Page 1

M896

69-1089B-1

Damper Actuator

INSTALLATION INSTRUCTIONS

APPLICA TION

The M896 Damper Actuator is a 24 Vac motor with an

external shaft for coupling. Powered rotation is counterclockwise (ccw), with a maximum rotation of 110°. The

actuator is designed as a replacement actuator for the

D892 and D896 Automatic Vent Dampers or as the

original actuator on similar OEM dampers. Maximum OEM

damper operating torque cannot exceed ten in.-oz.

OPERATION

On a call for heat, the actuator automatically opens the

damper and the furnace or boiler begins its ignition cycle.

When the heating cycle ends, the burner turns off and the

actuator automatically closes the damper. Heating system

efficiency is increased because the closed damper

reduces the loss of residual appliance heat and heated

room air through the draft diverter.

INST ALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained experienced service

technician.

4. Install the M896 Damper Actuator as a replacement

only on AGA/CGA-approved damper systems.

5. After installation is complete, check out actuator

operation as provided in the Checkout section.

W ARNING

Severe illness or death possible.

Prevent dangerous buildup of

carbon monoxide.

Be sure damper used with M896 has a return

spring that opens the damper if the coupler fails.

CA UTION

Electrical shock or equipment

damage possible.

1. Disconnect power supply.

2. Do not negate the action of any existing safety

or operational control.

3. Make sure that the damper return spring is

operational prior to installing the actuator.

4. Label all wires prior to disconnecting when

servicing controls. Wiring errors can cause

improper and dangerous operation.

To Install the M896 Damper Actuator:

1. Remove the existing actuator.

2. Make sure the damper return spring is operational.

(The damper return spring must open the damper

when the actuator coupling is removed to prevent a

dangerous buildup of carbon monoxide.)

