Page 1

APPLICATION

The Series 72 Modutrol IV Motors are used to control

dampers and valves. The motors accept a current or voltage

signal from an electronic controller to position a damper or

valve at any point between open and closed.

Series 72

Modutrol IV™ Motors

PRODUCT DATA

FEATURES

• Replaces M744S,T,Y and M745S,T,Y Motors.

• M7261, M7274, M7281, M7284, and M7294 are

non-spring return motors; M7272, M7282, M7285,

and M7286 are spring return motors.

• Oil immersed motor and gear train for reliable

performance and long life.

• Wiring box provides NEMA 3 weather protection.

• Actuator motor and circuitry operate from 24 Vac.

Models available with factory installed transformer

or an internal transformer can be field added.

• Quick connect terminals standard—screw terminal

adapter available.

• Adapter bracket for matching shaft height of older

motors is standard with replacement motors.

• Nominal timing of 30 seconds for 90° stroke and

60 seconds for 160° stroke.

• Valve and damper linkages, explosion-proof housing,

and auxiliary switches available as accessories.

• Spring return motors are rated for 25 lb.-in. and

60 lb.-in torque.

• Non-spring return motors are rated for 35 lb.-in.,

75 lb.-in., 150 lb.-in., and 300 lb.-in. torque.

• Models available with adjustable start (zero) and span.

• Models available with 4 to 20 mA input signal.

• Models available with 2 to 10 Vdc input signal.

• Die-cast aluminum housing.

® U.S. Registered Trademark

Copyright © 2000 Honeywell • All Rights Reserved

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 5

Settings and Adjustments ................................................. 10

Operation and Checkout .................................................. 12

®

Contents

63- 2202-4

Page 2

SERIES 72 MODUTROL IV™ MOTORS

SPECIFICATIONS

Models:

provide ease of stocking, ease of handling and maximum

replacement value. TRADELINE model specifications are the

same as those of st andard model s unless sp ecified ot herwise.

TRADELINE models have auxiliary switch cams.

NOTE: Auxiliary switches can only be added to motors that

M

TRADELINE models are selected and packaged to

include auxiliary switch cams. (These cams cannot

be field-added.)

