Page 1

Electronic Fan Coil Thermostats

APPLICATION

The T6380 series of electronic fan coil thermostats provide

precision line voltage control of fan-forced Heating, Ventilating and Air Conditioning equipment. Models are available for

cooling-only, manual heat-cool changeover, or remote heatcool changeover systems. Hydronic source heat-cool

systems may be two or four-pipe configuration with 0, 1, or 2

valves. Fan control options include constant, cycled, or userselectable "On-Auto" operation. Manual fan speed selection

is standard. All models feature an “Off” switch.

T6380 Series

PRODUCT DATA

FEATURES

• Electronic temperature sensing provides energy-

efficient, precision operation for maximum comfort.

• Contemporary white sculpted styling.

• Vertical or horizontal mounting configurations.

• Adjustment ranges 55° to 90°F or 13° to 32°C.

• Easy-to-use set point knob.

• LED system status indicator. "OFF" de-energizes all

connected loads.

• Three level fan speed selection.

• Constant, cycled, or on-auto selectable fan operation

available.

• Models for manual or remote heat-cool changeover,

heating-only, or cooling-only systems.

• Models for 2 or 4-pipe systems.

• Rugged molded thermoplastic housing with captive

mounting screws, mounts on single-gang NEMA-

standard (U.S.) electrical box.

• Screw terminal block connections.

• Suitable for inductive-rated loads such as valves,

relays, contactors and fans.

• Range stops and cover locking kit available.

• UL Listed. CSA Certified.

Contents

Specifications .................................................................. 2

Ordering Information ....................................................... 2

Installation ....................................................................... 3

Wiring .............................................................................. 3

Operations .................................................................... 5

Check-out ..................................................................... 5

M.O'D. 8/98 © Honeywell Ltd.—Honeywell Ltée. 1998 Printed in Canada Form Number 95C-10758

Page 2

T6380 - SPECIFICATIONS, ORDERING INFORMATION

SPECIFICATIONS

MODELS:

Fan Coil System

2-pipe System

• Cooling only

• Heating only

2-pipe Heat-Cool

• Manual Change/Over

• Seasonal, auto C/O

• Seasonal, auto C/O

with aux. electric heat

4-pipe Heat-Cool

• Manual C/O

Electrical Ratings:

T6380 Series - Power Supply: 110-130 or 208-277 Vac

T6381, T6387 - Output Rating, cycled (“Auto”) fan control

* Equivalent to NEMA 1/8 horsepower rating for a hermetically-sealed

T6383 – Output Rating, constant fan operation

Thermostat (Heat and Cool outputs):

Fan (Air Handler):

50-60 Hz

Full Load Amps**

Locked Rotor

** Equivalent to NEMA 1/4 horsepower rating for a hermetically-sealed

+10/-15%, 50-60 Hz.

50-60 Hz 120 V 208 V 230 V 277 V

Full Load Amps* 3.8 2.1 1.9 1.6

Locked Rotor 22.8 12.6 11.4 9.5

Pilot Duty 125 VA

motor such as a compressor. Allowable connected load must be

determined by adding nameplate full load and locked rotor (inrush) ratings

of all loads.

50-60 Hz 120 V 208 V 230 V 277 V

Full Load Amps 3.8 2.1 1.9 1.6

Locked Rotor A 22.8 12.6 11.4 9.5

Pilot Duty 125 VA

Resistive (heat only)

110-130V

motor. Allowable load must be determined from fan nameplate

ratings .

† North American national electrical codes require all ungrounded

conductors to electric resistance heating to be broken at the thermostat

OFF setting. The 208V and 230V resistive ratings are not UL approved.

The 230V rating is site-approveable in Canada on 416V 4-wire Wye

distributed systems. The non-inductive rating for 230V “a.c. mains”

with one ungrounded conductor is 6.0A.

