Page 1

HONEYWELL I

TRADELINE

I CONTROLS

T6051 A; T6052A.B

HEAVY DUTY THERMOSTATS

The T6051 Heavy Duty Thermostat may be used in

heating only systems, cooling only systems, combination

heat-cool systems (system changeover means must be

provided), or as a series 60 controller for valves or motors.

The T6052A is for two stage heating or two stage

cooling systems. The T6052B is for one stage heatingcooling systems with automatic changeover.

The Q651 Subbase may be used with the T6051 and

T6052B thermostats to provide system witching at the

thermostat location. Refer to applicable specification

sheet for additional information.

INSTALLATION

---

--------------------------------------—

LOCATION

Locate the thermostat about five feet above the floor

on an inside wall where it will be affected only by the

average temperature of the room. The T6051A may be

mounted either vertically or horizontally.

If using a 0651 Subbase, refer to the instructions

packed with the subbase.

MOUNTING

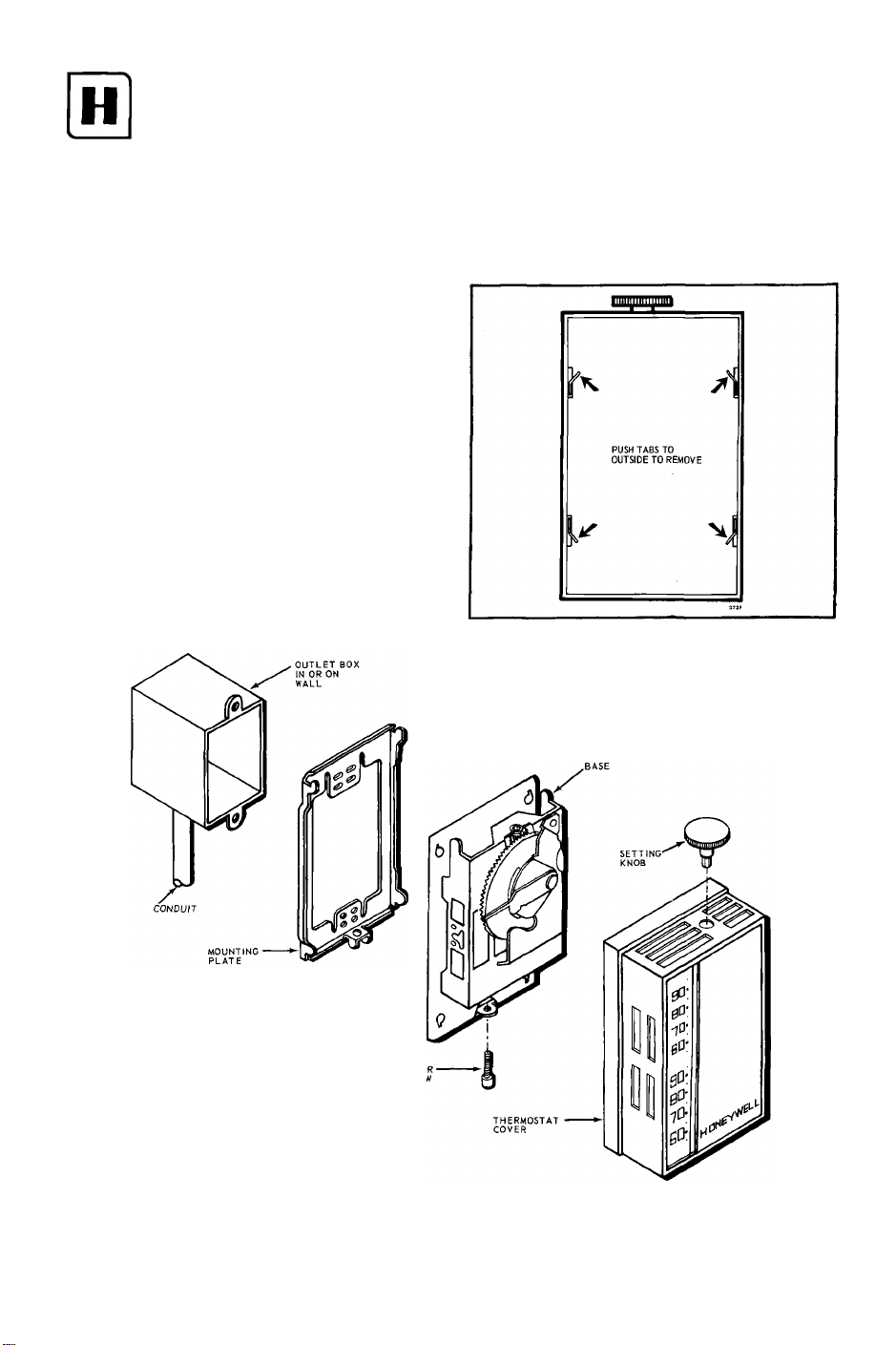

1. If mounting horizontally, coverplate must be

changed. To remove vertical coverplate, bend four

corner tabs to outside and oush out on cover. Place

horizontal coverplate on cover frame and bend four

corner tabs to inside. (See Fig. 1).