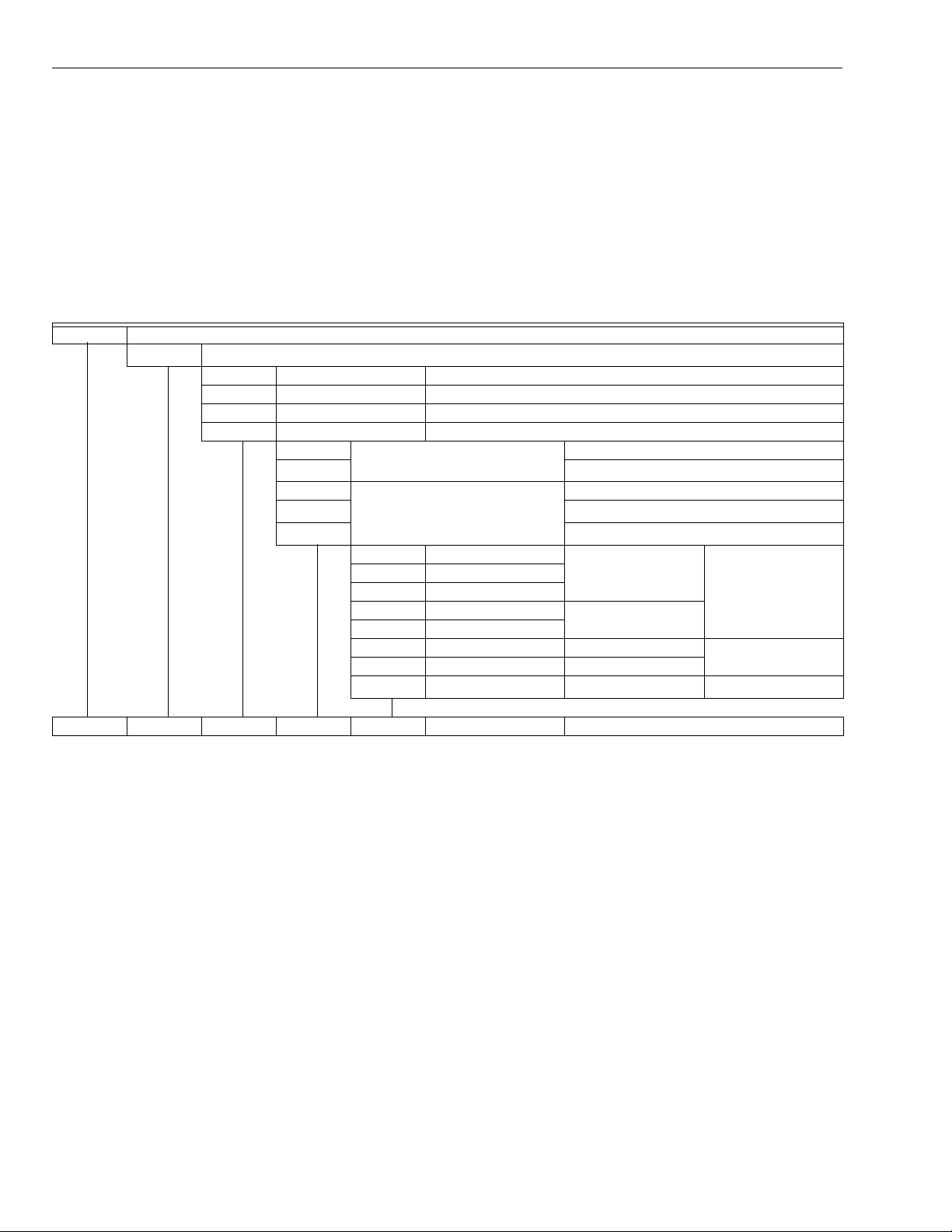

Table 1. Modutrol IV Order Number Guide.

Motor

72

4-20 mA or 2-10 Vdc Control

6

7

8

9

— 35 lb-in. Non-Spring Return

25 lb-in. Spring Return 75 lb-in. Non-Spring Return

60 lb-in. Spring Return 150 lb-in. Non-Spring Return

— 300 lb-in. Non-Spring Return

1

a

Single-ended shaft Non-Spring Return

2

4

Dual-ended shaft Non-Spring Return

5

6

A

B

C

D

F

G

L

Q

IMPORTANT

The specifications given in this publication do not

include normal manufa cturin g tolera nces. Therefor e,

an individual unit may not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions and

some minor differences in performance can be

expected if those conditions are cha nged.

Modutrol IV Order Number Guide:

