Page 1

T6031E-H,J,K Thermostats

PRODUCT DATA

T6031 Thermostats control heating or cooling systems, or act

as changeover thermostats.

• T6031E,F models are unit thermostats.

• T6031G,H,J, are changeover thermostats.

• T6031K models are refrigeration thermostats for use in

freezers, chillers, and display cases.

• Models with case mount through holes in the back of

the case.

• Models without case mount with front or back mounting

brackets.

• Enclosed switches resist the effects of dust and

moisture.

• Setpoint adjusts with knob or screw on front of thermostat.

T6031G.H,J,K T6031E,F

Copyright © 1995 Honeywell Inc. • All Rights Reserved

63-2118-3

Page 2

T6031E-H,J,K THERMOSTATS

SPECIFICATIONS

Models:

T6031E,F,G,H,J,K. See Table 1 and description that follows.

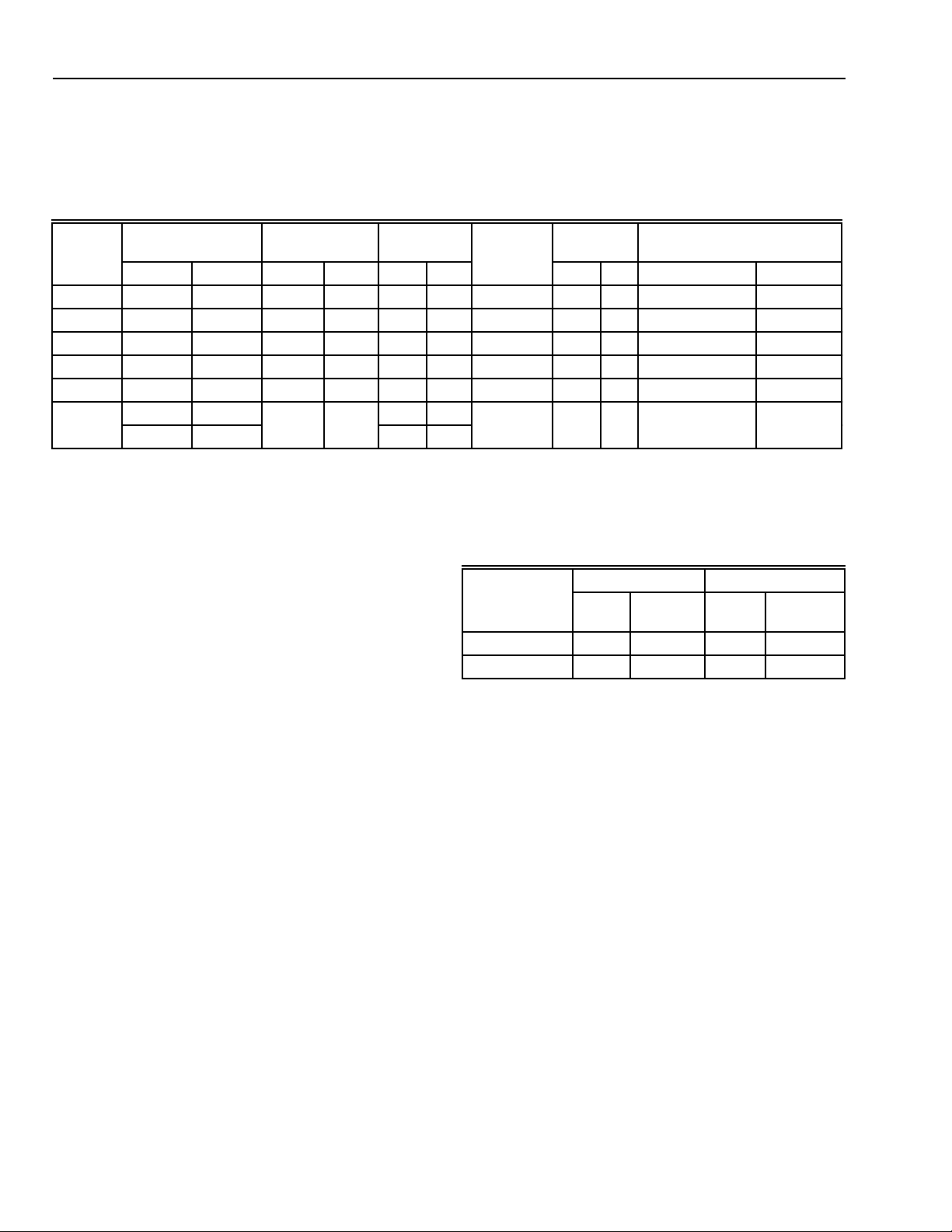

Table 1. Model numbers and description.

Model

Number

T6031E 55 to 90a13 to 3 2 150 66 1-1/2 1 enclosed 5-1/2 1.7 5/16 x 11-11/16 8 X 297

T6031F 55 to 90a13 to32 150 66 1-1/2 1 front 5-1/2 1.7 5/16 x 11-11/16 8 X 297

T6031G 0 to 90 -18 to32 155 68 2 — back 6-1/4 1.9 3/8 x 3 10 X 76

T6031 H 0 to 95 -18 to 35 150 66 3 2 back 2 0.6 3/8 x 3-1 /2 10 X 89

T6031J 55 to 85 13 to 29 205 96 5 3 enclosed 5-1/2 1.7 3/8 x 3 10 x 76

T6031K 15 to 75 -9 to 24 155 68 5 3 enclosed 5-1/2 1.7 3/8 x 3 10 x 76

a

Knob marked warmer-cooler.

Control Range

°F °C °F °C °F °C

-20 to 50 -29 to 10 2 1