Fig. 1—Changing coverplate for horizontal mounting.

2-72

E.S.

Fig. 2—Mounting Thermostat on Outlet Box.

THERMOSTAT

Form Number

95-6980-1

Residential Div.

Page 2

2. Mount the 2 by 4 inch outlet box either vertically

or horizontally, as desired.

3. Run conduit between the outlet box, power source,

and the unit being controlled. Leave about six inches of

wire in the box for connections. (Refer to the WIRING

section for the number of wires required.)

4. Place the mounting plate on the outlet box either

vertically or horizontally. Insert the two furnished

mounting screws, leaving them loose enough to move

the mounting plate for leveling. See Fig. 2.

5. Level the mounting plate and tighten the mounting

screws. (See Fig. 2.)

6. Connect the heating and/or cooling system wires

or the Series 60 equipment wires to the back terminals

of the thermostat. See Figs. 3—10.

7. When wiring is complete, secure the fiber insulator

by snapping the holes in the flap over the switch rivet

heads. When the normally open terminal is used, clip the

flap to allow it to pass around the wire.

8. Hang thermostat on mounting plate tabs, see

Fig. 2.

9. Take socket-head cover mounting screw (furnished)

and insert it in tab at bottom of base. Do not tighten.

Replace cover.

10. Insert set point knob into socket-head screw and

tighten. This fastens cover and thermostat to the mount

ing plate previously attached to outlet box. Remove knob.

WIRING

CAUTION

Disconnect power supply before making wiring

connections to prevent electrical shock and

equipment damage.

All wiring must agree with local electrical codes and

ordinances. Refer to the wiring diagrams below, instruc

tions packed with the subbase, and heating and/or cooling

equipment manufacturer's instructions.

