Honeywell M6284D1026, M6284D4004, M6284D1000, M6284F1070, M6285A1005 Series Manual

...

Series 61 and Series 62

Modutrol IV™ Motors

FEATURES

• Replaces M644, M944B,E,G,H,J,K,R,S and

• Integral junction box provides NEMA 3 weather

• Integral spring return returns motor to normal position

• Motor and circuitry operate from 24 Vac. Models

• Quick-connect terminals are standard—screw terminal

• Adapter bracket for matching shaft height of older

• Motors have field adjustable stroke (90° to 160°).

• Die-cast aluminum housing.

• Integral auxiliary switches are available factory

APPLICATION

The Series 61 and Series 62 Modutrol IV™ Motors are

three-wire spring return and non-spring return floating control

motors. Use these motors with controllers that provide a

switched spdt or floating output to operate dampers or valves.

The Series 62 motors have an internal electrically isolated

feedback potentiometer that provides indication of the motor

shaft position and can be used for slaving Series 90 Motors or

rebalancing an external control circuit.

• Nominal timing standard of 30 seconds (90° stroke),

• Spring return motors can operate valve linkages from

• All models have dual shafts (slotted and tapped on

• All models have auxiliary switch cams.

• Fixed torque throughout the entire voltage range.

• Motors are designed for either normally open or

• Series 62 models include electrically isolated feedback

• Series 62 TRADELINE models have linear feedback,

PRODUCT DATA

M945B,C,G,K,L,AD Motors.

protection.

when power is interrupted.

available with factory installed transformer, or a field

added internal transformer.

adapter is available.

motors is available.

mounted, or can be field added.

and 60 seconds (160° stroke). Other timings available.

power end or auxiliary end shafts for normally closed

or normally open valve applications.

both ends).

normally closed valves and dampers.

potentiometer that provides shaft position indication.

configurable for slaving Series 90 Motors.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Settings and Adjustments ................................................. 7

Operation .......................................................................... 10

Checkout .......................................................................... 10

Replacement .................................................................... 10

63-2629—2

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

SPECIFICATIONS

Models: TRADELINE models are selected and packaged to

provide ease of stocking, ease of handling and maximum

replacement value. TRADELINE model specifications are the

same as those of standard models unless specified otherwise.

