Page 1

M7410G

LINEAR VALVE ACTUATOR

WITH LON CAPABILITIES AND OPTIONAL PI-CONTROL

PRODUCT DATA

CONTENTS

APPLICATION............................................................ 2

FEATURES................................................................. 2

DEVICE SPECIFICATIONS ....................................... 3

OPERATION............................................................... 3

VERSIONS.................................................................. 3

PLUG-INS, XIF FILES AND DRF FILES.................... 3

Plug-Ins.................................................................... 4

XIF Files................................................................... 4

DRF- Files................................................................ 4

MOUNTING POSITION ..............................................4

MOUNTING................................................................. 4

ELECTRIC WIRING.................................................... 4

Wiring Colors ...........................................................5

Digital Input .............................................................. 5

COMMISSIONING ADVICE .......................................5

SERVICE LEDS AND SERVICE PIN DESCRIPTION5

Priorities of the different possible situations .......17

Factory Settings ..................................................17

Behaviour of the Controller after Power On /

Reset / Offline-Online..........................................17

Node Object (actuators with PI-controller only) .....18

LNS PLUG-IN DESCRIPTION..................................19

Actuator Object.......................................................19

Diagnostic and Test ............................................19

Configuration Screen ..........................................20

PI-Controller Object................................................24

Monitoring ...........................................................24

Configuration of PI-Controller .............................26

APPLICATION EXAMPLE FOR M7410G1032 /

M7410G1040 / M7410G1057....................................27

DIMENSIONS (MM).................................................... 6

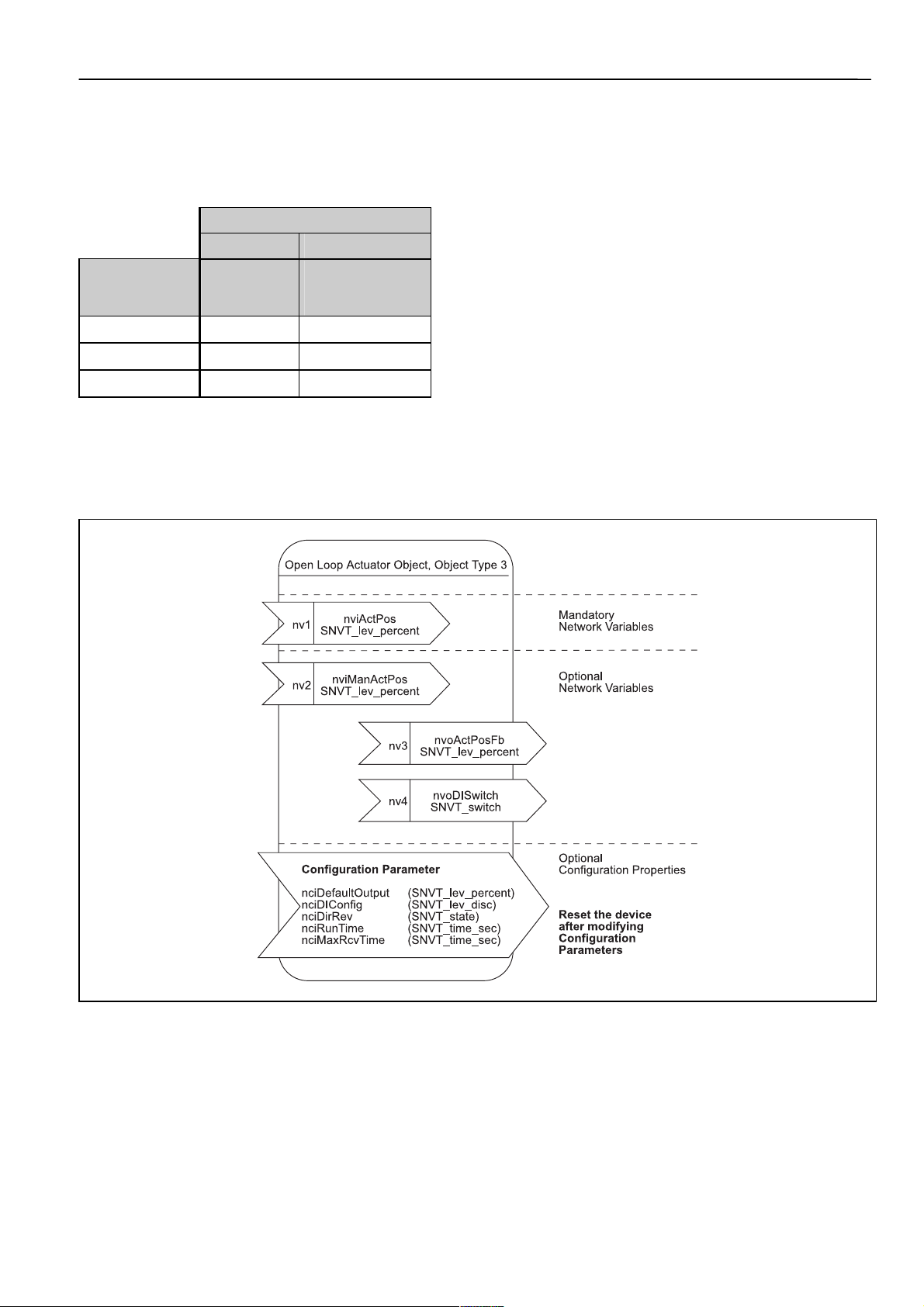

LONMARK NETWORK INTERFACE ........................ 7

Actuator object ......................................................... 7

Description of used SNVTs* and SCPTs** .......... 8

Selection of digital input usage........................... 11

Watchdog for the supervision of the actuation

signal ..................................................................11

Factory settings ..................................................11

Behavior of the Actuator after Power-on /

Reset / Offline-Online ......................................... 11

Interruption of the synchronization ..................... 11

What happens at Offline-Online Mode Changes 12

Controller Object (actuators with PI-controller only)13

Description of used SNVTs and SCPTs............. 14

Relation between nviOccupancy, nciSetpoint,

nviSetpoint and nviSetPtOffset........................... 15

Echelon, Lon, LonMark, LonWorks, and the LonMark Logo

are Registered Trademarks of Echelon Corporation

Copyright © 2002 Honeywell Inc.

All Rights Reserved. EN0B-0235 GE51R0802

Page 2

PRODUCT DATA

FEATURES

Fig.1 M7410G Actuator

SERVICE LED

STATUS LED

SERVICE PIN

APPLICATION

The M7410G small linear actuator with LON capabilities is

targeted for decentralized building structures and gives

customers an effective new capability in energy management

and product flexibility. The actuator works with standard

SNVTs to provide interoperability with controllers based on

LonWorks technology.

The M7410G actuator is specifically designed to provide

LonMark capabilities together with the radiator and zone valve

series of small linear valves and are used in fan coil units,

induction units, small reheaters, recoolers and for zone

control applications. They are employed in electronic

temperature control systems using hot and / or cold water as

the controlled medium.

The M7410G actuator is suitable for Honeywell Excel series

controllers as well as for any other controllers based on

LonWorks technology. Using standard Echelon configuration

tools, the actuator can be configured with job specific settings.

The M7410G actuator is well suited for applications where

space is limited and minimum power consumption is required.

The actuator is both, attractive and robust in design.

The M7410G actuator is available in two variants, one

standard variant and and a variant with additional PIController. The PI-Controller variant allows the creation of a

control loop independently of an Excel controller for use in

small applications.

• FTT10A communication

• Digital input may used for window or humidity

switch

• The actuator is a flexible tool and LON is a flexible

platform

• Simplifying complex HVAC plants

• Simple wiring

• Open products for third party integration

• Supplied with prewired connection cable

• Simple, standardized valve/actuator coupling

• No tools required for mounting

• Visual valve position indicator furnished with

actuator

• Manual operation provided by the valve adjustment

cap

• High-precision proportional valve actuator

• Standard network variables for ambient

temperature, setpoint temperature, temperature

offset, application mode (Heat / Cool), occupancy or

valve position ensure easiest installation and

proper operation (M7410G1032 / M7410G1040 /

M7410G1057 only)

• Three actuators (M7410G1032 / M7410G1040 /

M7410G1057) are equipped with an additional PI

controller. The combination of actuator and PI

controller in one device makes it easy and cheap to

establish a hydronic or chilled ceiling room control

loop

EN0B-0235 GE51R0802 2

Page 3

PRODUCT DATA

DEVICE SPECIFICATIONS

Input voltage: 24 Vac ± 20 %, 50/60 Hz

Power consumption: 1.4 VA

Input signal: SNVT_lev_percent 0-100%

Control mode: LON (FTT10A)

Stroke: 2.5 - 4 mm 6.5 mm

Running time: 75 s at 50 Hz

63 s at 60 Hz

Stem force: depending on type (see table)

Protection standard: IP 42

Insulation class: III

Connection cable: 1.5 m

Ambient operating

temperature limits:

Weight: 0.3 kg

Suitable valves: see table

Manual operation: see table

0 ... 55 °C

150s at 50

Hz

120s at 60

Hz

OPERATION

The movement of the electric actuator is produced by a screw

spindle which is driven in both directions by a synchronous

motor through a set of gears. A magnetic clutch limits the

torque of the gear assembly and the driving force of the

actuator. The actuator is fixed to the valve body by means of

a coupling ring requiring no tools for mounting. The actuator is

maintenance-free and supplied completely with a ready-towire connecting cable.