3-Speed Fan Operation

Constant

T6383A T6381A T6387A

Fig. 2a Fig. 5a Fig. 8a

T6383A T6381A T6387A

Fig. 2b

T6383B

Fig. 3

T6383A

Fig. 2c

T6383B

Fig. 4b Fig. 7b

T6383B

Fig. 4a Fig. 7a

10.0 A

5.8 3.2

34.8 19.2

Cycled

Fig. 5b Fig. 8a

T6381B N/A

Fig. 6

T6381A

Fig. 5c

T6381B

T6381B

N/A

208 V

220-240V

N/A 5.6

2.9

17.4

On-Auto

T6387A

Fig. 8c

N/A

N/A

277 V

14.4

2.4

Operating range:

32 to + 104 F [0 to +40 C], 5 to 95% RH, non-condensing.

Performance Specifications:

Precision: ±1°F temperature swing [0.9°C differential].

Accuracy: 2°F [1°C] droop with 4 A load.

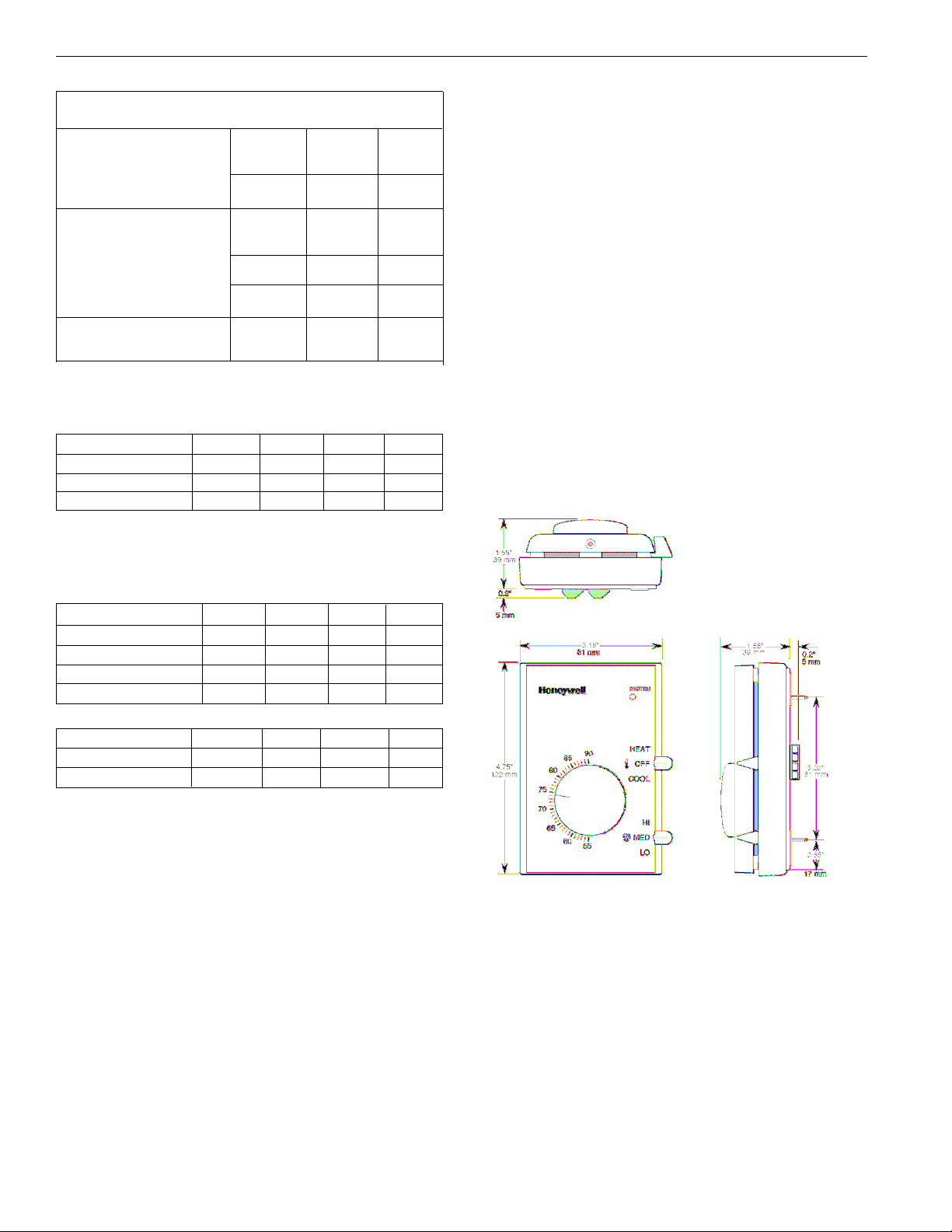

Dimensions:

See Fig. 1 - Nominal Dimensions.

Mounting:

Direct mounting on single-gang NEMA 2" x 3" flush-mount

or 2" x 4" surface-mount electrical box, or on 4" x 4" box

Models available for vertical or horizontal mount.

Wiring Connections:

Screw terminal block suitable for 1 – 14 AWG, 2 – 18 AWG,

2

or 1 – 1.5 mm

copper wire.

Approvals:

CSA Certified LR1322

Underwriters Laboratories Listed E47434.

Accessories:

272824A-T6380 Range stop/cover locking kit.

272827A-T6380 replacement cover with Cool-Warmer

Fig. 1 — Nominal dimensions in inches and

millimetres

ORDERING INFORMATION

Before ordering please determine the following:

1. The body type: 2-way or 3-way

2. The actuator voltage : 24V/50-60Hz

3. The pipe fitting, size, and flow capacity rating (Cv) required.

4. Order Specification Number

5. Accessories, if desired.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Home and Building Control Sales Office (please check the white pages of your phone directory).

