Page 1

Direct-acting Pressure Reducer RMG 213 (D 36 Hb)

RMG 213.20

OPERATING AND MAINTENANCE INSTRUCTIONS /

SPARE PARTS Version 11/2011

Serving the Gas Industry

Worldwide

Page 2

Contents Page

1. General information 3

1.1 Safety information 3

2. Specific operating instructions 4

3. Specific maintenance instructions 4

3.1 Lubricants 4

4. Spare parts

4.1 Spare parts drawing 5

4.2 Spare parts list 6, 7

4.3 Parts for maintenance purposes 8

213.20 p.02

Page 3

Note

1. General information

All persons involved with the assembly, operation and / or maintenance of the pressure reducer RMG 213 must

read and understand all of the following documents:

- Technical product information 213.00 – this RMG document contains the technical data and dimensions of

the equipment as well as instructions concerning construction and mode of operation.

- General operating manual for gas pressure regulators and safety devices – this RMG document contains

information on assembly and operation as well as general information on troubleshooting.

- Operating and maintenance instructions, spare parts 213.20 – this RMG document contains more

detailed information on assembly and operation of the pressure reducer RMG 213.

There are national laws and regulations for all sorts of jobs on gas pressure governors, from planning to

maintenance. Be sure to comply. (In Germany, for instance, DVGW work sheets G 600, G 459/II, G 491

and G 495.)

Inspection and maintenance intervals depend mostly on operating conditions and the nature and properties of

the gas. There are no general rules or recommendations for intervals. For Germany, we recommend to

consider maintenance intervals as stated in DVGW work sheet G 495 in a first instance. However, in the

mid-term, intervals must be adapted to the requirements of each specific equipment.

During maintenance, components must be cleaned and then checked thoroughly. This is necessary even if

there have not been any unusual observations during operation and / or functional testing. Checks must focus,

in particular, on diaphragms and seals and all movable parts and their respective bearings. Any and all

defective parts must be replaced with new ones. The same applies to O rings removed during disassembly.

Do not use any spare / wear parts and / or oils & lubricants not specifically recommended in the RMG

operating and maintenance instructions for spare parts. In the event spare / wear parts and / or lubricants &

oils other than those specifically recommended are used, RMG shall not be held liable for any defects and / or

consecutive damages attributable to such use of illegal parts, lubricants, oils etc.

Item numbers mentioned in the specific operating and maintenance instructions correspond with the numbers

in the spare parts lists and drawings.

Some parts in the lists and drawings are marked with a letter "W". We recommend to always have a reserve of

those parts in stock for maintenance purposes. Those spare parts are put together in another separate list at

the end of the spare parts list.