VERSIONS

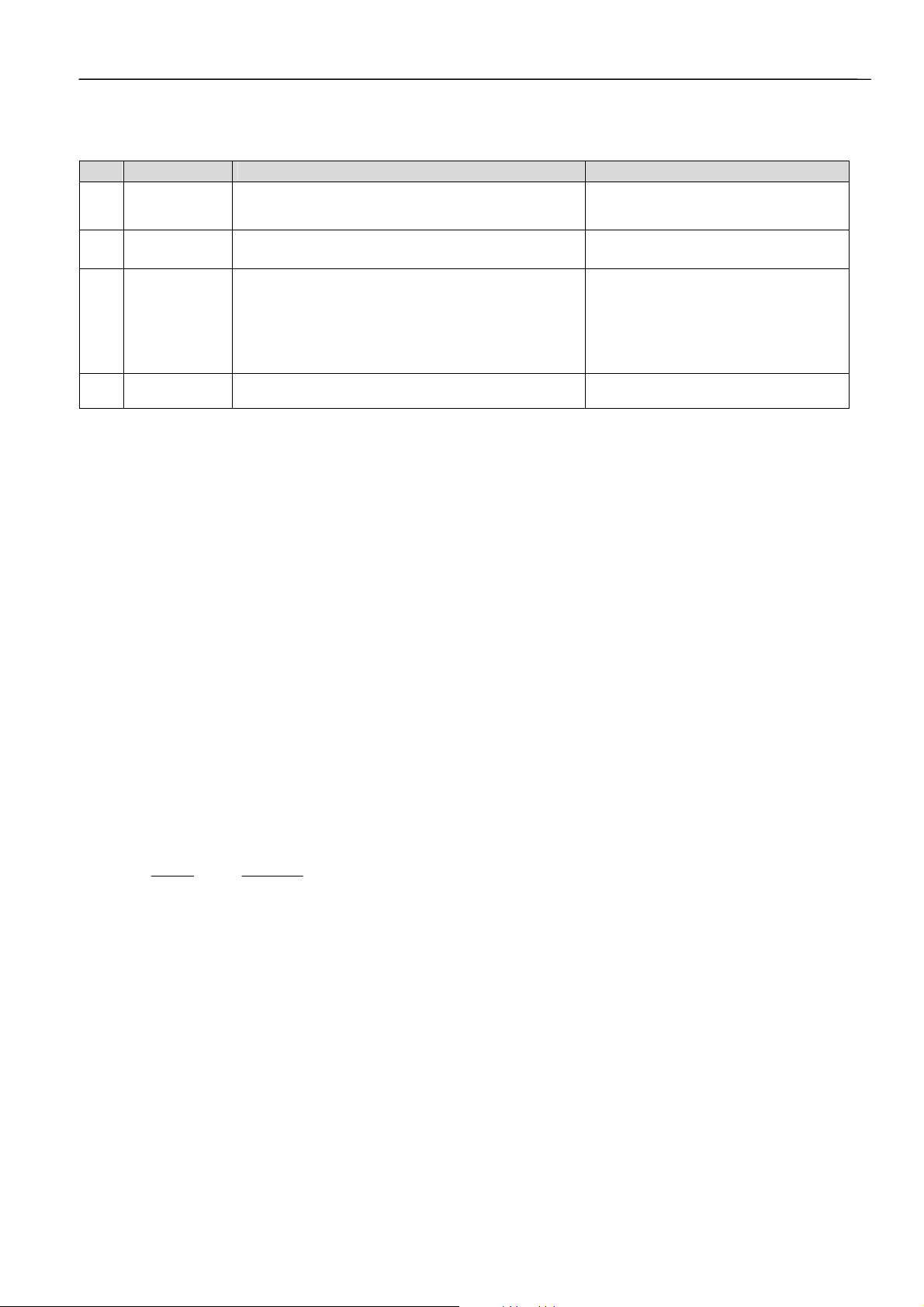

Order Number PI-Controller Force Stroke Compatible Valves

M7410G1008

M7410G1032

M7410G1016

M7410G1040

M7410G1024

M7410G1057

-

z

-

z

-

z

90 N 3.5 mm V100 (Thermostatic valves)

V5822A4 / V5823A4

V5832C4 / V5832A4

V5833A4 / V5833C4

180 N 6.5 mm V5822A / V5832A

V5823A / V5833A

V5823C / V5833C

300 N 6.5 mm V5832B / V5833A

V5872B / V5872D

PLUG-INS, XIF FILES AND DRF FILES

External interface files and the plug-ins (device ressource files included) can be downloaded at http://www.honeywell.de/plugin.

For XIF-files take the link to the LonMark server.

Order Number PlugIn Name XIF-File DRF-File

M7410G1008 / M7410G1016 / M7410G1024 ILONAS ilona_s.xif No

M7410G1032 / M7410G1040 / M7410G1057 ILONASPI ilonaspi.xif Yes

3 EN0B-0235 GE51R0802

Page 4

PRODUCT DATA

PLUG-INS

Plug-Ins give you the possibility to simplify start-up,

maintenance, configuration and to reduce the installation

effort.

XIF FILES

An External Interface File (XIF file) including the whole LON

interface of the device can be used e.g. for offline

configuration or binding of the device via a LON Tool.

For detailed description, please refer to the LNS-Plug-In

Description chapter.

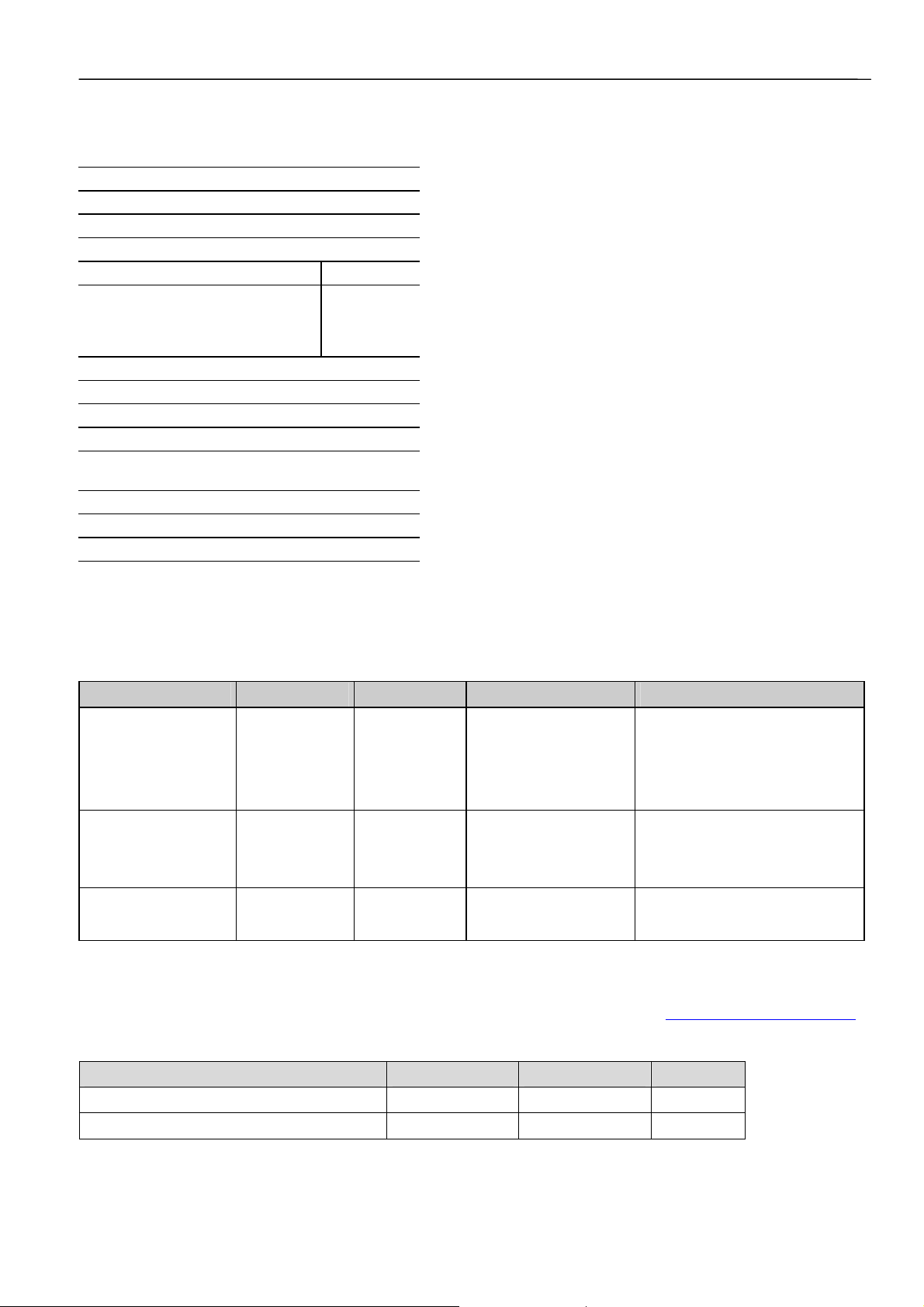

MOUNTING POSITION

The actuator may only be mounted beside or above the

valve. Adjust the valve in the right position before mounting

the actuator.