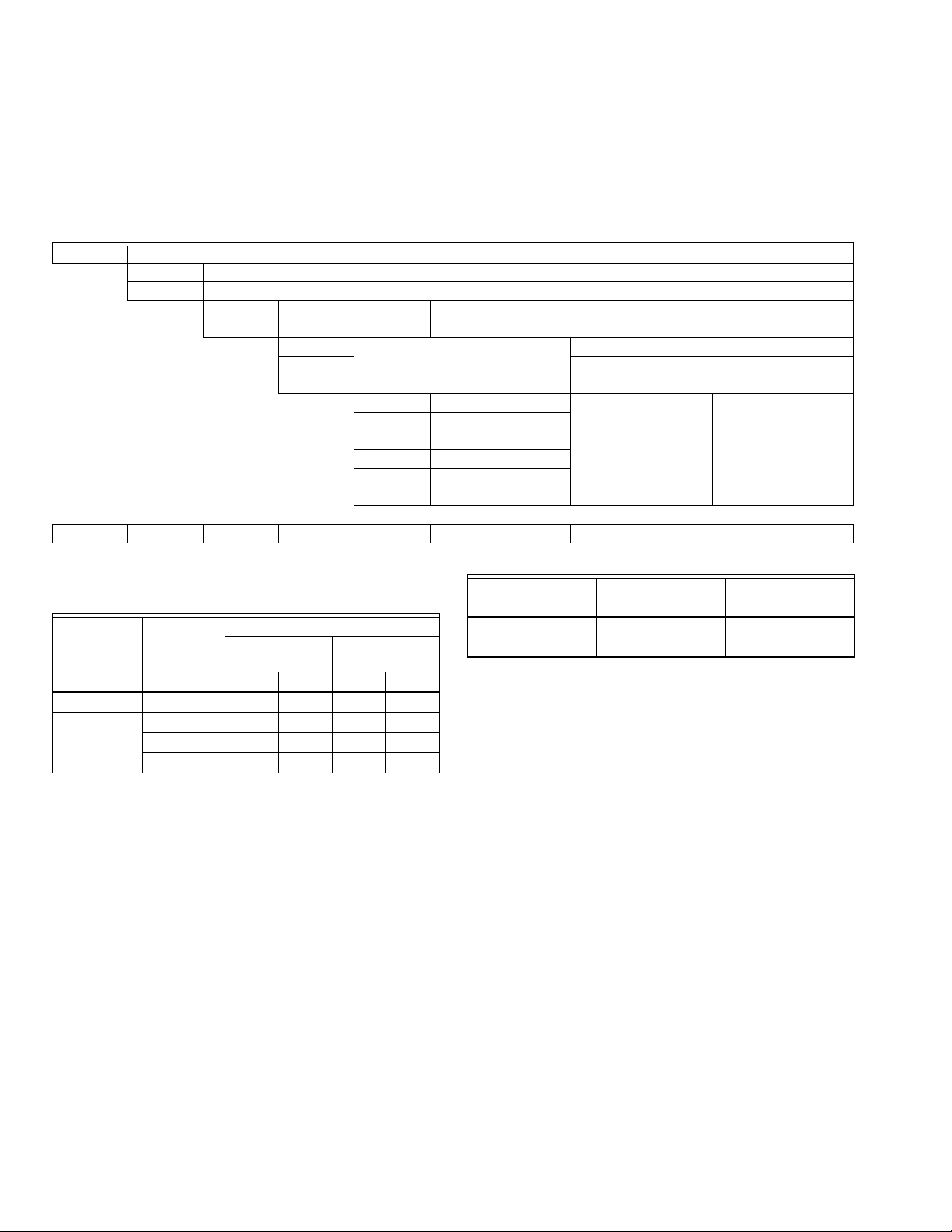

Table 1. Modutrol IV Series 2 Version Order Number Guide.

M Motor

61 Floating Control

62 Floating Control with feedback

8 60 lb-in. Spring Return 150 lb-in. Non-Spring Return

9 — 300 lb-in. Non-Spring Return

2 Dual-ended shaft Normally Closed Spring Return

4 Non-Spring Return

5 Normally Closed Spring Return

A 0 Auxiliary Switches Adjustable Stroke

B 1 Auxiliary Switch

C 2 Auxiliary Switches

D 0 Auxiliary Switch

E 1 Auxiliary Switch

F 2 Auxiliary Switches

M 61 8 4 A XXXX See Catalog for Complete O.S. Number

Electrical Ratings: See Table 2.

Table 2. Series 61 and 62 Modutrol IV Motor

Power Consumption Ratings.

Power Consumption

Non-Spring

Internal

Transformer

No 24 13 6 19 9

Yes 24 1 3 6 19 9

Auxiliary Switch Ratings: See Table 3.

Control Inputs:

Floating three-wire (Series 60): drive open, hold, drive closed.

Series 62 models include an internal, electrically isolated feed-

back potentiometer that provides shaft position

indication.

Voltage at

50/60 Hz

120 13 6 19 9

230 13 6 19 9

Return Spring Return

(VA) (W) (VA) (W)

Modutrol IV Order Number Guide: See Table 1.