1.1 Safety information

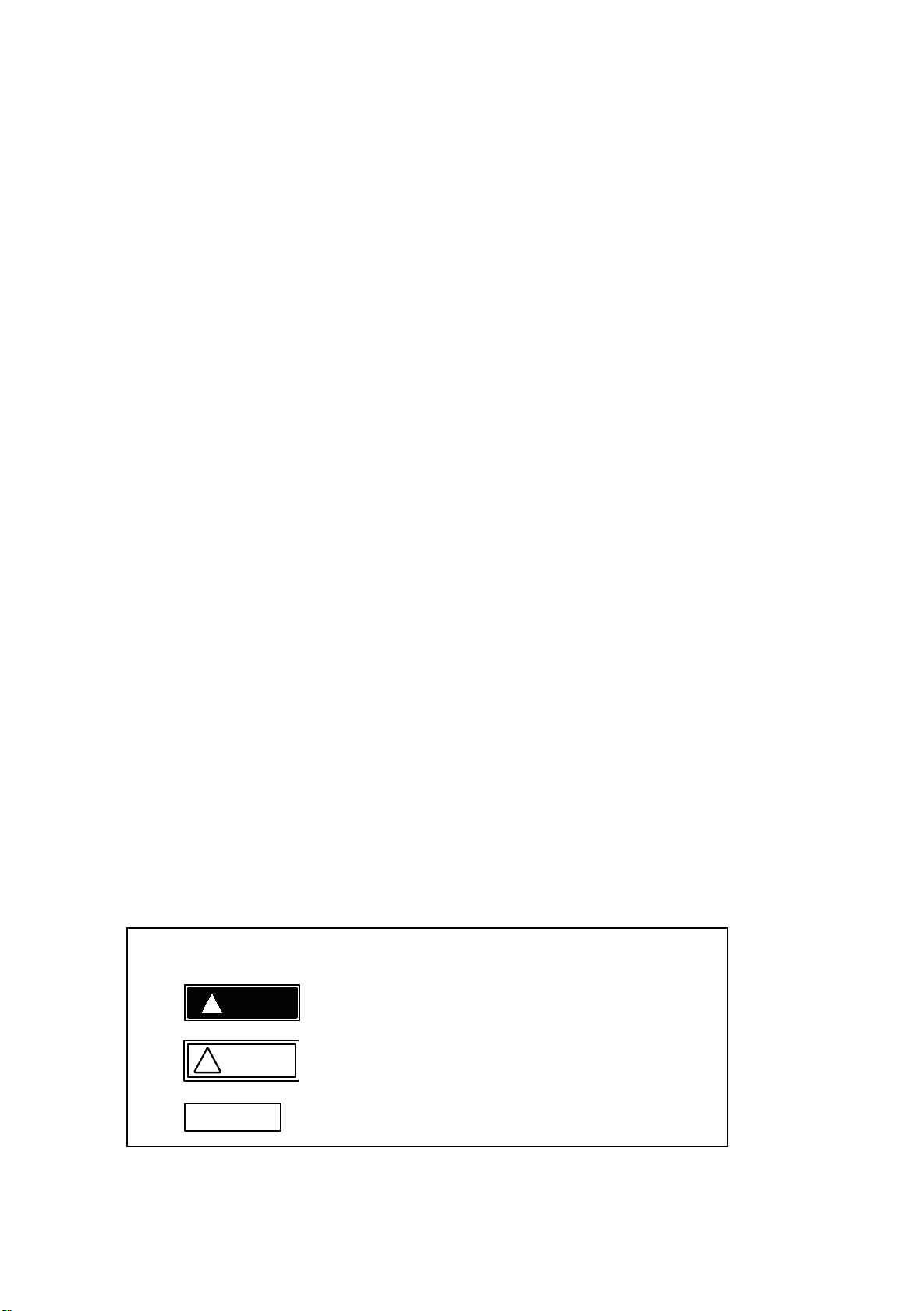

In this manual, safety information is highlighted by means of the following signal words and eye catchers:

Eye catcher Used for:

Danger

!

Danger to life and limb

Caution

!

Danger of damage to property and/or

the environment

Important additional information

213.20 p.03

Page 4

2. Specific operating instructions

Note

Control deviations

•

Admissible control deviations / offsets are design-related and may be due to the

- effect of the inlet pressure (see table in 213.00 or RMG booklet)

- spring's dependence on the flow rate (see table 213.00 or RMG booklet)

- flow resistance inside outlet channels - which increases with higher volumes.

Bubble-tight shut-off

•

The devices are equipped with shut-offs with plastic seals. That means they close at zero flow.

3. Specific maintenance instructions

Piston (15)

•

The shut-off piston (157) can be removed by removing the upper shut-off screw (11).

3.1

Internal parts

•

- Internal parts are accessible by removing the cap (6) on the bottom side of the device.

- Internal parts must not be damaged and must move easily. The measuring diaphragm must not be

damaged / bulged due to the effect of the gas.

When you re-install the cap, be sure not to tighten too much. The diaphragm must not be

squeezed more than about a millimetre. That's perfectly sufficient to prevent leaks.

Lubricants

Components Lubricants RMG part no.

