactor controlled by the thermostat.

parameters.

• Selectable °C or °F display.

• Adjustable deadband (some models) for heat and cool

control.

• Selectable energy savings setup cooling and setback

heating setpoints.

• Adjustable maximum heating and minimum cooling

setpoint limits.

• Adjustable minimum relay off-times (heating or

cooling) for compressor short-cycle protection.

• EEPROM permanently retains user settings during

power loss (no batteries required).

• Capability to display temperature sensor failure for

easier troubleshooting.

• Optional remote sensor (T8575D only).

Application......................................................................... 1

Features ............................................................................ 1

Specifications .................................................................... 2

Ordering Information ......................................................... 2

Installation ......................................................................... 3

Operation........................................................................... 4

Operating Modes............................................................... 5

Wiring ................................................................................ 6

PRODUCT DATA

Contents

95C-10897-6

Page 2

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

SPECIFICATIONS

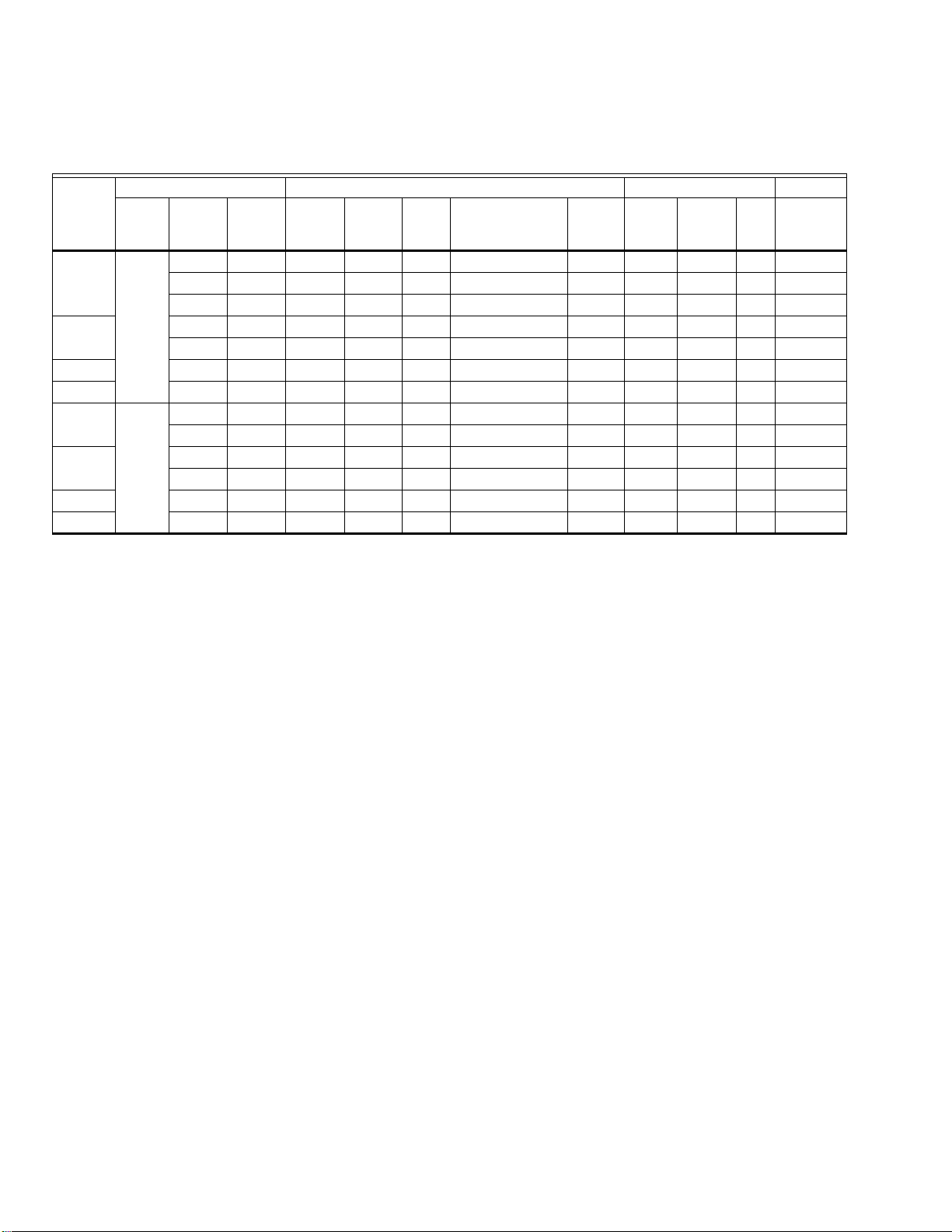

Table 1.

Applications Features Switches Control

2-Pipe

Models

Vol tag e

Fan Coil

T6574B •

120V,

208~

T6575B

277V,

50 -

4-Pipe

2

1

•

3

•

Fan Coil

Relays

• 2 • • • • Fig. 9

• 2 • • • • Fig. 10, 13

T6575C 60 Hz • 2 • • • • Fig. 11, 13

T6575D • 2 • • • • • Fig. 12, 13

Number

T8574B •

24V,

T8575B

50 -

60 Hz

2

1

•

• 2 • • • • Fig. 17

• 2 • • • • Fig. 18

T8575C • 2 • • • • Fig. 19

T8575D • 2 • • • •

1

Heating application

2

Cooling application

3

2-pipe system with external aquastat.