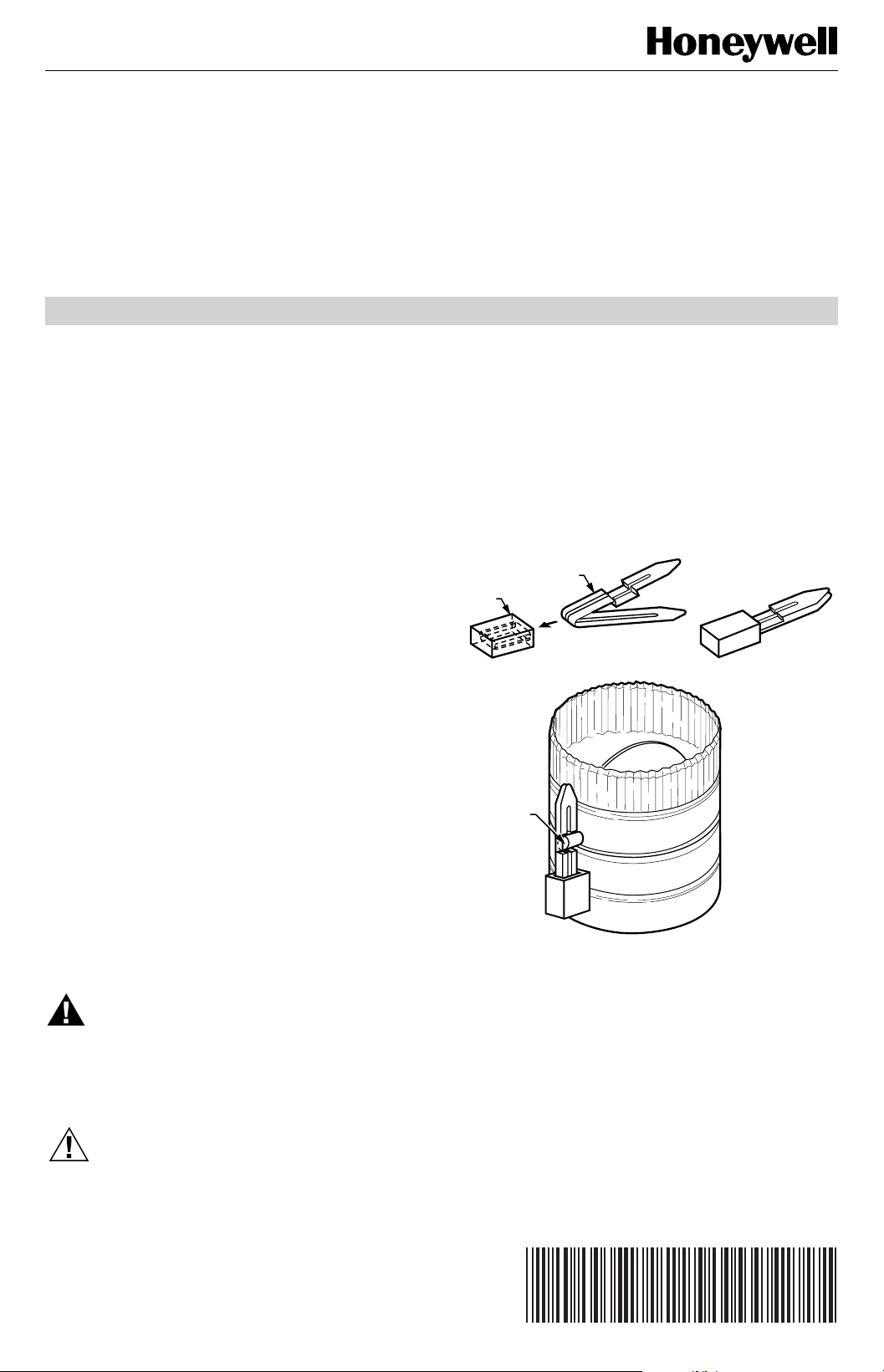

3. Locate the arrow coupler and keeper clip

(see Fig. 1).

ARROW

KEEPER

CLIP

4. Slip keeper clip over arrow coupler as shown in Fig.

5. Install the arrow coupler in the slot on the damper

6. Align the slot on the actuator shaft with the arrow

7. Attach the actuator to the damper bracket using the

8. Remove the keeper clip from the arrow coupler.

9. Connect the Molex plug to the M896 Harness Cable

COUPLER

AB

DAMPER

SHAFT

Fig. 1. Installing arrow coupler on damper

1. This compresses the arrow coupler.

shaft with the arrow pointing up.

coupler and attach the actuator to the damper.

See Fig. 2. (If the actuator output shaft is not

properly aligned with the arrow coupler, manually

turn the motor knob with a screwdriver to align the

actuator shaft.)

screws removed in step 1.

Connector.

shaft using keeper clip.