DRF- FILES

In case a LON network management tool is used, DRF files

must be installed. Device Resource Files (DRF files) are

needed to display special manufacturer defined network

variables or configuration parameters correctly.

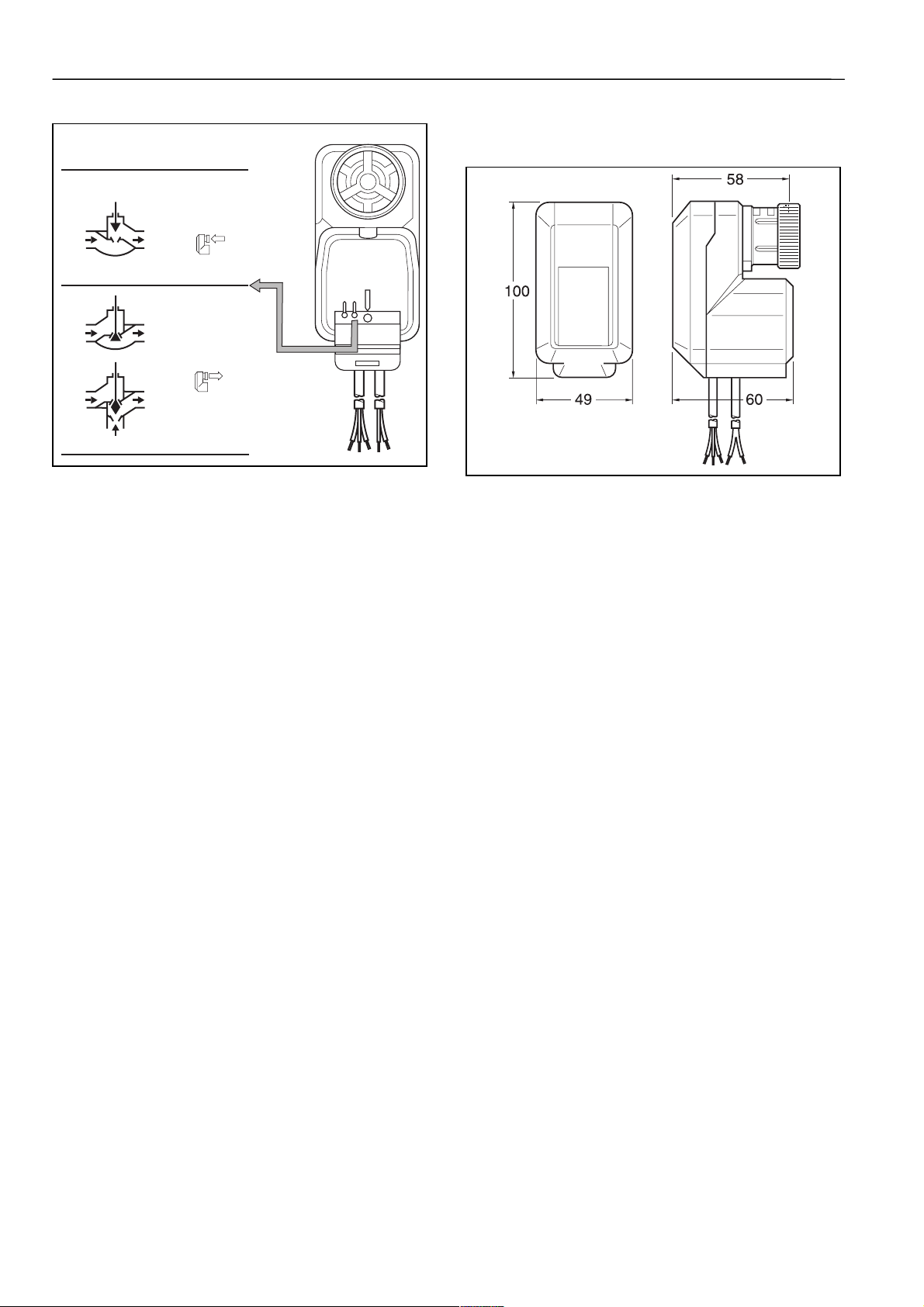

Fig.2 Mounting Positions

MOUNTING

Before the actuator is fixed to the valve, the adjustment cap

must be removed (Fig. 2). Make sure that the actuator is in

the open position (factory supplied position) before fixing the

actuator to the valve body.

Fig. 3 Remove Protection Cap

The actuator must be mounted by hand. Don't use tools or

additional forces, because actuator and valve may be

damaged.

Fig. 4 Mounting the Actuator

ELECTRIC WIRING

The electrical installation must comply with the wiring

diagram shown in Fig. 5 and Fig. 6.

Fig. 5 Electric Wiring

EN0B-0235 GE51R0802 4

Page 5

PRODUCT DATA

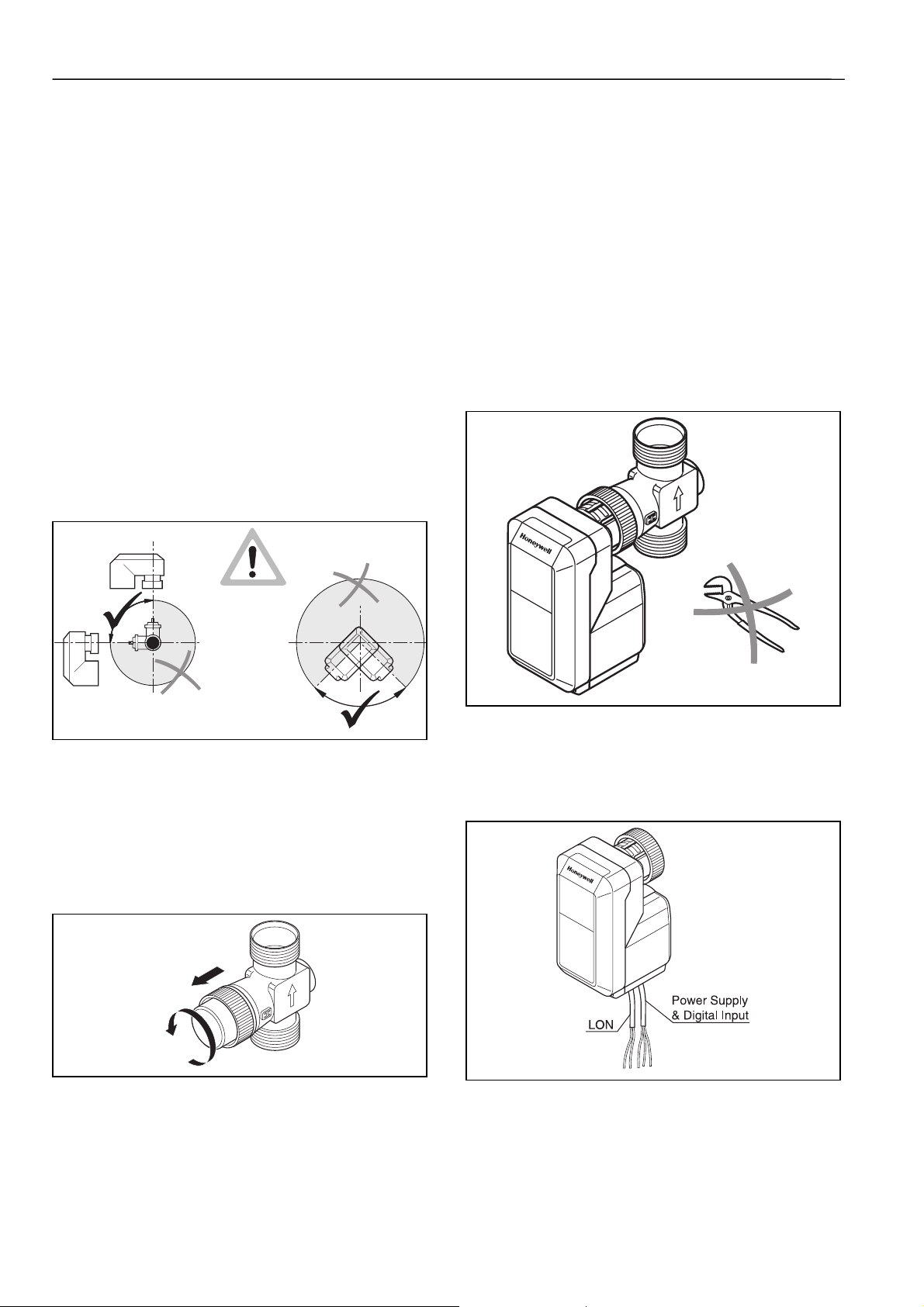

WIRING COLORS

Fig. 6 Wiring Colors

DIGITAL INPUT

Fig. 7 Digital Input

Node state

Service LED

Applicationless and

unconfigured

Unconfigured

(but with an

application)

Configured,

Hard Off-line

Configured 4 off —

Table 1 Node States Service LED

Status LED Blink Modes

Mode 1 1s on, 1s off, for 10 times -

if a wink message was received

Mode 2 4s on, 1s off -

direct acting and normal operation

Mode 3 4s off, 1s on -

reverse acting and normal operation

Mode 4 continuously off -

the device is in the offline-mode

Table 2 Blink Modes Status LED

hF01F

Status

code

3 on 76

2 Flashing 0.51

6 off —

Service

LED

Pulse rate

(Hz)

COMMISSIONING ADVICE

A functional check of the valve actuator can be carried out by

changing the nviManActPos (SNVT_lev_percent).