Max. Element

Temperature Differential

Type of

Mounting

Capillary

Length Bulb Size

f t m in. mm

Models (also refer to Table 1):

T6031E Unit Thermostat: 1 light duty spdt switch; with base

and cover.

T6031F,G Unit Thermostat: 1 light duty spdt switch; without

case.

T6031G,H Changeover Thermostat: 1 standard spdt switch;

without case.

T6031J Changeover Thermostat: 1 standard spdt switch;

with case and cover.

T6031K Refrigeration Thermostat: 1 standard spdt switch;

with case and cover.

Terminals:

8/32 binder-head screws and cup-washers.

Electrical Ratings (A):

Switches—

Refer to

Model Used

Light Duty 3.2 19.2 1.6 9.6

Standard 8.0 48.0 5.1 30.6

T6031H,J,K: 0.25A at 1 /4V to 12 Vdc inductive load.

120 Vac 240 Vac

Full

Load

Locked

Rotor

Full

Load

Locked

Rotor

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the price

sheets for complete ordering number, or specify—

1. Model number 4. Optional specifications, if desired.

2. Scale range. 5. Accessories, if desired.

3. Mounting bracket on models without case.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Residential Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Satisfaction

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

(In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Road, Scarborough, Ontario M1P2V9)

International sales and service offices in all principal cities of the world.

