Page 1

T4031A,B,P; T6031A,B

60-2177-3

Refrigeration Temperature Controllers

PRODUCT DATA

FEATURES

• Wide control temperature range is suitable for controlling ducts, tanks, freezers, coolers, display cases. and

defrost termination.

• Universal mounting bracket is available for easy

replacement of other controllers.

• Models are available with various control ranges.

• Control setpoint is dial-knob adjustable.

• Models are available with fixed or adjustable temperature differentials.

• Capillary lengths are 5, 8, or 20 ft (1.5, 2.4, 6.1m)

depending on model.

GENERAL

The T4031A,B,P and T6031A,B are temperature controllers

used in a variety of cooling applications where remote mounting

of the sensing element in the controlled medium is required.

• Reliable snap-acting spst or spdt switch.

• Ambient temperature compensated.

• Insert supplied with TRADELINE® models replaces

setpoint knob to discourage tampering.

Contents

General.................................................................................. 1

Features ................................................................................ 1

Specifications......................................................................... 2

Ordering Information .............................................................. 2

Installation ............................................................................. 3

Operation and Checkout ........................................................ 5

Copyright © 1995 Honeywell Inc. • All Rights Reserved

Page 2

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

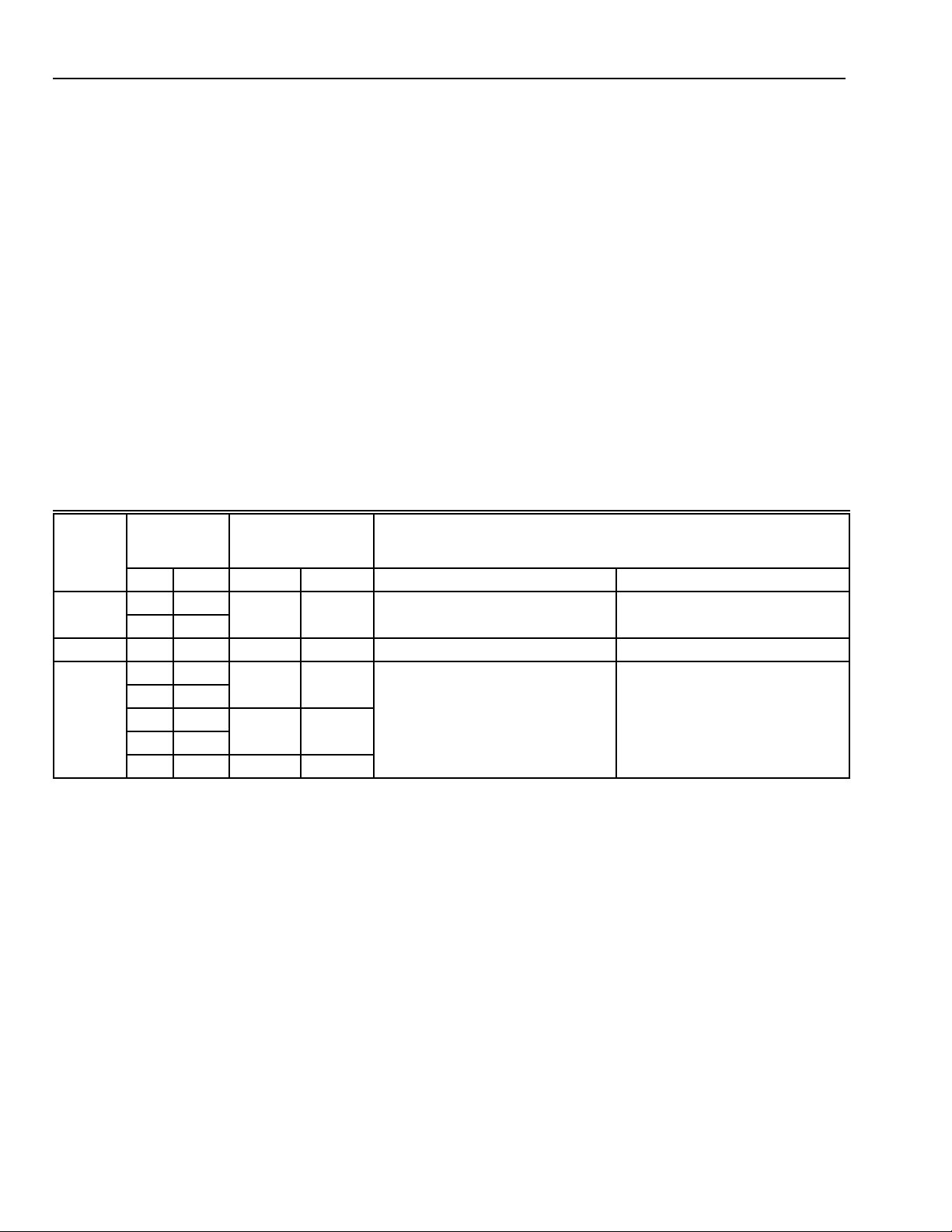

SPECIFICATIONS

IMPORTANT

TRADELINE® Models

TRADELINE® Model Available:

Capillary Lengths and Temperature Ranges:

T4031A,B 5 1.5 -30 to 50 -34 to 10 Fixed at 3.5 Fixed at 1.6

T6031A,B 5 1.5 -15 to +90 -9 to +32 Fixed at 3.5 or Adjust. from 3.5 to 12 Fixed at 1.6 or Adjust. from 1.6 to 7

a

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the specifications