M3949

Copyright © 1997 Honeywell Inc. • All Rights Reserved

X-XX UL

Page 2

M896 DAMPER ACTUATOR

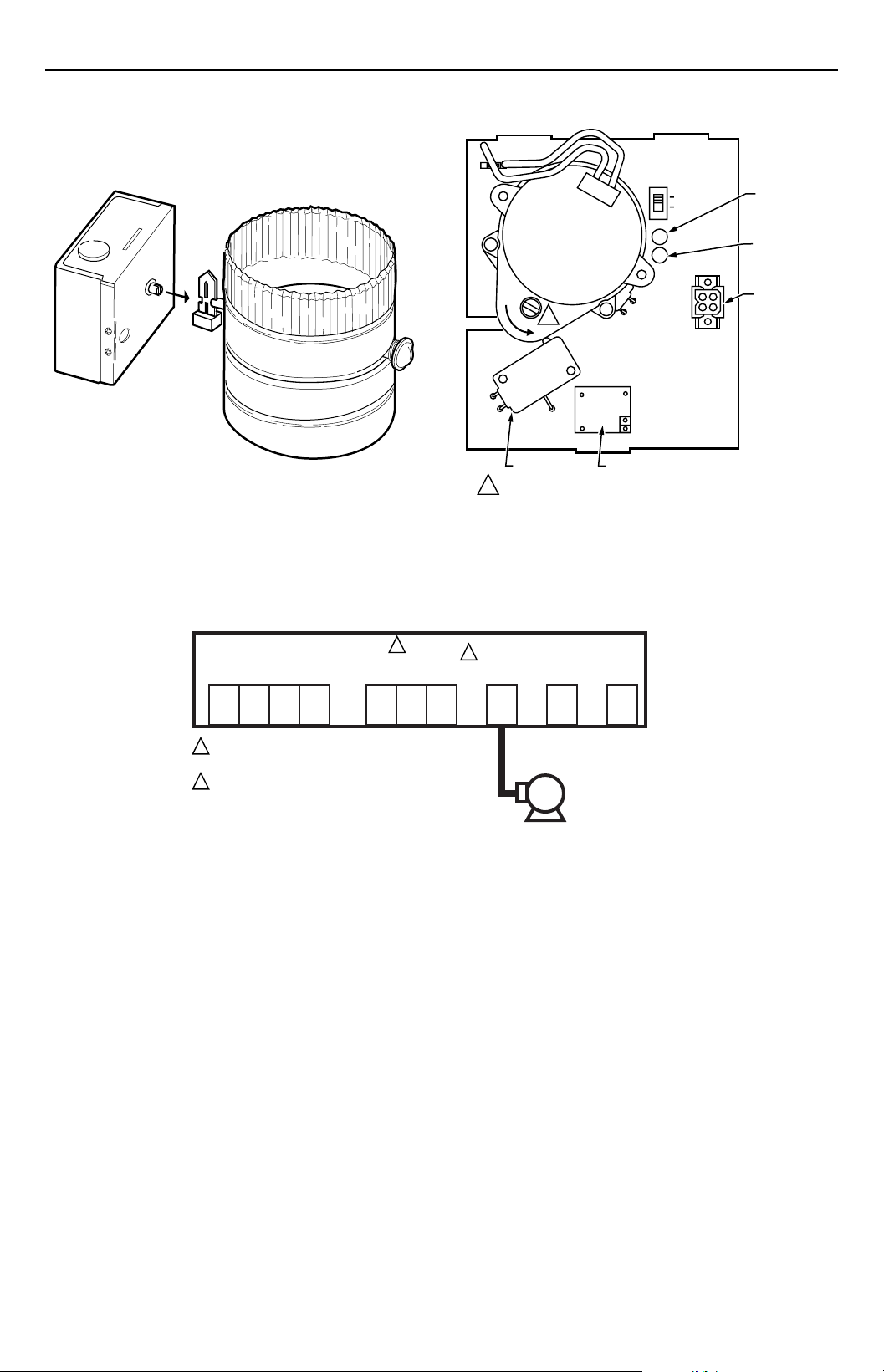

Other wiring connections are necessary. Follow the

furnace or boiler manufacturer wiring instructions, or

refer to Fig. 3 through 5.

DAMPER BRACKET

REMOVED FOR CLARITY

Fig. 2. Installing M896 Damper Actuator on damper.

M3947

M896

SERVICE

SWITCH

NORM

SERV

1

S3 SWITCH

1

USE STANDARD SCREWDRIVER TO MANUALLY OPEN AND

CLOSE VENT DAMPER. PLACE SCREWDRIVER IN SLOTTED

KNOB AND ROTATE COUNTERCLOCKWISE UNTIL

BOTH LEDS TURN ON.

RELAY 1K

Fig 3. M896 with cover removed.