63-2118—3

2

Page 3

M7525

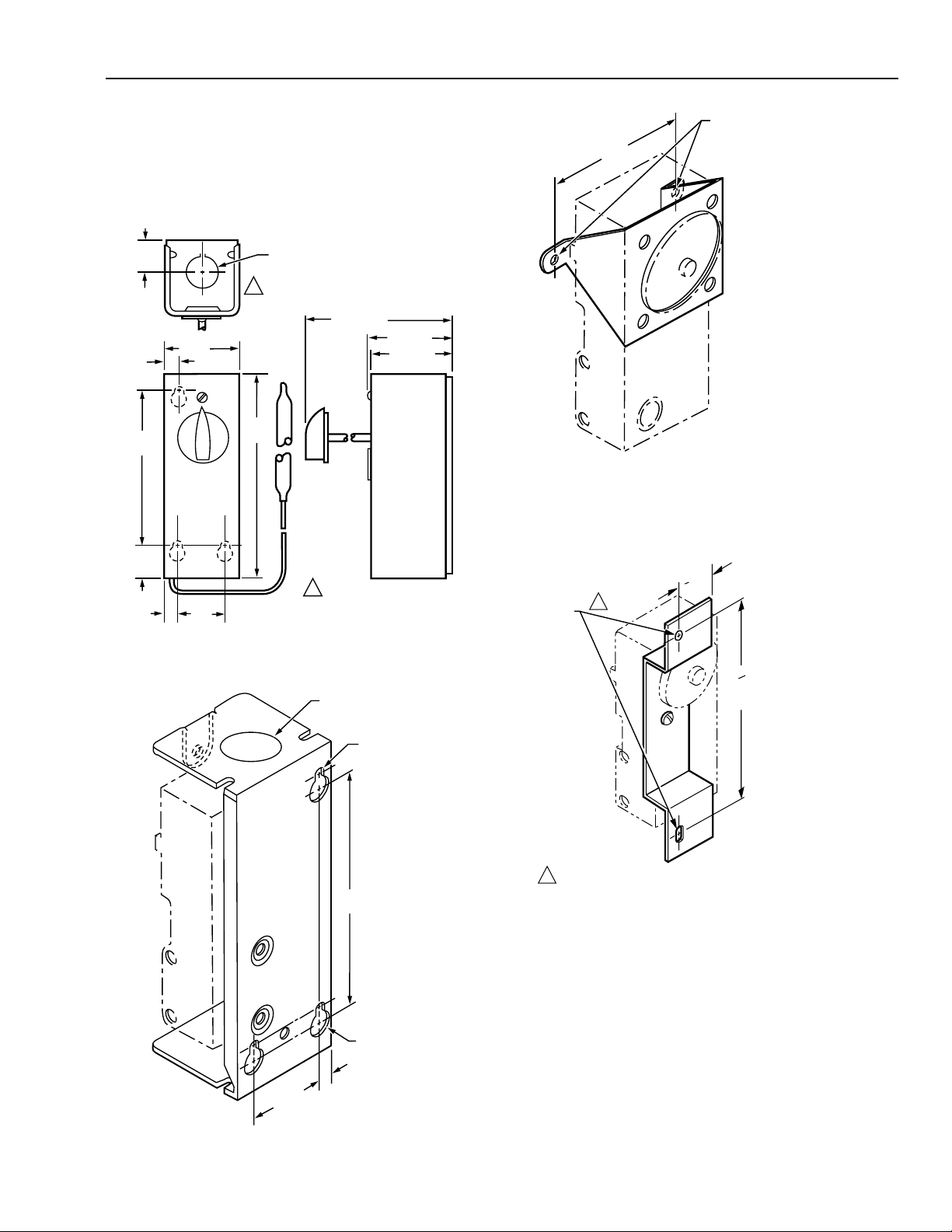

BRACKET DEPTH–1-11/16 (43)

OVERALL LENGTH–3-11/16 (94)

OVERALL DEPTH

(LESS SHAFT)–2-1/8 (54)

CLEARANCE BETWEEN

BRACKET AND BASE

OF DIAL–1/4 (6)

NO. 10-32 TAP (2)

2-1/4

(57)

Mounting Means:

ON THE 114496 BRACKET, THE MOUNTING HOLES ARE TWO

NO. 8-32 TAPPED HOLES. THE 107940 BRACKET IS MOUNTED

WITH A 5/32 (4) DIAMETER HOLE AT THE TOP AND A VERTICAL

5/32 X 5/16 (4 X 8) SLOT AT THE BOTTOM.

1

1

M9090

3

16

4

(106)

3

4

(19)

MOUNTING

HOLES

OVERALL LENGTH: 5 (127)

OVERALL DEPTH LESS

ADJUSTING DIAL SHAFT:

2-1/8 (54)

T6031E,J,K: holes in back of case.

T6031F,G,H: front or back mounting.

Dimensions:

Case: see Fig.1 and 2.

Models without case, including brackets: see Fig. 3 and 4.