2. Honeywell Limited, 155 Gordon Baker Rd., North York, ON M2H 3N7.

In U.S.A. - Honeywell Inc., 1885 Douglas Drive North, Minneapolis, Minnesota 55422-4386 (612) 951-1000. International Sales and Service

Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands, Spain,

Taiwan, United Kingdom, U.S.A.

2

Page 3

T6380 - INSTALLATION, WIRING

)

)

r

(

)

)

INSTALLATION

MOUNTING:

Mount the thermostat on an inside wall 4’ to 5' [1.5 m] above

the floor. Do not mount where thermostat can be affected by

drafts, radiant heat from the sun, or other sources of heat.

T6380's mount on NEMA standard 2"x3" single gang flush or

2"x4" surface mount electrical box, or on 4"x4" box with mud

ring adaptor (not provided).

WIRING

3Internal schematic and external wiring connections are

shown in Fig. 2a through Fig. 8c. Wiring connections may be

made to the 8 position screw terminal block with 1- 14 AWG,

or 2- 18 AWG, solid or stranded copper wires.

Fig. 2a – T6383A for 2-pipe, constant fan, cooling only

T6383A

FAN

BLK

L1(HOT)

Off

WHT

L2

(NEUTRAL)

Cool (YEL)

Heat (ORG)

3

(BRN)

(BLU)

2

(RED)

1

(VIO)

TO COOLING

VALVE

External jumper

HI

MED

FAN

LO

Fig. 2c – T6383A: 2-pipe, heat/cool, seasonal auto-changeover,

constant fan

.

T6383A

AQUASTAT

W

R

B

FAN

TOHEAT/COOL

VALVE

1

BLK

L1(HOT)

FAN

Off

L2

(NEUTRAL)

Cool (YEL)

Heat (ORG)

WHT

3

(BRN) HI

2

(BLU) MED

(RED) LO

1

(VIO)

1

External jumper

Fig. 3 – T6383B: 2-pipe, heat/cool, manual changeover, constant

fan

T6383B

SYSTEM

Cool

Off

Heat

Cool (YEL)

Heat (ORG)

FAN

Hi (BRN)

Med (BLU)

Lo (RED)