listed. Also, this product is tested and calibrated under

closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

TRADELINE® models are selected and packaged to

provide ease of stocking, ease of handling, and maximum

replacement value. TRADELINE® model specifications are

the same as those of standard models except as noted

below.

T6031A Refrigeration Temperature Controller-spdt switch,

adjustable temperature differential, tamper-resistant insert.

Copper

Capillary

Tube Length Setting Range

Model ft m °F °C °F °C

20 6.1

T4031P 8 2.4 -30 to +90 -34 to +32 3.5 to 16 1.6 to 9

20 6.1

5 1.5 -30 to +50 -34 to +10

20 6.1

8 2.4 -30 to +90 -34 to +32

Dial scale markings in degrees Fahrenheit

a

Capillary Length:

8 ft (2.4m)

Additional Features:

TRADELINE® pack with cross reference label and special

instructions

Standard Models

T4031A Refrigeration Temperature Controller-spst switch

makes on temperature rise; fixed differential

T4031B Refrigeration Temperature Controller—same as

T4031A but less case

T4031P Refrigeration Temperature Controller—same as

T4031A but uses screw, not knob, to adjust setpoint

T6031A Refrigeration Temperature Controller-spdt switch,

fixed or adjustable temperature differential

T6031B Refrigeration Temperature Controller—same as

T6031A but less case

Switch Action:

T4031A,B,P spst switch makes R to W on temperature rise

T6031A,B spdt switch makes R to W on temperature rise,

R to B on temperature fall

Differential

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the

TRADELINE® catalog or price sheets for complete ordering number, or specify:

1. Order number. 4. Length of copper capillary tube.

2. Setting range. 5. Accessories, if desired.

3. Fixed or adjustable differential (T6031).

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Home and Building Control Sales office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International

Sales and Service Offices in all principal cities of the world.

