Page 1

Application

The M847D is a two position, 24 Vac spring return damper

actuator designed to operate directly driven zone dampers,

used to control air flow in ducts. The synchronous motor

actuator can be driven open (or closed) using any 24 volt

rated two position switch - eg. a wall switch or a thermostat

subbase switch.

The M847D replaces the RDMH and RDMZ damper

actuators for use on Trol-A-Temp® ARD and ZD dampers.

Specifications

Electrical Rating: 24 Vac 60 Hz 0.32 Amp., 8 VA

Electrical Connection: 1/2" conduit

Nominal Angular Rotation: 90° ( max. 105° )

Torque: Min. 423 mNm (milli newton meter) [60 in.oz] output

torque available when motor is energized and device is at

the spring returned initial start position.

Nominal Motor Timing: (@25°C ambient)

Energized at rated load - 30 seconds.

De-energized (spring return) - 10 seconds.

Ambient Temperature Rating: 5 to 60°C (+40 to 140°F)

Finish: zinc plated steel, anodized aluminium

Direction of Shaft Rotation: clockwise, when energized

and viewed from the base or shaft end.

Mounting Means: direct connection to damper shaft.

Mounting Position: Multi-poise.

Dimensions: See Figure 1.

Direct Drive Damper Actuator

M847D

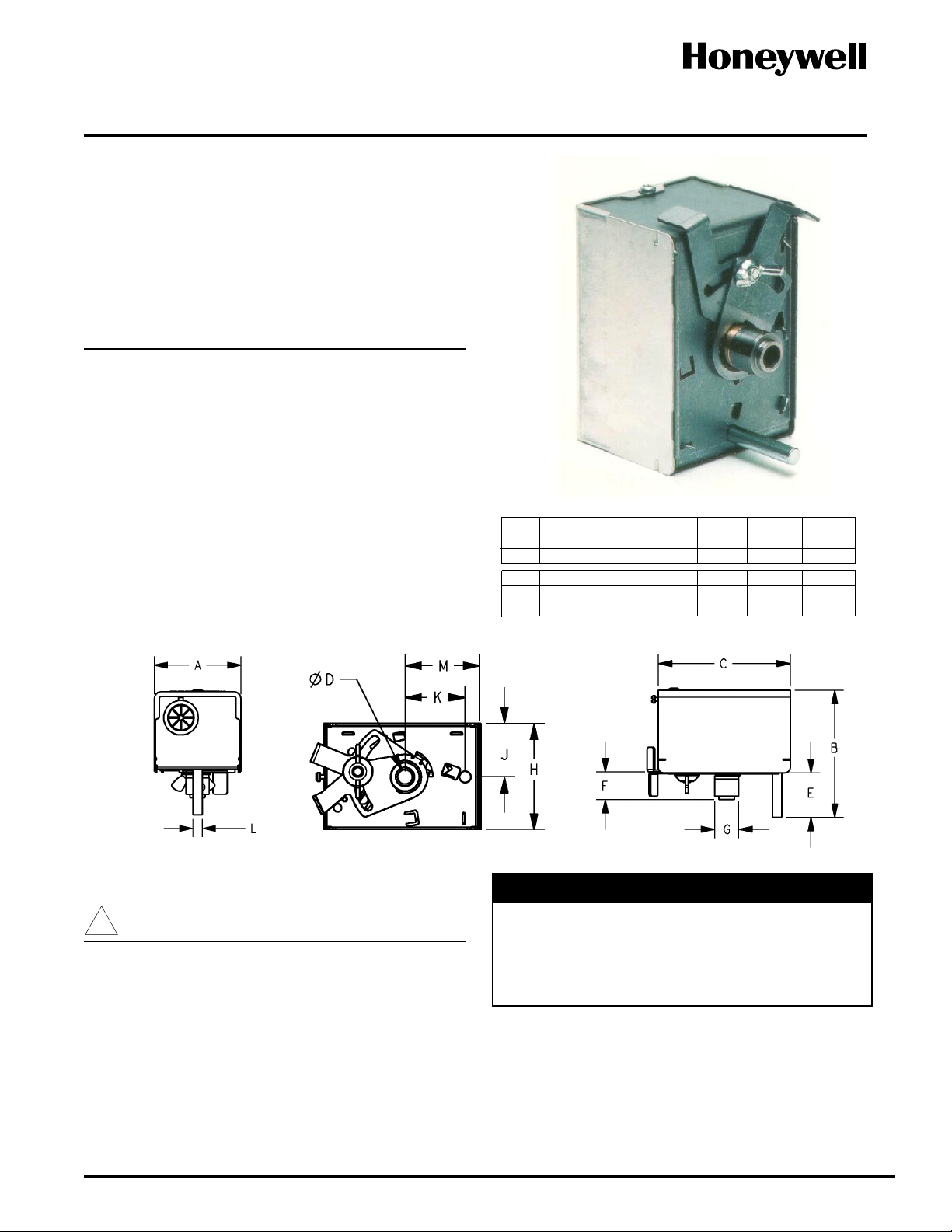

Nominal Device Dimension

ABCDEF

mm 60 84.5 88 8.2 31.5 19.3

in 2-3/8 3-3/8 3-1/2 5/16 1-1/4 3/4

GH JKL M

mm 15.8 58.6 29.3 33.5 6.4 40.4

in 5/8 2-5/16 1-3/16 1-5/16 1/4 1-9/16

Fig. 1 - Dimensional Details

INSTALLATION AND CHECKOUT

!

