Page 1

68-0151-1

GENERAL

T4800A Precision Electronic

Electric Heating Thermostat

PRODUCT DATA

FEATURES

• CSA Certified and Performance Certified, Underwriters

Laboratories Inc. Listed. Conforms to NEMA standard

DC3 for thermostat accuracy.

• Rugged, molded thermoplastic mounting base with

captive mounting screws.

• Energy efficient and economical.

•Patented electronic switch requires no leveling.

• High sensitivity, solid-state temperature sensing

element.

• Nonpolarized leadwire connections.

• Adjustment range is 40° to 80°F (5° to 25°C).

• Premier White® finish.

• One-piece decorative cover.

• Red LED status indication.

• Suitable for noninductive rated fan-forced heaters,

radiant cable or convectors.

The T4800A Electric Heating Thermostat provides precise,

accurate line voltage control of resistance-rated heating

equipment. A patented Cool Switch™ design activates the

heating circuit on temperature fall and results in longer life for

the thermostat.

CONTENTS

General ............................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Installation ........................................................................... 3

Setting and Checkout .......................................................... 4

Operation ............................................................................ 4

Copyright © 1996 Honeywell Inc. • • All Rights Reserved

Page 2

T4800A PRECISION ELECTRONIC ELECTRIC HEATING THERMOSTAT

SPECIFICATIONS

IMPORTANT

The Specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions, and

some minor differences in performance can be

expected if those conditions are changed. For exact

engineering specifications, contact your Honeywell

sales representative.

TRADELINE® Models

TRADELINE® models are selected and packaged to provide

ease of stocking and handling and also maximum

replacement value. TRADELINE® model specifications are

as follows:

Model:

T4800A makes heating circuit on temperature fall. Single

pole, single throw. (See Fig. 2.) Range: 40° to 80°F (5° to

25°C).

Type of Switching:

Cool Switch Triac/relay combination.

Accuracy: 1°F (0.5°C) droop average for range of loads.

Conforms to NEMA DC3 standard applied to low voltage

thermostats.

Setpoint Adjustment:

Control knob on front of thermostat.

Sensing Element:

Electronic thermistor.