4

optional accessory.

of

Energy

Savings

Input

Fan

On/

Auto

Changeover

Deadband Adjust

Auto

Remote

Sensor

On/Off

(SPST)

3-Speed

Fan

(SP3T)

Heat/

Cool

Wiring

Diagram

1 • • • • Fig. 6

1 • • • • Fig. 7

1 • • • Fig. 8

1 • • • • Fig. 15

1 • • • • Fig. 16

4

• • Fig. 20

Setpoint Range: 10°C to 30°C (50°F to 90°F). Enclosure: (cover, base, and wallplate) Plastic.

Supply Voltages: 24 (NEMA - rated transformer), 120, 230, Control Performance: On/Off control with P+I algorithm

277 Vac (±10%), 50/60 Hz. (depending on model select ed) gives typical control to 0.75°C (1.5°F) at 22°C (72°F) and

0.5 A. 50% duty cycle.

Ambient Ratings: Junction Box Mounting: Direct mounting on single gang

Temperature: NEMA 2" x 4" surface mount electrical box, or on 4" x 4"

Operating Range: 5°C to 45°C (41°F to 113°F). box with optional 272878 adapter plate.

Shipping and Storage Range: -20°C to 55°C (-4°F to

131°F). Wiring: 11 terminals; screw-in terminals capable of accepting

Humidity Range: 5 to 95% RH, non-condensing at 26°C up to 2 x 18 AWG, 1 x 14 AWG, or 1.5 mm2 wires. Some

(79°F). terminals pre-fitted with color-coded flyleads.

Thermostat Output: 1spdt or 2 spst relay outputs (depending

on model).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada–Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

95C-10897–6 2

Page 3

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

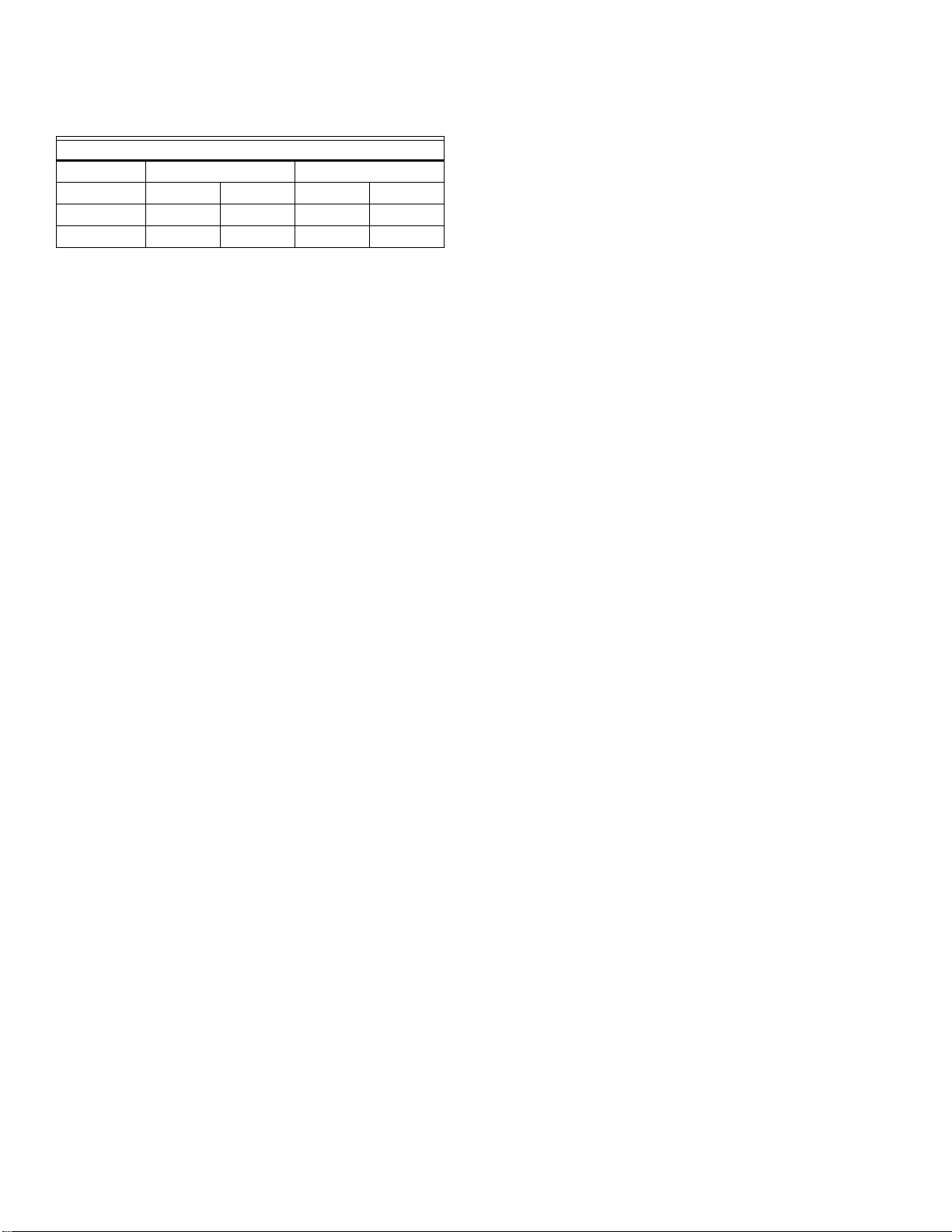

Table 2. Electrical Rating

50-60 Hz 24V 120V 208V 230V 277V

Amps (Resistive) 3.8 3.8 3.8 3.8 3.8

Full Load Inductive 3.0

3.0

1

3.0 3.0 3.0

Pilot Duty 100 VA

1

Equivalent to NEMA 1/8 horsepower rating; allowable load

must be determined by adding nameplate full load and locked

rotor rating of all loads.