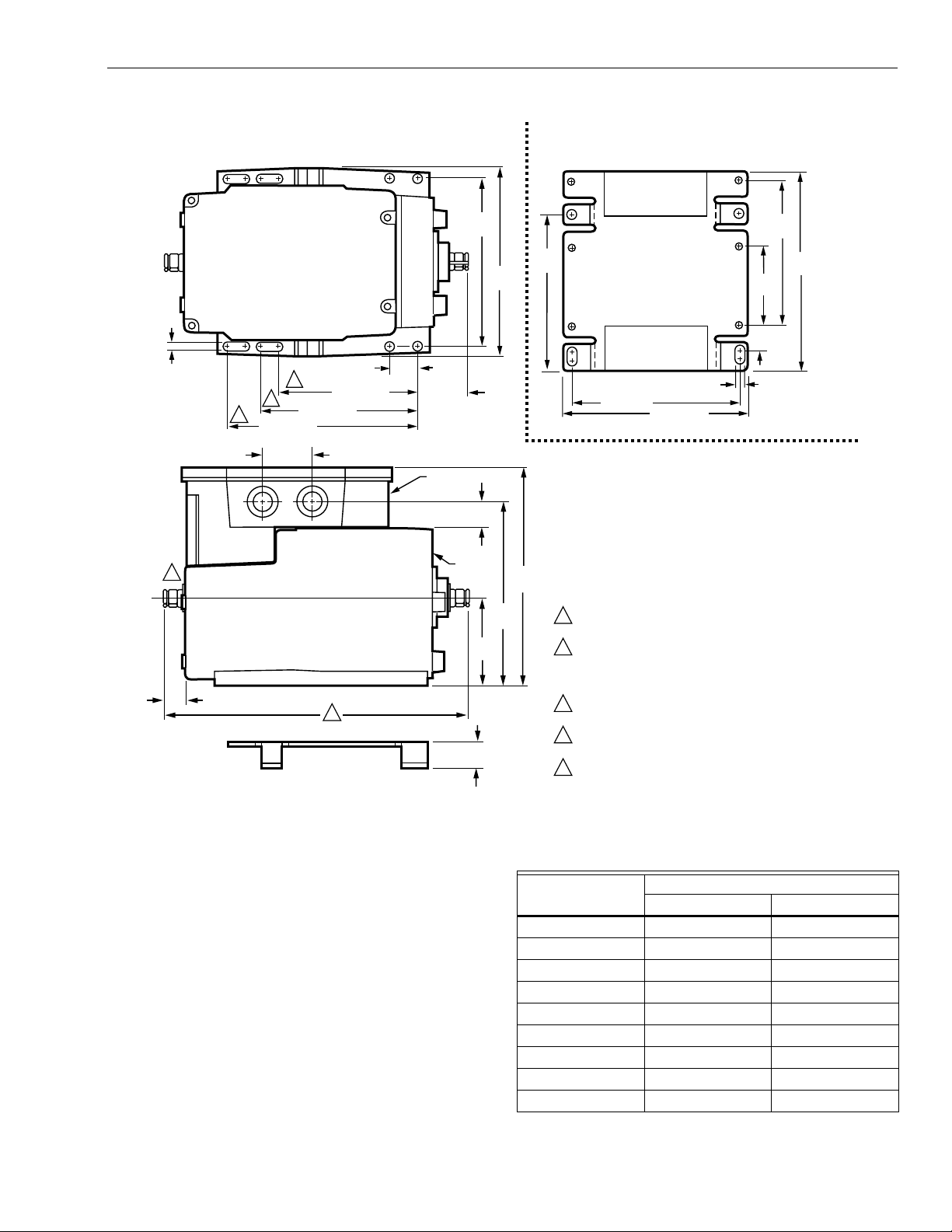

Dimensions:

See Fig. 1.

Normally Closed

Normally Closed

Normally Openc Spring Return

0 Auxiliary Switches Fixed Stroke

1 Auxiliary Switch

2 Auxiliary Switches

0 Auxiliary Switch Adjustable Stroke

2 Auxiliary Switches

0 Auxiliary Switch Fixed Stroke

1 Auxiliary Switch Adjustable Stroke

2 Auxiliary Switches Fixed Stroke

See Table 1.

b

Spring Return

b

Spring Return

Normally Closed

Normally Open

Normally Closed

b

c

b

M6184AXXXX

a

Adjustable zero and span.

b

Electrically normally clos ed. Shaf t rotates clock wise (v iewed fro m the powe r end) wit h incre ase i n control s ignal . Moto r drives to

See Catalog for Complete O.S. Number

normally closed positi on when power ed with control wiring not connected.

c

Electrically normally open. Shaft rotates counterclockwise (viewed from the power end) with increase in control signal. Motor

drives to normally open position when powered with control wiring not connected.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.

Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2202—42

Page 3

SERIES 72 MODUTROL IV™ MOTORS

TOP VIEW OF BRACKET TOP VIEW

1/4

(7)

1

AUXILARY

END

9/16 (15)

ADAPTER

BRACKET

5

3

4

4-1/16 (103)

1-1/2 (37)

4-1/16 (103)

4-1/16 (103)

2

13/16

(20)

POWER

END

1-1/2 (37)

WIRING

BOX

4-7/8

(124)

3/4

(19)

MOTOR

2-9/16

(66)

3/4

(19)

5-1/2

(140)

5-3/8

(137)

6-7/16

(164)

4-5/8

(116)

11/16

POWER END

1/4 (7)

4-7/8 (124)

5-9/16 (141)

SPRING RETURN MODEL SHOWN

SOME MODELS DO NOT HAVE AN AUXILIARY

1

SHAFT. ALL OTHER DIMENSIONS ARE THE SAME.

2

FOR HIGH TORQUE (60 LB-IN.) SPRING RETURN

MODELS 8-3/4 (222); FOR LOW TORQUE (25 LB-IN.)

SPRING RETURN MODELS 8-1/4 (210);

NON-SPRING RETURN MODELS 7-5/16 (185).

FOR HIGH TORQUE (60 LB-IN.) SPRING

3

RETURN MODELS (SHOWN).

4

FOR LOW TORQUE (25 LB-IN.) SPRING

RETURN MODELS.

5

FOR NON-SPRING RETURN MODELS.

2-5/16

(58)

(17)

4-1/4

(107)

5-13/16

(148)

M17089BB

Fig. 1. Series 72 Modutrol IV Motor dimensions in in. (mm).

Controller:

These motors can be used with any electronic

controller that provides a stable noise-free proportional

current output as specified in Electrical Ratings, Input

Range below.

Electrical Ratings:

Power Consumption: See Table 2.

Input Range:

Current, Nonadjustable: 4 to 20 mA nominal, 25 mA

maximum.

Current, Adjustable: 4 to 20 mA adjustable, 50 mA

maximum.