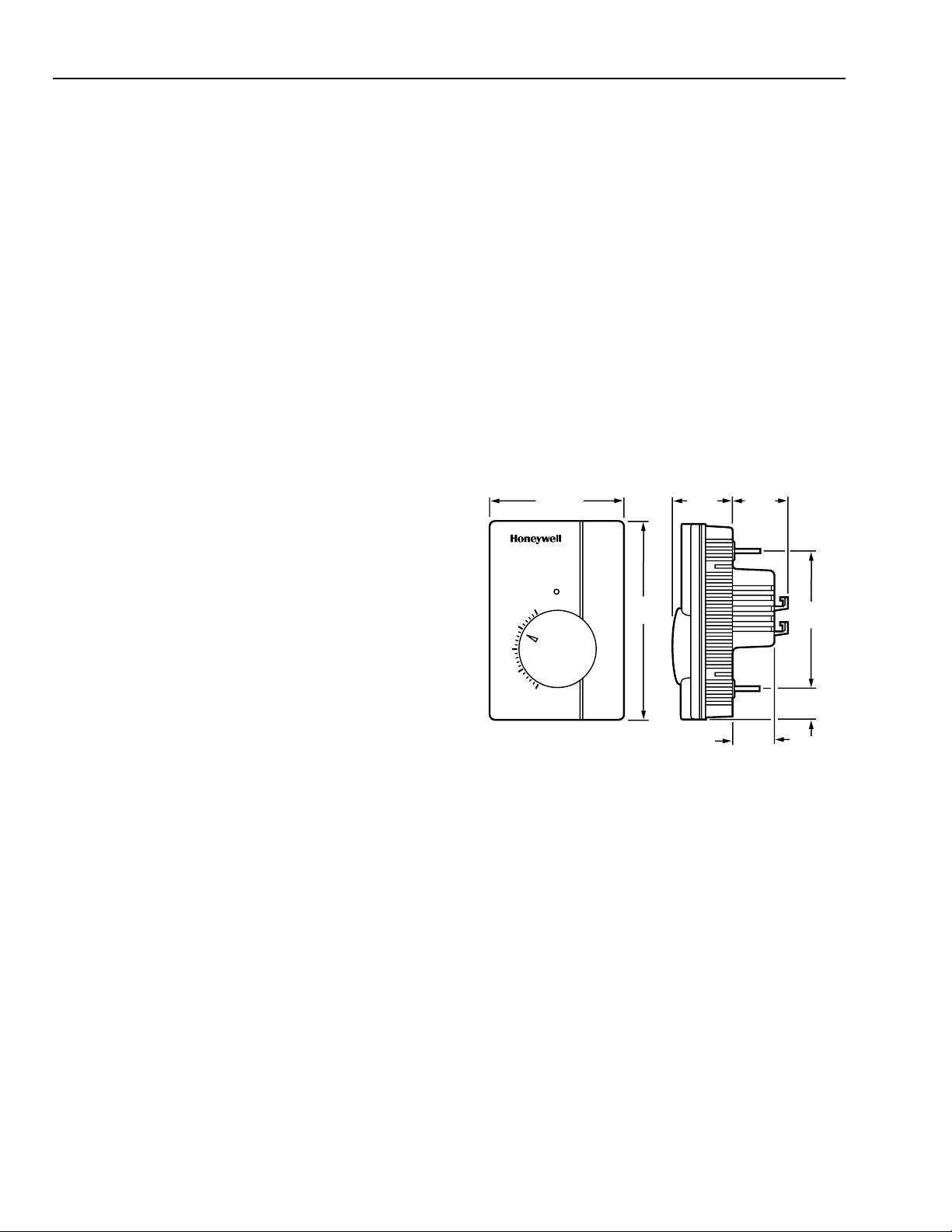

Dimensions:

See Fig. 1.

Red LED Indicator:

Lights as heat comes on.

Mounting Means:

Mount directly on vertical 2 x 4 inch outlet box, or on

4 x 4 inch outlet box with ring adapter (ordered separately).

Approvals:

CSA certified: LR1322.

Underwriters Laboratories Inc. Listed: File No. E47434,

Guide No. XAPX.

3-1/8 (80) 1-5/16

(34)

1-5/16

(34)

Wiring Connections:

6 in. (150 mm) stranded copper leadwires, suitable for

connecting to aluminum wiring when approved special

service CO/ALR solderless connectors are used.

Electrical Rating:

Noninductive (resistive) rating:

2.7A minimum (750W @ 240V; 560W @ 208V) to

16A maximum (3800W @ 240V; 3300W @ 208V)

80

70

60

50

40

°F

4-3/4

(120)

3-1/4

(82)

3/4

(19)

Performance Certification:

16A at 208 or 240 Vac.

Performance Specifications:

Fig. 1. Nominal dimensions in in. (mm).

7/8 (23)

M7102

Precision: ±1°F (0.5°C) differential with thermistor time

constant of 10 seconds.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number or specify

1. Model number

2. Voltage.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Honeywell Customer Relations

Honeywell, 1885 Douglas Drive North

Golden Valley, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Dr, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0151—1

2

Page 3

T4800A PRECISION ELECTRONIC ELECTRIC HEATING THERMOSTAT

M7103

L1

(HOT)

L2

L1

T1

1

2

4

3

SOLDERLESS

CONNECTORS

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

USE SPECIAL SERVICE CO/ALR SOLDERLESS CONNECTORS

WHEN CONNECTING ALUMINUM CONDUCTORS OR A FIRE

HAZARD MAY RESULT.

BREAKS HEATING CIRCUIT ON A TEMPERATURE RISE.

USE A SEPARATE LIMIT CONTROL IN THE HEATING APPLIANCE.

1

2

3

4

T4800A

ELECTRIC

HEATER

BLACK

BLACK

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do

not

place your old

control in the trash.

Contact your local waste management authority for

instructions regarding recycling and the proper

disposal of your old control.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow these

instructions could damage the product or cause a

hazardous condition.

2. Check the ratings on the product to make sure the

product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

HIGH VOLTAGE CONTROL.

ELECTRICAL SHOCK HAZARD.

Follow local codes and ordinances when installing this

thermostat. Improper handling may cause serious

injury or death.

CAUTION

1. Disconnect power supply to prevent electrical

shock or equipment damage.