CAUTION

1. Read these instructions carefully. Failure to follow them could

cause a hazardous condition.

2. Disconnect powersupply before beginning of installation and

wiring of control to prevent electrical shock or equipment

damage.

3. Check the ratings given in the instructions and on the product

to make sure the product is suitable for your application.

4. All wiring must comply with local electrical codes, ordinances,

and regulations.

5. Installer must be a trained, experienced service technician.

6. After installation is complete, check out the product operation

as provided in these instructions.

WARNING

1. DO NOT install this actuator on a flue damper.

2. DO NOT attempt to rotate the actuator by turning the

connection coupling or the damper shaft when it is

connected to the actuator or damage to the gear train

may occur.

STANDARD MOUNTING (For 5/16" dia. damper shaft)

The M847D can be attached directly to the protruding 5/16"

diameter damper shaft using the sleeve of the output shaft. Drill

A 5/16" (8mm) hole 1-5/16"

shaft opening to accept the anti-rotation shaft protruding from

the base of the motor. The length of the damper shaft to which

the connection coupling is attached is such as to firmly hold the

actuator in a position to adequately engage the anti-rotation pin

in the warm air duct. See Figure 1. for the critical dimensions.

11-01 © Honeywell Limited. 2001 • Form Number: 95C-10905-1

(33.5mm) directly below the damper

Page 2

M847D

INSTALLATION AND CHECKOUT CONTINUED

Replacing M847D on aTrol-A-Temp® ARD damper

1.Disconnect the motor wiring.

2.Using a 1/8 in. hex wrench to loosen the motor coupling from

the blade shaft, remove the existing motor assembly.

3.Observe that the damper blades are in the normal, spring

open or spring closed position.

4.Place the new motor onto the shaft and tighten the coupling.

5.Reconnect the motor wiring.