T6031E-H,J,K THERMOSTATS

15/16

(24)

4-3/16

(106)

15/16

(24)

3/8

(10)

2 (51)

1-7/32

(31)

3/8 (10)

KNOCKOUT FOR

1/2 CONDUIT (BOTH ENDS)

1

5-5/8

(143)

1

4-7/16 (113)

2-1/4 (57)

2-1/8 (54)

TOP KNOCKOUT IS 7/8 FOR

ALL BUT T6031H ENCLOSED.

M7523

Fig. 1. T6031 mounting dimensions in in. (mm).

7/8 (22) DIA. KNOCKOUT

(BOTH ENDS)

Fig. 3. Front mounting bracket in in. (mm).

Fig. 2. Case mounting holes in in. (mm).

1-7/32

(31)

3/16 (5) DIA.

4-3/16

(106)

3/8 (10) DIA.

5/16 (9)

M7524

Fig. 4. Back mounting bracket in in. (mm).

Finish:

Gray.

Underwriters Laboratories Inc. listed:

T6031F-H: File E4436, Vol. 4, Guide XAPX2;

T6031E,J: File E4436, Vol. 4, Guide XAPX;

T6031K: File SA481, Vol. 1, Guide SDFY.

Accessories:

105900 Mounting Clamp for mounting element to a pipe; for

T60031G,H,J Changeover Thermostats.