Minimum Operational Life (at maximum load): Thermostat

contacts (at 120 Vac): 100,000 cycles

Manual Switches: 10,000 operations.

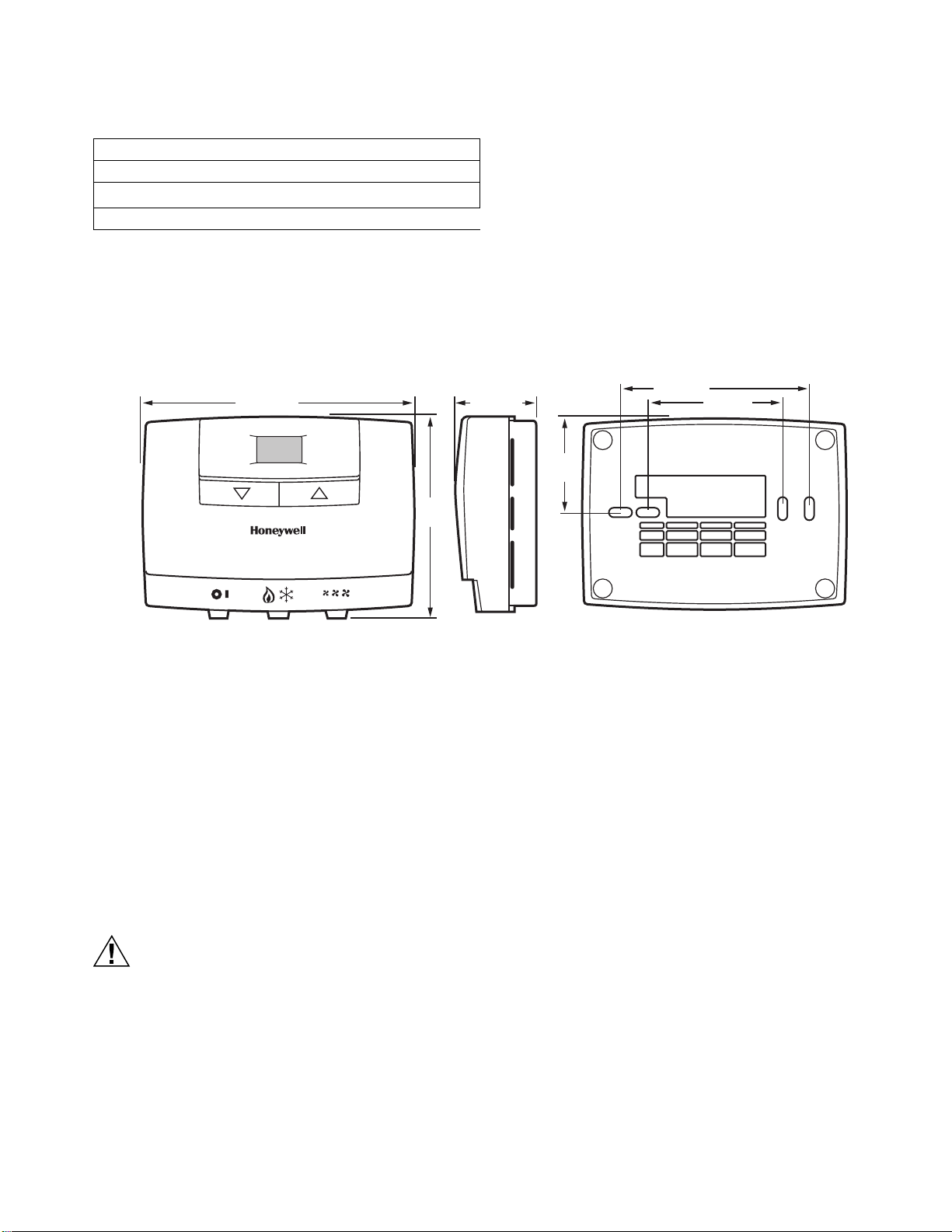

4-3/16 (122)

3-11/16

(94)

Energy Savings Input: 24 Vdc dry contact, maximum resis-

tance of 1000 ohms. Note 'Caution', page 3.

Protection Class: IP30.

Approvals: CSA Certified C/US LR158158 for Canada and

the U.S.A. Meets CE requirements.

Accessories: Adapter plate for mounting on single- or double-

gang NEMA-standard vertical switch box:

272878 - line voltage models, 24V 2000 series

272881 - 24 V models, 1000 series

T8109 - remote temperature sensor for

T8575D W6380 - fan switching center for T8574/T8575

products

1-7/16 (37)

1-1/2

(38)

3-5/16 (84)

2-3/8 (60)

Fig. 1. Nominal dimensions in inches (mm)

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service techni-

cian.