2. If connecting with aluminum conductors, use

CO/ALR solderless wire connectors to avoid fire

hazard.

Replacement Applications

쐃 Disconnect power to the thermostat to prevent electrical

shock or equipment damage. All wiring must comply

with local electrical codes and ordinances.

쐇 Remove the old thermostat from the wall, taking care

not to damage the wiring insulation.

쐋 Check the old wire insulation for cracks, nicks or

fraying. Apply approved electrical tape to insulate wires

or replace wires as necessary.

쐏 Carefully remove thermostat cover by gently lifting at

top edge with a flathead screwdriver. Using wire

connectors approved for No. 12 wires, make line

voltage connections directly to leadwires on thermostat.

See Fig. 2 for typical wiring connections. Be sure all

wiring connections are tight.

쐄 Prebend and push solid wires into the outlet box.

쐂 Secure the thermostat on the outlet box by tightening

the two mounting screws. (Rotate control knob to more

easily access lower mounting screw.)

쐆 Snap thermostat cover in place.

New Applications

쐃 Disconnect power to the thermostat to prevent electrical

shock or equipment damage. All wiring must comply

with local electrical codes and ordinances.

쐇 Carefully remove thermostat cover by gently lifting at

top edge with a flathead screwdriver. Using wire

connectors approved for No. 12 wires, make line

voltage connections directly to leadwires on thermostat.

See Fig. 2 for typical wiring connections. Be sure all

wiring connections are tight.

쐋 Prebend and push solid wires into the outlet box.

쐏 Secure the thermostat on the outlet box by tightening

the two mounting screws. (Rotate control knob to more

easily access lower mounting screw.)

쐄 Snap thermostat cover in place.

Location

Install a vertical outlet box, which is used to mount the

thermostat on, about 5 ft (1.5m) above the floor in an area

with good air circulation at room temperature.

Do not install the thermostat where it may be affected by:

— drafts or dead spots behind doors, in corners or under

cabinets.

— hot air from convectors.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

Wiring and Mounting

CAUTION

1. Handle the thermostat with care to avoid damage.

2. Use a separate limit control in the heating

appliance.

3. Do not short 208 or 240 volt supply wires with

thermostat. This will damage the T4800 and void

the warranty.

Fig. 2. Typical wiring connections for T4800A.

3

68-0151—1

Page 4

T4800A PRECISION ELECTRONIC ELECTRIC HEATING THERMOSTAT

SETTING AND CHECKOUT

IMPORTANT

Make sure that all wiring connections are secure

before beginning checkout.

After the thermostat has been installed and powered up,

simulate normal operation as follows:

쐃 Tu rn control knob all the way clockwise . LED

should light and electric heater should start to warm up.

쐇 Tu rn knob all the way counterclockwise . LED

should go off, the power circuit should be broken and

electric heater should start to cool.

NOTE: The T4800 has a load-responsive time delay

to reduce equipment wear, which makes the

mechanical switching differential appear wider,

the faster the knob is rotated. This time delay

does not affect the thermal operation of the

T4800.

쐋 Allow thermostat to operate for several hours to

determine appropriate temperature setting. Adjust the

setting as necessary, moving the knob only one or two

degrees at a time. The precise temperature control of

the T4800 allows the user to select a lower temperature

setting, which saves energy while maintaining comfort.

OPERATION

The T4800 Thermostat provides precise temperature control

with minimum droop of resistance-rated electric baseboard

heating equipment. The T4800 controls room temperature

within 1°F (0.5°C) for average baseboard heater loads.

Electric heat thermostats are often affected by the heat

generated in the control. Temperature control points may vary

or droop 2° to 4°F (1° to 3°C) depending on the load demand.

Temperature settings are adjusted to offset this. The T4800

provides precise control with minimum droop. This allows

better control of room temperatures from day to night and

season to season while saving energy.

The development of this technology was assisted by the electric power industry of the United States under the sponsorship of

EPRI, the Electric Power Research Institute.

Automation and Control Solutions

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

68-0151—1 C.B. Rev. 4-96 Printed in U.S.A.

68-0151—1

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario

M1V 4Z9

Printed on recycled paper containing at

4

least 10% post-consumer paper fibers.

Loading...

Loading...