IGNITION GAS

PWR LED

CALL FOR

HEAT LED

HARNESS

CABLE

CONNECTOR

M11367

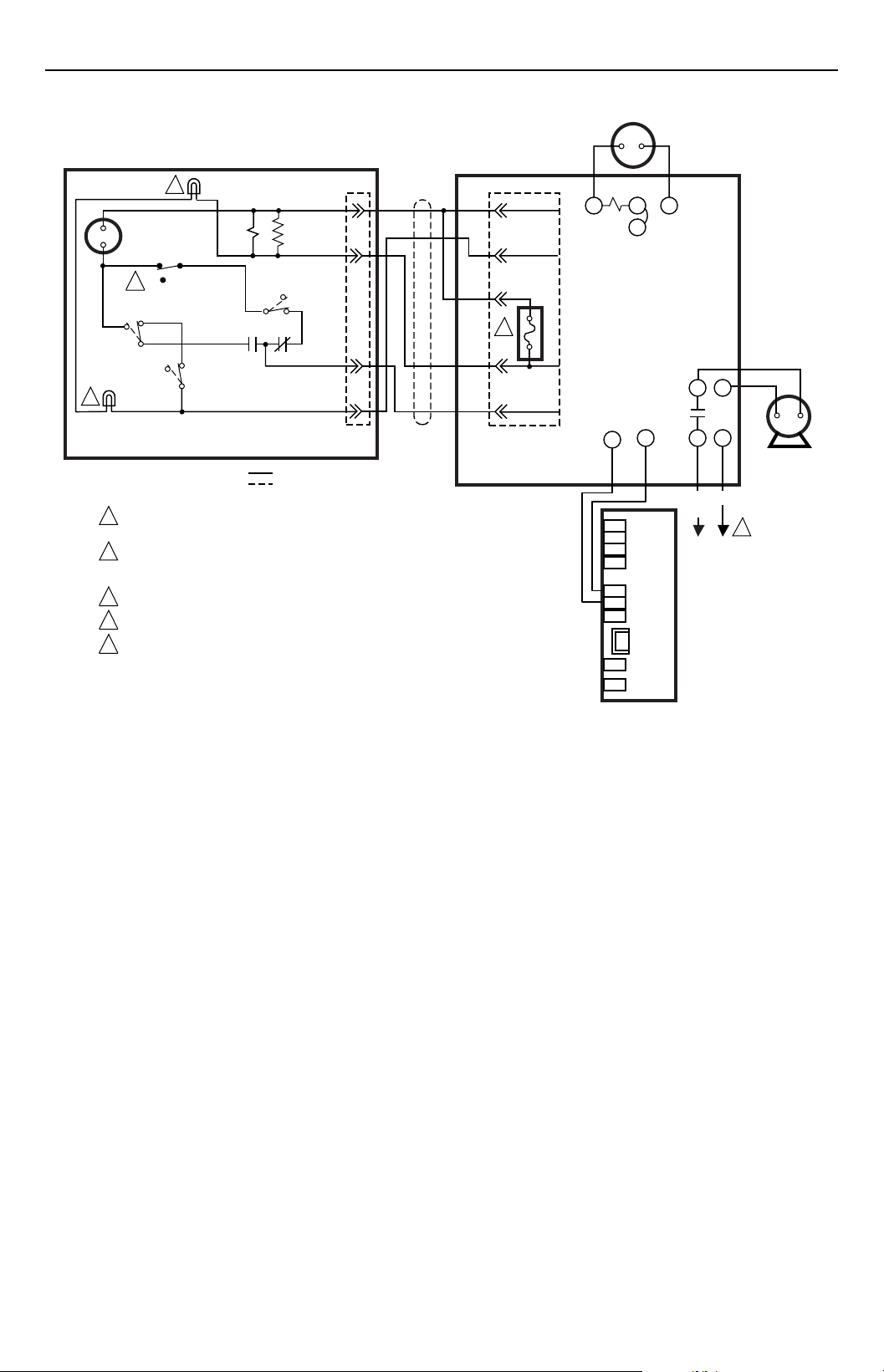

S8600F, H, M; S8610F,H

1

GND

MV MV/PV PV

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

REMOVE PLUG ONLY IF USING VENT DAMPER. FUSE

2

BLOWS ON STARTUP WHEN PLUG IS REMOVED;

THEN MODULE OPERATES ONLY WHEN VENT

DAMPER IS CONNECTED.

(BURNER)

24V

GND

24V SPARK

2

VENT

DAMPER

PLUG

WIRING

HARNESS

SENSETH-W

M896/D896

VENT

DAMPER

M11369

Fig. 4. Wiring diagram for M896 (D896) connection to L8148E1166 using wiring harness with two Molex plugs.

69-1089B–1

2

Page 3

M896/D896

LED 2

4

N.O.

S2

C

K1

C

N.O.

S3

K1

DAMPER OPEN

DAMPER CLOSED

MOTOR

NORMAL

S4

5

SERVICE

N.O.

N.C.

S1

C

N.C.

LED 1

3

POLARIZED 4-PRONG MALE MOLEX PLUG AND

4-PRONG FEMALE MATING PLUG ON CABLE

SWITCHES AS SHOWN: S1,S2,S3

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

AFTER M896/D896 VENT DAMPER IS PLUGGED TO L8148E1166, FUSE

2

BLOWS WHEN THERMOSTAT FIRST CLOSES. AFTER FUSE BLOWS,

L8148E1166 OPERATES ONLY WHEN VENT DAMPER IS CONNECTED.

3

LED 1 LIGHTS WHEN DAMPER IS OPEN.

4

LED 2 LIGHTS WITH CALL FOR HEAT.

5

SERVICE SWITCH. THE NORMAL SWITCH SETTING IS NORM. IF THE

SWITCH IS MOVED TO THE SERV POSITION, THE DAMPER REMAINS OPEN.

R1, R2, R3

250 OHMS

N.C.

4

2

1

3

WIRING

HARNESS

24 Vac

THERMOSTAT

4

2

3

FUSE

2

5

1

6-PRONG FEMALE MOLEX

RECEPTACLE IN L8148E

AND 5-PRONG MALE

MOLEX PLUG ON CABLE

M896 DAMPER ACTUATOR

L8148E1166

TW

1K

B1

Z

24V GND

24V

TV

C2

C1

1K1

L2

L1B2

CIRCULATOR

L1

L2

(HOT)

1

M11368

Fig. 5. Wiring diagram for M896 (D896) connection to S8600/S8610 using wiring harness with two Molex plugs.