4. After installation is complete, check out product opera-

tion as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

M12081A

IMPORTANT

T6570 Series are line voltage powered devices.

All wiring must comply with national and local electrical codes, ordinances and regulations.

Provide disconnect means and overload protection as required.

T8570 Series thermostats must be powered by an

Approved 24 Vac, Class 2 transformer (such as a

W6380 Relay Control Center).

Location

The T6570, T8570 series thermostats are the temperature

control element in a fan-coil or air-conditioning system. They

must be located about 1.5m (5 ft.) above the floor in a position

with good air circulation to sense room temperature.

The optional T8109 sensor can be used to sense temperature

in return air ductwork, instead of at the thermostat

IMPORTANT

Do not mount device where it can be affected by:

1. Drafts or dead spots behind doors or in corners.

2. Hot or cold air from ducts.

3. Radiant heat from the sun or appliances.

4. Unheated (uncooled) areas such as an outside wall

behind the thermostat.

5. Concealed pipes or chimneys.

3 95C-10897–6

Page 4

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

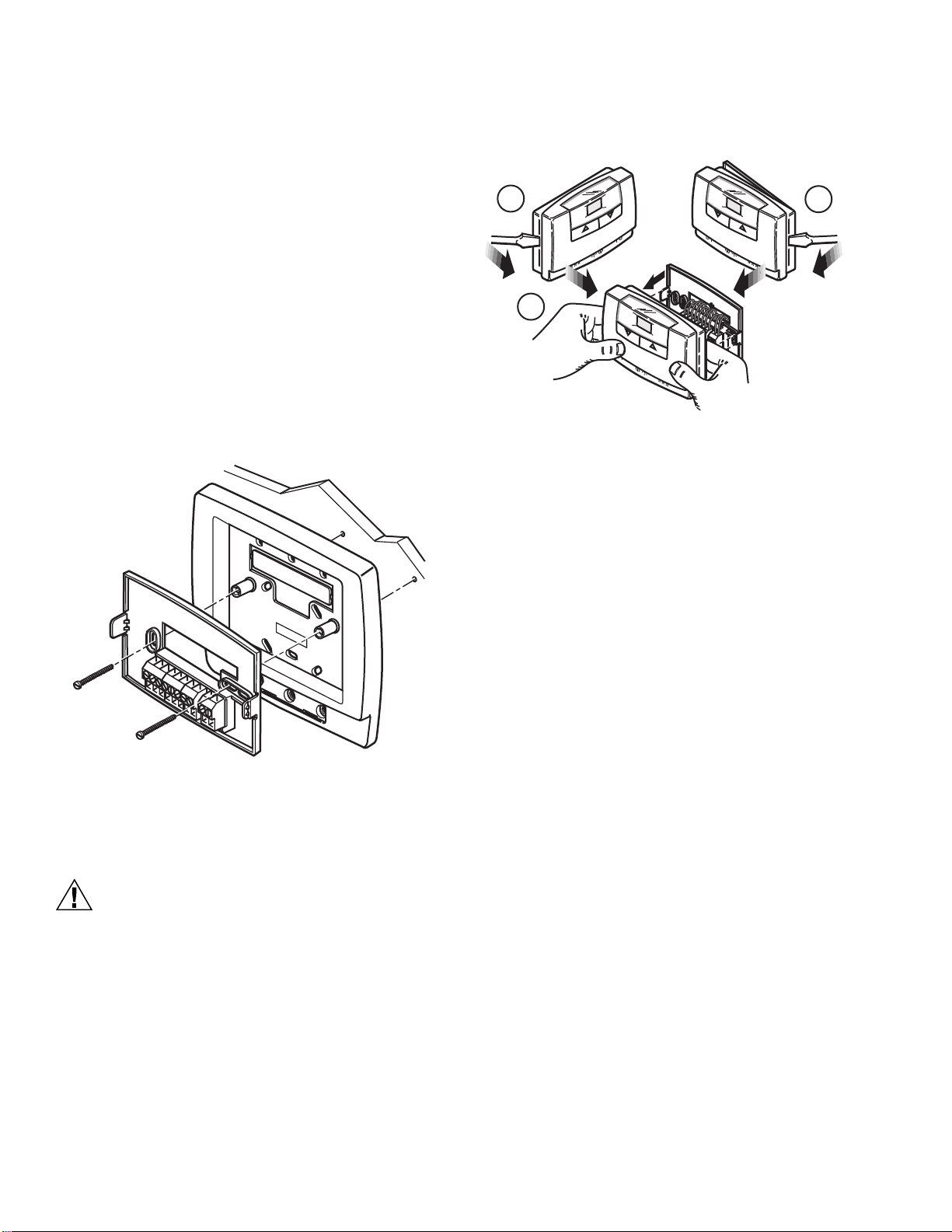

Mounting

Any T6570, T8570 series thermostat can be mounted directly

on the wall on a 65x65mm junction box, or a 2"x4" horizontal

junction box. An optional adapter plate is available for

mounting on a 4"x4" or vertical junction box. (See Fig. 2)

Mounting screws are supplied for alternatives.