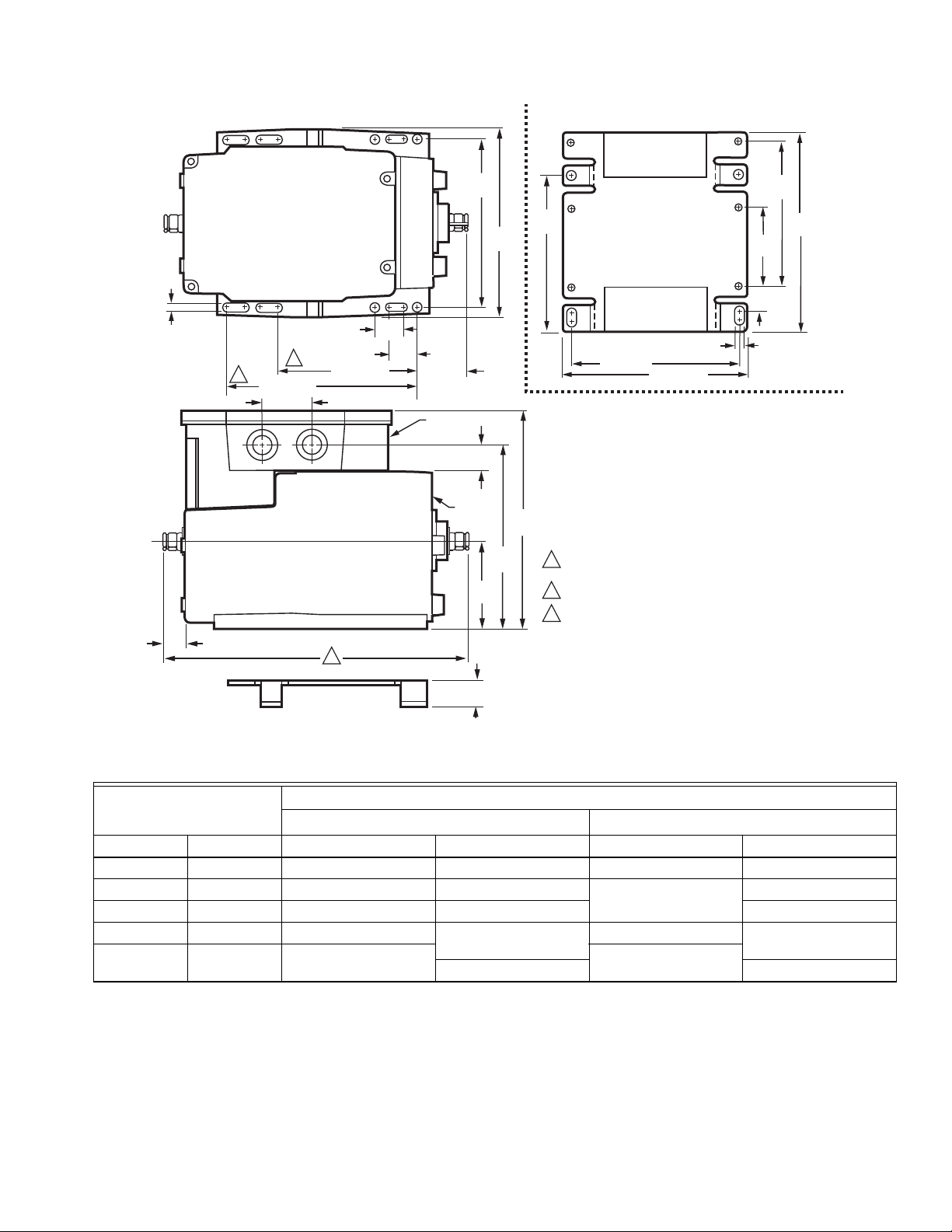

Dimensions: See Fig. 1.

Normally Closed

Table 3. Auxiliary Switch Ratings.

Single Contact

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

a

40 VA pilot duty, 120/240 Vac on opposite contact.

Ambient Temperature Ratings:

Maximum: 150°F (66°C) at 25% duty cycle.

Minimum: -40°F (-40°C).

Dead Weight Load On Shaft:

Power or Auxiliary End: 200 lb (90.8 kg) maximum.

Maximum Combined Load: 300 lb (136 kg).

Crankshaft: 3/8 in. (9.5 mm) square.

Stroke: Adjustable Stroke Models: Available field-adjustable

from 90° to 160°. (See Stroke Setting procedure.)

Timing And Torque: See Table 4.

Rating

a

120V (in Amps) 240V (in Amps)

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2629—2 2

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

M18998B

4-7/8

(124)

5-1/2

(140)

13/16

(20)

4-1/16 (103)

1/4

(7)

1-1/2 (37)

4-1/16 (103)

JUNCTION

BOX

MOTOR

AUXILARY

END

POWER

END

ADAPTER

BRACKET

2-9/16

(66)

5-3/8

(137)

6-7/16

(164)

9/16 (15)

3/4

(19)

TOP VIEW OF BRACKET TOP VIEW

4-5/8

(116)

4-1/4

(107)

2-5/16

(58)

11/16

(17)

4-7/8 (124)

5-9/16 (141)

1/4 (7)

5-13/16

(148)

1

POWER END

2

3

1-1/2 (37)

3/4

(19)

SPRING RETURN MODEL SHOWN

FOR 60 LB-IN. SPRING RETURN MODELS 8-3/4 (222).

FOR NON-SPRING RETUIRN MODELS 7-5/16 (185).

FOR 60 LB-IN. SPRING RETURN MODELS (SHOWN).

FOR NON-SPRING RETURN MODELS.

1

2

3

13/16

(20)

Fig. 1. Series 61 and 62 Modutrol IV Motor mounting dimensions in inches (mm).

Table 4. Series 61 and 62 Modutrol IV Motor Timing and Torque Ratings.