SETTINGS

The service switch has both a normal (NORM ) and a

service (SERV) mode.

NORM — M896 opens on a call for heat and closes at

the end of the heating cycle.

SERV — M896 electrically opens after the thermostat

has a call for heat and remains open.

CHECKOUT

Heating

1. Turn off the power supply.

2. If using a thermostat, set the heat anticipator to

0.13A.

3. Set the thermostat or controller to 10°F (6°C) above

the room temperature to call for heat.

4. Check that the M896 Damper Actuator opens the

damper before the gas valve opens and the pilot or

main burner ignites. See Fig. 6.

NOTE: If a boiler gas control is sequenced by the

Aquastat® Controller, be sure that the

actuator opens the damper prior to the

opening of the gas control.

5. Turn the thermostat or controller 10°F (6°C) below

the room temperature. Check that the M896 Damper

Actuator closes the damper.

6. Cycle the heating system three times using the

thermostat or controller to assure that the system is

operating safely.

3

69-1089B–1

Page 4

M896 DAMPER ACTUATOR

THE AIR DUCT IS CLOSED WHEN THE

INDICATOR POINTS PERPENDICULAR TO

THE DIRECTION OF THE AIR DUCT

M3943

Fig. 6. Determining damper position.

Cooling

CA UTION

Damage to air conditioner condenser possible.

Do not operate cooling if outdoor temperature is

below 50°F (10°C).

1. Set the thermostat or controller to cool. Move the

setpoint 10°F (6°C) below the room temperature.

2. Make sure the cooling system operates.

3. Check that the damper remains in the closed

position. See Fig. 6.

4. Return the thermostat or controller to the desired

settings.

THE AIR DUCT IS OPEN WHEN

THE INDICATOR POINTS IN THE

DIRECTION OF THE AIR DUCT

NOTE: If there is a power failure, the damper remains

Set the thermostat or controller below the room temperature. Wait one minute and turn the thermostat or controller

above the room temperature to call for heat. If the system

does not start, leave the thermostat or controller calling for

heat and troubleshoot the M896/D896 as follows:

exactly where it is at the moment of failure (open,

closed, or somewhere between). When power is

restored, the damper opens if the thermostat is

calling for heat or closes if the thermostat is not

calling for heat.

NOTE TO INSTALLER:

Explain to the homeowner that a yearly inspection by a trained, experienced service technician

is necessary for safe, efficient operation of the

vent damper and heating system. The homeowner should check for deterioration from

corrosion or other sources between service

technician calls.

TROUBLESHOOTING

W ARNING

Fire or explosion hazard.

Can cause property damage,

severe injury or death.

Explosion or carbon monoxide poisoning possible.

Never apply a jumper across or short gas control

terminals or wires. This can force the damper to

remain closed and cause an explosion.

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

Use a voltmeter and check for 24 Vac at the S8600,

S8610, L8148E, gas valve or other control.

1. If no voltage, check the transformer, limit controller

and wiring.

2. If 24 Vac is present, and the D896 is open, refer to

the furnace or boiler manufacturer instructions.

3. If D896 is closed:

a. Place the service switch in the SERV position.

See Fig. 4.

b. Manually open the damper using a standard

screwdriver. Place screwdriver in slotted knob

(see Fig. 4) and rotate counterclockwise until

both LEDs turn on.

c. If system does not light with damper in the

fully open position, replace the M896.

Helping You Control Your World

®

69-1089B–1

69-1089B–1 G.H. 9-97 Printed in U.S.A.

4

Page 5

Actionneur de registre

69-1089B-1

M896

INSTALLATION INSTRUCTIONS

APPLICA TION

Le moteur de registre M896 est un moteur 24 V c.a. avec

arbre extérieur servant à l’accouplement. La rotation

motorisée a lieu dans le sens antihoraire sur une course

de 110 degrés. L’actionneur est conçu comme pièce de

rechange pour les registres d’aération automatiques D896

ou comme pièce d’origine de registres similaires. Le

couple de service maximal du registre du fabricant ne

peut dépasser 10 po-oz.