1. Feed leadwires through wiring access hole of wallplate

and adaptor plate (if used).

2. Attach supply wires using wire nuts (not provided), or

screw terminals, as appropriate.

3. Locate wallplate in the horizontal mounting position. See

Fig. 2 if using the vertical junction box adapter plate.

4. Push leadwires into electrical junction box and attach

wallplate to box using machine screws provided in the

appropriate mounting holes.

5. Attach thermostat to wallplate:

a. Locate the two center side holes on the back of the

thermostat.

b. Align the holes with the two wallplate side tabs.

c. Press down firmly to snap thermostat into place.

3. Use both hands to pull the thermostat straight away from

the wallplate.

1

2

3

M15396

Fig. 3. Removing the thermostat

Thoroughly check wiring to the wallplate before finally

mounting the thermostat on the wall.

OPERATION

40007507-001

M17505

Fig. 2. Mounting the vertical junction box adapter plate

M17505 Optional adapter plate.

Removing the thermostat

CAUTION

Equipment Damage Hazard.

Improper removal can damage the thermostat.

Carefully follow the thermostat removal directions.

If it is necessary to remove the thermostat from the wallplate

(see Fig. 3):

1. Use a screwdriver to pry thermostat left side away from

the base.

2. Use the screwdriver to pry thermostat's right side away

from the wallplate.

Control

PROPORTIONAL + INTEGRAL (P+I) CONTROL

Like a mechanical thermostat, the T6570, T8570 Series have

On/Off control output. However, this output is regulated by a

P+I algorithm, enabling the thermostat to control closer to

setpoint than conventional thermostats. This results in

performance where the space temperature is maintained within

0.75°C (1.5°F) of the setpoint regardless of fan speed.

P+I action minimizes the difference between the temperature

setpoint and the effective control point by adjusting the output

on-time until the control point matches the setpoint. The ontime is based on a fixed cycle rate of 4 cycles/hour for cooling

(8 cycles/hour for heating), and the proportional band is 1.6°C

(2.9°F).

NOTE: Integral action corrects the temperature control errors

of proportional-only control, but it is slower to react to

large temperature or setpoint changes.

These thermostats also feature optional built-in time

delays for equipment protection which can inhibit

rapid response to large setpoint changes if active.

SINGLE-STAGE COOLING OR HEATING CONTROL (SEE FIG. 4)

In cooling mode the user setpoint will be positioned at the

bottom of the Proportional Band, so the setpoint will effectively

be the temperature where the cooling switches off. In heating

mode the user setpoint will be positioned at the top of the

Proportional Band, and this will be the temperature where the

heating switches off.

NOTE: This also applies to models with manual heat/cool

changeover.

95C-10897–6 4

Page 5

SINGLE STAGE COOLING

C

23.0

22.5

22.0

21.5

21.0

20.5

20.0

SINGLE STAGE HEATING

C

23.0

22.5

22.0

21.5

21.0

20.5

20.0

PROPORTIONAL

BAND

USER

1

SETPOINT

USER

1

SETPOINT

PROPORTIONAL

BAND

1 USER SETPOINT CHANGED

TO 21.5 C (71 F) FROM

23 C (73 F) OR 20 C (68 F).

M17477

Fig. 4. Single stage control.

AUTOMATIC CHANGEOVER WITH ZERO ENERGY DEADBAND

(SEE FIG. 5)

This type of control is available on auto-changeover models

only. The user setpoint centers on the Zero Energy Deadband.

The cooling switch-off-point is positioned at the bottom end of

the cooling proportional band. Likewise, the heating switch-off

point is positioned at the top end of the heating proportional

band.

Zero Energy Deadband width is selectable in the Installer

Setup mode.

EXAMPLE: Using a deadband of 2°C (4°F) and a user setpoint

of 22°C (72°F), the effective heating setpoint is 21°C (70°F)

and the effective cooling setpoint is 23°C (74°F). A change to

the user setpoint causes both heating and cooling setpoints to

change in parallel. This change is restricted to the minimum

cooling setpoint or maximum heating setpoint limits set within

the Installer Setup mode.

C

25.5

25.0

24.5

24.0

23.5

23.0

22.5

22.0

21.5

21.0

20.5

20.0

1

COOLING

PROPORTIONAL

BAND

DEADBAND

HEATING

PROPORTIONAL

BAND

USER SETPOINT CHANGED FROM

1

22 C (72 F) TO 23.5 C (74 F).

USER

SETPOINT

M17478

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

OFF MODE

When the system switch is set to Off, power is removed from

the thermostat electronics and output terminals, and the

display will go blank. The thermostat will reboot when power is

restored with the On/Off switch.

NOTE: This On/Off switch is a functional switch and should

not be used as an isolating switch.

STARTUP

On first powering up, or after the On/Off switch has been set to

On, the thermostat undergoes a startup and self-checking

sequence: First, all LCD display segments are illuminated to

check the display. Next a number appears to indicate the

software version. The final check is a check of the sensor. On

completion of the startup sequence, after approximately 2

seconds, the thermostat will resume normal control in either

Comfort or Economy mode. On initial power on, the

temperature setpoint defaults are as shown in the following

table. The current setpoint is stored in EEPROM, and if the

thermostat is switched off, then on again, it will resume control

at the last known setpoint.

