Page 1

M6410C/L, M7410C

Small 3-Position Linear Valve Actuators

PRODUCT DATA

FEATURES

• Small size allows installation where space is limited

• Low power consumption

• Reliable longtime operation because mechanical

feedback potentiometers and mechanical end

switches are not required

• Magnetic coupling for stem force limitation and self-

adjustment of the close-off-point

• Reversible synchronous AC motor

• Suitable for three-position modulating control without

proportional feedback

• Supplied with pre-wired connection cable

• Simple, standardized valve/actuator coupling; no

tools required for mounting

• Visual valve position indicator furnished with

actuators

• Manual operation provided by the valve adjustment

cap, extra knob, or with a hexagon key

• Auxiliary switch

GENERAL

The Honeywell M6410C/L and M7410C actuators are

specifically designed to provide floating control together with

the V5822/23 and V5832/33 series of small linear valves.

The M6410C/L and M7410C actuators are used in fan-coilunits, induction units, small reheaters and recoolers and for

zone control applications. They are employed in electronic

temperature control systems using hot and/or cold water as

the controlled medium.

The M6410C/L and M7410C actuators are suitable for

Honeywell Excel series controllers as well as for Honeywell

individual room temperature controllers. These controllers

track the precise valve position by counting the number of

individual control pulses which move the valve from one

position to another. For this reason, the actuators do not need

endswitches or a feedback potentiometer. The absence of

these mechanical components ensures longtime reliability.

The M6410C/L and M7410C actuators are also compatible

with any controller providing intelligent position control and

having a built-in shut-off function.

These actuators are well suited for applications where space

is limited and minimum power consumption is required. The

actuators are both attractive and robust in design.

SPECIFICATIONS

Motor

Input voltage 24 Vac +10%/-30%; 50/60 Hz

230 Vac +10%/-30%; 50/60 Hz

Power consumption 0.7 VA (24-V models)

7.0 VA (230-V models)

Control mode floating

Stroke 6.5 mm

Running time 150 s at 50 Hz, 125 s at 60 Hz

Stem force depends on version (see table)

Protection standard IP 43 as per EN60529

Insulation class II/III, depending on type (as per

EN 60730)

Connection cables 1.5 m

Ambient operating limits 0…60 °C

Weight 0.4 kg

Suitable valves see table

Manual operation see table

The controller output stage must be suitable for current

peaks of up to 800 volts.

Auxiliary Switches

Ratings 5…24 V, max. 100 mA

24…230 Vac, max 3 (1) A

Switch position S1 (fixed): 17.8 ± 0.2 mm

(factory-supplied) S2 (adjustable): 11.7 ± 0.2 mm

® U.S. Registered Trademark EN0B-0096GE51 R0206

Copyright © 2006 Honeywell Inc. • All rights reserved

Page 2

M6410C/L, M7410C Small 3-Position Linear Valve Actuators

OPERATION

General

The movement of the electric actuators is produced by a

screw spindle which is driven in both directions by a synchronous motor through a set of gears. A magnetic clutch

limits the torque of the gear assembly and the driving force of

the actuators. The actuators are fixed to the valve body by

means of a coupling ring requiring no tools for mounting. The

actuators are maintenance-free and supplied completely with

a ready-to-wire connecting cable.