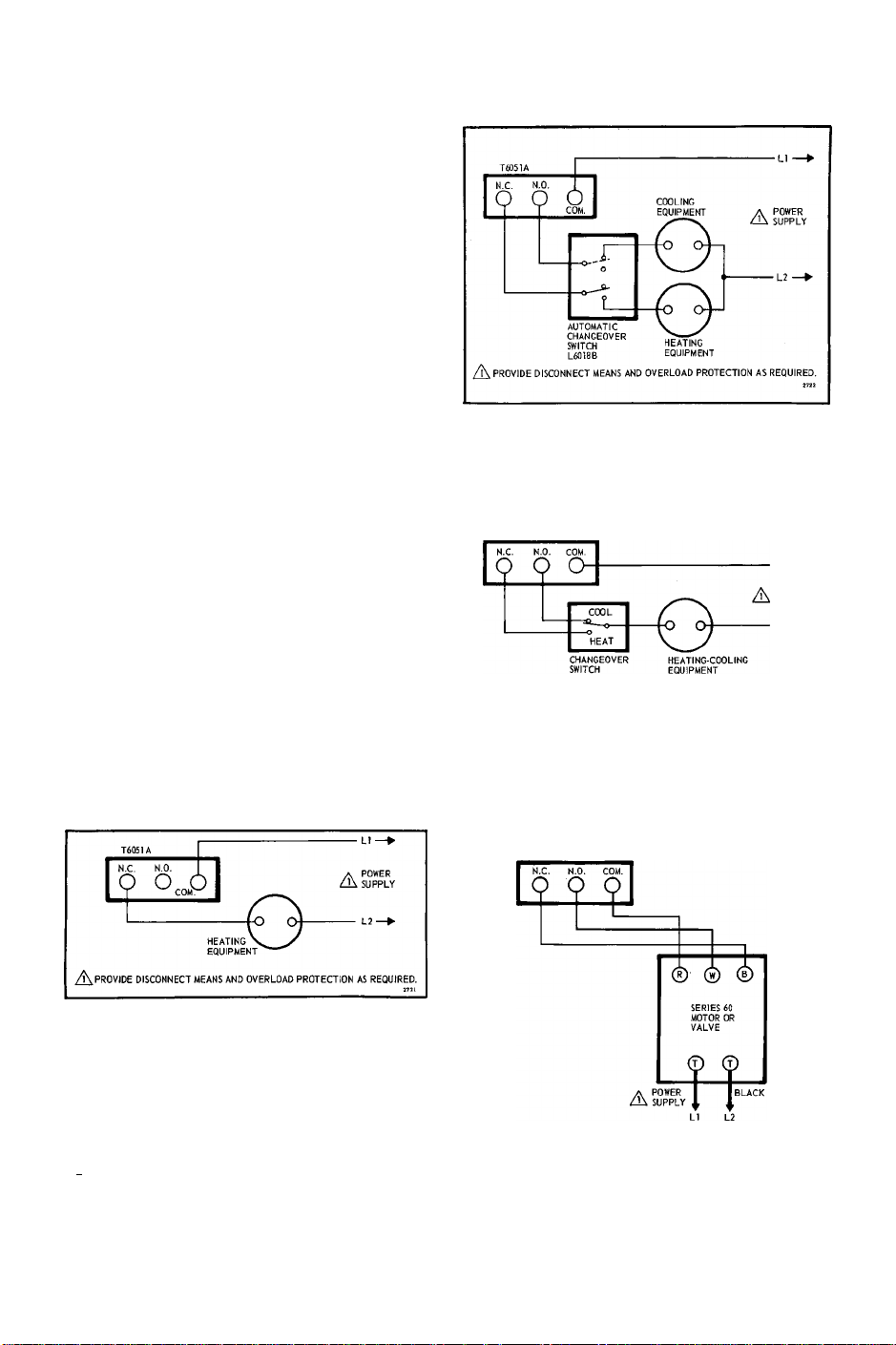

Fig. 5-T6051A heating-cooling control for separate

heating and cooling equipment.

/^PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 6—T6051 heating-cooling control with changeover

switch for combination heating-cooling

equipment.

POWER

SUPPLY

Fig. 3—T6051A used in heating only application.

N.C. N.O

O ‘

cooLmc

EQUIPMENT.O'

/i\ PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

A

POWER

Fig. 4—T6051A used in cooling only application.

SUPPLY

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

A

Fig. 7—T6051 used as a series 60 control. 3-wire, line

voltage, two position control.

Page

2

Page 3

POWER

SUPPLY

A

/К PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

Fig. 8--Typical hookup of T6052A to control two

stage heating system.

A\ PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

Fig. 9—Typical hookup of T6052A to control two

stage cooling system.

POWER

SUPPLY

A

POWER

SUPPLY

Each notch on the calibration mechanism represents

2,000 feet. If you are above sea level use the chart to

determine how far to move the indicator:

ALTITUDE CALIBRATION

This thermostat was calibrated at the factory for

accuracy at 1,000 feet above sea level. It may be nec

essary to reset the thermostat for the altitude of your

locality. If you do not know your altitude, consult your

local U.S. Weather Bureau or Public Library.

Elevation (in feet)

0 to 2,000

2,000 to 4,000

4,000 to 6,000

6,000 and above

OPERATION AND CHECKOUT

Indicator

Leave as is

Move down 1 notch

Move down 2 notches

Move down 3 notches

------------------------

After the thermostat is installed and wired, operate

it manually to make certain it is connected properly.

Checkout will depend on type of hookup and controlled

equipment. For cooling control check, turn the setting

knob to move the indicator down the scale. This ini

tiates a call for cooling and the cooling equipment

should respond. For heating control check, turn the

setting knob to move the indicator up the scale. This

initiates a call for heat, and the heating equipment

should respond. For heating/cooling control, check

both heating and cooling as described above. For

Series 60 control check, cycle the equipment through

A

the T6051A and make sure it functions as intended.

CAUTION

If the thermostat is controlling a compressor, allow

at least two minutes between on cycles to equalize

the internal pressure. Rapid cycling might damage

the compressor and overload the electrical circuit.

Д PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

Fig. 10—Typical hookup of T6052B to control heating

cooling system with auto changeover.

TO LOCK

After altitude adjustment is complete, replace the

cover and set cover screw with set point knob. With

the knob again in place, move the set point indicator

to the desired temperature setting. Remove the set

point knob to lock the set point.

Page

3

Page 4

WARRANTY “Utüess otherwise specified, the Company warrants all Residential Division equipment manufactured by It and bearing its nameplate to be free from defects in worhmandiip

and materials under normal use and service as follows:

1. Equipment which is received transportation prepaid at the factory originating shipment (1) within twelve months after date of manufacture, or (2) with a certification by the installer to be

within twelve months after date of installation, and found by the Company’s inspection to be defective in workmanship or materials within the guarantee, will be repaired or replaced at the

Company's option, free of charge and returned lovrest cost transportation prepaid. Premium transportation will be used at customer's request and expense;

2. If inspection by the Company does not disclose any defect covered by the guarantee, equipment will be repaired or replaced and the Company's regular service charge will apply;

3. WITH EXCEPTION OF THE FOREGOING AND UNLESS SPECIFICALLY EXPRESSED IN WRITING, THE COMPANY MAKES NO EXPRESS WARRANTIES, NO WARRAN’HES

OF MERCHANTABILITY AND NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE FACE HEREOF."___________________________________________

HONEYWELL MINNEAPOLIS, MINN. 55408 INTERNATIONAL Sales Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

Loading...

Loading...