Table 3. Power Up Default Setpoints

Power Up Default Setpoints

1 relay or heat cool changeover

models

2 relay + cool

sequence models

°C Scale °F Scale °C Scale °F Scale

Setpoint

22 73 22 73

Default

Cooling OFF

– – 23 75

point

Heating OFF

– – 21 71

point

COMFORT MODE

This is the normal operating mode where the thermostat

controls to the setpoint selected by the user. On initial power

up, the user setpoint will return to the last known or default

value. Control action will be determined by either the default

settings or the installer-set parameters. (See page 6)

ENERGY SAVINGS MODE

Energy Savings mode is activated by a dry contact closure on

the special Energy Management System (EMS) input from an

occupancy detector, window contact, etc. If the signal via input

terminals 10 and 11 is calling for Energy Savings mode, then

the thermostat will control to user/installer defined setback

setpoints for increased energy savings. The display will show a

$ symbol to indicate the Energy Savings mode is active.

Fig. 5. Sequence control with deadband.

OPERATING MODES

The thermostat has two main operating modes: Comfort and

Energy Savings. It also has an OFF mode selected by the On/

Off switch.

5 95C-10897–6

For example, if the user setpoint is 21°C (70°F) and the Energy

Savings mode setpoint for cooling (unoccupied cooling

setpoint) has been set to 28°C (82°F), then the thermostat

controls to 28°C (82°F) when the input signal activates the

economy mode. There is no user override as long as the EMS

signal is present. The default Energy Savings mode setpoints

are shown in table 4.

The Energy Savings mode input can be configured within the

installer setup mode to be activated by either a short-circuit

(default) or open-circuit signal.

Page 6

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

Table 4. Energy Saving Mode Default Settings

Energy Savings Mode – Setpoints

Heating Setpoint Cooling Setpoint

Description Default Range Default Range

°C Scale 18°C 10-18°C 25°C 25-30°C

°F Scale 65°F 50-65°F 77°F 77-90°F

Additional Switches

FAN SPEED SWITCH (SP3T LINE VOLTAGE)

Where supplied, the fan switch allows the selection of three

different settings: low, medium, or high.

NOTE: The installer should select Constant Fan mode if the

fan motor is a type that does not start reliably at low

speed.

SYSTEM HEAT/COOL SWITCH (SPST LOW VOLTAGE)

Where supplied, this switch signals the microprocessor to

operate the relays in either heating or cooling mode: In heating

mode, the cooling relay is disabled. In cooling mode, the

heating relay is disabled.

User Programming Modes

TEMPERATURE (COMFORT) SETPOINT

The temperature setpoint can be adjusted between 10°C and

30°C in steps of 0.5°C by using the [UP] and [DOWN] keys. If

°F is set within the installer setup mode (see later), the range

will be 50°F to 90°F, adjustable in 1°F steps.

DISPLAY

The measured room temperature is normally displayed (unless

rt = 0 in the installer setup mode), and the first press of the

[UP] or [DOWN] keys will switch to display the user setpoint. If

no key is pressed for 5 seconds, the display will return to

showing the room temperature.

When the cooling relay is closed, this will be indicated by a

(snowflake) symbol, whereas closure of the heating relay will

be indicated by a (flame) symbol.

If there is a wiring problem or the room temperature is less

than 5°C (40°F) or over 38°C (100°F) the display will return a

SF (Sensor Failure) warning. If this warning is not due to a

wiring problem it will disappear once the remote sensor or

thermostat comes within the 4.5 to 37.8°C (40 to 100°F) range.

If the SF warning is due to a faulty remote sensor connection

the thermostat will not transfer measurement to the internal

sensor. To resolve the faulty connection the thermostat must

be powered down, the remote sensor connection must be

removed or fixed and then the thermostat must be re-powered.

Installer Setup Mode

The thermostat allows many of its operating parameters to be

adjusted via an Installer Setup Mode. Each operating

parameter has a two-letter identifier code, which is shown on

the display during the Installer Setup Mode programming

sequence. A description of these is shown in Table 5.

PROGRAMMING PARAMETERS

The installer setup mode is accessed by reducing the setpoint

to 10°C (50°F), waiting 3 seconds or until the room

temperature is displayed, and then pressing the [UP] and

[DOWN] keys simultaneously for 3 seconds.

If the installer setup has previously been entered and the

Minimum Cooling Setpoint increased above 10°C (50°F), the

installer setup mode is accessed by reducing the setpoint to

the new value before pressing the two buttons.

The first parameter identifier will be displayed at this point and

the parameter value can be changed by pressing the [UP] key.

The first press displays the default value and any subsequent

press alters the value. The values will wrap around.

To select the parameter value and move to the next parameter,

press [DOWN]. After the final parameter is selected, a further

press of the [DOWN] key will exit from the programming mode.

PARAMETER VALUES

Each parameter has a default value that is used when the

thermostat is first powered up. This value can be changed from

within the Installer Setup Mode, and once changed, it will be

stored in the EEPROM so it is not lost in the event of power

interruption.

If the user wishes to restore the parameters to the default

values, this can be done by changing the temperature scale tS

from °C to °F (or °F to °C) and back again.