Rated Torque in lb-in. (N•m)

Nominal Timing

90° Stroke 160° Stroke Spring Return Non-Spring Return Spring Return Non-Spring Return

15 30 — 75 (8.5) — 150 (17.0)

30 60 60 (6.8) 35 (4.0) 120 (13.6) 70 (7.9)

60 120 300 (34.0) 600 (68.0)

120 240 —

a

Timings apply to all TRADELINE models. Some OEM models are available with non-standard timing/torque.

b

Torque ratings for dual-ended shaft motors are the sum of the shaft torques (power-end torque plus auxiliary-end torque).

c

Breakaway torque is the maximum torque available to overcome occasional large loads such as a seized damper or valve.

a

in sec

Normal Running Torque Breakaway Torque

150 (17.0) 300 (34.0)

150 (17.0) 300 (34.0)

—

b

NOTE: Torque designation corresponds to torque rating at

standard timing (nominally 60 seconds for 160° and

30 seconds for 90° except for 300 lb-in. motors that

have timings of 2 or 4 minutes).

IMPORTANT

Never use motor continuously at the Breakaway

Torque rating.

Feedback Potentiometer (Series 62 Models Only):

TRADELINE Models (Can be shunted for slaving a

Series 90 Motor).

3 63-2629—2

c

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

CAUTION

CAUTION

Approvals:

Underwriters Laboratories Inc. Listed: File No. E4436, Guide

No. XAPX.

Canadian Standards Association Certified: General Listed File

No. LR1620, Guide No. 400-E.

U.S. Patents: pending

Accessories:

220736A Internal Auxiliary Switch Kit; one switch, can be field-

installed.

220736B Internal Auxiliary Switch Kit; two switches, can be

field-installed.

220738A Adapter Bracket raises motor shaft height by 3/4 inch

(19 mm) to match that of previous Modutrol Motor models.

220741A Screw Terminal Adapter converts the standard quick-

connect terminals to screw terminals.

221455A Infinitely Adjustable Crank Arm, can rotate through

downward position and clear motor base without requiring

an adapter bracket.

220738A Adapter Bracket for Modutrol IV Motor to match shaft

height of Modutrol III Motor

4074ERU Weatherproofing Kit provides NEMA 3 rating for

Modutrol IV Motors mounted in position other than upright.

50017460-001 Internal Transformer; 24/120/230 Vac 50/60 Hz

primary, 24 Vac secondary, quick connect terminals.

50017460-003 Internal Transformer; 120 Vac 50/60 Hz

primary, 24 Vac secondary, quick connect terminals.

7617ADW Crank Arm, can rotate through downward position

and clear motor base without requiring an adapter bracket.

Q100 Linkage connects Modutrol Motor to V51 Butterfly Valve.

Requires the 220738A Adapter Bracket.

Q181 Auxiliary Potentiometer for sequence or unison control of

1 to 4 additional modulating (Series 90) motors.

Q5001 Bracket and Linkage Assembly connects Modutrol IV

Motor to water or steam valve.

Q605 Damper Linkage connects motor to damper. Includes

motor crank arm.

Q607 External Auxiliary Switch controls auxiliary equipment as

a function of motor position.

ES650-117 Explosion-Proof Housing encloses motor for use in

explosive atmospheres. Not for use with Q5001 (or any

other valve linkages). Order separately from Nelson Enclosures. To order, contact: Nelson Enclosures and Controls,

(281) 449-6271; or write to:

Nelson Enclosures and Controls

P.O. Box 471650

Tulsa, OK 74147-1650

Requires Honeywell 7617DM Coupling.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear train

and stroke limit contacts.

IMPORTANT

Always conduct a thorough checkout when

installation is complete.

Location

Allow enough clearance for accessory installation and motor

servicing when selecting a location (see Fig. 1). If located

outdoors, use liquid-tight conduit connectors with the junction

box to provide NEMA 3 weather protection. If mounted

outdoors in a position other than upright, install a 4074ERU

Weatherproofing Kit and liquid-tight connectors to provide

NEMA 3 protection.

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

In excessive salt environments, mounting base and screws

should be zinc or cadmium plated, not stainless steel or brass.

Use the 220738A Adapter Bracket for mounting on these

surfaces.

Mounting

Use the following guidelines for proper motor mounting:

• Always install motors with the crankshaft horizontal.

• Mounting flanges extending from motor housing base are

drilled for 1/4 inch (6.4 mm) machine screws or bolts.

• Non-Spring Return Motors are shipped from the factory in

the closed position (at the limit of counterclockwise rotation,

as viewed from the power end of the motor).

• Spring Return Motors are shipped from the factory in their

normal position.

• Normally closed models are shipped at the limit of

counterclockwise rotation, as viewed from the power end of

the motor.

NOTE: Refer to Fig. 2 for graphical representation of

fully-open and fully-closed positions.

63-2629—2 4

Loading...

Loading...