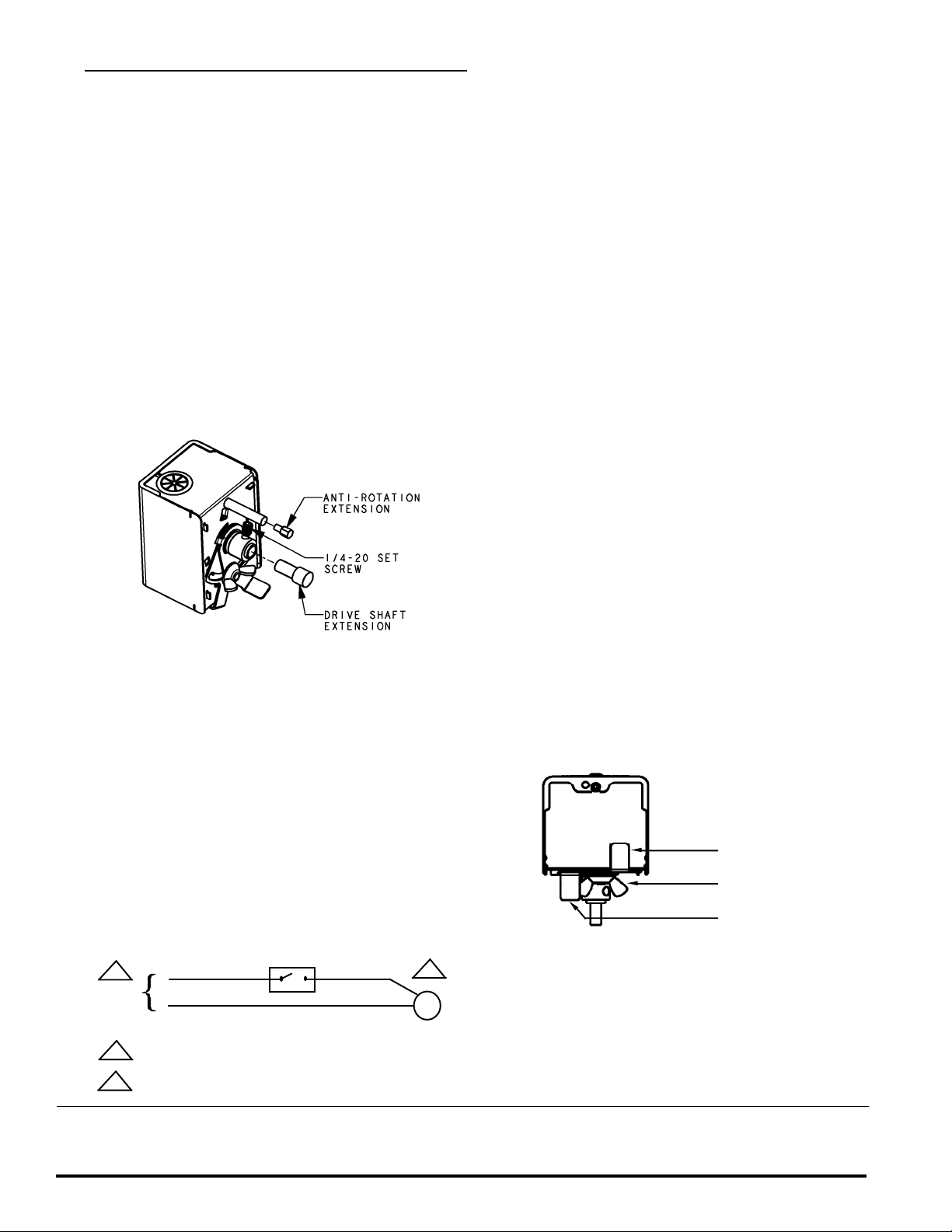

ALTERNATE MOUNTING (For 7/16"dia. coupling style

dampers)

Before installing the M847D actuator to a damper with a 7/

16" coupling, insert the drive shaft extension into the drive

shaft and tighten with the set screw provided. See Fig. 2.

Also install the anti-rotation extension to the end of the

anti-rotation rod. Install the actuator on the damper and

tighten the coupling screw.

Fig 2. For 7/6" COUPLING MODEL DAMPERS ONLY

Replacing M847D on aTrol-A-Temp® ZDS or ZDB damper

1.Disconnect the motor wiring.

2.Using a 3/16 in. hex wrench to loosen the Allen screw located

above the faceplate at the motor coupling.

3.Remove the existing motor.

4.Observe that the damper blades are in the open position with

the setscrew pointing toward the damper label.

5. Attach the new motor to the coupling. Make sure that the

standoff on the motor is positioned in the grommet on the

faceplate.

6.Tighten the set screw.

7.Reconnect the motor wiring.

CHECKOUT

After completing the installation, check that the equipment

operates correctly as follows:

1.When 24 Vac is applied to the motor leads, the motor powers

to the closed or open position.

2. When power is removed, the motor releases and spring

returns to the normal position.

If full opening and closing is not achieved, check the lower

adjustment lever is to the extreme left and the upper lever is to

the extreme right. See Fig. 4 (Air Flow Adjustments)

AIR FLOW ADJUSTMENTS

Note: The following describes the adjustments available with

the actuator installed in the power closed mode. If the damper

you are installing is to operate in the power open mode, the

function of the upper and lower levers is reversed.

1.When viewed on end, the lower lever is normally positioned

to the extreme left. (See Fig. 4) This position allows the

damper to fully open 90° when de-energized.

2.To restrict the air flow in the open position, loosen (do not

remove) the wing nut and move the lower lever to the right

until the desired position is reached. Tighten the wing nut. In

the extreme right position the damper should open approx.

50° with the power off.

3.The upper lever is normally positioned to the right to

provide complete shut off when the acutuator is energized.

(See Fig. 4)

4.If desired, to prevent complete closure of the damper, loosen

(do not remove) the wing nut on the bottom of the unit and

move the upper lever to the left until the desired position is

achieved. Tighten the wing nut. In the extreme left position

the damper should close to approx. 40° with the power on.

5.If additional rotation is required beyond 90°, an additional 15°

may be obtained by removing the Upper Lever. To do this,

first, remove the actuator from the damper. Remove the wing

nut and retaining ring then remove the levers. Reassemble

and install.

Fig. 4 - Air Flow Adjustment

UPPER LEVER

WIRING

See Figure 3. for typical wiring hook-ups of the M847D.

Figure 3 - Typical M847D Hookup

Zoning Switch

1

24 VAC

60 Hz

PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

NOMINAL CURRENT 0.32 AMP

Automation and Control Solutions

Environment Control Products

1985 Douglas Drive North

Golden Valley, MN

55422-3992

In Canada:

Honeywell Limited

35 Dynamic Drive

Toronto, ON

M1V 4Z9

Orange

Yellow

2

Operator

Motor

This material is proprietary to

Honeywell Limited and shall not be

reproduced, copied or used in any manner

without prior written consent of Honeywell Limited.

Printed In Canada

WING NUT

LOWER LEVER

Helping You Control Your World

Loading...

Loading...