The movement of the actuator stem (Fig. 7) indicates

whether the valve is opening or closing. If the direction of

travel is not correct, the configuration parameter nciDirRev

(SNVT-state) can be used for changing the direction of

action.

17.8 mm 11.7 mm

Fig. 8 Movement of the Actuator Stem

SERVICE LEDS AND SERVICE PIN DESCRIPTION

Service LED: Defined by Echelon firmware in the neuron

chip (see table 1)

Status LED: Is blinking if wink was sent and indicates

reverse or direct acting

(see table 2 and diagram 1)

Service pin: Accessible under the cover and will be used to

send the neuron ID over the network during

the installation

Diagram 1 Blink Modes Status LED

5 EN0B-0235 GE51R0802

Page 6

PRODUCT DATA

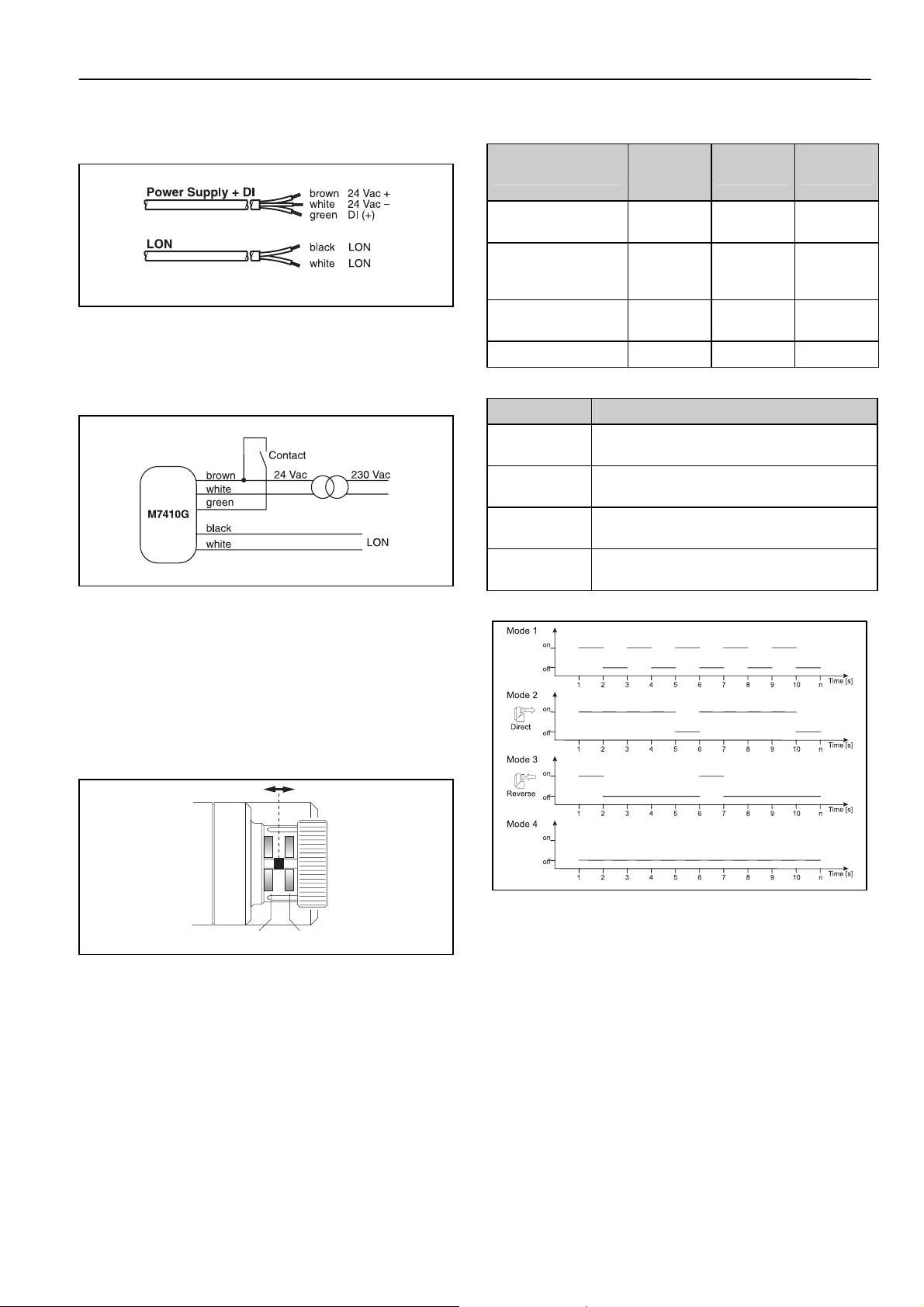

AB

AB

AAB

100% 0%

0% 100%

SERVICE LED

STATUS LED

DIMENSIONS (MM)

SERVICE PIN

B

Fig. 9 Selecting Valve Type and Output Signal

Fig. 10 Housing

EN0B-0235 GE51R0802 6

Page 7

LONMARK NETWORK INTERFACE

The Lon Network Interface for the two actuator variants (Standard and with PI-Controller) differs as follows:

Standard With PI-Controller

LON Object M7410G1008

M7410G1016

M7410G1024

Actuator object

Controller object

Node object

ACTUATOR OBJECT

The actuator object supports the following network variables used for the communication and configuration

Actuator Type

M7410G1032

M7410G1040

M7410G1057

z z

-

-

z

z

PRODUCT DATA

Fig.11 Actuator Object

7 EN0B-0235 GE51R0802

Page 8

PRODUCT DATA

DESCRIPTION OF USED SNVTS* AND SCPTS**

This table shows all used standard network variables and standard configuration parameters, their default values, a short

description, the range and the send conditions and service of the outputs.

Standard Network

Variable

Mandatory

Network Variables

nviActPos

Optional Network

Variables

nvoActPosFb

* SNVTs = Standard Network Variable Types

** SCPTs = Standard Configuration Parameter Types

Type

{Range}

{factory settings}

SNVT_lev_percent

{ 0...100 % ; 163.835}

{163.835} = INVALID

SNVT_lev_percent

{ 0...100 % ; 163.835}

{163.835} = INVALID

Adjustment of the different functionalities and the explanation of the shown

values.

Definition Explanation

nviActPos = 163.835 [INVALID]

⇒ After Power-on or Reset

⇒ Controller is sending [INVALID].

The actuator will run to the safety

position defined in

[nciDefaultOutput].

⇒ Watchdog has “detected”;

Only possible if the watchdog was

selected in [nciMaxRcvTime] and

will correspond on the made

selection in [nciDefaultOutput].

The actuator will run to the safety

position defined in

[nciDefaultOutput].

nviActPos = 0% oder 100%

⇒ Synchronization with full running

time + 30%.

The synchronization can be

interrupted if new values are

received.

(excluding during synchronization

after Power-on or Reset)

0% < nviActPos < 100%

⇒ The actuator runs to the position

received by the controller.

(Exceptional case is after Power on or Reset)

Definition Explanation

nvoActPosFb = 163.835 (INVALID)

⇒ After Power-on or Reset.

⇒ No defined stroke position

feedback possible.

0% <= nvoActPosFb <= 100%

⇒ The actual calculated position of

the stem according to the time to

stroke model.

The actuating signal received from a

controller defined in the range of 0-100%

which defines the stroke position of the

connected valve.

Received values below 0% are calculated like

0% and values over 100% will be calculated

with 100%. The only exception is the value

163.835 = [INVALID]. Is this value received,

the actuator drives to the safety position

which is defined in the [nciDefaultOutput].

The received values will be never overwritten

by the software of the actuator.

The variable [nviActPos] is only be used, if

the variable with higher priority

[nviManActPos] for manual operation is set to

[INVALID] = 163.835.

The cyclic received actuating signal can be

supervised. In this case, the maximum

timeframe for the cyclic received values can

be defined in the configuration parameter

[nciMaxRcvTime].

Is this timeframe passed, the actuator will be

running to the safety position defined in the

configuration parameter [nciDefaultOutput].

This value shows the actual calculated stem

position.

M7410G1008 / M7410G1016 / M7410G1024

For old version ILAS_V1

(stored in sd_string of device)

nvoActPosFb will be updated cyclic every 0,5

sec, if it changes or not. The timing is hard

coded and is not adjustable. So be careful

about making bindings of many actuator

feedback variables, e. g. to a controller for

trending charts. If you have too many output

variables bound to one device it could be

overloaded. If you need this requirement than

make a download of the new controller

software revision ILAS_V2, which has a

behavior as described below. To get the

actual revision contact our Technical

Assistance Center +49-7031-637-760.

EN0B-0235 GE51R0802 8

Page 9

PRODUCT DATA

Optional Network

Variables

nvoActPosFb

nviManActPos

nvoDISwitch

SNVT_lev_percent

{ 0...100 % ; 163.835}

{163.835} = INVALID

SNVT_lev_percent

{ 0...100 % ; 163.835}

{163.835} = INVALID

SNVT_switch

Possible values

1. {0.0 , 0 }

2. {100.0 , 1}

3. {x, 0xFF=255=-1)}

Definition Explanation

nvoActPosFb = 163.835 (INVALID)

⇒ After Power-on or Reset.