FONCTIONNEMENT

Lors d’un appel de chaleur, l’actionneur ouvre

automatiquement le registre, et le générateur d’air chaud

ou la chaudière commence son cycle d’allumage. Lorsque

le cycle de chauffage prend fin, le brûleur s’éteint et

l’actionneur referme automatiquement le registre.

L’efficacité du système de chauffage s’accroît car la

fermeture du registre réduit la perte de chaleur résiduelle

et de chaleur ambiante par l’ouverture du coupe tirage.

INST ALLATION

Avant d’installer ce produit…

1. Lire les instructions attentivement. Le fait de ne pas

les suivre risque de constituer un danger.

2. Vérifier les caractéristiques spécifiées dans les

instructions et indiquées sur le produit, et s’assurer

que celui-ci correspond à l’application prévue.

3. L’installateur doit être un technicien d’expérience

ayant reçu une formation pertinente.

4. Installer l’actionneur de registre M896 comme pièce

de rechange uniquement dans les systèmes à

registre approuvés par l’AGA/CGA.

5. Une fois l’installation terminée, vérifier le

fonctionnement du produit comme l’indique la

section Vérification.

MISE EN GARDE

Risque de choc électrique ou de dommage

au matériel.

1. Couper l’alimentation.

2. Ne pas empêcher le fonctionnement de tout

dispositif de commande ou de sécurité déjà

en place.

3. S’assurer que le ressort de rappel du registre

fonctionne comme il se doit avant d’installer

l’actionneur.

4. Étiqueter tous les fils avant de les débrancher

au moment de l’entretien des régulateurs. Les

erreurs de raccordement peuvent empêcher

l’actionneur de bien fonctionner et provoquer

un danger.

Pour installer l’actionneur de registre M896 :

1. Retirer l’actionneur existant.

2. S’assurer que le ressort de rappel du registre

fonctionne bien. (Le ressort de rappel du registre

doit faire ouvrir le registre lorsque l’accouplement

de l’actionneur est enlevé afin d’empêcher

l’accumulation dangereuse de monoxyde

de carbone.)

3. Repérer l’accouplement en flèche et la goupille

(voir Fig. 1 ).

ACCOUPLEMENT

EN FLÈCHE

GOUPILLE

ARBRE DU

REGISTRE

A

B

AVERTISSEMENT

Peut causer des maladies graves et entraîner la

mort. Empêcher l’accumulation dangereuse au

monoxyde de carbone.

S’assurer que le registre employé avec le M896

est muni d’un ressort de rappel qui ouvre le

registre si l’actionneur fait défaut.

Copyright © 1997 Honeywell Inc. • All Rights Reserved

MF3949

Fig. 1. Installation d’un accouplement en flèche sur un

arbre de registre à l’aide d’une goupille.

X-XX UL

Page 6

ACTIONNEUR DE REGISTRE M896

4. Faire glisser la goupille par-dessus l’accouplement

en flèche, comme l’illustre la Fig. 1. Cela a pour

effet de comprimer l’accouplement en flèche.

5. Installer l’accouplement en flèche dans la fente de

l’arbre du registre en faisant pointer la flèche vers

le haut.

6. Placer la fente de l’arbre du registre vis-à-vis

l’accouplement en flèche et fixer l’actionneur au

registre. Voir la Fig. 2. (Si l’arbre qui sort de

l’actionneur n’est pas vis-à-vis l’accouplement en

flèche, faire tourner le bouton du moteur à la main à

l’aide d’un tournevis pour que l’arbre de l’actionneur

soit aligné.

SUPPORT DU REGISTRE

RETIRÉ POUR PLUS DE CLARTÉ

MF3947

Fig. 2. Installation de l’actionneur de registre

M896 sur le registre.

7. Fixer l’actionneur au support du registre à l’aide des

vis retirées à l’étape B.

8. Retirer la goupille de l’accouplement en flèche.

9. Brancher la prise molex au faisceau de fils du M896.

Il faut maintenant effectuer d’autres raccordements. Suivre

les directives du fabricant du générateur d’air chaud ou de

la chaudière, ou consulter les figures 3 à 5.

M896

INTERRUPTEUR

DE SERVICE

NORM

SERV

1

INTERRUPTEUR S3

1

UTILISER UN TOURNEVIS STANDARD POUR OUVRIR ET FERMER

MANUELLEMENT LE REGISTRE D’AÉRATION. INSÉRER LE TOURNEVIS

DANS LE BOUTON FENDU ET FAIRE TOURNER DANS LE SENS

ANTIHORAIRE JUSQU’À CE QUE LES DEUX VOYANTS SOIENT ALLUMÉS.