3

63-2118—3

Page 4

T6031E-H,J,K THERMOSTATS

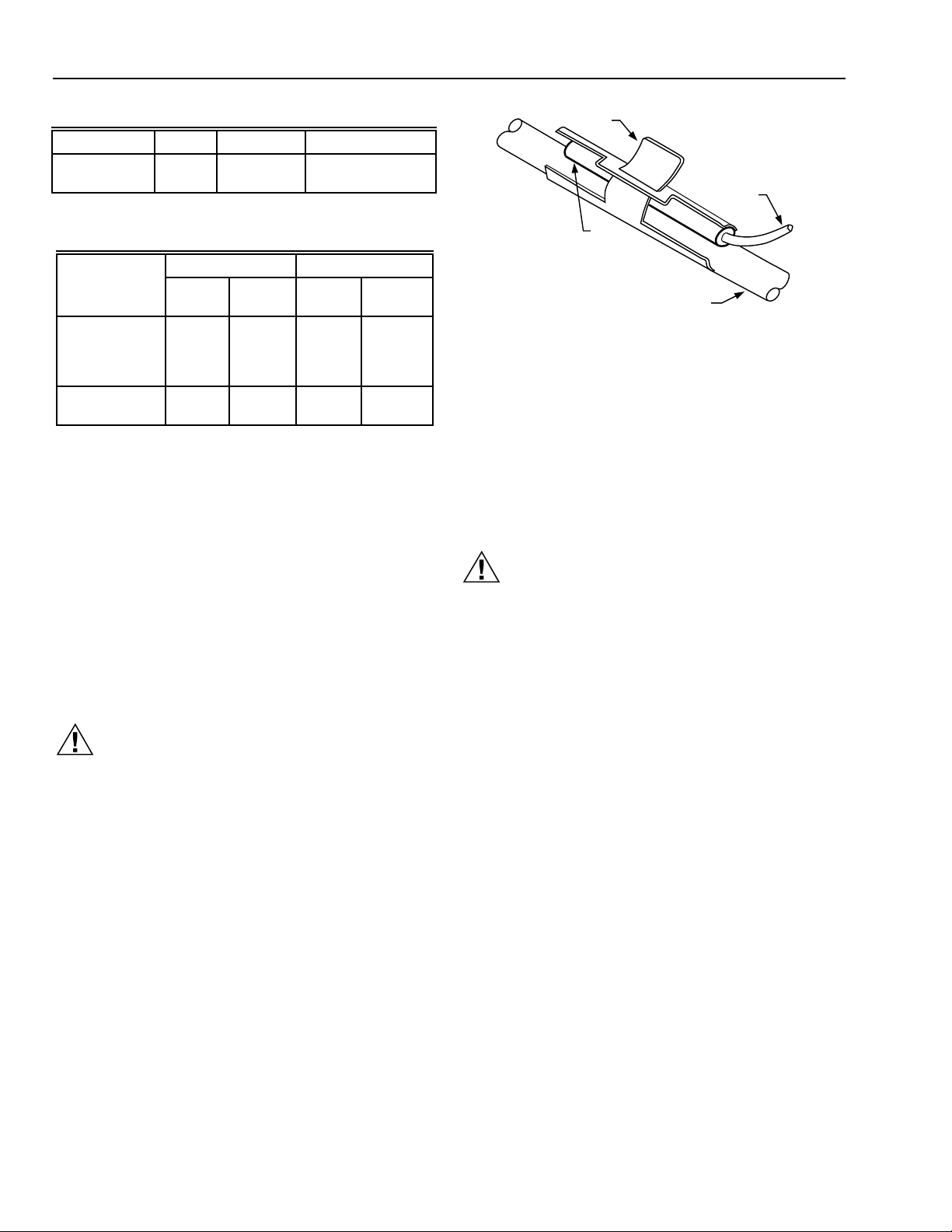

Compression fittings:

Bulb Size Brass Mild Steel Stainless Steel

Up to 1/2 in.

(127 mm) dia.

Waste nuts: for 1/2 in. NPT opening;

7617BF for 3/4 in. NPT opening.

Immersion well assemblies:

Bulb Size

3/8 x 3 in.

(9 5 x 76.2 mm)

(1-1/2 in. [38.1]

insulation)

(3 in. [76.2 mm]

insulation)

For additional information on accessory parts, refer to the

TRADELINE® Catalog.

7617M 7617Y 7617BE

Copper Stainless Steel

1/2 in.

NPT

121371A 121371B 121371E 121371F

121371L 121371M — —

3/4 in.

NPT

1/2 in.

NPT

3/4 in.

NPT

INSTALLA TION

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage product or cause a hazardous condition.

2. Check ratings given in instructions and on product to

make sure product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product operation

as provided in these instructions.

CA UTION

Disconnect power supply before beginning installation

to prevent electrical shock and equipment damage.

T-CLAMP

CAPILLARY

TUBING

BULB

SUPPLY WATER PIPE

Fig. 5. Bulb strapped to supply water pipe with 105900

T-clamp.

M8836

Mounting Sensing Elements

T6031E,G,H models—install bulb in return airflow.

T6031G,H,J models—install bulb in water supply where water

of average temperatures circulates around it The bulb may be

strapped to a water pipe using a 105900 Clamp (see Fig. 5) or

as follows:

1. Secure controller bulb to pipe with duct hanger wire or

metal hose clamps (Fig 6. top).

CA UTION

Do not over tighten clamps to point of distorting sensor

bulb. Over tightening clamps will cause a significant

shift in bulb calibration

(Steps 2 and 3 are optional and are to be used when large

fluctuations in the ambient temperature occur near the pipe)

2. Cover bulb and pipe with foam rubber insulation extending at least 6 in. (152 mm) beyond both ends of bulb (Fig.

6, bottom).

3. Secure foam rubber with duct tape. DO NOT ALLOW

DUCT TAPE TO CONTACT PIPE.

Location and Mounting

T6031 Thermostats mount either vertically or horizontally on a

wall or panel. The remote bulb can be located as far from

controller as capillary tubing allows. The bulb should be located

where it senses the average temperature of the medium to be

controlled.