⇒ No defined stroke position

feedback possible.

0% <= nvoActPosFb <= 100%

⇒ The actual calculated position of

the stem according to the time to

stroke model.

IMPORTANT:

If control signal requires 0 and 100 %

respectively, then nvoActPosFb turns

immediately to 0 and 100 %

respectively.

nviManActPos = 163.835 (INVALID)

⇒ After Power-on or Reset

⇒ Manual operation is switched off

nviManActPos = 0% or 100%

⇒ Synchronization with full running

time + 30%.

The synchronization can be

interrupted if new values are

received.

(excluding during synchronization

after Power-on or Reset.

0% < nviManActPos < 100%

⇒ The actuator is running to the

manual set value. (Exceptional

case is after Power-on or Reset)

The possible conditions can be

selected by the configuration parameter

[nciDIConfig].

A detailed description is made in the

Selection of Digital Input Usage section.

M7410G1008 / M7410G1016 / M7410G1024

For version ILAS_V2 or higher

(revision stored in sd_string of device)

nvoActPosFb will be measured internally

every 5 sec. If the value changes at the latest

after 5 seconds the value will be updated. If

the value does not change after 60 sec, the

value will be send one time.

M7410G1032 / M7410G1040 / M7410G1057

nvoActPosFb will be measured internally

every 5 seconds. If it changes permanently,

the value will be send maximum every 5

seconds. After 15 minutes the value will be

send one time if it has changed in between or

not.

The actuator can be operated manually. To

have most accuracy a synchronization to the

completely retract position has to be done.

The watchdog [nciMaxRcvTime] is operating

in the background (if selected).

The manual operation has in each case a

higher priority than the received actuating

signal [nviActPos]. After changing the value

for manual operation [nviManActPos] to

[INVALID] the actuator is running according to

the received values of [nviActPos].

Received values below 0% are calculated like

0% and values over 100% will be calculated

with 100%. The only exception is the value

163.835 = [INVALID]. Is this value received,

the actuator drives to the safety position

which is defined in [nciDefaultOutput].

The received values are never overwritten by

the software of the actuator.

Actual state of the sensor, connected to the

digital input (e. g. window-contact or

dewpoint-sensor).

M7410G1008 / M7410G1016 / M7410G1024

For old version ILAS_V1

(stored in sd_string of device)

nvoDIswitch will be updated cyclic every 3

sec if it changes or not. The timing is hard

coded and is not adjustable. So be careful

about making bindings of many digital input

variables, e.g. to a controller for trending

charts. If you have too many output variables

bound to one device it could be overloaded.

If you need this requirement than make a

download of the new controller software

revision ILAS_V2, which has a behavior as

described below. To get the actual revision

contact our Technical Assistance Center +497031-637-760.

For version ILAS_V2 or higher

(revision stored in sd_string of device)

nvoDIswitch will be measured internally

every 5 sec. If the value changes at the latest

after 5 seconds the value will be updated. If

the value doesn’t changes after 60 sec the

value will be send one time.

M7410G1032 / M7410G1040 / M7410G1057

nvoDIswitch will be measured internally every

5 seconds. If it changes, the value will be

send at the latest after 5 seconds. After 15

minutes the value will be send one time if it

has changed in between or not.

9 EN0B-0235 GE51R0802

Page 10

PRODUCT DATA

Standard

Configuration

Parameters

Definition Explanation

nciDirRev

nciMaxRcvTime

nciDefaultOutput

nciDIconfig

nciRunTime

SCPT Master List -

Names from

Echelon

SCPTdirection

SCPTmaxRcvTime SNVT_time_sec

SCPTdefOutput SNVT_lev_percent

SCPTinvrtOut SNVT_lev_disc

SCPTDriveTime SNVT_time_sec

Type

{Range}

{factory settings}

SNVT_state

{Bits = 1 or 0}

M7410G1008 /-16 /-24

{1111111111111111}

M7410G1032 /-40 /-57

{1000000000000000}

{0...6553 sec}

{0}

Only integer values are

accepted and numbers

after a comma will be

ignored.

{ 0; 100 % ; 163.835}

{163.835} = INVALID

{ST_ON}

{ST_OFF}

{0...6553.5 sec}

{6553.5} = INVALID

Adjustment of the different functionalities and the explanation of

the shown values.

Is no value [nviActPos], in a certain

timeframe [nciMaxRcvTime]

received, the actuator will run to the

position defined in

[nciDefaultOutput].

This is called a heartbeat control or

watchdog function.

This configuration parameter defines

the condition what will happen if the

timeframe [nciMaxRcvTime] of the

watchdog is passed or if an

undefined situation takes place.

For example: The controller failed

and no values are received. In this

case the actuator can run to a safety

position or stops immediately. The

selection should be done according

to the applications requirements.

See Selection of Digital Input Usage

section

The selection of the running time will

be done automatically.

To adapt the valve stroke to the

running time afterwards and to

secure the accuracy for the time to

stroke model this configuration

parameter is used.

Inverse the direction of action

M7410G1008 / -16 / -24

1111111111111111= Direct

0000000000000000 = Reverse

M7410G1032 / -40 / -57

Bit 0 = 1 ⇒ Direct

Bit 0 = 0 ⇒ Reverse

Watchdog for the Controller /

Actuator supervision

[nciMaxRcvTime] = 0

Watchdog is deactivated

[nciMaxRcvTime] =

for example 60 [sec]

Watchdog expires, if for 60

seconds no new value is

received on [nviActPos]. The

actuator will run to the position,

defined in the configuration

parameter [nciDefaultOutput].

Safety position in case of

controller failure

100 % = Actuator will do a

synchronization to 100 %, 100%

running time +30% safety.

0 % = Actuator will do an

synchronization to 0%, 100%

running time +30% safety.

[INVALID] = 163.835 = Actuator

stops immediately

All other values are the same as

163.835

Configuration of the digital input

Possibility of overwriting the

value for the running time, which

is normally done automatically.

This should only be done in case

of adapting a different valve to

the actuator.

Setting nciRunTime to

(INVALID) and resetting the

node, the selection of runtime will

be as factory setting.

The running time is automatically

selected and depending on the

power supply frequency

[50Hz/60Hz] which is measured

by the hard-/software

environment.

EN0B-0235 GE51R0802 10

Page 11

SELECTION OF DIGITAL INPUT USAGE

PRODUCT DATA

Network variable

Configuration parameter

(SCPT...nciDIconfig)

Type: SNVT_lev_disc

default:

nciDIconfig

=ST_OFF

switch

nciDIconfig =

ST_ON

nciDIconfig = ST_NUL (0xFF)

switch

closed

switch

opened

opened

switch

closed

(SNVT...nvoDIswitch)

Type: SNVT_switch

Value State User

100.0 1 X

0 0 x

100.0 1 X

0 0 x

0 0xFF (=255=-1) x

WATCHDOG FOR THE SUPERVISION OF THE ACTUATION SIGNAL

Activation of the watchdog-timer

Is the SCPT [nciMaxRcvTime] set to 0, the watchdog is

generally switched off. To activate the watchdog, a value >0

has to be selected. This value has to be in the range of

values. Values after a comma will be ignored.

Start of the watchdog-timer after Power-on

The watchdog-timer is starting after a first value was received

by [nviActPos]. Up to that point, the actuator will stay in the

defined safety position [nciDefaultOutput].

Watchdog-timer in case of manual operation.

Is the actuator working in the manual operation mode

(nviManActPos

the background. This means, if the controller fails, the

watchdog-timer expires and after switching manual operation

[nviManActPos] to [INVALID] the actuator is running to the

safety position according to the definition in

[nciDefaultOutput].

≠ INVALID) the watchdog-timer is working in

FACTORY SETTINGS

State of the Network and Configuration Parameters:

nviActPos = 163.835 (INVALID)

nviManActPos = 163.835 (INVALID)

nviActPosFb = 163.835 (INVALID)

nvoDIswitch = [ 0.0 -1 ]

after initialization (3 sec.) = [ 0.0 0 ]

(if there is no switch connected)

nciDefaultOutput = 163.835 (INVALID)

nciDirRev = 1111111111111111

(for M7410G1008 / -16 / -24)

nciDirRev = 100000000000000

(for M7410G1032 / -40 / -57)

nciMaxRcvTime = 0.0 sec

nciDIconfig = ST_OFF

nciRunTime = 6553.5 (INVALID)

Meaning

defined

DI not used or device

offline or first 3 sec after

Power-on/Reset/online

BEHAVIOR OF THE ACTUATOR AFTER POWER-ON / RESET / OFFLINE-ONLINE

The behavior of the motor is dependent on the configuration

parameter nciDefaultOutput.

There are three possible states.

nciDefaultOutput Behavior of the motor after

default:

163.835 = INVALID

0 % The actuator synchronizes to the position

100 % The actuator synchronizes to the position

Power-on / Reset

The actuator makes no movement and

waits. The first received value from the

controller or manual will be saved as the

actual position of the motor - no

movement. The second received value

will be compared to the first, and the

motor runs to the new required position

(and so on...).

referring to 0 % and runs then to the

position according to the controller/

manual value, if one is received.