60-2177—3

2

Page 3

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

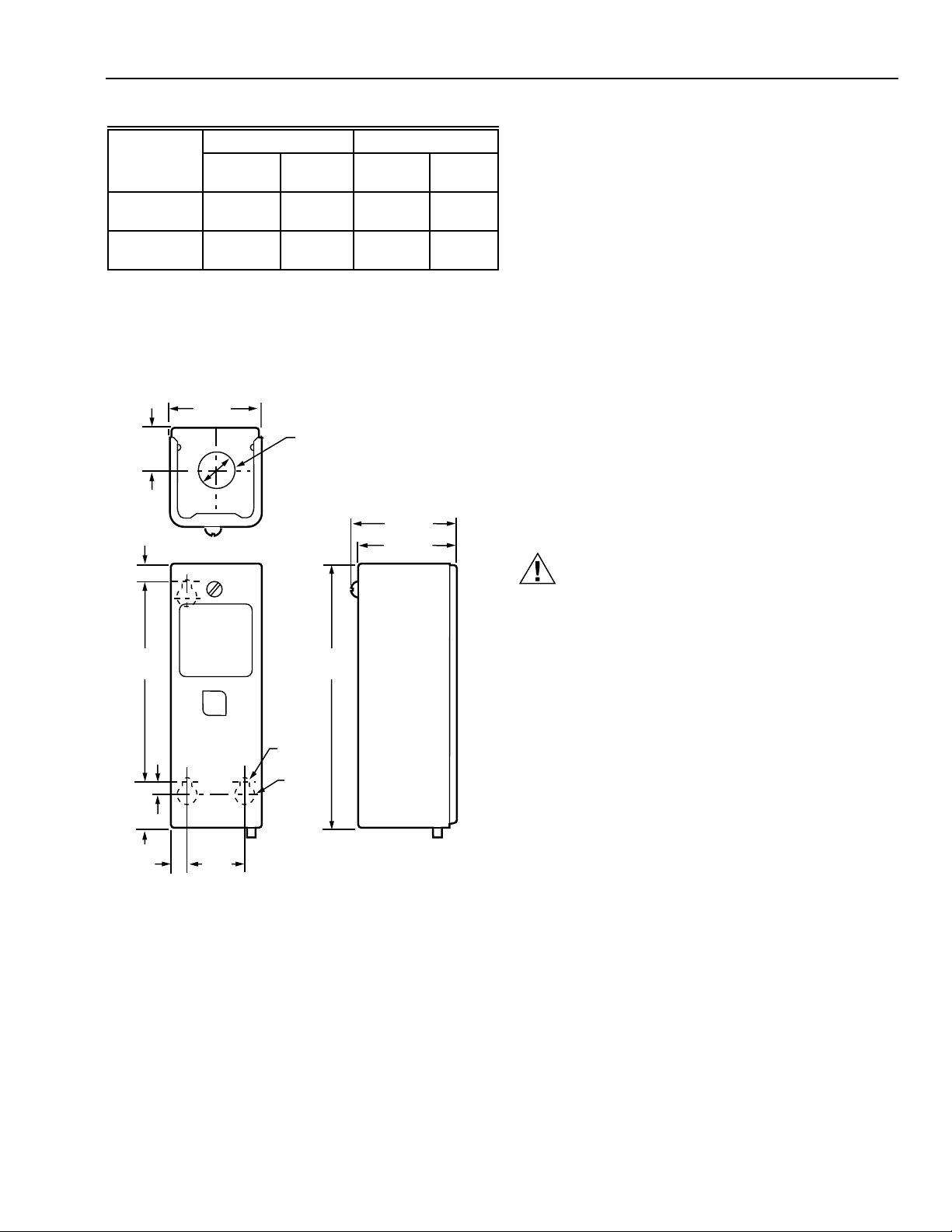

Electrical Ratings:

Normally

Closed

Full Load

8165.1 8

Amp

Locked Rotor

48 80 30.6 40

Amp

a

Makes on temperature rise.

Pilot Duty:

125 VA

Dimensions:

See Fig. 1

2 (51)

15/16

(24)

17/32

(13)

120 Vac 240 Vac

Normally

Open

KNOCKOUT FOR 1/2 IN. (13 MM)

CONDUIT (2)

a

Normally

Closed

2-1/4 (57)

2-1/8 (54)

Normally

Open

7617ABZ Bag Assembly—for mounting controller to fan coil

units

801534 Calibration Wrench

a

7640HY Standoff Bracket Bag Assembly—to mount

controller to an insulated duct

130883 Universal Mounting Bracket

194899 Tamper-resisting Insert Button

Celsius Scaleplates:

194486 D: -15°C to +35°C replaces (0°F to 100°F)

scaleplate

194486H: 15°C to 75°C replaces (55°F to 175°F)

194486F: 75°C to 125°C replaces (160°F to 260°F)

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation

as provided in these instructions.

4-3/16

(107)

29/32

(23)

3/8

(9)

7/32

(6)

1-3/16

(30)

7/32 (6)

DIA. (3)

3/8 (10)

DIA. (3)

5-5/8

(136)

Fig. 1. Dimensions of T4031, T6031 in in. (mm).

Underwriters Laboratories Inc.:

Listed

Maximum Ambient Operating Temperature:

125°F (52°C)

CAUTION

• Disconnect power supply before installation to prevent

electrical shock and equipment damage.

• Do not damage or change shape of capsule. Deformed capsule will cause calibration offset.