63-2118—3

4

Page 5

T6031E-H,J,K THERMOSTATS

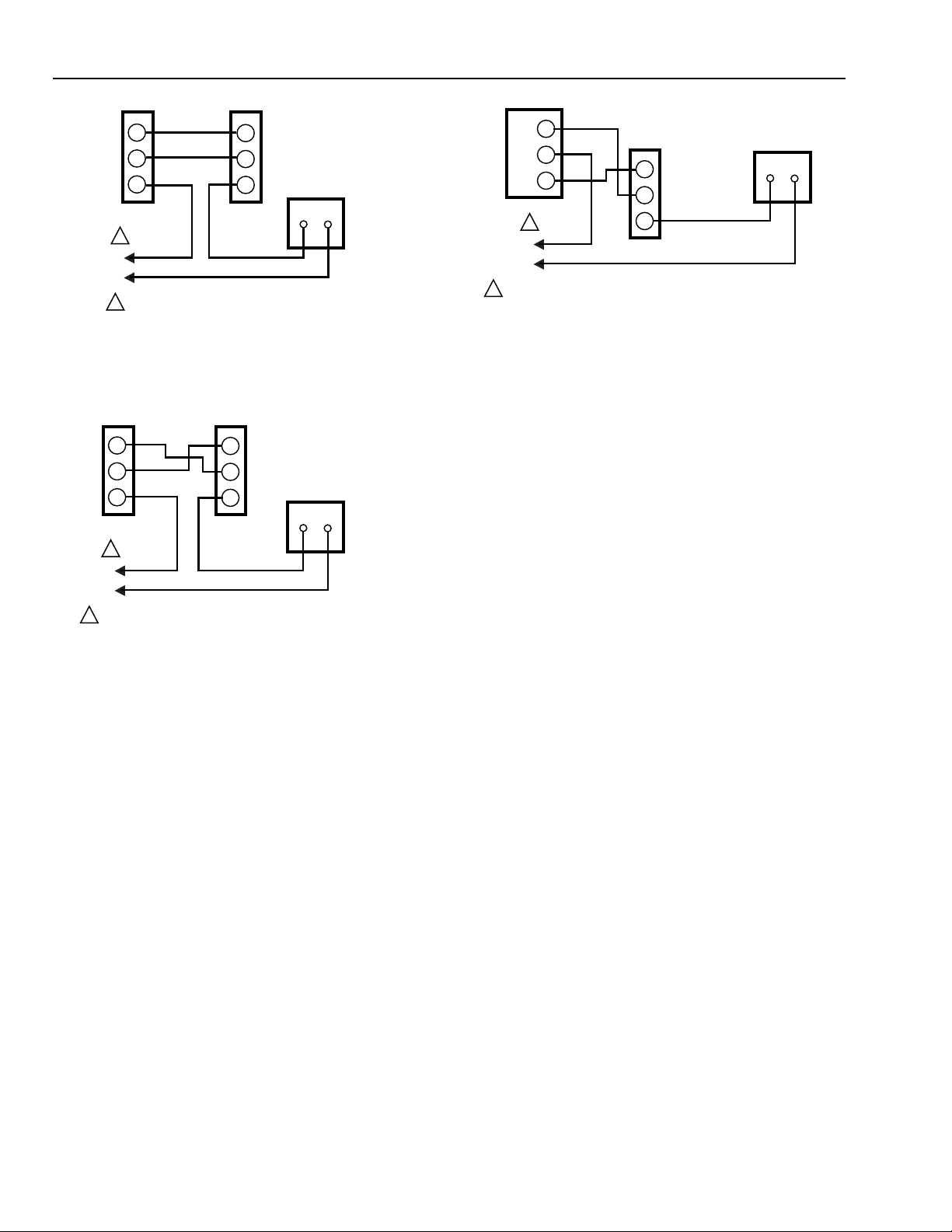

SET POINT

FOR T6031H

SET POINT

SWITCH

DIFFERENTIAL

TEMPERATURE

RISE

R AND W LOCATIONS

DEPEND ON MODEL

AND CONSTRUCTION

W

B

R

BREAKS R-B;

MAKES R-W

ON RISE

MAKES R-B;

BREAKS R-W

ON FALL

M9089

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

W

W

W

B

B

B

R

R

R

W

B

R

T

T

T6031E,F UNIT

THERMOSTAT

T678C CHANGEOVER

THERMOSTAT-ELEMENT

ON SUPPLY WATER PIPE

V2045/V5045

RADIATOR

VALVE

M7538

BULB STRAPPED TO PIPE

CAUTION

DO NOT OVERTIGHTEN CLAMPS TO AVOID SENSOR

BULB DISTORTION. OVERTIGHTENING CLAMPS

MAY CAUSE A SIGNIFICANT SHIFT IN CALIBRATION.