PROGRAMMING EXAMPLE

To enter the installer setup mode:

1. Press to change the temperature setpoint to 10°C

(50°F).

2. Wait 3 seconds, or until the room temperature is dis-

played.

3. Press and hold together until [tS] is displayed.

4. Press once to show the default Temperature Scale

value. Continue to show all possible values of this

parameter in sequence.

5. When the desired value is displayed, it is selected by

pressing once. This will also move to the next parameter,

whose identifier will now be displayed.

6. Continue to use to move from one parameter to the next,

and to alter the parameter value.

7. When the last parameter [rt] has been selected, a final

press of will return the display to its normal operating

mode.

95C-10897–6 6

Page 7

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

Table 5. Thermostat Parameter Options

°C Scale °F Scale

Parameter ID Description

Temperature Scale tS Allows selection of either °C or °F scale Yes – No –

Dead Band db Setting deadband (Zero Energy Band) 2 2, 3, 4 4 3, 4, 5

Heat or Cool

Operating Mode

Unoccupied Cooling

Setpoint

Unoccupied Heating

Setpoint

Minimum Cooling

Off Time

Minimum Heating

Off Time

Minimum Cooling

Setpoint (Low Limit)

Maximum Heating

Setpoint (High Limit)

Energy Savings

Configuration

Display of Room

Temperature

OP Setting operating mode on single relay,

non-changeover models, to either Heat

or Cool

uC Program unoccupied cooling setpoint

for energy savings.

uH Program unoccupied heating setpoint

for energy savings

CO Setting cooling off-time for short cycle

prevention.

HO Setting heating off-time for short cycle

prevention.

CL Sets the minimum allowable cooling

setpoint.

HL Sets the maximum allowable heating

setpoint.

ES Activate energy savings mode by a

choice of either contact closure or

contact opening.

rt Allows installer to restrict temperature

display to set point only. With this

parameter, the unit will only display the

set point temperature. Useful where

setpoint limits (HL and CL) will affect

control performance and Room

Temperature display will disagree with

user setpoint.

Default Values Default Values

0 0: cool

1: heat

25 25 to 30 77 77 to 90

18 10 to 18 65 50 to 65

0 0, 3, 4, 5 0 0, 3, 4, 5

0 0, 3, 4, 5 0 0, 3, 4, 5

10 10 to 30 50 50 to 90

30 10 to 30 90 50 to 90

1 1: normally open

0: normally closed

1 1: room temp.

0: setpoint only

0 0: cool

1: heat

1 1: normally open

0: normally closed

1 1: room temp.

0: setpoint only

WIRING

Table 6. Leadwire Color Code (if fitted)

Terminal Color Use

1 Black (BK) L1 (Hot)

2 White (WH) L2 (N)

3 Orange (OR) Heat

4 Yellow (YL) Cool

5 Gray (GY) Damper

6 Violet (VI) Fan Common

7 Red (RD) Fan Low

8 Blue (BU) Fan Medium

9 Brown (BN) Fan High

10 – Energy Mgt.