Zero/Null (Motor Closed): 0.08 to 18 mA.

Span: 1.8 to 18 mA.

Voltage, Nonadjustable: 2 to 10 Vdc.

Input Impedance:

4 to 20 mA Input: 100 ohms.

2 to 10 Vdc Input: 400K ohms.

Table 2. Series 72 Modutrol IV Motor Power

Consumption Ratings (at 120 Vac, 50/60 Hz).

Power Consumption

Model

Watts Amps

M7261 19 0.20

M7272 26 0.26

M7274 15 0.71

M7281 23 0.24

M7282 28 0.28

M7284 23 0.24

M7285 28 0.28

M7286 23 1.00

M7294 23 0.24

3 63-2202—4

Page 4

SERIES 72 MODUTROL IV™ MOTORS

Auxiliary Switch Ratings (in Amps):

See Table 3.

Table 3. Auxiliary Switch Ratings (in Amps).

One Contact

Rating

a

120V 240V

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

a

40 VA pilot duty, 120/240 Vac on opposite contact.

Stroke:

Fixed 90° or 160° models available. Other models

available with field adjustable strokes from 90° to 160°.

Stroke adjusted by means of cams located in the wiring

compartment.

Timing:

Nominal 30 seconds for 90° stroke and 60 seconds

for 160° stroke.

Dead Weight Load On Shaft:

200 lb (91 kg) on motor power

or auxiliary end; maximum combined load of 300 lb (136 kg).

Motor Rotation:

Closed: Counterclockwise rotation limit as viewed from motor

power end.

Open: Clockwise rotation limit as viewed from motor power

end.

Mechanically Normal ly Closed: Sprin g return. Normally clo sed

motors rotate to closed position on power loss.

Mechanically Normally Open: Spring return. Normally open

motors rotate to open position on power loss.

Electrically Normally Closed: Both spring return and non-

spring motors return to closed position on minimum signal.

Electrically Normall y Op en: Both sp rin g re turn an d n on-s pri ng

return motors return to open position on minimum signal.

Ambient Temperature Ratings:

Shaft:

3/8 in. [9.5 mm] square.

-40 to 150°F (-40 to 66°C).

Approvals:

Underwriters Laboratories Inc. Listed: File No. E4436; Guide

No. XAPX.

Canadian Standards As soc ia tio n Certi fied: General listed File

No. LR1620; Guide No. 400-E.

Accessories:

198162AA Internal Transformer 120/208/240 Vac 50/60 Hz

primary, 24 Vac secondary.

198162EA Internal Transformer; 120 Vac 50/60 Hz primary,

24 Vac sec ond ary.

198162GA Internal Transformer; 220 Vac 50/60 Hz primary,

24 Vac sec ond ary.

198162JA Internal Transformer; 24 Vac 50/60 Hz primary,

24 Vac secondary (for electrical isolation).

220736A Internal Auxiliary Switch Kit; one switch, can be

field-installed on TRADELINE models.

220736B Internal Auxiliary Switch Kit; two switches, can be

field-installed on TRADELINE models.

220738A Adapter Bracke t rais es m otor shaf t heig ht by 19 mm

to match that of previous Modutrol

®

Motor models.

220741A Screw Terminal Adapter converts the standard

quick-connect terminals to screw terminals.

221455A Infinitely Adjustable Crank Arm, can rotate through

downward position and clear motor base without requiring

an adapter bracket.

4074ERU Weatherproofing Kit provides NEMA 3 rating for

Modutrol IV Motors mounted in position other than upright.

4074EZE Bag Assembly with parts that can provide CE

compliance.

7617ADW Crank Arm, can rotate through downward position

and clear motor base without requiring an adapter bracket.

ES650-117 Explosion-Proof Housing encloses motor for use

in explosive atmospheres. Not for use with Q5001 (or any

other valve linkages). Order separately from O-Z/Gedney

Inc. T o order , contac t: O-Z/Gedney, Nelson Enclosures and

Controls,

(918) 641-7381 or (918) 641-7374; or write to:

O-Z/Gedney, Nelson Enclosures and Controls

P.O. Box 471650

Tulsa, OK 74147-1 65 0

(Requires Honeywell 7617DM Coupling.)

Q100 Linkage connects Modu trol

®

Motor to V51 Butterfly

Valve. Requires the 220738A Adapter Bracket.

Q181 Auxiliary Potentiometer for sequence or unison control

of 1 to 4 additional modulating (Series 90) motors.

Q5001 Bracket and Linkage Assembly connects Modutrol IV

Motor to water or steam valve.