All fastening screws and

screwed pipe connections Assembly paste 27091

213.20 p.04

Page 5

A

4.1 Spare parts drawing

Section A

Safety outlet

B

Partial section B

Safety outlet E10L

20

21

22

23

24

25

26

W 3

W 4

10

1

2

5

6

7

8

9

11

12

13

14

15 W

16

17

18

19

31, 32

27

W 28

29

30

33

W Parts should be held in stock for maintenance purposes.

213.20 p. 05

Page 6

4.2 Spare parts list RMG 213

Item Part no.

no. Denomination

1 Casing 1 10016570 10016570 10016570

2 Pressure spring 1 NFSt 10016863 10016863 10016863

3 Sheet steel diaphragm 1 W FSt 2807

4 Diaphragm (3 mm thick) 1 W KG 10016583 10016583 10016583

5 Fibreglass ring 1 Fibreglass 3085 3085 3085

6 Cap 1 Ms 10016526 10016548 10016555

7 Control spring, optional:

7 Control spring F1 Ø 3.8 Wds 0.2 to 4 bar 1 FSt 10016535

7 Control spring F2 Ø 4.75 Wds 1.0 to 10 bar 1 FSt 10016536

7 Control spring F3 Ø 5.5 Wds 1.0 to 20 bar 1 FSt 10015117

7 Control spring F4 Ø 6.0 Wds 2.0 to 30 bar 1 FSt 10016554

7 Control spring F5 Ø 6.5 Wds 3.0 to 70 bar 1 FSt 10016545

8 Spring-loaded valve cone 1 St 10016531 10016550 10016550

9 Adjusting screw 1 NSt 10016580 10016580 10016580

10 Hex nut 1 St 13100 13100 13100

11 Shut-off screw 1 NSt 10016844 10016844 10016844

12 Sealing ring 1 LM 18819 18819 18819

13 Sealing ring, at option:

13 Sealing ring, 0.5 mm thick 2 LM 18788 18788 18788

13 Sealing ring, 1.0 mm thick 2 LM 18323 18323 18323

14 Compensation piece 1 Ms 10016865 10016865 10016865

15 Piston, complete 1 W NSt/K 10016926 10016926 10016926

16 Nozzle 1 Ms 10016868 10016868 10016868

17 Nozzle nut 1 NSt 10016848 10016848 10016848

18 Guiding piece 1 NSt 10018066 10018066 10018066

19 Diaphragm disc 1 LM 10016527

19 Diaphragm disc 1 Ms 10016549

19 Diaphragm disc 1 St 10016556

20 Pressure gauge, 0 to 400 bar 1 Ms 26772 26772 26772

21 Pressure gauge, at option:

21 Pressure gauge, 0 to 6 bar 1 Ms 26474

21 Pressure gauge, 0 to 16 bar 1 Ms 26476

21 Pressure gauge, 0 to 25 bar 1 Ms 26477

21 Pressure gauge, 0 to 60 bar 1 Ms 26478

21 Pressure gauge, 0 to 100 bar 1 Ms 26479

Number

W Materials

Measuring unit M Measuring unit H Measuring unit S

W Parts should be held in stock for maintenance purposes

German abbreviations stand for the following materials:

St ... Steel LM ... Light metal / alloy GMs ... Cast brass

NSt ... Stainless steel Ms ... Brass GZn ... Cast zinc

FSt ... Spring steel GS ... Cast steel AlBz ... Aluminium bronze

NFSt ... Stainless spring steel GGG ... Spheroidal graphite cast iron K ... Synthetic materials

Bz ... Bronze GBz ... Cast bronze KG ... Gummous synthetic materials

Cu ... Copper GLM ... Cast light metal SSt ... Foamed materials

213.20 p.06

Page 7

Item Part no.