RELAIS K1

VOYANT

IGNITION

GAS POWER

VOYANT CALL

FOR HEAT

CONNECTEUR

À FAISCEAU

DE FILS

MF11367

Fig. 3. M896 sans couvercle.

S8600F, H, M; S8610F,H

GND

MV MV/PV PV

1

ALIMENTATION. FOURNIR, AU BESOIN, UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE

LES SURCHARGES.

2

ENLEVER LA PRISE SEULEMENT SI LE REGISTRE

EST UTILISÉ. LE FUSIBLE FONDRA À LA MISE EN

SERVICE; PAR LA SUITE, LE MODULE NE

FONCTIONNERA QUE SI LE REGISTRE

D’AÉRATION EST BRANCHÉ.

(BURNER)

1

24V

GND

24V SPARK

2

VENT

DAMPER

PLUG

FAISCEAU

DE FILS

SENSETH-W

REGISTRE

D’AÉRATION

M896/D896

MF11369

Fig. 4. Schéma de raccordement d’un M896 (D896) au L8148E1166 à l’aide d’un faisceau de fils et

de deux prises molex.

69-1089B-1

2

Page 7

M896/D896

VOYANT 2

4

N.O.

S2

C

K1

N.O.

C

S3

K1

MOTEUR

NORMAL

S4

5

SERVICE

N.O.

N.F.

S1

C

N.F.

VOYANT 1

3

PRISE MOLEX MÂLE À 4 BROCHES POLARISÉES

ET PRISE MOLEX FEMELLE À 4 BROCHES

CORRESPONDANTE SUR LE CÂBLE

1

ALIMENTATION. FOURNIR, AU BESOIN, UN DISPOSITIF DE COUPURE

ET UNE PROTECTION CONTRE LES SURCHARGES.

UNE FOIS LE REGISTRE M896/D896 RACCORDÉ AU L8148E1166, LE FUSIBLE

2

FONDRA LORSQUE LE THERMOSTAT SE REFERMERA POUR LA PREMIÈRE FOIS.

UNE FOIS LE FUSIBLE FONDU, LE L8148E1166 NE FONCTIONNERA QUE SI LE

REGISTRE D’AÉRATION EST BRANCHÉ.

3

LE VOYANT 1 S’ALLUME LORSQUE LE REGISTRE EST OUVERT.

4

LE VOYANT 2 S’ALLUME LORS D’UN APPEL DE CHALEUR.

INTERRUPTEUR DE SERVICE. LA POSITION NORMALE DE CET INTERRUPTEUR

5

EST NORM. SI L’INTERRUPTEUR EST À LA POSITION SERV, LE REGISTRE RESTE OUVERT.

R1, R2, R3

250 OHMS

N.F.

4

2

1

3

FAISCEAU

DE FILS

ACTIONNEUR DE REGISTRE M896

THERMOSTAT

24 V c.a

4

2

3

FUSIBLE

2

5

1

RÉCEPTACLE DE PRISE

MOLEX FEMELLE À 6

BROCHES DANS LE

L8148E ET PRISE MOLEX

MÂLE À 5 BROCHES

SUR LE CÂBLE

TW

1K

B1

24V MISE

24V À LA

TERRE

TV

Z

L8148E1166

C1

1K1

L1B2

L1

(SOUS

TENSION)

C2

L2

CIRCULATEUR

L2

1

MF11368

Fig. 5. Schéma de raccordement d’un M896 (D896) au S8600/S8610 à l’aide d’un faisceau de fils et

de deux prises molex.

RÉGLAGES

L’interrupteur d’entretien comporte la position normale

(NORM) et la position service (SERV).

NORM—Le M896 s’ouvre lors d’une demande de

chaleur et se referme à la fin du cycle de chauffage.

SERV—Le M896 s’ouvre électriquement après un

appel de chaleur du thermostat et reste ouvert.

VÉRIFICATION

Chauffage

1. Couper l’alimentation électrique.

2. Si on utilise un thermostat, régler la résistance

anticipatrice de chaleur à 0,13 A.

3. Régler le thermostat ou le régulateur à 6 °C (10 °F)

au-dessus de la température ambiante pour

provoquer une demande de chaleur.

4. Vérifier si l’actionneur de registre M896 ouvre le

registre avant que la vanne à gaz ne s’ouvre et

que la veilleuse du brûleur principal s’allume. Voir

la Fig. 6.