APPROX. 3 FT

(0.9 M)

CAPILLARY

TUBE

DUCT HANGER WIRE OR

METAL HOSE CLAMPS

FOAM TAPED OVER STRAPPED BULB (OPTIONAL)

CAPILLARY

TUBE

DUCT TAPE

FOAM RUBBER WRAP

(EXTENDS 6 in. (152 mm)

BEYOND ENDS OF SENSOR)

WIRING

Disconnect power supply before connecting wiring to prevent

electrical shock and equipment damage. All wiring must comply

with local codes and ordinances.

When wiring, refer to wiring diagrams furnished with system

equipment and to Fig. 7 through 11.

T6140 BULB

PIPE

PIPE

M8835

Fig. 6. Strap-on mounting of T6031 bulb on a boiler

discharge pipe.

Mounting Controller

Models With Case

1. Loosen the captive mounting screw above the dial on the

face of the thermostat and remove cover (On models

with adjustment knob, remove knob first by loosening the

setscrew.)

2. Fasten case to wall or panel through mounting holes in the

back of case with furnished screws. (See Fig.1 and 2.)

3. Run tubing through the most convenient of the four

corner notches in case. Do not bend tubing so sharply

that flow is restricted. Leave excess tubing coiled near

the thermostat.

4. Make wiring connections according to instructions in the

WIRING section.

5. Replace cover, careful not to not pinch tubing. Tighten

cover mounting screw.

Models Without Case

Front or back mounting brackets are available. See Fig. 3 and 4

for mounting information and dimensions.

Fig. 7. T6031 switch terminal arrangement and switching.

Fig. 8. Typical hookup for T6031E,F with T678C

changeover thermostat controlling V2045/V5045 Valve on

5

both heating and cooling cycles.

63-2118—3

Page 6

T6031E-H,J,K THERMOSTATS

T6031F UNIT

THERMOSTAT

W

B

R

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

T6031G,H CHANGEOVER

THERMOSTAT

W

B

MOTORIZED OR SOLENOID

VALVE IN WATER SUPPLY

R

TO UNIT CONTROLLER

M7539

Fig. 9. Typical hookup for T6031F with T6031G,H

changeover thermostat controlling N.O. Valve on both

heating and cooling cycles.

T6031F UNIT

THERMOSTAT

W

B

R

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

T6031G,H

CHANGEOVER

W

THERMOSTAT

B

MOTORIZED OR SOLENOID

VALVE IN WATER SUPPLY

TO UNIT CONDITIONER

R

M7540

Fig. 10. Typical hookup for T6031F unit thermostat with

T6031G,H changeover thermostat controlling motorized or

solenoid valve on both heating and cooling cycles.

T6051 HEAVY–DUTY

1

THERMOSTAT

T6031J

CHANGEOVER

W

THERMOSTAT

B

R

SOLENOID

OR FAN

M7541

N.O.

COM

N.C.

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

Fig. 11. Typical hookup for T6031J changeover thermostat

used with T6051 line voltage thermostat to control N.O.

valve or fan on both heating and cooling cycles.

OPERA TION AND CHECKOUT

After the T6031 is installed and wired into the system, check

controller action by raising the temperature set point about 10°F

(5.6°C) above room temperature. Heating equipment should

stop or cooling equipment should begin operation, depending

on the application. Lower setpoint below room temperature.

Heating equipment should begin operation or cooling equipment should stop, depending on application.

For questions about installation, operation, or checkout of this

equipment, contact your distributor or local Honeywell representative.

63-2118—3

6

Page 7

T6031E-H,J,K THERMOSTATS

7

63-2118—3

Page 8

T6031E-H,J,K THERMOSTATS

Home and Building Control

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Home and Building Control

Honeywell Limited-Honeywell Limitée

740 Ellesmere Road

Scarborough, Ontario

M1P 2V9

63-2118—3 J.H. Rev. 4-95 Printed in U.S.A. www.honeywell.com

63-2118—3

8

Loading...

Loading...