If not, the actuator waits.

referring to 100 % and runs then to the

position according to the controller/

manual value, if one is received.

If not, the actuator waits.

INTERRUPTION OF THE SYNCHRONIZATION

The interruption of the synchronization after Power-on / Reset

(nciDefaultOutput = 0 or 100 %) is not possible. Later

synchronizations can be interrupted every time.

11 EN0B-0235 GE51R0802

Page 12

PRODUCT DATA

WHAT HAPPENS AT OFFLINE-ONLINE MODE

CHANGES

If the actuator is taken offline by a network management tool

the application program of the device stops, and the following

actions will be done before the offline mode takes place:

Online-Offline change

• The motor stops, if it is running

• The Status LED is taken off

• The network variable

(163.835), to show that the actuator is in a undefined

situation

• The state-value of the network variable

set to INVALID (255 = 0xFF = -1), to show that the

actuator is in a undefined situation.

nviActPosFb will be set to INVALID

nviDIswitch will be

Offline-Online change

• Application restart. Same situation as Power-on or Reset.

EN0B-0235 GE51R0802 12

Page 13

CONTROLLER OBJECT (ACTUATORS WITH PI-CONTROLLER ONLY)

The controller object supports the following network variables used for the communication and configuration

Controller Object

Controller Object, Object Type 5

PRODUCT DATA

nviActualTemp

nv1

SNVT_temp_p

nviSetpoint

nv2

SNVT_temp_p

nviSetPtOffset

nv3

SNVT_temp_p

nviEnergyHoldOff

nv4

SNVT_switch

nviOccupancy

nv5

SNVT_occupancy

nviApplicMode

nv5

SNVT_hvac_mode

Configuration Parameter

nc 78 - nciSetpoint (SNVT_temp_p)

UCPT - nciPIGains[2]

UCPT - nciPIConfig (Heat / Cool)

nvoValvePosition

nv7

SNVT_lev_percent

nciPIGains.pi_Xp (SNVT_temp_p)

nciPIGains.pi_Tn (SNVT_time_sec)

Network Variables

Optional

Configuration Properties

Modify SCPT´s anytime (no reset of

device)

Fig.12 Controller Object

13 EN0B-0235 GE51R0802

Page 14

PRODUCT DATA

DESCRIPTION OF USED SNVTS AND SCPTS

This table shows all used standard network variables and standard configuration parameters, their default values, a short

description, the range and the send conditions and service of the outputs.

Standard Network

Variable

Network Variables

nviActualTemp

nviSetpoint

nviSetPtOffset

nviEnergyHoldOff

nviOccupancy

Type

{Range}

{factory settings}

SNVT_temp_p

{-163,80 to 163,80;

327,67}

{327,67} = INVALID

SNVT_temp_p

{-157,80 to 157,80 [°C]

327,67}

{327,67} = INVALID

SNVT_temp_p

{-157,80 to 157,80 [°C];

327,67}

{327,67} = INVALID

SNVT_switch

Possible values:

Value/State

1.) {0,0;0}

2.) {>0;1}

{0,0;-1}

SNVT_occupancy

{ OC_OCCUPIED,

OC_UNOCCUPIED,

OC_BYPASS,

OC_STANDBY,

OC_NUL}

{OC_NUL}

Adjustment of the different functionalities and the explanation of the shown

values.

Definition Explanation

nviActualTemp = 327,67 [INVALID]

⇒ after Power on or Reset.

If nviActualTemp is INVALID than

nvoValvePosition will be Invalid, too,

cause no control loop is possible.

not equal 327,67 [INVALID]

⇒ normal operation

If nviActualTemp is not INVALID

than normal operation is possible.

nviSetpoint = 327,67 [INVALID]

⇒ after power on or reset.

If nviSetpoint is INVALID the internal

nciSetpoint will be used as the

actual required temperature.

nviSetpoint not equal 327,67 [INVALID]

⇒ normal operation

If nviSetpoint is not INVALID than this

parameter has higher priority than the

setpoint adjusted in the SCPT nciSetpoint

nviSetPtOffset = 327,67 [INVALID]

⇒ after Power on or Reset.

If nviSetPtOffset is INVALID than it

will be ignored.

nviSetpoint not equal 327,67 [INVALID]

⇒ normal operation

If nviSetptOffset is not INVALID it will be

added to the actual valid setpoint

{ 0.0,0} the controller works in

normal operation mode

{100,1} the value nvoValvePosition

will be overwritten with 0

%. So energy will be

switched off.

All other cases have the same meaning

than {0.0,0}

Description from LonMark

0 OC_OCCUPIED

Area is occupied

1 OC_UNOCCUPIED

Area is unoccupied

2 OC_BYPASS

Area is temporarily occupied

for the bypass period

3 OC_STANDBY

Area is temporarily unoccupied

0xFF OC_NUL

Value not available

nviActualTemp includes the actual

temperature delivered by an separate LON

temperature sensor.

Received values below –163,80°C are

calculated like –163,80°C and values above

163,80°C will be calculated with 163,80°C.

The only exception is the value 327,67 =

[INVALID]. Is this value received, the output

of the controller nvoValvePosition will be

set to INVALID, too.

Received values below –157,80°C are

calculated like –157,80°C and values above

157,80°C will be calculated with 157,80°C.

The only exception is the value 327,67 =

[INVALID]. Is this value received, the

internally setpoint [nciSetpoint] will be taken

as the actual one.

If the SNVT nviSetPtOffset is not INVALID

than the required temperature will be

evaluated like this.

Setpoint = nviSetpoint + nviSetPtOffset

nviSetPtOffset works together with

nviSetpoint or nciSetpoint and is part of the

actual required temperature.

Received values below –157,80°C are

calculated like –157,80°C and values above

157,80°C will be calculated with 157,80°C.

The only exception is the value 327,67 =

[INVALID]. Is this value received, it will be

ignored.

Can be used for binding of a physical digital

input, e.g. nvoDIswitch from the internal

actuator object. So the energy could be

saved if an open window or a dewpoint

sensor detects a situation to switch off the

energy = close the valve totally. This means

no more heating in HEATING applications

or no more cooling in COOLING

applications

For binding of an occupancy sensor.

The state has influence on the setpoint

to optimize the energy consumption.

Heating

If [OC_NUL] or

[OCCUPIED] or

[OC_BYPASS] 0 K substracted from

setpoint

If [OC_STANDBY] 3 K substracted from

setpoint

If [OC_UNOCCUPIED] 6 K substracted

from setpoint

EN0B-0235 GE51R0802 14

Page 15

PRODUCT DATA

Cooling

If [OC_NUL] or

[OCCUPIED] or

[OC_BYPASS] 0 K added to setpoint

If [OC_STANDBY] 3 K added to setpoint

If [OC_UNOCCUPIED] 6 K added to

setpoint

K = Kelvin

nviApplicMode

nvoValvePosition

SNVT_hvac_mode

{ HVAC_AUTO,

HVAC_HEAT,

HVAC_MRNG_WRMUP

HVAC_COOL,

HVAC_NIGHT_PURGE,

HVAC_PRE_COOL,

HVAC_OFF,

HVAC_TEST,

HVAC_EMERG_HEAT,

HVAC_FAN_ONLY,

HVAC_FREE_COOL,

HVAC_ICE,

HVAC_NUL}

{HVAC_NUL}

SNVT_lev_percent

{0-100; 163,835}

{163,835} = INVALID

Description from LonMark:

0 HVAC_AUTO

1 HVAC_HEAT

2 HVAC_MRNG_WRMUP

3 HVAC_COOL

4 HVAC_PRE_COOL

5 HVAC_NIGHT_PURGE

6 HVAC_PRE_COOL

7 HVAC_OFF

8 HVAC_TEST

9 HVAC_EMERG_HEAT

10 HVAC_FAN_ONLY

11 HVAC_FREE_COOL

12 HVAC_ICE

0xFF HVAC_NUL

nvoValvePosition = 163,835 [INVALID]

⇒ after Power on or Reset.

PI-Controller cannot deliver a

required actuator position

If nvActualTemp is not INVALID

⇒ nvoValvePosition = 0...100 %

Required Actuator / Valve

position

If [HVAC_HEAT] than nciPiConfig will be

overwritten and HEAT Application is active.

If [HVAC_COOL] than nciPiConfig will be

overwritten and COOL Application is active.

If nviApplicMode is not [HVAC_HEAT] and

not [HVAC_COOL] than the Application

mode will be adjusted via nciPiConfig.

IMPORTANT:

If application mode changes than the picontroller will be reseted internally.

nvoValvePosition includes the actual

required valve position. This parameter

could be bound with the SNVT nviActPos of

the internal actuator object.

IMPORTANT:

If nvoValvePosition changes it will be send

at the latest within 5 seconds. After 15

minutes the value will be send one time if it

has changed in between or not .