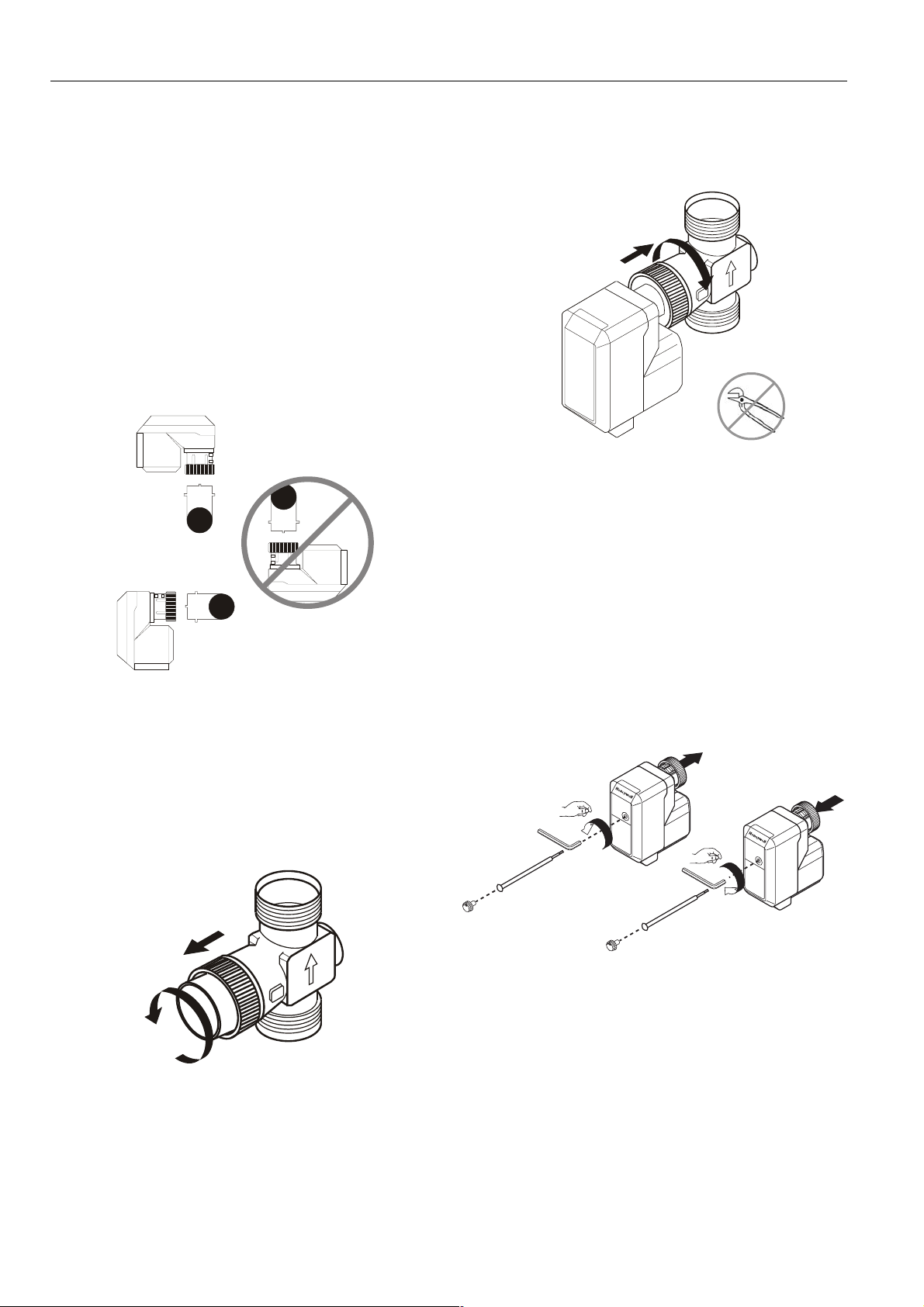

MOUNTING POSITION

The actuator may only be mounted beside or above the valve.

Adjust the valve to the correct position before mounting the

actuator.

The actuator must be mounted by hand. Don't use tools or

additional force because actuator and valve may be

damaged.

Fig. 3 Mounting the actuator

ELECTRIC WIRING OF MOTOR

A fuse with a contact gap of at least 3 mm for each pole must

be fitted with the fixed installation. The fuse rate is max. 2 A.

The electrical installation must comply with the wiring diagram

shown in Fig. 4.

Fig. 1 Mounting positions

MOUNTING

Before the actuator is fixed to the valve, you must remove the

adjustment cap (Fig. 2). Make sure that the actuator is in the

retract position (factory-supplied position) before fixing the

actuator to the valve body.