Q605 Damper Linkage connects motor to damper. Includes

motor crank arm.

Q607 External Auxiliary Switch controls auxiliary equipment

as a function of motor position.

63-2202—44

Page 5

INSTALLATION

FULLY OPEN

90 DEGREE STROKE

160 DEGREE STROKE

M5509

VERTICAL

REFERENCE

FULLY CLOSED

160

10

VERTICAL

REFERENCE

FULLY CLOSED

90

10

FULLY OPEN

VERTICAL

REFERENCE

VERTICAL

REFERENCE

FULLY CLOSED

FULLY OPEN

FULLY

CLOSED

FULLY

OPEN

90 DEGREE STROKE 160 DEGREE STROKE

NON-SPRING RETURN MOTORS

160

10

90

45

SPRING RETURN MOTORS

M7272, M7282, M7285, M7286

M7261, M7274, M7281, M7284, M7294

SERIES 72 MODUTROL IV™ MOTORS

When Installing this Product...

1.

Read these instructio ns c aref ull y. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

IMPORTANT

Always conduct a thorough checkout when

installation is complete.

Mounting

Use the following guidelines for proper motor mounting:

• Always install motors with the crankshaft horizon tal.

• Mounting flanges extending from motor housing base are

drilled for 1/4 inch (6.4 mm) machine screws or bolts.

• Non-Spring Return Motors are shipped from the factory in

the closed position (at the counterclockwise rotation limit,

as viewed from the motor power end).

• Spring Return Motors are shipped from the factory in their

normal position.

• Normally closed models are shipped at the counterclockwise

rotation limit, as viewed from the motor power end.

• Normally open models are shipped at the clockwise

rotation limit, as viewed from the motor power end.

Location

Allow enough clearance for accessory installation and motor

servicing when selecting a location (see Fig. 1). If located

outdoors, use liquid-tight conduit connectors with the junction

box to provide NEMA 3 weather protection. If mounted

outdoors in a position other than upright, install a 4074ERU

Weatherproofing Kit and liquid-tight connectors to provide

NEMA 3 protection.

CAUTION

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

In excessive salt environments, mounting base and screws

should be zinc or cadmiu m plated, not stai nless steel or bra ss.

Use the 220738A Adapter Bracket for mounting on these

surfaces.

Fig. 2. Motor shaft position at limit of rotation

(viewed from motor power end).

5 63-2202—4

Page 6

SERIES 72 MODUTROL IV™ MOTORS

Adapter Bracket

The 220738A Adapter Brack et , pos iti one d be tw een the motor

and the equipment, raises motor shaft height by 0.75 in.

(19 mm) to match that of previous Modutrol

The following applications require this bracket:

• Q607 External Auxiliary Switch.

• Damper linkage applications requiring added clearance to

allow:

— Crank arm rotation through the downward position.

— Sufficient damper linkage to reach the motor shaft.

• All valve linkages except the Q5 001 .

NOTE: When the bracket is not used in a replacement

application, the damper linkage requires adjustment

for the new shaft position.

To mount the motor with the bracket:

1.

Mount the bracket to the equipment with existing or

standard bolts.

2.

Using the provided b olts, mount t he motor to the br acket

threaded holes. See Fig. 3.

For valve linkage applications (other than the Q5001):

1.

Mount the bracket to the linkage.

2.

Position the motor on the bracket to align the motor

shaft with the linkage.

3.

Attach the motor to the bracket with the four bolts

provided. See Fig. 4.

®

Motor models.

Damper Linkages

The motor does not inc lud e a c ran k arm . O rde r the c r an k ar m

separately (see Ac cessories in the Specifi cations se ction). For

detailed instructions on the assembly of specific linkages,

refer to the Installation Instructions packed with the linkage.

CAUTION

Equipment Damage Hazard.

Stalling a motor can damage the drive shaft.

Ensure installation of motors and linkages allows the

motor to drive through full stroke without obstruction.

Valve Linkages

The Q100 Linkage requires a 220 738A Adapter Brac ket for all

valve application s. Applicat ions with the Q 5001 Valve Linkage

do not require the 220738A Adapter Bracket (see Fig. 4).

For detailed instructions on specific linkage assemblies, refer

to the instruction sheet packed with the linkage. In general,

check the following points whe n inst alling a moto r and l inkag e:

• Adjust valve and louver-type damper linkages so the

damper or valve moves through only the maximum required

distance while the motor moves through its full stroke.

• With modulating cont rol, maximum dam per opening sh ould

be no more than 60 degrees. Little additional airflow is

provided beyond this point.