REMARQUE:

Si la vanne à gaz d’une chaudière est

commandée en séquence par un régulateur

Aquastat®, s ‘assurer que l’actionneur fait

ouvrir le registre ouvre avant l’ouverture de la

vanne à gaz.

5. Remettre le thermostat ou le régulateur à 6 °C

(10 °F) au-dessous de la température ambiante.

Vérifier si l’actionneur de registre M896 referme

le registre.

6. Faire faire au moins trois cycles de chauffage au

système au moyen du thermostat ou du

régulateur et s’assurer que le système fonctionne

en toute sécurité.

3

69-1089B–1

Page 8

ACTIONNEUR DE REGISTRE M896

LA GAINE D’AIR EST FERMÉE LORSQUE LA FLÈCHE POINTE

PERPENDICULAIREMENT AU SENS DE LA GAINE D’AIR.

MF3431

Fig. 6. Comment déterminer la position du registre.

Refroidissement

AVERTISSEMENT

Risque d’endommager le condenseur du

climatiseur.

Ne pas faire fonctionner le système de

refroidissement si la température extérieure est

inférieure à 10 °C (50 °F).

1. Régler le régulateur ou le thermostat est à la

position COOL. Déplacer le curseur à 6 °C (10 °) audessous de la température ambiante.

2. S’assurer que le système de refroidissement

fonctionne.

3. S’assurer que le registre est en position fermée. Voir

la Fig. 6.

4. Remettre le thermostat ou le régulateur au point de

consigne souhaité.

REMARQUE À L’INTENTION DE L’INSTALLATEUR:

Expliquer au propriétaire qu’une inspection

annuelle par un technicien d’expérience ayant

reçu une formation pertinente s’impose pour

des questions de sécurité et pour assurer le

bon fonctionnement du registre d’aération et du

système de chauffage. Le propriétaire devrait

vérifier s’il y a des signes de détérioration

causée par la corrosion ou d’autres causes

entre les visites du technicien.

DÉP ANNAGE

MISE EN GARDE

Risque d’incendie ou d’explosion. Peut causer

des dommages à la propriété, et provoquer des

blessures ou même entraîner la mort.

Risque d’explosion ou d’empoisonnement au

monoxyde de carbone. Ne jamais placer de

cavalier entre les bornes ou les fils du régulateur à

gaz et ne jamais court-circuiter le régulateur à gaz.

Cela pourrait forcer le registre à rester en position

de fermeture et provoquer une explosion.

LA GAINE D’AIR EST OUVERTE LORSQUE LA

FLÈCHE POINTE DANS LA SENS DE LA GAINE D’AIR.

REMARQUE:

Régler le thermostat ou le régulateur au-dessous de la

température ambiante. Attendre une minute et remettre le

thermostat ou le régulateur à un point de consigne

supérieur à la température ambiante pour provoquer une

demande de chaleur. Si le système ne se met pas en

marche, laisser le thermostat ou le régulateur au même

réglage (pour provoquer une demande de chaleur) et

vérifier le fonctionnement du M896/D896 comme suit :

Au moyen d’un voltmètre, vérifier s’il y a du courant 24 V

c.a. au S8600, S8610 ou L8148E, à la vanne à gaz ou

autre régulateur.

En cas de panne de courant, le registre restera

exactement à la position où il se trouve au

moment de la panne (ouvert, fermé ou entre les

deux). Lorsque le courant sera rétabli, le

registre ouvrira si le thermostat demande de la

chaleur ou se refermera si le thermostat ne

demande pas de chaleur.

1. S’il n’y a pas de courant, vérifier le transformateur, le

limiteur et le câblage.

2. S’il y a du courant 24 V c.a et que le registre D896

est ouvert, consulter les instructions du fabricant de

la chaudière ou du générateur d’air chaud.

3. Si le D896 est fermé:

a. Placer l’interrupteur d’entretien à la position

SERV. Voir la Fig. 4.

b. Ouvrir manuellement le registre à l’aide d’un

tournevis. Insérer le tournevis dans le bouton

fendu (voir la Fig. 4) et tourner dans le sens

antihoraire jusqu’à ce que les deux voyants

s’allument.

c. Si le système ne s’allume pas et que le

registre est en position d’ouverture complète,

remplacer le M896.

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

69-1089B-1

69-1089B–1 G.H. 9-97 Imprimé aux États-Unis

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

Pour la maîtriste de votre univers

4

®

Loading...

Loading...