11 –

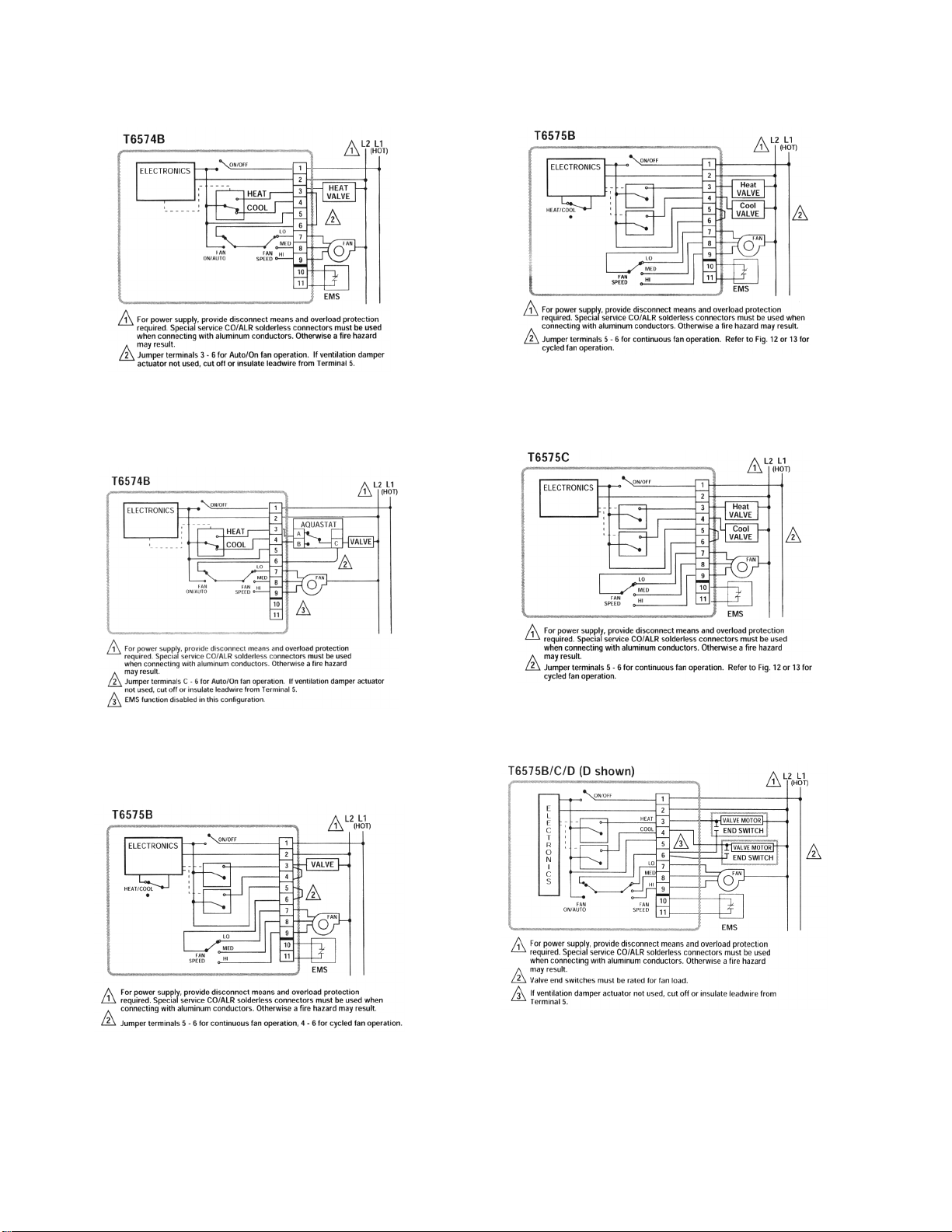

Fig. 6. Wiring 2-pipe cool-only thermostat with fan On/Auto

switch.

System

7 95C-10897–6

Page 8

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

Fig. 7. Wiring 2-pipe heat-only thermostat with fan On/Auto

switch.

Fig. 10. Wiring 4-pipe, heat/cool with manual heat/cool

changeover switch, continuous fan.

Fig. 8. Wiring 2-pipe seasonal heat/cool changeover with

external aquastat, fan On/Auto switch.

Fig. 9. Wiring 2-pipe heat/cool with manual heat/cool

changeover switch, continuous fan or cycled fan.

Fig. 11. Wiring 4-pipe, auto heat/cool changeover.

Fig. 12. Wiring 4-pipe, auto heat/cool changeover, with fan

On/Auto switch.

95C-10897–6 8

Page 9

Fig. 13. Wiring 4-pipe, heat/cool with manual heat/cool

changeover switch, cycled fan, using external relay.

Fan-Relay Control Center

T8570 thermostats are typically used with load relays to switch

line voltage loads. Honeywell offers a convenient fan-relay

center, the W6380, that provides 24 Vac power, three

interlocked fan relays, and wiring center terminations for valve,

relay and contactor loads. The W6380 schematic can be found

in Fig. 14.

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

Fig. 16. Wiring 2-pipe 24V heat thermostat with fan On/

Auto switch.

Fig. 14. W6380 wiring diagram.

Fig. 15. Wiring 2-pipe, 24V cool-only thermostat with fan

On/Auto switch.

Fig. 17. Wiring 2-pipe heat/cool with manual heat/cool

changeover switch, continuous or cycled fan.

Fig. 18. Wiring 4-pipe 24V heat/cool with manual heat/cool

changeover switch, continuous fan.

9 95C-10897–6

Page 10

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

Fig. 19. Wiring 4-pipe 24V auto heat/cool changeover with

continuous fan.

T8575D will find the new sensor source and use this for

control. To extend the sensor cable, up to a maximum of 70

feet (20m), use only shielded cable. For example, Beldfoil® 18

AWG cable is a suitable cable. The sensor connections are

polarity sensitive, so be sure to connect the shielded wire to

the sensor blue wire, as shown in Fig. 21 below.

Fig. 21. Wiring optional remote sensor for the T8575D

model.

Fig. 20. Wiring 4-pipe 24V auto heat/cool changeover

thermostat with fan On/Auto switch.

Wiring Remote Sensor

The T8109 is a optional remote sensor that can be used as an

alternative to the internal sensor of the T8575D. The T8109

remote sensor plugs into the J2 header in the back of the

thermostat. On power-up the T8575D will look for a T8109 and

if there is one connected it will use this control. If it does not

find a T8109 connected it will use the internal sensor. To

change the sensor source, turn off the thermostat power and

disconnect the current sensor source. Then connect the new

sensor source and re-power the thermostat. On powerup the

CAUTION

Equipment Damage Hazard.

Operation at low temperatures can cause fan coil

damage.

This thermostat is not a safety device. Do not use it

where the space temperature is outside of the device

operating range.

A display of SF indicates a space temperature outside

of the thermostat operating range (5°C to 45°C).

With SF displayed, the thermostat ceases to

operate.

CAUTION

Equipment Damage Hazard.

Improper operation can cause compressor

damage.

Do not operate cooling if outdoor temperature is below

50ºF (10°C). Refer to manufacturer recommendations.

To avoid compressor damage, allow the compressor to

remain off for five minutes before restarting.

95C-10897–6 10

Page 11

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

95C-10897–6 11

Page 12

T6570, T8570 SERIES DIGITAL FAN-COIL THERMOSTATS

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2005 Honeywell International Inc.

95C-10897–6 M.A. Rev. 09-05

Loading...

Loading...