Mounting

Install controller in any convenient location. Make sure that the

sensing bulb reaches the system to be controlled. The ambient

temperature must not exceed 125°F (52°C) in the area where

the controller is installed.

Install the sensing element where it can sense the average

temperature. Avoid sharp bends or kinks in the capillary tubing

that can affect the accuracy of the controller. Carefully coil the

excess capillary tubing and leave it directly beneath the

controller.

M4496

The 130883 Mounting Plate furnished with TRADELINE®

models allows the control to be mounted in existing mounting

holes.

Duct Installation

Position the sensing bulb in the duct to sense the average air

temperature. Avoid mounting the bulb close to hot pipes,

cooling coils, etc.

Accessories:

112622AA Immersion Well—short-necked, 1/2 in. NPT,

copper

7617ABY Compression Fitting—50 psi water, 15 psi air

107324A Bulb Holder—for duct installation

105900 T-strap—for strapping bulb to pipe

The 107324A Bulb Holder is available for suspending the bulb

in a duct. See Fig. 2.

3

60-2177—3

Page 4

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

COMPOSITION

PACKING

M8970

Fig. 2. 107324A bulb holder.

To install duct:

1. Make a hole in duct wall to admit sensing bulb into

holder.

2. Using holder as template, mark and drill mounting holes.

3. Break off bulb holder to required length. (Be sure holder

is long enough to hold sensing bulb away from duct wall

and in freely circulating air.)

4. Place capillary tubing in bulb holder channel, with bulb at

inner end of holder. Pinch together top edges of channel

segments.

5. Insert assembled bulb and holder into duct, and fasten to

duct wall with screws supplied.

(SLIT)

PACKING NUT

Fig. 3. Compression fitting installation.

THREAD

SLOTTED WASHERS

ASSEMBLED

IN PAIRS:

BULB RETAINING

CLAMP

SENSING

BULB

BOILER PLUG

M4492

IMMERSION WELL

Tank Installation

The sensing bulb can be inserted directly into a tank using a

compression fitting; or the bulb can be inserted into an immersion well (order separately), which is screwed into a tank or

boiler.

Select a location where liquid of average temperature can

circulate freely around the sensing bulb.

Using Compression Fitting (Fig. 3)

1. Drain system. Screw boiler plug into properly sized and

threaded boiler or pipe tapping.

2. Place packing nut on capillary tubing.

3. Slide sensing bulb completely through boiler plug.

4. Place composition disc and the four slotted brass

washers on capillary tubing.

5. Slide assembly into boiler plug and tighten packing nut.

6. Refill system and check for leaks. Neatly coil excess

capillary tubing.

Using Immersion Well (Fig. 4)

1. Drain system. Screw the well into threaded fitting.

2. Refill system and check for leaks.

3. Insert sensing bulb into well until it bottoms.

4. Fit bulb retaining clamp over immersion well flange and

capillary tubing, and tighten screw.

CAPILLARY

WELL SPUD

M4493

Fig. 4. Immersion well installation.

Cold Room Installation

Locate the bulb in freely circulating air in the controlled area or

on the suction side of a refrigerant line, and secure the bulb in

position.

Wiring (Fig. 5)

All wiring must comply with local electrical codes and ordinances.

Two knockouts are provided, one at the top and one at the

bottom of the case for 1/2 in. conduit. Follow the wiring

instructions furnished with the heating or cooling system. For

replacement, make sure the new control is wired into the

system to operate the same as the old control.

TEMPERATURE FALL

2

B-R MAKES

TEMPERATURE RISE

R-W MAKES

60-2177—3

1

B

R

B TERMINAL ON T6031 CONTROLLERS ONLY.

1

AT SETPOINT MINUS DIFFERENTIAL SETTING.

2

W

M4494

Fig. 5. Wiring terminals on T4031 and T6031 temperature

controllers.

4

Page 5

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

OPERATION AND CHECKOUT

When the temperature at the sensing bulb rises above the

controller setpoint, a circuit is made between the R-W terminals. During a temperature fall, the R-W circuit breaks at the

setpoint temperature

minus

the switch differential. Controllers

with a B terminal break the B-R terminal circuit on a temperature rise to the setpoint. B-R makes again when R-W breaks on

a temperature drop. See Fig. 6.