HI

MED

LO

TOHEATING/

COOLING

VALVE

External jumpe

FAN

Fig. 2b – T6383A for 2-pipe, constant fan, heating only

T6383A

FAN

Off

BLK

L1(HOT)

(NEUTRAL)

L2

Cool (YEL)

Heat (ORG)

WHT

3

(BRN)

(BLU)

2

(RED)

1

(VIO)

TO HEATING

VALVE

HI

MED

LO

External jumper

FAN

BLK

L1(HOT

WHT

L2(NEUTRAL

To internal heat/cool

circuits

Fig. 4a – T6383B: 4-pipe, heat/cool, manual changeover,

constant fan

T6383B

SYSTEM

BLK

L1(HOT

Cool

Off

Heat

WHT

L2

NEUTRAL

Cool (YEL)

Heat (ORG)

FAN

Hi (BRN)

Med (BLU)

Lo (RED)

To internal heat/cool

circuits

TO COOLING

VALVE

TO HEATING

VALVE

HI

MED

LO

FAN

3

Page 4

T6380

/

L2(NEUTRAL)

L1(HOT)

SYSTEM

FAN

Heat

Off

Cool

Cool (YEL)

FAN

TO HEATING/COOLING

VALVE

Fig. 4b – T6383B: 2-pipe, heat/cool, auto changeover, with aux.

electric heat, constant fan

T6383B

SYSTEM

Cool (YEL)

Cool

Off

Heat

BLK

Heat (ORG)

FAN

Hi (BRN)

Med (BLU)

Lo (RED)

WHT

L2(NEUTRAL)L1(HOT)

To internal heat/cool

circuits

HI

MED

LO

.

W

.

R

B

W

R

B

TO HEAT/ COOL

VALVE

TO SUPPLEMENTARY

HEAT

FAN

Fig. 5a – T6381A: 2-pipe, cooling only, cycled fan

T6381A

FAN

Cool (YEL)

L1 (HOT)

Fig. 5c – T6381A: 2-pipe, heat/cool, auto-changeover, cycled fan

AQUASTAT

W

R

B

HI

MED

LO

FAN

L2 (NEUTRAL)

L1 (HOT)

FAN

Off

T6381A

Cool (YEL)

Heat (ORG)

3

(BRN)

2

(BLU)

(RED)

1

WHT

(VIO)

External jumper

TO HEATING

COOLING VALVE

Fig. 6 – T6381B: 2-pipe, heat/cool, manual changeover, cycled

fan

T6381B

.

Heat (ORG)

(BRN)

Off

3

2

(BLU)

(RED)

1

WHT

HI

MED

LO

L2

(NEUTRAL)

BLK

(VIO)

External jumper

TO COOLING

VALVE

Fig. 5b – T6381A: 2-pipe, heating only, cycled fan

T6381A

FAN

Cool (YEL)

L1 (HOT)

HI

MED

FAN

LO

L2

(NEUTRAL)

External jumper

BLK

Off

Heat (ORG)

(BRN)

3

2

(BLU)

(RED)

1

WHT

(VIO)

FAN

External jumper

BLK

Heat (ORG)

(BRN)

(BLU)

(RED)

WHT

HI

MED

LO

Fig. 7a – T6381B: 4-pipe, heat/cool, manual changeover, cycled

fan

.

SYSTEM

Cool

Off

Heat

T6381B

Cool (YEL)

Heat (ORG)

FAN

(BRN)

(BLU)

(RED)

TO COOLING

VALVE

TO HEATING

VALVE

HI

MED

LO

FAN

TO HEATING

VALVE

4

BLK

L1(HOT)

WHT

L2(NEUTRAL)

Page 5

T6380 - OPERATION

(

)

)

)

Fig. 7b – T6381B: 2-pipe, heat/cool, auto-changeover, cycled fan Fig. 8c – T6387A: 2-pipe, heat/cool, auto-changeover, on–

with aux. heat auto fan

.

HI

MED

LO

W

.