no. Denomination

Number W

Materials

Measuring unit M Measuring unit H Measuring unit S

22 Locking screw 1 St 10547 10547 10547

23 Sealing ring 1 Cu 18586 18586 18586

24 Cap nut 1 NSt 10009248 10009248 10009248

25 Setting screw 1 Ms 10016828 10016828 10016828

26 Control spring, optional:

26 Control spring Ø 1.5 Wds up to 4 bar 1 FSt 10014334

26 Control spring Ø 2.0 Wds up to 10 bar 1 FSt 10014335

26 Control spring Ø 2.25 Wds up to 30 bar 1 FSt 10014336

26 Control spring Ø 2.8 Wds up to 70 bar 1 FSt 10014337

27 Valve cone 1 Ms 10016831 10016831 10016831

28 Sealing washer 1 W KG 10014082 10014083 10014083

29 Threaded pin 1 Ms 12471 12471 12471

30 Sealing ring 1 LM 18819 18819 18819

31 Union nut 1 St 30803 30803 30803

32 Cutting ring 1 St 30903 30903 30903

33 Connection pipe 1 St 30110 30110 30110

213.20 p. 07

Page 8

4.3 Parts for maintenance purposes

Item Part no.

no. Denomination Number

3 Sheet steel diaphragm 1 2807

4 Diaphragm (3mm thick) 1 10016583 10016583 10016583

15 Piston, complete 1 10016926 10016926 10016926

28 Sealing washer 1 10014082 10014083 10014083

Measuring unit M Measuring unit H Measuring unit S

213.20 p.08

Page 9

For More Information

To learn more about RMG´s advanced gas

solutions, contact your RMG

account manager or visit

www.rmg.com

GERMANY

Honeywell Process Solutions

RMG Regel + Messtechnik GmbH

Osterholzstrasse 45

34123 Kassel, Germany

Tel: +49 (0)561 5007-0

Fax: +49 (0)561 5007-107

Honeywell Process Solutions

RMG Messtechnik GmbH

Otto-Hahn-Strasse 5

35510 Butzbach, Germany

Tel: +49 (0)6033 897-0

Fax: +49 (0)6033 897-130

Honeywell Process Solutions

RMG Gaselan Regel + Messtechnik GmbH

Julius-Pintsch-Ring 3

15517 Fürstenwalde, Germany

Tel: +49 (0)3361 356-60

Fax: +49 (0)3361 356-836

Honeywell Process Solutions

WÄGA Wärme-Gastechnik GmbH

Osterholzstrasse 45

34123 Kassel, Germany

Tel: +49 (0)561 5007-0

Fax: +49 (0)561 5007-207

POLAND

Honeywell Process Solutions

Gazomet Sp. z o.o.

ul. Sarnowska 2

63-900 Rawicz, Poland

Tel: +48 (0)65 5462401

Fax: +48 (0)65 5462408

ENGLAND

Honeywell Process Solutions

Bryan Donkin RMG Gas Controls Ltd.

Enterprise Drive, Holmewood

Chesterfield S42 5UZ, England

Tel: +44 (0)1246 501-501

Fax: +44 (0)1246 501-500

CANADA

Honeywell Process Solutions

Bryan Donkin RMG Canada Ltd.

50 Clarke Street South, Woodstock

Ontario N4S 0A8, Canada

Tel: +1 (0)519 5398531

Fax: +1 (0)519 5373339

USA

Honeywell Process Solutions

Mercury Instruments LLC

3940 Virginia Avenue

Cincinnati, Ohio 45227, USA

Tel: +1 (0)513 272-1111

Fax: +1 (0)513 272-0211

TURKEY

Honeywell Process Solutions

RMG GAZ KONT. SIS. ITH. IHR. LTD. STI.

Birlik Sanayi Sitesi, 6.

Cd. 62. Sokak No: 7-8-9-10

TR - Sasmaz / Ankara, Turkey

Tel: +90 (0)312 27810-80

Fax: +90 (0)312 27828-23

RMG 213.20

2011-11

© 2011 Honeywell International Inc.

Loading...

Loading...