For example, if a controller with a 3°F (1.7°C) differential is set

at 39°F (3.9°C), R-W makes when the bulb temperature rises to

39°F. Then during a temperature fall, R-W breaks when the

temperature drops to 35°F (1.7°C) (39°F minus the 3°F

differential [3.9°C minus the 1.7°C differential]).

On models with a B terminal, B-R makes when R-W breaks.

Then the temperature has to climb past the control differential

to the set point of 39°F (3.9°C) before the B-R circuit breaks

and the R-W circuit makes.

B R-WR-WB

CONTROL

39°F (4°C)

B-R MAKES

R-W BREAKS

B-R W B-R W

SWITCH ACTION ON

TEMPERATURTE RISE

SETPOINT

3.5°F (1.6°C)

DIFFERENTIAL

SWITCH ACTION ON

TEMPERATURE FALL

39°F (4°C)

35.5°F (2°C)

B-R MAKES

R-W BREAKS

M4495

Fig. 6. Operation of switch on temperature rise and fall.

SETTING

Set the controller to the system manufacturer’s recommended

settings, if available.

Temperature Setpoint Knob—Turn the knob on the front of the

case until the pointer indicates the temperature to be maintained in the controlled medium.

Screw—Insert a flatheaded screwdriver into the slot on the

shaft, which is located in the center of the scaleplate. Turn the

screwdriver clockwise to increase the temperature

control point. Turn the screwdriver counterclockwise to

decrease the temperature control point.

Adjustable Differential—With the cover off, turn the differential

adjustment wheel (marked 3-6-9-12°F) until the desired

differential is aligned with the notch in the frame. See Fig. 7.

Calibration

All controllers are carefully tested and calibrated at the factory

under controlled conditions. If the controller is not operating at a

temperature corresponding to the scale and differential setting,

verify that the bulb senses the average temperature of the

medium. If the temperature of the controlled medium is

changing rapidly, the differential will appear wider than its

setting.

TERMINAL SCREWS (3)

T6031 DIFFERENTIAL

ADJUSTMENT

Fig. 7. Internal view showing differential adjustment wheel

(applicable models).

For calibration, take an accurate temperature reading of the

controlled medium. Place an accurate thermometer near the

bulb of the controller, or refer to a thermometer installed as part

of the system. If the bulb of the controller is installed in an

inaccessible area, or if the controlled medium is unstable,

remove the bulb and place in a controlled bath for accurate

calibration.

These controllers are calibrated so the dial setting is the point

at which the R-W switch contacts make (B-R contacts break)

on a temperature rise. Measure the temperature at the bulb.

Rotate the dial counterclockwise from the top of the

scale, simulating a temperature rise, until the R-W switch

contacts make. Note the dial reading. If it differs from the

setpoint, calibrate the dial as follows:

1. Determine the number of degrees difference between the

set point and the point at which the contacts make.

2. Remove the dial knob and slip the fingers of the calibration wrench into the slots of the dial. Rotate the dial until

the fingers of the wrench drop into the slots of the

calibration nut under the dial. Note the dial indication at

this point. Turn the dial and the calibration nut up or down

scale the number of degrees that the set point differs

from the point at which the contacts make (determined in

step 1). For example, move the dial from 45 to 65

degrees for a 20 degree change in calibration.

3. Check the calibration adjustment by moving the dial up

and down the scale while watching the contacts make

and break. If dial is still out of calibration, repeat calibration procedure.

4. To install tamper-resisting insert on TRADELINE®

model, remove screw from adjustment knob, remove

knob, and install insert.

M4497

Fixed differential models are 3.5°F at midscale.

5

60-2177—3

Page 6

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

60-2177—3

6

Page 7

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

7

60-2177—3

Page 8

T4031A,B,P; T6031A,B REFRIGERATION TEMPERATURE CONTROLLERS

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the

literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including

attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Home and Building Control

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

60-2177—3 J.H. Rev. 5-95 Printed in U.S.A.

60-2177—3

Home and Building Control

Honeywell Limited-Honeywell Limitée

740 Ellesmere Road

Scarborough, Ontario

M1P 2V9

8

Helping You Control Your World

QUALITY IS KEY

www.honeywell.com/building/components

Loading...

Loading...