• Do not exceed load and torque ratings in any application.

Junction Box

When used with liquid-tight conduit connectors, the junction

box provides NEMA 3 weather protection for the motor. The

junction box, standard w ith repl ac eme nt m oto rs, e ncl os es the

terminals and provid es knoc kouts fo r wiring co nduits. H ousing

an internal transformer or internal auxiliary switches requires

using a junction box.

63-2202—46

Page 7

STANDARD

BOLTS (4)

1

POWER END

EQUIPMENT

BASE

No. 12 OR 1/4 in. ZINC PLATED

1

MACHINE SCREWS OR BOLTS

ADAPTER

BRACKET

POWER END

BOLTS

PROVIDED (4)

WIRING

BOX

MOTOR

SERIES 72 MODUTROL IV™ MOTORS

POWER END

Q5001

VALVE

LINKAGE

M452E

POWER

END OF

MOTOR

NON-SPRING RETURN

Fig. 3. Mounting the motor with an adapter bracket.

WIRING

BOX

MOTOR

1/4-20 UNC

1 in. LONG

MOUNTING

VALVE

BOLTS

M17092

SPRING RETURN

Fig. 4. Mounting the motor on a Q5001 Valve Linkage.

7 63-2202—4

Page 8

SERIES 72 MODUTROL IV™ MOTORS

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

1.

Ensure that the voltage and frequency stamped on the

motor correspond with the power supply characteristics.

2.

When connecting sev eral motors in p arallel, en sure that

the power supply VA rating is large enough to provide

power to all motors used without overloading.

3.

Fig. 5 shows that motor terminals are quick-connects

located on top of the printed circuit board.

4.

To access the wiring compartment:

a. Remove the four screws from the junction box top.

b. Lift off the cover.

5.

Fig. 6 shows the internal wiring schematic.

6.

Refer to Fig. 7 and 8 for typical wiring.

Wire the motor as follows:

1.

Remove the wiring box cover by removing the four

screws holding the cover to the motor.

2.

Wire motor to system using quick-connect terminals in

wiring box.

3.

Replace wiring box cover.

A

RIGHT/INNER

AUXILIARY

SWITCH

F (TEST)

V(-)

Y(+)

T2

T1

NOTE: FEATURES AVAILABLE ON SOME MODELS ONLY.

2 TO 10 VDC INPUT MOTORS 4 TO 20 mA NONADJUSTABLE INPUT MOTORS

INNER AUXILIARY

SWITCH CAM (BLUE)

POWER

END

OUTER AUXILIARY

SWITCH CAM (RED)

LEFT/OUTER

AUXILIARY

SWITCH

NOTE: FEATURES AVAILABLE ON SOME MODELS ONLY.

B

NOTE: FEATURES AVAILABLE ON SOME MODELS ONLY.

C

(+)

F

SPAN ADJUST

MIN MAX

(–)

T2

START ADJUST

T1

4 TO 20 mA ADJUSTABLE INPUT MOTORS

MIN MAX

START ADJUST POTENTIOMETER

(+)

F

(-)

T2

T1

SPAN ADJUST

POTENTIOMETER

RIGHT/INNER

AUXILIARY

SWITCH

INNER AUXILIARY

SWITCH CAM (BLUE)

OUTER AUXILIARY

SWITCH CAM (RED)

LEFT/OUTER

AUXILIARY

SWITCH

POWER

END

RIGHT/INNER

AUXILIARY

SWITCH

INNER AUXILIARY

SWITCH CAM (BLUE)

POWER

END

OUTER AUXILIARY

SWITCH CAM (RED)

LEFT/OUTER

AUXILIARY

SWITCH

M5777

Fig. 5. Terminals and adjustments.

63-2202—48

Page 9

SERIES 72 MODUTROL IV™ MOTORS

–+ F

T2

BRAKE

ELECTRONIC

CIRCUIT

TRIAC

SWITCHING

FEEDBACK

POTENTIOMETER

CLOSE

LIMIT

CCW

WINDING

(CLOSE)

1

2

3

4

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

DIRECTION OF MOTOR TRAVEL AS VIEWED FROM POWER END.

INTERNALLY MOUNTED TRANSFORMER. DO NOT CONNECT

POWER SUPPLY TO T1 AND T2.

BRAKE CIRCUITRY ONLY ON SPRING RETURN MODELS.

TRIAC

SWITCHING

OPEN

LIMIT

CW

WINDING

(OPEN)

2

CIRCUITRY

4

3

T1

Fig. 6. Series 72 motor internal wiring schematic.