RELATION BETWEEN NVIOCCUPANCY, NCISETPOINT, NVISETPOINT AND NVISETPTOFFSET

The adjusted value via nviOccupancy (0 K, 3K or 6K)

⇒ will be ADDED to the actual setpoint in COOLING MODE

⇒ will be SUBSTRACTED from the actual setpoint in HEATING MODE

OC_NUL

OC_OCCUPIED

OC_BYPASS

± 0 K

OC_STANDBY ... ± 3 K

OC_UNOCCUPIED ... ± 6 K

15 0C 18 0C

21 0C

24 0C27

0

C

nciSetpoint + nviSetPtOffset

or

nviSetpoint + nviSetPtOffset

Example 1: nviSetpoint = INVALID, nciSetpoint = 21 °C, nviSetPtOffset = 5 K,

nviOccupancy = OC_STANDBY, nciPiConfig = HEAT, nviApplicMode = INVALID

0C

[

]

15 EN0B-0235 GE51R0802

Page 16

PRODUCT DATA

Actual Setpoint = nciSetpoint + nviSetPtOffset – occupancy_value

= 21°C + 5K

Example 2: nviSetpoint = 23°C, nviSetPtOffset = -4 K, nviOccupancy = OC_UNOCCUPIED,

nciPiConfig = COOL, nviApplicMode = INVALID

Actual Setpoint = nviSetpoint + nviSetPtOffset – occupancy_value

= 23°C – 4K

Standard

Configuration

parameter

nciPiConfig

nciPiGains

nciSetpoint SCPTheatSetpt SNVT_temp_p

SCPT Master

List – names

from Echelon or

User defined

Types

UCPT_PiConfig

UCPT_PiGains

Type

{Range}

{factory settings}

UNVT_PiConfig

{

0 = HEAT;

1 = COOL;

}

{HEAT}

If application mode changes than the pi-controller

will be reseted internally.

UNVT_PiGains

nciPiGains.pi_Xp [SNVT_tmp_p]

{3 – 25 [K]}

{4}

nciPiGains.pi_Tn [SNVT_time_sec]

{10 – 1000 [sec]}

{300}

{-157,80 - 157,80 [°C]}

{21°C}

– 3K = 23 °C

+ 6 K = 25°C

Adjustment of the different functionalities

and the explanation of the shown values.

Decides if a heating or a cooling application

should be controlled. nciPiConfig is only the

decider if nviApplicMode is not set to

HVAC_HEAT or HVAC_COOL. In this cases

nviApplicMode decides if a heating or a

cooling application is active.

Regardless you have the HVAC mode HEAT

or COOL , the internal frost protection

function starts working if the actual

temperature reaches the critical value < 6 ° C.

In this case the value nvoValvePosition will

be overriden with 100 % in heating mode and

with 0 % in cooling mode. So there will be

prevent damages caused by too low

temperature. If a value of > 8 °C is reached

the frost protection will be switched off again.

nciPiGains.pi_Xp =

p value of pi controller

nciPiGains.pi_Tn =

i value of pi controller in

If the temperature deviation between setpoint

and actual temperature is higher than 4,8 K

the linearity of the P-portion gets lost and the

P-Control is working in a limited range. In this

case the I-Portion takes care for accurate

controlling.

The setpoint is the actual required

temperature. If the SNVT nviSetPtOffset is

not 0 than the required temperature will be

evaluated like this.

Setpoint = nciSetpoint + nviSetPtOffset

Values below –157,80°C are calculated like –

157,80°C and values above 157,80°C will be

calculated with 157,80°C.

EN0B-0235 GE51R0802 16

Page 17

PRODUCT DATA

PRIORITIES OF THE DIFFERENT POSSIBLE SITUATIONS

Prio Action Occurs... nvoValvePosition will be set to...

1 Frost Protection ...if the actual temperature runs below 6 ° C. Frost Protection

2 Energy Off ...if nviEnergyHoldOff, which displays the state of a physical

3 no control loop

possible

4 Normal Operation ...if priorities 1-3 are not active. PI-Algorithm works. The

mode is active till temperature rises above 8° C.

digital switch, turns to [value>0,state=1].

...if nviActualTemp is [INVALID] than nvoValvePosition will be

set to INVALID, too.

If the bound internal Actuator (nviActPos) receives INVALID

from nvoValvePosition it runs to the adjustable safety position.

The safety position could be adjusted in the actuator object

via variable nciDefaultOutput.

actual required valve position will be evaluated.

100 % if heating mode

0 % if cooling mode

0 %

163,835 [INVALID]

the valve position evaluated by the PIalgorithm

FACTORY SETTINGS

State of the SNVTs/SCPTs (factory setting):

nviSetpoint = 327,67 (INVALID)

nviSetptOffset = 327,67 (INVALID)

nviActualTemp = 327,67 (INVALID)

nviOccupancy = OC_NUL

nviEnergyHoldOff = {0,0;-1}

nviApplicMode = HVAC_NUL

nvoValvePosition = 163.835 (INVALID)

nciPiConfig = HEAT

nciPiGains.pi_Xp = 4

nciPiGains.pi_Tn = 300

nciSetpoint = 21 °C

BEHAVIOUR OF THE CONTROLLER AFTER POWER ON / RESET / OFFLINE-ONLINE

If power-on or reset or offline to online happens an application reset occurs.

Used PI-Algorithm

%100

jG

ϖ

)(

1

+×=

ϖ

1

Tjxp

×

N

Xp = Proportional band [nciPiGains.pi_Xp]

T

= Integral reset time [nciPiGains.pi_Tn]

N

17 EN0B-0235 GE51R0802

Page 18

PRODUCT DATA

NODE OBJECT (ACTUATORS WITH PI-CONTROLLER ONLY)

The node object is implemented to fullfill the LonMark guidelines, but it has no functionallity in this device.

Node Object

Node Object, Object Type 0

nviRequest

nv1

SNVT_obj_request

nvoStatus

nv2

SNVT_obj_status

None

Fig.13 Node Object

Mandotary

Network

Variables

Optional

Configuration

Properties

EN0B-0235 GE51R0802 18

Page 19

LNS PLUG-IN DESCRIPTION

ACTUATOR OBJECT

DIAGNOSTIC AND TEST

The following descriptions apply to both actuator types (with / without PI-controller).

PRODUCT DATA

Fig.14 Diagnostic and Test Screen

There are two Plug-In versions available, one for each type of actuator (with / without PI-controller).

Monitor Shows the current status of the actuator and of the physical digital input.

REQUESTED ACTUATOR POSITION (nviActPos)

Monitoring of the requested actuator position of the controller.

The range of nviActPos is 0...100 %. Received values below 0 % are calculated like 0 % and values

above 100 % will be calculated like 100 %. The only exception is the value 163.835 % = [INVALID]. Is

this value received the actuator drives to the safety positon adjusted in the Configuration dialog box.

100 % means synchronization to the 100 % - position with 130 % running of full motor runtime. The

synchronization can be interrupted.

Special Case: power on / reset / offline-online.

The synchronization caused by nciDefaultOutput can not be interrupted.

0 % means synchronization to the 0 % - position with 130 % running of full motor runtime. The

synchronization can be interrupted.

Special Case: power on / reset / offline-online.

The synchronization caused by nciDefaultOutput can not be interrupted.

CALCULATED ACTUATOR FEEDBACK (nvoActPosFb)

Monitoring of the actual calculated actuator position. It is important to know that the internal

synchronous motor has no physical feedback sensor. The shown feedback is only a calculated value

and should only be used for trend diagrams or to check motor movements. The correctness of this

value is not guaranteed. The range of nviActPosFb is 0...100 %. (The invalid-string signalizes an

undefined situation). For send timing description, please refer to "Description of used SNVTS* and

SCPTS" section.

19 EN0B-0235 GE51R0802

Page 20

PRODUCT DATA

STATE OF PHYSICAL DIGITAL INPUT (nvoDIswitch)

Monitoring of the actual state of the sensor connected to the physical digital input. (e.g. window-contact

or dewpoint-sensor). The possible conditions can be selected by the [Digital Input – Mode] – field on

the Configuration - dialog box. The states of nvoDIswitch can be ON / OFF / INVALID. For send timing

description, please refer to "Description of used SNVTS* and SCPTS" section.

Manual Override Allows to operate the actuator manually.

MANUAL REQUESTED ACTUATOR POSITION (nviManActPos)

To operate the actuator manually, click check box and enter desired value:

The manual operation has in each case a higher priority than the received controller signal [nviActPos].

The range of nviManActPos is 0...100 %. Received values below 0 % are calculated like 0 % and

values above 100 % will be calculated like 100 %.

100 % means synchronization to the 100 % - position with 130 % runningnof full motor runtime. The

synchronization can be interrupted.

Special Case: power on / reset / offline-online.

The synchronization caused by nciDefaultOutput can not be interrupted.

0 % means synchronization to the 0 % - position with 130 % running of full motor runtime. The

synchronization can be interrupted.

Special Case: power on / reset / offline-online.

The synchronization caused by nciDefaultOutput can not be interrupted.

To have most accuracy with the manual override a synchronization to the stem completely retract

position has to be done.

After switching off the manual override the actuator is running according to the received controller

values (nviActPos).

CONFIGURATION SCREEN

The following descriptions apply to both actuator types (with / without PI-controller).

Actuator Settings

Configures the functionality of the actuator and the physical digital input.