R

B

W

R

B

FAN

BLK

Cool

Off

Heat

SYSTEM

WHT

L2(NEUTRAL)L1(HOT)

T6381B

Cool (YEL)

Heat (ORG)

FAN

Hi (BRN)

Med (BLU)

Lo (RED)

To internal heat/cool

circuits

Fig. 8a – T6387A: 2-pipe, cooling only on–auto fan

T6387A

SYSTEM

On

Off

Auto

BLK

L1(HOT

WHT

L2

Cool (YEL)

Heat (ORG)

FAN

(BRN)

(BLU)

(RED)

(VIO)

External jumper

NEUTRAL

Fig. 8b – T6387A: 2-pipe, heating only on–auto fan

T6387A

SYSTEM

On

Off

Auto

BLK

L1(HOT) L2(NEUTRAL

WHT

Cool (YEL)

Heat (ORG)

FAN

(BRN)

(BLU)

(RED)

(VIO)

TO HEATING

VALVE

HI

MED

LO

External jumper

FAN

TO HEAT/ COOL

VALVE

TO SUPPLEMENTARY

HEAT

TO COOLING

VALVE

HI

MED

LO

FAN

SYSTEM

On

Off

Auto

BLK

L1(HOT) L 2(NEUTRAL)

CAUTION

!

1. Disconnect power supply before connecting

wiring to prevent electrical shock and equipment

damage.

2. Never jumper the supply wires or actuator terminals

even temporarily. This may damage the thermostat.

OPERATION

As the temperature changes, the thermostat makes to

open a valve and/or power a blower to provide heating or

cooling. The speed at which the air is circulated is controlled by the FAN switch. Continuous (

AUTO) fan operation is determined by model number.

(

CHECK-OUT

Turn power on. Check out operation according to the

SYSTEM switch present.

• SYSTEM switch OFF de-energizes valve and fan

circuits.

Models T6381B,: T6383B

• SYSTEM: HEAT - OFF - COOL

Set the SYSTEM switch to HEAT. Rotate the

thermostat knob clockwise to energize the heating

valve and/or fan (fan auto/cycled mode). The

system LED on the thermostat will light when the

heating circuit is energized.

Set the SYSTEM switch to COOL. Rotate the thermo

stat knob counter-clockwise to energize the cooling

valve and/or fan (fan auto/cycled mode). The

system LED on the thermostat will light.

Model T6387A

• SYSTEM: ON -AUTO - OFF

• Set the SYSTEM switch to ON. The valve will

operate on heating or cooling cycle depending on

whether hot or chilled water is being supplied. The

fan will run continuously.

Set the SYSTEM to AUTO. The fan will cycle with the

heating or cooling operation.

WHT

T6387A

Cool (YEL)

Heat (ORG)

FAN

(BRN)

(BLU)

(RED)

(VIO)

W

R

B

HI

MED

LO

1

External jumper

ON) or intermittent

AQUASTAT

TOHEAT/COOL

FAN

VALVE

5

Page 6

Models: T6381A; T6383A

• SYSTEM: HI-OFF-MED-LO

• Set the SYSTEM switch to HI. Rotate the thermostat

knob clockwise to energize the heating\cooling valve

and/or fan ( constant or cycled fan). The system

LED on the thermostat will light when the heating or

cooling circuit is energized.

SETTING:

The T6380 temperature scale is marked 55 to 90°F or 13 to

32°C, depending on the model. Set the dial indicator marker

to the desired temperature.

CALIBRATION:

T6380 thermostats are accurately calibrated at the factory

under controlled conditions. Do not attempt to field calibrate

this device.This thermostat has line voltage connections.

T6380

Home and Building Control In U.S.A.

Honeywell Ltd. Honeywell Inc.

155 Gordon Baker Road 1985 Douglas Drive North

North York, Ontario M2H 3N7 Golden Valley, MN 55422-3992

Printed in Canada

Helping You Control Your World

Loading...

Loading...