M5511

1

L1

(HOT)

L2

MOTOR

CONTROLLER

-

+

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQURED.

CONNECTING F TO

2

T1

T2

24V

-

+

2

F

– WILL DRIVE MOTOR TO FULLY OPEN.

Fig. 7. Typical system wiring.

-20 mA

ONTROLLER

-

+

MOTOR

-

+

F

MOTOR

-

+

F

MOTOR

-

+

F

T1

T2

2

T1

T2

2

T1

T2

2

1

L1

(HOT)

L1

(HOT)

L2

L2

M5778

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQURED.

CONNECTING F TO

2

– WILL DRIVE MOTOR TO FULLY OPEN.

M5774

Fig. 8. Driving up to six motors from

one 4 to 20 mA controller.

9 63-2202—4

Page 10

SERIES 72 MODUTROL IV™ MOTORS

SETTINGS AND ADJUSTMENTS

Zero and Span Adjustment for M7284Q and M7285Q Motors (Fig. 5.)

1.

Adjust the start potentiometer fully clockwise (maximum

zero) and the span p otentio meter full y counte rclockw ise

(minimum span).

2.

Set the controller current to the value required to drive

the motor to the closed position.

3.

Turn the start potentiometer slowly counterclockwise

until the motor begins to open. This is defined as the

start or zero setting.

4.

Set the controller current to the value required to drive

the motor to the fully open positi on. The motor wi ll open.

5.

Turn the span potentiometer clockwise until the motor

starts to close. The difference between the fully open

span position current and the zero position current is

defined as the operating span.

6.

Recheck the start and readjust the span potentiometer

P1 if necessary. Turn the start potentiometer clockwise

to increase the zero position.

7.

Recheck the span and readjust the span potentiometer

if necessary. Turn it clockwise to increase the full span

position.

8.

For sequential operation, as shown in Fig. 9, repeat the

above steps for each motor.

FOR ADJUSTABLE ZERO AND SPAN MODELS

20

(10)

16

(8)

12

(6)

8

(4)

CONTROL OUTPUT

mA CURRENT (OR VOLTS DC)

4

(2)

SEQUENTIAL OPERATION

Auxiliary Switches

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

Adjustable cams actuate the auxiliary switches. These cams

can be set to actuate the switches at any angle within the

motor stroke. Select switch differential of 1° or 10°.

Motors with factory added auxiliary switches are shipped in

the closed position (fully counterclockwise, as viewed from the

motor power end) with auxiliary cams set to actuate switches

30° from the closed position and to provide 1° degree

differential. With the motor in the closed (fully

counterclockwise) position, the auxiliary switch breaks

contacts R-B. See Fig. 10 for auxiliary switch wiring.

TRADELINE Motors are shipped with auxiliary switch cams

that permit acceptance of 220 736A,B Interna l Auxiliary Switc h

Kits. Refer to form 63-2228 for 220736A,B Installation

Instructions.

0

CLOSED

MOTOR 1 PROPORTIONS BETWEEN 4 AND 12 mA; FULLY

1

CLOSED AT 4 mA, FULLY OPENED AT 12 mA.

MOTOR 2 PROPORTIONS BETWEEN 8 AND 16 mA; FULLY

CLOSED AT 8 mA, FULLY OPENED AT 16 mA.

MOTOR 3 PROPORTIONS BETWEEN 12 AND 20 mA SIGNAL;

FULLY CLOSED AT 12 mA, FULLY OPENED AT 20 mA.

UP TO 6 MOTORS CAN BE DRIVEN SEQUENTIALY OR IN

2

UNISON FROM ONE CONTROLLER.

ADJUST ZERO ADJUST AND SPAN ADJUST POTENTIOMETERS

3

TO ACHIEVE DESIRED SEQUENCE.

OPEN

MOTOR 1 MOTOR 2 MOTOR 3

1 3 3 3

CLOSED

OPEN

CLOSED OPEN

M2893A

2

Fig. 9. Sequential operation of motors.

63-2202—410

Page 11

Auxiliary Switch Adjustment

SERIES 72 MODUTROL IV™ MOTORS

IMPORTANT

When adjusting the auxiliary switch cams use the

following procedure:

1.Insert 1/8 in. screwdriver blade into a slot on cam

and move the screwdriv er top as far as pos sible in

the required direction. See Fig. 10.

2.Repeat step 1 in successive cam slots until the

cam is in the required position.

Use the following procedure to obtain the desired auxiliary

switch settings:

1.

Remove the top cover from the motor to gain access

to the motor terminals and auxiliary cams.