Fig.15 Configuration Screen

EN0B-0235 GE51R0802 20

Page 21

Direct / Reverse - Mode Inverses the direction of action

(nciDirRev)

Service PIN

MODE 1

(10x)1 sec 1 sec

nviActPos

MODE 2

Direct

SNVT_Lev_percent

PRODUCT DATA

Neuron ID

Wink

4 sec 1 sec

AB

100% 0%

SERVICE LED

STATUS LED

SERVICE PIN

MODE 3

Reverse

4 sec1 sec

MODE 4

off

DIRECT_MODE

Requested actuator position = 0 %. Actuator runs to position “stem totally extract”.

Requested actuator position = 100 %. Actuator runs to position “stem totally retract”.

Status LED blinking: 4s on / 1 s off (Mode 2).

REVERSE_MODE

Requested actuator position = 0 %. Actuator runs to position stem totally retract.

Requested actuator position = 100 %. Actuator runs to position stem totally extract.

Status LED blinking: 1s on / 4 s off (Mode 3).

Heartbeat Heartbeat of the connected controller.

(nciMaxRcvTime)

MAXIMUM RECEIVE TIME

Is no requested actuator position value (nviActPos) received in a certain timeframe

defined in the [Heartbeat] - field, the actuator will run to the position defined in the

[Safety Position] - field.

MAXIMUM RECEIVE TIME = 0 seconds. Heartbeat supervision = OFF

0 < MAXIMUM RECEIVE TIME <= 6553 seconds. Heartbeat supervision = ON and timeframe

adjusted.

Additional information

Only integer values are accepted and numbers after a comma will be ignored.

AB

0% 100%

AAB

B

Offline

Fig.16 Modes

21 EN0B-0235 GE51R0802

Page 22

PRODUCT DATA

Start of the heartbeat supervision after power on / reset / offline-online:

The heartbeat supervision starts after a first value was received by the controller (nviActPos). Up to that

point, the actuator will stay in the defined safety position (nciDefaultOutput).

Heartbeat supervision in case of manual operation.

When the actuator is working in the manual operation mode ([nviManActPos] active), the heartbeat

supervision is working in the backround. This means, if the controller fails, the timeframe is passed.

Then the manual operation is switched off, and the actuator is running to the definition of the [Safety

Position] - field.

Safety Position Safety position of the actuator in case of controller failure, power on / reset / offline-(nciDefaultOutput)

online or any other undefined situation.

Defines the condition what will happen if the timeframe defined in the [Heartbeat] - field is passed or if

an undefined situation like power on / reset / offline-online occurs.

100 %

The actuator will do a synchronization to the 100 % - position with 130 % running of full motor runtime.

The synchronization can be interrupted.

Special Case: power on / reset / offline-online.

The synchronization can not be interrupted.

0 %

The actuator will do a synchronization to the 0 % - position with 130 % running of full motor runtime.

The synchronization can be interrupted.

Special Case: power on / reset / offline-online.

The synchronization can not be interrupted.

STOP_MOVEMENT

Actuator stops immediately.

Special Case: power on / reset / offline-online.

The Actuator makes no movement and waits. The first received value for the requested position from

the controller or manual override will be saved as the actual position of the motor – no movement. The

second received value will be compared to the first, and the motor runs to the new required position

(and so on...).

Digital Input - Mode Configuration of the digital input.

(nciDIswitch)

Digital Input – Mode (nciDIswitch)

[Configuration-dialog box]

Switch closed ON NORMALLY OPEN

Switch opened OFF

Switch opened ON NORMALLY CLOSED

Switch closed OFF

NOT USED Switch ignored INVALID*

* The invalid-string is shown the first three seconds after power on / reset / online - offline till the

initialization of the actuator is finished too)

Motor Runtime Possibility of overwriting the automatically detected motor runtime and to secure the

(nciRunTime)accuracy for the time to stroke model. This should only be done in case of adapting a

different valve to the actuator

AUTOMATIC

After power on / reset / offline-online the actuator automatically detects the motor runtime and software

adapts the motor runtime to the 50 / 60 Hz mains frequency.

MANUAL

If the manual mode is activated it is possible to adjust another motor runtime

(the values 0 and 6553,5 are not allowed).

General Information

The actuator automatically sends a service pin message after power on / reset / offline- online.

If the Actuator receives a wink message (executed by the network management tool) the status LED is blinking 10 times with a

frequncy of one second and so the actuator could be located in the field.

State of Digital Input (nvoDIswitch)

[Diagnostic and Test – dialog box]

EN0B-0235 GE51R0802 22

Page 23

PRODUCT DATA

ONLINE-OFFLINE change executed by the network management tool:

• The motor stops if it is running

• The status LED is taken off

• The calculated actuator feedback (nvoActPosFb) will be set to INVALID, to show that the actuator is in an undefined situation.

• The state of the physical digital input will be set to INVALID.

OFFLINE-ONLINE change executed by the network management tool:

• Application restart. Same situation as power-on / reset

Wiring Diagram

Diagram 2: Wiring

Wiring Colors

Power Supply + Digital Input

Brown 24 Vac +

White 24 Vac Green DI (+)

LON (E-Bus)

Black LON

White LON

Input Voltage: Input Voltage for power supply

24 Vac ± 20 %, 50 / 60 Hz

LON (E-Bus): Connection of the LON Bus FTT-10A. The LON Bus is insensitive to polarity, eliminating wiring errors during

installation.

Connection

Cable: 1,5 m

23 EN0B-0235 GE51R0802

Page 24

PRODUCT DATA

PI-CONTROLLER OBJECT

The PI-Controller Descriptions of the Plug-In only apply to the actuator types which have the PI-Controller

integrated.

MONITORING

Fig.17 Monitoring Screen

Priority Table

EN0B-0235 GE51R0802 24

Page 25

PRODUCT DATA

Actual and Required ACTUAL TEMPERATURE (nviActualTemp)

Temperature Shows the actual temperature received from a LON temperature sensor. For INVALID state refer to the

priority table above (priority 3).

EFFECTIVE SETPOINT

The effective setpoint is the required temperature which depends on the

- Application Mode (nviApplicMode or nciPiConfig)

- the Setpoint (nviSetpoint or nciSetpoint)

- the Setpoint Offset (nviSetPtOffset)

- the Occupancy State (nviOccupancy)

Output of PI- REQUIRED VALVE POSITION (nvoValvePosition)

Controller Shows the required valve position evaluated from the PI-controller.

For the different priorities refer to the priority table above.

Further Values HEATING OR COOLING MODE ADJUSTED (nviApplicMode)

for PI-Control If the HEATING mode is adjusted via nviApplicMode, the internal configuration parameter nciPiConfig

will be overridden and the controller works in the HEATING application mode.

If the COOLING mode is adjusted via nviApplicMode, the internal configuration parameter nciPiConfig

will be overridden and the controller works in the COOLING application mode.

If the nviApplicMode edit field shows INVALID, the application mode will be adjusted via the internal

configuration parameter nciPiConfig.

If the application mode changes between HEATING and COOLING, the PI-controller will be reset

internally.

EXTERNAL TEMPERATURE SETPOINT (nviSetpoint)

Shows the temperature setpoint adjusted from the outside of the device. If this value is adjusted, the

internal configuration parameter nciSetpoint will be overwritten. If nviSetpoint shows INVALID, the

internal setpoint (nciSetpoint) is active.

TEMPERATURE SETPOINT OFFSET (nviSetPtOffset)

Shows the temperature offset adjusted from the outside of the device.

STATE OF OCCUPANCY (nviOccupancy)

Shows the actual occupancy state received from a occupancy sensor.

For description, see the table below.

VALUE ADDED TO SETPOINT CAUSED BY OCCUPANCY (nviOccupancy)

For description, see the table above.

SAVE ENERGY SWITCH (nviEnergyHoldOff)

For the behaviour of the controller if nviEnergyHoldOff turns to ON, refer to the priority table above

(priority 2)

.

25 EN0B-0235 GE51R0802

Page 26

PRODUCT DATA

CONFIGURATION OF PI-CONTROLLER

If nviApplicMode APPLICATION MODE (nciPiConfig)

is invalid Defines whether the controller should work in heating or cooling application mode. Internal

configuration parameter nciPiConfig is only active, if external nviApplicMode is inactive (INVALID).

If the application mode changes between HEATING and COOLING, the PI-controller will be reset

internally.

Adjustment of PI- PROPORTIONAL BAND (Xp)

Control Parameters Temperature deviation between the required temperature (effective setpoint) and the actual

temperature (nviActualTemp), which causes the control output to modulate from 0 % to 100 %

(nvoValvePosition).

INTEGRAL RESET TIME (Tn)

Integral reset time of the PI-controller.

If nviSetpoint INTERNAL SETPOINT (nciSetpoint)

is invalid Actual internal adjusted setpoint. This variable is only VALID if the external setpoint (nviSetpoint) is

INVALID.

EN0B-0235 GE51R0802 26

Page 27

PRODUCT DATA

APPLICATION EXAMPLE FOR M7410G1032 / M7410G1040 / M7410G1057

The following picture shows the easiest way for a complete decentral temperature control loop with an additional Energy Hold

Off signal from, e.g. a dewpoint sensor or a window contact.

27 EN0B-0235 GE51R0802

Page 28

Home and Building Control

Honeywell AG

Böblinger Straβe 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany Manufacturing location certified to

EN0B-0235 GE51R0802

Loading...

Loading...