MANUAL OPERATION

The actuators with integrated manual operation (see table

"Versions") feature a hexagonal key hole for manual

operation. For more comfort, an additional knob for manual

adjustment is packed separately. To avoid damaging the

valve, separate the actuator from the power supply before

adjusting manually.

4 mm

Fig. 5 Manual operation

Fig. 2 Remove protection cap

EN0B-0096GE51 R0206

2

Page 3

M6410C/L, M7410C Small 3-Position Linear Valve Actuators

A

ABABABABABA

A

230 Vac: L 2A, VDE 0641, IEC 269

M

CABLE COLORS FOR 24-V MODELS (M6410C, M7410C)

COM

WHITE

GREEN

CABLE COLORS FOR 230-V MODELS (M6410L)

BROWN

N

BLUE

DN15

-

DN20

DN25

-

DN40

BLACK

BROWN

WORKING OPERATION PORT A

closingopening

AB

closing

opening

A B

closing

opening

B

DN15

-

DN40

A

B

B

closing

opening

DN15

DN20

-

A

B

Fig. 4 Electric wiring of motor

B

COMMISSIONING ADVICE

A functional check of the valve actuator can be carried out by

changing the controller setpoint by 5 °C or more. The movement of the actuator stem (Fig. 6) indicates whether the valve

is opening or closing.

a

b

c

a

b

c

Fig. 7 Auxiliary switch cables

Adjustment of Auxiliary Switch 2

Auxiliary switch 2 should be adjusted by a skilled person,

only.

Move the actuator to the position where the switch is to be

tripped. Cut the plastic skin with a sharp knife. Below the skin,

the adjustment screw can be accessed. Turn the screw

clockwise until the end stop is reached. Turn the screw

counterclockwise until the switch point is achieved. To check

that the required position has been set, move the actuator.

Finally, seal the adjustment hole with a piece of tape.

Fig. 8 Adjustment of auxiliary switch S2

Electric Wiring of Auxiliary Switches

The electrical installation must comply with the wiring diagram

shown in Fig. 9. If the auxiliary switch is connected to

230 Vac, a switch with a contact gap of at least 3 mm for each

pole must be fitted with the installation.

17.8 mm

11.7 mm

Fig. 6 Movement of the actuator stem

AUXILIARY SWITCHES

The actuators with the OS-number M*****40** feature two

auxiliary switches, each with its own cable. Auxiliary switch S1

switches when the stem reaches its fixed

Auxiliary switch S2 switches when the stem reaches its

adjustable

switchpoint.

switchpoint.

3

EN0B-0096GE51 R0206

Page 4

M6410C/L, M7410C Small 3-Position Linear Valve Actuators

(1)

M6410C/L

M7410E

A

A B

AB

AB

A

A

BLUE

DN15

-

DN20

DN25

-

DN40

DN15

-

DN40

DN15

-

DN20

S1

S2

(230 Vac, only):

open

AB AB AB

close

A B A B

close

A

AB A

B

close

A

AB A

B

BROWN

BLUE

BLACK

BROWN

BLACKBLUE

24 Vac: max. 100 mA

230 Vac: max. 5

BLUE

B

B

BROWN

BLACK

BROWN

BLACKBLUE

Fig. 9 Electric wiring of auxiliary switch

Application Example: Switching Off an

Electrical Appliance

2-Way-Valve

DN 15, DN 20

B

B

BROWN

BLACK

BROWN

BLACKBLUE

All Other Valves

DN 15 - DN 40 DN 25 - DN 40DN 15 - DN 20

close

open

open

AB

open

AB

E. g. fan, pump etc.

max. 5 (1)A

BLUE

BLACK

Fig. 11 Application example of auxiliary switch

DIMENSIONS (MM)

58

80

49

60

housing type ‘A’

49

82

100

housing type ‘B’

58

60

109

E. g. fan, pump etc.

BLUE

87

housing type ‘C’

max. 5 (1)A

Fig. 10 Application example of auxiliary switch

BLACK

Fig. 13 Housing types

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Straβe 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0096GE51 R0206

Loading...

Loading...