2.

Disconnect the controller from the motor.

3.

Connect a current source to the positive and negative

terminals.

4.

Drive the motor to the position where the auxiliary

equipment is to be switched by in creasing or de creasing

the current.

5.

For a switch differential of 1°, check continuity of auxiliary

switch contacts R-B and rotate the cam as follows:

a. If the contacts are open, rotate the cam clockwise

until the R-B contacts close.

b. If the contacts are closed, rotate the cam

counterclockwise until the R-B contacts open.

MOVE SCREWDRIVER AT

TOP ONLY TO ADJUST CAM.

1/8 INCH

STRAIGHT-BLADE

SCREWDRIVER

6.

For a switch differential of 10° rotate the cam

approximately 180° so the slow-rise portion of the

cam actuates the switch.

7.

Check continuity of the auxiliary switch contacts R-B.

8.

Rotate the cam as follows:

a. If the contacts are open, rotate the cam

counterclockwise until the R-B contacts close.

b. If the contacts are closed, rotate the cam clockwise

until the R-B contacts open.

c. Make final adjustment in the proper direction to

obtain contact make or break at the desired position.

9.

Check for the proper differential and switching of the

auxiliary equipment by driving the motor though the full

stroke in both directions.

10.

Disconnect power, remove current source, reconnect

the controller, and replace the top cover on the motor.

NOTE: Changing the differential from 1° to 10° reverses the

switching action. For exa mple, with a 10° dif fer ential,

switch contacts R-B make and R-W break on a

counterclockwise (closed) rotation. With a 1°

differential, switch contacts R-W make and R-B

break on a counterclockwise (closed) rotation.

NOTE: CAMS ARE OFFSET

VERTICALLY TO PROVIDE

BETTER VIEW OF BACK CAM.

SLOW RISE

PORTION

(APPROX.

10° DIFF.)

LEFT/OUTER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1° DIFF.)

MOTOR

OPEN

INNER

AUXILIARY

CAM

(BLUE)

OUTER

AUXILIARY

CAM

(RED)

POWER

END

RIGHT/INNER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1° DIFF.)

SLOW RISE

PORTION

(APPROX.

10° DIFF.)

MOTOR

CLOSE

LEFT/OUTER

AUXILIARY

SWITCH

POWER END

OF MOTOR

Fig. 10. Auxiliary switch adjustment.

RIGHT/INNER

AUXILIARY SWITCH

INNER AUXILIARY

CAM (BLUE)

OUTER AUXILIARY

CAM (RED)

M17101

11 63-2202—4

Page 12

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

SERIES 72 MODUTROL IV™ MOTORS

OPERATION AND CHECKOUT

Operation

The motor feedback potentiometer and control current input

circuit form a bridge circuit. As long as the final control

element remains at the position proportional to the input

current from the controller, the circuit is balanced, and the

motor does not run. When the value of the controlled medium

changes, the current from the controller changes, and

unbalance is amplified to energize the Triac switching to run

the motor in the proper direction to correct the change in the

temperature or the pressure. The motor turns the feedback

potentiometer to rebalance the circuit and stop the motor.

Checkout

After installation and linkage adjustment, operate the motor

through the controller. Make sure that:

• The motor properly operates the damper or valve.

• The motor responds properly as the input is varied.

• The auxiliary switch, if used, operates at the desired point

of motor rotation.

Inspect the motor, linkage, and valve or damper to see that all

mechanical connections are correct and secure.

In damper installations, the pushrod should not extend more

than a few inches past the ball joints. Check to see that

there is adequate clearance for the linkage to move through

its stroke without binding or striking other objects.

See controller or system instructions for additional checkout

procedures.

Motor Operation Checkout

Check motor operation as follows:

1.

To close the motor, open terminals +, -, and F.

2.

To open the motor, connect terminal F to the

negative (-) motor terminal.

Home and Building Control Home and Building Control Honeywell Asia Pacific Inc. Honeywell Europe S.A. Honeywell Latin American

Honeywell Honeywell Limited-Honeywell Limitée Room 3213-3225 3 Avenue du Bourget Region

1985 Douglas Drive North 35 Dynamic Drive Sun Hung Kai Centre 1140 Brussels 480 Sawgr ass Corporate Parkway

Golden Valley, MN 55422 Scarborough, Ontario No. 30 Harbour Road Belgium Suite 200

63-2202—4 B.B. Rev. 11-00 www.honeywell.com

M1V 4Z9 Wanchai Sunrise FL 33325

Hong Kong

Loading...

Loading...